instrument cluster CHRYSLER VOYAGER 2004 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1020 of 2585

8W-52 TURN SIGNALS

Component Page

Body Control Module........... 8W-52-2, 3, 4, 5

Fuse 24............................ 8W-52-5

G102.............................. 8W-52-2

G200............................ 8W-52-2, 3

G302.............................. 8W-52-4

Instrument Cluster................... 8W-52-5

Instrument Panel Switch Bank....... 8W-52-2, 3

Integrated Power Module.......... 8W-52-2, 3, 5

Left Front Park/Turn Signal Lamp....... 8W-52-2

Left Rear Lamp Assembly............. 8W-52-4Component Page

Left Repeater Lamp.................. 8W-52-5

Left Turn Signal Lamp................ 8W-52-3

Multi-Function Switch.............. 8W-52-2, 3

Right Front Park/Turn Signal Lamp..... 8W-52-2

Right Rear Lamp Assembly............ 8W-52-4

Right Repeater Lamp................. 8W-52-5

Right Turn Signal Lamp............... 8W-52-3

Trailer Tow Connector................ 8W-52-4

RS8W-52 TURN SIGNALS8W-52-1

Page 1098 of 2585

Component Page

Floor Console Lamp................. 8W-80-72

Floor Console Power Outlet........... 8W-80-72

Front Blower Module C1 (ATC)........ 8W-80-73

Front Blower Module C2 (ATC)........ 8W-80-73

Front Cigar Lighter................. 8W-80-73

Front Control Module................ 8W-80-74

Front Intrusion Sensor (United

Kingdom)....................... 8W-80-75

Front Reading Lamps/Switch.......... 8W-80-75

Fuel Heater (Diesel)................. 8W-80-75

Fuel Injector No. 1 (2.4L/3.3L/3.8L)..... 8W-80-75

Fuel Injector No. 1 (Diesel)............ 8W-80-75

Fuel Injector No. 2 (2.4L/3.3L/3.8L)..... 8W-80-76

Fuel Injector No. 2 (Diesel)............ 8W-80-76

Fuel Injector No. 3 (2.4L/3.3L/3.8L)..... 8W-80-76

Fuel Injector No. 3 (Diesel)............ 8W-80-76

Fuel Injector No. 4 (2.4L/3.3L/3.8L)..... 8W-80-77

Fuel Injector No. 4 (Diesel)............ 8W-80-77

Fuel Injector No. 5 (3.3L/3.8L)......... 8W-80-77

Fuel Injector No. 6 (3.3L/3.8L)......... 8W-80-77

Fuel Pressure Sensor (Diesel).......... 8W-80-78

Fuel Pressure Solenoid (Diesel)........ 8W-80-78

Fuel Pump Module.................. 8W-80-78

Generator......................... 8W-80-78

Glow Plug Relay (Diesel)............. 8W-80-79

Headlamp Switch................... 8W-80-79

Headlamp Washer Pump Motor (Export) . 8W-80-79

High Note Horn.................... 8W-80-79

Hood Ajar Switch (Export)............ 8W-80-80

Idle Air Control Motor (Gas)........... 8W-80-80

Ignition Coil (2.4L).................. 8W-80-80

Ignition Coil (3.3L/3.8L).............. 8W-80-80

Ignition Switch..................... 8W-80-80

Inlet Air Temperature Sensor.......... 8W-80-81

Input Speed Sensor................. 8W-80-81

Instrument Cluster.................. 8W-80-81

Instrument Panel Switch Bank (Heated

Seats).......................... 8W-80-81

Instrument Panel Switch Bank (Except Heated

Seats).......................... 8W-80-82

Integrated Power Module C1.......... 8W-80-82

Integrated Power Module C2.......... 8W-80-83

Integrated Power Module C3.......... 8W-80-83

Integrated Power Module C4.......... 8W-80-84

Integrated Power Module C5.......... 8W-80-84

Integrated Power Module C6.......... 8W-80-84

Integrated Power Module C7.......... 8W-80-85

Integrated Power Module C8.......... 8W-80-85

Integrated Power Module C9.......... 8W-80-86

Knock Sensor (2.4L)................. 8W-80-86

Knock Sensor (3.3L/3.8L ABS Except

Export)......................... 8W-80-86

Left B-Pillar Switch (Power Sliding

Door).......................... 8W-80-86Component Page

Left Cinch/Release Motor (Power Sliding

Door).......................... 8W-80-87

Left Cylinder Lock Switch............ 8W-80-87

Left Door Speaker (Highline).......... 8W-80-87

Left Door Speaker (Lowline)........... 8W-80-87

Left Fog Lamp (Except Export)........ 8W-80-87

Left Fog Lamp (Export).............. 8W-80-88

Left Front Door Ajar Switch (Base)..... 8W-80-88

Left Front Door Lock Motor/Ajar Switch (Except

Base).......................... 8W-80-88

Left Front Impact Sensor (Except

Export)......................... 8W-80-88

Left Front Park/Turn Signal Lamp (Except

Export)......................... 8W-80-89

Left Front Wheel Speed Sensor........ 8W-80-89

Left Full Open Switch (Power Sliding

Door).......................... 8W-80-89

Left Headlamp (Except Export)........ 8W-80-89

Left Headlamp Leveling Motor (Export) . . 8W-80-90

Left High Beam Lamp (Export)........ 8W-80-90

Left Instrument Panel Speaker........ 8W-80-90

Left Liftgate Flood Lamp (Power

Liftgate)........................ 8W-80-90

Left Low Beam Lamp (Export)......... 8W-80-90

Left Mid Reading Lamp (Premium/

Luxury)........................ 8W-80-91

Left Park Lamp (Export)............. 8W-80-91

Left Power Mirror................... 8W-80-91

Left Rear Lamp Assembly............ 8W-80-91

Left Rear Pillar Speaker.............. 8W-80-92

Left Rear Reading Lamp (Luxury)...... 8W-80-92

Left Rear Speaker (Lowline)........... 8W-80-92

Left Rear Speaker (Highline).......... 8W-80-92

Left Rear Vent Motor................ 8W-80-92

Left Rear Wheel Speed Sensor......... 8W-80-93

Left Remote Radio Switch............ 8W-80-93

Left Repeater Lamp (Export).......... 8W-80-93

Left Seat Airbag.................... 8W-80-93

Left Side Impact Sensor 1 (Premium

ORC).......................... 8W-80-94

Left Sliding Door Control Module C1 (Power Sliding

Door).......................... 8W-80-94

Left Sliding Door Control Module C2 (Power Sliding

Door).......................... 8W-80-94

Left Sliding Door Latch Sensing Switch (Power

Sliding Door).................... 8W-80-95

Left Sliding Door Lock Motor (Power Sliding

Door).......................... 8W-80-95

Left Sliding Door Lock Motor/Ajar Switch (Manual

Sliding Door).................... 8W-80-95

Left Sliding Door Motor (Power Sliding

Door).......................... 8W-80-95

Left Speed Control Switch............ 8W-80-96

Left Turn Signal Lamp (Export)........ 8W-80-96

RS8W-80 CONNECTOR PIN-OUTS8W-80-3

Page 1112 of 2585

BODY CONTROL MODULE C4 - BLACK/GRAY 34 WAY

CAV CIRCUIT FUNCTION

1- -

2 E12 20OR/GY PANEL LAMPS DRIVER (HVAC)

3- -

4- -

5 G150 22VT/BR INSTRUMENT CLUSTER WAKE UP SENSE

6- -

7 P162 20LG/DG (EXPORT) PASSENGER FOLDING MIRROR RELAY CONTROL

8- -

9 L161 20WT/LG LEFT TURN INDICATOR DRIVER

10 F504 20GY/PK FUSED IGNITION SWITCH OUTPUT (RUN)

11 E14 20OR/TN PANEL LAMPS DRIVER (RADIO)

12 E13 20OR/WT PANEL LAMPS DRIVER (INSTRUMENT CLUSTER)

13 X920 22GY/OR RADIO CONTROL MUX RETURN

14 G900 20VT/DB IGNITION SWITCH SENSE RETURN

15 - -

16 - -

17 L160 20WT/TN RIGHT TURN INDICATOR DRIVER

18 - -

19 - -

20 - -

21 - -

22 G902 22VT/LB MULTI-FUNCTION SWITCH MUX RETURN

23 - -

24 - -

25 - -

26 - -

27 - -

28 - -

29 - -

30 - -

31 - -

32 B27 20DG/WT (TRACTION CONTROL) TRACTION CONTROL SWITCH SENSE

33 P136 20TN/YL (EXPORT) FOLDING MIRROR SWITCH SENSE

34 G26 22VT/OR CHIME DRIVER

RS8W-80 CONNECTOR PIN-OUTS8W-80-17

Page 1176 of 2585

INLET AIR TEMPERATURE SENSOR - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 K21 18DB/LG INLET AIR TEMPERATURE SENSOR SIGNAL

2 K900 20DB/DG SENSOR GROUND

INPUT SPEED SENSOR - GRAY 2 WAY

CAV CIRCUIT FUNCTION

1 T13 18DG/VT SPEED SENSOR GROUND

2 T52 18DG/WT INPUT SPEED SENSOR SIGNAL

INSTRUMENT CLUSTER - BLACK 13 WAY

CAV CIRCUIT FUNCTION

1 E13 20OR/WT PANEL LAMPS DRIVER

2 L160 20WT/TN (LOWLINE) RIGHT TURN INDICATOR DRIVER

3 G7 20VT/GY (LHD EXPORT) LOW OIL PRESSURE INDICATOR DRIVER

4 G3 20VT/LB (LHD EXPORT) MALFUNCTION INDICATOR LAMP DRIVER

5 L134 20WT/GY (HIGHLINE) HIGH BEAM INDICATOR DRIVER

6 A701 18BR/RD FUSED B(+) (HAZARD)

7 Z108 18BK/LG GROUND

8 L161 20WT/LG (LOWLINE) LEFT TURN INDICATOR DRIVER

9 D25 20WT/VT PCI BUS

10 B25 16DG/WT (LHD EXCEPT EXPORT) PARK BRAKE SWITCH SENSE

10 B25 18DG/WT (LHD EXPORT) PARK BRAKE SWITCH SENSE

10 B25 20DG/WT (RHD) PARK BRAKE SWITCH SENSE

11 G26 22VT/OR CHIME DRIVER

12 G150 22VT/BR INSTRUMENT CLUSTER WAKE UP SENSE

13 Z18 18BK/LB GROUND

INSTRUMENT PANEL SWITCH BANK (EXCEPT HEATED SEATS)-6WAY

CAV CIRCUIT FUNCTION

1 E14 20OR/TN PANEL LAMPS DRIVER

2- -

3 F201 20PK/OR ORC RUN-START DRIVER

4 L91 22WT/DB HAZARD SWITCH SENSE

5- -

6 Z406 20BK/BR GROUND

RS8W-80 CONNECTOR PIN-OUTS8W-80-81

Page 1237 of 2585

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Ignition Coil (2.4L) BK Top of Valve Cover 10, 11

Ignition Coil (3.3L/ 3.8L) DKGY Top of Engine 17, 18

Ignition Switch BK Rear of Switch at Steering Column 20, 21, 22, 23, 31

Inlet Air Temperature Sensor BK Top Left of Engine 9, 10, 11, 17

Input Speed Sensor GY Front of Transmission 14, 19

Instrument Cluster BK Rear of Cluster 20, 21, 28

Instrument Panel Switch Bank

(Heated Seats)BK Right Center of Instrument Panel 20, 23, 25

Instrument Panel Switch Bank

(Except Heated Seats)Right Center of Instrument Panel 20, 23, 25

Integrated Power Module C1 Left Fender Shield 6, 7

Integrated Power Module C2 GN/BL Left Fender Shield 6, 7

Integrated Power Module C3 Left Fender Shield 6, 7, 11

Integrated Power Module C4 BL Left Fender Shield 6, 7, 11

Integrated Power Module C5 BK Left Fender Shield 6, 7

Integrated Power Module C6 NAT Left Fender Shield 6, 7

Integrated Power Module C7 Left Fender Shield 6, 7

Integrated Power Module C8 OR Left Fender Shield 6, 7

Integrated Power Module C9 BK Left Fender Shield 6, 7

Knock Sensor (2.4L) BK At Engine Block N/S

Knock Sensor (3.3L/3.8L ABS

Except Export)GY Front of Cylinder Block 11

Left B Pillar Switch (Power

Sliding Door)GY Left B Pillar 40

Left Cinch/Release Motor (Power

Sliding Door)GY Left Sliding Door N/S

Left Cylinder Lock Switch BK At Switch 43

Left Door Speaker (Highline) BK/RD At Speaker 43

Left Door Speaker (Lowline) In Door N/S

Left Fog Lamp (Except Export) BK At Lamp N/S

Left Fog Lamp (Export) WT At Lamp 5

Left Front Door Ajar Switch

(Base)BK At Switch N/S

Left Front Door Lock Motor/Ajar

Switch (Except Base)BK Left Door 43

Left Front Impact Sensor (Except

Export)BK Near T/O for C300 N/S

Left Front Park/Turn Signal Lamp

(Except Export)DKGY At Lamp 1

Left Front Wheel Speed Sensor GY Left Fender Side Shield 5, 11

Left Full Open Switch (Power

Sliding Door)BK Left Sliding Door N/S

Left Headlamp (Except Export) BK At Lamp 1

Left Headlamp Leveling Motor

(Export)WT At Motor N/S

8W - 91 - 6 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONRS

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1245 of 2585

SPLICE NUMBER LOCATION FIG.

S126 In Right Headlamp Leveling Assembly N/S

S127 (Diesel) In T/O for Engine Starter Motor N/S

S128 (Diesel) Near T/O for Engine Starter Motor N/S

S129 (Diesel) Near T/O for Battery (+) N/S

S130 (Diesel) Near T/O for Battery (+) N/S

S131 Near T/O for Transmission Control Module 11

S131 (3.3L/3.8L) Near T/O for C110 N/S

S132 (Diesel) Near T/O for Battery (+) N/S

S134 (Diesel) IN T/O for Engine Control Module N/S

S135 (Diesel) Near T/O for Glow Plug No.2 N/S

S136 (Diesel) In T/O for Radiator Fan Relays 2

S137 (Diesel) Above Starter 15

S138 (Diesel) Between T/O for Radiator Fan No.2 and T/O for G102 N/S

S139 (Diesel) Between T/O for Engine Starter Motor and T/O for

Engine Control Module C115, 16

S141 (2.4L) Near T/O for C110 11

S141 (Diesel) Near T/O for G100 N/S

S141 (3.3L/3.8L) Near T/O for Powertrain Control Module N/S

S142 (3.3L/3.8L) Near T/O for A/C Compressor Clutch 18

S144 (Diesel) Between T/O for Battery Temperature Sensor and T/O

for C103N/S

S148 (Diesel) Near T/O for Engine Starter Motor 5

S150 (Diesel) Between T/O for Battery Temperature Sensor and T/O

for C103N/S

S151 (Diesel) Near T/O for Radiator Fan Relays 2

S152 (Diesel) Near T/O for Radiator Fan No.1 N/S

S157 (Diesel) Near T/O for Glow Plug No.4 15

S177 In Right Headlamp Wiring Assembly N/S

S179 In Left Headlamp Wiring Assembly N/S

S187 (Diesel) In T/O for Engine Control Module C1 N/S

S188 (Diesel) Near T/O for Radiator Fan Relays 2

S201 In T/O to Instrument Panel Speaker 20, 26

S202 Near T/O for Instrument Panel Switch Bank 20, 26

S203 Near T/O for Instrument Panel Switch Bank 26

S204 Near T/O to Instrument Panel Speaker 20, 26

S205 Near T/O for C201 N/S

S206 Near T/O for Instrument Cluster 20

S207 Near T/O for A/C Heater Control 20, 26

S208 (RHD) Between T/O for Antenna Connector and T/O for Front

Cigar Lighter26

S209 Near T/O for Evaporator Temperature Sensor N/S

S210 (RHD) Near T/O for C203 26

S211 In Steering Column Wiring Assembly N/S

8W - 91 - 14 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONRS

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1438 of 2585

(7) Lower vehicle and install oil dipstick.

(8) Connect negative cable to battery.

(9) Fill crankcase with oil to proper level.

OIL PRESSURE RELIEF VALVE

REMOVAL

(1) Remove oil pan (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - REMOVAL).

(2) Drill a 3.175 mm (1/8 in.) hole in the center of

the retainer cap (Fig. 103). Insert a self-threading

sheet metal screw into the cap.

(3) Using suitable pliers, remove cap and discard.

(4) Remove spring and relief valve (Fig. 103).

INSTALLATION

(1) Clean relief valve, spring and bore.

NOTE: Lubricate relief valve with clean engine oil

before installing.

(2) Install relief valve and spring into housing.

(3) Install new retainer cap until flush with seal-

ing surface.

(4) Install oil pan (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - INSTALLATION).

(5) Fill crankcase with proper oil to correct level.

OIL PRESSURE SWITCH

DESCRIPTION

The engine oil pressure switch is located on the

lower left front side of the engine. It screws into the

oil filter adapter. The normally closed switch provides

an input through a single wire to the low pressure

indicator light on the instrument cluster.

OPERATION

The oil pressure switch provides a ground for the

instrument cluster low oil pressure indicator light.

The switch receives oil pressure input from the

engine main oil gallery. When engine oil pressure is

greater than 27.5 Kpa (4 psi), the switch contacts

open, providing a open circuit to the low pressure

indicator light. For wiring circuits and diagnostic

information, (Refer to Appropriate Wiring/Diagnostic

Information).

REMOVAL

(1) Raise vehicle on hoist.

(2) Disconnect electrical connector from switch.

(3) Remove oil pressure switch (Fig. 104).

INSTALLATION

(1) Install oil pressure switch. Torque oil pressure

switch to 23 N´m (200 in. lbs.) (Fig. 104).

(2) Connect electrical connector to switch.

(3) Lower the vehicle.

(4) Start engine and check for leaks.

(5) Check engine oil level. Adjust as necessary.

Fig. 102 Oil Pan Sealing

1 - SEALER LOCATIONS

Fig. 103 Oil Pressure Relief Valve

1 - RELIEF VALVE

2 - SPRING

3 - RETAINER CAP

RSENGINE 3.3/3.8L9 - 141

OIL PAN (Continued)

Page 1557 of 2585

WARNING: THE AIR BAG SYSTEM IS A SENSITIVE,

COMPLEX ELECTRO-MECHANICAL UNIT. BEFORE

ATTEMPTING TO DIAGNOSE, REMOVE OR INSTALL

THE AIR BAG SYSTEM COMPONENTS YOU MUST

FIRST DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE. THEN WAIT TWO

MINUTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE. FAILURE TO DO SO COULD RESULT IN

ACCIDENTAL DEPLOYMENT OF THE AIR BAG AND

POSSIBLE PERSONAL INJURY. THE FASTENERS,

SCREWS, AND BOLTS, ORIGINALLY USED FOR

THE AIR BAG COMPONENTS, HAVE SPECIAL

COATINGS AND ARE SPECIFICALLY DESIGNED

FOR THE AIR BAG SYSTEM. THEY MUST NEVER

BE REPLACED WITH ANY SUBSTITUTES. ANYTIME

A NEW FASTENER IS NEEDED, REPLACE WITH

THE CORRECT FASTENERS PROVIDED IN THE

SERVICE PACKAGE OR FASTENERS LISTED IN

THE PARTS BOOKS.

WARNING: SAFETY GOGGLES SHOULD BE WORN

AT ALL TIMES WHEN WORKING ON STEERING

COLUMNS.

CAUTION: Disconnect negative (ground) cable from

the battery before servicing any column compo-

nent.

CAUTION: Do not attempt to remove the pivot pins

to disassemble the tilting mechanism. Damage will

occur.

DIAGNOSIS AND TESTING - STEERING

COLUMN

For diagnosis of conditions relating to the steering

column (Refer to 19 - STEERING - DIAGNOSIS AND

TESTING) and (Refer to 19 - STEERING - DIAGNO-

SIS AND TESTING).

REMOVAL

NOTE: Before proceeding, (Refer to 19 - STEERING/

COLUMN - WARNING).

(1) Make sure the front wheels of the vehicle are

in the STRAIGHT AHEAD position before beginning

the column removal procedure.

(2) Disconnect negative (ground) cable from the

battery and isolate cable from battery terminal.

(3) Remove the lower shroud (Refer to 19 -

STEERING/COLUMN/LOWER SHROUD - REMOV-

AL).

(4) Remove the traction off switch.

(5) Remove the upper shroud.

(6) Remove the cluster trim bezel (Refer to 23 -

BODY/INSTRUMENT PANEL/CLUSTER BEZEL -

REMOVAL).

(7) Remove the knee blocker (Refer to 23 - BODY/

INSTRUMENT PANEL/STEERING COLUMN

OPENING COVER - REMOVAL).

(8) Remove the parking brake handle link.

(9) Remove the knee blocker reinforcement (Refer

to 23 - BODY/INSTRUMENT PANEL/KNEE

BLOCKER - REMOVAL).

(10) Remove the airbag (Refer to 8 - ELECTRI-

CAL/RESTRAINTS/DRIVER AIRBAG - REMOVAL).

(11) Remove the steering wheel retaining nut.

(12) Remove the vibration damper weight.

(13) Remove the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

REMOVAL). (Fig. 3)

(14) Disconnect the wiring harness connectors

from the clockspring, multi-function switch, halo

lamp, SKIM module, ignition switch and BTSI sole-

noid.

(15) Disconnect the shift cable at the lever. (Fig. 4)

(16) Remove the pinch side clip, then remove the

cable from the bracket on the column.

(17) Remove the pinch bolt coupling. (Fig. 5)

(18) Loosen the two lower mounting nuts.

(19) Remove the two upper mounting nuts

(20) Remove the steering column.

1 - CLOCKSPRING WIRING

2 - STEERING WHEEL

3 - UPPER SHROUD

4 - FIXED SHROUD

5 - SCREW

6 - STEERING COLUMN MOUNTING PLATE

7 - NUT

8 - DASH PANEL STEERING COLUMN MOUNTING BRACKET

9 - STUDS (4)

10 - STEERING COLUMN LOCKING PIN

11 - NUT/WASHER ASSEMBLY

12 - STEERING COLUMN ASSEMBLY

13 - LOWER SHROUD

14 - SCREWS

15 - STEERING WHEEL RETAINING NUT16 - STEERING WHEEL DAMPER

17 - CLOCKSPRING

18 - SCREW

19 - MULTI-FUNCTION SWITCH

20 - PINCH BOLT

21 - STEERING COLUMN COUPLER

22 - PINCH BOLT RETAINING PIN

23 - DASH PANEL

24 - SILENCER SHELL

25 - INTERMEDIATE SHAFT SHIELD AND SEAL

26 - INTERMEDIATE SHAFT

27 - ROLL PIN

28 - POWER STEERING GEAR

29 - FRONT SUSPENSION CRADLE/CROSSMEMBER

19 - 12 COLUMNRS

COLUMN (Continued)

Page 1559 of 2585

(10) Install the coupling onto the intermediate

shaft and install the pinch bolt. Tighten the pinch

bolt to 28 N´m (250 in. lbs.).

(11) Install the cable from the bracket on the col-

umn, then install the pinch side clips.

(12) Reconnect the shift cable at the lever.

(13) Reconnect the wiring harness connectors to

the clockspring, multi-function switch, halo lamp,

SKIM module, ignition switch and BTSI solenoid.

(14) Install the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

INSTALLATION).

(15) Install the vibration damper weight.

(16) Install the steering wheel retaining nut.

Tighten the nut to 61 N´m (45 ft. lbs.)

(17) Install the airbag (Refer to 8 - ELECTRICAL/

RESTRAINTS/DRIVER AIRBAG - INSTALLATION).

(18) Install the knee blocker reinforcement (Refer

to 23 - BODY/INSTRUMENT PANEL/KNEE

BLOCKER - INSTALLATION).

(19) Install the parking brake handle link.

(20) Install the knee blocker (Refer to 23 - BODY/

INSTRUMENT PANEL/STEERING COLUMN

OPENING COVER - INSTALLATION).

(21) Install the cluster trim bezel (Refer to 23 -

BODY/INSTRUMENT PANEL/CLUSTER BEZEL -

INSTALLATION).

(22) Install the upper shroud (Refer to 19 -

STEERING/COLUMN/LOWER SHROUD - INSTAL-

LATION).

(23) Install the traction off switch.

(24) Install the lower shroud.

SPECIFICATIONS

COLUMN TORQUE

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Driver Airbag Attaching Bolts 10 Ð 90

Steering Column Coupling

Pinch Bolt28 Ð 250

Steering Column Mounting

Nuts12 Ð 105

Steering Wheel Retaining

Nut61 45 Ð

IGNITION SWITCH

REMOVAL

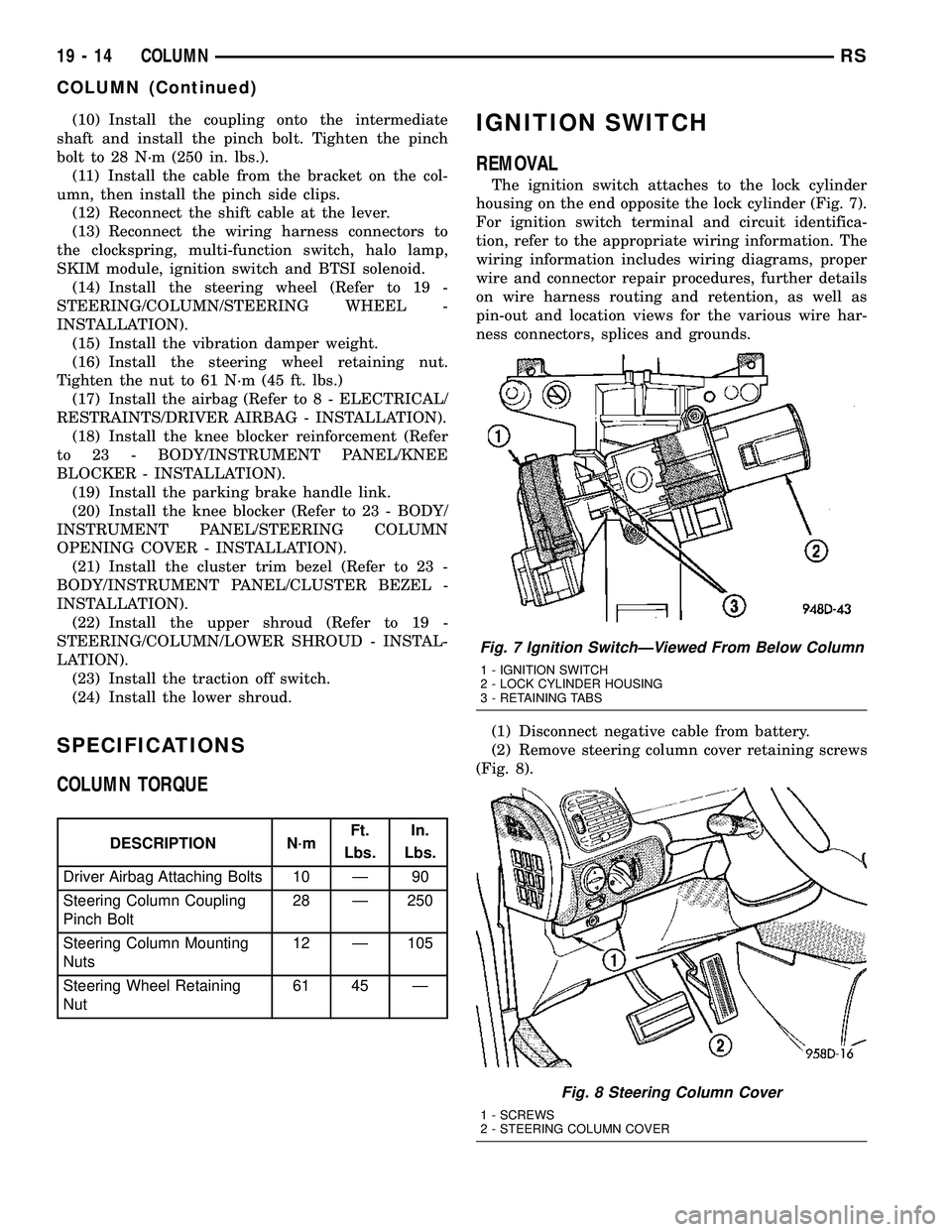

The ignition switch attaches to the lock cylinder

housing on the end opposite the lock cylinder (Fig. 7).

For ignition switch terminal and circuit identifica-

tion, refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds.

(1) Disconnect negative cable from battery.

(2) Remove steering column cover retaining screws

(Fig. 8).

Fig. 7 Ignition SwitchÐViewed From Below Column

1 - IGNITION SWITCH

2 - LOCK CYLINDER HOUSING

3 - RETAINING TABS

Fig. 8 Steering Column Cover

1 - SCREWS

2 - STEERING COLUMN COVER

19 - 14 COLUMNRS

COLUMN (Continued)

Page 1562 of 2585

LOCK CYLINDER HOUSING

DESCRIPTION - IGNITION INTERLOCK

All vehicles equipped with automatic transaxles

have an interlock system. The system prevents shift-

ing the vehicle out of Park unless the ignition lock

cylinder is in the Unlock, Run or Start position. In

addition, the operator cannot rotate the key to the

lock position unless the shifter is in the park posi-

tion. On vehicles equipped with floor shift refer to

the - Transaxle for Automatic Transmission Shifter/

Ignition Interlock.

REMOVAL

NOTE: Before proceeding, review all Steering Col-

umn and Airbag Warnings and Cautions. (Refer to

19 - STEERING/COLUMN - WARNING)(Refer to 8 -

ELECTRICAL/RESTRAINTS - WARNING)

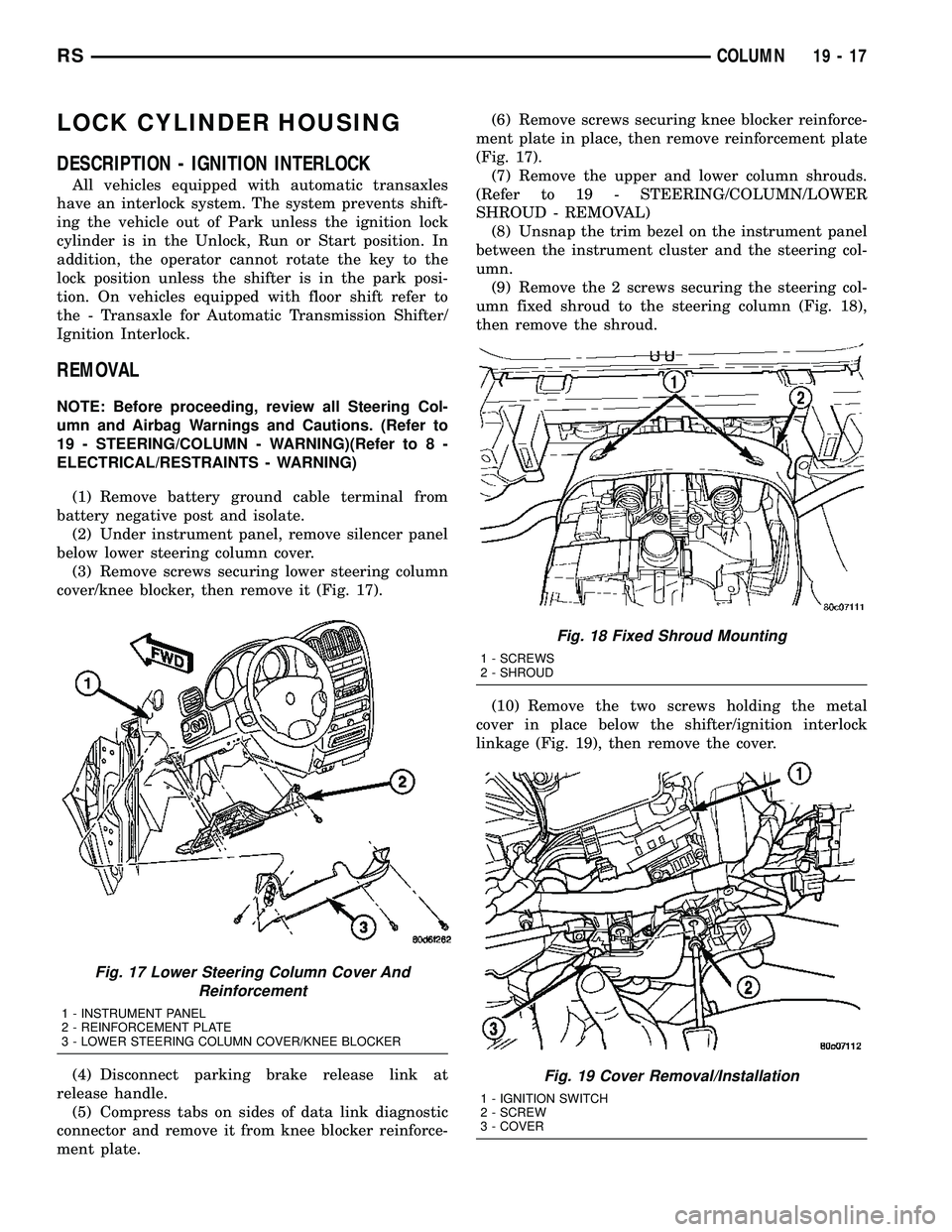

(1) Remove battery ground cable terminal from

battery negative post and isolate.

(2) Under instrument panel, remove silencer panel

below lower steering column cover.

(3) Remove screws securing lower steering column

cover/knee blocker, then remove it (Fig. 17).

(4) Disconnect parking brake release link at

release handle.

(5) Compress tabs on sides of data link diagnostic

connector and remove it from knee blocker reinforce-

ment plate.(6) Remove screws securing knee blocker reinforce-

ment plate in place, then remove reinforcement plate

(Fig. 17).

(7) Remove the upper and lower column shrouds.

(Refer to 19 - STEERING/COLUMN/LOWER

SHROUD - REMOVAL)

(8) Unsnap the trim bezel on the instrument panel

between the instrument cluster and the steering col-

umn.

(9) Remove the 2 screws securing the steering col-

umn fixed shroud to the steering column (Fig. 18),

then remove the shroud.

(10) Remove the two screws holding the metal

cover in place below the shifter/ignition interlock

linkage (Fig. 19), then remove the cover.

Fig. 17 Lower Steering Column Cover And

Reinforcement

1 - INSTRUMENT PANEL

2 - REINFORCEMENT PLATE

3 - LOWER STEERING COLUMN COVER/KNEE BLOCKER

Fig. 18 Fixed Shroud Mounting

1 - SCREWS

2 - SHROUD

Fig. 19 Cover Removal/Installation

1 - IGNITION SWITCH

2 - SCREW

3 - COVER

RSCOLUMN19-17