instrument cluster CHRYSLER VOYAGER 2004 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1566 of 2585

GEAR SHIFT LEVER

REMOVAL

(1) Remove the knee blocker (Refer to 23 - BODY/

INSTRUMENT PANEL/STEERING COLUMN

OPENING COVER - REMOVAL).

(2) Remove the knee blocker reinforcement (Refer

to 23 - BODY/INSTRUMENT PANEL/KNEE

BLOCKER - REMOVAL).

(3) Remove the upper and lower shrouds (Refer to

19 - STEERING/COLUMN/LOWER SHROUD -

REMOVAL).

(4) Remove the cluster trim bezel (Refer to 23 -

BODY/INSTRUMENT PANEL/CLUSTER BEZEL -

REMOVAL).

(5) Remove the fixed shroud from the column.

(6) Disconnect the electrical connector to the BTSI.

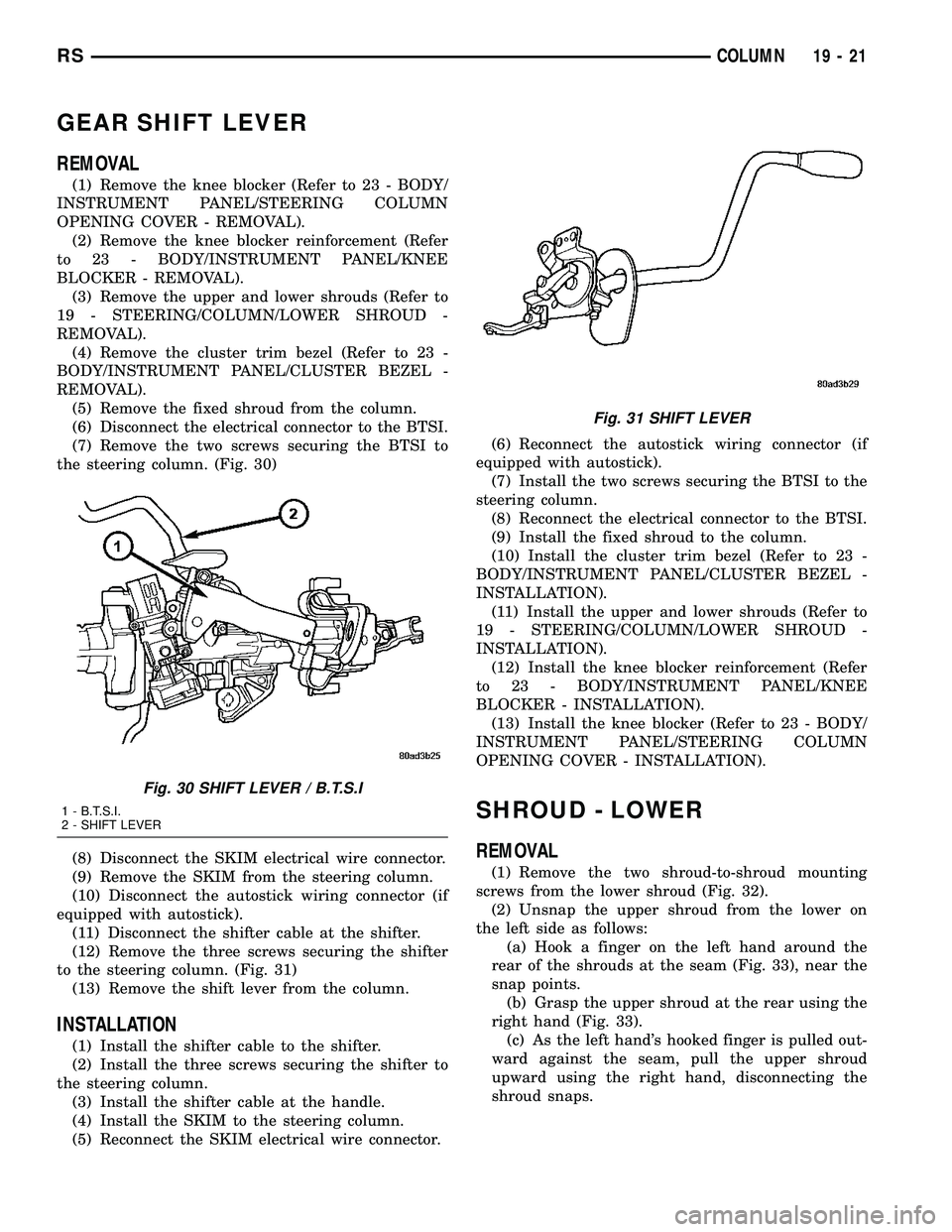

(7) Remove the two screws securing the BTSI to

the steering column. (Fig. 30)

(8) Disconnect the SKIM electrical wire connector.

(9) Remove the SKIM from the steering column.

(10) Disconnect the autostick wiring connector (if

equipped with autostick).

(11) Disconnect the shifter cable at the shifter.

(12) Remove the three screws securing the shifter

to the steering column. (Fig. 31)

(13) Remove the shift lever from the column.

INSTALLATION

(1) Install the shifter cable to the shifter.

(2) Install the three screws securing the shifter to

the steering column.

(3) Install the shifter cable at the handle.

(4) Install the SKIM to the steering column.

(5) Reconnect the SKIM electrical wire connector.(6) Reconnect the autostick wiring connector (if

equipped with autostick).

(7) Install the two screws securing the BTSI to the

steering column.

(8) Reconnect the electrical connector to the BTSI.

(9) Install the fixed shroud to the column.

(10) Install the cluster trim bezel (Refer to 23 -

BODY/INSTRUMENT PANEL/CLUSTER BEZEL -

INSTALLATION).

(11) Install the upper and lower shrouds (Refer to

19 - STEERING/COLUMN/LOWER SHROUD -

INSTALLATION).

(12) Install the knee blocker reinforcement (Refer

to 23 - BODY/INSTRUMENT PANEL/KNEE

BLOCKER - INSTALLATION).

(13) Install the knee blocker (Refer to 23 - BODY/

INSTRUMENT PANEL/STEERING COLUMN

OPENING COVER - INSTALLATION).

SHROUD - LOWER

REMOVAL

(1) Remove the two shroud-to-shroud mounting

screws from the lower shroud (Fig. 32).

(2) Unsnap the upper shroud from the lower on

the left side as follows:

(a) Hook a finger on the left hand around the

rear of the shrouds at the seam (Fig. 33), near the

snap points.

(b) Grasp the upper shroud at the rear using the

right hand (Fig. 33).

(c) As the left hand's hooked finger is pulled out-

ward against the seam, pull the upper shroud

upward using the right hand, disconnecting the

shroud snaps.

Fig. 30 SHIFT LEVER / B.T.S.I

1 - B.T.S.I.

2 - SHIFT LEVER

Fig. 31 SHIFT LEVER

RSCOLUMN19-21

Page 1787 of 2585

Moving the switch up causes an upshift and moving

the switch down causes a downshift. The instrument

cluster will illuminate the selected gear. The vehicle

can be launched in 1st, 2nd, or 3rd gear while in the

Autostick mode. The speed control is operable in 3rd

and 4th gear Autostick mode. Speed control will be

deactivated if the transaxle is shifted to 2nd gear.

Shifting into OD position cancels the Autostick mode,

and the transaxle resumes the OD shift schedule.

DRIVING CLUTCHES

DESCRIPTION

Three hydraulically applied input clutches are used

to drive planetary components. The underdrive, over-

drive, and reverse clutches are considered input

clutches and are contained within the input clutch

assembly (Fig. 172). The input clutch assembly also

contains:

²Input shaft

²Input hub

²Clutch retainer

²Underdrive piston

²Overdrive/reverse piston

²Overdrive hub

²Underdrive hub

OPERATION

The three input clutches are responsible for driving

different components of the planetary geartrain.

NOTE: Refer to the ªElements In Useº chart in Diag-

nosis and Testing for a collective view of which

clutch elements are applied at each position of the

selector lever.

UNDERDRIVE CLUTCH

The underdrive clutch is hydraulically applied in

first, second, and third (direct) gears by pressurized

fluid against the underdrive piston. When the under-

drive clutch is applied, the underdrive hub drives the

rear sun gear.

OVERDRIVE CLUTCH

The overdrive clutch is hydraulically applied in

third (direct) and overdrive gears by pressurized fluid

against the overdrive/reverse piston. When the over-

drive clutch is applied, the overdrive hub drives the

front planet carrier.

REVERSE CLUTCH

The reverse clutch is hydraulically applied in

reverse gear only by pressurized fluid against the

overdrive/reverse piston. When the reverse clutch is

applied, the front sun gear assembly is driven.

FINAL DRIVE

DISASSEMBLY

NOTE: The differential is serviced as an assembly.

Differential service is limited to bearing cups and

cones. Any other differential component failure

must be remedied by differential assembly and

transfer shaft replacement.

Fig. 172 Input Clutch Assembly

1 - INPUT SHAFT

2 - UNDERDRIVE CLUTCH

3 - OVERDRIVE CLUTCH

4 - REVERSE CLUTCH

5 - OVERDRIVE SHAFT

6 - UNDERDRIVE SHAFT

21 - 190 41TE AUTOMATIC TRANSAXLERS

AUTOSTICK SWITCH (Continued)

Page 1838 of 2585

SPEED SENSOR - OUTPUT

DESCRIPTION

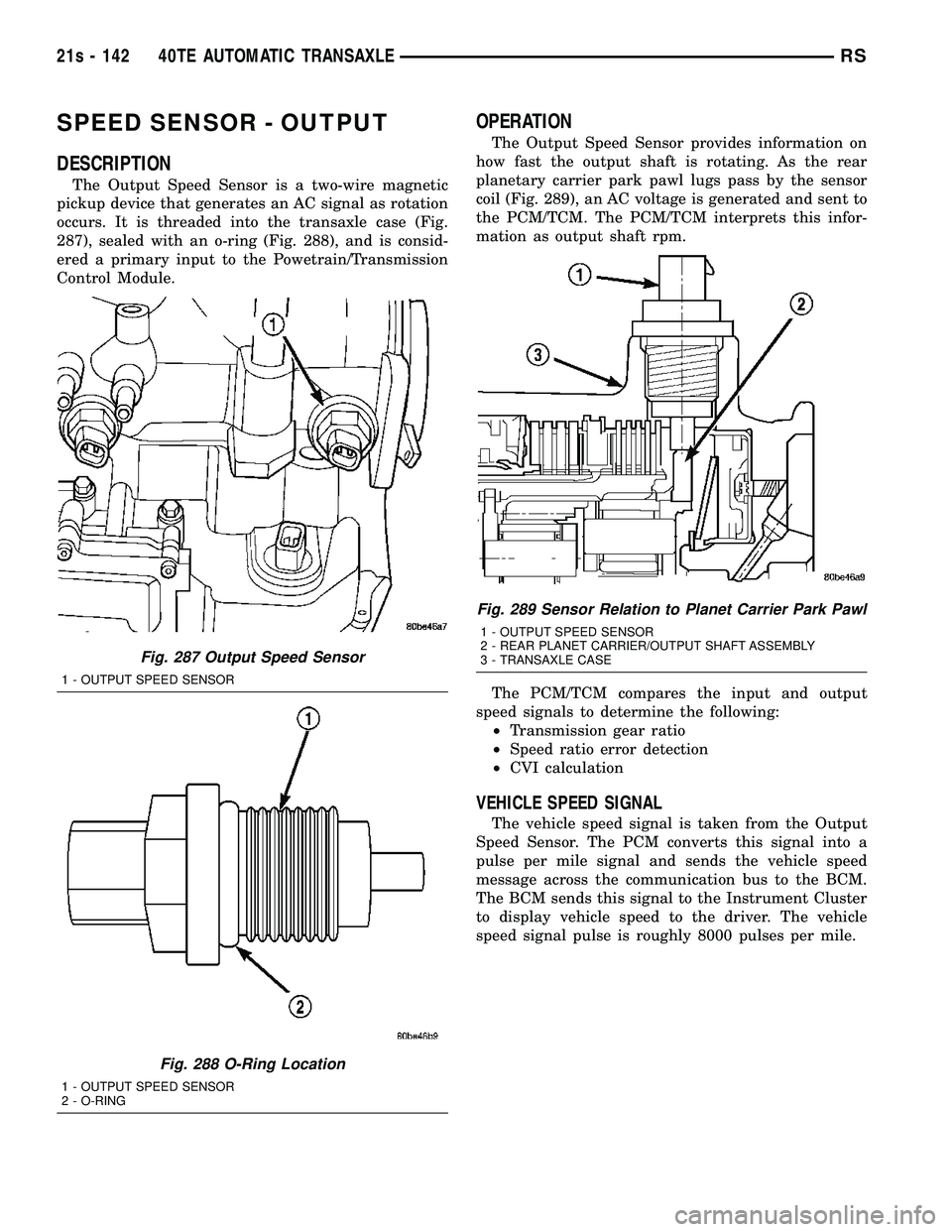

The Output Speed Sensor is a two-wire magnetic

pickup device that generates an AC signal as rotation

occurs. It is threaded into the transaxle case (Fig.

313), sealed with an o-ring (Fig. 314), and is consid-

ered a primary input to the Powetrain/Transmission

Control Module.

OPERATION

The Output Speed Sensor provides information on

how fast the output shaft is rotating. As the rear

planetary carrier park pawl lugs pass by the sensor

coil (Fig. 315), an AC voltage is generated and sent to

the PCM/TCM. The PCM/TCM interprets this infor-

mation as output shaft rpm.

The PCM/TCM compares the input and output

speed signals to determine the following:

²Transmission gear ratio

²Speed ratio error detection

²CVI calculation

VEHICLE SPEED SIGNAL

The vehicle speed signal is taken from the Output

Speed Sensor. The PCM converts this signal into a

pulse per mile signal and sends the vehicle speed

message across the communication bus to the BCM.

The BCM sends this signal to the Instrument Cluster

to display vehicle speed to the driver. The vehicle

speed signal pulse is roughly 8000 pulses per mile.

REMOVAL

(1) Disconnect battery negative cable.

(2) Raise vehicle on hoist.

(3) Disconnect output speed sensor connector.

(4) Unscrew and remove output speed sensor (Fig.

316).

(5) Inspect speed sensor o-ring (Fig. 317) and

replace if necessary.

Fig. 313 Output Speed Sensor

1 - OUTPUT SPEED SENSOR

Fig. 314 O-Ring Location

1 - OUTPUT SPEED SENSOR

2 - O-RING

Fig. 315 Sensor Relation to Planet Carrier Park Pawl

1 - OUTPUT SPEED SENSOR

2 - REAR PLANET CARRIER/OUTPUT SHAFT ASSEMBLY

3 - TRANSAXLE CASE

RS41TE AUTOMATIC TRANSAXLE21 - 241

Page 2003 of 2585

SPEED SENSOR - OUTPUT

DESCRIPTION

The Output Speed Sensor is a two-wire magnetic

pickup device that generates an AC signal as rotation

occurs. It is threaded into the transaxle case (Fig.

287), sealed with an o-ring (Fig. 288), and is consid-

ered a primary input to the Powetrain/Transmission

Control Module.

OPERATION

The Output Speed Sensor provides information on

how fast the output shaft is rotating. As the rear

planetary carrier park pawl lugs pass by the sensor

coil (Fig. 289), an AC voltage is generated and sent to

the PCM/TCM. The PCM/TCM interprets this infor-

mation as output shaft rpm.

The PCM/TCM compares the input and output

speed signals to determine the following: ² Transmission gear ratio

² Speed ratio error detection

² CVI calculation

VEHICLE SPEED SIGNAL

The vehicle speed signal is taken from the Output

Speed Sensor. The PCM converts this signal into a

pulse per mile signal and sends the vehicle speed

message across the communication bus to the BCM.

The BCM sends this signal to the Instrument Cluster

to display vehicle speed to the driver. The vehicle

speed signal pulse is roughly 8000 pulses per mile.

Fig. 287 Output Speed Sensor

1 - OUTPUT SPEED SENSOR

Fig. 288 O-Ring Location

1 - OUTPUT SPEED SENSOR

2 - O-RING

Fig. 289 Sensor Relation to Planet Carrier Park Pawl

1 - OUTPUT SPEED SENSOR

2 - REAR PLANET CARRIER/OUTPUT SHAFT ASSEMBLY

3 - TRANSAXLE CASE

21s - 142 40TE AUTOMATIC TRANSAXLERS

Page 2174 of 2585

INSTRUMENT PANEL

TABLE OF CONTENTS

page page

CLUSTER BEZEL

REMOVAL.............................63

INSTALLATION.........................63

CUP HOLDER

REMOVAL.............................64

INSTALLATION.........................64

GLOVE BOX

REMOVAL.............................64

INSTALLATION.........................64

GLOVE BOX LATCH

REMOVAL.............................64

INSTALLATION.........................64

GLOVE BOX LATCH STRIKER

REMOVAL.............................64

INSTALLATION.........................64

INSTRUMENT PANEL ASSEMBLY

REMOVAL.............................65

INSTALLATION.........................66

INSTRUMENT PANEL CENTER BEZEL

REMOVAL.............................68

INSTALLATION.........................68

INSTRUMENT PANEL END CAP

REMOVAL.............................68INSTALLATION.........................68

INSTRUMENT PANEL TOP COVER

REMOVAL.............................68

INSTALLATION.........................69

LOWER CONSOLE

REMOVAL.............................69

INSTALLATION.........................69

LOWER INSTRUMENT PANEL

REMOVAL.............................69

INSTALLATION.........................69

LOWER STEERING COLUMN COVER

REMOVAL.............................70

INSTALLATION.........................70

STEERING COLUMN COVER BACKING PLATE

REMOVAL.............................70

INSTALLATION.........................70

OVER STEERING COLUMN COVER

REMOVAL.............................70

INSTALLATION.........................70

INSTRUMENT PANEL TOP PAD ASSEMBLY

REMOVAL.............................71

INSTALLATION.........................72

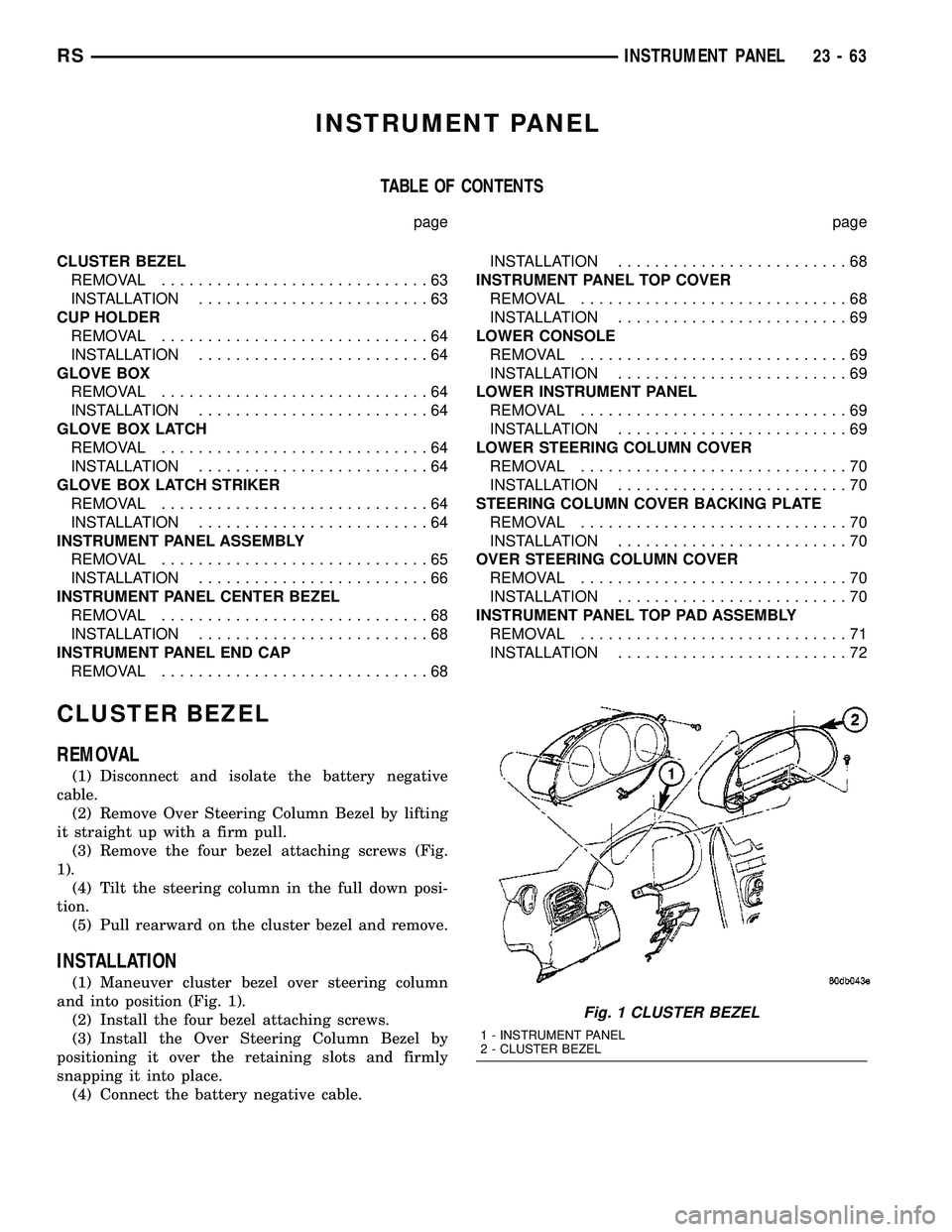

CLUSTER BEZEL

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove Over Steering Column Bezel by lifting

it straight up with a firm pull.

(3) Remove the four bezel attaching screws (Fig.

1).

(4) Tilt the steering column in the full down posi-

tion.

(5) Pull rearward on the cluster bezel and remove.

INSTALLATION

(1) Maneuver cluster bezel over steering column

and into position (Fig. 1).

(2) Install the four bezel attaching screws.

(3) Install the Over Steering Column Bezel by

positioning it over the retaining slots and firmly

snapping it into place.

(4) Connect the battery negative cable.

Fig. 1 CLUSTER BEZEL

1 - INSTRUMENT PANEL

2 - CLUSTER BEZEL

RSINSTRUMENT PANEL23-63

Page 2182 of 2585

INSTRUMENT PANEL TOP PAD

ASSEMBLY

REMOVAL

(1) Remove the instrument cluster (Fig. 14). (Refer

to 8 - ELECTRICAL/INSTRUMENT CLUSTER -

REMOVAL)

(2) Remove the message center (Fig. 14). (Refer to

8 - ELECTRICAL/MESSAGE CENTER - REMOVAL)

(3) Remove the radio (Fig. 14). (Refer to 8 - ELEC-

TRICAL/AUDIO/RADIO - REMOVAL)

(4) Remove the headlamp switch (Fig. 14). (Refer

to 8 - ELECTRICAL/LAMPS/LIGHTING - EXTERI-

OR/HEADLAMP SWITCH - REMOVAL)

(5) Remove the lower console (Fig. 14). (Refer to 23

- BODY/INSTRUMENT PANEL/LOWER CONSOLE

- REMOVAL)

(6) Remove the lower panel. (Refer to 23 - BODY/

INSTRUMENT PANEL/LOWER INSTRUMENT

PANEL TRIM - REMOVAL)

(7) Remove the instrument panel assembly. (Refer

to 23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - REMOVAL)

(8) Remove the instrument panel speakers.

(9) Remove the glove box light.

(10) Remove the two passenger air bag mounting

bolts (Fig. 15).

(11) Loosen the three passenger air bag support

bracket bolts to the hydro-form rail (Fig. 15).

(12) Remove the 16 screws along the upper edge of

the pad & panel assembly.

(13) Remove the 19 screws along the lower edge of

the pad & panel assembly.

(14) Remove the pad and panel assembly (Fig. 14).

Fig. 13 OVER STEERING COLUMN COVER

1 - INSTRUMENT PANEL OVER STEERING COLUMN COVER

2 - INSTRUMENT PANEL

Fig. 14 INSTRUMENT PANEL ASSEMBLY

1 - INSTRUMENT CLUSTER

2 - MESSAGE CENTER

3 - TOP COVER

4 - PAD AND PANEL ASSEMBLY

5 - LOWER CONSOLE

6 - LOWER PANEL

7 - RADIO

8 - HEADLAMP SWITCH

Fig. 15 AIRBAG MOUNTING HARDWARE

1 - AIR BAG SCREWS (2)

2 - ELECTRICAL CONNECTOR

3 - AIR BAG SUPPORT BRACKET BOLTS (3)

4 - HYDRO-FORM INSTRUMENT PANEL SUPPORT RAIL

RSINSTRUMENT PANEL23-71

OVER STEERING COLUMN COVER (Continued)

Page 2183 of 2585

INSTALLATION

(1) Position the pad & panel assembly onto the

instrument panel support structure.

(2) Install the 19 screws along the lower edge of

the pad & panel assembly.

(3) Install the 16 screws along the upper edge of

the pad & panel assembly.

(4) Install and tighten the two passenger air bag

mounting screws.

(5) Tighten the three passenger air bag support

bracket bolts to the hydro-form tube.

(6) Install the glove box light.

(7) Install the instrument panel speakers.

(8) Install the instrument panel assembly. (Refer

to 23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - INSTALLATION)

(9) Install the lower panel. (Refer to 23 - BODY/

INSTRUMENT PANEL/LOWER INSTRUMENT

PANEL TRIM - INSTALLATION)(10) Install the lower console. (Refer to 23 - BODY/

INSTRUMENT PANEL/LOWER CONSOLE -

INSTALLATION)

(11) Install the headlamp switch. (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

HEADLAMP SWITCH - INSTALLATION)

(12) Install the radio. (Refer to 8 - ELECTRICAL/

AUDIO/RADIO - INSTALLATION)

(13) Install the message center. (Refer to 8 -

ELECTRICAL/MESSAGE CENTER - INSTALLA-

TION)

(14) Install the instrument cluster. (Refer to 8 -

ELECTRICAL/INSTRUMENT CLUSTER - INSTAL-

LATION)

23 - 72 INSTRUMENT PANELRS

INSTRUMENT PANEL TOP PAD ASSEMBLY (Continued)

Page 2546 of 2585

BASE COAT/CLEARCOAT FINISH -

DESCRIPTION.......................23-85

BATTERY - DESCRIPTION...............8F-7

BATTERY - DIAGNOSIS AND TESTING.....8F-9

BATTERY - OPERATION.................8F-9

BATTERY - REMOVAL............8F-14,8F-15

BATTERY - SPECIFICATIONS.............8N-5

BATTERY CABLE - DIAGNOSIS AND

TESTING...........................8F-16

BATTERY CABLES - DESCRIPTION.......8F-16

BATTERY CABLES - INSTALLATION.......8F-18

BATTERY CABLES - OPERATION.........8F-16

BATTERY CABLES - REMOVAL..........8F-18

BATTERY CHARGING - STANDARD

PROCEDURE, CONVENTIONAL..........8F-11

BATTERY CHARGING - STANDARD

PROCEDURE, SPIRAL PLATE............8F-10

BATTERY ELECTROLYTE LEVEL -

STANDARD PROCEDURE, CHECKING.....8F-14

BATTERY HOLDDOWN - DESCRIPTION....8F-15

BATTERY HOLDDOWN - INSTALLATION . . . 8F-16

BATTERY HOLDDOWN - OPERATION.....8F-15

BATTERY HOLDDOWN - REMOVAL . . 8F-15,8F-16

BATTERY REPLACEMENT - STANDARD

PROCEDURE....................8N-42,8N-5

BATTERY, SPECIFICATIONS.............8N-43

BATTERY SYSTEM - CLEANING.......8F-4,8F-5

BATTERY SYSTEM - DESCRIPTION........8F-1

BATTERY SYSTEM - DIAGNOSIS AND

TESTING............................8F-2

BATTERY SYSTEM - INSPECTION.....8F-5,8F-6

BATTERY SYSTEM - OPERATION.........8F-2

BATTERY SYSTEM - SPECIFICATIONS......8F-6

BATTERY SYSTEM SPECIAL TOOLS,

SPECIAL TOOLS......................8F-7

BATTERY TEMPERATURE SENSOR -

DESCRIPTION.......................8F-23

BATTERY TEMPERATURE SENSOR -

OPERATION.........................8F-23

BATTERY TEMPERATURE SENSOR -

REMOVAL..........................8F-23

BATTERY TEMPERATURE SENSOR -

SPECIFICATIONS.....................8F-22

BATTERY TRAY - DESCRIPTION.........8F-18

BATTERY TRAY - INSTALLATION.........8F-19

BATTERY TRAY - OPERATION......8F-18,8F-19

BATTERY TRAY - REMOVAL............8F-19

BEARING - DESCRIPTION, HUB.......2-30,2-4

BEARING - DIAGNOSIS AND TESTING,

HUB.............................2-31,2-5

BEARING - INSTALLATION, CLUTCH

RELEASE LEVER.......................6-7

BEARING - INSTALLATION, END COVER

BALL..............................21-10

BEARING - INSTALLATION, HUB.......2-33,2-6

BEARING - OPERATION, HUB.........2-30,2-4

BEARING - REMOVAL, CLUTCH RELEASE

LEVER...............................6-6

BEARING - REMOVAL, END COVER BALL . . . 21-9

BEARING - REMOVAL, HUB..........2-31,2-5

BEARING CLEARANCE - STANDARD

PROCEDURE, MEASURING

CONNECTING ROD...................9-120

BEARING CLEARANCE USING

PLASTIGAGE - STANDARD

PROCEDURE, MEASURING..........9-12,9-84

BEARING FITTING - STANDARD

PROCEDURE, MAIN...................9-123

BEARING PRELOAD - ADJUSTMENT,

DIFFERENTIAL......................21-199

BEARING PRELOAD MEASUREMENT

AND ADJUSTMENT, ADJUSTMENTS -

DIFFERENTIAL.....................21s-100

BEARINGS - INSTALLATION,

CRANKSHAFT MAIN..................9-124

BEARINGS - REMOVAL, CRANKSHAFT

MAIN..............................9-124

BEARINGS (IN BLOCK) - DESCRIPTION,

CAMSHAFT.........................9-115

BEARINGS (IN BLOCK) - INSPECTION,

CAMSHAFT

.........................9-115

BEARINGS (IN BLOCK) - INSTALLATION,

CAMSHAFT

.........................9-115

BEARINGS (IN BLOCK) - OPERATION,

CAMSHAFT

.........................9-115

BEARINGS (IN BLOCK) - REMOVAL,

CAMSHAFT

.........................9-115

BELLCRANK - INSTALLATION

...........23-35BELLCRANK - REMOVAL...............23-35

BELT - DIAGNOSIS AND TESTING,

ACCESSORY DRIVE.....................7-7

BELT - INSTALLATION, TIMING...........9-65

BELT - REMOVAL, TIMING..............9-63

BELT & RETRACTOR - FIRST ROW -

OUTBOARD - INSTALLATION, SEAT......8O-14

BELT & RETRACTOR - FIRST ROW -

OUTBOARD - REMOVAL, SEAT..........8O-14

BELT & RETRACTOR - OUTBOARD -

FRONT - INSTALLATION, SEAT..........8O-14

BELT & RETRACTOR - OUTBOARD -

FRONT - REMOVAL, SEAT..............8O-14

BELT & RETRACTOR - SECOND ROW -

LEFT OUTBOARD - INSTALLATION,

SEAT ..............................8O-17

BELT & RETRACTOR - SECOND ROW -

LEFT OUTBOARD - REMOVAL, SEAT.....8O-17

BELT & RETRACTOR - SECOND ROW -

RIGHT OUTBOARD - INSTALLATION,

SEAT ..............................8O-15

BELT & RETRACTOR - SECOND ROW -

RIGHT OUTBOARD - REMOVAL, SEAT....8O-15

BELT & RETRACTOR - SECOND ROW -

RIGHT OUTBOARD WITH REAR HVAC -

LWB - INSTALLATION, SEAT............8O-16

BELT & RETRACTOR - SECOND ROW -

RIGHT OUTBOARD WITH REAR HVAC -

LWB - REMOVAL, SEAT...............8O-16

BELT BUCKLE - FIRST ROW - BENCH -

INSTALLATION, SEAT.................8O-13

BELT BUCKLE - FIRST ROW - BENCH -

REMOVAL, SEAT.....................8O-13

BELT BUCKLE - FIRST ROW INBOARD -

QUAD BUCKET - INSTALLATION, SEAT....8O-12

BELT BUCKLE - FIRST ROW INBOARD -

QUAD BUCKET - REMOVAL, SEAT.......8O-12

BELT BUCKLE - FRONT INBOARD -

INSTALLATION, SEAT.................8O-12

BELT BUCKLE - FRONT INBOARD -

REMOVAL, SEAT.....................8O-12

BELT BUCKLE - SECOND ROW - THREE

PASSENGER BENCH - INSTALLATION,

SEAT ..............................8O-15

BELT BUCKLE - SECOND ROW - THREE

PASSENGER BENCH - REMOVAL, SEAT . . . 8O-15

BELT BUCKLE - SECOND ROW INBOARD

- 50/50 BENCH - INSTALLATION, SEAT . . . 8O-13

BELT BUCKLE - SECOND ROW INBOARD

- 50/50 BENCH - REMOVAL, SEAT.......8O-13

BELT COVER(S) - INSTALLATION,

TIMING.............................9-62

BELT COVER(S) - REMOVAL, TIMING......9-61

BELT HEIGHT ADJUSTER-BOR

C-PILLAR - INSTALLATION, SEAT........8O-13

BELT HEIGHT ADJUSTER-BOR

C-PILLAR - REMOVAL, SEAT...........8O-13

BELT HEIGHT ADJUSTER KNOB -

INSTALLATION, SEAT.................8O-14

BELT HEIGHT ADJUSTER KNOB -

REMOVAL, SEAT.....................8O-14

BELT MOLDING - INSTALLATION, FRONT

DOOR INNER.......................23-115

BELT MOLDING - INSTALLATION, FRONT

DOOR OUTER......................23-113

BELT MOLDING - REMOVAL, FRONT

DOOR INNER.......................23-115

BELT MOLDING - REMOVAL, FRONT

DOOR OUTER......................23-113

BELT TENSION - STANDARD

PROCEDURE, CHECKING POWER

STEERING............................7-8

BELT TENSION, SPECIFICATIONS -

ACCESSORY DRIVE.....................7-5

BELT TENSIONER - 2.4L - INSTALLATION . . 7-10

BELT TENSIONER - 2.4L - REMOVAL......7-10

BELT TENSIONER - 3.3/3.8L -

INSTALLATION........................7-12

BELT TENSIONER - 3.3/3.8L - REMOVAL . . . 7-12

BELT TENSIONER - DESCRIPTION, SEAT . . 8O-17

BELT TENSIONER - OPERATION, SEAT....8O-17

BELT TENSIONER & PULLEY -

INSTALLATION, TIMING

.................9-69

BELT TENSIONER & PULLEY -

REMOVAL, TIMING

....................9-68

BELTS - 2.4L - ADJUSTMENTS, DRIVE

.....7-10

BELTS - 2.4L - CLEANING, DRIVE

..........7-9

BELTS - 2.4L - INSPECTION, DRIVE

........7-9BELTS - 2.4L - INSTALLATION, DRIVE.....7-10

BELTS - 2.4L - REMOVAL, DRIVE..........7-8

BELTS - 3.3/3.8L - CLEANING, DRIVE......7-11

BELTS - 3.3/3.8L - INSPECTION, DRIVE....7-11

BELTS - 3.3/3.8L - INSTALLATION, DRIVE . . 7-12

BELTS - 3.3/3.8L - REMOVAL, DRIVE......7-11

BENCH - INSTALLATION, SEAT BACK

HINGE COVERS - QUAD BUCKET, 50/50

SPLIT.............................23-101

BENCH - INSTALLATION, SEAT BELT

BUCKLE - FIRST ROW................8O-13

BENCH - INSTALLATION, SEAT BELT

BUCKLE - SECOND ROW - THREE

PASSENGER........................8O-15

BENCH - INSTALLATION, SEAT BELT

BUCKLE - SECOND ROW INBOARD -

50/50..............................8O-13

BENCH - INSTALLATION, SEAT CUSHION

COVER - QUAD BUCKET, 50/50 SPLIT . . . 23-100

BENCH - REMOVAL, SEAT BACK HINGE

COVERS - QUAD BUCKET, 50/50 SPLIT . . 23-101

BENCH - REMOVAL, SEAT BELT BUCKLE

- FIRST ROW.......................8O-13

BENCH - REMOVAL, SEAT BELT BUCKLE

- SECOND ROW - THREE PASSENGER....8O-15

BENCH - REMOVAL, SEAT BELT BUCKLE

- SECOND ROW INBOARD - 50/50.......8O-13

BENCH - REMOVAL, SEAT CUSHION

COVER - QUAD BUCKET, 50/50 SPLIT . . . 23-100

BENCH SEAT - REMOVAL, CHILD SEAT

MODULE...........................23-87

BENCH SEAT BACK - INSTALLATION.....23-103

BENCH SEAT BACK - REMOVAL........23-103

BENCH SEAT BACK COVER -

INSTALLATION......................23-103

BENCH SEAT BACK COVER - REMOVAL . . 23-103

BENCH SEAT BACK HINGE - REMOVAL . . 23-102

BENCH SEAT RISER - 50/50 SPLIT -

INSTALLATION......................23-100

BENCH SEAT RISER - 50/50 SPLIT -

REMOVAL.........................23-100

BENCH SEAT RISER - SECOND ROW -

INSTALLATION......................23-101

BENCH SEAT RISER - SECOND ROW -

REMOVAL.........................23-101

BENCH SEAT RISER - THIRD ROW -

INSTALLATION......................23-101

BENCH SEAT RISER - THIRD ROW -

REMOVAL.........................23-101

BENCH SEAT TRACK - INSTALLATION . . . 23-104

BENCH SEAT TRACK - REMOVAL.......23-104

BENCH SEATBACK PANEL -

INSTALLATION.......................23-99

BENCH SEATBACK PANEL - REMOVAL....23-99

BEZEL - INSTALLATION, CLUSTER.......23-63

BEZEL - INSTALLATION, INSTRUMENT

PANEL CENTER......................23-68

BEZEL - INSTALLATION, SLIDING DOOR

STOP BUMPER......................23-25

BEZEL - REMOVAL, CLUSTER...........23-63

BEZEL - REMOVAL, INSTRUMENT PANEL

CENTER............................23-68

BEZEL - REMOVAL, SLIDING DOOR

STOP BUMPER......................23-25

BEZEL OUTLETS - INSTALLATION,

CENTER............................24-45

BEZEL OUTLETS - REMOVAL, CENTER

....24-44

BI-DIRECTIONAL OVERRUNNING

CLUTCH - DESCRIPTION

................3-34

BI-DIRECTIONAL OVERRUNNING

CLUTCH - OPERATION

.................3-36

BIN - INSTALLATION, UNDER SEAT

STORAGE

..........................23-105

BIN - REMOVAL, UNDER SEAT STORAGE

. 23-105

BIN GUIDE - INSTALLATION, UNDER

SEAT STORAGE

.....................23-105

BIN GUIDE - REMOVAL, UNDER SEAT

STORAGE

..........................23-105

BIN LOCK/LATCH - INSTALLATION,

UNDER SEAT STORAGE

...............23-105

BIN LOCK/LATCH - REMOVAL, UNDER

SEAT STORAGE

.....................23-105

BLADES - CLEANING, WIPER

...........8R-14

BLADES - INSTALLATION, WIPER

........8R-14

BLADES - REMOVAL, WIPER

...........8R-14

BLEEDING - STANDARD PROCEDURE,

ANTILOCK BRAKE SYSTEM

..............5-78

RSINDEX3

Description Group-Page Description Group-Page Description Group-Page

Page 2550 of 2585

CHAIN WEAR - STANDARD PROCEDURE,

MEASURING TIMING..................9-153

CHANGE - STANDARD PROCEDURE,

DIFFERENTIAL ASSEMBLY FLUID.........3-40

CHANGE - STANDARD PROCEDURE,

ENGINE OIL AND FILTER...........9-137,9-53

CHANGE - STANDARD PROCEDURE,

OVERRUNNING CLUTCH HOUSING

FLUID..............................3-41

CHANGE - STANDARD PROCEDURE, PTU

FLUID..............................21-5

CHANGER - DESCRIPTION, CD...........8A-7

CHANGER - INSTALLATION, CD..........8A-8

CHANGER - OPERATION, CD.............8A-7

CHANGER - REMOVAL, CD..............8A-8

CHANNEL - INSTALLATION, WATER.....23-121

CHANNEL - REMOVAL, WATER.........23-121

CHARGE - STANDARD PROCEDURE,

REFRIGERANT SYSTEM...............24-72

CHARGE LEVEL TEST - 2.5L DIESEL -

DIAGNOSIS AND TESTING, SYSTEM......24-68

CHARGE LEVEL TEST - GASOLINE

ENGINES - DIAGNOSIS AND TESTING,

SYSTEM............................24-67

CHARGING - STANDARD PROCEDURE,

CONVENTIONAL BATTERY..............8F-11

CHARGING - STANDARD PROCEDURE,

SPIRAL PLATE BATTERY...............8F-10

CHARGING SYSTEM - DESCRIPTION.....8F-20

CHARGING SYSTEM - OPERATION.......8F-20

CHARTS - DIAGNOSIS AND TESTING,

STEERING SYSTEM DIAGNOSIS...........19-3

CHARTS - SPECIFICATIONS, COLOR

CODE..............................23-84

CHATTER COMPLAINTS - DIAGNOSIS

AND TESTING, CLUTCH.................6-6

CHECK - DIAGNOSIS AND TESTING,

COOLING SYSTEM FLOW................7-3

CHECK - DIAGNOSIS AND TESTING,

EXHAUST SYSTEM RESTRICTION.........11-2

CHECK - STANDARD PROCEDURE,

COOLANT LEVEL.......................7-5

CHECK - STANDARD PROCEDURE,

ENGINE OIL LEVEL...................9-137

CHECK - STANDARD PROCEDURE, FLUID

LEVEL.............................21-71

CHECK, STANDARD PROCEDURE -

ENGINE OIL LEVEL....................9-53

CHECK, STANDARD PROCEDURE - FLUID

LEVEL AND CONDITION........21-201,21s-102

CHECK STRAP - INSTALLATION.........23-15

CHECK STRAP - REMOVAL.............23-15

CHECKING - STANDARD PROCEDURE,

BRAKE FLUID LEVEL..............5-32,5s-31

CHECKING - STANDARD PROCEDURE,

POWER STEERING FLUID LEVEL........19-44

CHECKING BATTERY ELECTROLYTE

LEVEL - STANDARD PROCEDURE........8F-14

CHECKING ENGINE OIL PRESSURE -

DIAGNOSIS AND TESTING..............9-52

CHECKING POWER STEERING BELT

TENSION - STANDARD PROCEDURE.......7-8

CHILD RESTRAINT ANCHOR -

DESCRIPTION........................8O-4

CHILD RESTRAINT ANCHOR -

OPERATION..........................8O-4

CHILD SEAT - INSTALLATION, QUAD.....23-89

CHILD SEAT - REMOVAL, QUAD.........23-89

CHILD SEAT MODULE, BENCH SEAT -

REMOVAL..........................23-87

CHIME SYSTEM - DIAGNOSIS AND

TESTING

............................8B-1

CHIME/BUZZER - DESCRIPTION

..........8B-1

CHIME/BUZZER - OPERATION

............8B-1

CHIME/BUZZER - WARNING

.............8B-1

CHIME/THERMISTOR - DESCRIPTION

....8N-10

CHIME/THERMISTOR - INSTALLATION

....8N-10

CHIME/THERMISTOR - OPERATION

......8N-10

CHIME/THERMISTOR - REMOVAL

.......8N-10

CHIRP PREFERENCE - STANDARD

PROCEDURE, HORN

..............8N-42,8N-5

CIRCUIT - DIAGNOSIS AND TESTING,

AMBIENT TEMPERATURE SENSOR

......8M-12

CIRCUIT FUNCTIONS - DESCRIPTION

. . 8W-01-6

CIRCUIT INFORMATION - DESCRIPTION

. 8W-01-5

CIRCUIT RESISTANCE TEST -

DIAGNOSIS AND TESTING, FEED

. . . 8F-32,8F-34CIRCUIT TEST - DIAGNOSIS AND

TESTING, CONTROL..............8F-30,8F-32

CIRCUIT TEST - DIAGNOSIS AND

TESTING, FEED.................8F-33,8F-35

CIRCUITS - OPERATION, NON-

MONITORED.........................25-5

CIRCUITS AND VALVES - OPERATION,

HYDRAULIC..........................5-83

CLAMP - STANDARD PROCEDURE,

HOSES..............................14-7

CLAMPS - DESCRIPTION, FUEL

LINES/HOSES........................14-6

CLAMPS - DESCRIPTION, HOSE...........7-1

CLAMPS - OPERATION, HOSE.............7-2

CLEAN, CLEANING...................21-114

CLEARANCE - STANDARD PROCEDURE,

MEASURING CONNECTING ROD

BEARING...........................9-120

CLEARANCE USING PLASTIGAGE -

STANDARD PROCEDURE, MEASURING

BEARING........................9-12,9-84

CLOCK SPRING - DESCRIPTION..........8O-4

CLOCK SPRING - INSTALLATION.........8O-5

CLOCK SPRING - OPERATION...........8O-4

CLOCK SPRING - REMOVAL.............8O-5

CLOCK SPRING CENTERING -

STANDARD PROCEDURE...............8O-5

CLUSTER - DESCRIPTION, INSTRUMENT . . . 8J-1

CLUSTER - OPERATION, INSTRUMENT.....8J-1

CLUSTER BEZEL - INSTALLATION........23-63

CLUSTER BEZEL - REMOVAL.............23-63

CLUSTER DIAGNOSIS - DIAGNOSIS AND

TESTING............................8J-2

CLUSTER ILLUMINATION LAMPS -

INSTALLATION.......................8L-21

CLUSTER ILLUMINATION LAMPS -

REMOVAL..........................8L-21

CLUSTER LENS - INSTALLATION........8J-10

CLUSTER LENS - REMOVAL............8J-10

CLUTCH - DESCRIPTION.................6-1

CLUTCH - DESCRIPTION, BI-

DIRECTIONAL OVERRUNNING...........3-34

CLUTCH - OPERATION, BI-DIRECTIONAL

OVERRUNNING.......................3-36

CLUTCH AIR PRESSURE TESTS -

DIAGNOSIS AND TESTING.......21-122,21s-30

CLUTCH ASSEMBLY - ASSEMBLY,

INPUT.....................21-216,21s-116

CLUTCH ASSEMBLY - DISASSEMBLY,

INPUT.....................21-208,21s-107

CLUTCH ASSY - 2.4L GAS -

INSTALLATION, MODULAR..............6-11

CLUTCH ASSY - 2.4L GAS - REMOVAL,

MODULAR...........................6-11

CLUTCH CHATTER COMPLAINTS -

DIAGNOSIS AND TESTING...............6-6

CLUTCH COIL - DIAGNOSIS AND

TESTING, A/C COMPRESSOR...........24-15

CLUTCH COVER AND DISC RUNOUT -

DIAGNOSIS AND TESTING...............6-6

CLUTCH DISC AND PRESSURE PLATE -

2.5L TD - INSTALLATION

...............6-12

CLUTCH DISC AND PRESSURE PLATE -

2.5L TD - REMOVAL

...................6-11

CLUTCH HOUSING FLUID CHANGE -

STANDARD PROCEDURE,

OVERRUNNING

.......................3-41

CLUTCH PEDAL INTERLOCK SWITCH -

INSTALLATION

........................6-14

CLUTCH PEDAL INTERLOCK SWITCH -

REMOVAL

...........................6-13

CLUTCH PEDAL UPSTOP SWITCH -

INSTALLATION

........................6-16

CLUTCH PEDAL UPSTOP SWITCH -

REMOVAL

...........................6-15

CLUTCH RELAY - DESCRIPTION, A/C

COMPRESSOR

.......................24-19

CLUTCH RELAY - INSTALLATION, A/C

COMPRESSOR

.......................24-20

CLUTCH RELAY - OPERATION, A/C

COMPRESSOR

.......................24-19

CLUTCH RELAY - REMOVAL, A/C

COMPRESSOR

.......................24-20

CLUTCH RELEASE LEVER AND BEARING

- INSTALLATION

.......................6-7

CLUTCH RELEASE LEVER AND BEARING

- REMOVAL

...........................6-6CLUTCH SYSTEM - DIAGNOSIS AND

TESTING.............................6-3

CLUTCH/COIL - DESCRIPTION, A/C

COMPRESSOR.......................24-15

CLUTCH/COIL - INSPECTION, A/C

COMPRESSOR.......................24-17

CLUTCH/COIL - INSTALLATION, A/C

COMPRESSOR.......................24-17

CLUTCH/COIL - OPERATION, A/C

COMPRESSOR.......................24-15

CLUTCH/COIL - REMOVAL, A/C

COMPRESSOR.......................24-16

CLUTCHES - DESCRIPTION, DRIVING . . . 21-190,

21s-95

CLUTCHES - DESCRIPTION, HOLDING . . . 21-207,

21s-106

CLUTCHES - OPERATION, DRIVING.....21-190,

21s-95

CLUTCHES - OPERATION, HOLDING....21-207,

21s-106

COAT/CLEARCOAT FINISH -

DESCRIPTION, BASE..................23-85

CODE - DESCRIPTION, PAINT...........23-85

CODE CHARTS - SPECIFICATIONS,

COLOR.............................23-84

CODE PLATE - DESCRIPTION, BODY....Intro.-1

CODES - STANDARD PROCEDURE,

ERASING TRANSMITTER..............8M-11

CODES - STANDARD PROCEDURE,

OBTAINING DIAGNOSTIC TROUBLE......8E-15

CODES - STANDARD PROCEDURE,

SETTING TRANSMITTER..............8M-11

COIL - DESCRIPTION, IGNITION............8I-6

COIL - DIAGNOSIS AND TESTING, A/C

COMPRESSOR CLUTCH...............24-15

COIL - OPERATION, IGNITION............8I-7

COLLAR - INSTALLATION, STRUCTURAL . . . 9-48

COLLAR - REMOVAL, STRUCTURAL.......9-47

COLOR CODE CHARTS -

SPECIFICATIONS.....................23-84

COLUMN - DESCRIPTION, STEERING.....19-10

COLUMN - DIAGNOSIS AND TESTING,

STEERING..........................19-12

COLUMN COVER - INSTALLATION,

LOWER STEERING...................23-70

COLUMN COVER - INSTALLATION, OVER

STEERING..........................23-70

COLUMN COVER - REMOVAL, LOWER

STEERING..........................23-70

COLUMN COVER - REMOVAL, OVER

STEERING..........................23-70

COLUMN COVER BACKING PLATE -

INSTALLATION, STEERING.............23-70

COLUMN COVER BACKING PLATE -

REMOVAL, STEERING.................23-70

COLUMN TORQUE, SPECIFICATIONS.....19-14

COMBUSTION PRESSURE LEAKAGE

TEST - DIAGNOSIS AND TESTING,

CYLINDER........................9-83,9-9

COMMON PROBLEM CAUSES -

DIAGNOSIS AND TESTING.............21-30

COMMUNICATION RECEIVE - PCM INPUT

- OPERATION, DATA BUS..............8E-15

COMMUNICATIONS INTERFACE (PCI)

BUS, OPERATION - PROGRAMMABLE....14-21

COMPASS CALIBRATION - STANDARD

PROCEDURE.........................8M-3

COMPASS DEMAGNETIZING -

STANDARD PROCEDURE...............8M-4

COMPASS MINI-TRIP COMPUTER -

DIAGNOSIS AND TESTING.............8M-10

COMPASS VARIATION ADJUSTMENT -

STANDARD PROCEDURE...............8M-5

COMPASS/MINI-TRIP COMPUTER -

DESCRIPTION........................8M-9

COMPASS/MINI-TRIP COMPUTER -

INSTALLATION......................8M-10

COMPASS/MINI-TRIP COMPUTER -

OPERATION.........................8M-9

COMPASS/MINI-TRIP COMPUTER -

REMOVAL..........................8M-10

COMPLAINTS - DIAGNOSIS AND

TESTING, CLUTCH CHATTER

..............6-6

COMPRESSION PRESSURE TEST -

DIAGNOSIS AND TESTING, CYLINDER

. . 9-83,9-9

COMPRESSOR - DESCRIPTION, A/C

......24-73

COMPRESSOR - OPERATION, A/C

........24-73

COMPRESSOR - REMOVAL

.............24-74

RSINDEX7

Description Group-Page Description Group-Page Description Group-Page

Page 2561 of 2585

INBOARD - 50/50 BENCH - REMOVAL,

SEAT BELT BUCKLE - SECOND ROW.....8O-13

INBOARD - INSTALLATION, SEAT BELT

BUCKLE - FRONT....................8O-12

INBOARD - QUAD BUCKET -

INSTALLATION, SEAT BELT BUCKLE -

FIRST ROW.........................8O-12

INBOARD - QUAD BUCKET - REMOVAL,

SEAT BELT BUCKLE - FIRST ROW.......8O-12

INBOARD - REMOVAL, SEAT BELT

BUCKLE - FRONT....................8O-12

INDICATOR LAMP - DESCRIPTION,

VTSS/SKIS..........................8Q-7

INDICATOR LAMP - OPERATION,

VTSS/SKIS..........................8Q-8

INDICATORS - DIAGNOSIS AND

TESTING, TREAD WEAR..........22-16,22s-8

INFLATION PRESSURES - STANDARD

PROCEDURE, TIRE..............22-16,22s-8

INFO CENTER - DESCRIPTION,

ELECTRONIC VEHICLE.................8M-6

INFO CENTER - INSTALLATION,

ELECTRONIC VEHICLE.................8M-9

INFO CENTER - OPERATION,

ELECTRONIC VEHICLE.................8M-7

INFO CENTER - REMOVAL, ELECTRONIC

VEHICLE............................8M-9

INFRARED TEMPERATURE SENSOR -

DESCRIPTION.......................24-29

INFRARED TEMPERATURE SENSOR -

OPERATION.........................24-29

INITIAL OPERATION - STANDARD

PROCEDURE, POWER STEERING

PUMP.............................19-37

INJECTION SYSTEM - OPERATION.......14-18

INJECTOR - DESCRIPTION, FUEL........14-26

INJECTOR - OPERATION, FUEL..........14-26

INLET AIR TEMPERATURE SENSOR -

DESCRIPTION.......................14-30

INLET FILTER - INSTALLATION..........14-13

INLET FILTER - REMOVAL..............14-13

INLET HOSE - INSTALLATION, HEATER....24-86

INLET HOSE - REMOVAL, HEATER.......24-85

INLET TUBE - 2.4L - DESCRIPTION,

WATER PUMP........................7-35

INLET TUBE - 2.4L - INSTALLATION,

WATER PUMP........................7-35

INLET TUBE - 2.4L - REMOVAL, WATER

PUMP..............................7-35

INLET TUBE - 3.3/3.8L - INSTALLATION,

WATER PUMP........................7-36

INLET TUBE - 3.3/3.8L - REMOVAL,

WATER PUMP........................7-36

INNER - INSTALLATION, CV BOOT.........3-6

INNER - REMOVAL, CV BOOT.............3-6

INNER BELT MOLDING - INSTALLATION,

FRONT DOOR......................23-115

INNER BELT MOLDING - REMOVAL,

FRONT DOOR......................23-115

INNER SEAL - INSTALLATION, HALF

SHAFT.............................21-12

INNER SEAL - REMOVAL, HALF SHAFT . . . 21-12

INNER/OUTER - INSTALLATION, CV

BOOT...............................3-17

INNER/OUTER - REMOVAL, CV BOOT......3-15

INPUT - DESCRIPTION, SPEED SENSOR . 21-239,

21s-140

INPUT - INSTALLATION, SPEED

SENSOR....................21-240,21s-141

INPUT - OPERATION, DATA BUS

COMMUNICATION RECEIVE - PCM.......8E-15

INPUT - OPERATION, IGNITION SENSE -

PCM...............................8E-15

INPUT - OPERATION, SENSOR RETURN -

PCM...............................8E-15

INPUT - OPERATION, SPEED SENSOR . . . 21-240,

21s-140

INPUT - REMOVAL, SPEED SENSOR....21-240,

21s-141

INPUT CLUTCH ASSEMBLY - ASSEMBLY . 21-216,

21s-116

INPUT CLUTCH ASSEMBLY -

DISASSEMBLY...............21-208,21s-107

INPUT FLANGE SEAL - INSTALLATION

.....3-45

INPUT FLANGE SEAL - REMOVAL

.........3-44

INPUT SHAFT - ASSEMBLY

........21-96,21s-5

INPUT SHAFT - DESCRIPTION

.....21-93,21s-1

INPUT SHAFT - DISASSEMBLY

.....21-93,21s-1INPUT SHAFT COVER SEAL -

INSTALLATION.......................21-14

INPUT SHAFT COVER SEAL - REMOVAL . . . 21-13

INPUT SHAFT END SEAL -

INSTALLATION.......................21-16

INPUT SHAFT END SEAL - REMOVAL.....21-15

INPUT SHAFT SEAL - INSTALLATION.....21-18

INPUT SHAFT SEAL - REMOVAL.........21-17

INSIDE HANDLE ACTUATOR -

INSTALLATION.......................23-27

INSIDE HANDLE ACTUATOR - REMOVAL . . 23-27

INSIDE HANDLE CABLE - INSTALLATION . . 23-38

INSIDE HANDLE CABLE - REMOVAL......23-37

INSIDE LATCH HANDLE - INSTALLATION . . 23-34

INSIDE LATCH HANDLE - REMOVAL......23-34

INSPECT, INSPECTION...............21-114

INSTRUMENT CLUSTER - DESCRIPTION . . . 8J-1

INSTRUMENT CLUSTER - OPERATION.....8J-1

INSTRUMENT PANEL - INSTALLATION,

LOWER............................23-69

INSTRUMENT PANEL - REMOVAL,

LOWER............................23-69

INSTRUMENT PANEL ANTENNA CABLE -

INSTALLATION.......................8A-9

INSTRUMENT PANEL ANTENNA CABLE -

REMOVAL...........................8A-8

INSTRUMENT PANEL ASSEMBLY -

INSTALLATION.......................23-66

INSTRUMENT PANEL ASSEMBLY -

REMOVAL............................23-65

INSTRUMENT PANEL CENTER BEZEL -

INSTALLATION.......................23-68

INSTRUMENT PANEL CENTER BEZEL -

REMOVAL..........................23-68

INSTRUMENT PANEL DEMISTER DUCTS

- INSTALLATION.....................24-55

INSTRUMENT PANEL DEMISTER DUCTS

- REMOVAL.........................24-55

INSTRUMENT PANEL DUCTS -

INSTALLATION.......................24-55

INSTRUMENT PANEL DUCTS - REMOVAL . 24-55

INSTRUMENT PANEL END CAP -

INSTALLATION.......................23-68

INSTRUMENT PANEL END CAP -

REMOVAL..........................23-68

INSTRUMENT PANEL OUTLET -

INSTALLATION.......................24-46

INSTRUMENT PANEL OUTLET -

REMOVAL..........................24-45

INSTRUMENT PANEL TOP COVER -

INSTALLATION.......................23-69

INSTRUMENT PANEL TOP COVER -

REMOVAL..........................23-68

INSTRUMENT PANEL TOP PAD

ASSEMBLY - INSTALLATION............23-72

INSTRUMENT PANEL TOP PAD

ASSEMBLY - REMOVAL................23-71

INTAKE MANIFOLD - DESCRIPTION . . 9-144,9-58

INTAKE MANIFOLD - INSTALLATION,

LOWER............................9-149

INTAKE MANIFOLD - INSTALLATION,

UPPER.............................9-147

INTAKE MANIFOLD - LOWER -

CLEANING..........................9-148

INTAKE MANIFOLD - LOWER -

INSPECTION....................9-148,9-60

INTAKE MANIFOLD - LOWER -

INSTALLATION........................9-60

INTAKE MANIFOLD - LOWER - REMOVAL . . 9-60

INTAKE MANIFOLD - REMOVAL, LOWER . . 9-148

INTAKE MANIFOLD - REMOVAL, UPPER . . . 9-145

INTAKE MANIFOLD - UPPER -

INSPECTION.........................9-59

INTAKE MANIFOLD - UPPER -

INSTALLATION........................9-59

INTAKE MANIFOLD - UPPER - REMOVAL . . . 9-58

INTAKE MANIFOLD LEAKS - DIAGNOSIS

AND TESTING...................9-145,9-58

INTAKE MANIFOLD VACUUM PORT

REPAIR - STANDARD PROCEDURE.......9-145

INTAKE PIPE - INSTALLATION, AIR

......24-114

INTAKE PIPE - REMOVAL, AIR

.........24-113

INTAKE/EXHAUST VALVES & SEATS -

CLEANING

.................9-105,9-32,9s-22

INTAKE/EXHAUST VALVES & SEATS -

DESCRIPTION

..............9-104,9-32,9s-21

INTAKE/EXHAUST VALVES & SEATS -

INSPECTION

...................9-105,9s-22INTAKE/EXHAUST VALVES & SEATS -

INSTALLATION..................9-106,9s-23

INTAKE/EXHAUST VALVES & SEATS -

OPERATION....................9-104,9s-21

INTAKE/EXHAUST VALVES & SEATS -

REMOVAL.....................9-105,9s-22

INTEGRAL ANTENNA - EXPORT -

DESCRIPTION, QUARTER GLASS.........8A-9

INTEGRAL ANTENNA - EXPORT -

DIAGNOSIS AND TESTING, QUARTER

GLASS..............................8A-9

INTEGRAL ANTENNA - EXPORT -

OPERATION, QUARTER GLASS...........8A-9

INTEGRATED POWER MODULE -

DESCRIPTION.....................8W-97-2

INTEGRATED POWER MODULE -

INSTALLATION....................8W-97-3

INTEGRATED POWER MODULE -

OPERATION.......................8W-97-2

INTEGRATED POWER MODULE -

REMOVAL........................8W-97-2

INTERACTIVE SPEED CONTROL (4

SPEED EATX ONLY) - OPERATION........8P-2

INTERFACE (PCI) BUS, OPERATION -

PROGRAMMABLE COMMUNICATIONS....14-21

INTERIOR LAMPS, SPECIFICATIONS......8L-20

INTERLOCK - DESCRIPTION, IGNITION....19-17

INTERLOCK SOLENOID - DESCRIPTION,

SHIFT......................21-233,21s-133

INTERLOCK SOLENOID - DIAGNOSIS

AND TESTING, BRAKE/TRANSMISSION

SHIFT......................21-235,21s-135

INTERLOCK SOLENOID - INSTALLATION,

SHIFT.......................21-236,21s-136

INTERLOCK SOLENOID - OPERATION,

SHIFT......................21-233,21s-134

INTERLOCK SOLENOID - REMOVAL,

SHIFT......................21-235,21s-135

INTERLOCK SWITCH - INSTALLATION,

CLUTCH PEDAL.......................6-14

INTERLOCK SWITCH - REMOVAL,

CLUTCH PEDAL.......................6-13

INTERMEDIATE SHAFT - ASSEMBLY....21-107,

21s-17

INTERMEDIATE SHAFT - DESCRIPTION . . 21-100,

21s-9

INTERMEDIATE SHAFT - DISASSEMBLY . 21-100,

21s-10

INTERNATIONAL SYMBOLS -

DESCRIPTION......................Intro.-5

INTERNATIONAL SYMBOLS -

DESCRIPTION.........................0-1

INTRODUCTION - DIAGNOSIS AND

TESTING, ENGINE DIAGNOSIS........9-3,9-76

IOD FUSE - DESCRIPTION...........8W-97-3

IOD FUSE - OPERATION.............8W-97-3

JOINT - DESCRIPTION, LOWER BALL......2-10

JOINT - DIAGNOSIS AND TESTING,

LOWER BALL........................2-10

JOINT - OPERATION, LOWER BALL.......2-10

JOINT MOLDING - INSTALLATION, ROOF . . 23-58

JOINT MOLDING - REMOVAL, ROOF......23-58

JOUNCE BUMPER - DESCRIPTION........2-36

JOUNCE BUMPER - OPERATION..........2-36

JUMP STARTING - STANDARD

PROCEDURE.........................0-27

JUNCTION BLOCK - DESCRIPTION,

NON-ABS.......................5-33,5s-32

JUNCTION BLOCK - INSTALLATION,

NON-ABS.......................5-33,5s-32

JUNCTION BLOCK - OPERATION,

NON-ABS.......................5-33,5s-32

JUNCTION BLOCK - REMOVAL, NON-ABS . . 5-33,

5s-32

KEY - DESCRIPTION, TRANSPONDER.....8Q-6

KEY - OPERATION, TRANSPONDER.......8Q-6

KEY IMMOBILIZER MODULE -

DESCRIPTION, SENTRY................8E-18

KEY IMMOBILIZER MODULE -

INSTALLATION, SENTRY

...............8E-19

KEY IMMOBILIZER MODULE -

OPERATION, SENTRY

.................8E-18

KEY IMMOBILIZER MODULE - REMOVAL,

SENTRY

............................8E-18

KEY REMOTE ENTRY MODULE -

DESCRIPTION, SENTRY

................8Q-3

KEY REMOTE ENTRY MODULE -

DIAGNOSIS AND TESTING, SENTRY

.......8Q-5

18 INDEXRS

Description Group-Page Description Group-Page Description Group-Page