seats CHRYSLER VOYAGER 2004 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1233 of 2585

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Blower Motor Resistor C1 (MTC) BK Right Side of HVAC N/S

Blower Motor Resistor C2 (MTC) BK Right Side of HVAC N/S

Body Control Module C1 BK Under Left Instrument Panel 41, 42

Body Control Module C2 BK/GN Under Left Instrument Panel 41, 42

Body Control Module C3 BK/WT Under Left Instrument Panel 41, 42

Body Control Module C4 BK/GY Under Left Instrument Panel 20, 21, 30

Body Control Module C5 BK Under Left Instrument Panel 20, 21, 30

Boost Pressure Sensor (Diesel) BK Top Left of Engine 15

Brake Fuid Level Switch BK On Master Cylinder 6

Brake Lamp Switch BK At Top Of Brake Pedal 41, 42

Brake Transmission Shift

Interlock Solenoid (EATX)BK Near Steering Column 20, 21, 22, 31

C100 BK Left Fender Shield 5, 11

C101 LTGY Left Fender Shield 5

C102 (Gas) BK At Fuel Rail 11, 17

C103 (Diesel) BK Left Side Engine Compartment N/S

C104 (Except Export LTGY Near Controller Antilock Brake 18

C106 (Export) BK/YL Near Left Headlamp Leveling Motor N/S

C107 (Export) BK/YL Near Right Headlamp Leveling

MotorN/S

C110 (Gas Export) BK Left Front Engine 11

C111 (EATX) LTGY Left Front Engine 11

C112 (Except Export) BK Near T/O for C101 N/S

C200 GY Left Side Instrument Panel 20, 21, 30, 41, 42

C201 YL Left Side Instrument Panel 20, 21, 30, 41, 42

C202 GY Right Side Instrument Panel A/C

Heater Unit20, 24, 29

C204 (Premium NAT/WT Rear of Radio 50

C300 (LHD) BK Left Front Door Lower 36, 43

C300 (RHD) BK Right Front Door Lower N/S

C301 LTGY Left Front Door Upper 36, 43

C302 LTGY Right Front Door Upper 8, 39, 44

C303 (LHD) BK Right Front Door Lower 8, 44

C303 (RHD) BK Left Front Door Lower 39, 44

C304 Left Wire Track Seat to Body 32

C305 GY Wire Track Seat to Body 32 33

C306 (RHD) YL Right Wire Track Seat to Body 33

C307 (Heated Seats) GY Right Wire Track Seat to Body N/S

C308 GN Left Rear Sliding Door 40

C309 GN/GY Right Rear Sliding Door 32, 33, 39

C310 (Front Console) BK At Front Console 34

C311 (3 Zone HVAC) GY Rear A/C Switch 40

C312 GY Right B Pillar 33, 39, 50

8W - 91 - 2 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONRS

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1237 of 2585

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Ignition Coil (2.4L) BK Top of Valve Cover 10, 11

Ignition Coil (3.3L/ 3.8L) DKGY Top of Engine 17, 18

Ignition Switch BK Rear of Switch at Steering Column 20, 21, 22, 23, 31

Inlet Air Temperature Sensor BK Top Left of Engine 9, 10, 11, 17

Input Speed Sensor GY Front of Transmission 14, 19

Instrument Cluster BK Rear of Cluster 20, 21, 28

Instrument Panel Switch Bank

(Heated Seats)BK Right Center of Instrument Panel 20, 23, 25

Instrument Panel Switch Bank

(Except Heated Seats)Right Center of Instrument Panel 20, 23, 25

Integrated Power Module C1 Left Fender Shield 6, 7

Integrated Power Module C2 GN/BL Left Fender Shield 6, 7

Integrated Power Module C3 Left Fender Shield 6, 7, 11

Integrated Power Module C4 BL Left Fender Shield 6, 7, 11

Integrated Power Module C5 BK Left Fender Shield 6, 7

Integrated Power Module C6 NAT Left Fender Shield 6, 7

Integrated Power Module C7 Left Fender Shield 6, 7

Integrated Power Module C8 OR Left Fender Shield 6, 7

Integrated Power Module C9 BK Left Fender Shield 6, 7

Knock Sensor (2.4L) BK At Engine Block N/S

Knock Sensor (3.3L/3.8L ABS

Except Export)GY Front of Cylinder Block 11

Left B Pillar Switch (Power

Sliding Door)GY Left B Pillar 40

Left Cinch/Release Motor (Power

Sliding Door)GY Left Sliding Door N/S

Left Cylinder Lock Switch BK At Switch 43

Left Door Speaker (Highline) BK/RD At Speaker 43

Left Door Speaker (Lowline) In Door N/S

Left Fog Lamp (Except Export) BK At Lamp N/S

Left Fog Lamp (Export) WT At Lamp 5

Left Front Door Ajar Switch

(Base)BK At Switch N/S

Left Front Door Lock Motor/Ajar

Switch (Except Base)BK Left Door 43

Left Front Impact Sensor (Except

Export)BK Near T/O for C300 N/S

Left Front Park/Turn Signal Lamp

(Except Export)DKGY At Lamp 1

Left Front Wheel Speed Sensor GY Left Fender Side Shield 5, 11

Left Full Open Switch (Power

Sliding Door)BK Left Sliding Door N/S

Left Headlamp (Except Export) BK At Lamp 1

Left Headlamp Leveling Motor

(Export)WT At Motor N/S

8W - 91 - 6 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONRS

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1295 of 2585

POWER OUTLET

DESCRIPTION

Accessory power outlets are standard equipment on

this model. Two power outlets are installed in the

instrument panel center lower bezel, which is located

near the bottom of the instrument panel center stack

area. Two additional power outlets are also incorpo-

rated into the vehicle, one on the left rear C-pillar

trim and the other in the center console, if equipped.

The power outlets bases are secured by a snap fit in

the appropriate bezels. A hinged plug flips closed to

conceal and protect the power outlet base when the

power outlet is not being used.

The power outlet receptacle unit and the power

outlet plugs are each available for service replace-

ment.

OPERATION

The power outlet base or receptacle shell is con-

nected to ground, and an insulated contact in the

bottom of the shell is connected to battery current.

The power outlet on the instrument panel marked

with a battery receives battery voltage from a fuse in

the Integrated Power Module (IPM) at all times. The

other power outlet on the instrument panel marked

with a key receives battery voltage only when the

key is in the on position.

The power outlet located in the center console

receives battery voltage all the time when positioned

between thefront seatsand key-on voltage when

positioned between therear seats. The power outlet

located on the C-pillar receives battery voltage only

when the key is in the on position.

DIAGNOSIS AND TESTING

DIAGNOSIS & TESTING - POWER OUTLET

For complete circuit diagrams, refer toCigar

Lighter/Power Outletin Wiring Diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO RESTRAINTS BEFORE ATTEMPT-

ING ANY STEERING WHEEL, STEERING COLUMN,

SEAT OR INSTRUMENT PANEL COMPONENT DIAG-

NOSIS OR SERVICE. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Check the fused B(+) fuse in the Integrated

Power Module (IPM). If OK, go to Step 2. If not OK,

repair the shorted circuit or component as required

and replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

in the IPM. If OK, go to Step 3. If not OK, repair the

open fused B(+) circuit to the IPM fuse as required.

(3) Open the power outlet door. Check for continu-

ity between the inside circumference of the power

outlet receptacle and a good ground. There should be

continuity. If OK, go to Step 4. If not OK, go to Step

5.

(4) Check for battery voltage at the insulated con-

tact located at the back of the power outlet recepta-

cle. If not OK, go to Step 5.

(5) Disconnect and isolate the battery negative

cable. Remove the appropriate bezel. Check for conti-

nuity between the ground circuit cavity of the power

outlet wire harness connector and a good ground.

There should be continuity. If OK, go to Step 6. If not

OK, repair the open ground circuit to ground as

required.

(6) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

power outlet wire harness connector. If OK, replace

the faulty power outlet receptacle. If not OK, repair

the open fused B(+) circuit to the IPM fuse as

required.

8W - 97 - 4 8W-97 POWER DISTRIBUTION SYSTEMRS

Page 1298 of 2585

ENGINE

TABLE OF CONTENTS

page page

ENGINE 2.4L.............................. 1ENGINE 3.3/3.8L......................... 74

ENGINE 2.4L

TABLE OF CONTENTS

page page

ENGINE 2.4L

DESCRIPTION..........................3

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - INTRODUCTION............3

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - PERFORMANCE............4

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - MECHANICAL..............6

DIAGNOSIS AND TESTING - ENGINE OIL

LEAK INSPECTION.....................8

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE TEST.........9

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE

TEST................................9

STANDARD PROCEDURE

STANDARD PROCEDURE - ENGINE CORE

AND OIL GALLERY PLUGS..............10

STANDARD PROCEDURE - REPAIR OF

DAMAGED OR WORN THREADS.........10

STANDARD PROCEDURE - HYDROSTATIC

LOCKED ENGINE.....................10

STANDARD PROCEDURE - FORM-IN-

PLACE GASKETS AND SEALERS.........11

STANDARD PROCEDURE - ENGINE

GASKET SURFACE PREPARATION........11

STANDARD PROCEDURE - MEASURING

BEARING CLEARANCE USING

PLASTIGAGE........................12

REMOVAL - ENGINE ASSEMBLY...........13

INSTALLATION - ENGINE ASSEMBLY........16

SPECIFICATIONS

SPECIFICATIONS - 2.4L ENGINE.........17

SPECIFICATIONS - TORQUE............20

SPECIAL TOOLS

2.4L ENGINE.........................21AIR CLEANER ELEMENT

REMOVAL.............................24

INSTALLATION.........................24

AIR CLEANER HOUSING

REMOVAL.............................24

INSTALLATION.........................24

CYLINDER HEAD

DESCRIPTION.........................24

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET............................24

REMOVAL - CYLINDER HEAD.............25

CLEANING............................26

INSPECTION..........................26

INSTALLATION - CYLINDER HEAD..........26

CAMSHAFT OIL SEAL(S)

REMOVAL.............................27

INSTALLATION.........................28

CAMSHAFT(S)

DESCRIPTION.........................28

OPERATION...........................28

STANDARD PROCEDURE - MEASURING

CAMSHAFT END PLAY.................29

REMOVAL.............................29

CLEANING............................29

INSPECTION..........................30

INSTALLATION.........................30

CYLINDER HEAD COVER

REMOVAL.............................31

CLEANING............................31

INSPECTION..........................31

INSTALLATION.........................31

INTAKE/EXHAUST VALVES & SEATS

DESCRIPTION.........................32

CLEANING............................32

VALVE SPRINGS & SEALS

REMOVAL

REMOVAL - CYLINDER HEAD ON.........32

RSENGINE9-1

Page 1303 of 2585

DIAGNOSIS AND TESTING - ENGINE DIAGNOSIS - MECHANICAL

CONDITION POSSIBLE CAUSES CORRECTION

NOISY VALVES 1. High or low oil level in

crankcase.1. Check and correct engine oil

level.

2. Thin or diluted oil. 2. Change oil to correct viscosity.

3. Thick oil 3. (a) Change engine oil and filter.

(b) Run engine to operating

temperature.

(c) Change engine oil and filter

again.

4. Low oil pressure. 4. Check and correct engine oil

pressure problem.

5. Dirt in hydraulic lifters/lash

adjusters.5. Replace hydraulic lifters/lash

adjusters.

6. Worn rocker arms. 6. Inspect oil supply to rocker arms.

7. Worn hydraulic lifters/lash

adjusters.7. Replace hydraulic lifters/lash

adjusters.

8. Worn valve guides. 8. Replace cylinder head assembly.

9. Excessive runout of valve seats

on valve faces.9. Grind valve seats and valves.

CONNECTING ROD NOISE 1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Thick oil 4. (a) Change engine oil and filter.

(b) Run engine to operating

temperature.

(c) Change engine oil and filter

again.

5. Excessive bearing clearance. 5. Measure bearings for correct

clearance. Repair as necessary.

6. Connecting rod journal

out-of-round.6. Replace crankshaft or grind

surface.

7. Misaligned connecting rods. 7. Replace bent connecting rods.

9 - 6 ENGINE 2.4LRS

ENGINE 2.4L (Continued)

Page 1321 of 2585

AIR CLEANER ELEMENT

REMOVAL

(1) Unsnap 2 clips.

(2) Lift cover and pull toward the engine and

remove cover tabs from air box.

(3) Lift cover and remove the element (Fig. 11).

INSTALLATION

(1) Install the air filter element into air box (Fig.

11).

(2) Move cover so that the tabs insert into the air

box.

(3) Push cover down and snap the 2 clips.

AIR CLEANER HOUSING

REMOVAL

(1) Disconnect the negative battery cable.

(2) Disconnect the inlet air temperature sensor

(Fig. 12).

(3) Remove the inlet hose to throttle body (Fig. 11).

(4) Remove the bolt for air box at upper radiator

cross member.

(5) Pull air box up and off over the single locating

pin.

(6) Remove air box from vehicle

INSTALLATION

(1) Install air box into vehicle and onto the locat-

ing pin.(2) Install bolt to hold air box to the upper radia-

tor cross member.

(3) Install the inlet hose to the throttle body.

(4) Connect the inlet air temperature sensor (Fig.

12).

(5) Connect the negative battery cable.

CYLINDER HEAD

DESCRIPTION

The cross flow designed, aluminum cylinder head

contains dual over-head camshafts with four valves

per cylinder (Fig. 13). The valves are arranged in two

in-line banks. The intake valves face toward the

front of the vehicle. The exhaust valves face the dash

panel. The cylinder head incorporates powdered

metal valve guides and seats. The cylinder head is

sealed to the block using a multi-layer steel head

gasket and retaining bolts.

Integral oil galleries provide lubrication passages

to the hydraulic lash adjusters, camshafts, and valve

mechanisms.

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

²Loss of engine power

²Engine misfiring

²Poor fuel economy

Possible indications of the cylinder head gasket

leaking between a cylinder and an adjacent water

jacket are:

²Engine overheating

²Loss of coolant

Fig. 11 AIR BOX COVER

Fig. 12 IAT SENSOR 2.4L

9 - 24 ENGINE 2.4LRS

Page 1329 of 2585

(6) If the PCV valve was removed, apply Mopart

Thread Sealant with Teflon to threads and install

valve to cylinder head cover. Tighten PCV valve to 8

N´m (70 in. lbs.).

(7) Connect PCV and make-up air hoses to cylin-

der head cover.

(8) Install upper intake manifold. (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION)

INTAKE/EXHAUST VALVES &

SEATS

DESCRIPTION

The valves are made of heat resistant steel. They

have chrome plated stems to prevent scuffing. Viton

rubber valve stem seals are integral with the spring

seats. The valves have three-bead lock keepers to

retain springs and to promote valve rotation.

CLEANING

(1) Clean all valves thoroughly and discard

burned, warped and cracked valves.

VALVE SPRINGS & SEALS

REMOVAL

REMOVAL - CYLINDER HEAD ON

(1) Remove cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(2) Remove camshafts (Refer to 9 - ENGINE/CYL-

INDER HEAD/CAMSHAFT(S) - REMOVAL).

(3) Rotate crankshaft until piston is at TDC on

compression.

(4) With air hose attached to adapter tool installed

in spark plug hole, apply 90-120 psi air pressure.(5) Using Special Tool MD-998772-A with adapter

6779 (Fig. 33), compress valve springs and remove

valve locks.

(6) Remove valve spring(s).

(7) Remove valve stem seal(s) by a using valve

stem seal tool (Fig. 35).

REMOVAL - CYLINDER HEAD OFF

(1) With cylinder head removed from cylinder

block, compress valve springs using a universal valve

spring compressor.

(2) Remove valve retaining locks, valve spring

retainers, valve stem seals and valve springs.

(3) Before removing valves,remove any burrs

from valve stem lock grooves to prevent dam-

age to the valve guides.Identify valves, locks and

retainers to insure installation in original location.

(4) Inspect the valves. (Refer to 9 - ENGINE/CYL-

INDER HEAD/VALVE SPRINGS - INSPECTION)

INSPECTION

(1) Whenever valves have been removed for inspec-

tion, reconditioning or replacement, valve springs

should be tested for correct tension. Discard the

springs that do not meet specifications. The following

specifications apply to both intake and exhaust

valves springs:

²Valve Closed Nominal TensionÐ76 lbs. @ 38.0

mm (1.50 in.)

²Valve Open Nominal TensionÐ136 lbs. @ 29.75

mm (1.17 in.)

(2) Inspect each valve spring for squareness with a

steel square and surface plate, test springs from both

ends. If the spring is more than 1.5 mm (1/16 inch)

out of square, install a new spring.

Fig. 32 Cylinder Head Cover Tightening Sequence

(Typical Cover Shown)

Fig. 33 Valve Spring - Removal/Installation

1 - VALVE SPRING COMPRESSOR MD 998772A

2 - AIR HOSE

9 - 32 ENGINE 2.4LRS

CYLINDER HEAD COVER (Continued)

Page 1371 of 2585

ENGINE 3.3/3.8L

TABLE OF CONTENTS

page page

ENGINE 3.3/3.8L

DESCRIPTION.........................76

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - INTRODUCTION...........76

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - PERFORMANCE...........78

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - MECHANICAL.............80

DIAGNOSIS AND TESTING - ENGINE OIL

LEAK INSPECTION....................82

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE TEST........83

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE

TEST...............................83

STANDARD PROCEDURE

STANDARD PROCEDURE - MEASURING

BEARING CLEARANCE USING

PLASTIGAGE........................84

STANDARD PROCEDURE - FORM-IN-

PLACE GASKETS AND SEALERS.........84

STANDARD PROCEDURE - ENGINE

GASKET SURFACE PREPARATION........85

STANDARD PROCEDURE - HYDROSTATIC

LOCKED ENGINE.....................85

STANDARD PROCEDURE - REPAIR OF

DAMAGED OR WORN THREADS.........86

STANDARD PROCEDURE - ENGINE CORE

AND OIL GALLERY PLUGS..............86

REMOVAL - ENGINE ASSEMBLY...........86

INSTALLATION - ENGINE ASSEMBLY........89

SPECIFICATIONS

3.3/3.8L ENGINE......................91

SPECIFICATIONS - TORQUE............95

SPECIAL TOOLS

3.3/3.8L ENGINE......................95

AIR CLEANER ELEMENT

REMOVAL.............................98

INSTALLATION.........................98

AIR CLEANER HOUSING

REMOVAL.............................99

INSTALLATION.........................99

CYLINDER HEAD

DESCRIPTION.........................99

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET............................99

REMOVAL - CYLINDER HEAD............100

CLEANING...........................100INSPECTION.........................101

INSTALLATION - CYLINDER HEAD.........101

CYLINDER HEAD COVER(S)

DESCRIPTION........................102

CYLINDER HEAD COVER - RIGHT

REMOVAL............................102

INSTALLATION........................103

CYLINDER HEAD COVER - LEFT

REMOVAL............................103

INSTALLATION........................103

INTAKE/EXHAUST VALVES & SEATS

DESCRIPTION........................104

OPERATION..........................104

STANDARD PROCEDURE - REFACING

VALVESANDVALVESEATS ............104

REMOVAL............................105

CLEANING...........................105

INSPECTION.........................105

INSTALLATION........................106

VALVE SPRINGS

DESCRIPTION........................106

OPERATION..........................106

REMOVAL

REMOVAL - CYLINDER HEAD OFF.......106

REMOVAL - CYLINDER HEAD ON........106

INSPECTION.........................108

INSTALLATION

INSTALLATION - CYLINDER HEAD OFF . . . 108

INSTALLATION - CYLINDER HEAD ON....108

ROCKER ARMS

DESCRIPTION

DESCRIPTION - ROCKER ARMS.........109

DESCRIPTION - PUSHRODS...........109

OPERATION

OPERATION - ROCKER ARMS..........109

OPERATION - PUSHRODS.............109

REMOVAL - ROCKER ARMS AND SHAFT....109

DISASSEMBLY - ROCKER ARMS AND SHAFT. . 109

ASSEMBLY - ROCKER ARMS AND SHAFT . . . 109

INSTALLATION - ROCKER ARMS AND SHAFT..110

VALVE STEM SEALS

DESCRIPTION........................111

REMOVAL............................112

INSTALLATION........................112

ENGINE BLOCK

DESCRIPTION........................112

STANDARD PROCEDURE - CYLINDER BORE

HONING............................112

CLEANING...........................112

9 - 74 ENGINE 3.3/3.8LRS

Page 1377 of 2585

DIAGNOSIS AND TESTING - ENGINE DIAGNOSIS - MECHANICAL

CONDITION POSSIBLE CAUSES CORRECTION

NOISY VALVES 1. High or low oil level in

crankcase.1. Check and correct engine oil

level.

2. Thin or diluted oil. 2. Change oil to correct viscosity.

3. Thick oil 3. (a) Change engine oil and filter.

(b) Run engine to operating

temperature.

(c) Change engine oil and filter

again.

4. Low oil pressure. 4. Check and correct engine oil

pressure problem.

5. Dirt in hydraulic lifters/lash

adjusters.5. Replace hydraulic lifters/lash

adjusters.

6. Worn rocker arms. 6. Inspect oil supply to rocker arms.

7. Worn hydraulic lifters/lash

adjusters.7. Replace hydraulic lifters/lash

adjusters.

8. Worn valve guides. 8. Replace cylinder head assembly.

9. Excessive runout of valve seats

on valve faces.9. Grind valve seats and valves.

CONNECTING ROD NOISE 1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Thick oil 4. (a) Change engine oil and filter.

(b) Run engine to operating

temperature.

(c) Change engine oil and filter

again.

5. Excessive bearing clearance. 5. Measure bearings for correct

clearance. Repair as necessary.

6. Connecting rod journal

out-of-round.6. Replace crankshaft or grind

surface.

7. Misaligned connecting rods. 7. Replace bent connecting rods.

9 - 80 ENGINE 3.3/3.8LRS

ENGINE 3.3/3.8L (Continued)

Page 1396 of 2585

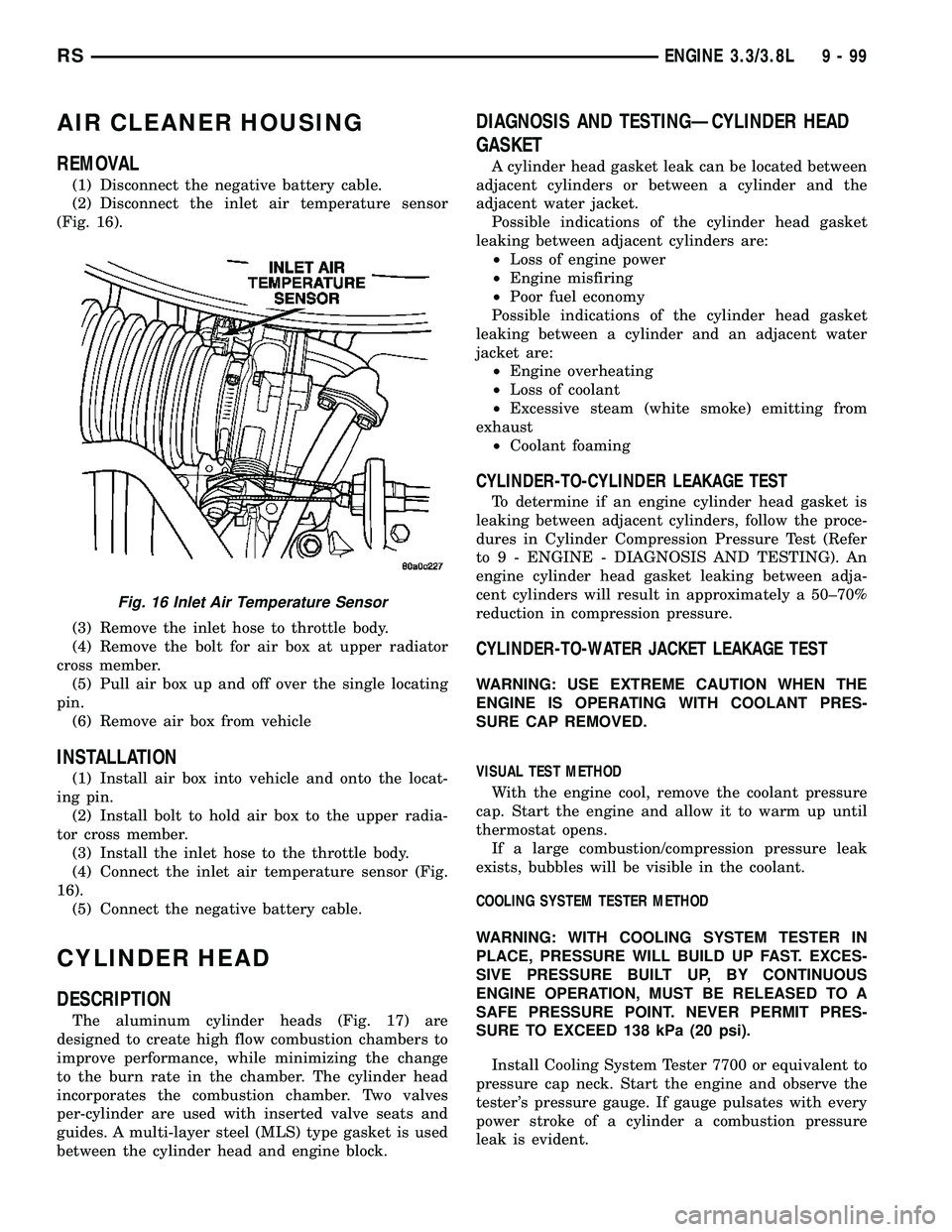

AIR CLEANER HOUSING

REMOVAL

(1) Disconnect the negative battery cable.

(2) Disconnect the inlet air temperature sensor

(Fig. 16).

(3) Remove the inlet hose to throttle body.

(4) Remove the bolt for air box at upper radiator

cross member.

(5) Pull air box up and off over the single locating

pin.

(6) Remove air box from vehicle

INSTALLATION

(1) Install air box into vehicle and onto the locat-

ing pin.

(2) Install bolt to hold air box to the upper radia-

tor cross member.

(3) Install the inlet hose to the throttle body.

(4) Connect the inlet air temperature sensor (Fig.

16).

(5) Connect the negative battery cable.

CYLINDER HEAD

DESCRIPTION

The aluminum cylinder heads (Fig. 17) are

designed to create high flow combustion chambers to

improve performance, while minimizing the change

to the burn rate in the chamber. The cylinder head

incorporates the combustion chamber. Two valves

per-cylinder are used with inserted valve seats and

guides. A multi-layer steel (MLS) type gasket is used

between the cylinder head and engine block.

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

²Loss of engine power

²Engine misfiring

²Poor fuel economy

Possible indications of the cylinder head gasket

leaking between a cylinder and an adjacent water

jacket are:

²Engine overheating

²Loss of coolant

²Excessive steam (white smoke) emitting from

exhaust

²Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is

leaking between adjacent cylinders, follow the proce-

dures in Cylinder Compression Pressure Test (Refer

to 9 - ENGINE - DIAGNOSIS AND TESTING). An

engine cylinder head gasket leaking between adja-

cent cylinders will result in approximately a 50±70%

reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING WITH COOLANT PRES-

SURE CAP REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

Fig. 16 Inlet Air Temperature Sensor

RSENGINE 3.3/3.8L9-99