spark plugs CHRYSLER VOYAGER 2004 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1475 of 2585

(3) Assemble gasket to cylinder cover by inserting

the bolt assemblies through each bolt hole on the

cover and gasket (Fig. 9).

(4) Install cylinder head cover and bolts (Fig. 10).

(5) Tighten cylinder head cover bolts to 12 N´m

(105 in. lbs.) (Fig. 10).

(6) Connect PCV hose to cylinder head cover.

(7) Connect spark plug wires to spark plugs.

(8) Install wiper module. (Refer to 8 - ELECTRI-

CAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION)

(9) Connect negative cable to battery.

CYLINDER HEAD COVER-LEFT

REMOVAL

(1) Disconnect spark plug wires from spark plugs.

(2) Disconnect crankcase vent hose from cylinder

head cover.

(3) Remove cylinder head cover bolts.(4) Remove cylinder head cover and gasket.

INSTALLATION

(1) Clean cylinder head and cover mating surfaces.

Inspect cylinder head cover surface for flatness.

Replace gasket as necessary.

(2) Assemble gasket to cylinder cover by inserting

the fasteners through each bolt hole on cover and

gasket (Fig. 9).

(3) Install the cylinder head cover and bolts (Fig.

10).

(4) Tighten cylinder head cover bolts to 12 N´m

(105 in. lbs.) (Fig. 10).

(5) Connect crankcase vent hose.

(6) Connect spark plug wires to spark plugs.

Fig. 9 CYLINDER HEAD COVER GASKET

1 - CYLINDER HEAD COVER

2 - BOLT

3 - SEAL (SERVICED WITH BOLT)

4 - GASKET

Fig. 10 Cylinder Head Cover

1 - CYLINDER HEAD COVER

2 - BOLT

9s - 20 ENGINE 3.3/3.8L SUPPLEMENTRS

CYLINDER HEAD COVER-RIGHT (Continued)

Page 1479 of 2585

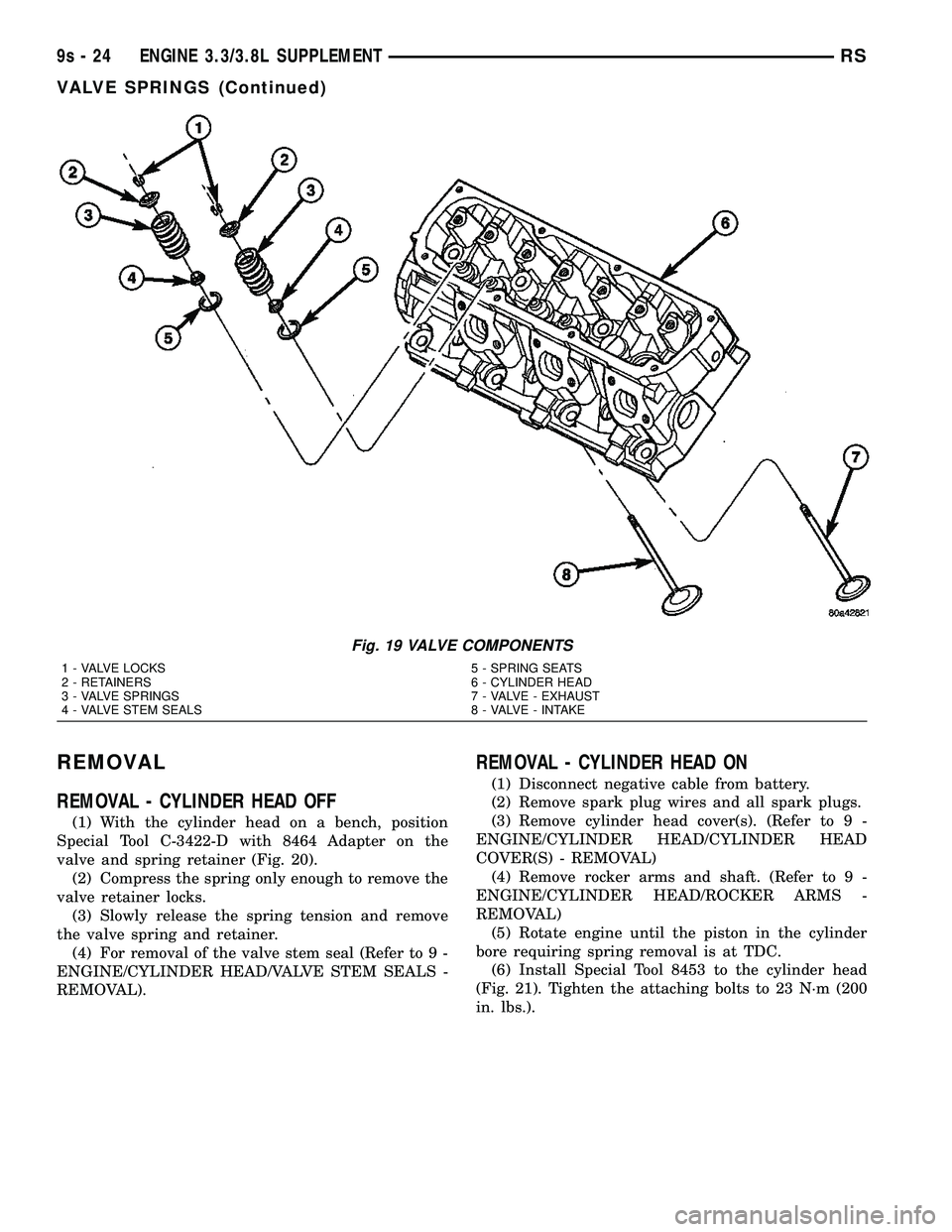

REMOVAL

REMOVAL - CYLINDER HEAD OFF

(1) With the cylinder head on a bench, position

Special Tool C-3422-D with 8464 Adapter on the

valve and spring retainer (Fig. 20).

(2) Compress the spring only enough to remove the

valve retainer locks.

(3) Slowly release the spring tension and remove

the valve spring and retainer.

(4) For removal of the valve stem seal (Refer to 9 -

ENGINE/CYLINDER HEAD/VALVE STEM SEALS -

REMOVAL).

REMOVAL - CYLINDER HEAD ON

(1) Disconnect negative cable from battery.

(2) Remove spark plug wires and all spark plugs.

(3) Remove cylinder head cover(s). (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL)

(4) Remove rocker arms and shaft. (Refer to 9 -

ENGINE/CYLINDER HEAD/ROCKER ARMS -

REMOVAL)

(5) Rotate engine until the piston in the cylinder

bore requiring spring removal is at TDC.

(6) Install Special Tool 8453 to the cylinder head

(Fig. 21). Tighten the attaching bolts to 23 N´m (200

in. lbs.).

Fig. 19 VALVE COMPONENTS

1 - VALVE LOCKS 5 - SPRING SEATS

2 - RETAINERS 6 - CYLINDER HEAD

3 - VALVE SPRINGS 7 - VALVE - EXHAUST

4 - VALVE STEM SEALS 8 - VALVE - INTAKE

9s - 24 ENGINE 3.3/3.8L SUPPLEMENTRS

VALVE SPRINGS (Continued)

Page 1481 of 2585

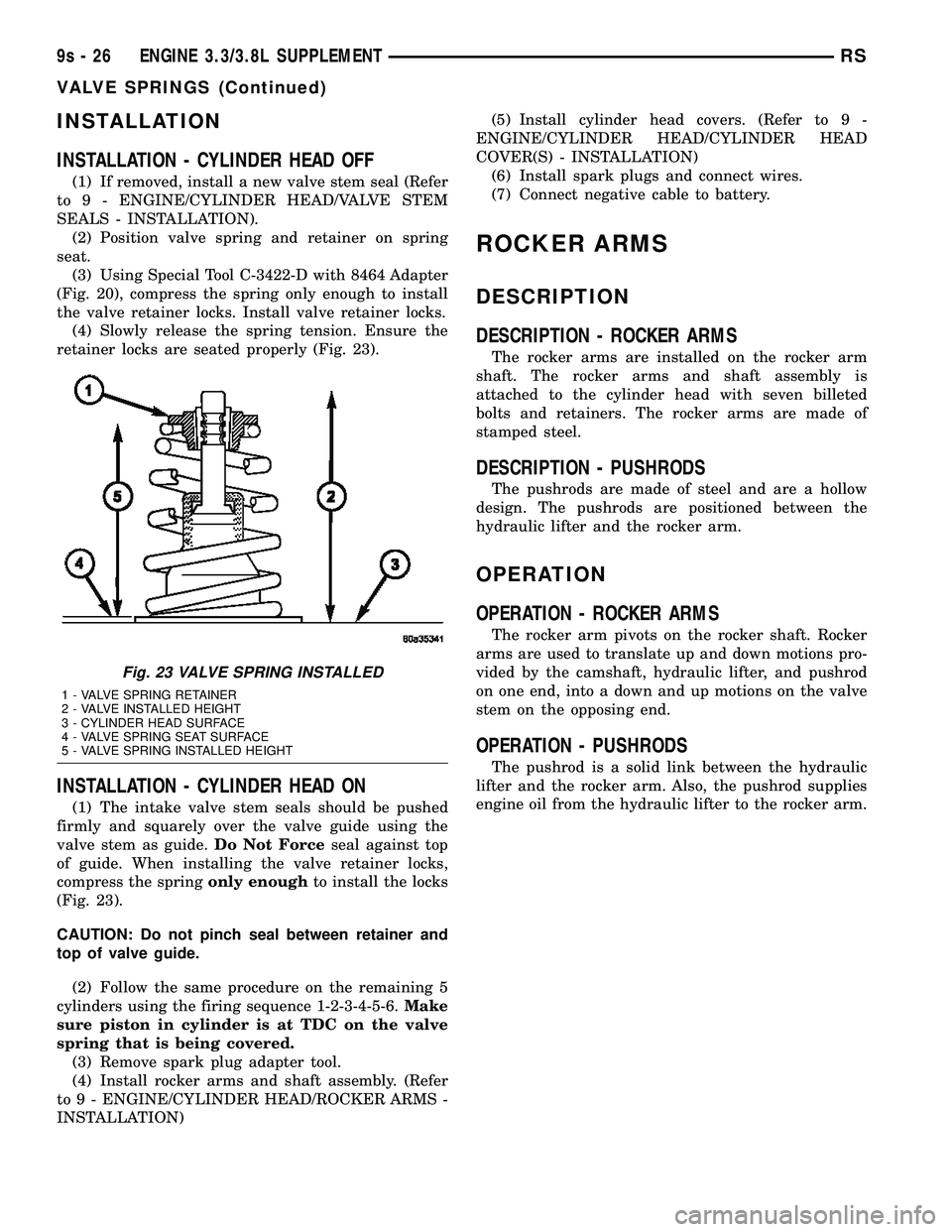

INSTALLATION

INSTALLATION - CYLINDER HEAD OFF

(1) If removed, install a new valve stem seal (Refer

to 9 - ENGINE/CYLINDER HEAD/VALVE STEM

SEALS - INSTALLATION).

(2) Position valve spring and retainer on spring

seat.

(3) Using Special Tool C-3422-D with 8464 Adapter

(Fig. 20), compress the spring only enough to install

the valve retainer locks. Install valve retainer locks.

(4) Slowly release the spring tension. Ensure the

retainer locks are seated properly (Fig. 23).

INSTALLATION - CYLINDER HEAD ON

(1) The intake valve stem seals should be pushed

firmly and squarely over the valve guide using the

valve stem as guide.Do Not Forceseal against top

of guide. When installing the valve retainer locks,

compress the springonly enoughto install the locks

(Fig. 23).

CAUTION: Do not pinch seal between retainer and

top of valve guide.

(2) Follow the same procedure on the remaining 5

cylinders using the firing sequence 1-2-3-4-5-6.Make

sure piston in cylinder is at TDC on the valve

spring that is being covered.

(3) Remove spark plug adapter tool.

(4) Install rocker arms and shaft assembly. (Refer

to 9 - ENGINE/CYLINDER HEAD/ROCKER ARMS -

INSTALLATION)(5) Install cylinder head covers. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION)

(6) Install spark plugs and connect wires.

(7) Connect negative cable to battery.

ROCKER ARMS

DESCRIPTION

DESCRIPTION - ROCKER ARMS

The rocker arms are installed on the rocker arm

shaft. The rocker arms and shaft assembly is

attached to the cylinder head with seven billeted

bolts and retainers. The rocker arms are made of

stamped steel.

DESCRIPTION - PUSHRODS

The pushrods are made of steel and are a hollow

design. The pushrods are positioned between the

hydraulic lifter and the rocker arm.

OPERATION

OPERATION - ROCKER ARMS

The rocker arm pivots on the rocker shaft. Rocker

arms are used to translate up and down motions pro-

vided by the camshaft, hydraulic lifter, and pushrod

on one end, into a down and up motions on the valve

stem on the opposing end.

OPERATION - PUSHRODS

The pushrod is a solid link between the hydraulic

lifter and the rocker arm. Also, the pushrod supplies

engine oil from the hydraulic lifter to the rocker arm.

Fig. 23 VALVE SPRING INSTALLED

1 - VALVE SPRING RETAINER

2 - VALVE INSTALLED HEIGHT

3 - CYLINDER HEAD SURFACE

4 - VALVE SPRING SEAT SURFACE

5 - VALVE SPRING INSTALLED HEIGHT

9s - 26 ENGINE 3.3/3.8L SUPPLEMENTRS

VALVE SPRINGS (Continued)

Page 1490 of 2585

The combustion reaction caused by the catalyst

releases additional heat in the exhaust system, caus-

ing temperature increases in the area of the reactor

under severe operating conditions. Such conditions

can exist when the engine misfires or otherwise does

not operate at peak efficiency.Do notremove spark

plug wires from plugs or by any other means short

out cylinders, if exhaust system is equipped with a

catalytic converter. Failure of the catalytic converter

can occur due to temperature increases caused by

unburned fuel passing through the converter. This

deterioration of the catalyst core can result in exces-

sively high emission levels, noise complaints, and

exhaust restrictions.

Unleaded gasoline must be used to avoid ruining

the catalyst core. Do not allow engine to operate

above 1200 RPM in neutral for extended periods over

5 minutes. This condition may result in excessive

exhaust system/floor pan temperatures because of no

air movement under the vehicle.

The flex joint allows flexing as the engine moves,

preventing breakage that could occur from the back-

and-forth motion of a transverse mounted engine.

CAUTION: Due to exterior physical similarities of

some catalytic converters with pipe assemblies,

extreme care should be taken with replacement

parts. There are internal converter differences

required in some parts of the country (particularly

vehicles built for States with strict emission

requirements) and between model years.

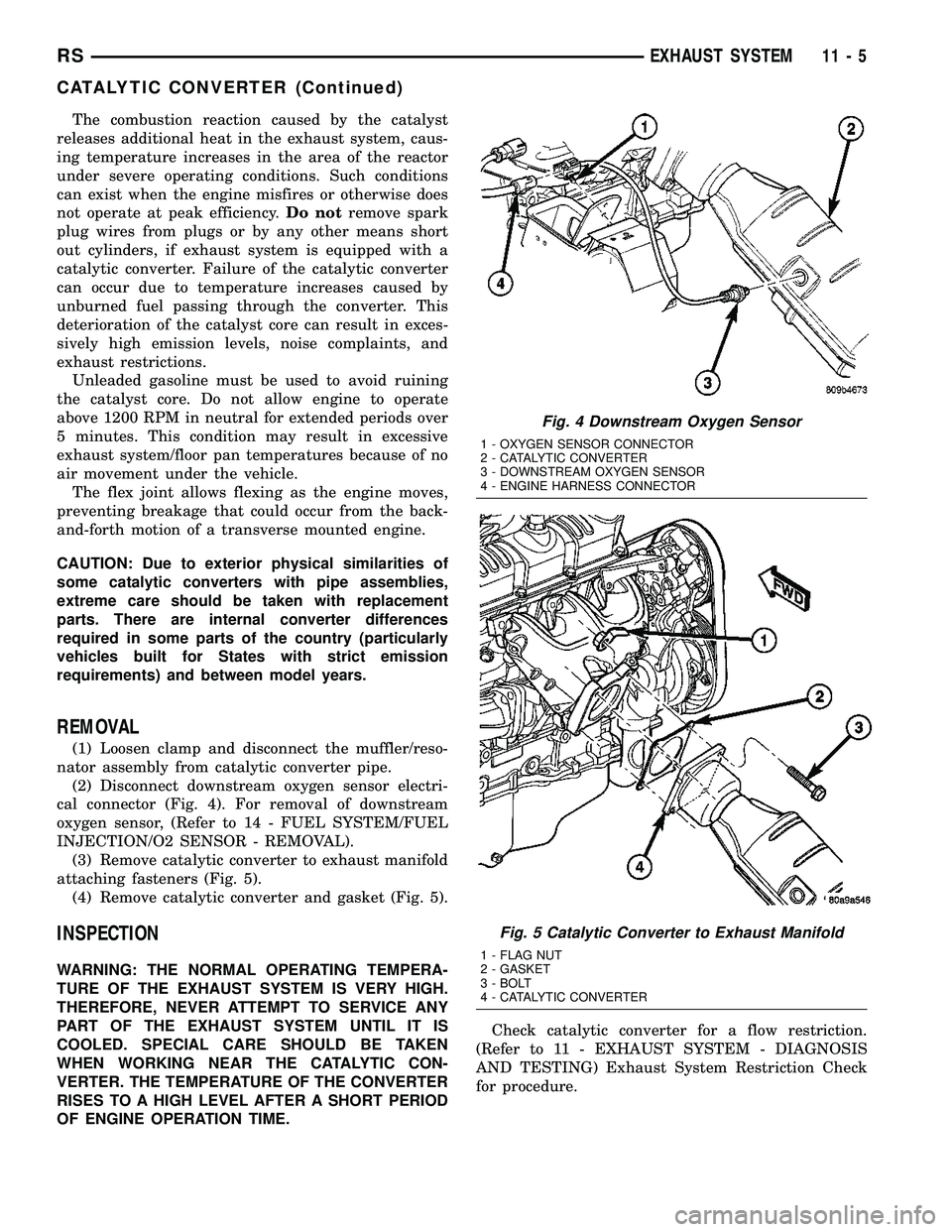

REMOVAL

(1) Loosen clamp and disconnect the muffler/reso-

nator assembly from catalytic converter pipe.

(2) Disconnect downstream oxygen sensor electri-

cal connector (Fig. 4). For removal of downstream

oxygen sensor, (Refer to 14 - FUEL SYSTEM/FUEL

INJECTION/O2 SENSOR - REMOVAL).

(3) Remove catalytic converter to exhaust manifold

attaching fasteners (Fig. 5).

(4) Remove catalytic converter and gasket (Fig. 5).

INSPECTION

WARNING: THE NORMAL OPERATING TEMPERA-

TURE OF THE EXHAUST SYSTEM IS VERY HIGH.

THEREFORE, NEVER ATTEMPT TO SERVICE ANY

PART OF THE EXHAUST SYSTEM UNTIL IT IS

COOLED. SPECIAL CARE SHOULD BE TAKEN

WHEN WORKING NEAR THE CATALYTIC CON-

VERTER. THE TEMPERATURE OF THE CONVERTER

RISES TO A HIGH LEVEL AFTER A SHORT PERIOD

OF ENGINE OPERATION TIME.Check catalytic converter for a flow restriction.

(Refer to 11 - EXHAUST SYSTEM - DIAGNOSIS

AND TESTING) Exhaust System Restriction Check

for procedure.

Fig. 4 Downstream Oxygen Sensor

1 - OXYGEN SENSOR CONNECTOR

2 - CATALYTIC CONVERTER

3 - DOWNSTREAM OXYGEN SENSOR

4 - ENGINE HARNESS CONNECTOR

Fig. 5 Catalytic Converter to Exhaust Manifold

1 - FLAG NUT

2 - GASKET

3 - BOLT

4 - CATALYTIC CONVERTER

RSEXHAUST SYSTEM11-5

CATALYTIC CONVERTER (Continued)

Page 2520 of 2585

period the switch ratio reaches a predetermined

value, a counter is incremented by one. The monitor

is enabled to run another test during that trip. When

the test fails 6 times, the counter increments to 3, a

malfunction is entered, and a Freeze Frame is stored,

the code is matured and the MIL is illuminated. If

the first test passes, no further testing is conducted

during that trip.

The MIL is extinguished after three consecutive

good trips. The good trip criteria for the catalyst

monitor is more stringent than the failure criteria. In

order to pass the test and increment one good trip,

the downstream sensor switch rate must be less than

45% of the upstream rate. The failure percentages

are 59% respectively.

Enabling ConditionsÐThe following conditions

must typically be met before the PCM runs the cat-

alyst monitor. Specific times for each parameter may

be different from engine to engine.

²Accumulated drive time

²Enable time

²Ambient air temperature

²Barometric pressure

²Catalyst warm-up counter

²Engine coolant temperature

²Vehicle speed

²MAP

²RPM

²Engine in closed loop

²Fuel level

Pending ConditionsÐ

²Misfire DTC

²Front Oxygen Sensor Response

²Front Oxygen Sensor Heater Monitor

²Front Oxygen Sensor Electrical

²Rear Oxygen Sensor Rationality (middle check)

²Rear Oxygen Sensor Heater Monitor

²Rear Oxygen Sensor Electrical

²Fuel System Monitor

²All TPS faults

²All MAP faults

²All ECT sensor faults

²Purge flow solenoid functionality

²Purge flow solenoid electrical

²All PCM self test faults

²All CMP and CKP sensor faults

²All injector and ignition electrical faults

²Idle Air Control (IAC) motor functionality

²Vehicle Speed Sensor

²Brake switch (auto trans only)

²Intake air temperature

ConflictÐThe catalyst monitor does not run if any

of the following are conditions are present:

²EGR Monitor in progress (if equipped)

²Fuel system rich intrusive test in progress

²EVAP Monitor in progress²Time since start is less than 60 seconds

²Low fuel level-less than 15 %

²Low ambient air temperature

²Ethanol content learn is taking place and the

ethanol used once flag is set

SuspendÐThe Task Manager does not mature a

catalyst fault if any of the following are present:

²Oxygen Sensor Monitor, Priority 1

²Oxygen Sensor Heater, Priority 1

²EGR Monitor, Priority 1 (if equipped)

²EVAP Monitor, Priority 1

²Fuel System Monitor, Priority 2

²Misfire Monitor, Priority 2

OPERATION - NON-MONITORED CIRCUITS

The PCM does not monitor all circuits, systems

and conditions that could have malfunctions causing

driveability problems. However, problems with these

systems may cause the PCM to store diagnostic trou-

ble codes for other systems or components. For exam-

ple, a fuel pressure problem will not register a fault

directly, but could cause a rich/lean condition or mis-

fire. This could cause the PCM to store an oxygen

sensor or misfire diagnostic trouble code.

The major non-monitored circuits are listed below

along with examples of failures modes that do not

directly cause the PCM to set a DTC, but for a sys-

tem that is monitored.

FUEL PRESSURE

The fuel pressure regulator controls fuel system

pressure. The PCM cannot detect a clogged fuel

pump inlet filter, clogged in-line fuel filter, or a

pinched fuel supply or return line. However, these

could result in a rich or lean condition causing the

PCM to store an oxygen sensor, fuel system, or mis-

fire diagnostic trouble code.

SECONDARY IGNITION CIRCUIT

The PCM cannot detect an inoperative ignition coil,

fouled or worn spark plugs, ignition cross firing, or

open spark plug cables. The misfire will however,

increase the oxygen content in the exhaust, deceiving

the PCM in to thinking the fuel system is too lean.

Also see misfire detection.

CYLINDER COMPRESSION

The PCM cannot detect uneven, low, or high engine

cylinder compression. Low compression lowers O2

content in the exhaust. Leading to fuel system, oxy-

gen sensor, or misfire detection fault.

EXHAUST SYSTEM

The PCM cannot detect a plugged, restricted or

leaking exhaust system. It may set a EGR (if

equipped) or Fuel system or O2S fault.

RSEMISSIONS CONTROL25-5

EMISSIONS CONTROL (Continued)

Page 2568 of 2585

PINS (DISC/DRUM BRAKES) -

INSTALLATION, DISC BRAKE CALIPER

GUIDE..............................5-31

PINS (DISC/DRUM BRAKES) - REMOVAL,

DISC BRAKE CALIPER GUIDE............5-31

PINS (TRW BRAKES) - INSTALLATION,

DISC BRAKE CALIPER GUIDE...........5s-30

PINS (TRW BRAKES) - REMOVAL, DISC

BRAKE CALIPER GUIDE................5s-30

PIPE - 3.3/3.8L - INSTALLATION,

CROSS-OVER........................11-6

PIPE - 3.3/3.8L - REMOVAL, CROSS-

OVER...............................11-6

PIPE - INSTALLATION, AIR INTAKE......24-114

PIPE - REMOVAL, AIR INTAKE.........24-113

PISTON & CONNECTING ROD -

DESCRIPTION...................9-116,9-42

PISTON & CONNECTING ROD -

INSTALLATION........................9-44

PISTON & CONNECTING ROD -

REMOVAL...........................9-43

PISTON AND SEAL - ASSEMBLY,

CALIPER..............5-26,5-29,5s-25,5s-28

PISTON AND SEAL - DISASSEMBLY,

CALIPER..............5-24,5-28,5s-23,5s-27

PISTON RING, FITTING.................9-45

PISTON RING FITTING - STANDARD

PROCEDURE........................9-121

PISTON RINGS - INSTALLATION.........9-121

PISTON RINGS - REMOVAL............9-121

PISTON TO CYLINDER BORE FITTING -

STANDARD PROCEDURE................9-42

PISTONS - STANDARD PROCEDURE,

FITTING............................9-117

PLANETARY GEARTRAIN -

DESCRIPTION...............21-232,21s-132

PLANETARY GEARTRAIN - OPERATION . . 21-232,

21s-132

PLASTIC BODY PANEL REPAIR -

STANDARD PROCEDURE................23-3

PLASTIC GROCERY BAG RETAINER -

INSTALLATION......................23-105

PLASTIC GROCERY BAG RETAINER -

REMOVAL.........................23-104

PLASTIGAGE - STANDARD PROCEDURE,

MEASURING BEARING CLEARANCE

USING..........................9-12,9-84

PLATE - 2.5L TD - INSTALLATION,

CLUTCH DISC AND PRESSURE...........6-12

PLATE - 2.5L TD - REMOVAL, CLUTCH

DISC AND PRESSURE..................6-11

PLATE - DESCRIPTION, BODY CODE....Intro.-1

PLATE - DESCRIPTION, MANUFACTURER . Intro.-11

PLATE - DRUM BRAKE - INSTALLATION,

SUPPORT.......................5-56,5s-58

PLATE - DRUM BRAKE - REMOVAL,

SUPPORT.......................5-56,5s-58

PLATE - INSTALLATION, DOOR SILL

TRIM..............................23-77

PLATE - INSTALLATION, FLEX...........9-131

PLATE - INSTALLATION, LIFTGATE SILL . . . 23-79

PLATE - INSTALLATION, SLIDING DOOR

SILL...............................23-82

PLATE - INSTALLATION, STEERING

COLUMN COVER BACKING.............23-70

PLATE - REMOVAL, DOOR SILL TRIM....23-77

PLATE - REMOVAL, FLEX..............9-131

PLATE - REMOVAL, LIFTGATE SILL.......23-79

PLATE - REMOVAL, SLIDING DOOR SILL . . 23-82

PLATE - REMOVAL, STEERING COLUMN

COVER BACKING.....................23-70

PLATE BATTERY CHARGING -

STANDARD PROCEDURE, SPIRAL........8F-10

PLATE MISALIGNMENT - DIAGNOSIS

AND TESTING, DRIVE...................6-6

PLATES - ADHESIVE ATTACHED -

INSTALLATION, EXTERIOR NAME........23-51

PLATES - ADHESIVE ATTACHED -

REMOVAL, EXTERIOR NAME............23-51

PLATES - TAPE ATTACHED -

INSTALLATION, EXTERIOR NAME

........23-51

PLATES - TAPE ATTACHED - REMOVAL,

EXTERIOR NAME

.....................23-51

PLATINUM PLUGS - DESCRIPTION

........8I-9

PLAY - ADJUSTMENT, DIFFERENTIAL

SIDE GEAR END

.....................21-70

PLAY - STANDARD PROCEDURE,

CRANKSHAFT END

................9-36,9s-6PLAY - STANDARD PROCEDURE,

MEASURING CAMSHAFT END............9-29

PLAY - STANDARD PROCEDURE,

MEASURING CRANKSHAFT END.........9-125

PLAYER - DESCRIPTION, DVD...........8A-8

PLAYER - INSTALLATION, DVD...........8A-8

PLAYER - OPERATION, DVD.............8A-8

PLAYER - REMOVAL, DVD..............8A-8

PLUG CABLE - DESCRIPTION, SPARK.....8I-10

PLUG CABLE RESISTANCE,

SPECIFICATIONS - SPARK...............8I-2

PLUG, SPECIFICATIONS - SPARK.........8I-2

PLUGS - DESCRIPTION, PLATINUM........8I-9

PLUGS - STANDARD PROCEDURE,

ENGINE CORE AND OIL GALLERY....9-10,9-86

POINTS - DESCRIPTION, LUBRICATION.....0-7

POLISHING - DESCRIPTION, FINESSE

SANDING/BUFFING...................23-85

PORT REPAIR - STANDARD

PROCEDURE, INTAKE MANIFOLD

VACUUM...........................9-145

PORT VALVE CORE - DESCRIPTION,

SERVICE...........................24-94

PORT VALVE CORE - INSTALLATION,

SERVICE...........................24-94

PORT VALVE CORE - REMOVAL,

SERVICE...........................24-94

POSITION SENSOR - DESCRIPTION,

CAMSHAFT...........................8I-4

POSITION SENSOR - DESCRIPTION,

CRANKSHAFT.......................14-25

POSITION SENSOR - DESCRIPTION,

THROTTLE..........................14-36

POSITION SENSOR - OPERATION,

CAMSHAFT...........................8I-4

POSITION SENSOR - OPERATION,

CRANKSHAFT.......................14-25

POSITION SENSOR - OPERATION,

THROTTLE..........................14-36

POSITION SENSOR - REMOVAL,

CRANKSHAFT.......................14-25

POTENTIAL - STANDARD PROCEDURE,

TESTING OF VOLTAGE..............8W-01-9

POWER - INSTALLATION, WINDOW

REGULATOR........................23-22

POWER - REMOVAL, WINDOW

REGULATOR........................23-22

POWER ADJUSTER - INSTALLATION,

FRONT SEAT TRACK..................23-95

POWER ADJUSTER - REMOVAL, FRONT

SEAT TRACK........................23-95

POWER BRAKE BOOSTER -

DESCRIPTION...................5-40,5s-43

POWER BRAKE BOOSTER - DIAGNOSIS

AND TESTING...................5-41,5s-44

POWER BRAKE BOOSTER - OPERATION . . . 5-41,

5s-44

POWER DISTRIBUTION SYSTEM -

DESCRIPTION.....................8W-97-1

POWER DISTRIBUTION SYSTEM -

OPERATION.......................8W-97-1

POWER DISTRIBUTION SYSTEMS,

SPECIAL TOOLS...................8W-97-1

POWER DOOR LEARN CYCLE -

STANDARD PROCEDURE..............8N-28

POWER FOLDAWAY MIRROR SWITCH -

EXPORT - DESCRIPTION...............8N-48

POWER FOLDAWAY MIRROR SWITCH -

EXPORT - INSTALLATION..............8N-49

POWER FOLDAWAY MIRROR SWITCH -

EXPORT - OPERATION................8N-48

POWER FOLDAWAY MIRROR SWITCH -

EXPORT - REMOVAL..................8N-48

POWER LIFTGATE CONTROL MODULE -

DESCRIPTION.......................8E-10

POWER LIFTGATE CONTROL MODULE -

INSTALLATION.......................8E-11

POWER LIFTGATE CONTROL MODULE -

OPERATION.........................8E-11

POWER LIFTGATE CONTROL MODULE -

REMOVAL

..........................8E-11

POWER LIFTGATE LEARN CYCLE -

STANDARD PROCEDURE

...............8N-9

POWER LIFTGATE SYSTEM -

DESCRIPTION

........................8N-2

POWER LIFTGATE SYSTEM - DIAGNOSIS

AND TESTING

........................8N-4

POWER LIFTGATE SYSTEM - OPERATION

. . 8N-3POWER LOCKS - DESCRIPTION.....8N-1,8N-38

POWER LOCKS - OPERATION......8N-2,8N-39

POWER MIRRORS - DESCRIPTION......8N-45

POWER MIRRORS - DIAGNOSIS AND

TESTING...........................8N-46

POWER MIRRORS - OPERATION........8N-45

POWER MODULE - BLOWER MOTOR -

DESCRIPTION.......................24-31

POWER MODULE - BLOWER MOTOR -

INSTALLATION.......................24-32

POWER MODULE - BLOWER MOTOR -

OPERATION.........................24-31

POWER MODULE - BLOWER MOTOR -

REMOVAL..........................24-31

POWER MODULE - DESCRIPTION,

INTEGRATED......................8W-97-2

POWER MODULE - INSTALLATION,

INTEGRATED......................8W-97-3

POWER MODULE - OPERATION,

INTEGRATED......................8W-97-2

POWER MODULE - REAR BLOWER

MOTOR - DESCRIPTION...............24-41

POWER MODULE - REAR BLOWER

MOTOR - INSTALLATION...............24-42

POWER MODULE - REAR BLOWER

MOTOR - OPERATION.................24-41

POWER MODULE - REAR BLOWER

MOTOR - REMOVAL..................24-41

POWER MODULE - REMOVAL,

INTEGRATED......................8W-97-2

POWER OUTLET - DESCRIPTION......8W-97-4

POWER OUTLET - DIAGNOSIS &

TESTING.........................8W-97-4

POWER OUTLET - OPERATION........8W-97-4

POWER SEAT SYSTEM - DIAGNOSIS

AND TESTING...................8N-52,8N-9

POWER SEAT SYSTEM - OPERATION....8N-52,

8N-9

POWER SEAT TRACK - DESCRIPTION,

DRIVER.......................8N-15,8N-58

POWER SEAT TRACK - DESCRIPTION,

PASSENGER...................8N-16,8N-59

POWER SEAT TRACK - DIAGNOSIS AND

TESTING......................8N-17,8N-60

POWER SEAT TRACK - DIAGNOSIS AND

TESTING, DRIVER...............8N-15,8N-58

POWER SEAT TRACK - INSTALLATION,

DRIVER.......................8N-16,8N-59

POWER SEAT TRACK - INSTALLATION,

PASSENGER...................8N-18,8N-61

POWER SEAT TRACK - OPERATION,

DRIVER.......................8N-15,8N-58

POWER SEAT TRACK - OPERATION,

PASSENGER...................8N-17,8N-60

POWER SEAT TRACK - REMOVAL,

DRIVER.......................8N-16,8N-59

POWER SEAT TRACK - REMOVAL,

PASSENGER...................8N-18,8N-61

POWER SLIDING DOOR SYSTEM -

DESCRIPTION.......................8N-19

POWER SLIDING DOOR SYSTEM -

DIAGNOSIS AND TESTING.............8N-22

POWER SLIDING DOOR SYSTEM -

OPERATION.........................8N-21

POWER STEERING BELT TENSION -

STANDARD PROCEDURE, CHECKING.......7-8

POWER STEERING FASTENER TORQUE,

SPECIFICATIONS......................19-9

POWER STEERING FLUID LEVEL

CHECKING - STANDARD PROCEDURE....19-44

POWER STEERING GEAR, SPECIAL

TOOLS.............................19-34

POWER STEERING PUMP INITIAL

OPERATION - STANDARD PROCEDURE . . . 19-37

POWER STEERING PUMP, SPECIAL

TOOLS.............................19-43

POWER STEERING, SPECIAL TOOLS......19-9

POWER STEERING SYSTEM -

DESCRIPTION........................19-1

POWER STEERING SYSTEM -

OPERATION

..........................19-1

POWER STEERING SYSTEM FLOW AND

PRESSURE TEST - DIAGNOSIS AND

TESTING

............................19-1

POWER TRANSFER UNIT - DESCRIPTION

. . 21-1

POWER TRANSFER UNIT - OPERATION

....21-3

POWER TRANSFER UNIT FLUID -

DESCRIPTION, AWD

....................0-6

RSINDEX25

Description Group-Page Description Group-Page Description Group-Page