coolant temperature CHRYSLER VOYAGER 2004 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1652 of 2585

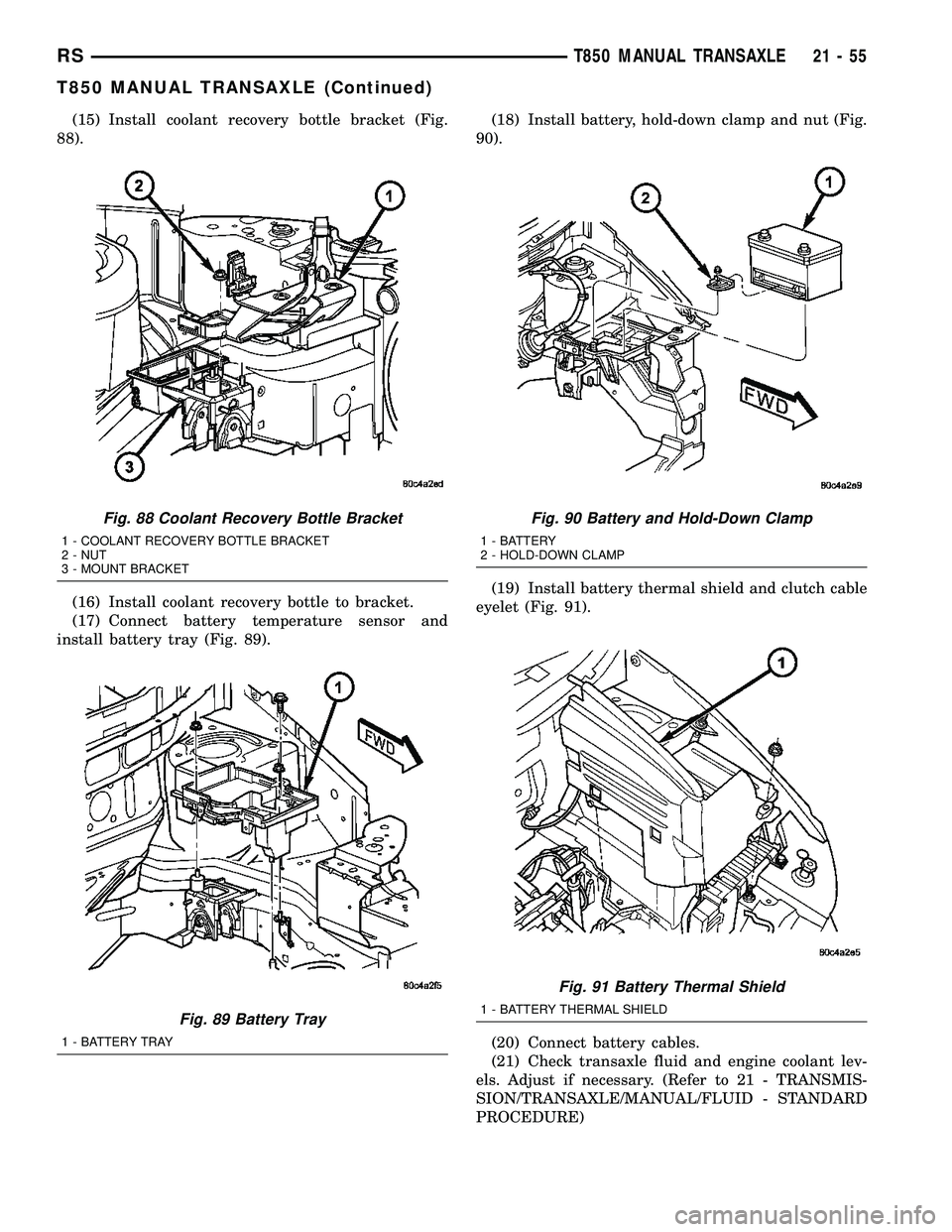

(15) Install coolant recovery bottle bracket (Fig.

88).

(16) Install coolant recovery bottle to bracket.

(17) Connect battery temperature sensor and

install battery tray (Fig. 89).(18) Install battery, hold-down clamp and nut (Fig.

90).

(19) Install battery thermal shield and clutch cable

eyelet (Fig. 91).

(20) Connect battery cables.

(21) Check transaxle fluid and engine coolant lev-

els. Adjust if necessary. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/MANUAL/FLUID - STANDARD

PROCEDURE)

Fig. 88 Coolant Recovery Bottle Bracket

1 - COOLANT RECOVERY BOTTLE BRACKET

2 - NUT

3 - MOUNT BRACKET

Fig. 89 Battery Tray

1 - BATTERY TRAY

Fig. 90 Battery and Hold-Down Clamp

1 - BATTERY

2 - HOLD-DOWN CLAMP

Fig. 91 Battery Thermal Shield

1 - BATTERY THERMAL SHIELD

RST850 MANUAL TRANSAXLE21-55

T850 MANUAL TRANSAXLE (Continued)

Page 1672 of 2585

(10)2.4L Gas equipped models goto Step 15.

2.5L TD models:Remove battery thermal shield

(Fig. 138).

(11) Remove battery hold down nut, clamp, and

battery (Fig. 139).(12) Remove battery tray (Fig. 140). Disconnect

battery temperature sensor.

(13) Remove coolant recovery bottle from bracket.

(14) Remove coolant recovery bottle mounting

bracket (Fig. 141).

Fig. 138 Battery Thermal Shield

1 - BATTERY THERMAL SHIELD

Fig. 139 Battery and Hold-Down Clamp

1 - BATTERY

2 - HOLD-DOWN CLAMP

Fig. 140 Battery Tray

1 - BATTERY TRAY

Fig. 141 Coolant Recovery Bottle Bracket

1 - COOLANT RECOVERY BOTTLE BRACKET

2 - NUT

3 - MOUNT BRACKET

RST850 MANUAL TRANSAXLE21-75

GEARSHIFT CABLE - CROSSOVER (Continued)

Page 1674 of 2585

(6) Install coolant recovery bottle to bracket.

(7) Connect battery temperature sensor to battery

tray. Install battery tray into position (Fig. 145).

(8) Install battery, hold-down clamp, and nut (Fig.

146).(9) Install battery thermal shield (Fig. 147).

(10) Install crossover cable to gearshift mechanism

(Fig. 148). Install retainer clip (Fig. 149).

Fig. 145 Battery Tray

1 - BATTERY TRAY

Fig. 146 Battery and Hold-Down Clamp

1 - BATTERY

2 - HOLD-DOWN CLAMP

Fig. 147 Battery Thermal Shield

1 - BATTERY THERMAL SHIELD

Fig. 148 Crossover Cable at Gearshift Mechanism

1 - GEARSHIFT MECHANISM

2 - CROSSOVER CABLE

RST850 MANUAL TRANSAXLE21-77

GEARSHIFT CABLE - CROSSOVER (Continued)

Page 1680 of 2585

(11) Remove battery hold down nut, clamp, and

battery (Fig. 168).

(12) Remove battery tray (Fig. 169). Disconnect

battery temperature sensor.(13) Remove coolant recovery bottle from bracket.

(14) Remove coolant recovery bottle mounting

bracket (Fig. 170).

(15) Disconnect crossover cable from transaxle

crossover lever (Fig. 171).

(16) Remove crossover cable retainer clip and dis-

engage cable from mount bracket (Fig. 171).

Fig. 168 Battery and Hold-Down Clamp

1 - BATTERY

2 - HOLD-DOWN CLAMP

Fig. 169 Battery Tray

1 - BATTERY TRAY

Fig. 170 Coolant Recovery Bottle Bracket

1 - COOLANT RECOVERY BOTTLE BRACKET

2 - NUT

3 - MOUNT BRACKET

Fig. 171 Gearshift Cables at Transaxle

1 - SELECTOR CABLE

2 - CABLE RETAINER

3 - CABLE RETAINER

4 - CROSSOVER CABLE

5 - MOUNT BRACKET

RST850 MANUAL TRANSAXLE21-83

GEARSHIFT CABLE - SELECTOR (Continued)

Page 1681 of 2585

(17) Raise vehicle on hoist.

(18) Remove selector cable from engine compart-

ment, then remove cable from passenger compart-

ment through opening in floor pan.

INSTALLATION

(1) From underneath vehicle, install gearshift

selector cable into passenger compartment through

floor pan hole. Install remainder of cable into posi-

tion in engine compartment.

(2) Lower vehicle.

(3) Install selector cable to mount bracket and

secure with retainer clip (Fig. 172).

(4) Install cable to transaxle selector lever (Fig.

172).

(5)2.4L Gas models goto Step 10. 2.5L TD

models:Install coolant recovery bottle bracket (Fig.

173).(6) Install coolant recovery bottle to bracket.

(7) Connect battery temperature sensor to battery

tray. Install battery tray into position (Fig. 174).

Fig. 172 Gearshift Cables at Transaxle

1 - SELECTOR CABLE

2 - CABLE RETAINER

3 - CABLE RETAINER

4 - CROSSOVER CABLE

5 - MOUNT BRACKET

Fig. 173 Coolant Recovery Bottle Bracket

1 - COOLANT RECOVERY BOTTLE BRACKET

2 - NUT

3 - MOUNT BRACKET

Fig. 174 Battery Tray

1 - BATTERY TRAY

21 - 84 T850 MANUAL TRANSAXLERS

GEARSHIFT CABLE - SELECTOR (Continued)

Page 1844 of 2585

TORQUE CONVERTER CLUTCH (TCC)

In a standard torque converter, the impeller and

turbine are rotating at about the same speed and the

stator is freewheeling, providing no torque multipli-

cation. By applying the turbine's piston to the front

cover's friction material, a total converter engage-

ment can be obtained. The result of this engagement

is a direct 1:1 mechanical link between the engine

and the transmission.

The engagement and disengagement of the TCC

are automatic and controlled by the Powertrain Con-

trol Module (PCM). The engagement cannot be acti-

vated in the lower gears because it eliminates the

torque multiplication effect of the torque converter

necessary for acceleration. Inputs that determine

clutch engagement are: coolant temperature, vehicle

speed and throttle position. The torque converter

clutch is engaged by the clutch solenoid on the valve

body. The clutch will engage at approximately 56

km/h (35 mph) with light throttle, after the shift to

third gear.

REMOVAL

(1) Remove transmission and torque converter

from vehicle. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 41TE - REMOVAL)

(2) Place a suitable drain pan under the converter

housing end of the transmission.

CAUTION: Verify that transmission is secure on the

lifting device or work surface, the center of gravity

of the transmission will shift when the torque con-

verter is removed creating an unstable condition.

The torque converter is a heavy unit. Use caution

when separating the torque converter from the

transmission.

(3) Pull the torque converter forward until the cen-

ter hub clears the oil pump seal.

(4) Separate the torque converter from the trans-

mission.

INSTALLATION

Check converter hub and drive notches for sharp

edges, burrs, scratches, or nicks. Polish the hub and

notches with 320/400 grit paper or crocus cloth if nec-

essary. The hub must be smooth to avoid damaging

the pump seal at installation.

(1) Lubricate converter hub and oil pump seal lip

with transmission fluid.

(2) Place torque converter in position on transmis-

sion.

CAUTION: Do not damage oil pump seal or bushing

while inserting torque converter into the front of the

transmission.(3) Align torque converter to oil pump seal open-

ing.

(4) Insert torque converter hub into oil pump.

(5) While pushing torque converter inward, rotate

converter until converter is fully seated in the oil

pump gears.

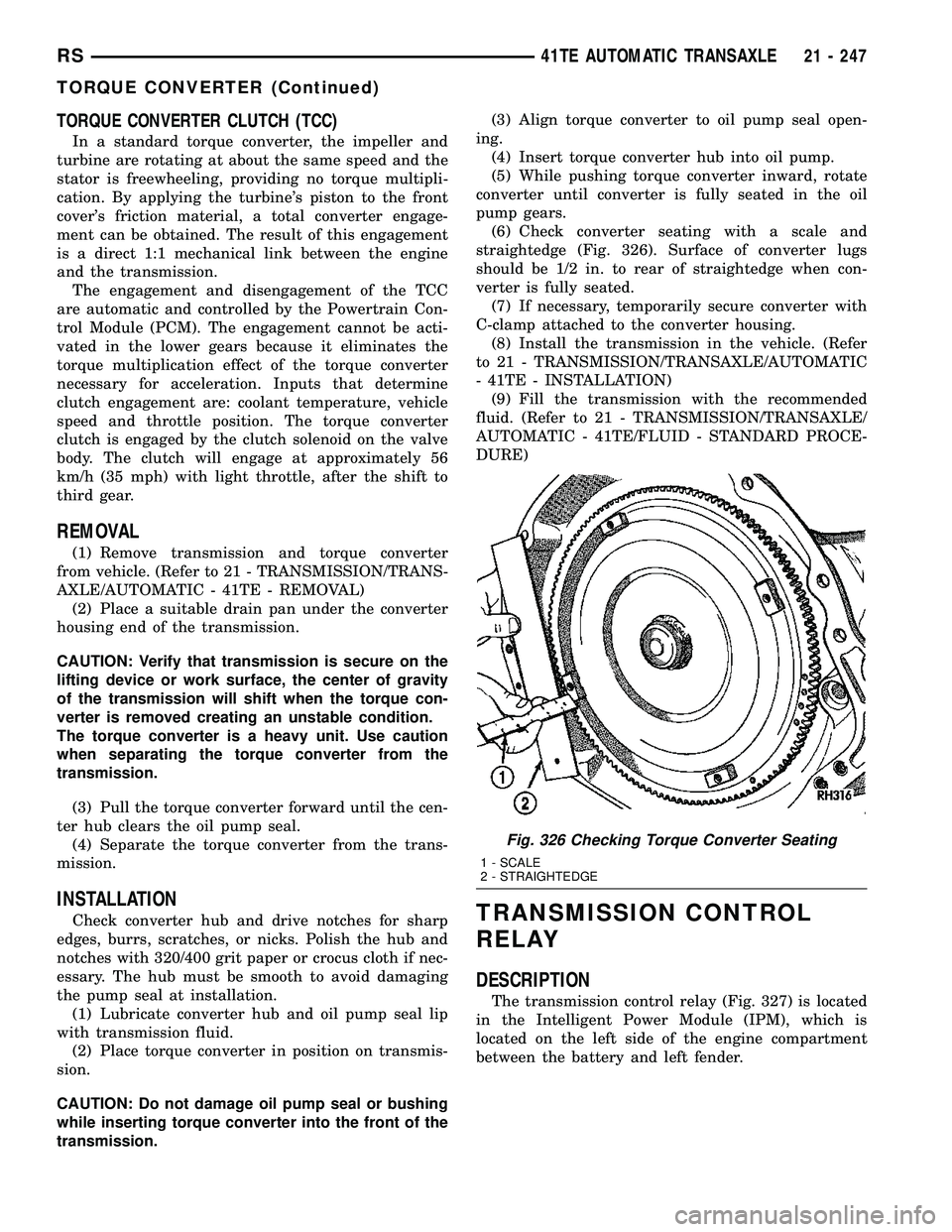

(6) Check converter seating with a scale and

straightedge (Fig. 326). Surface of converter lugs

should be 1/2 in. to rear of straightedge when con-

verter is fully seated.

(7) If necessary, temporarily secure converter with

C-clamp attached to the converter housing.

(8) Install the transmission in the vehicle. (Refer

to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC

- 41TE - INSTALLATION)

(9) Fill the transmission with the recommended

fluid. (Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC - 41TE/FLUID - STANDARD PROCE-

DURE)TRANSMISSION CONTROL

RELAY

DESCRIPTION

The transmission control relay (Fig. 327) is located

in the Intelligent Power Module (IPM), which is

located on the left side of the engine compartment

between the battery and left fender.

Fig. 326 Checking Torque Converter Seating

1 - SCALE

2 - STRAIGHTEDGE

RS41TE AUTOMATIC TRANSAXLE21 - 247

TORQUE CONVERTER (Continued)

Page 1846 of 2585

Since there are four switches, there are 16 possible

combinations of open and closed switches (codes).

Seven of these codes are related to gear position and

three are recognized as ªbetween gearº codes. This

results in six codes which should never occur. These

are called ªinvalidº codes. An invalid code will result

in a DTC, and the PCM/TCM will then determine the

shift lever position based on pressure switch data.

This allows reasonably normal transmission opera-

tion with a TRS failure.

TRS SWITCH STATES

SLP T42 T41 T3 T1

PCL CL CL OP

RCL OP OP OP

NCL CL OP CL

ODOP OP OP CL

3OP OP CL OP

LCL OP CL CL

TRANSMISSION TEMPERATURE SENSOR

The TRS has an integrated thermistor (Fig. 329)

that the PCM/TCM uses to monitor the transmis-

sion's sump temperature. Since fluid temperature

can affect transmission shift quality and convertor

lock up, the PCM/TCM requires this information to

determine which shift schedule to operate in. The

PCM also monitors this temperature data so it can

energize the vehicle cooling fan(s) when a transmis-

sion ªoverheatº condition exists. If the thermistor cir-

cuit fails, the PCM/TCM will revert to calculated oil

temperature usage.

CALCULATED TEMPERATURE

A failure in the temperature sensor or circuit will

result in calculated temperature being substituted for

actual temperature. Calculated temperature is a pre-

dicted fluid temperature which is calculated from a

combination of inputs:

²Battery (ambient) temperature

²Engine coolant temperature

²In-gear run time since start-up

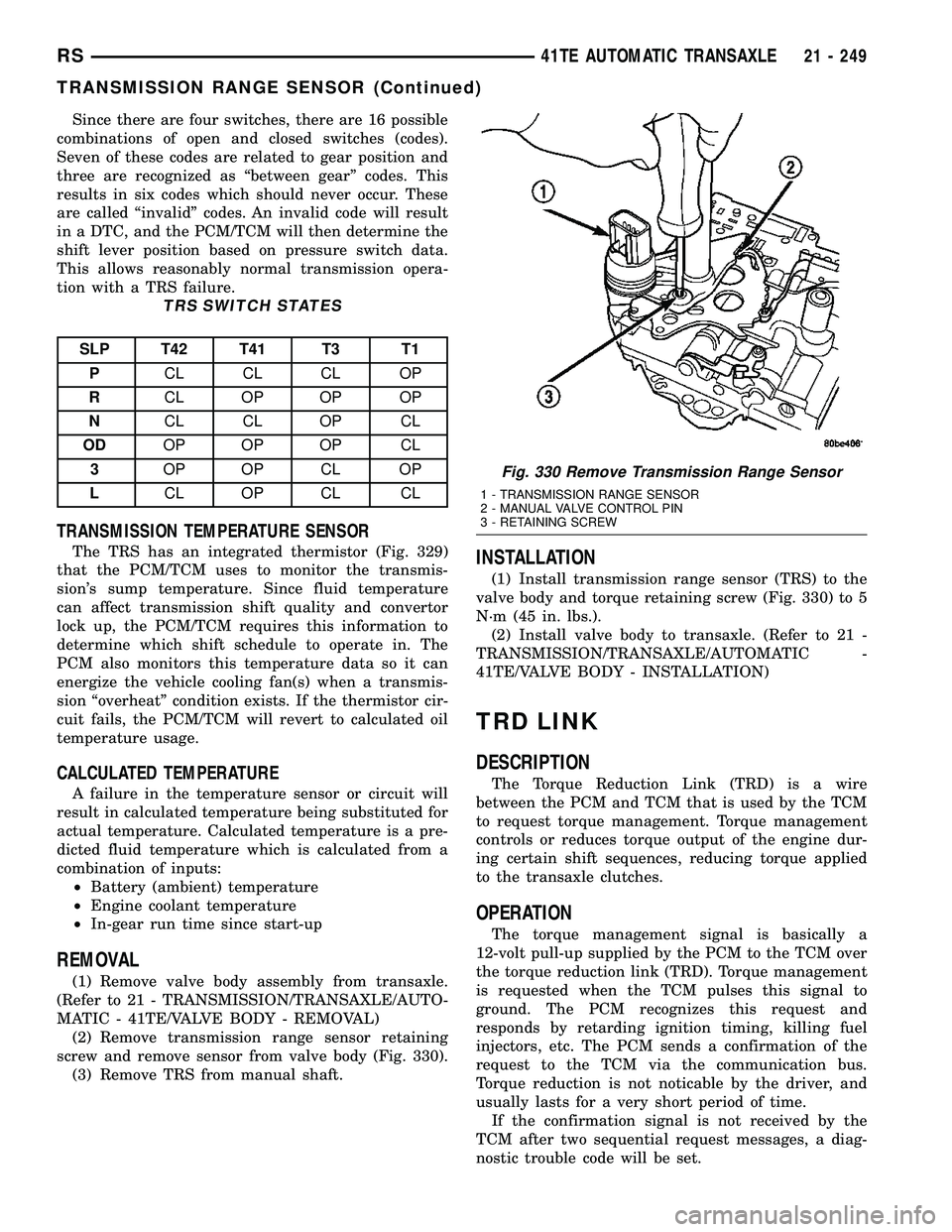

REMOVAL

(1) Remove valve body assembly from transaxle.

(Refer to 21 - TRANSMISSION/TRANSAXLE/AUTO-

MATIC - 41TE/VALVE BODY - REMOVAL)

(2) Remove transmission range sensor retaining

screw and remove sensor from valve body (Fig. 330).

(3) Remove TRS from manual shaft.

INSTALLATION

(1) Install transmission range sensor (TRS) to the

valve body and torque retaining screw (Fig. 330) to 5

N´m (45 in. lbs.).

(2) Install valve body to transaxle. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

41TE/VALVE BODY - INSTALLATION)

TRD LINK

DESCRIPTION

The Torque Reduction Link (TRD) is a wire

between the PCM and TCM that is used by the TCM

to request torque management. Torque management

controls or reduces torque output of the engine dur-

ing certain shift sequences, reducing torque applied

to the transaxle clutches.

OPERATION

The torque management signal is basically a

12-volt pull-up supplied by the PCM to the TCM over

the torque reduction link (TRD). Torque management

is requested when the TCM pulses this signal to

ground. The PCM recognizes this request and

responds by retarding ignition timing, killing fuel

injectors, etc. The PCM sends a confirmation of the

request to the TCM via the communication bus.

Torque reduction is not noticable by the driver, and

usually lasts for a very short period of time.

If the confirmation signal is not received by the

TCM after two sequential request messages, a diag-

nostic trouble code will be set.

Fig. 330 Remove Transmission Range Sensor

1 - TRANSMISSION RANGE SENSOR

2 - MANUAL VALVE CONTROL PIN

3 - RETAINING SCREW

RS41TE AUTOMATIC TRANSAXLE21 - 249

TRANSMISSION RANGE SENSOR (Continued)

Page 2010 of 2585

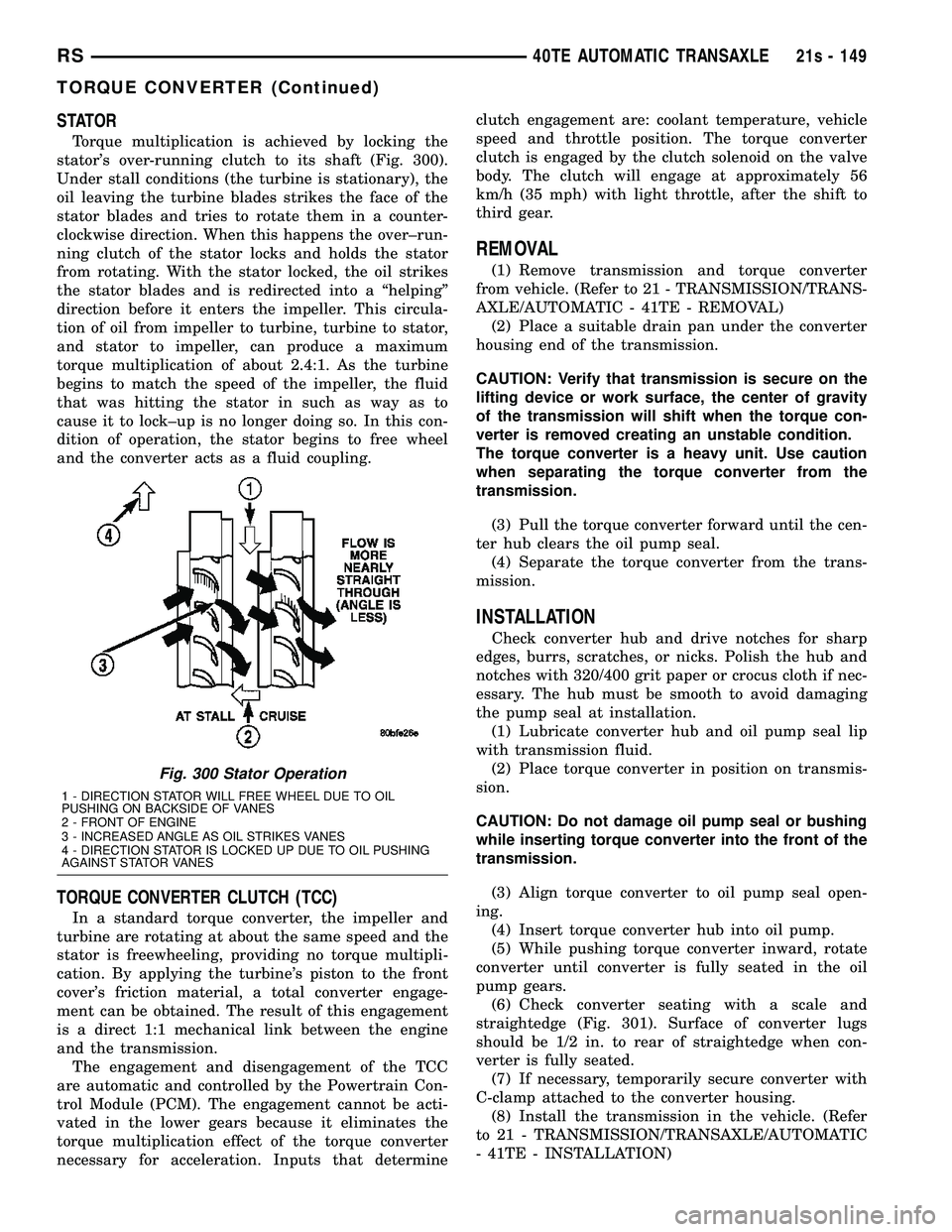

STATOR

Torque multiplication is achieved by locking the

stator's over-running clutch to its shaft (Fig. 300).

Under stall conditions (the turbine is stationary), the

oil leaving the turbine blades strikes the face of the

stator blades and tries to rotate them in a counter-

clockwise direction. When this happens the over±run-

ning clutch of the stator locks and holds the stator

from rotating. With the stator locked, the oil strikes

the stator blades and is redirected into a ªhelpingº

direction before it enters the impeller. This circula-

tion of oil from impeller to turbine, turbine to stator,

and stator to impeller, can produce a maximum

torque multiplication of about 2.4:1. As the turbine

begins to match the speed of the impeller, the fluid

that was hitting the stator in such as way as to

cause it to lock±up is no longer doing so. In this con-

dition of operation, the stator begins to free wheel

and the converter acts as a fluid coupling.

TORQUE CONVERTER CLUTCH (TCC)

In a standard torque converter, the impeller and

turbine are rotating at about the same speed and the

stator is freewheeling, providing no torque multipli-

cation. By applying the turbine's piston to the front

cover's friction material, a total converter engage-

ment can be obtained. The result of this engagement

is a direct 1:1 mechanical link between the engine

and the transmission. The engagement and disengagement of the TCC

are automatic and controlled by the Powertrain Con-

trol Module (PCM). The engagement cannot be acti-

vated in the lower gears because it eliminates the

torque multiplication effect of the torque converter

necessary for acceleration. Inputs that determine clutch engagement are: coolant temperature, vehicle

speed and throttle position. The torque converter

clutch is engaged by the clutch solenoid on the valve

body. The clutch will engage at approximately 56

km/h (35 mph) with light throttle, after the shift to

third gear.

REMOVAL

(1) Remove transmission and torque converter

from vehicle. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 41TE - REMOVAL) (2) Place a suitable drain pan under the converter

housing end of the transmission.

CAUTION: Verify that transmission is secure on the

lifting device or work surface, the center of gravity

of the transmission will shift when the torque con-

verter is removed creating an unstable condition.

The torque converter is a heavy unit. Use caution

when separating the torque converter from the

transmission.

(3) Pull the torque converter forward until the cen-

ter hub clears the oil pump seal. (4) Separate the torque converter from the trans-

mission.

INSTALLATION

Check converter hub and drive notches for sharp

edges, burrs, scratches, or nicks. Polish the hub and

notches with 320/400 grit paper or crocus cloth if nec-

essary. The hub must be smooth to avoid damaging

the pump seal at installation. (1) Lubricate converter hub and oil pump seal lip

with transmission fluid. (2) Place torque converter in position on transmis-

sion.

CAUTION: Do not damage oil pump seal or bushing

while inserting torque converter into the front of the

transmission.

(3) Align torque converter to oil pump seal open-

ing. (4) Insert torque converter hub into oil pump.

(5) While pushing torque converter inward, rotate

converter until converter is fully seated in the oil

pump gears. (6) Check converter seating with a scale and

straightedge (Fig. 301). Surface of converter lugs

should be 1/2 in. to rear of straightedge when con-

verter is fully seated. (7) If necessary, temporarily secure converter with

C-clamp attached to the converter housing. (8) Install the transmission in the vehicle. (Refer

to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC

- 41TE - INSTALLATION)

Fig. 300 Stator Operation

1 - DIRECTION STATOR WILL FREE WHEEL DUE TO OIL

PUSHING ON BACKSIDE OF VANES

2 - FRONT OF ENGINE

3 - INCREASED ANGLE AS OIL STRIKES VANES

4 - DIRECTION STATOR IS LOCKED UP DUE TO OIL PUSHING

AGAINST STATOR VANES

RS 40TE AUTOMATIC TRANSAXLE21s - 149

TORQUE CONVERTER (Continued)

Page 2012 of 2585

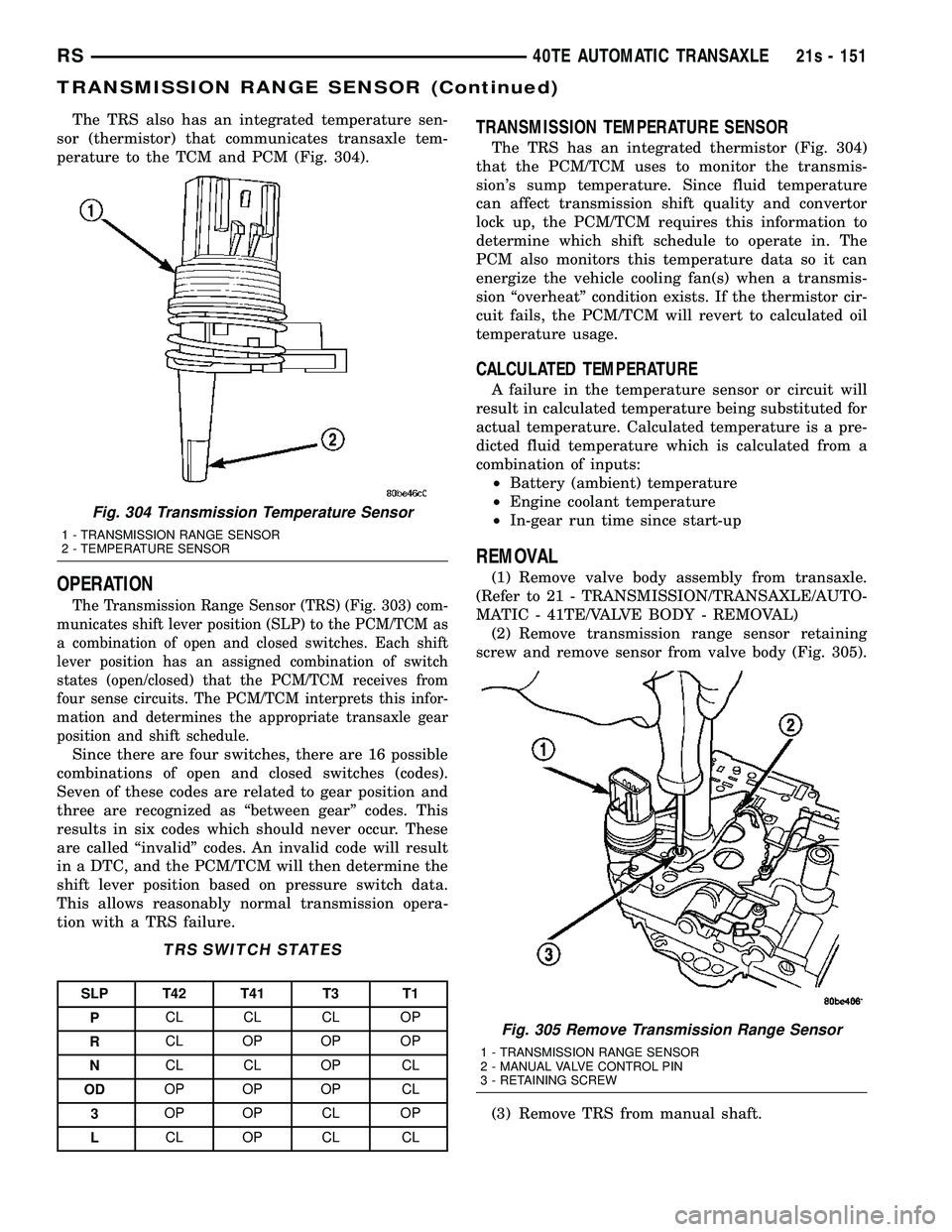

The TRS also has an integrated temperature sen-

sor (thermistor) that communicates transaxle tem-

perature to the TCM and PCM (Fig. 304).

OPERATION

The Transmission Range Sensor (TRS) (Fig. 303) com-

municates shift lever position (SLP) to the PCM/TCM as

a combination of open and closed switches. Each shift

lever position has an assigned combination of switch

states (open/closed) that the PCM/TCM receives from

four sense circuits. The PCM/TCM interprets this infor-

mation and determines the appropriate transaxle gear

position and shift schedule.

Since there are four switches, there are 16 possible

combinations of open and closed switches (codes).

Seven of these codes are related to gear position and

three are recognized as ªbetween gearº codes. This

results in six codes which should never occur. These

are called ªinvalidº codes. An invalid code will result

in a DTC, and the PCM/TCM will then determine the

shift lever position based on pressure switch data.

This allows reasonably normal transmission opera-

tion with a TRS failure.

TRS SWITCH STATES

SLP T42 T41 T3 T1

P CL CL CL OP

R CL OP OP OP

N CL CL OP CL

OD OP OP OP CL

3 OP OP CL OP

L CL OP CL CL

TRANSMISSION TEMPERATURE SENSOR

The TRS has an integrated thermistor (Fig. 304)

that the PCM/TCM uses to monitor the transmis-

sion's sump temperature. Since fluid temperature

can affect transmission shift quality and convertor

lock up, the PCM/TCM requires this information to

determine which shift schedule to operate in. The

PCM also monitors this temperature data so it can

energize the vehicle cooling fan(s) when a transmis-

sion ªoverheatº condition exists. If the thermistor cir-

cuit fails, the PCM/TCM will revert to calculated oil

temperature usage.

CALCULATED TEMPERATURE

A failure in the temperature sensor or circuit will

result in calculated temperature being substituted for

actual temperature. Calculated temperature is a pre-

dicted fluid temperature which is calculated from a

combination of inputs: ² Battery (ambient) temperature

² Engine coolant temperature

² In-gear run time since start-up

REMOVAL

(1) Remove valve body assembly from transaxle.

(Refer to 21 - TRANSMISSION/TRANSAXLE/AUTO-

MATIC - 41TE/VALVE BODY - REMOVAL) (2) Remove transmission range sensor retaining

screw and remove sensor from valve body (Fig. 305).

(3) Remove TRS from manual shaft.

Fig. 304 Transmission Temperature Sensor

1 - TRANSMISSION RANGE SENSOR

2 - TEMPERATURE SENSOR

Fig. 305 Remove Transmission Range Sensor

1 - TRANSMISSION RANGE SENSOR

2 - MANUAL VALVE CONTROL PIN

3 - RETAINING SCREW

RS 40TE AUTOMATIC TRANSAXLE21s - 151

TRANSMISSION RANGE SENSOR (Continued)

Page 2398 of 2585

REAR CONTROL PANEL

The rear A/C-heater control centrally mounted in

the headliner allows intermediate seat passengers to

adjust rear air distribution, temperature and blower

motor speed when the center knob on the front A/C-

heater control is set to the Rear position. The rear

A/C-heater control contains:

²a rotary adjustment knob for temperature.

²a rotary adjustment for fan speed control.

DESCRIPTION - AUTOMATIC THREE ZONE

The automatic temperature control (ATC), three

zone, front and rear heating and air conditioning sys-

tem allows both the driver and front occupants and

the rear intermediate occupants to select individual

comfort temperatures.

NOTE: Individual comfort temperatures are the per-

ceived temperature level at the individual seating

areas, NOT the actual passenger compartment air

temperature.

The ATC system includes a particulate air filter.

The filter element is the same size as the air condi-

tioning evaporator to ensure ample capacity. A door

at the base of the HVAC housing below the glove box

provides easy access to the filter element.

The ATC computer utilizes integrated circuitry and

information carried on the programmable communi-

cations interface (PCI) data bus network to monitor

many sensors and switch inputs throughout the vehi-

cle. In response to those inputs, the internal circuitry

and programming of the ATC computer allow it to

control electronic functions and features of the ATC

system. The inputs to the ATC computer are:

²Vehicle Speed/Engine RPM± The ATC com-

puter monitors engine rpm, vehicle speed and mani-

fold absolute pressure information from the

powertrain control module (PCM).

²Coolant Temperature± ATC computer moni-

tors coolant temperature received from the PCM and

converts it to degrees Fahrenheit.

²Ambient Temperature± ATC computer moni-

tors ambient temperature from the compass mini trip

computer (CMTC) and converts it to degrees Fahren-

heit.

²Engine Miscellaneous Sensor Status±ATC

computer monitors A/C disable information from the

PCM.

²Refrigerant Pressure± ATC computer moni-

tors barometric pressure, intake air temperature,

high side pressure and methanol content as broad-

cast by the PCM.

²Door Ajar Status± The ATC computer moni-

tors driver front door, passenger front door, left rear

door, right rear door and liftgate ajar information, asidentified by the body control module (BCM), to

determine if all in-car temperatures should be main-

tained.

²Dimming± The ATC computer monitors dim-

ming status from the BCM to determine the required

level of brightness and will dim accordingly.

²Vehicle Odometer± The ATC computer moni-

tors the vehicle odometer information from the BCM

to prevent flashing the vacuum-flourescent (VF) dig-

ital display icons if the manual motor calibration or

manual cool down tests have failed. Flashing of the

display icons will cease when the vehicle odometer is

greater than 3 miles.

²English/Metric± The ATC computer monitors

the English/Metric information broadcast by the

CMTC. The set temp displays for both the front and

rear control heads will be set accordingly.

²Vehicle Identification Number± The ATC

computer monitors the last eight characters of the

VIN broadcast by the PCM and compares it to the

information stored in EEPROM. If it is different, the

new number will be stored over the old one and a

motor calibration shall be initiated.

²A/C System Information± The ATC computer

will send a message for evaporator temperature too

low, fan blower relay status, evaporator sensor fail-

ure, rear window defogger relay and A/C select.

FRONT CONTROL PANEL

The front A/C-heater control and integral computer

is mounted in the instrument panel and contains:

²a power button which allows the system to be

completely turned off. The display is blank when the

system is off.

²a rocker switch that selects a cool-down rate.

LO-AUTO or HI-AUTO are displayed when the sys-

tem is in automatic operation.

²three rocker switches that select comfort temper-

atures from 15É to 30É C (59É to 85É F), which are

shown in the VF digital display. If the set temp is 15É

C (59É F) and the down button is pressed, the set

temp value will become 13É C (55É F) but the display

will show LO. If the set temp is 29É C (85É F) and the

up button is pressed, the set temp value will become

32É C (90É F) but the display will show HIGH. Tem-

peratures can be displayed in either metric or Fahr-

enheit, which is controlled from the overhead console.

²an air conditioning button that allows the com-

pressor to be turned off. A Snowflake symbol is illu-

minated when air conditioning is on, whether under

manual or automatic control.

²an air recirculation button. A Recirculation sym-

bol appears in the display when the button is

pressed, or when the system exceeds 80 percent cir-

culated air under automatic control due to high air

conditioning demand.

RSHEATING & AIR CONDITIONING24-3

HEATING & AIR CONDITIONING (Continued)