differential CHRYSLER VOYAGER 2004 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1638 of 2585

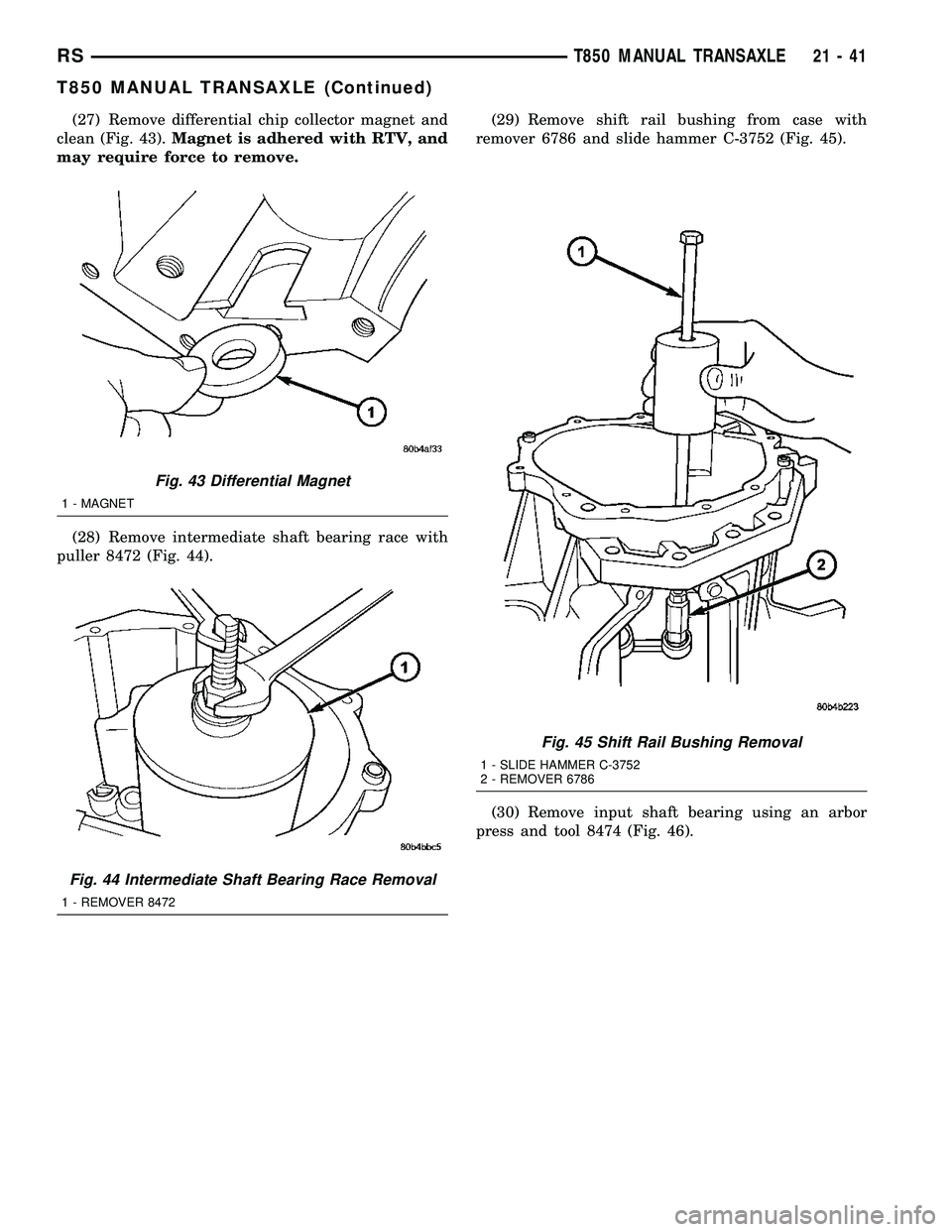

(27) Remove differential chip collector magnet and

clean (Fig. 43).Magnet is adhered with RTV, and

may require force to remove.

(28) Remove intermediate shaft bearing race with

puller 8472 (Fig. 44).(29) Remove shift rail bushing from case with

remover 6786 and slide hammer C-3752 (Fig. 45).

(30) Remove input shaft bearing using an arbor

press and tool 8474 (Fig. 46).

Fig. 43 Differential Magnet

1 - MAGNET

Fig. 44 Intermediate Shaft Bearing Race Removal

1 - REMOVER 8472

Fig. 45 Shift Rail Bushing Removal

1 - SLIDE HAMMER C-3752

2 - REMOVER 6786

RST850 MANUAL TRANSAXLE21-41

T850 MANUAL TRANSAXLE (Continued)

Page 1639 of 2585

ASSEMBLY

NOTE: When assembling this transaxle, always use

NEW snap rings.

NOTE: Before assembling transaxle, differential

turning torque must be measured and adjusted.

(Refer to 21 - TRANSMISSION/TRANSAXLE/MANU-

AL/DIFFERENTIAL - ADJUSTMENTS). Differential

turning torque must be measured with geartrain out

of case.

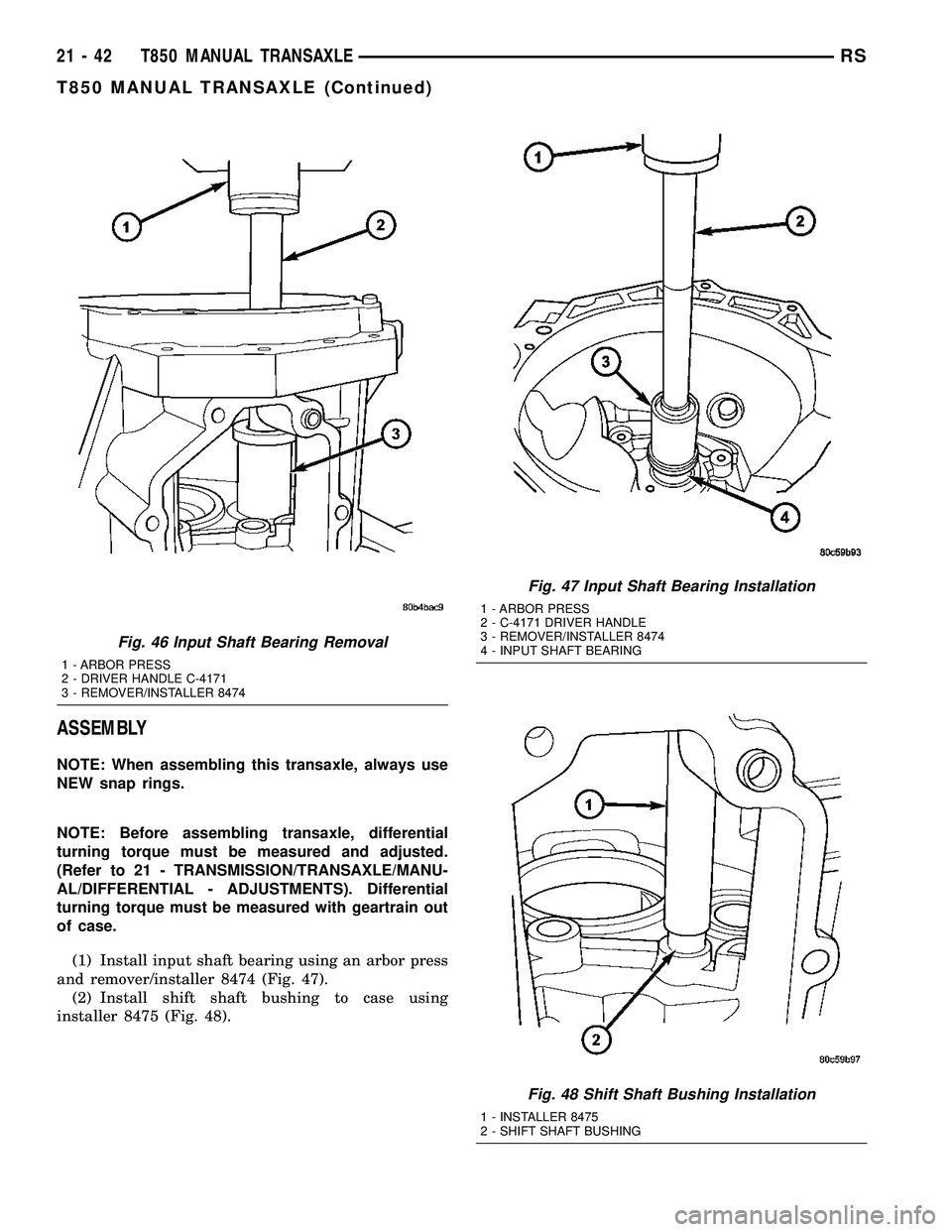

(1) Install input shaft bearing using an arbor press

and remover/installer 8474 (Fig. 47).

(2) Install shift shaft bushing to case using

installer 8475 (Fig. 48).

Fig. 46 Input Shaft Bearing Removal

1 - ARBOR PRESS

2 - DRIVER HANDLE C-4171

3 - REMOVER/INSTALLER 8474

Fig. 47 Input Shaft Bearing Installation

1 - ARBOR PRESS

2 - C-4171 DRIVER HANDLE

3 - REMOVER/INSTALLER 8474

4 - INPUT SHAFT BEARING

Fig. 48 Shift Shaft Bushing Installation

1 - INSTALLER 8475

2 - SHIFT SHAFT BUSHING

21 - 42 T850 MANUAL TRANSAXLERS

T850 MANUAL TRANSAXLE (Continued)

Page 1645 of 2585

(23) Install back up lamp switch and torque to 23

N´m (17 ft. lbs.) (Fig. 66).

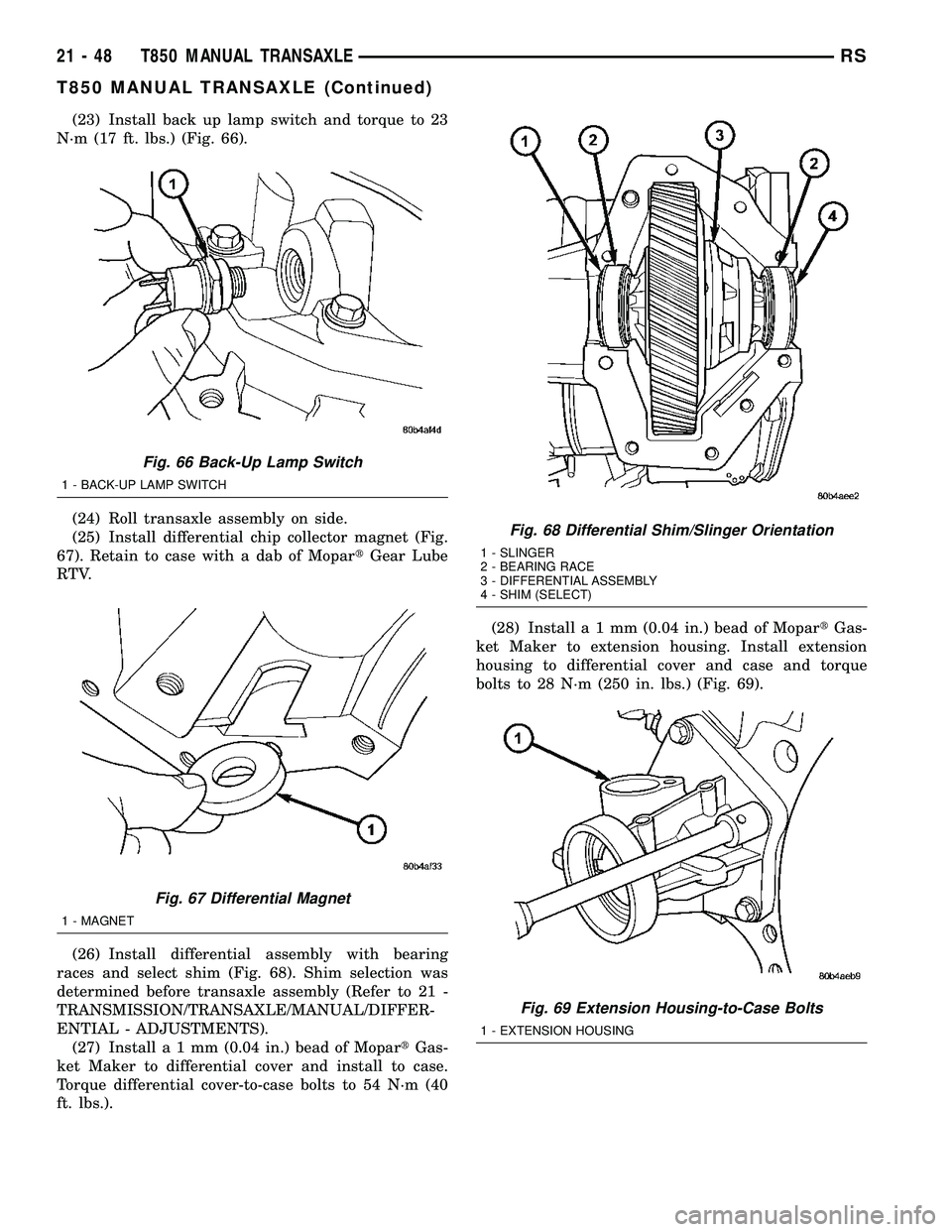

(24) Roll transaxle assembly on side.

(25) Install differential chip collector magnet (Fig.

67). Retain to case with a dab of MopartGear Lube

RTV.

(26) Install differential assembly with bearing

races and select shim (Fig. 68). Shim selection was

determined before transaxle assembly (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL/DIFFER-

ENTIAL - ADJUSTMENTS).

(27) Installa1mm(0.04 in.) bead of MopartGas-

ket Maker to differential cover and install to case.

Torque differential cover-to-case bolts to 54 N´m (40

ft. lbs.).(28) Installa1mm(0.04 in.) bead of MopartGas-

ket Maker to extension housing. Install extension

housing to differential cover and case and torque

bolts to 28 N´m (250 in. lbs.) (Fig. 69).

Fig. 66 Back-Up Lamp Switch

1 - BACK-UP LAMP SWITCH

Fig. 67 Differential Magnet

1 - MAGNET

Fig. 68 Differential Shim/Slinger Orientation

1 - SLINGER

2 - BEARING RACE

3 - DIFFERENTIAL ASSEMBLY

4 - SHIM (SELECT)

Fig. 69 Extension Housing-to-Case Bolts

1 - EXTENSION HOUSING

21 - 48 T850 MANUAL TRANSAXLERS

T850 MANUAL TRANSAXLE (Continued)

Page 1648 of 2585

INSTALLATION

INSTALLATION - 2.4L GAS

(1) Install modular clutch assembly to transaxle.

Assemble transaxle to engine.

(2) Install and torque transaxle-to-engine bolts to

95 N´m (70 ft. lbs.).

(3) Raise transaxle/engine assembly into position

and install upper mount through-bolt. Torque

through-bolt to 75 N´m (55 ft. lbs.).

(4) Remove screw jack.

(5) Install and torque modular clutch assembly-to-

drive plate bolts to 88 N´m (65 ft. lbs.)

(6) Install structural collar.

(7) Connect back-up lamp switch connector.

(8) Install starter motor into position (Fig. 78).

Install and torque bolts to 54 N´m (40 ft. lbs.).

(9) Install engine front mount bracket. Install and

torque bracket-to-transaxle bolts to 102 N´m (75 ft.

lbs.). Install and torque bracket-to-engine bolts to 68

N´m (50 ft. lbs.). Torque through-bolt and nut to 68

N´m (50 ft. lbs.).(10) Install clutch slave cylinder into position, not-

ing orientation of different sized lugs (Fig. 79). While

depressing inward, rotate slave cylinder clockwise

60tÉ into position until nylon locating tab rests

within transaxle case cutout, and hydraulic tube is

vertical. Connect ªquick-connectº connection until an

audible ªclickº is heard. Verify connection by pulling

outward on connection.

(11) Install halfshafts and front wheel/tire assem-

blies. (Refer to 3 - DIFFERENTIAL & DRIVELINE/

HALF SHAFT - INSTALLATION)

(12) Lower vehicle.

Fig. 78 Starter Motor Removal/Installation

1 - STARTER MOTOR

2 - BOLT (3)

Fig. 79 Slave Cylinder Removal/Installation

1 - MOUNTING HOLE

2 - SLAVE CYLINDER

3 - ACCESS HOLE

4 - NYLON ANTI-ROTATION TAB

5 - QUICK CONNECT

RST850 MANUAL TRANSAXLE21-51

T850 MANUAL TRANSAXLE (Continued)

Page 1651 of 2585

(8) Install engine front mount bracket. Install and

torque bracket-to-transaxle bolts to 102 N´m (75 ft.

lbs.). Install and torque bracket-to-engine bolts to 68

N´m (50 ft. lbs.). Torque through-bolt and nut to 68

N´m (50 ft. lbs.).

(9) Install clutch slave cylinder into position, not-

ing orientation of different sized lugs (Fig. 85). While

depressing inward, rotate slave cylinder clockwise

60É into position until nylon locating tab rests within

transaxle case cutout, and hydraulic tube is vertical.

Connect ªquick-connectº connection until an audible

ªclickº is heard. Verify connection by pulling outward

on connection.

(10) Install underbody splash panel.

(11) Install halfshafts and front wheel/tire assem-

blies. (Refer to 3 - DIFFERENTIAL & DRIVELINE/

HALF SHAFT - INSTALLATION)

(12) Lower vehicle.

(13) Install right mount bracket to transaxle (Fig.

86).

(14) Connect gearshift cables to shift levers/cover

assembly (Fig. 87). Install cables into position at

mount bracket and secure with retaining clips.

Fig. 85 Slave Cylinder Removal/Installation

1 - MOUNTING HOLE

2 - SLAVE CYLINDER

3 - ACCESS HOLE

4 - NYLON ANTI-ROTATION TAB

5 - QUICK CONNECT

Fig. 86 Transaxle Right Mount and Bracket

1 - MOUNT BRACKET

2 - BOLT (3)

3 - MOUNT

4 - BOLT (1)

Fig. 87 Gearshift Cables at Transaxle

1 - SELECTOR CABLE

2 - CABLE RETAINER

3 - CABLE RETAINER

4 - CROSSOVER CABLE

5 - MOUNT BRACKET

21 - 54 T850 MANUAL TRANSAXLERS

T850 MANUAL TRANSAXLE (Continued)

Page 1653 of 2585

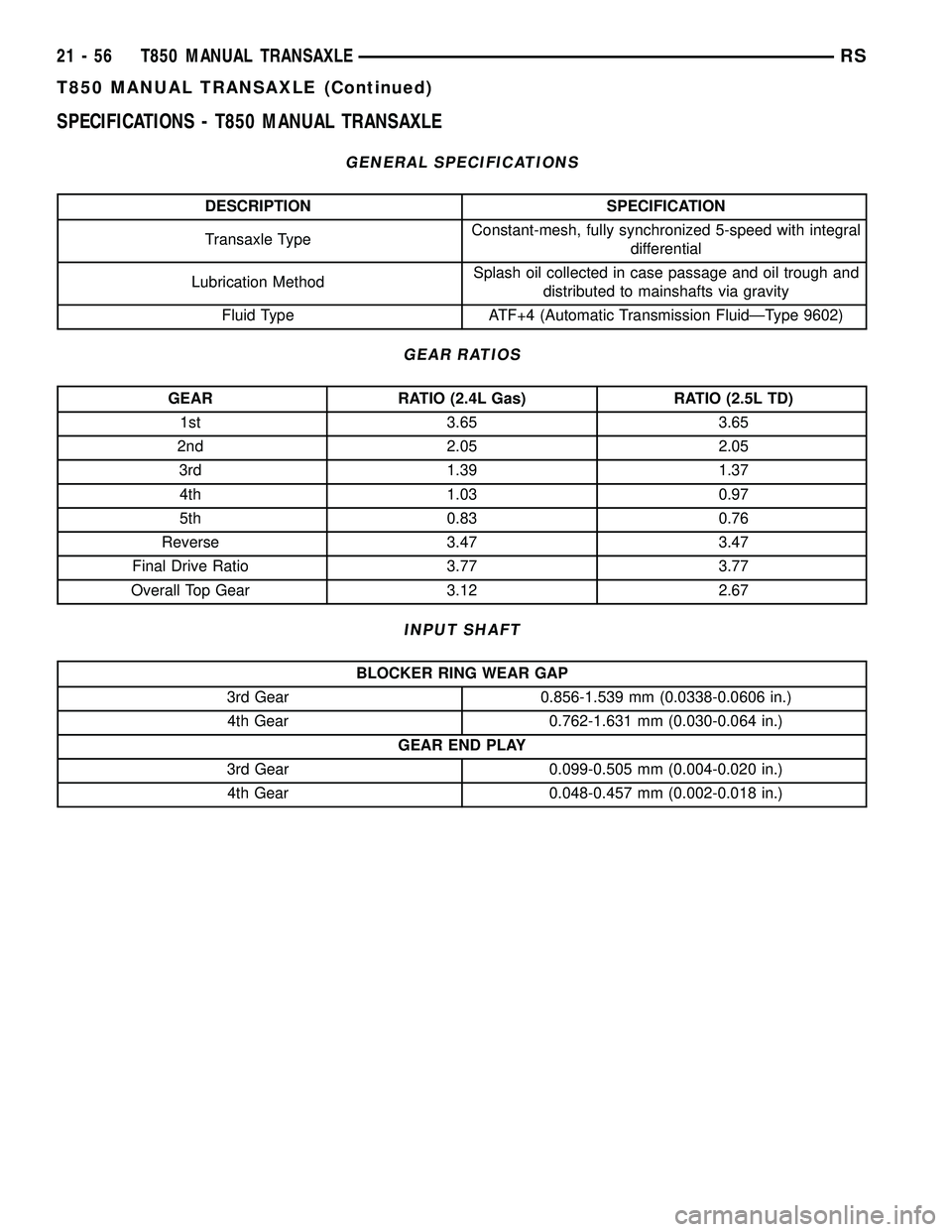

SPECIFICATIONS - T850 MANUAL TRANSAXLE

GENERAL SPECIFICATIONS

DESCRIPTION SPECIFICATION

Transaxle TypeConstant-mesh, fully synchronized 5-speed with integral

differential

Lubrication MethodSplash oil collected in case passage and oil trough and

distributed to mainshafts via gravity

Fluid Type ATF+4 (Automatic Transmission FluidÐType 9602)

GEAR RATIOS

GEAR RATIO (2.4L Gas) RATIO (2.5L TD)

1st 3.65 3.65

2nd 2.05 2.05

3rd 1.39 1.37

4th 1.03 0.97

5th 0.83 0.76

Reverse 3.47 3.47

Final Drive Ratio 3.77 3.77

Overall Top Gear 3.12 2.67

INPUT SHAFT

BLOCKER RING WEAR GAP

3rd Gear 0.856-1.539 mm (0.0338-0.0606 in.)

4th Gear 0.762-1.631 mm (0.030-0.064 in.)

GEAR END PLAY

3rd Gear 0.099-0.505 mm (0.004-0.020 in.)

4th Gear 0.048-0.457 mm (0.002-0.018 in.)

21 - 56 T850 MANUAL TRANSAXLERS

T850 MANUAL TRANSAXLE (Continued)

Page 1654 of 2585

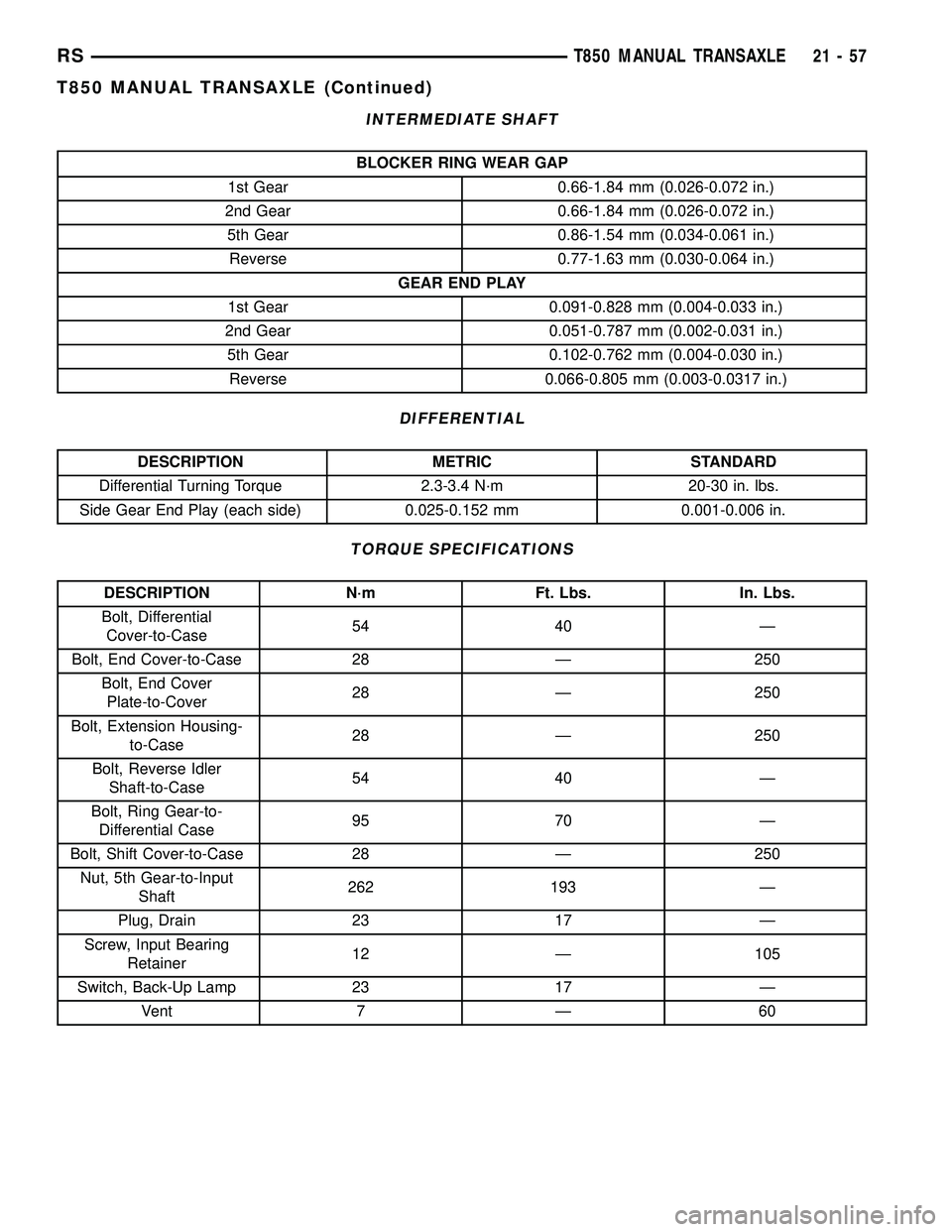

INTERMEDIATE SHAFT

BLOCKER RING WEAR GAP

1st Gear 0.66-1.84 mm (0.026-0.072 in.)

2nd Gear 0.66-1.84 mm (0.026-0.072 in.)

5th Gear 0.86-1.54 mm (0.034-0.061 in.)

Reverse 0.77-1.63 mm (0.030-0.064 in.)

GEAR END PLAY

1st Gear 0.091-0.828 mm (0.004-0.033 in.)

2nd Gear 0.051-0.787 mm (0.002-0.031 in.)

5th Gear 0.102-0.762 mm (0.004-0.030 in.)

Reverse 0.066-0.805 mm (0.003-0.0317 in.)

DIFFERENTIAL

DESCRIPTION METRIC STANDARD

Differential Turning Torque 2.3-3.4 N´m 20-30 in. lbs.

Side Gear End Play (each side) 0.025-0.152 mm 0.001-0.006 in.

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Bolt, Differential

Cover-to-Case54 40 Ð

Bolt, End Cover-to-Case 28 Ð 250

Bolt, End Cover

Plate-to-Cover28 Ð 250

Bolt, Extension Housing-

to-Case28 Ð 250

Bolt, Reverse Idler

Shaft-to-Case54 40 Ð

Bolt, Ring Gear-to-

Differential Case95 70 Ð

Bolt, Shift Cover-to-Case 28 Ð 250

Nut, 5th Gear-to-Input

Shaft262 193 Ð

Plug, Drain 23 17 Ð

Screw, Input Bearing

Retainer12 Ð 105

Switch, Back-Up Lamp 23 17 Ð

Vent 7 Ð 60

RST850 MANUAL TRANSAXLE21-57

T850 MANUAL TRANSAXLE (Continued)

Page 1658 of 2585

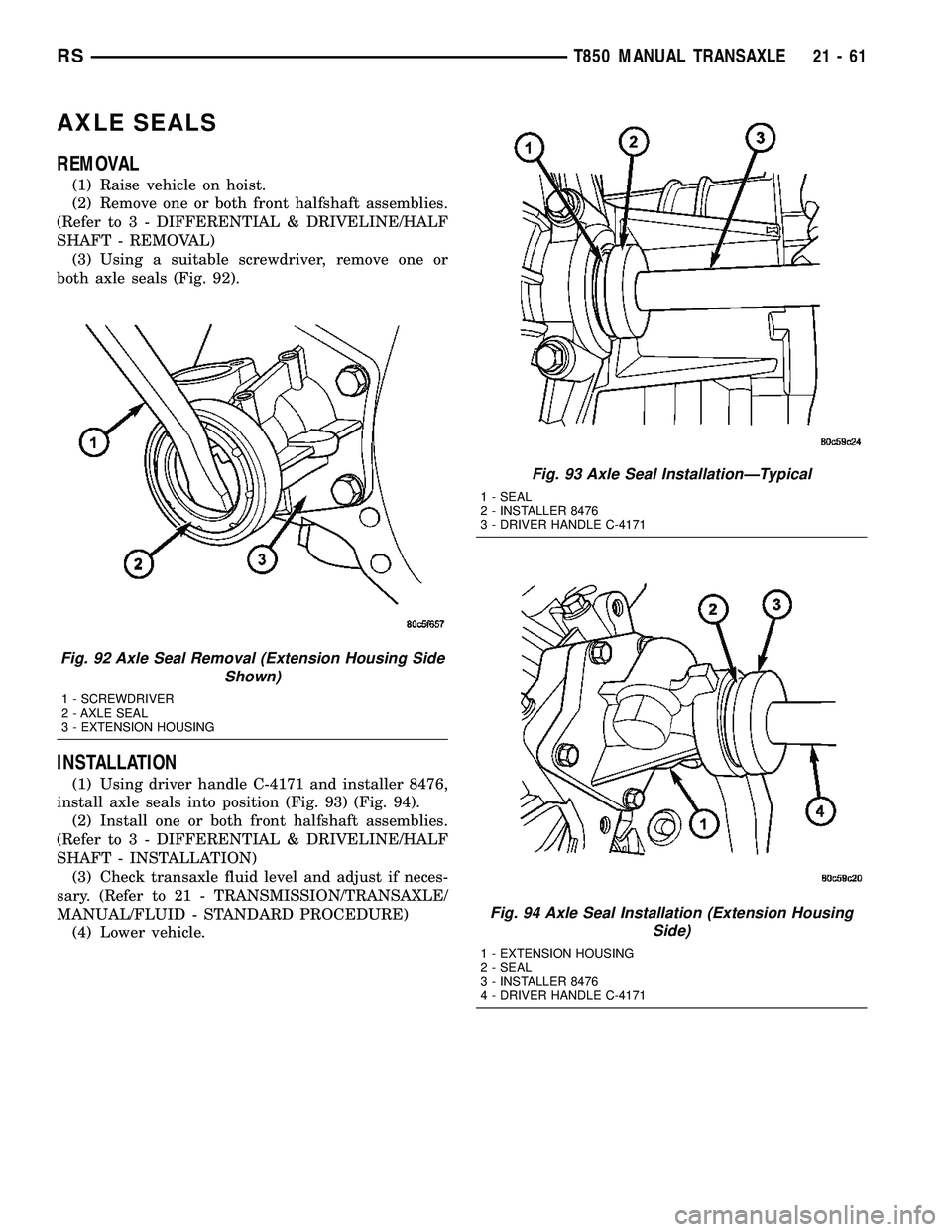

AXLE SEALS

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove one or both front halfshaft assemblies.

(Refer to 3 - DIFFERENTIAL & DRIVELINE/HALF

SHAFT - REMOVAL)

(3) Using a suitable screwdriver, remove one or

both axle seals (Fig. 92).

INSTALLATION

(1) Using driver handle C-4171 and installer 8476,

install axle seals into position (Fig. 93) (Fig. 94).

(2) Install one or both front halfshaft assemblies.

(Refer to 3 - DIFFERENTIAL & DRIVELINE/HALF

SHAFT - INSTALLATION)

(3) Check transaxle fluid level and adjust if neces-

sary. (Refer to 21 - TRANSMISSION/TRANSAXLE/

MANUAL/FLUID - STANDARD PROCEDURE)

(4) Lower vehicle.

Fig. 92 Axle Seal Removal (Extension Housing Side

Shown)

1 - SCREWDRIVER

2 - AXLE SEAL

3 - EXTENSION HOUSING

Fig. 93 Axle Seal InstallationÐTypical

1 - SEAL

2 - INSTALLER 8476

3 - DRIVER HANDLE C-4171

Fig. 94 Axle Seal Installation (Extension Housing

Side)

1 - EXTENSION HOUSING

2 - SEAL

3 - INSTALLER 8476

4 - DRIVER HANDLE C-4171

RST850 MANUAL TRANSAXLE21-61

Page 1659 of 2585

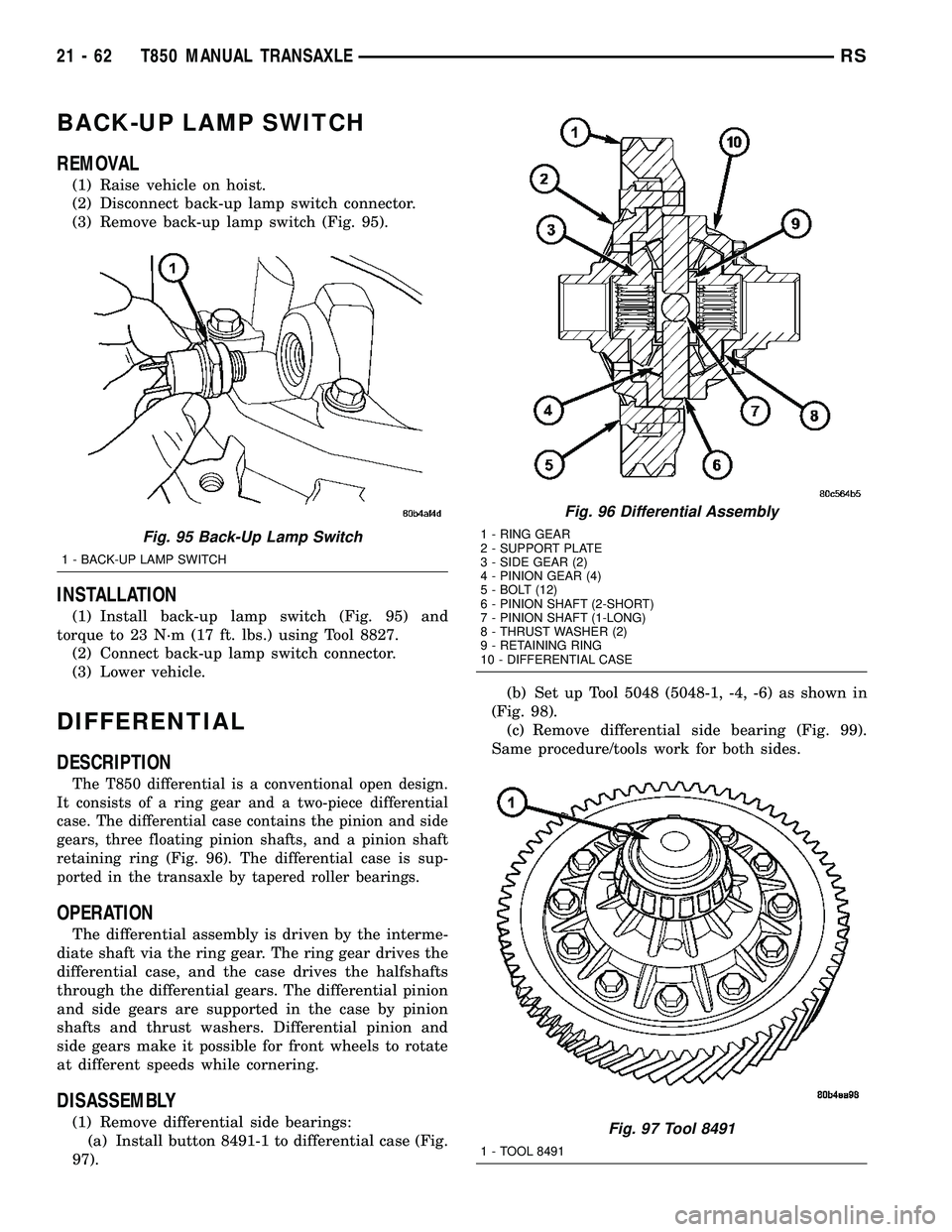

BACK-UP LAMP SWITCH

REMOVAL

(1) Raise vehicle on hoist.

(2) Disconnect back-up lamp switch connector.

(3) Remove back-up lamp switch (Fig. 95).

INSTALLATION

(1) Install back-up lamp switch (Fig. 95) and

torque to 23 N´m (17 ft. lbs.) using Tool 8827.

(2) Connect back-up lamp switch connector.

(3) Lower vehicle.

DIFFERENTIAL

DESCRIPTION

The T850 differential is a conventional open design.

It consists of a ring gear and a two-piece differential

case. The differential case contains the pinion and side

gears, three floating pinion shafts, and a pinion shaft

retaining ring (Fig. 96). The differential case is sup-

ported in the transaxle by tapered roller bearings.

OPERATION

The differential assembly is driven by the interme-

diate shaft via the ring gear. The ring gear drives the

differential case, and the case drives the halfshafts

through the differential gears. The differential pinion

and side gears are supported in the case by pinion

shafts and thrust washers. Differential pinion and

side gears make it possible for front wheels to rotate

at different speeds while cornering.

DISASSEMBLY

(1) Remove differential side bearings:

(a) Install button 8491-1 to differential case (Fig.

97).(b) Set up Tool 5048 (5048-1, -4, -6) as shown in

(Fig. 98).

(c) Remove differential side bearing (Fig. 99).

Same procedure/tools work for both sides.

Fig. 95 Back-Up Lamp Switch

1 - BACK-UP LAMP SWITCH

Fig. 96 Differential Assembly

1 - RING GEAR

2 - SUPPORT PLATE

3 - SIDE GEAR (2)

4 - PINION GEAR (4)

5 - BOLT (12)

6 - PINION SHAFT (2-SHORT)

7 - PINION SHAFT (1-LONG)

8 - THRUST WASHER (2)

9 - RETAINING RING

10 - DIFFERENTIAL CASE

Fig. 97 Tool 8491

1 - TOOL 8491

21 - 62 T850 MANUAL TRANSAXLERS

Page 1660 of 2585

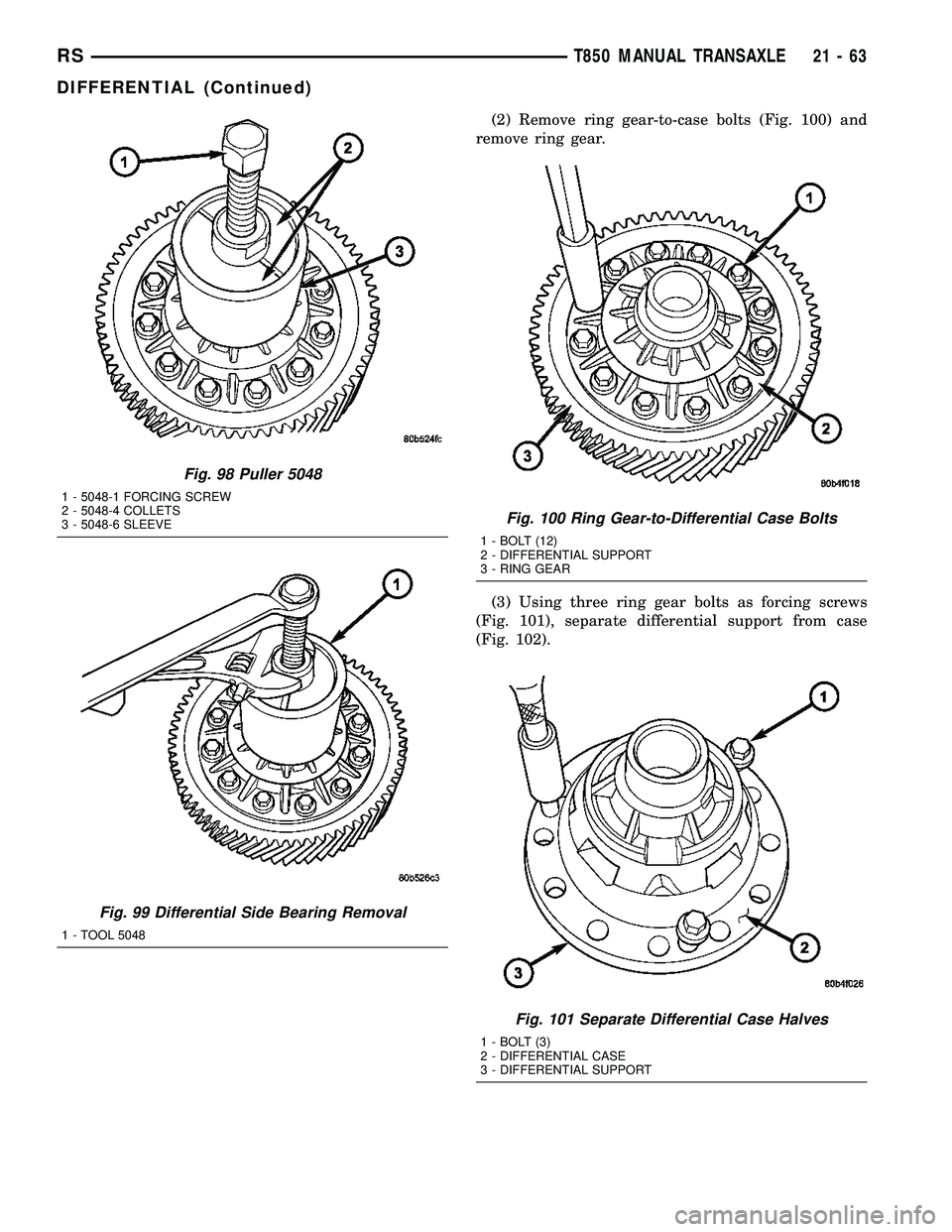

(2) Remove ring gear-to-case bolts (Fig. 100) and

remove ring gear.

(3) Using three ring gear bolts as forcing screws

(Fig. 101), separate differential support from case

(Fig. 102).

Fig. 98 Puller 5048

1 - 5048-1 FORCING SCREW

2 - 5048-4 COLLETS

3 - 5048-6 SLEEVE

Fig. 99 Differential Side Bearing Removal

1 - TOOL 5048

Fig. 100 Ring Gear-to-Differential Case Bolts

1 - BOLT (12)

2 - DIFFERENTIAL SUPPORT

3 - RING GEAR

Fig. 101 Separate Differential Case Halves

1 - BOLT (3)

2 - DIFFERENTIAL CASE

3 - DIFFERENTIAL SUPPORT

RST850 MANUAL TRANSAXLE21-63

DIFFERENTIAL (Continued)