psi CHRYSLER VOYAGER 2004 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1891 of 2585

DIAGNOSIS AND TESTING - CLUTCH AIR

PRESSURE TESTS

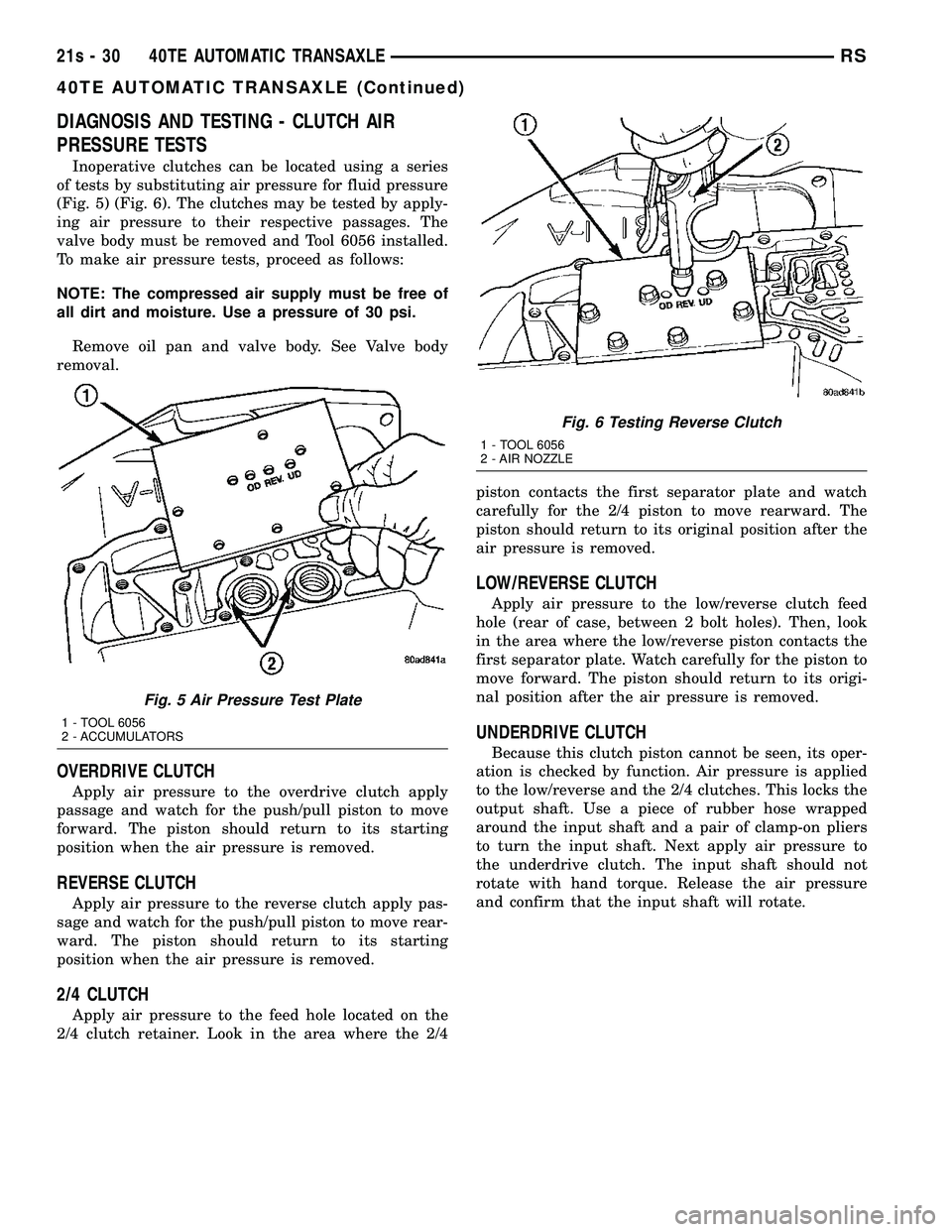

Inoperative clutches can be located using a series

of tests by substituting air pressure for fluid pressure

(Fig. 5) (Fig. 6). The clutches may be tested by apply-

ing air pressure to their respective passages. The

valve body must be removed and Tool 6056 installed.

To make air pressure tests, proceed as follows:

NOTE: The compressed air supply must be free of

all dirt and moisture. Use a pressure of 30 psi.

Remove oil pan and valve body. See Valve body

removal.

OVERDRIVE CLUTCH

Apply air pressure to the overdrive clutch apply

passage and watch for the push/pull piston to move

forward. The piston should return to its starting

position when the air pressure is removed.

REVERSE CLUTCH

Apply air pressure to the reverse clutch apply pas-

sage and watch for the push/pull piston to move rear-

ward. The piston should return to its starting

position when the air pressure is removed.

2/4 CLUTCH

Apply air pressure to the feed hole located on the

2/4 clutch retainer. Look in the area where the 2/4 piston contacts the first separator plate and watch

carefully for the 2/4 piston to move rearward. The

piston should return to its original position after the

air pressure is removed.

LOW/REVERSE CLUTCH

Apply air pressure to the low/reverse clutch feed

hole (rear of case, between 2 bolt holes). Then, look

in the area where the low/reverse piston contacts the

first separator plate. Watch carefully for the piston to

move forward. The piston should return to its origi-

nal position after the air pressure is removed.

UNDERDRIVE CLUTCH

Because this clutch piston cannot be seen, its oper-

ation is checked by function. Air pressure is applied

to the low/reverse and the 2/4 clutches. This locks the

output shaft. Use a piece of rubber hose wrapped

around the input shaft and a pair of clamp-on pliers

to turn the input shaft. Next apply air pressure to

the underdrive clutch. The input shaft should not

rotate with hand torque. Release the air pressure

and confirm that the input shaft will rotate.

Fig. 5 Air Pressure Test Plate

1 - TOOL 6056

2 - ACCUMULATORS

Fig. 6 Testing Reverse Clutch

1 - TOOL 6056

2 - AIR NOZZLE

21s - 30 40TE AUTOMATIC TRANSAXLERS

40TE AUTOMATIC TRANSAXLE (Continued)

Page 1984 of 2585

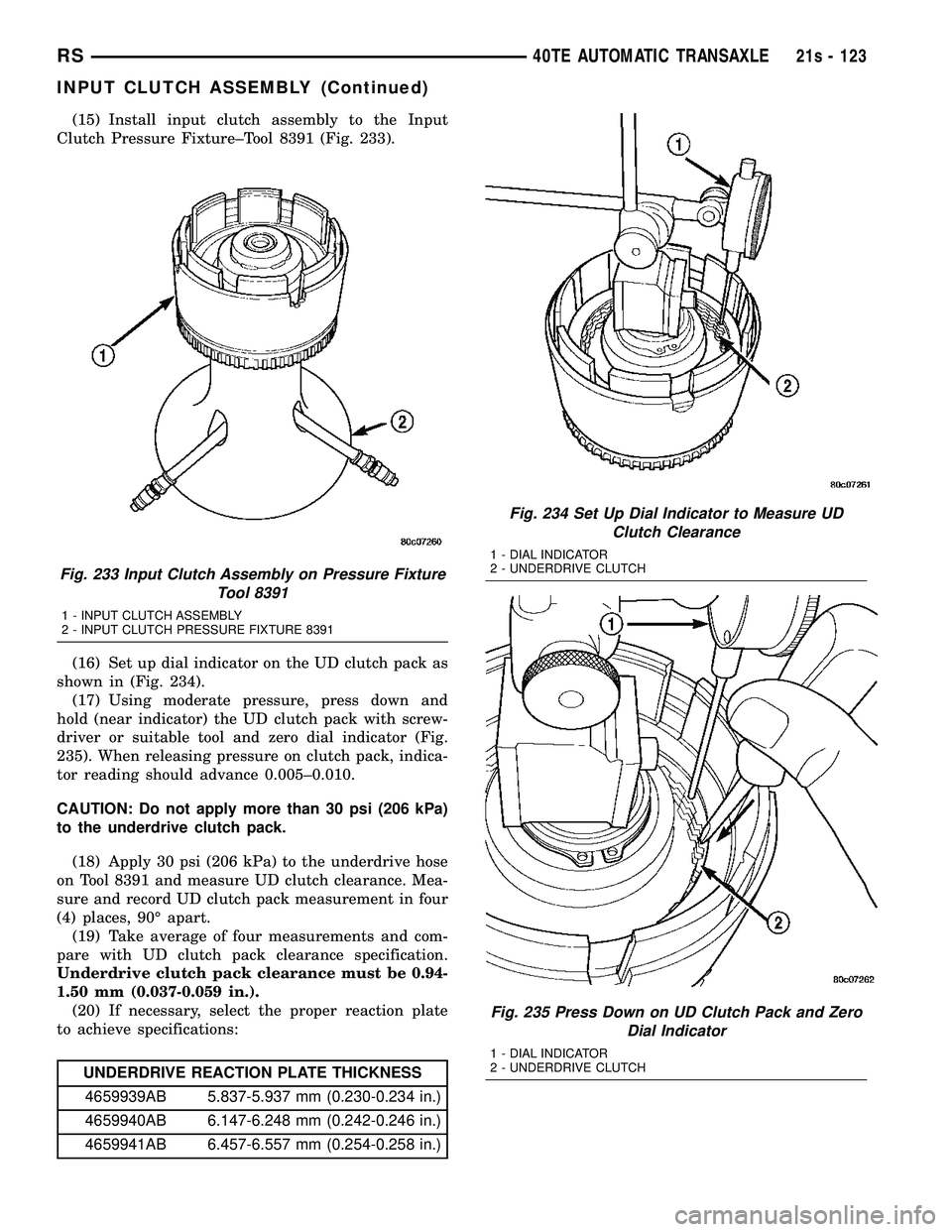

(15) Install input clutch assembly to the Input

Clutch Pressure Fixture±Tool 8391 (Fig. 233).

(16) Set up dial indicator on the UD clutch pack as

shown in (Fig. 234). (17) Using moderate pressure, press down and

hold (near indicator) the UD clutch pack with screw-

driver or suitable tool and zero dial indicator (Fig.

235). When releasing pressure on clutch pack, indica-

tor reading should advance 0.005±0.010.

CAUTION: Do not apply more than 30 psi (206 kPa)

to the underdrive clutch pack.

(18) Apply 30 psi (206 kPa) to the underdrive hose

on Tool 8391 and measure UD clutch clearance. Mea-

sure and record UD clutch pack measurement in four

(4) places, 90É apart. (19) Take average of four measurements and com-

pare with UD clutch pack clearance specification.

Underdrive clutch pack clearance must be 0.94-

1.50 mm (0.037-0.059 in.). (20) If necessary, select the proper reaction plate

to achieve specifications:

UNDERDRIVE REACTION PLATE THICKNESS

4659939AB 5.837-5.937 mm (0.230-0.234 in.)

4659940AB 6.147-6.248 mm (0.242-0.246 in.)

4659941AB 6.457-6.557 mm (0.254-0.258 in.)

Fig. 233 Input Clutch Assembly on Pressure Fixture Tool 8391

1 - INPUT CLUTCH ASSEMBLY

2 - INPUT CLUTCH PRESSURE FIXTURE 8391

Fig. 234 Set Up Dial Indicator to Measure UDClutch Clearance

1 - DIAL INDICATOR

2 - UNDERDRIVE CLUTCH

Fig. 235 Press Down on UD Clutch Pack and Zero Dial Indicator

1 - DIAL INDICATOR

2 - UNDERDRIVE CLUTCH

RS 40TE AUTOMATIC TRANSAXLE21s - 123

INPUT CLUTCH ASSEMBLY (Continued)

Page 1987 of 2585

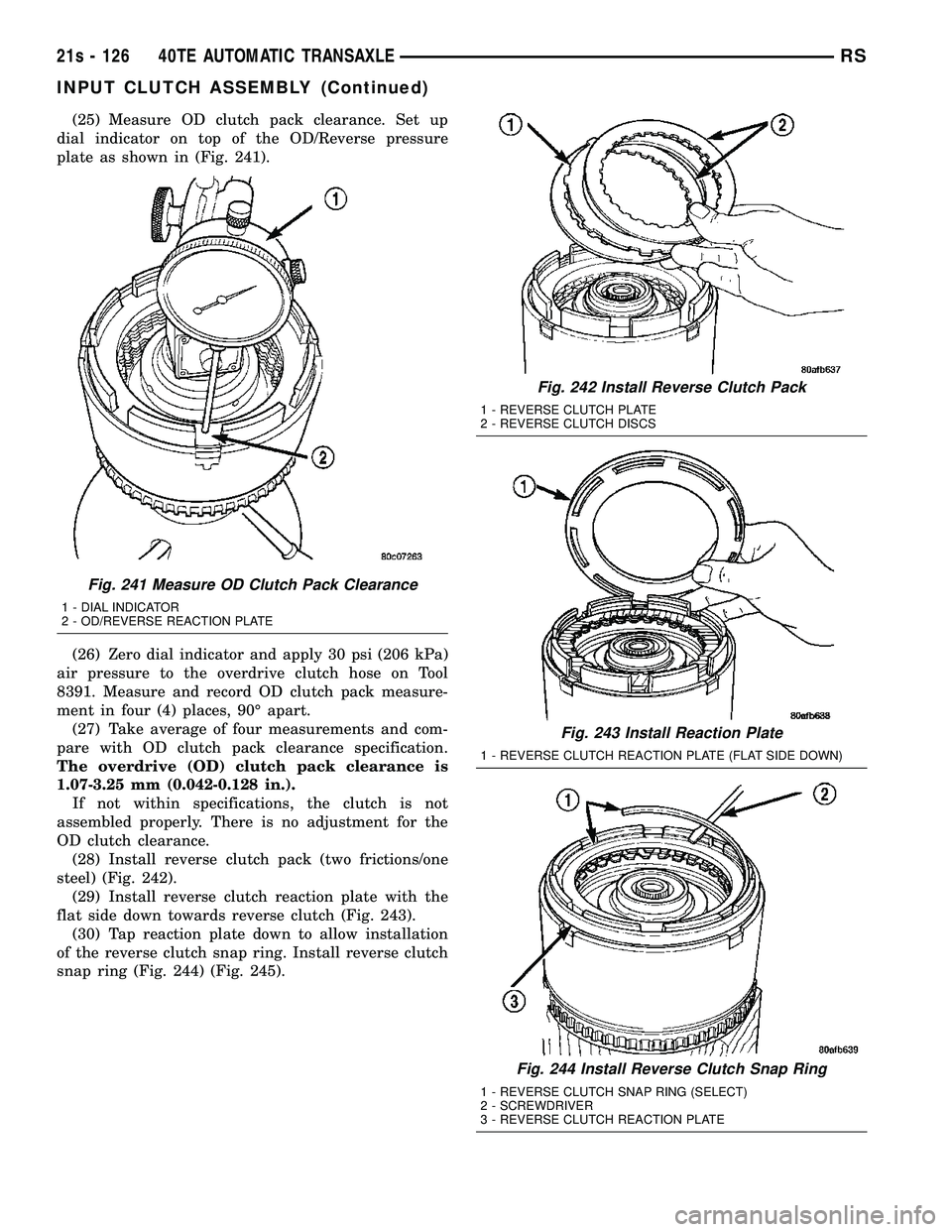

(25) Measure OD clutch pack clearance. Set up

dial indicator on top of the OD/Reverse pressure

plate as shown in (Fig. 241).

(26) Zero dial indicator and apply 30 psi (206 kPa)

air pressure to the overdrive clutch hose on Tool

8391. Measure and record OD clutch pack measure-

ment in four (4) places, 90É apart. (27) Take average of four measurements and com-

pare with OD clutch pack clearance specification.

The overdrive (OD) clutch pack clearance is

1.07-3.25 mm (0.042-0.128 in.). If not within specifications, the clutch is not

assembled properly. There is no adjustment for the

OD clutch clearance. (28) Install reverse clutch pack (two frictions/one

steel) (Fig. 242). (29) Install reverse clutch reaction plate with the

flat side down towards reverse clutch (Fig. 243). (30) Tap reaction plate down to allow installation

of the reverse clutch snap ring. Install reverse clutch

snap ring (Fig. 244) (Fig. 245).

Fig. 241 Measure OD Clutch Pack Clearance

1 - DIAL INDICATOR

2 - OD/REVERSE REACTION PLATE

Fig. 242 Install Reverse Clutch Pack

1 - REVERSE CLUTCH PLATE

2 - REVERSE CLUTCH DISCS

Fig. 243 Install Reaction Plate

1 - REVERSE CLUTCH REACTION PLATE (FLAT SIDE DOWN)

Fig. 244 Install Reverse Clutch Snap Ring

1 - REVERSE CLUTCH SNAP RING (SELECT)

2 - SCREWDRIVER

3 - REVERSE CLUTCH REACTION PLATE

21s - 126 40TE AUTOMATIC TRANSAXLERS

INPUT CLUTCH ASSEMBLY (Continued)

Page 1989 of 2585

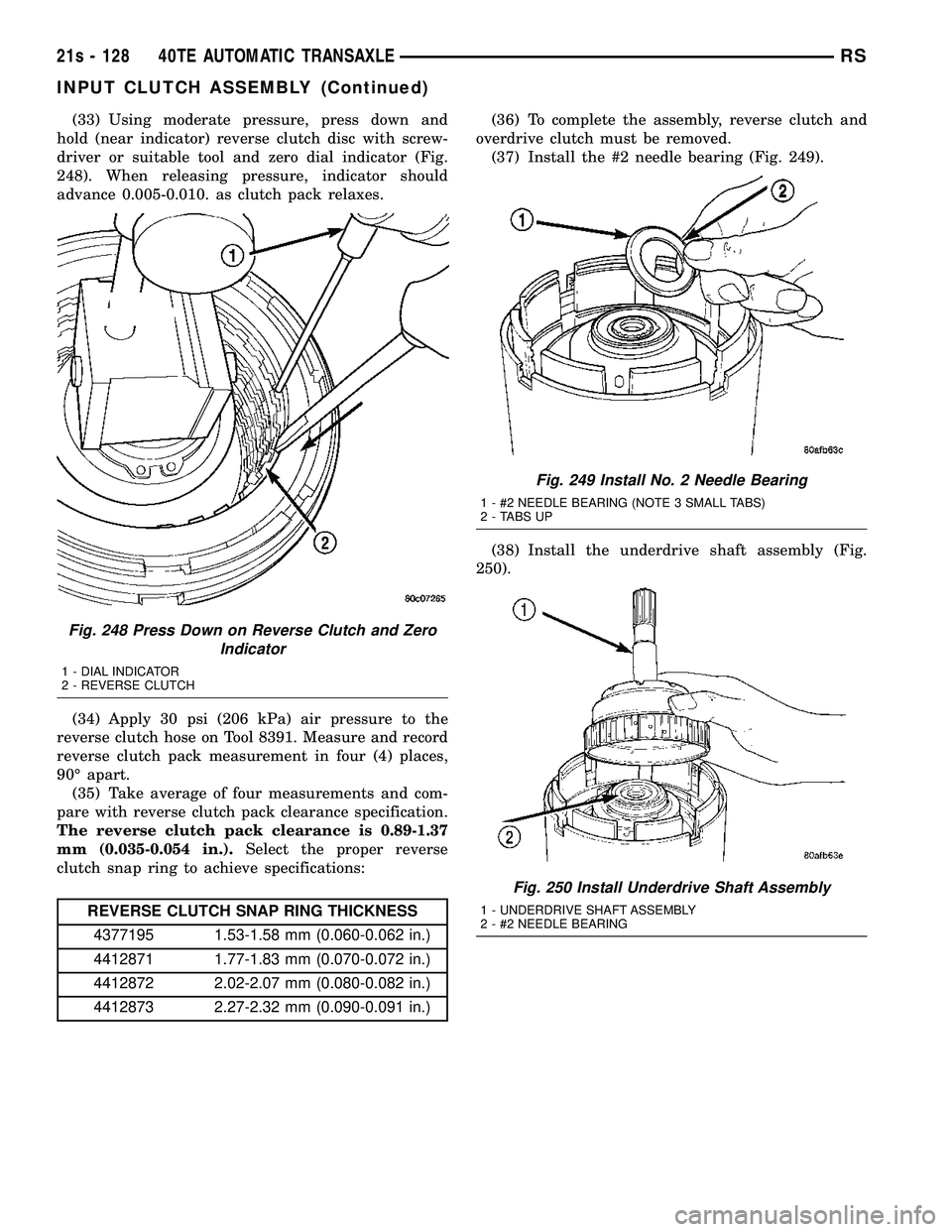

(33) Using moderate pressure, press down and

hold (near indicator) reverse clutch disc with screw-

driver or suitable tool and zero dial indicator (Fig.

248). When releasing pressure, indicator should

advance 0.005-0.010. as clutch pack relaxes.

(34) Apply 30 psi (206 kPa) air pressure to the

reverse clutch hose on Tool 8391. Measure and record

reverse clutch pack measurement in four (4) places,

90É apart. (35) Take average of four measurements and com-

pare with reverse clutch pack clearance specification.

The reverse clutch pack clearance is 0.89-1.37

mm (0.035-0.054 in.). Select the proper reverse

clutch snap ring to achieve specifications:

REVERSE CLUTCH SNAP RING THICKNESS

4377195 1.53-1.58 mm (0.060-0.062 in.)

4412871 1.77-1.83 mm (0.070-0.072 in.)

4412872 2.02-2.07 mm (0.080-0.082 in.)

4412873 2.27-2.32 mm (0.090-0.091 in.) (36) To complete the assembly, reverse clutch and

overdrive clutch must be removed. (37) Install the #2 needle bearing (Fig. 249).

(38) Install the underdrive shaft assembly (Fig.

250).

Fig. 248 Press Down on Reverse Clutch and Zero Indicator

1 - DIAL INDICATOR

2 - REVERSE CLUTCH

Fig. 249 Install No. 2 Needle Bearing

1 - #2 NEEDLE BEARING (NOTE 3 SMALL TABS)

2 - TABS UP

Fig. 250 Install Underdrive Shaft Assembly

1 - UNDERDRIVE SHAFT ASSEMBLY

2 - #2 NEEDLE BEARING

21s - 128 40TE AUTOMATIC TRANSAXLERS

INPUT CLUTCH ASSEMBLY (Continued)

Page 1999 of 2585

should be detected by the PCM/TCM during this test.

It no spike is detected, the circuit is tested again to

verify the failure. In addition to the periodic testing,

the solenoid circuits are tested if a speed ratio or

pressure switch error occurs.

PRESSURE SWITCHES

The PCM/TCM relies on three pressure switches to

monitor fluid pressure in the L/R, 2/4, and OD

hydraulic circuits. The primary purpose of these

switches is to help the PCM/TCM detect when clutch

circuit hydraulic failures occur. The range for the

pressure switch closing and opening points is 11-23

psi. Typically the switch opening point will be

approximately one psi lower than the closing point.

For example, a switch may close at 18 psi and open

at 17 psi. The switches are continuously monitored

by the PCM/TCM for the correct states (open or

closed) in each gear as shown in the following chart:

PRESSURE SWITCH STATES

GEAR L/R 2/4 OD

ROPOPOP

P/N CL OP OP 1st CL OP OP

2nd OP CL OP DOPOPCL

OD OP CL CL OP = OPEN

CL = CLOSED

A Diagnostic Trouble Code (DTC) will set if the

PCM/TCM senses any switch open or closed at the

wrong time in a given gear. The PCM/TCM also tests the 2/4 and OD pressure

switches when they are normally off (OD and 2/4 are

tested in 1st gear, OD in 2nd gear, and 2/4 in 3rd

gear). The test simply verifies that they are opera-

tional, by looking for a closed state when the corre-

sponding element is applied. Immediately after a

shift into 1st, 2nd, or 3rd gear with the engine speed

above 1000 rpm, the PCM/TCM momentarily turns

on element pressure to the 2/4 and/or OD clutch cir-

cuits to identify that the appropriate switch has

closed. If it doesn't close, it is tested again. If the

switch fails to close the second time, the appropriate

Diagnostic Trouble Code (DTC) will set.

REMOVAL

NOTE: If solenoid/pressure switch assembly is

being replaced, it is necessary to perform the TCM

Quick Learn Procedure. (Refer t o 8 - ELECTRICAL/

ELECTRONIC CONTROL MODULES/TRANSMISSION

CONTROL MODULE - STANDARD PROCEDURE)

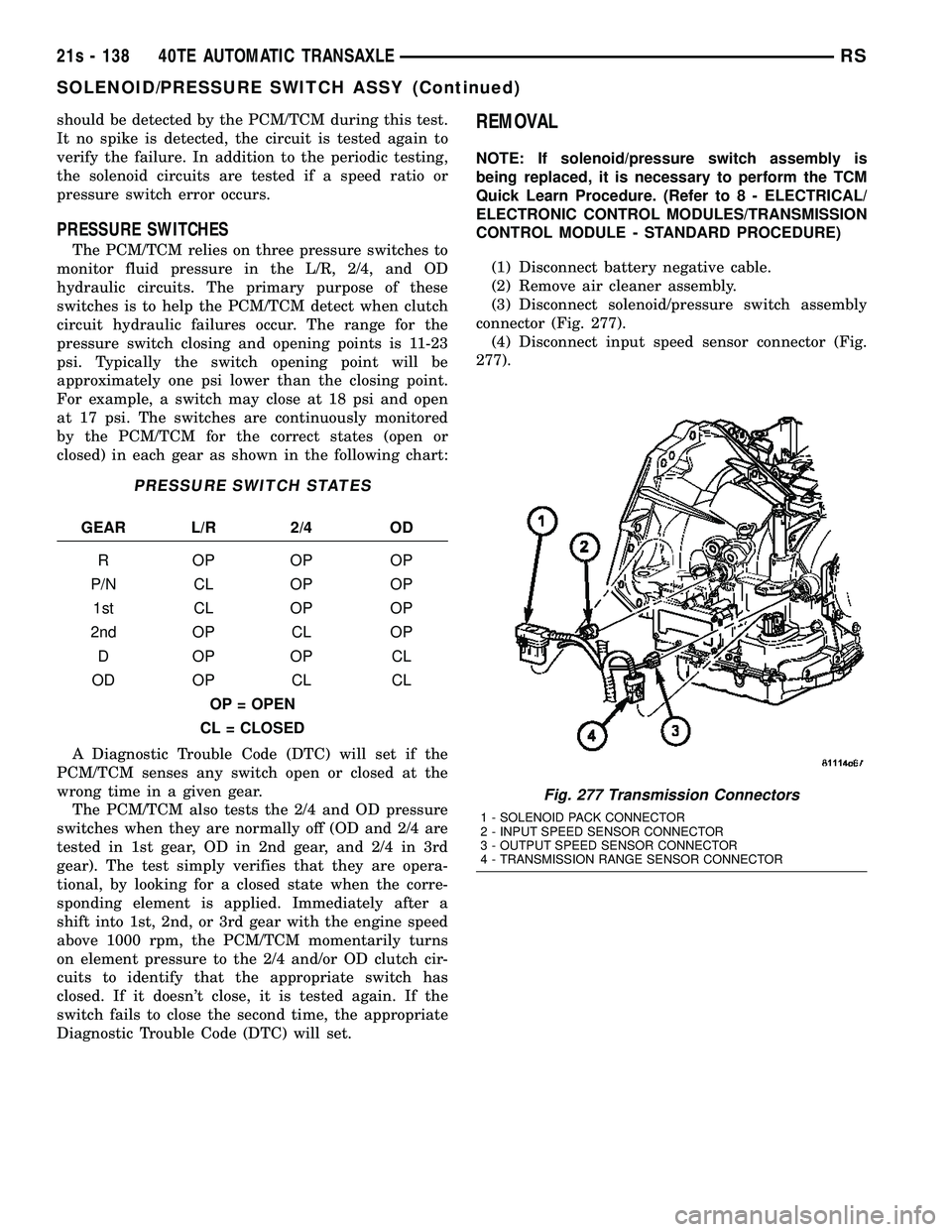

(1) Disconnect battery negative cable.

(2) Remove air cleaner assembly.

(3) Disconnect solenoid/pressure switch assembly

connector (Fig. 277). (4) Disconnect input speed sensor connector (Fig.

277).

Fig. 277 Transmission Connectors

1 - SOLENOID PACK CONNECTOR

2 - INPUT SPEED SENSOR CONNECTOR

3 - OUTPUT SPEED SENSOR CONNECTOR

4 - TRANSMISSION RANGE SENSOR CONNECTOR

21s - 138 40TE AUTOMATIC TRANSAXLERS

SOLENOID/PRESSURE SWITCH ASSY (Continued)

Page 2089 of 2585

If a road tire is replaced by the spare, the TPM

system will detect the swap and the message9SPARE

TIRE IN USE? Y/N9(along with a chime) will be dis-

played.

For further information, refer to the Owners Man-

ual or the Appropriate Diagnostic Information.

TPM THRESHOLD PRESSURES

High Pressure ON Threshold 48 PSI (331 kPa)

High Pressure OFF Threshold 43 PSI (296 kPa)

Placard Pressure (Cold) 36 PSI (248 kPa)

Low Pressure OFF Threshold 33 PSI (228 kPa)

Low Pressure ON Threshold 28 PSI (193 kPa)

SENSOR - TPM

DESCRIPTION

On vehicles equipped with Tire Pressure Monitor-

ing, one tire pressure sensor is mounted to each

wheel (Fig. 19). Each sensor has an internal battery

that lasts up to 10 years. The battery is not service-

able. At the time of battery failure, the sensor must

be replaced. The serviceable components of the tire

pressure sensor are:

²Sensor-To-Wheel Grommet

²Valve Stem Cap

²Valve Stem Core

Valve stem caps and cores are specifically designed

for the tire pressure monitoring sensors. Although

similar to standard valve stem caps and cores, they

are different.

CAUTION: Do not use a standard valve stem cap or

core in a tire pressure sensor. Always use the orig-

inal equipment style sensor cap and core.

CAUTION: Do not reuse the Sensor-To Wheel Grom-

met. Always use a new grommet when installing a

pressure sensor and properly torque the sensor

nut.

CAUTION: Do not try to install a tire pressure sen-

sor in a steel wheel or aftermarket wheel. Use only

in original style factory wheels.

OPERATION

Tire pressure sensors are battery operated. They

transmit tire pressure data once every minute at

speeds above 20 mph (32 km/h) or up to once every

hour when stationary (parked). For additional infor-

mation, refer to Appropriate Diagnostic Information.

CAUTION

CAUTION: The use of tire sealants is strictly prohib-

ited for vehicles equipped with the Tire Pressure

Monitoring system. Tire sealants can clog tire pres-

sure sensors.

CAUTION: Tire pressure sensor valve stem caps

and cores are specially designed for the sensors.

Due to risk of corrosion, do not use a standard

valve stem cap or core in a tire pressure sensor in

place of the original equipment style sensor cap

and core.

CAUTION: Do not attempt to install a tire pressure

sensor in a steel wheel or aftermarket wheel. Use

tire pressure sensors in original style factory

wheels only.

NOTE: TPM thresholds have been established for

the original tire size equipped on the vehicle. Use

original size tires only to maintain system accuracy.

DIAGNOSIS AND TESTING - TIRE PRESSURE

SENSOR

NOTE: Tire pressure may increase from 2 to 6 psi

(14 to 41 kPa) during normal driving conditions. Do

NOT reduce this normal pressure build up.

If a fault in the system is detected, always check

air pressure in the tires first with a known accurate

air gauge and correct the inflation pressure. If any

tire is low, inspectalltires.

If gauge-read pressure in the tires does not reflect

the reading on the EVIC, retrain the sensors, then

reevaluate (Refer to 22 - TIRES/WHEELS/TIRE

PRESSURE MONITORING/SENSOR - STANDARD

PROCEDURE). Refer to the appropriate diagnostic

information for complete diagnosis of the Tire Pres-

sure Monitoring System.

STANDARD PROCEDURE - TIRE PRESSURE

SENSOR RETRAIN

WARNING: DEATH OR SERIOUS INJURY CAN

OCCUR IF MAGNETICALLY SENSITIVE DEVICES

ARE EXPOSED TO THE RELEARN MAGNET. MAG-

NETS CAN AFFECT PACEMAKERS.

22 - 10 TIRES/WHEELSRS

TIRE PRESSURE MONITORING (Continued)

Page 2096 of 2585

pressures may increase from 2 to 6 pounds per

square inch (psi) (14 to 41 kPa) during operation. Do

not reduce this normal pressure buildup.

Improper inflation can cause:

²Uneven wear patterns

²Reduced tread life

²Reduced fuel economy

²Unsatisfactory ride

²The vehicle to drift.

WARNING: OVER OR UNDER INFLATED TIRES CAN

AFFECT VEHICLE HANDLING. THE TIRE CAN FAIL

SUDDENLY, RESULTING IN LOSS OF VEHICLE

CONTROL.

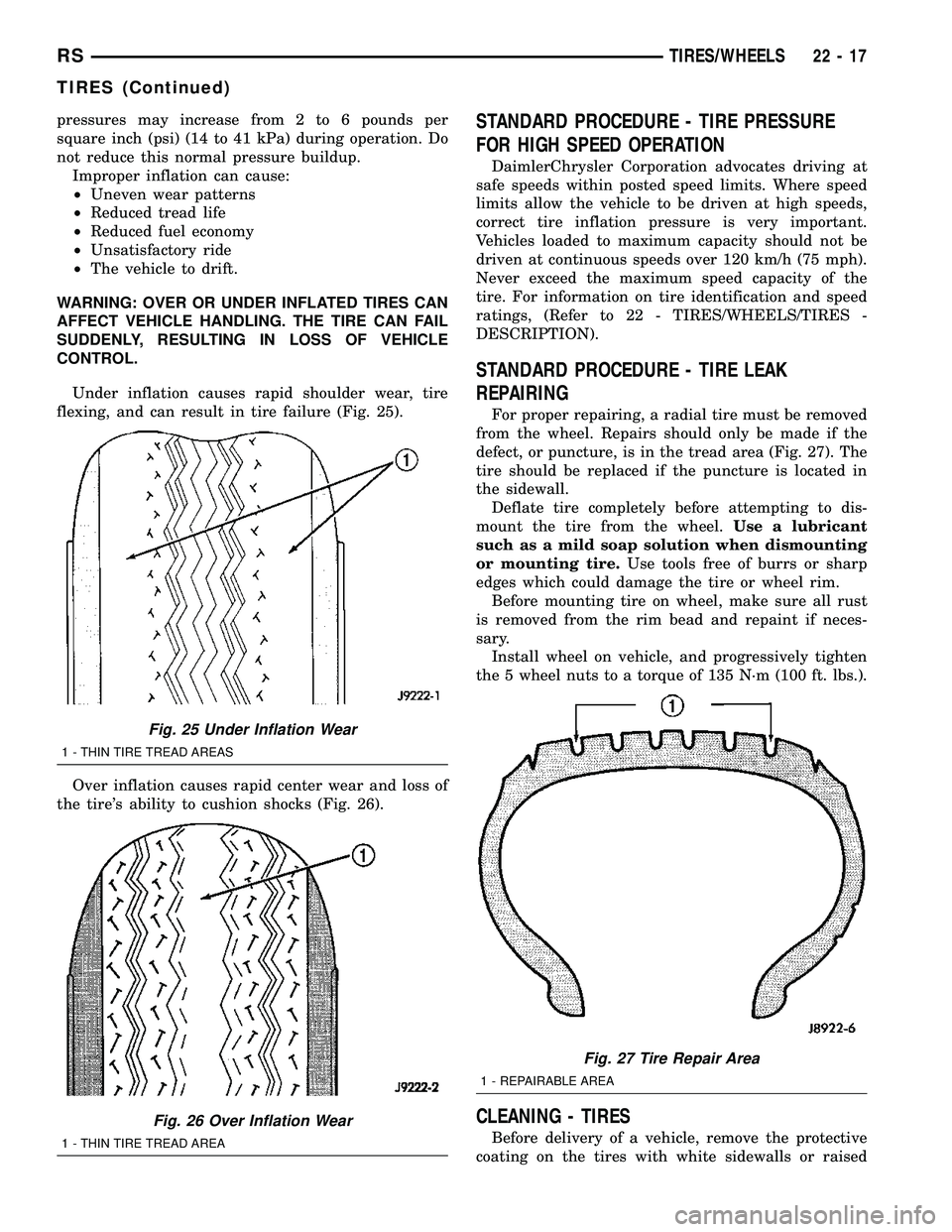

Under inflation causes rapid shoulder wear, tire

flexing, and can result in tire failure (Fig. 25).

Over inflation causes rapid center wear and loss of

the tire's ability to cushion shocks (Fig. 26).STANDARD PROCEDURE - TIRE PRESSURE

FOR HIGH SPEED OPERATION

DaimlerChrysler Corporation advocates driving at

safe speeds within posted speed limits. Where speed

limits allow the vehicle to be driven at high speeds,

correct tire inflation pressure is very important.

Vehicles loaded to maximum capacity should not be

driven at continuous speeds over 120 km/h (75 mph).

Never exceed the maximum speed capacity of the

tire. For information on tire identification and speed

ratings, (Refer to 22 - TIRES/WHEELS/TIRES -

DESCRIPTION).

STANDARD PROCEDURE - TIRE LEAK

REPAIRING

For proper repairing, a radial tire must be removed

from the wheel. Repairs should only be made if the

defect, or puncture, is in the tread area (Fig. 27). The

tire should be replaced if the puncture is located in

the sidewall.

Deflate tire completely before attempting to dis-

mount the tire from the wheel.Use a lubricant

such as a mild soap solution when dismounting

or mounting tire.Use tools free of burrs or sharp

edges which could damage the tire or wheel rim.

Before mounting tire on wheel, make sure all rust

is removed from the rim bead and repaint if neces-

sary.

Install wheel on vehicle, and progressively tighten

the 5 wheel nuts to a torque of 135 N´m (100 ft. lbs.).

CLEANING - TIRES

Before delivery of a vehicle, remove the protective

coating on the tires with white sidewalls or raised

Fig. 25 Under Inflation Wear

1 - THIN TIRE TREAD AREAS

Fig. 26 Over Inflation Wear

1 - THIN TIRE TREAD AREA

Fig. 27 Tire Repair Area

1 - REPAIRABLE AREA

RSTIRES/WHEELS22-17

TIRES (Continued)

Page 2103 of 2585

CAUTION: Do not try to install a tire pressure sen-

sor in a steel wheel or aftermarket wheel. Use only

in original style factory wheels.

OPERATION

The tire pressure sensors are battery operated.

Each sensor transmits tire pressure data approxi-

mately once every minute at speeds above 13 mph

(20 km/h). Each sensor's (transmitter) broadcast is

uniquely coded so that the SKREEM can monitor the

states of each individual sensor on the vehicle.

Unlike prior model year TPM systems, a magnet is

not required to retrain the system. The SKREEM

automatically learns while driving after a sensor has

been replaced. (Refer to 22 - TIRES/WHEELS/TIRE

PRESSURE MONITORING/SENSOR - STANDARD

PROCEDURE) For additional information, refer to Appropriate

Diagnostic Information.

CAUTION

CAUTION: The use of tire sealants is strictly prohib-

ited for vehicles equipped with the Tire Pressure

Monitoring system. Tire sealants can clog tire pres-

sure sensors.

CAUTION: Tire pressure sensor valve stem caps

and cores are specially designed for the sensors.

Due to risk of corrosion, do not use a standard

valve stem cap or core in a tire pressure sensor in

place of the original equipment style sensor cap

and core.

CAUTION: Do not attempt to install a tire pressure

sensor in a steel wheel or aftermarket wheel. Use

tire pressure sensors in original style factory

wheels only.

NOTE: TPM thresholds have been established for

the original tire size equipped on the vehicle. Use

original size tires only to maintain system accuracy.

DIAGNOSIS AND TESTING - TIRE PRESSURE

SENSOR

NOTE: Tire pressure may increase from 2 to 6 psi

(14 to 41 kPa) during normal driving conditions. Do

NOT reduce this normal pressure build up.

If a fault in the system is detected, always check

air pressure in the tires first with a known accurate

air gauge and correct the inflation pressure. If any

tire is low, inspect allthe tires. If the gauge-read pressure in the tires does not

indicate a tire pressure issue, refer to the appropri-

ate diagnostic information.

STANDARD PROCEDURE - TIRE PRESSURE

SENSOR RETRAIN

CAUTION: If a sensor is replaced, the vehicle must

be parked for a minimum of 15 minutes for the sys-

tem to be ready to learn the new sensor ID code.

(1) Park the car for a minimum of 15 minutes.

(2) Drive the vehicle for a minimum of five min-

utes while maintaining a continuous speed above 13

mph (20 km/h). During this time the system will

learn the new sensor ID code and will clear any

DTC's automatically.

NOTE: If a sensor cannot be trained, refer to appro-

priate diagnostic information.

REMOVAL

(1) Remove tire and wheel assembly from vehicle.

(Refer to 22 - TIRES/WHEELS - REMOVAL)

CAUTION: The cap used on this valve stem con-

tains an O-ring seal to prevent contamination and

moisture from entering the valve stem. Retain this

valve stem cap for reuse. Do not substitute a regu-

lar valve stem cap in its place.

CAUTION: The valve stem used on this vehicle is

made of aluminum and the core is nickel plated

brass. The original valve stem core must be rein-

stalled and not substituted with a valve stem core

made of a different material. This is required to pre-

vent corrosion in the valve stem caused by the dif-

ferent metals.

(2) Dismount tire from wheel following tire

changer manufacturers instructions while paying

special attention to the following to avoid damaging

the pressure sensor: (a) When breaking the tire bead loose from the

wheel rim, avoid using the Bead Breaker in the

area of the sensor. That includes both front and

rear beads of the tire. (b) When preparing to dismount the tire from

the wheel, carefully insert the mounting/dimount-

ing tool at the valve stem 10É (Fig. 1), then pro-

ceed to dismount the tire from the wheel. Use this

process on both the upper and lower tire beads.

(3) Using a thin wall socket, remove special nut

retaining sensor to wheel (Fig. 2). (4) Remove sensor from wheel (Fig. 2).

22s - 2 TIRE PRESSURE MONITORINGRS

SENSOR - TPM (Continued)

Page 2110 of 2585

pressures may increase from 2 to 6 pounds per

square inch (psi) (14 to 41 kPa) during operation. Do

not reduce this normal pressure buildup.Improper inflation can cause:

² Uneven wear patterns

² Reduced tread life

² Reduced fuel economy

² Unsatisfactory ride

² The vehicle to drift.

WARNING: OVER OR UNDER INFLATED TIRES CAN

AFFECT VEHICLE HANDLING. THE TIRE CAN FAIL

SUDDENLY, RESULTING IN LOSS OF VEHICLE

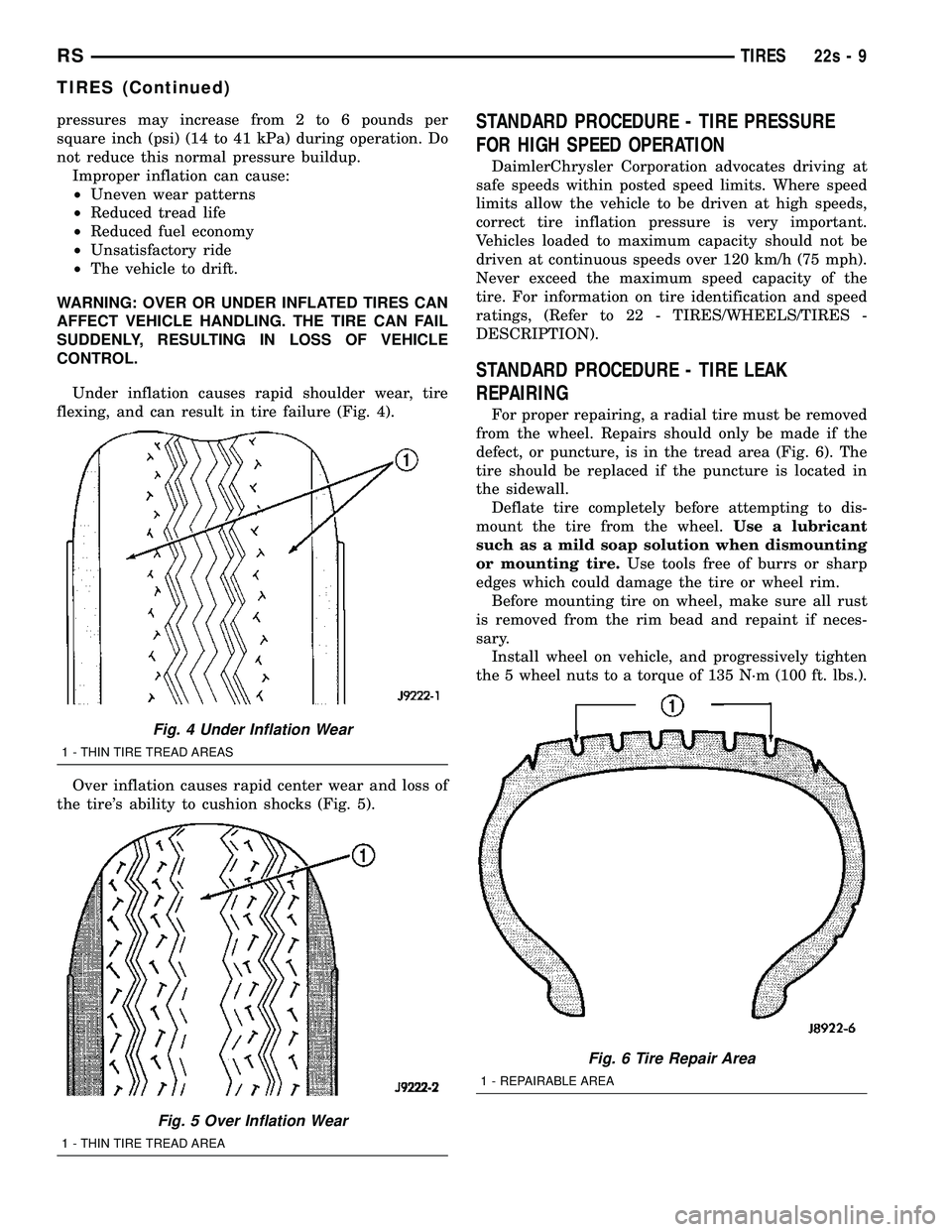

CONTROL. Under inflation causes rapid shoulder wear, tire

flexing, and can result in tire failure (Fig. 4).

Over inflation causes rapid center wear and loss of

the tire's ability to cushion shocks (Fig. 5).STANDARD PROCEDURE - TIRE PRESSURE

FOR HIGH SPEED OPERATION

DaimlerChrysler Corporation advocates driving at

safe speeds within posted speed limits. Where speed

limits allow the vehicle to be driven at high speeds,

correct tire inflation pressure is very important.

Vehicles loaded to maximum capacity should not be

driven at continuous speeds over 120 km/h (75 mph).

Never exceed the maximum speed capacity of the

tire. For information on tire identification and speed

ratings, (Refer to 22 - TIRES/WHEELS/TIRES -

DESCRIPTION).

STANDARD PROCEDURE - TIRE LEAK

REPAIRING

For proper repairing, a radial tire must be removed

from the wheel. Repairs should only be made if the

defect, or puncture, is in the tread area (Fig. 6). The

tire should be replaced if the puncture is located in

the sidewall. Deflate tire completely before attempting to dis-

mount the tire from the wheel. Use a lubricant

such as a mild soap solution when dismounting

or mounting tire. Use tools free of burrs or sharp

edges which could damage the tire or wheel rim. Before mounting tire on wheel, make sure all rust

is removed from the rim bead and repaint if neces-

sary. Install wheel on vehicle, and progressively tighten

the 5 wheel nuts to a torque of 135 N´m (100 ft. lbs.).

Fig. 4 Under Inflation Wear

1 - THIN TIRE TREAD AREAS

Fig. 5 Over Inflation Wear

1 - THIN TIRE TREAD AREA

Fig. 6 Tire Repair Area

1 - REPAIRABLE AREA

RS TIRES22s-9

TIRES (Continued)

Page 2403 of 2585

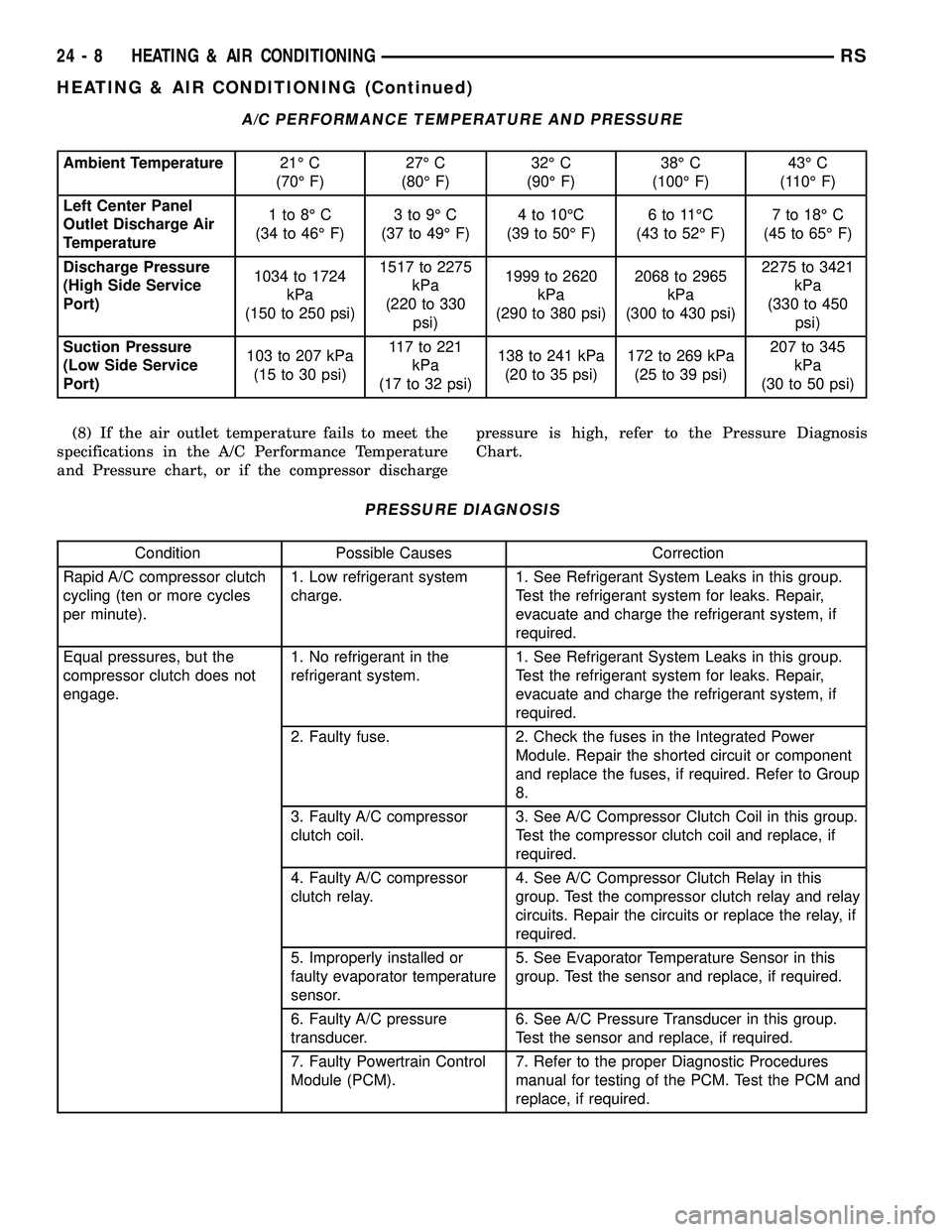

A/C PERFORMANCE TEMPERATURE AND PRESSURE

Ambient Temperature21É C

(70É F)27É C

(80É F)32É C

(90É F)38É C

(100É F)43É C

(110É F)

Left Center Panel

Outlet Discharge Air

Temperature1to8ÉC

(34 to 46É F)3to9ÉC

(37 to 49É F)4 to 10ÉC

(39 to 50É F)6to11ÉC

(43 to 52É F)7 to 18É C

(45 to 65É F)

Discharge Pressure

(High Side Service

Port)1034 to 1724

kPa

(150 to 250 psi)1517 to 2275

kPa

(220 to 330

psi)1999 to 2620

kPa

(290 to 380 psi)2068 to 2965

kPa

(300 to 430 psi)2275 to 3421

kPa

(330 to 450

psi)

Suction Pressure

(Low Side Service

Port)103 to 207 kPa

(15 to 30 psi)117to221

kPa

(17 to 32 psi)138 to 241 kPa

(20 to 35 psi)172 to 269 kPa

(25 to 39 psi)207 to 345

kPa

(30 to 50 psi)

(8) If the air outlet temperature fails to meet the

specifications in the A/C Performance Temperature

and Pressure chart, or if the compressor dischargepressure is high, refer to the Pressure Diagnosis

Chart.

PRESSURE DIAGNOSIS

Condition Possible Causes Correction

Rapid A/C compressor clutch

cycling (ten or more cycles

per minute).1. Low refrigerant system

charge.1. See Refrigerant System Leaks in this group.

Test the refrigerant system for leaks. Repair,

evacuate and charge the refrigerant system, if

required.

Equal pressures, but the

compressor clutch does not

engage.1. No refrigerant in the

refrigerant system.1. See Refrigerant System Leaks in this group.

Test the refrigerant system for leaks. Repair,

evacuate and charge the refrigerant system, if

required.

2. Faulty fuse. 2. Check the fuses in the Integrated Power

Module. Repair the shorted circuit or component

and replace the fuses, if required. Refer to Group

8.

3. Faulty A/C compressor

clutch coil.3. See A/C Compressor Clutch Coil in this group.

Test the compressor clutch coil and replace, if

required.

4. Faulty A/C compressor

clutch relay.4. See A/C Compressor Clutch Relay in this

group. Test the compressor clutch relay and relay

circuits. Repair the circuits or replace the relay, if

required.

5. Improperly installed or

faulty evaporator temperature

sensor.5. See Evaporator Temperature Sensor in this

group. Test the sensor and replace, if required.

6. Faulty A/C pressure

transducer.6. See A/C Pressure Transducer in this group.

Test the sensor and replace, if required.

7. Faulty Powertrain Control

Module (PCM).7. Refer to the proper Diagnostic Procedures

manual for testing of the PCM. Test the PCM and

replace, if required.

24 - 8 HEATING & AIR CONDITIONINGRS

HEATING & AIR CONDITIONING (Continued)