transmission oil CHRYSLER VOYAGER 2004 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1381 of 2585

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1,379

kPa (200 psi) maximum, with 552 kPa (80 psi) rec-

ommended.

Perform the test procedures on each cylinder

according to the tester manufacturer's instructions.

While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage per cylinder.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

STANDARD PROCEDURE

STANDARD PROCEDURE - MEASURING

BEARING CLEARANCE USING PLASTIGAGE

Engine crankshaft bearing clearances can be deter-

mined by use of Plastigage or equivalent. The follow-

ing is the recommended procedure for the use of

Plastigage:

(1) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

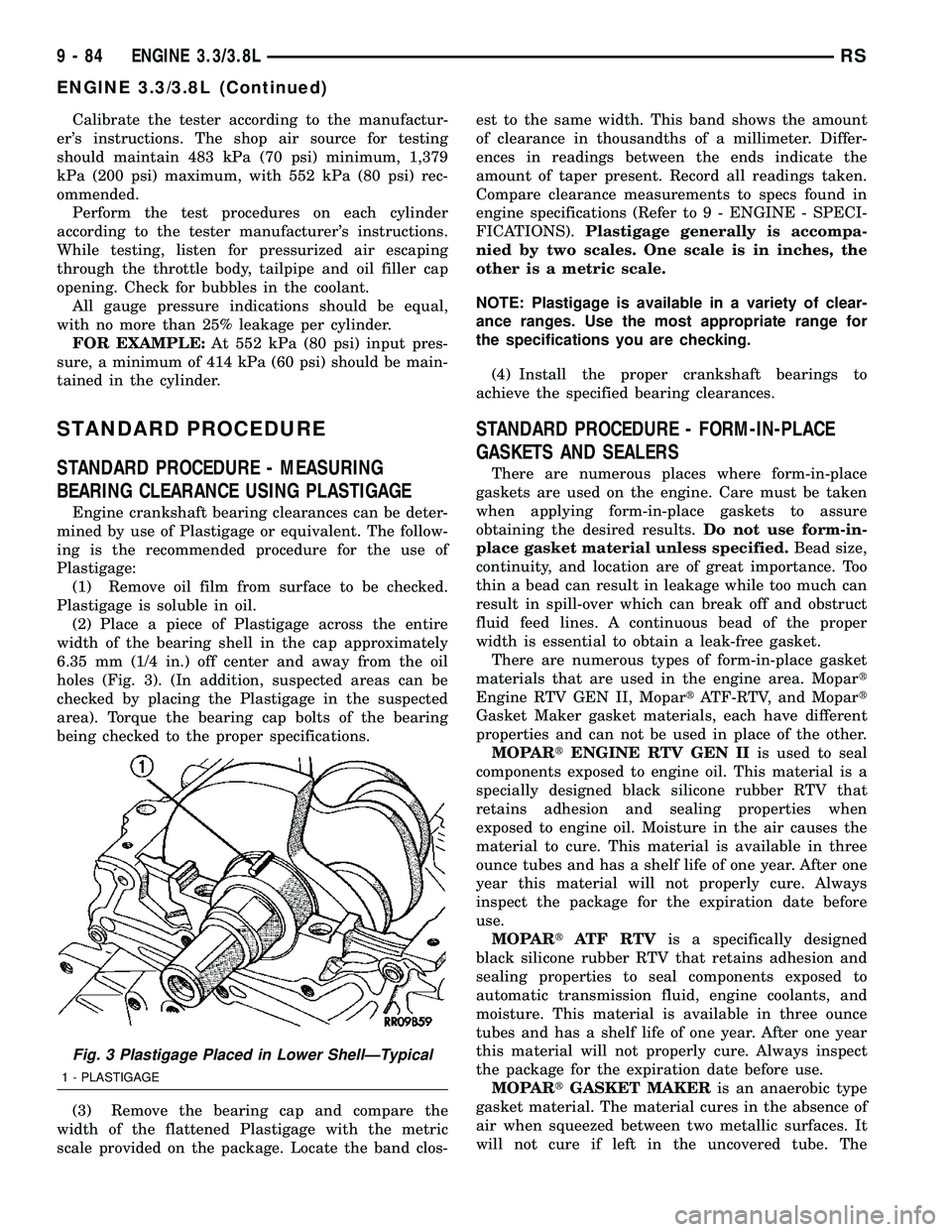

(2) Place a piece of Plastigage across the entire

width of the bearing shell in the cap approximately

6.35 mm (1/4 in.) off center and away from the oil

holes (Fig. 3). (In addition, suspected areas can be

checked by placing the Plastigage in the suspected

area). Torque the bearing cap bolts of the bearing

being checked to the proper specifications.

(3) Remove the bearing cap and compare the

width of the flattened Plastigage with the metric

scale provided on the package. Locate the band clos-est to the same width. This band shows the amount

of clearance in thousandths of a millimeter. Differ-

ences in readings between the ends indicate the

amount of taper present. Record all readings taken.

Compare clearance measurements to specs found in

engine specifications (Refer to 9 - ENGINE - SPECI-

FICATIONS).Plastigage generally is accompa-

nied by two scales. One scale is in inches, the

other is a metric scale.

NOTE: Plastigage is available in a variety of clear-

ance ranges. Use the most appropriate range for

the specifications you are checking.

(4) Install the proper crankshaft bearings to

achieve the specified bearing clearances.

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN IIis used to seal

components exposed to engine oil. This material is a

specially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTVis a specifically designed

black silicone rubber RTV that retains adhesion and

sealing properties to seal components exposed to

automatic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKERis an anaerobic type

gasket material. The material cures in the absence of

air when squeezed between two metallic surfaces. It

will not cure if left in the uncovered tube. The

Fig. 3 Plastigage Placed in Lower ShellÐTypical

1 - PLASTIGAGE

9 - 84 ENGINE 3.3/3.8LRS

ENGINE 3.3/3.8L (Continued)

Page 1384 of 2585

(11) Disconnect the throttle cables from the throt-

tle body.

(12) Disconnect the MAP, IAC, and TPS electrical

connectors.

(13) Disconnect the EGR transducer electrical con-

nector (if equipped).

(14) Disconnect the vacuum hoses from throttle

body.

(15) Disconnect the brake booster and speed con-

trol vacuum hoses.

(16) Disengage wire harness clip from the right

side engine mount.

(17) Remove the power steering reservoir from

mounting position and set aside.Do notdisconnect

hose.

(18) Disconnect ground strap from rear of cylinder

head.

(19) Disconnect engine coolant temperature (ECT)

sensor and ignition coil electrical connectors.

(20) Disconnect the fuel injector electrical harness

connector and disengage clip from support bracket.

(21) Disconnect camshaft and crankshaft position

sensor electrical connectors.

(22) Evacuate air conditioning system. Refer to 24

- HEATING & AIR CONDITIONING.

(23) Disconnect A/C compressor electrical connec-

tor.

(24) Disconnect the A/C lines from compressor.

Cover and seal all openings of hoses and compressor.

(25) Remove the radiator upper hose.

(26) Disengage electrical harness clip at transaxle

dipstick tube.

(27) Remove transaxle dipstick tube. Seal opening

using a suitable plug.

NOTE: When the transaxle cooler lines are removed

from the rolled-groove type fittings at the transaxle,

damage to the inner wall of the hose will occur. To

prevent prevent potential leakage, the cooler hoses

must be cut off flush at the transaxle fitting, and a

service cooler hose splice kit must be installed

upon reassembly.

(28) Using a blade or suitable hose cutter, cut

transaxle oil cooler lines off flush with fittings. Plug

cooler lines and fittings to prevent debris from enter-

ing transaxle or cooler circuit. A service splice kit will

be installed upon reassembly.

(29) Disconnect transaxle shift linkage and electri-

cal connectors.

(30)

Raise vehicle on hoist and drain the engine oil.

(31) Remove the axle shafts. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/HALF SHAFT - REMOVAL)

(32) Remove crossmember cradle plate (Fig. 6).

(33)AWD equipped:Remove the power transfer

unit (PTU) (Refer to 21 - TRANSMISSION/TRANS-

AXLE/POWER TRANSFER UNIT - REMOVAL).(34) Disconnect exhaust pipe from the manifold

(Fig. 7).

(35) Remove front engine mount and bracket as an

assembly.

(36) Remove the engine rear mount bracket.

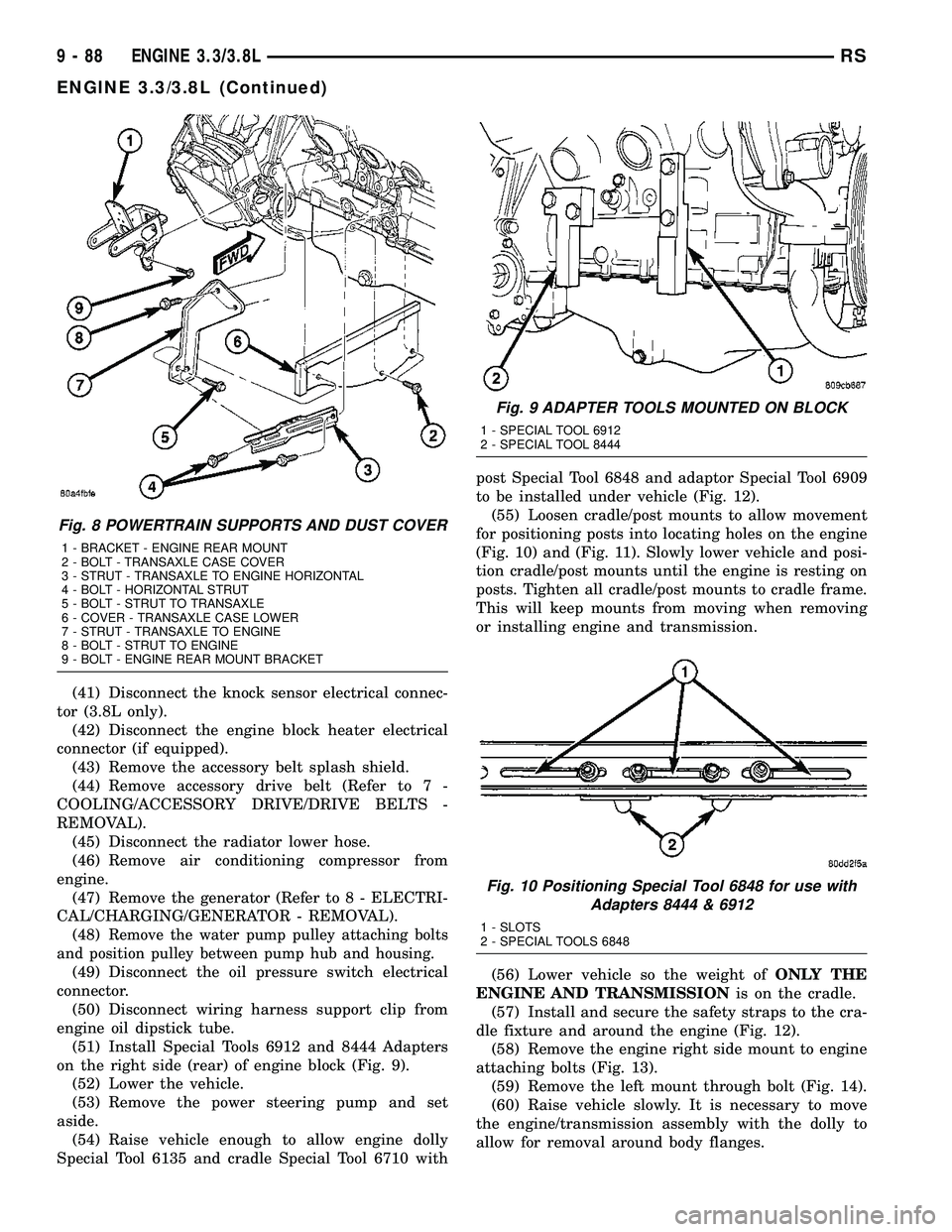

(37) Remove the engine to transaxle struts (Fig. 8).

(38) Remove transaxle case cover (Fig. 8).

(39) Remove flex plate to torque converter bolts.

Mark torque converter to flex plate for orientation for

reassembly.

(40) Remove the power steering pressure hose sup-

port clip attaching bolt.

Fig. 6 Crossmember Cradle Plate

1 - CRADLE PLATE

Fig. 7 Catalytic Converter to Exhaust Manifold

1 - FLAG NUT

2 - GASKET

3 - BOLT

4 - CATALYTIC CONVERTER

RSENGINE 3.3/3.8L9-87

ENGINE 3.3/3.8L (Continued)

Page 1385 of 2585

(41) Disconnect the knock sensor electrical connec-

tor (3.8L only).

(42) Disconnect the engine block heater electrical

connector (if equipped).

(43) Remove the accessory belt splash shield.

(44) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(45) Disconnect the radiator lower hose.

(46) Remove air conditioning compressor from

engine.

(47) Remove the generator (Refer to 8 - ELECTRI-

CAL/CHARGING/GENERATOR - REMOVAL).

(48)

Remove the water pump pulley attaching bolts

and position pulley between pump hub and housing.

(49) Disconnect the oil pressure switch electrical

connector.

(50) Disconnect wiring harness support clip from

engine oil dipstick tube.

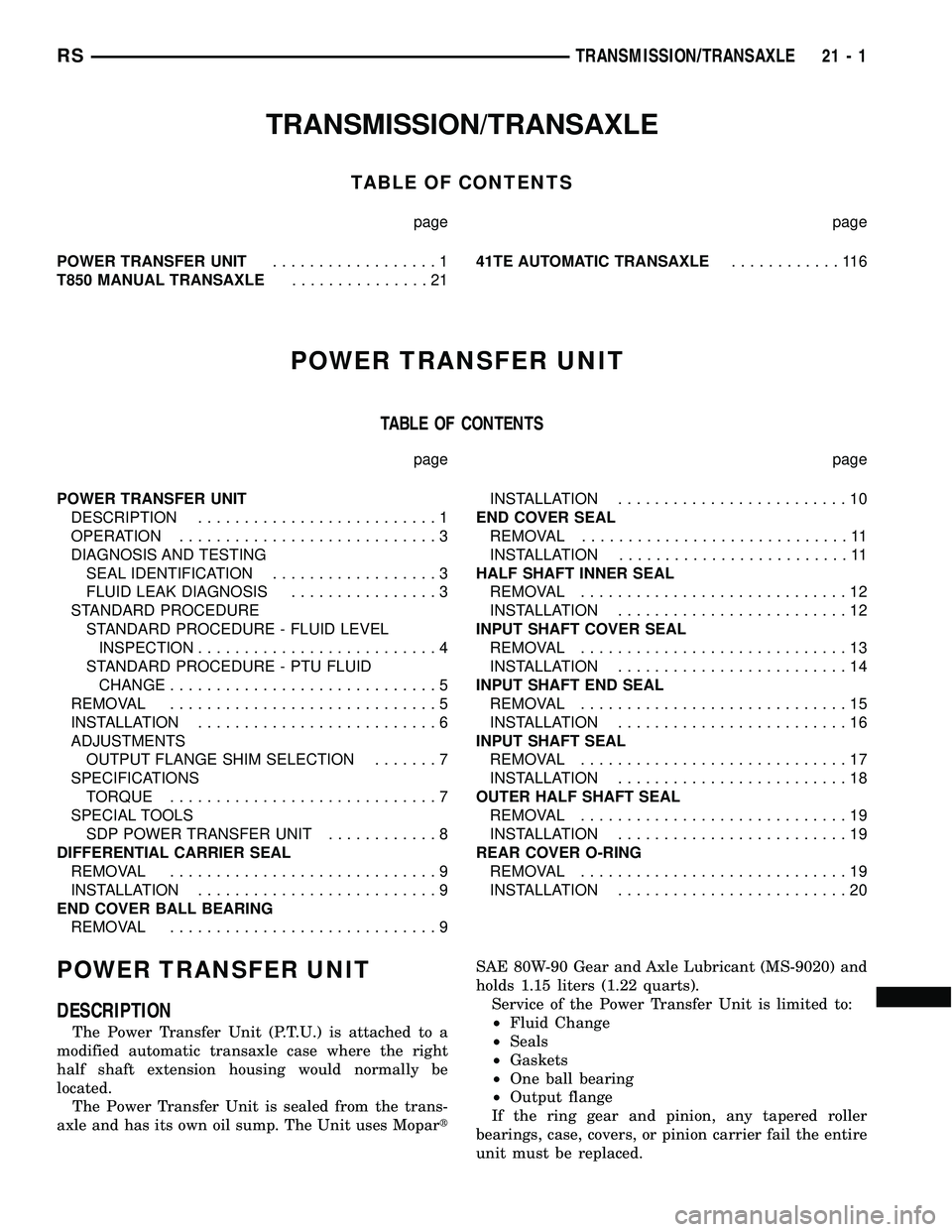

(51) Install Special Tools 6912 and 8444 Adapters

on the right side (rear) of engine block (Fig. 9).

(52) Lower the vehicle.

(53) Remove the power steering pump and set

aside.

(54) Raise vehicle enough to allow engine dolly

Special Tool 6135 and cradle Special Tool 6710 withpost Special Tool 6848 and adaptor Special Tool 6909

to be installed under vehicle (Fig. 12).

(55) Loosen cradle/post mounts to allow movement

for positioning posts into locating holes on the engine

(Fig. 10) and (Fig. 11). Slowly lower vehicle and posi-

tion cradle/post mounts until the engine is resting on

posts. Tighten all cradle/post mounts to cradle frame.

This will keep mounts from moving when removing

or installing engine and transmission.

(56) Lower vehicle so the weight ofONLY THE

ENGINE AND TRANSMISSIONis on the cradle.

(57) Install and secure the safety straps to the cra-

dle fixture and around the engine (Fig. 12).

(58) Remove the engine right side mount to engine

attaching bolts (Fig. 13).

(59) Remove the left mount through bolt (Fig. 14).

(60) Raise vehicle slowly. It is necessary to move

the engine/transmission assembly with the dolly to

allow for removal around body flanges.

Fig. 8 POWERTRAIN SUPPORTS AND DUST COVER

1 - BRACKET - ENGINE REAR MOUNT

2 - BOLT - TRANSAXLE CASE COVER

3 - STRUT - TRANSAXLE TO ENGINE HORIZONTAL

4 - BOLT - HORIZONTAL STRUT

5 - BOLT - STRUT TO TRANSAXLE

6 - COVER - TRANSAXLE CASE LOWER

7 - STRUT - TRANSAXLE TO ENGINE

8 - BOLT - STRUT TO ENGINE

9 - BOLT - ENGINE REAR MOUNT BRACKET

Fig. 9 ADAPTER TOOLS MOUNTED ON BLOCK

1 - SPECIAL TOOL 6912

2 - SPECIAL TOOL 8444

Fig. 10 Positioning Special Tool 6848 for use with

Adapters 8444 & 6912

1 - SLOTS

2 - SPECIAL TOOLS 6848

9 - 88 ENGINE 3.3/3.8LRS

ENGINE 3.3/3.8L (Continued)

Page 1386 of 2585

INSTALLATION - ENGINE ASSEMBLY

(1) Position engine and transmission assembly

under vehicle. Slowly lower the vehicle down over the

engine and transmission. It is necessary to move the

engine/transmission assembly with the dolly for

clearance around body flanges.

(2)

Align engine and transmission mounts to attach-

ing points. Install mounting bolts at the right engine

mount (Fig. 13) and left transmission mount (Fig. 14).

(3) Remove the safety straps from around engine.

(4) Slowly raise vehicle enough to remove the

engine dolly and cradle Special Tools 6135, 6710,

6848 and 6909 (Fig. 12).

(5) Remove Special Tools 6912 and 8444 (Fig. 9).

(6) Lower the vehicle.

(7) Install power steering pump and pressure line

support.

Fig. 11 Special Tools 6848 with Adapters 6909

1 - OIL FILTER

2 - SPECIAL TOOLS 6909

3 - OIL PAN

4 - SPECIAL TOOLS 6848

Fig. 12 Positioning Engine Cradle Support Post Mounts

1 - SPECIAL TOOL 8444

2 - SPECIAL TOOLS 6848

3 - SPECIAL TOOL 6912

4 - SPECIAL TOOLS 6135 & 67105 - SPECIAL TOOLS 6848

6 - SAFETY STRAPS

7 - SPECIAL TOOLS 6909

RSENGINE 3.3/3.8L9-89

ENGINE 3.3/3.8L (Continued)

Page 1387 of 2585

(8) Install the generator and wiring harness (Refer

to 8 - ELECTRICAL/CHARGING/GENERATOR -

INSTALLATION).

(9) Raise vehicle.

(10) Attach wiring harness support clip to the

engine oil dipstick tube.

(11) Connect oil pressure switch electrical connec-

tor.

(12) Install the A/C compressor.

(13) Install the water pump pulley.

(14) Connect the radiator lower hose.(15) Install the accessory drive belt and splash

shield (Refer to 7 - COOLING/ACCESSORY DRIVE/

DRIVE BELTS - INSTALLATION).

(16) Connect the engine block heater electrical con-

nector (if equipped).

(17) Connect the knock sensor electrical connector

(3.8L only).

(18) Install the torque converter to flex plate bolts.

(19) Install the transaxle case cover (Fig. 8).

(20) Install the powertrain struts (Fig. 8).

(21) Install the engine rear mount bracket.

(22) Install the engine front mount and bracket

assembly.

(23)AWD equipped;Install the power transfer

unit (PTU) (Refer to 21 - TRANSMISSION/TRANS-

AXLE/POWER TRANSFER UNIT - INSTALLA-

TION).

(24) Install the axle shafts (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/HALF SHAFT - INSTALLA-

TION).

(25) Connect exhaust pipe to manifold (Fig. 7).

(26) Install crossmember cradle plate (Fig. 6).

(27) Lower vehicle.

(28) Connect transaxle shift linkage.

(29) Connect transaxle electrical connectors.

(30) Remove plugs from transmission cooler hoses

and install transaxle oil cooler line service splice kit.

Refer to instructions included with kit.

(31) Install transaxle dipstick tube and attach

electrical harness clip.

(32) Connect the A/C lines to compressor.

(33) Connect the A/C compressor electrical connec-

tor.

(34) Evacuate and recharge A/C system.

(35) Connect crankshaft and camshaft position

sensors.

(36) Connect the fuel injector electrical harness

connector and engage clip to support bracket.

(37) Connect engine coolant temperature (ECT)

sensor and ignition coil electrical connectors.

(38) Connect the ground strap to rear of cylinder

head.

(39) Install power steering reservoir.

(40) Engage wire harness clip to engine right side

mount.

(41) Connect the brake booster and speed control

vacuum hoses.

(42) Connect the vacuum hoses to the throttle

body.

(43) Connect the EGR transducer electrical connec-

tor (if equipped).

(44) Connect the TPS, IAC, and MAP sensor elec-

trical connectors.

(45) Connect throttle cables to throttle body.

(46) Install the radiator fans (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - INSTALLATION).

Fig. 13 Right Mount to Engine

1 - BOLT

2 - MOUNT BRACKET

3 - ENGINE RIGHT MOUNT ASSEMBLY

Fig. 14 LEFT MOUNT TO FRAME BRACKET

1 - FRAME BRACKET

2 - FRAME RAIL - LEFT

3 - BOLT

4 - TRANSAXLE MOUNT

9 - 90 ENGINE 3.3/3.8LRS

ENGINE 3.3/3.8L (Continued)

Page 1388 of 2585

(47) Connect the radiator upper hose.

(48) Connect the heater hoses. Remove pinch-off

pliers from the rear heater hoses (if equipped).

(49) Install the radiator upper support crossmem-

ber (Refer to 23 - BODY/EXTERIOR/GRILLE OPEN-

ING REINFORCEMENT - INSTALLATION).

(50) Install the wiper module (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION).

(51) Connect the fuel line to fuel rail (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/FUEL LINES -

STANDARD PROCEDURE).

(52) Install the air cleaner and hoses.

(53) Install new oil filter. Fill engine crankcase

with proper oil to correct level.

(54) Connect negative cable to battery.

(55) Fill the cooling system (Refer to 7 - COOLING

- STANDARD PROCEDURE).

(56) Start engine and run until operating temper-

ature is reached.

(57) Adjust transmission linkage, if necessary.

SPECIFICATIONS

3.3/3.8L ENGINE

DESCRIPTION SPECIFICATION

General Specification

Type 60É V-6 Engine

Number of Cylinders 6

Displacement

Ð3.3L 3.3 Liters

(201 cu. in.)

Ð3.8L 3.8 Liters

(231 cu. in.)

Bore

Ð3.3L 93.0 mm

(3.66 in.)

Ð3.8L 96.0 mm

(3.779 in.)

Stroke

Ð3.3L 81.0 mm

(3.188 in.)

Ð3.8L 87.0 mm

(3.425 in.)

Compression Ratio

Ð3.3L 9.35:1

Ð3.8L 9.6:1

DESCRIPTION SPECIFICATION

Firing Order 1-2-3-4-5-6

Cylinder Number (Front

to Rear)

ÐFront Bank 2,4,6

ÐRear Bank 1,3,5

Compression PressureÐ

Minimum689.5 kPa

(100 psi)

Max. Variation Between

Cylinders25%

Cylinder Block

Cylinder Bore Diameter

(Standard)

Ð3.3L 92.993±93.007 mm

(3.661±3.6617 in.)

Ð3.8L 95.993±96.007 mm

(3.7792±3.780 in.)

Out-of-Round (Service

Limits)0.076 mm

(0.003 in.)

Taper (Service Limits) 0.051 mm

(0.002 in.)

Lifter Bore Diameter 22.980±23.010 mm

(0.905±0.906 in.)

Deck Surface Flatness

(Max.)0.1 mm

(0.004 in.)

Pistons

Piston Diameter

Ð3.3L ÐMeasured 39.8

mm (1.567 in.) from

piston top92.968±92.998 mm

(3.660±3.661 in.)

Ð3.8L ÐMeasured 33.01

mm (1.30 in.) from piston

top95.968±95.998 mm

(3.778±3.779 in.)

Clearance in Bore @

Size Location (New)-0.005±0.039 mm

(-0.0002±0.0015 in.)

Weight

Ð3.3L 362 5 grams

(12.77 0.1764 oz.)

Ð3.8L 426 5 grams

(15.03 0.1764 oz.)

Piston Pins

Type Press Fit in Rod

(Serviced as an

Assembly)

RSENGINE 3.3/3.8L9-91

ENGINE 3.3/3.8L (Continued)

Page 1409 of 2585

REMOVAL

(1) Remove the valve springs. (Refer to 9 -

ENGINE/CYLINDER HEAD/VALVE SPRINGS -

REMOVAL)

(2) Remove the valve stem seal (Fig. 43).

INSTALLATION

(1) Install the valve stem seal squarely over the

valve guide, using the valve stem as a guide (Fig.

43). Do not force the seal against top of the valve

guide.

(2) Install the valve spring. (Refer to 9 - ENGINE/

CYLINDER HEAD/VALVE SPRINGS - INSTALLA-

TION)

ENGINE BLOCK

DESCRIPTION

The cylinder block is made of cast iron and is a

deep skirt design.

STANDARD PROCEDURE - CYLINDER BORE

HONING

(1) Used carefully, the cylinder bore resizing hone,

recommended tool C-823 or equivalent, equipped

with 220 grit stones, is the best tool for this honing

procedure. In addition to deglazing, it will reduce

taper and out-of-round as well as removing light

scuffing, scoring or scratches. Usually a few strokes

will clean up a bore and maintain the required lim-

its.

(2) Deglazing of the cylinder walls may be done

using a cylinder surfacing hone, recommended tool

C-3501 or equivalent, equipped with 280 grit stones,

if the cylinder bore is straight and round. 20±60

strokes depending on the bore condition, will be suf-

ficient to provide a satisfactory surface. Use a light

honing oil.Do not use engine or transmission oil,

mineral spirits or kerosene.Inspect cylinder walls

after each 20 strokes.

(3) Honing should be done by moving the hone up

and down fast enough to get a cross-hatch pattern.

When hone marksintersectat 40-60 degrees, the

cross hatch angle is most satisfactory for proper seat-

ing of rings (Fig. 44).

(4) A controlled hone motor speed between

200±300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 40±60

degree angle. Faster up and down strokes increase

the cross-hatch angle.(5) After honing, it is necessary that the block be

cleaned again to remove all traces of abrasive.

CAUTION: Ensure all abrasives are removed from

engine parts after honing. It is recommended that a

solution of soap and hot water be used with a

brush and the parts then thoroughly dried. The bore

can be considered clean when it can be wiped

clean with a white cloth and cloth remains clean.

Oil the bores after cleaning to prevent rusting.

CLEANING

Clean cylinder block thoroughly using a suitable

cleaning solvent.

INSPECTION

ENGINE BLOCK

(1) Clean cylinder block thoroughly and check all

core hole plugs for evidence of leaking.

(2) If new core plugs are to be installed, (Refer to 9

- ENGINE - STANDARD PROCEDURE - ENGINE

CORE AND OIL GALLERY PLUGS).

(3) Examine block and cylinder bores for cracks or

fractures.

(4) Check block deck surfaces for flatness. Deck

surface must be within service limit of 0.1 mm (0.004

in.).

Fig. 44 Cylinder Bore Cross-Hatch Pattern

1 - CROSS-HATCH PATTERN

2 - 40ɱ60É

9 - 112 ENGINE 3.3/3.8LRS

VALVE STEM SEALS (Continued)

Page 1519 of 2585

INSTALLATION

(1) Position fuel tank on transmission jack. Con-

nect check valve hose. Connect fuel filler tube vent

hose to fuel filler tube.

(2) Feed filler vent line thru frame rail.

(3) Raise tank into position and carefully work fuel

filler metal tube into the rubber hose on fuel tank. A

light coating of clean engine oil on the tube end may

be used to aid assembly.

(4) Tighten strap bolts to 54 N´m (40 ft. lbs.)

torque. Tighten T strap bolt to 28.2 N´m (250 in.

lbs.). Remove transmission jack.

(5) Tighten filler hose clamp to 3.3 N´m (30 in.

lbs.).CAUTION: Ensure straps are not twisted or bent

before or after tightening strap screws.

(6) Connect fuel pump/module electrical connector.

Place retainer in locked position.

(7) Lubricate the fuel supply line with clean 30

weight engine oil, install the quick connect fuel fit-

ting. Refer to Tube/Fitting Assembly in the Fuel

Delivery section of this section.

(8) Connect the control vapor lines at front of

tank.

(9) Pull-pull-push on all connections to make sure

of connection.

(10) Fill fuel tank, replace cap, and connect bat-

tery negative cable.

(11) Use the DRBIIItscan tool to pressurize the

fuel system. Check for leaks.

FUEL TANK FILLER TUBE

REMOVAL

(1) Disconnect the negative battery cable.

(2) Remove the 3 screws at the filler door.

(3) Raise and support vehicle

(4) Remove the left rear tire.

(5) Remove the splash shield (Fig. 19) or (Fig. 18).

(6)For RGRemove the canister from filler tube

(Fig. 20).

(7)For RGDisconnect the vent at the top of the

filler tube.

(8) Remove the ground strap.

(9) Remove filler tube at tank.

Fig. 16 Pump Module Connector Retainer and Lock

1 - PUSH DOWN ON RETAINER

2 - CONNECTOR LOCK

Fig. 17 VENT HOSE

Fig. 18 FUEL FILLER TUBE (RS)

14 - 12 FUEL DELIVERYRS

FUEL TANK (Continued)

Page 1598 of 2585

TRANSMISSION/TRANSAXLE

TABLE OF CONTENTS

page page

POWER TRANSFER UNIT..................1

T850 MANUAL TRANSAXLE...............2141TE AUTOMATIC TRANSAXLE............116

POWER TRANSFER UNIT

TABLE OF CONTENTS

page page

POWER TRANSFER UNIT

DESCRIPTION..........................1

OPERATION............................3

DIAGNOSIS AND TESTING

SEAL IDENTIFICATION..................3

FLUID LEAK DIAGNOSIS................3

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

INSPECTION..........................4

STANDARD PROCEDURE - PTU FLUID

CHANGE.............................5

REMOVAL.............................5

INSTALLATION..........................6

ADJUSTMENTS

OUTPUT FLANGE SHIM SELECTION.......7

SPECIFICATIONS

TORQUE.............................7

SPECIAL TOOLS

SDP POWER TRANSFER UNIT............8

DIFFERENTIAL CARRIER SEAL

REMOVAL.............................9

INSTALLATION..........................9

END COVER BALL BEARING

REMOVAL.............................9INSTALLATION.........................10

END COVER SEAL

REMOVAL.............................11

INSTALLATION.........................11

HALF SHAFT INNER SEAL

REMOVAL.............................12

INSTALLATION.........................12

INPUT SHAFT COVER SEAL

REMOVAL.............................13

INSTALLATION.........................14

INPUT SHAFT END SEAL

REMOVAL.............................15

INSTALLATION.........................16

INPUT SHAFT SEAL

REMOVAL.............................17

INSTALLATION.........................18

OUTER HALF SHAFT SEAL

REMOVAL.............................19

INSTALLATION.........................19

REAR COVER O-RING

REMOVAL.............................19

INSTALLATION.........................20

POWER TRANSFER UNIT

DESCRIPTION

The Power Transfer Unit (P.T.U.) is attached to a

modified automatic transaxle case where the right

half shaft extension housing would normally be

located.

The Power Transfer Unit is sealed from the trans-

axle and has its own oil sump. The Unit uses MopartSAE 80W-90 Gear and Axle Lubricant (MS-9020) and

holds 1.15 liters (1.22 quarts).

Service of the Power Transfer Unit is limited to:

²Fluid Change

²Seals

²Gaskets

²One ball bearing

²Output flange

If the ring gear and pinion, any tapered roller

bearings, case, covers, or pinion carrier fail the entire

unit must be replaced.

RSTRANSMISSION/TRANSAXLE21-1

Page 1600 of 2585

OPERATION

The Transfer Unit provides the power to the rear

wheels through a hypoid ring gear and pinion set.

DIAGNOSIS AND TESTING

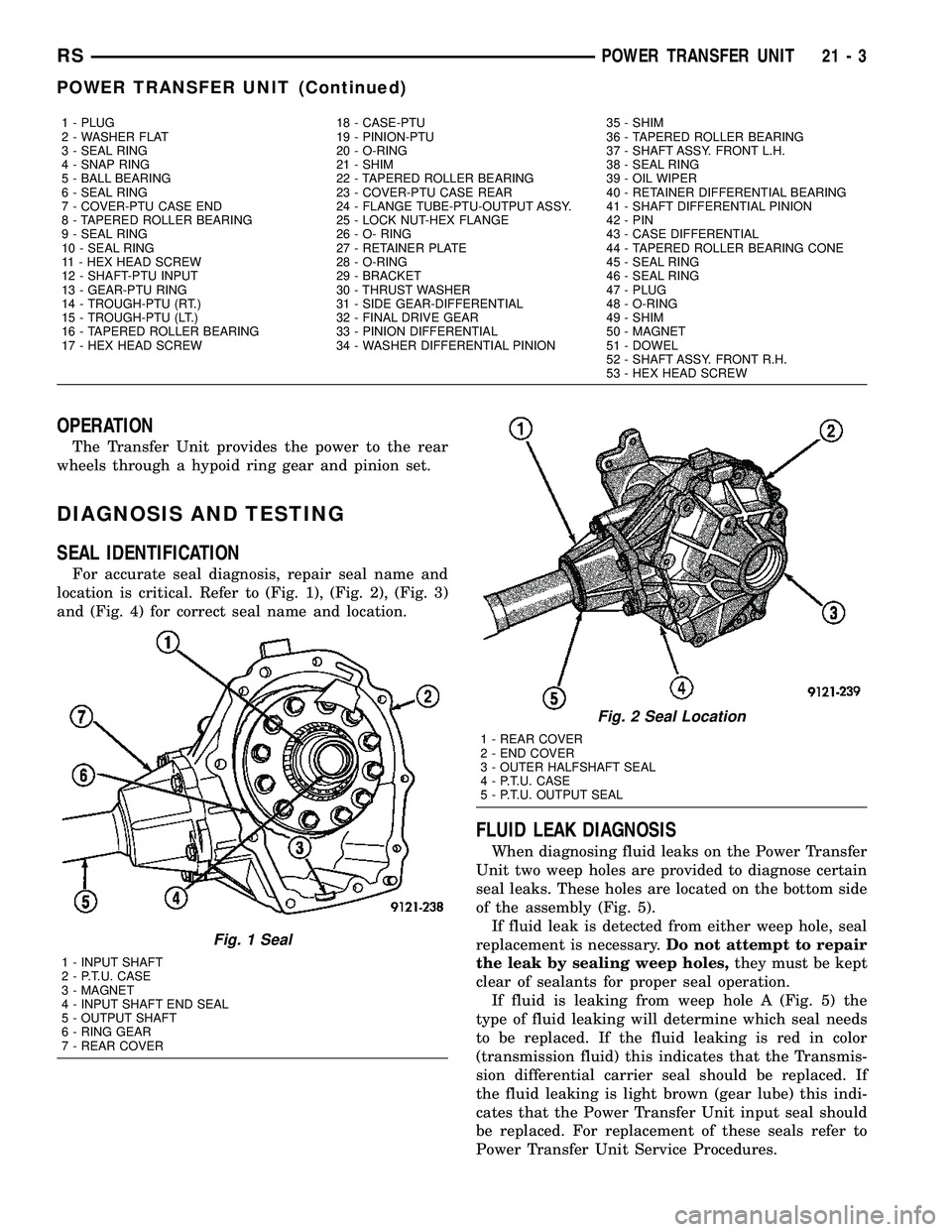

SEAL IDENTIFICATION

For accurate seal diagnosis, repair seal name and

location is critical. Refer to (Fig. 1), (Fig. 2), (Fig. 3)

and (Fig. 4) for correct seal name and location.

FLUID LEAK DIAGNOSIS

When diagnosing fluid leaks on the Power Transfer

Unit two weep holes are provided to diagnose certain

seal leaks. These holes are located on the bottom side

of the assembly (Fig. 5).

If fluid leak is detected from either weep hole, seal

replacement is necessary.Do not attempt to repair

the leak by sealing weep holes,they must be kept

clear of sealants for proper seal operation.

If fluid is leaking from weep hole A (Fig. 5) the

type of fluid leaking will determine which seal needs

to be replaced. If the fluid leaking is red in color

(transmission fluid) this indicates that the Transmis-

sion differential carrier seal should be replaced. If

the fluid leaking is light brown (gear lube) this indi-

cates that the Power Transfer Unit input seal should

be replaced. For replacement of these seals refer to

Power Transfer Unit Service Procedures.

1 - PLUG 18 - CASE-PTU 35 - SHIM

2 - WASHER FLAT 19 - PINION-PTU 36 - TAPERED ROLLER BEARING

3 - SEAL RING 20 - O-RING 37 - SHAFT ASSY. FRONT L.H.

4 - SNAP RING 21 - SHIM 38 - SEAL RING

5 - BALL BEARING 22 - TAPERED ROLLER BEARING 39 - OIL WIPER

6 - SEAL RING 23 - COVER-PTU CASE REAR 40 - RETAINER DIFFERENTIAL BEARING

7 - COVER-PTU CASE END 24 - FLANGE TUBE-PTU-OUTPUT ASSY. 41 - SHAFT DIFFERENTIAL PINION

8 - TAPERED ROLLER BEARING 25 - LOCK NUT-HEX FLANGE 42 - PIN

9 - SEAL RING 26 - O- RING 43 - CASE DIFFERENTIAL

10 - SEAL RING 27 - RETAINER PLATE 44 - TAPERED ROLLER BEARING CONE

11 - HEX HEAD SCREW 28 - O-RING 45 - SEAL RING

12 - SHAFT-PTU INPUT 29 - BRACKET 46 - SEAL RING

13 - GEAR-PTU RING 30 - THRUST WASHER 47 - PLUG

14 - TROUGH-PTU (RT.) 31 - SIDE GEAR-DIFFERENTIAL 48 - O-RING

15 - TROUGH-PTU (LT.) 32 - FINAL DRIVE GEAR 49 - SHIM

16 - TAPERED ROLLER BEARING 33 - PINION DIFFERENTIAL 50 - MAGNET

17 - HEX HEAD SCREW 34 - WASHER DIFFERENTIAL PINION 51 - DOWEL

52 - SHAFT ASSY. FRONT R.H.

53 - HEX HEAD SCREW

Fig. 1 Seal

1 - INPUT SHAFT

2 - P.T.U. CASE

3 - MAGNET

4 - INPUT SHAFT END SEAL

5 - OUTPUT SHAFT

6 - RING GEAR

7 - REAR COVER

Fig. 2 Seal Location

1 - REAR COVER

2 - END COVER

3 - OUTER HALFSHAFT SEAL

4 - P.T.U. CASE

5 - P.T.U. OUTPUT SEAL

RSPOWER TRANSFER UNIT21-3

POWER TRANSFER UNIT (Continued)