window CHRYSLER VOYAGER 2004 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1235 of 2585

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Driver Airbag Squib1 BN Steering Column N/S

Driver Airbag Squib2 BK Steering Column N/S

Driver Blend Door Actuator GY On HVAC N/S

Driver Door Courtesy Lamp GY At Lamp 43

Driver Door Lock Switch BK At Switch 43

Driver Heated Seat Back LTGN At Seat N/S

Driver Heated Seat Cushion BK At Seat N/S

Driver Heated Seat Module C1 GY Driver Heated Seat N/S

Driver Heated Seat Module C2 GY Driver Heated Seat Back N/S

Driver Heated Seat Module C3 GN At Seat N/S

Driver Power Seat Front Riser

MotorRD At Seat N/S

Driver Power Seat Front Riser

Position SensorBK At Seat N/S

Driver Power Seat Horizontal

MotorBK At Seat N/S

Driver Power Seat Horizontal

Position SensorBK At Seat N/S

Driver Power Seat Rear Riser

MotorRD At Seat N/S

Driver Power Seat Rear Riser

Position SensorBK At Seat N/S

Driver Power Seat Recliner Motor GN At Seat N/S

Driver Power Seat Recliner

Position SensorBK At Seat N/S

Driver Power Seat Switch GN At Switch N/S

Driver Power Window Motor RD At Motor 43

Driver Power Window Switch

(LHD Low Line)GN At Switch 43

Driver Power Window Switch

(LHD Except Low Line)LTGY At Switch N/S

Driver Power Window Switch

(RHD)NAT At Switch N/S

Driver Seat Belt Switch WT At Switch on Seat Harness N/S

Driver Seat Belt Tensioner yl On Seat Harness N/S

DVD Screen BK Headliner 50

DVD/CD Changer C1 Below Radio N/S

DVD/CD Changer C2 Below Radio N/S

DVD/CD Changer C3 BK At Radio 20

EGR Solenoid (Diesel) LTGY Above Transmission

Right Side of Engine15

EGR Solenoid (3.3L/3.8L) GY Above A/C Compressor Right Side

of Engine18

Engine Control Module C1

(Diesel)BK Right Side of Engine N/S

8W - 91 - 4 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONRS

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1240 of 2585

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Passenger Heated Seat Module

C2GY At Heated Seat Back N/S

Passenger Heated Seat Module

C3GN At Heated Seat N/S

Passenger Power Seat Front

Riser MotorRD Under Seat N/S

Passenger Power Seat Horizontal

MotorBK Under Seat N/S

Passenger Power Seat Rear

Riser MotorRD Under Seat N/S

Passenger Power Seat Recliner

MotorGN Under Seat N/S

Passenger Power Seat Switch GN At Switch N/S

Passenger Power Window Motor RD At Motor 44

Passenger Power Window Switch BK At Switch 44

Passenger Seat Belt Switch On Seat Harness N/S

Passenger Seat Belt Tensioner On Seat Harness N/S

Power Folding Mirror Switch

(Export)BK Near Steering Column 31

Power Liftgate Module C1 BK Left Quarter 46, 47

Power Liftgate Module C2 Left Quarter 46, 47

Power Liftgate Motor BK Left Quarter 47

Power Mirror Switch BK Rear of Switch 30

Power Outlet (Except Lowline) BK Instrument Panel 20, 23, 25

Power Seat Circuit Breaker GY Under Seat N/S

Powertrain Control Module C1 BK Left Front Engine Compartment 11

Powertrain Control Module C2 BK Left Front Engine Compartment 11

Powertrain Control Module C3 BK Left Front Engine Compartment 11

Powertrain Control Module C4

(EATX)DKGN Left Front Engine Compartment 11

Power Window Circuit Breaker GY Left Side Kick Panel 41 42

Power Window Switch (LHD

Lowline)BK Driver Door 43

Radiator Fan No.1 (Gas) BK Left Side At Motor 1

Radiator Fan No.1 (Diesel) GY Left Side At Motor 1

Radiator Fan No.2 (Gas) BK Right Side At Motor 1, 2

Radiator Fan No.2 (Diesel) GY Right Side At Motor 1, 2

Radiator Fan Relay (Gas) Top of Left Front Frame Rail 1

Radiator Fan Relay No. 1

(Diesel)BL Left Front Engine Compartment 2

Radiator Fan Relay No. 2

(Diesel)BL Left Front Engine Compartment 2

Radiator Fan Relay No. 3

(Diesel)BL Left Front Engine Compartment 2

Radio C1 Rear of Radio 20

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-9

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1246 of 2585

SPLICE NUMBER LOCATION FIG.

S212 In Steering Column Wiring Assembly N/S

S222 Near T/O for C204 N/S

S223 Near T/O for Multi-Function Switch 20

S224 Near T/O for Siren N/S

S302 In Floor Pan Track Wiring 37

S303 In T/O to Data Link Connector 37, 41, 42

S304 In Floor Pan Track Wiring 38

S305 Near T/O for Memory Seat/Mirror Module - C2 N/S

S306 In Floor Pan Track Wiring 34, 38

S307 Near T/O for Memory Power Seat Switch N/S

S309 In Floor Pan Track Wiring N/S

S310 Near T/O for C301 35, 36, 37

S311 In Floor Pan Track Wiring N/S

S312 Near T/O for C320 N/S

S313 Near T/O for Power Liftgate Module 47

S314 In Floor Pan Track Wiring 34

S315 In Floor Pan Track Wiring 34

S316 In Floor Pan Track Wiring 37

S317 Near T/O for C101 35, 36

S318 Near T/O for Power Seat Circuit Breaker 34

S319 In Floor Pan Track Wiring 38

S321 Ner T/O for C301 35, 36, 37

S322 Near T/O for C301 35, 37

S323 In Floor Pan Track Wiring 34

S324 In Floor Pan Track Wiring 34

S325 In Floor Pan Track Wiring 34

S326 Near T/O for C101 35, 36

S327 Near Left Side Impact Airbag Module 37, 40

S329 Near T/O to Left Rear Pillar Speaker 47

S330 Near T/O for Power Liftgate Module 47

S331 Near T/O for Power Liftgate Motor 47

S332 In Floor Pan Track Wiring N/S

S334 Near T/O to G301 34

S335 Near T/O for Left Rear Reading Lamp N/S

S336 Near T/O for Left Rear Reading Lamp N/S

S337 Near T/O for Right Mid Reading Lamp N/S

S338 Near T/O for Right Visor/Vanity Lamp N/S

S339 Near T/O for C312 N/S

S340 Near T/O for Passenger Power Window Switch N/S

S342 (LHD) Near T/O for Passenger Power Window Motor 44

S343 (LHD) Near T/O for Driver Power Window Motor 43

S344 In T/O to Right Sliding Door Control Module C2 45, 46

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-15

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1247 of 2585

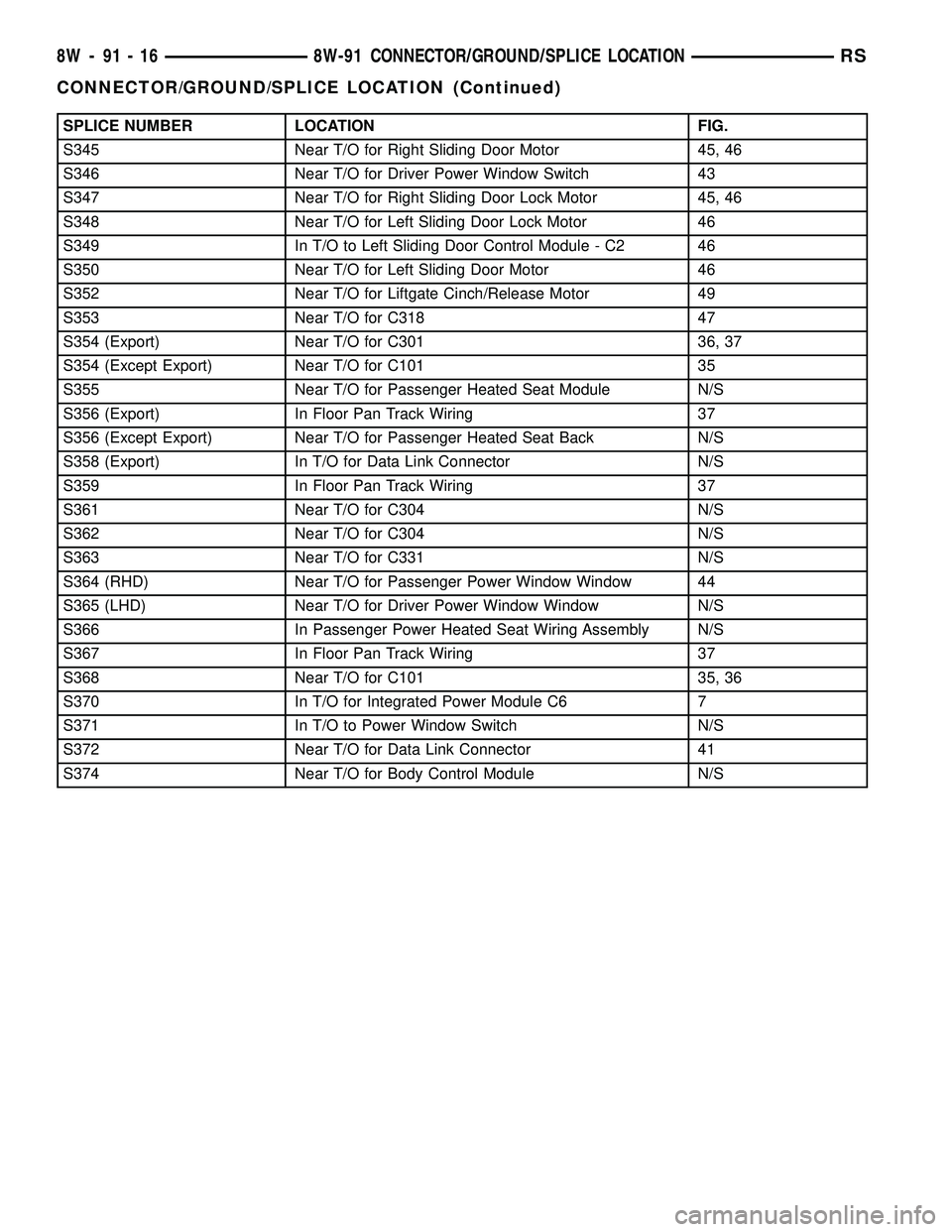

SPLICE NUMBER LOCATION FIG.

S345 Near T/O for Right Sliding Door Motor 45, 46

S346 Near T/O for Driver Power Window Switch 43

S347 Near T/O for Right Sliding Door Lock Motor 45, 46

S348 Near T/O for Left Sliding Door Lock Motor 46

S349 In T/O to Left Sliding Door Control Module - C2 46

S350 Near T/O for Left Sliding Door Motor 46

S352 Near T/O for Liftgate Cinch/Release Motor 49

S353 Near T/O for C318 47

S354 (Export) Near T/O for C301 36, 37

S354 (Except Export) Near T/O for C101 35

S355 Near T/O for Passenger Heated Seat Module N/S

S356 (Export) In Floor Pan Track Wiring 37

S356 (Except Export) Near T/O for Passenger Heated Seat Back N/S

S358 (Export) In T/O for Data Link Connector N/S

S359 In Floor Pan Track Wiring 37

S361 Near T/O for C304 N/S

S362 Near T/O for C304 N/S

S363 Near T/O for C331 N/S

S364 (RHD) Near T/O for Passenger Power Window Window 44

S365 (LHD) Near T/O for Driver Power Window Window N/S

S366 In Passenger Power Heated Seat Wiring Assembly N/S

S367 In Floor Pan Track Wiring 37

S368 Near T/O for C101 35, 36

S370 In T/O for Integrated Power Module C6 7

S371 In T/O to Power Window Switch N/S

S372 Near T/O for Data Link Connector 41

S374 Near T/O for Body Control Module N/S

8W - 91 - 16 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONRS

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1364 of 2585

(8) Check if the spring tang is within the tolerance

window (Fig. 125). If the spring tang is within the

tolerance window, the installation process is complete

and nothing further is required. If the spring tang is

not within the tolerance window, repeat Steps 5

through 7.

(9) Install engine mount bracket to engine (Fig.

115).

(10) Install timing belt front covers and bolts

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT COVER(S) - INSTALLATION).

(11) Install air conditioning/generator belt ten-

sioner and pulley (Refer to 7 - COOLING/ACCES-

SORY DRIVE/BELT TENSIONERS -

INSTALLATION).(12) Install right engine mount (Refer to 9 -

ENGINE/ENGINE MOUNTING/RIGHT MOUNT -

INSTALLATION).

(13) Install crankshaft vibration damper (Refer to

9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - INSTALLATION).

(14) Install accessory drive belts (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(15) Install drive belt splash shield.

(16) Install right front wheel.

(17) Connect make-up air hose to cylinder head

cover.

(18) Install air cleaner housing, upper cover, and

clean air tube.

Fig. 124 Crankshaft and Camshaft Timing

1 - CAMSHAFT TIMING MARKS

2 - CRANKSHAFT TDC MARKS

3 - TRAILING EDGE OF SPROCKET TOOTH

Fig. 125 Timing Belt Tension Verification

1 - SPRING TANG

2 - TOLERANCE WINDOW

RSENGINE 2.4L9-67

TIMING BELT AND SPROCKET(S) (Continued)

Page 1521 of 2585

QUICK CONNECT FITTING

STANDARD PROCEDURE - QUICK-CONNECT

FITTINGS

REMOVAL

When disconnecting a quick-connect fitting, the

retainer will remain on the fuel tube nipple.

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE DISCONNECTING A QUICK-CONNECT FIT-

TINGS. REFER TO THE FUEL PRESSURE RELEASE

PROCEDURE. THIS MAY RESULT IN PERSONAL

INJURY OR DEATH.

(1) Perform Fuel Pressure Release Procedure.

Refer to the Fuel Pressure Release Procedure in this

section.

(2) Disconnect negative cable from battery or aux-

iliary jumper terminal.

(3) Squeeze retainer tabs together and pull fuel

tube/quick-connect fitting assembly off of fuel tube

nipple. The retainer will remain on fuel tube.

INSTALLATION

CAUTION: Make sure that the o-ring in installed in

fitting. Never install a quick-connect fitting without

the retainer being either on the fuel tube or already

in the quick-connect fitting. In either case, ensure

the retainer locks securely into the quick-connect

fitting by firmly push-pulling-push on fuel tube and

fitting to ensure it is secured.

(1) Using a clean lint free cloth, clean the fuel tube

nipple and retainer.

(2) Prior to connecting the fitting to the fuel tube,

coat the fuel tube nipple with clean engine oil.

(3) Push the quick-connect fitting over the fuel

tube until theretainer seats and a click is heard.

(4) The plastic quick-connect fitting has windows

in the sides of the casing. When the fitting com-

pletely attaches to the fuel tube, the retainer locking

ears and the fuel tube shoulder are visible in the

windows. If they are not visible, the retainer was not

properly installed (Fig. 22).Do not rely upon the

audible click to confirm a secure connection.

(5) Connect negative cable to battery or auxiliary

jumper terminal.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for several minutes, until the test is stopped, or

until the ignition switch is turned to the Off posi-

tion.(6) Use the DRB IIItscan tool ASD Fuel System

Test to pressurize the fuel system. Check for leaks.

TWO-TAB TYPE FITTING

This type of fitting is equipped with tabs located on

both sides of the fitting (Fig. 23). These tabs are sup-

plied for disconnecting the quick-connect fitting from

component being serviced.

CAUTION: The interior components (O-rings, spac-

ers) of this type of quick-connect fitting are not ser-

viced separately, but new plastic retainers are

available. Do not attempt to repair damaged fittings

or fuel lines/tubes. If repair is necessary, replace

the complete fuel tube assembly.

Fig. 22 Plastic Quick-Connect Fitting/Fuel Tube

Connection

1 - WINDOW

2-TAB(2)

3 - EAR

4 - SHOULDER (ON TUBE)

Fig. 23 Typical Two-Tab Type Quick-Connect Fitting

1 - TAB(S)

2 - QUICK-CONNECT FITTING

14 - 14 FUEL DELIVERYRS

Page 2113 of 2585

the vehicle should not enter the passenger or luggage

compartment. Moving sealing surfaces will not

always seal water tight under all conditions. At

times, side glass or door seals will allow water to

enter the passenger compartment during high pres-

sure washing or hard driving rain (severe) condi-

tions. Overcompensating on door or glass

adjustments to stop a water leak that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After completing

a repair, water test vehicle to verify leak has stopped

before returning vehicle to use.

VISUAL INSPECTION BEFORE WATER LEAK TESTS

Verify that floor and body plugs are in place, body

drains are clear, and body components are properly

aligned and sealed. If component alignment or seal-

ing is necessary, refer to the appropriate section of

this group for proper procedures.

WATER LEAK TESTS

WARNING: DO NOT USE ELECTRIC SHOP LIGHTS

OR TOOLS IN WATER TEST AREA. PERSONAL

INJURY CAN RESULT.

When the conditions causing a water leak have

been determined, simulate the conditions as closely

as possible.

²If a leak occurs with the vehicle parked in a

steady light rain, flood the leak area with an open-

ended garden hose.

²If a leak occurs while driving at highway speeds

in a steady rain, test the leak area with a reasonable

velocity stream or fan spray of water. Direct the

spray in a direction comparable to actual conditions.

²If a leak occurs when the vehicle is parked on an

incline, hoist the end or side of the vehicle to simu-

late this condition. This method can be used when

the leak occurs when the vehicle accelerates, stops or

turns. If the leak occurs on acceleration, hoist the

front of the vehicle. If the leak occurs when braking,

hoist the back of the vehicle. If the leak occurs on left

turns, hoist the left side of the vehicle. If the leak

occurs on right turns, hoist the right side of the vehi-

cle. For hoisting recommendations (Refer to LUBRI-

CATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE).

WATER LEAK DETECTION

To detect a water leak point-of-entry, do a water

test and watch for water tracks or droplets forming

on the inside of the vehicle. If necessary, remove inte-

rior trim covers or panels to gain visual access to the

leak area. If the hose cannot be positioned without

being held, have someone help do the water test.Some water leaks must be tested for a considerable

length of time to become apparent. When a leak

appears, find the highest point of the water track or

drop. The highest point usually will show the point of

entry. After leak point has been found, repair the

leak and water test to verify that the leak has

stopped.

Locating the entry point of water that is leaking

into a cavity between panels can be difficult. The

trapped water may splash or run from the cavity,

often at a distance from the entry point. Most water

leaks of this type become apparent after accelerating,

stopping, turning, or when on an incline.

MIRROR INSPECTION METHOD

When a leak point area is visually obstructed, use

a suitable mirror to gain visual access. A mirror can

also be used to deflect light to a limited-access area

to assist in locating a leak point.

BRIGHT LIGHT LEAK TEST METHOD

Some water leaks in the luggage compartment can

be detected without water testing. Position the vehi-

cle in a brightly lit area. From inside the darkened

luggage compartment inspect around seals and body

seams. If necessary, have a helper direct a drop light

over the suspected leak areas around the luggage

compartment. If light is visible through a normally

sealed location, water could enter through the open-

ing.

PRESSURIZED LEAK TEST METHOD

When a water leak into the passenger compart-

ment cannot be detected by water testing, pressurize

the passenger compartment and soap test exterior of

the vehicle. To pressurize the passenger compart-

ment, close all doors and windows, start engine, and

set heater control to high blower in HEAT position. If

engine can not be started, connect a charger to the

battery to ensure adequate voltage to the blower.

With interior pressurized, apply dish detergent solu-

tion to suspected leak area on the exterior of the

vehicle. Apply detergent solution with spray device or

soft bristle brush. If soap bubbles occur at a body

seam, joint, seal or gasket, the leak entry point could

be at that location.

DIAGNOSIS AND TESTING - WIND NOISE

Wind noise is the result of most air leaks. Air leaks

can be caused by poor sealing, improper body compo-

nent alignment, body seam porosity, or missing plugs

in the engine compartment or door hinge pillar areas.

All body sealing points should be airtight in normal

driving conditions. Moving sealing surfaces will not

always seal airtight under all conditions. At times,

side glass or door seals will allow wind noise to be

23 - 2 BODYRS

BODY (Continued)

Page 2116 of 2585

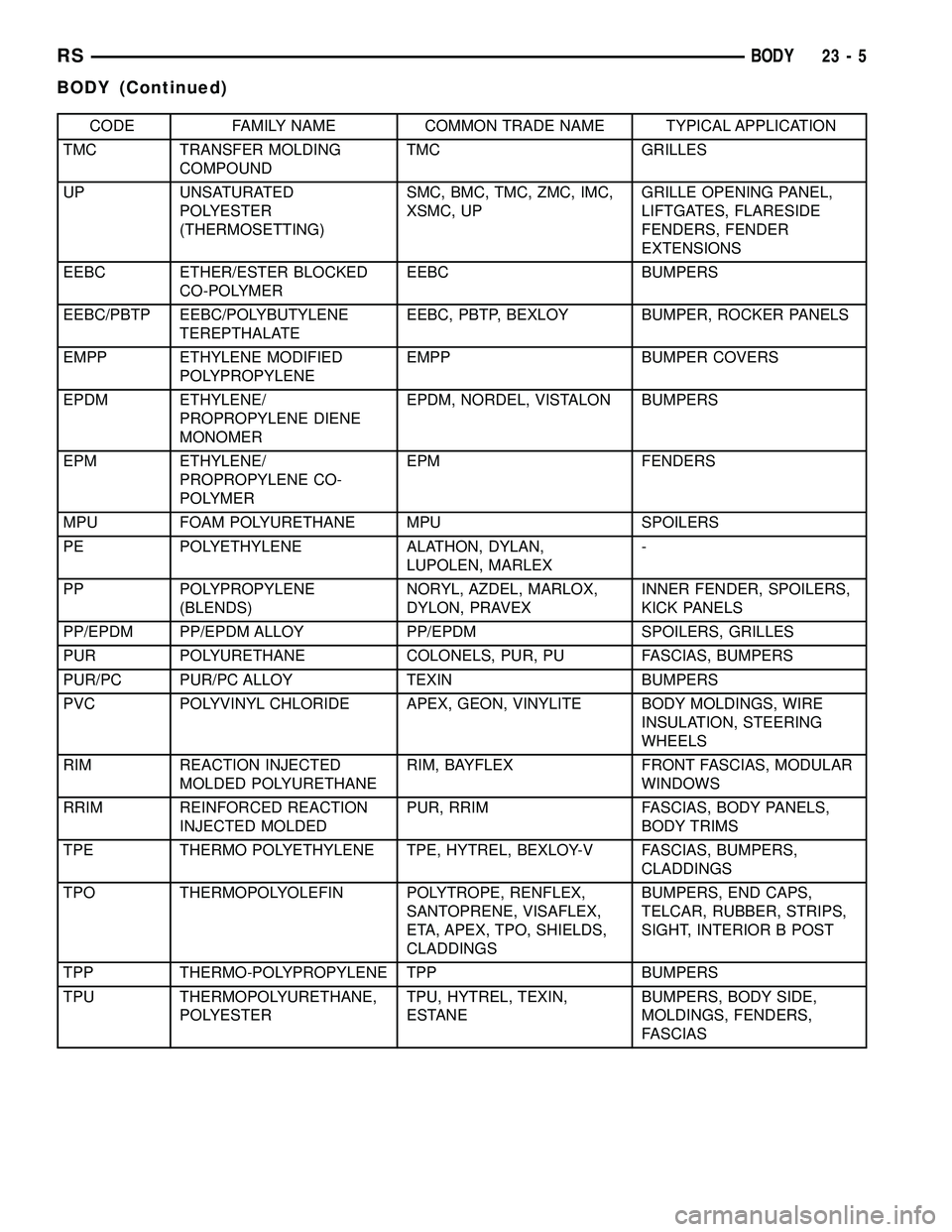

CODE FAMILY NAME COMMON TRADE NAME TYPICAL APPLICATION

TMC TRANSFER MOLDING

COMPOUNDTMC GRILLES

UP UNSATURATED

POLYESTER

(THERMOSETTING)SMC, BMC, TMC, ZMC, IMC,

XSMC, UPGRILLE OPENING PANEL,

LIFTGATES, FLARESIDE

FENDERS, FENDER

EXTENSIONS

EEBC ETHER/ESTER BLOCKED

CO-POLYMEREEBC BUMPERS

EEBC/PBTP EEBC/POLYBUTYLENE

TEREPTHALATEEEBC, PBTP, BEXLOY BUMPER, ROCKER PANELS

EMPP ETHYLENE MODIFIED

POLYPROPYLENEEMPP BUMPER COVERS

EPDM ETHYLENE/

PROPROPYLENE DIENE

MONOMEREPDM, NORDEL, VISTALON BUMPERS

EPM ETHYLENE/

PROPROPYLENE CO-

POLYMEREPM FENDERS

MPU FOAM POLYURETHANE MPU SPOILERS

PE POLYETHYLENE ALATHON, DYLAN,

LUPOLEN, MARLEX-

PP POLYPROPYLENE

(BLENDS)NORYL, AZDEL, MARLOX,

DYLON, PRAVEXINNER FENDER, SPOILERS,

KICK PANELS

PP/EPDM PP/EPDM ALLOY PP/EPDM SPOILERS, GRILLES

PUR POLYURETHANE COLONELS, PUR, PU FASCIAS, BUMPERS

PUR/PC PUR/PC ALLOY TEXIN BUMPERS

PVC POLYVINYL CHLORIDE APEX, GEON, VINYLITE BODY MOLDINGS, WIRE

INSULATION, STEERING

WHEELS

RIM REACTION INJECTED

MOLDED POLYURETHANERIM, BAYFLEX FRONT FASCIAS, MODULAR

WINDOWS

RRIM REINFORCED REACTION

INJECTED MOLDEDPUR, RRIM FASCIAS, BODY PANELS,

BODY TRIMS

TPE THERMO POLYETHYLENE TPE, HYTREL, BEXLOY-V FASCIAS, BUMPERS,

CLADDINGS

TPO THERMOPOLYOLEFIN POLYTROPE, RENFLEX,

SANTOPRENE, VISAFLEX,

ETA, APEX, TPO, SHIELDS,

CLADDINGSBUMPERS, END CAPS,

TELCAR, RUBBER, STRIPS,

SIGHT, INTERIOR B POST

TPP THERMO-POLYPROPYLENE TPP BUMPERS

TPU THERMOPOLYURETHANE,

POLYESTERTPU, HYTREL, TEXIN,

ESTANEBUMPERS, BODY SIDE,

MOLDINGS, FENDERS,

FASCIAS

RSBODY23-5

BODY (Continued)

Page 2125 of 2585

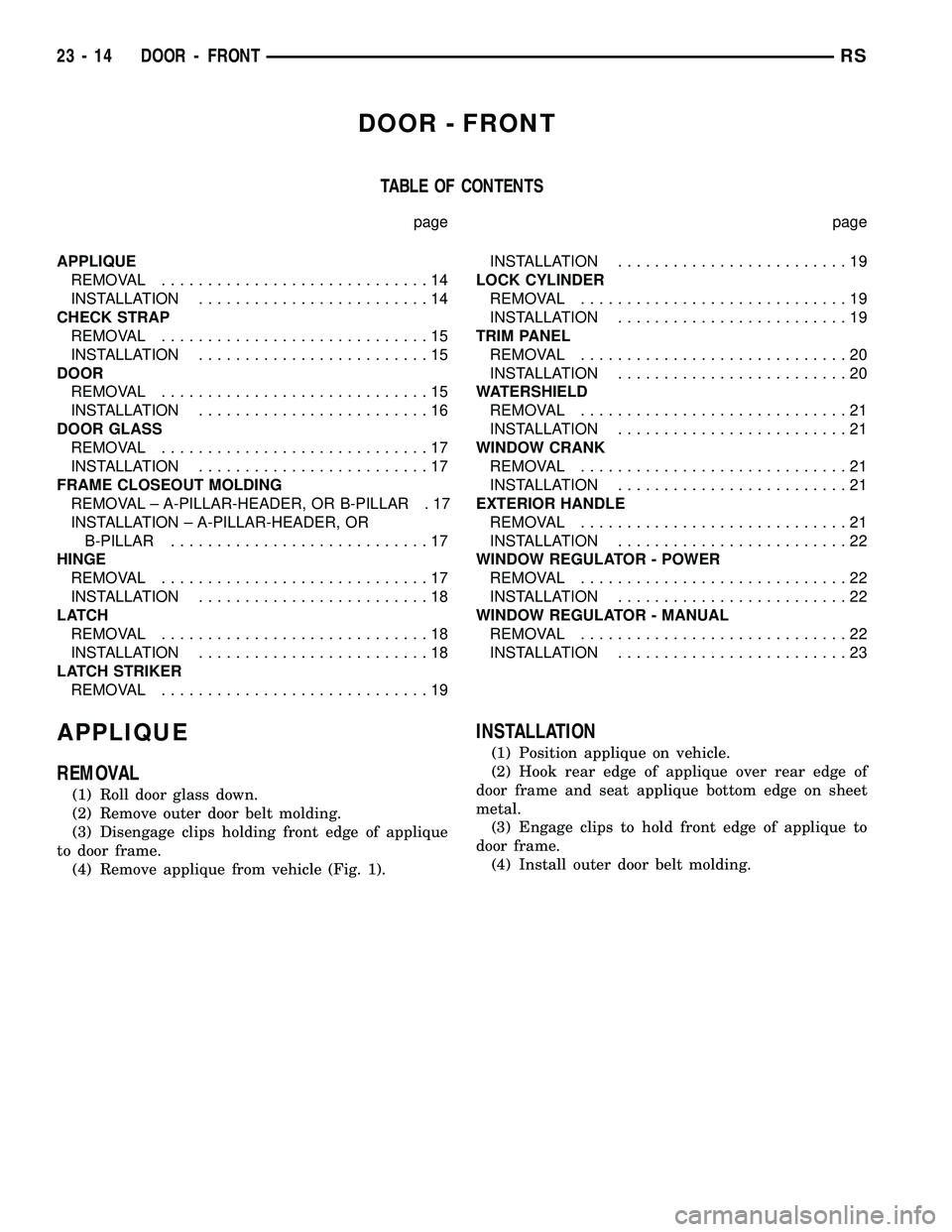

DOOR - FRONT

TABLE OF CONTENTS

page page

APPLIQUE

REMOVAL.............................14

INSTALLATION.........................14

CHECK STRAP

REMOVAL.............................15

INSTALLATION.........................15

DOOR

REMOVAL.............................15

INSTALLATION.........................16

DOOR GLASS

REMOVAL.............................17

INSTALLATION.........................17

FRAME CLOSEOUT MOLDING

REMOVAL ± A-PILLAR-HEADER, OR B-PILLAR . 17

INSTALLATION ± A-PILLAR-HEADER, OR

B-PILLAR............................17

HINGE

REMOVAL.............................17

INSTALLATION.........................18

LATCH

REMOVAL.............................18

INSTALLATION.........................18

LATCH STRIKER

REMOVAL.............................19INSTALLATION.........................19

LOCK CYLINDER

REMOVAL.............................19

INSTALLATION.........................19

TRIM PANEL

REMOVAL.............................20

INSTALLATION.........................20

WATERSHIELD

REMOVAL.............................21

INSTALLATION.........................21

WINDOW CRANK

REMOVAL.............................21

INSTALLATION.........................21

EXTERIOR HANDLE

REMOVAL.............................21

INSTALLATION.........................22

WINDOW REGULATOR - POWER

REMOVAL.............................22

INSTALLATION.........................22

WINDOW REGULATOR - MANUAL

REMOVAL.............................22

INSTALLATION.........................23

APPLIQUE

REMOVAL

(1) Roll door glass down.

(2) Remove outer door belt molding.

(3) Disengage clips holding front edge of applique

to door frame.

(4) Remove applique from vehicle (Fig. 1).

INSTALLATION

(1) Position applique on vehicle.

(2) Hook rear edge of applique over rear edge of

door frame and seat applique bottom edge on sheet

metal.

(3) Engage clips to hold front edge of applique to

door frame.

(4) Install outer door belt molding.

23 - 14 DOOR - FRONTRS

Page 2128 of 2585

DOOR GLASS

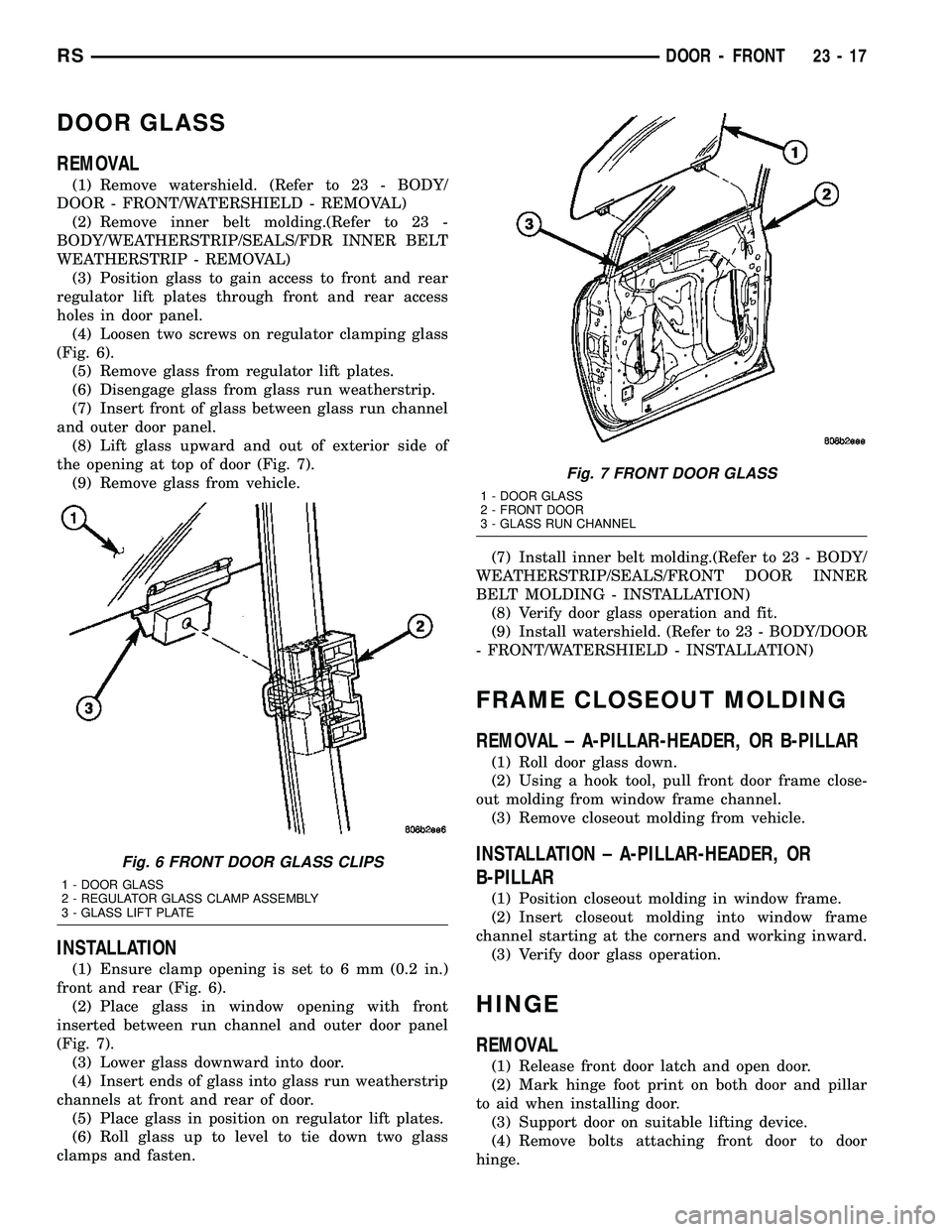

REMOVAL

(1) Remove watershield. (Refer to 23 - BODY/

DOOR - FRONT/WATERSHIELD - REMOVAL)

(2) Remove inner belt molding.(Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FDR INNER BELT

WEATHERSTRIP - REMOVAL)

(3) Position glass to gain access to front and rear

regulator lift plates through front and rear access

holes in door panel.

(4) Loosen two screws on regulator clamping glass

(Fig. 6).

(5) Remove glass from regulator lift plates.

(6) Disengage glass from glass run weatherstrip.

(7) Insert front of glass between glass run channel

and outer door panel.

(8) Lift glass upward and out of exterior side of

the opening at top of door (Fig. 7).

(9) Remove glass from vehicle.

INSTALLATION

(1) Ensure clamp opening is set to 6 mm (0.2 in.)

front and rear (Fig. 6).

(2) Place glass in window opening with front

inserted between run channel and outer door panel

(Fig. 7).

(3) Lower glass downward into door.

(4) Insert ends of glass into glass run weatherstrip

channels at front and rear of door.

(5) Place glass in position on regulator lift plates.

(6) Roll glass up to level to tie down two glass

clamps and fasten.(7) Install inner belt molding.(Refer to 23 - BODY/

WEATHERSTRIP/SEALS/FRONT DOOR INNER

BELT MOLDING - INSTALLATION)

(8) Verify door glass operation and fit.

(9) Install watershield. (Refer to 23 - BODY/DOOR

- FRONT/WATERSHIELD - INSTALLATION)

FRAME CLOSEOUT MOLDING

REMOVAL ± A-PILLAR-HEADER, OR B-PILLAR

(1) Roll door glass down.

(2) Using a hook tool, pull front door frame close-

out molding from window frame channel.

(3) Remove closeout molding from vehicle.

INSTALLATION ± A-PILLAR-HEADER, OR

B-PILLAR

(1) Position closeout molding in window frame.

(2) Insert closeout molding into window frame

channel starting at the corners and working inward.

(3) Verify door glass operation.

HINGE

REMOVAL

(1) Release front door latch and open door.

(2) Mark hinge foot print on both door and pillar

to aid when installing door.

(3) Support door on suitable lifting device.

(4) Remove bolts attaching front door to door

hinge.

Fig. 6 FRONT DOOR GLASS CLIPS

1 - DOOR GLASS

2 - REGULATOR GLASS CLAMP ASSEMBLY

3 - GLASS LIFT PLATE

Fig. 7 FRONT DOOR GLASS

1 - DOOR GLASS

2 - FRONT DOOR

3 - GLASS RUN CHANNEL

RSDOOR - FRONT23-17