brake fluid CHRYSLER VOYAGER 2004 Repair Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 231 of 2585

ABS PRIMARY HYDRAULIC CIRCUIT AND

SOLENOID VALVE FUNCTION (ABS WITHOUT

TRACTION CONTROL)

The hydraulic diagram (Fig. 7) shows the vehicle in

the ABS braking mode. The diagram shows one

wheel is slipping because the driver is attempting to

stop the vehicle at a faster rate than is allowed by

the surface on which the tires are riding.²The normally open and normally closed valves

modulate (build/decay) the brake hydraulic pressure

as required.

²The pump/motor is switched on so that the

brake fluid from the low pressure accumulators is

returned to the master cylinder circuits.

²The brake fluid is routed to either the master

cylinder or the wheel brake depending on the posi-

tion of the normally open valve.

Fig. 7 ABS Without Traction Control - Primary Hydraulic Circuit

1 - OUTLET VALVE

2 - PUMP PISTON

3 - PUMP MOTOR (ON)

4 - LOW PRESSURE ACCUMULATOR PRESSURE

5 - LOW PRESSURE ACCUMULATOR

6 - NORMALLY CLOSED VALVE (MODULATING)

7 - TO RIGHT FRONT WHEEL8 - NORMALLY OPEN VALVE (MODULATING)

9 - FROM MASTER CYLINDER

10 - MASTER CYLINDER PRESSURE

11 - CONTROLLED WHEEL PRESSURE

12 - PUMP INTERSTAGE PRESSURE

13 - NOISE DAMPER CHAMBER

5 - 84 BRAKES - ABSRS

HYDRAULIC/MECHANICAL (Continued)

Page 232 of 2585

ABS SECONDARY HYDRAULIC CIRCUIT AND

SOLENOID VALVE FUNCTION (ABS WITHOUT

TRACTION CONTROL)

The hydraulic diagram (Fig. 8) shows the vehicle in

the ABS braking mode. The diagram shows one

wheel is slipping because the driver is attempting to

stop the vehicle at a faster rate than is allowed by

the surface on which the tires are riding.

²The normally open and normally closed valves

modulate (build/decay) the brake hydraulic pressure

as required.²The pump/motor is switched on so that the

brake fluid from the low pressure accumulators is

returned to the master cylinder circuits.

²The brake fluid will then be routed to either the

master cylinder or the wheel brake depending on the

position of the normally open valve.

²In the secondary circuit, 1.2 cc brake fluid is

taken in by the lip seal saver to protect the lip seals

on the master cylinder piston.

Fig. 8 ABS Without Traction Control - Secondary Hydraulic Circuit

1 - OUTLET VALVE

2 - PUMP PISTON

3 - LOW PRESSURE ACCUMULATOR PRESSURE

4 - TO RIGHT FRONT WHEEL

5 - FROM MASTER CYLINDER6 - MASTER CYLINDER PRESSURE

7 - CONTROLLED WHEEL PRESSURE

8 - PUMP INTERSTAGE PRESSURE

9 - LIP SEAL SAVER (SECONDARY CIRCUIT ONLY)

RSBRAKES - ABS5-85

HYDRAULIC/MECHANICAL (Continued)

Page 234 of 2585

ABS BRAKING HYDRAULIC CIRCUIT, SOLENOID

VALVE, AND SHUTTLE VALVE FUNCTION (ABS

WITH TRACTION CONTROL)

The hydraulic diagram (Fig. 10) shows the vehicle

in the ABS braking mode. The diagram shows one

wheel is slipping because the driver is attempting to

stop the vehicle at a faster rate than is allowed by

the surface on which the tires are riding.

²The hydraulic shuttle valve closes upon brake

application so that the pump/motor cannot siphon

brake fluid from the master cylinder.²The normally open and normally closed valves

modulate (build/decay) the brake hydraulic pressure

as required.

²The pump/motor is switched on so that the

brake fluid from the low pressure accumulators is

returned to the master cylinder circuits.

²The brake fluid is routed to either the master

cylinder or the wheel brake depending on the posi-

tion of the normally open valve.

Fig. 10 ABS With Traction Control - ABS Braking Hydraulic Circuit

1 - OUTLET VALVE

2 - PUMP PISTON

3 - PUMP MOTOR (ON)

4 - SUCTION VALVE

5 - LOW PRESSURE ACCUMULATOR

6 - NORMALLY CLOSED VALVE (MODULATING)

7 - TO RIGHT FRONT WHEEL

8 - NORMALLY OPEN VALVE (MODULATING)9 - NORMALLY OPEN ASR VALVE (OFF)

10 - FROM MASTER CYLINDER

11 - HYDRAULIC SHUTTLE VALVE

12 - MASTER CYLINDER PRESSURE

13 - CONTROLLED WHEEL PRESSURE

14 - LOW PRESSURE ACCUMULATOR PRESSURE

15 - PUMP INTERSTAGE PRESSURE

16 - NOISE DAMPER CHAMBER

RSBRAKES - ABS5-87

HYDRAULIC/MECHANICAL (Continued)

Page 235 of 2585

ABS TRACTION CONTROL HYDRAULIC CIRCUIT,

SOLENOID VALVE, AND SHUTTLE VALVE

FUNCTION (ABS WITH TRACTION CONTROL)

The hydraulic diagram (Fig. 11) shows the vehicle

in the ABS braking mode. The diagram shows a drive

wheel is spinning and brake pressure is required to

reduce its speed.²The normally open ASR valve is energized to iso-

late the brake fluid being pumped from the master

cylinder and to isolate the driven wheel.

²The normally open ASR valve bypasses the

pump output back to the master cylinder at a fixed

pressure setting.

²The normally open and normally closed valves

modulate (build/decay) the brake pressure as

required to the spinning wheel.

Fig. 11 Traction Control Hydraulic Circuit

1 - OUTLET VALVE

2 - PUMP PISTON

3 - PUMP MOTOR (ON)

4 - LOW PRESSURE ACCUMULATOR PRESSURE

5 - LOW PRESSURE ACCUMULATOR

6 - NORMALLY CLOSED VALVE (MODULATING)

7 - TO RIGHT FRONT WHEEL (SPINNING)

8 - NORMALLY OPEN VALVE (MODULATING)

9 - NORMALLY OPEN ASR VALVE ON (REGULATING)10 - FROM MASTER CYLINDER

11 - HYDRAULIC SHUTTLE VALVE

12 - CONTROLLED WHEEL PRESSURE

13 - SUCTION VALVE

14 - PUMP INTERSTAGE PRESSURE

15 - NOISE DAMPER CHAMBER

16 - MASTER CYLINDER PRESSURE

17 - PUMP PRESSURE

5 - 88 BRAKES - ABSRS

HYDRAULIC/MECHANICAL (Continued)

Page 236 of 2585

HCU (HYDRAULIC CONTROL

UNIT)

DESCRIPTION

The hydraulic control unit (HCU) is mounted to

the CAB as part of the ICU (Fig. 22). The HCU con-

trols the flow of brake fluid to the brakes using a

series of valves and accumulators. A pump/motor is

mounted on the HCU to supply build pressure to the

brakes during an ABS stop.

The HCU on a vehicle equipped with ABS and

traction control has a valve block housing that is

approximately 1 inch longer on the low pressure fluid

accumulators side than a HCU on a vehicle that is

equipped with only ABS.

For more information, (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ICU (INTEGRATED CON-

TROL UNIT) - DESCRIPTION)

OPERATION

For information on the operation of the HCU as a

whole, refer to Hydraulic Circuits And Valve Opera-

tion which can be found elsewhere in this section.

For information on the operation of the components

within the HCU, refer to the following three topics.

VALVES AND SOLENOIDS

The valve block contains four inlet valves and four

outlet valves. The inlet valves are spring-loaded in

the open position and the outlet valves are spring-

loaded in the closed position during normal braking.

The fluid is allowed to flow from the master cylinder

to the wheel brakes.

During an ABS stop, these valves cycle to maintain

the proper slip ratio for each wheel. The inlet valve

closes preventing further pressure increase and the

outlet valve opens to provide a path from the wheel

brake to the HCU accumulators and pump/motor.

This releases (decays) pressure from the wheel brake,

thus releasing the wheel from excessive slippage.

Once the wheel is no longer slipping, the outlet valve

is closed and the inlet valve is opened to reapply

(build) pressure.

On vehicles with traction control, there is an extra

set of valves and solenoids. The ASR valves, mounted

in the HCU valve block, are normally in the open

position and close only when the traction control is

applied.

These isolator valves are used to isolate the rear

(non-driving) wheels of the vehicle from the hydraulic

pressure that the HCU pump/motor is sending to the

front (driving) wheels when traction control is being

applied. The rear brakes need to be isolated from the

master cylinder when traction control is being

applied so the rear wheels do not drag. For moreinformation, refer to Traction Control System in this

section.

BRAKE FLUID ACCUMULATORS

There are two fluid accumulators in the HCU±one

for the primary hydraulic circuit and one for the sec-

ondary hydraulic circuit. Each hydraulic circuit uses

a 5 cc accumulator.

The fluid accumulators temporarily store brake

fluid that is removed from the wheel brakes during

an ABS cycle. This stored fluid is used by the pump/

motor to provide build pressure for the brake hydrau-

lic system. When the antilock stop is complete, the

accumulators are drained by the pump/motor.

On ABS-only vehicles, there is a mini-accumulator

on the secondary hydraulic circuit that protects the

master cylinder seals during an ABS stop, and there

is a noise dampening chamber on the primary circuit.

On ABS with traction control vehicles, there are

two noise dampening chambers in the HCU.

PUMP/MOTOR

There are two pump assemblies in the HCUÐone

for the primary hydraulic circuit and one for the sec-

ondary hydraulic circuit. Both pumps are driven by a

common electric motor. This DC-type motor is inte-

gral to the HCU and is controlled by the CAB.

The pump/motor provides the extra amount of

brake fluid needed during antilock braking. Brake

fluid is released to the accumulators when the outlet

valve is opened during an antilock stop. The pump

mechanism consists of two opposing pistons operated

by an eccentric camshaft. In operation, one piston

draws fluid from the accumulators, and the opposing

piston pumps fluid to the master cylinder circuits.

When the antilock stop is complete, the pump/motor

drains the accumulators.

The CAB may turn on the pump/motor when an

antilock stop is detected. The pump/motor continues

to run during the antilock stop and is turned off after

the stop is complete. Under some conditions, the

pump/motor runs to drain the accumulators during

the next drive-off.

The pump/motor is not a serviceable item; if it

requires replacement, the HCU must be replaced.

ICU (INTEGRATED CONTROL

UNIT)

DESCRIPTION

The hydraulic control unit (HCU) and the control-

ler antilock brake (CAB) used with this antilock

brake system are combined (integrated) into one

unit, which is called the integrated control unit (ICU)

RSBRAKES - ABS5-89

Page 237 of 2585

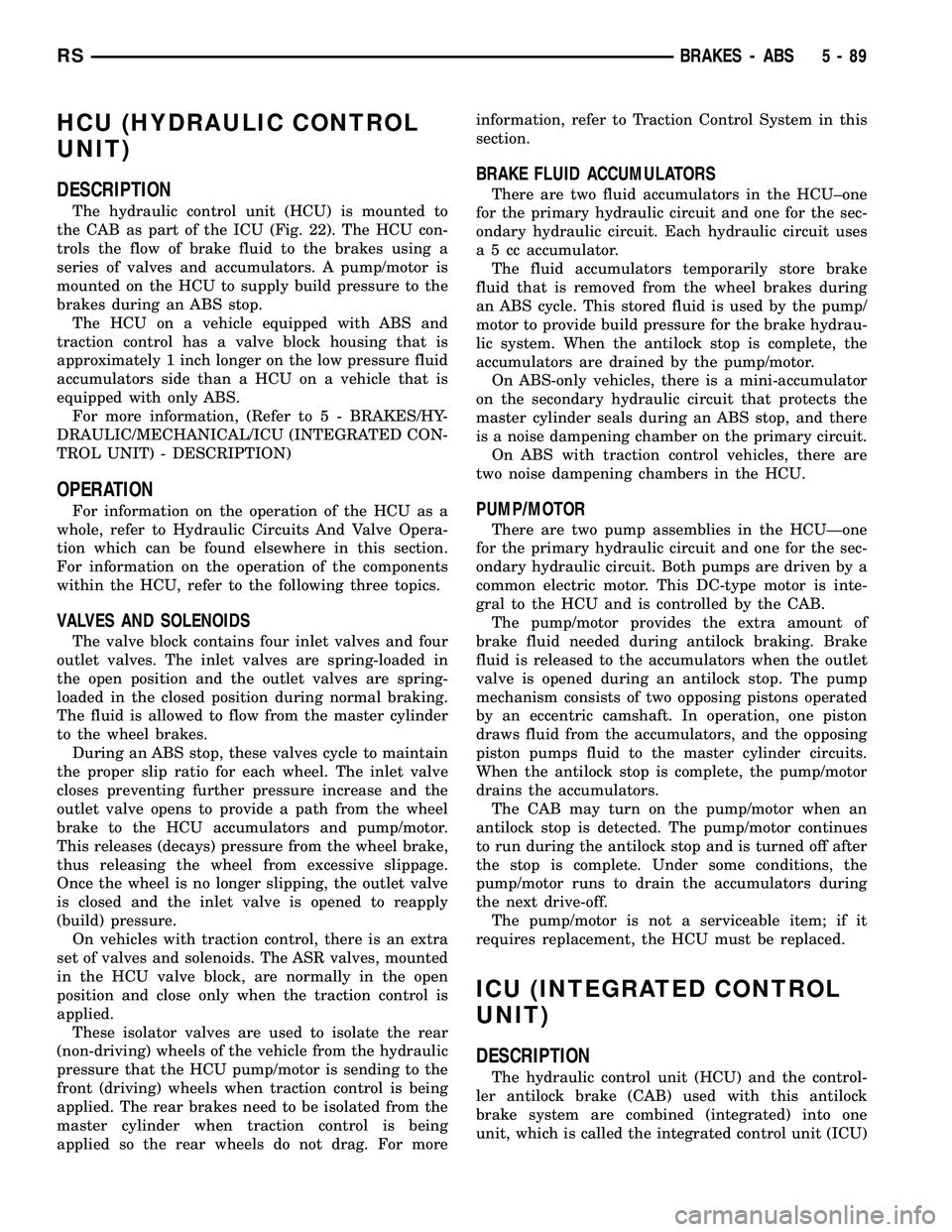

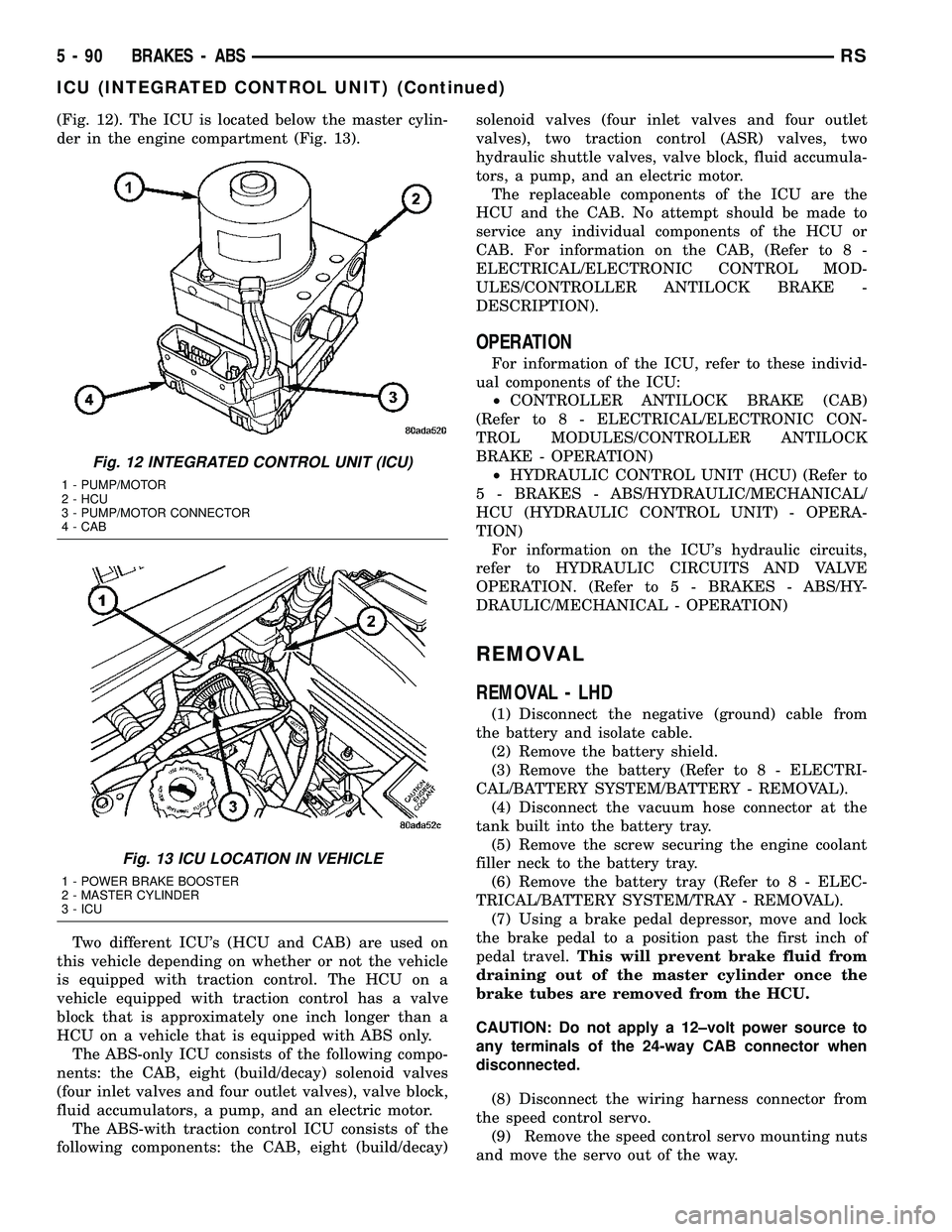

(Fig. 12). The ICU is located below the master cylin-

der in the engine compartment (Fig. 13).

Two different ICU's (HCU and CAB) are used on

this vehicle depending on whether or not the vehicle

is equipped with traction control. The HCU on a

vehicle equipped with traction control has a valve

block that is approximately one inch longer than a

HCU on a vehicle that is equipped with ABS only.

The ABS-only ICU consists of the following compo-

nents: the CAB, eight (build/decay) solenoid valves

(four inlet valves and four outlet valves), valve block,

fluid accumulators, a pump, and an electric motor.

The ABS-with traction control ICU consists of the

following components: the CAB, eight (build/decay)solenoid valves (four inlet valves and four outlet

valves), two traction control (ASR) valves, two

hydraulic shuttle valves, valve block, fluid accumula-

tors, a pump, and an electric motor.

The replaceable components of the ICU are the

HCU and the CAB. No attempt should be made to

service any individual components of the HCU or

CAB. For information on the CAB, (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/CONTROLLER ANTILOCK BRAKE -

DESCRIPTION).

OPERATION

For information of the ICU, refer to these individ-

ual components of the ICU:

²CONTROLLER ANTILOCK BRAKE (CAB)

(Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/CONTROLLER ANTILOCK

BRAKE - OPERATION)

²HYDRAULIC CONTROL UNIT (HCU) (Refer to

5 - BRAKES - ABS/HYDRAULIC/MECHANICAL/

HCU (HYDRAULIC CONTROL UNIT) - OPERA-

TION)

For information on the ICU's hydraulic circuits,

refer to HYDRAULIC CIRCUITS AND VALVE

OPERATION. (Refer to 5 - BRAKES - ABS/HY-

DRAULIC/MECHANICAL - OPERATION)

REMOVAL

REMOVAL - LHD

(1) Disconnect the negative (ground) cable from

the battery and isolate cable.

(2) Remove the battery shield.

(3) Remove the battery (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - REMOVAL).

(4) Disconnect the vacuum hose connector at the

tank built into the battery tray.

(5) Remove the screw securing the engine coolant

filler neck to the battery tray.

(6) Remove the battery tray (Refer to 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - REMOVAL).

(7) Using a brake pedal depressor, move and lock

the brake pedal to a position past the first inch of

pedal travel.This will prevent brake fluid from

draining out of the master cylinder once the

brake tubes are removed from the HCU.

CAUTION: Do not apply a 12±volt power source to

any terminals of the 24-way CAB connector when

disconnected.

(8) Disconnect the wiring harness connector from

the speed control servo.

(9) Remove the speed control servo mounting nuts

and move the servo out of the way.

Fig. 12 INTEGRATED CONTROL UNIT (ICU)

1 - PUMP/MOTOR

2 - HCU

3 - PUMP/MOTOR CONNECTOR

4 - CAB

Fig. 13 ICU LOCATION IN VEHICLE

1 - POWER BRAKE BOOSTER

2 - MASTER CYLINDER

3 - ICU

5 - 90 BRAKES - ABSRS

ICU (INTEGRATED CONTROL UNIT) (Continued)

Page 239 of 2585

(2) Using a brake pedal depressor, move and lock

the brake pedal to a position past the first inch of

pedal travel.This will prevent brake fluid from

draining out of the master cylinder when the

brake tubes are removed from the HCU.

(3) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

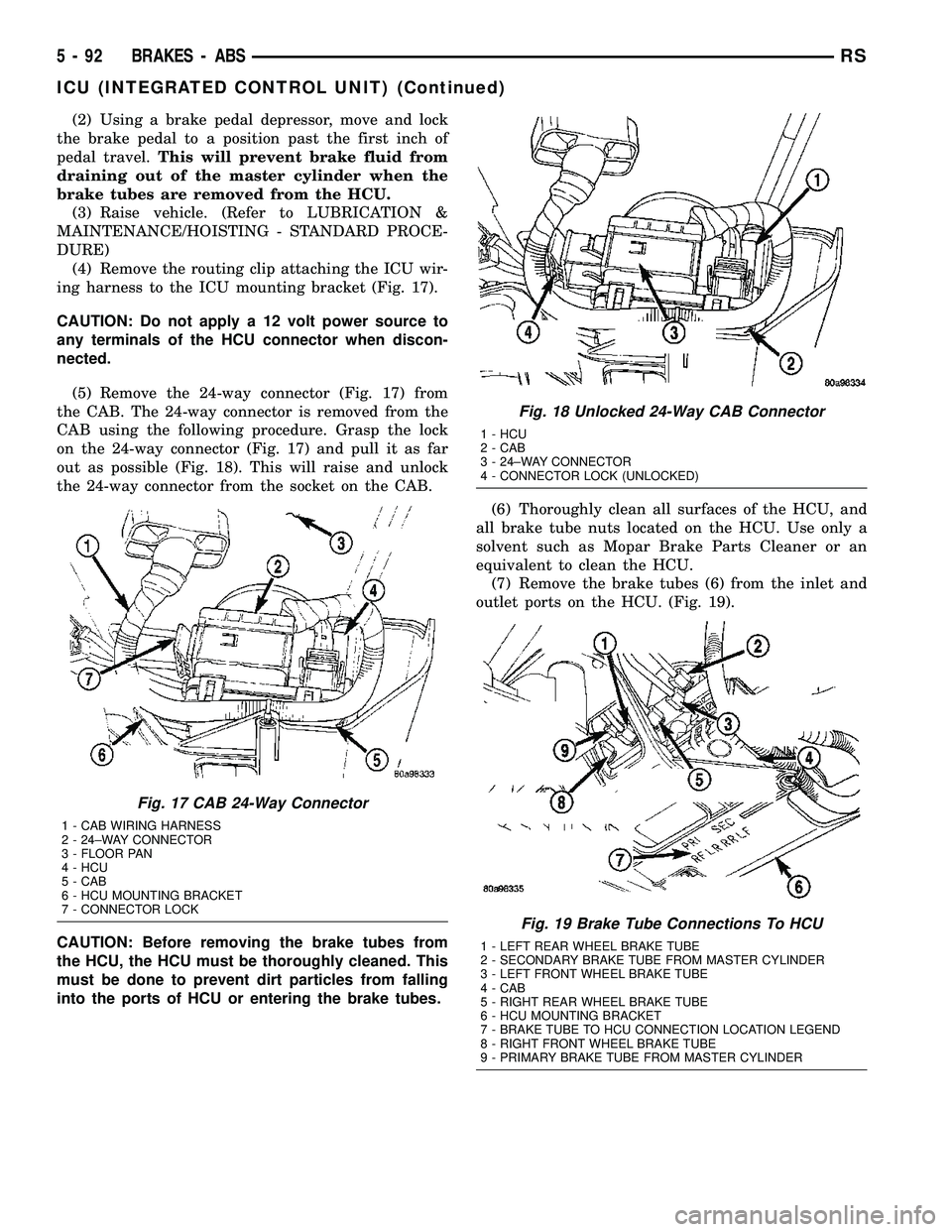

(4) Remove the routing clip attaching the ICU wir-

ing harness to the ICU mounting bracket (Fig. 17).

CAUTION: Do not apply a 12 volt power source to

any terminals of the HCU connector when discon-

nected.

(5) Remove the 24-way connector (Fig. 17) from

the CAB. The 24-way connector is removed from the

CAB using the following procedure. Grasp the lock

on the 24-way connector (Fig. 17) and pull it as far

out as possible (Fig. 18). This will raise and unlock

the 24-way connector from the socket on the CAB.

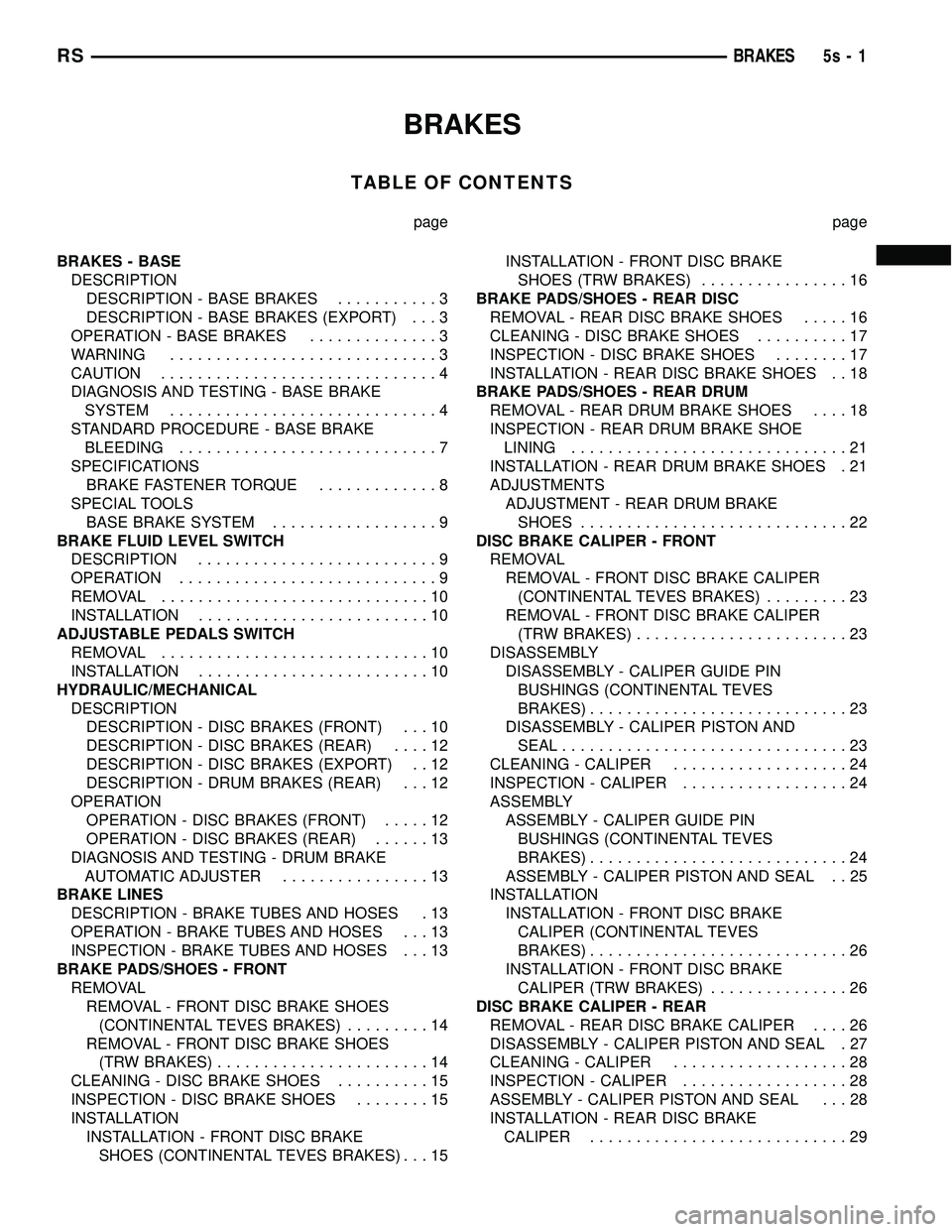

CAUTION: Before removing the brake tubes from

the HCU, the HCU must be thoroughly cleaned. This

must be done to prevent dirt particles from falling

into the ports of HCU or entering the brake tubes.(6) Thoroughly clean all surfaces of the HCU, and

all brake tube nuts located on the HCU. Use only a

solvent such as Mopar Brake Parts Cleaner or an

equivalent to clean the HCU.

(7) Remove the brake tubes (6) from the inlet and

outlet ports on the HCU. (Fig. 19).

Fig. 17 CAB 24-Way Connector

1 - CAB WIRING HARNESS

2 - 24±WAY CONNECTOR

3 - FLOOR PAN

4 - HCU

5 - CAB

6 - HCU MOUNTING BRACKET

7 - CONNECTOR LOCK

Fig. 18 Unlocked 24-Way CAB Connector

1 - HCU

2 - CAB

3 - 24±WAY CONNECTOR

4 - CONNECTOR LOCK (UNLOCKED)

Fig. 19 Brake Tube Connections To HCU

1 - LEFT REAR WHEEL BRAKE TUBE

2 - SECONDARY BRAKE TUBE FROM MASTER CYLINDER

3 - LEFT FRONT WHEEL BRAKE TUBE

4 - CAB

5 - RIGHT REAR WHEEL BRAKE TUBE

6 - HCU MOUNTING BRACKET

7 - BRAKE TUBE TO HCU CONNECTION LOCATION LEGEND

8 - RIGHT FRONT WHEEL BRAKE TUBE

9 - PRIMARY BRAKE TUBE FROM MASTER CYLINDER

5 - 92 BRAKES - ABSRS

ICU (INTEGRATED CONTROL UNIT) (Continued)

Page 244 of 2585

BRAKES

TABLE OF CONTENTS

page page

BRAKES - BASE DESCRIPTION DESCRIPTION - BASE BRAKES ...........3

DESCRIPTION - BASE BRAKES (EXPORT) . . . 3

OPERATION - BASE BRAKES ..............3

WARNING .............................3

CAUTION ..............................4

DIAGNOSIS AND TESTING - BASE BRAKE SYSTEM .............................4

STANDARD PROCEDURE - BASE BRAKE BLEEDING ............................7

SPECIFICATIONS BRAKE FASTENER TORQUE .............8

SPECIAL TOOLS BASE BRAKE SYSTEM ..................9

BRAKE FLUID LEVEL SWITCH DESCRIPTION ..........................9

OPERATION ............................9

REMOVAL .............................10

INSTALLATION .........................10

ADJUSTABLE PEDALS SWITCH REMOVAL .............................10

INSTALLATION .........................10

HYDRAULIC/MECHANICAL DESCRIPTION DESCRIPTION - DISC BRAKES (FRONT) . . . 10

DESCRIPTION - DISC BRAKES (REAR) ....12

DESCRIPTION - DISC BRAKES (EXPORT) . . 12

DESCRIPTION - DRUM BRAKES (REAR) . . . 12

OPERATION OPERATION - DISC BRAKES (FRONT) .....12

OPERATION - DISC BRAKES (REAR) ......13

DIAGNOSIS AND TESTING - DRUM BRAKE AUTOMATIC ADJUSTER ................13

BRAKE LINES DESCRIPTION - BRAKE TUBES AND HOSES . 13

OPERATION - BRAKE TUBES AND HOSES . . . 13

INSPECTION - BRAKE TUBES AND HOSES . . . 13

BRAKE PADS/SHOES - FRONT REMOVAL REMOVAL - FRONT DISC BRAKE SHOES(CONTINENTAL TEVES BRAKES) .........14

REMOVAL - FRONT DISC BRAKE SHOES (TRW BRAKES) .......................14

CLEANING - DISC BRAKE SHOES ..........15

INSPECTION - DISC BRAKE SHOES ........15

INSTALLATION INSTALLATION - FRONT DISC BRAKESHOES (CONTINENTAL TEVES BRAKES) . . . 15 INSTALLATION - FRONT DISC BRAKE

SHOES (TRW BRAKES) ................16

BRAKE PADS/SHOES - REAR DISC REMOVAL - REAR DISC BRAKE SHOES .....16

CLEANING - DISC BRAKE SHOES ..........17

INSPECTION - DISC BRAKE SHOES ........17

INSTALLATION - REAR DISC BRAKE SHOES . . 18

BRAKE PADS/SHOES - REAR DRUM REMOVAL - REAR DRUM BRAKE SHOES ....18

INSPECTION - REAR DRUM BRAKE SHOE LINING ..............................21

INSTALLATION - REAR DRUM BRAKE SHOES . 21

ADJUSTMENTS ADJUSTMENT - REAR DRUM BRAKESHOES .............................22

DISC BRAKE CALIPER - FRONT REMOVAL REMOVAL - FRONT DISC BRAKE CALIPER(CONTINENTAL TEVES BRAKES) .........23

REMOVAL - FRONT DISC BRAKE CALIPER (TRW BRAKES) .......................23

DISASSEMBLY DISASSEMBLY - CALIPER GUIDE PINBUSHINGS (CONTINENTAL TEVES

BRAKES) ............................23

DISASSEMBLY - CALIPER PISTON AND SEAL ...............................23

CLEANING - CALIPER ...................24

INSPECTION - CALIPER ..................24

ASSEMBLY ASSEMBLY - CALIPER GUIDE PINBUSHINGS (CONTINENTAL TEVES

BRAKES) ............................24

ASSEMBLY - CALIPER PISTON AND SEAL . . 25

INSTALLATION INSTALLATION - FRONT DISC BRAKECALIPER (CONTINENTAL TEVES

BRAKES) ............................26

INSTALLATION - FRONT DISC BRAKE CALIPER (TRW BRAKES) ...............26

DISC BRAKE CALIPER - REAR REMOVAL - REAR DISC BRAKE CALIPER ....26

DISASSEMBLY - CALIPER PISTON AND SEAL . 27

CLEANING - CALIPER ...................28

INSPECTION - CALIPER ..................28

ASSEMBLY - CALIPER PISTON AND SEAL . . . 28

INSTALLATION - REAR DISC BRAKE CALIPER ............................29

RS BRAKES5s-1

Page 245 of 2585

DISC BRAKE CALIPER ADAPTERREMOVAL - FRONT DISC BRAKE CALIPERADAPTER ...........................30

INSTALLATION - FRONT DISC BRAKE CALIPER ADAPTER ....................30

DISC BRAKE CALIPER GUIDE PINS REMOVAL - DISC BRAKE CALIPER GUIDEPINS (TRW BRAKES) ..................30

INSTALLATION - DISC BRAKE CALIPER GUIDE PINS (TRW BRAKES) .............30

DRUM REMOVAL .............................31

INSTALLATION .........................31

FLUID DIAGNOSIS AND TESTING - BRAKE FLUIDCONTAMINATION .....................31

STANDARD PROCEDURE - BRAKE FLUID LEVEL CHECKING .....................31

SPECIFICATIONS BRAKE FLUID ........................32

JUNCTION BLOCK DESCRIPTION - NON-ABS JUNCTION BLOCK . 32

OPERATION - NON-ABS JUNCTION BLOCK . . 32

REMOVAL - NON-ABS JUNCTION BLOCK ....32

INSTALLATION - NON-ABS JUNCTION BLOCK . 32

MASTER CYLINDER DESCRIPTION DESCRIPTION ........................33

DESCRIPTION - RHD ..................34

OPERATION ...........................34

STANDARD PROCEDURE - MASTER CYLINDER BLEEDING ..................34

REMOVAL REMOVAL - LHD ......................35

REMOVAL - RHD ......................36

DISASSEMBLY - MASTER CYLINDER (FLUID RESERVOIR) .........................36

ASSEMBLY - MASTER CYLINDER (FLUID RESERVOIR) .........................37

INSTALLATION INSTALLATION - LHD ..................37

INSTALLATION - RHD ..................38

PEDALS - ADJUSTABLE REMOVAL .............................38

INSTALLATION .........................40

PEDAL TORQUE SHAFT - RHD REMOVAL .............................42

INSTALLATION .........................43

POWER BRAKE BOOSTER DESCRIPTION .........................43

OPERATION ...........................44

DIAGNOSIS AND TESTING - POWER BRAKE BOOSTER ...........................44

REMOVAL REMOVAL - LHD ......................45

REMOVAL - RHD ......................47 INSTALLATION

INSTALLATION - LHD ..................49

INSTALLATION - RHD ..................50

PROPORTIONING VALVE DESCRIPTION - PROPORTIONING VALVE(HEIGHT SENSING) ....................51

OPERATION - PROPORTIONING VALVE (HEIGHT SENSING) ....................51

DIAGNOSIS AND TESTING - PROPORTIONING VALVE (HEIGHT

SENSING) ...........................52

REMOVAL - PROPORTIONING VALVE (HEIGHT SENSING) ....................53

INSTALLATION - PROPORTIONING VALVE (HEIGHT SENSING) ....................53

ROTOR DIAGNOSIS AND TESTING - BRAKE ROTOR . . 54

STANDARD PROCEDURE - BRAKE ROTORMACHINING ..........................56

REMOVAL - FRONT BRAKE ROTOR ........57

INSTALLATION - FRONT BRAKE ROTOR .....57

SPECIFICATIONS BRAKE ROTOR .......................57

BRAKE ROTOR - EXPORT ..............58

SUPPORT PLATE - DRUM BRAKE REMOVAL .............................58

INSTALLATION .........................58

WHEEL CYLINDERS REMOVAL .............................59

INSPECTION ..........................59

INSTALLATION .........................60

PARKING BRAKE DESCRIPTION DESCRIPTION ........................60

DESCRIPTION - EXPORT ...............60

OPERATION ...........................60

STANDARD PROCEDURE STANDARD PROCEDURE - PARKINGBRAKE AUTOMATIC ADJUSTER TENSION

RELEASE ...........................61

STANDARD PROCEDURE - PARKING BRAKE AUTOMATIC ADJUSTER TENSION

RESET .............................61

CABLES - PARKING BRAKE REMOVAL REMOVAL - PARKING BRAKE CABLE(FRONT) ............................62

REMOVAL - PARKING BRAKE CABLE (INTERMEDIATE) ......................62

REMOVAL - PARKING BRAKE CABLE (RIGHT REAR) ........................63

REMOVAL - PARKING BRAKE CABLE (LEFT REAR )..............................64

INSTALLATION INSTALLATION - PARKING BRAKE CABLE(FRONT) ............................65

5s - 2 BRAKESRS

Page 246 of 2585

INSTALLATION - PARKING BRAKE CABLE(INTERMEDIATE) ......................66

INSTALLATION - PARKING BRAKE CABLE (RIGHT REAR) ........................66

INSTALLATION - PARKING BRAKE CABLE (LEFT REAR) .........................66

ADJUSTMENTS ADJUSTMENT - PARKING BRAKE CABLES . 66

CABLES - PARKING BRAKE (EXPORT) REMOVAL - FRONT CABLE ...............67

INSTALLATION - FRONT CABLE ............67

LEVER - PARKING BRAKE REMOVAL .............................67 INSTALLATION

.........................67

LEVER - PARKING BRAKE (EXPORT) REMOVAL - PARKING BRAKE LEVER ANDFRONT CABLE .......................68

INSTALLATION - PARKING BRAKE LEVER AND FRONT CABLE ...................69

SHOES - PARKING BRAKE REMOVAL .............................69

INSTALLATION .........................75

ADJUSTMENTS ADJUSTMENT - PARKING BRAKE SHOES . . 76

BRAKES - BASE

DESCRIPTION

DESCRIPTION - BASE BRAKES

The base brake system consists of the following

components: ² Brake pedal

² Power brake booster

² Master cylinder

² Brake tubes and hoses

² Proportioning valve (non-ABS vehicles only)

² Disc brakes

² Drum brakes

² Brake lamp switch

² Brake fluid level switch

² Parking brakes

Front disc brakes control the braking of the front

wheels; rear braking is controlled by rear drum

brakes or rear disc brakes depending on options. The hydraulic brake system is diagonally split on

both the non-antilock braking systems and antilock

braking systems. That means the left front and right

rear brakes are on one hydraulic circuit and the right

front and left rear are on the other. For information on the brake lamp switch, (Refer

to 8 - ELECTRICAL/LAMPS/LIGHTING - EXTERI-

OR/BRAKE LAMP SWITCH - DESCRIPTION) Vehicles equipped with the optional antilock brake

system (ABS) use a system designated Mark 20e. It

is available with or without traction control. This

system shares most base brake hardware used on

vehicles without ABS. ABS components are described

in detail in ANTILOCK BRAKE SYSTEM.

DESCRIPTION - BASE BRAKES (EXPORT)

Four-Wheel Disc Antilock Brakes are standard on

all models.

OPERATION - BASE BRAKES

When a vehicle needs to be stopped, the driver

applies the brake pedal. The brake pedal pushes the

input rod of the power brake booster into the booster.

The booster uses vacuum to ease pedal effort as force

is transferred through the booster to the master cyl-

inder. The booster's output rod pushes in the master

cylinder's primary and secondary pistons applying

hydraulic pressure through the chassis brake tubes

to the brakes at each tire and wheel assembly. The parking brakes are foot-operated. When

applied, the parking brake lever pulls on cables that

actuate brake shoes at each rear wheel. These shoes

come in contact with a hub mounted drum (drum for

disc/drum brakes or drum-in-hat for disc/disc brakes)

and hold it in place.

WARNING

WARNING: DUST AND DIRT ACCUMULATING ON

BRAKE PARTS DURING NORMAL USE MAY CON-

TAIN ASBESTOS FIBERS FROM PRODUCTION OR

AFTERMARKET BRAKE LININGS. BREATHING

EXCESSIVE CONCENTRATIONS OF ASBESTOS

FIBERS CAN CAUSE SERIOUS BODILY HARM.

EXERCISE CARE WHEN SERVICING BRAKE

PARTS. DO NOT SAND OR GRIND BRAKE LINING

UNLESS EQUIPMENT USED IS DESIGNED TO CON-

TAIN THE DUST RESIDUE. DO NOT CLEAN BRAKE

PARTS WITH COMPRESSED AIR OR BY DRY

BRUSHING. CLEANING SHOULD BE DONE BY

DAMPENING THE BRAKE COMPONENTS WITH A

FINE MIST OF WATER, THEN WIPING THE BRAKE

COMPONENTS CLEAN WITH A DAMPENED CLOTH.

DISPOSE OF CLOTH AND ALL RESIDUE CONTAIN-

ING ASBESTOS FIBERS IN AN IMPERMEABLE

CONTAINER WITH THE APPROPRIATE LABEL. FOL-

LOW PRACTICES PRESCRIBED BY THE OCCUPA-

TIONAL SAFETY AND HEALTH ADMINISTRATION

(OSHA) AND THE ENVIRONMENTAL PROTECTION

AGENCY (EPA) FOR THE HANDLING, PROCESSING,

AND DISPOSING OF DUST OR DEBRIS THAT MAY

CONTAIN ASBESTOS FIBERS.

RS BRAKES5s-3