8e electrical CHRYSLER VOYAGER 2004 Manual Online

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 460 of 2585

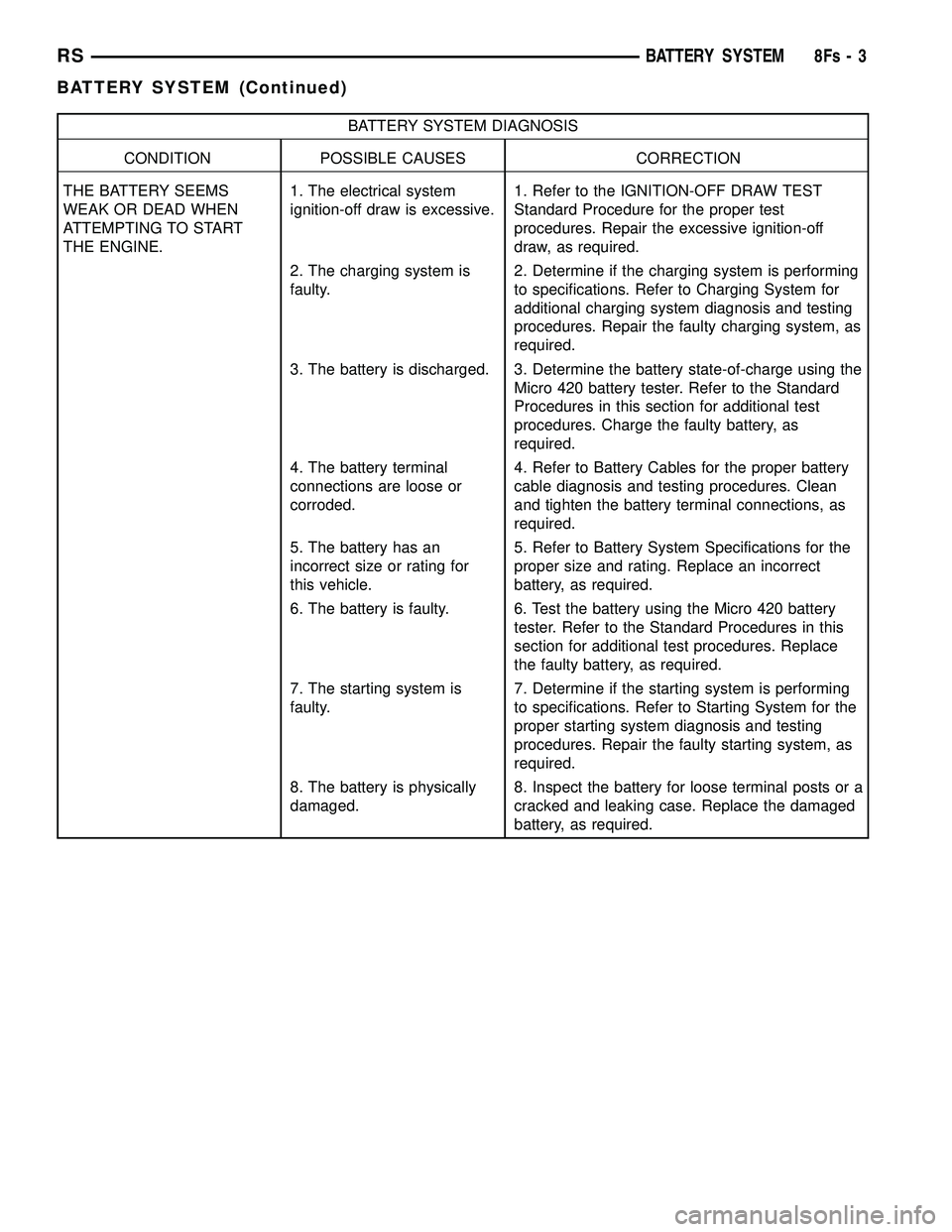

BATTERY SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

THE BATTERY SEEMS

WEAK OR DEAD WHEN

ATTEMPTING TO START

THE ENGINE. 1. The electrical system

ignition-off draw is excessive.

1. Refer to the IGNITION-OFF DRAW TEST

Standard Procedure for the proper test

procedures. Repair the excessive ignition-off

draw, as required.

2. The charging system is

faulty. 2. Determine if the charging system is performing

to specifications. Refer to Charging System for

additional charging system diagnosis and testing

procedures. Repair the faulty charging system, as

required.

3. The battery is discharged. 3. Determine the battery state-of-charge using the Micro 420 battery tester. Refer to the Standard

Procedures in this section for additional test

procedures. Charge the faulty battery, as

required.

4. The battery terminal

connections are loose or

corroded. 4. Refer to Battery Cables for the proper battery

cable diagnosis and testing procedures. Clean

and tighten the battery terminal connections, as

required.

5. The battery has an

incorrect size or rating for

this vehicle. 5. Refer to Battery System Specifications for the

proper size and rating. Replace an incorrect

battery, as required.

6. The battery is faulty. 6. Test the battery using the Micro 420 battery tester. Refer to the Standard Procedures in this

section for additional test procedures. Replace

the faulty battery, as required.

7. The starting system is

faulty. 7. Determine if the starting system is performing

to specifications. Refer to Starting System for the

proper starting system diagnosis and testing

procedures. Repair the faulty starting system, as

required.

8. The battery is physically

damaged. 8. Inspect the battery for loose terminal posts or a

cracked and leaking case. Replace the damaged

battery, as required.

RS

BATTERY SYSTEM8Fs-3

BATTERY SYSTEM (Continued)

Page 461 of 2585

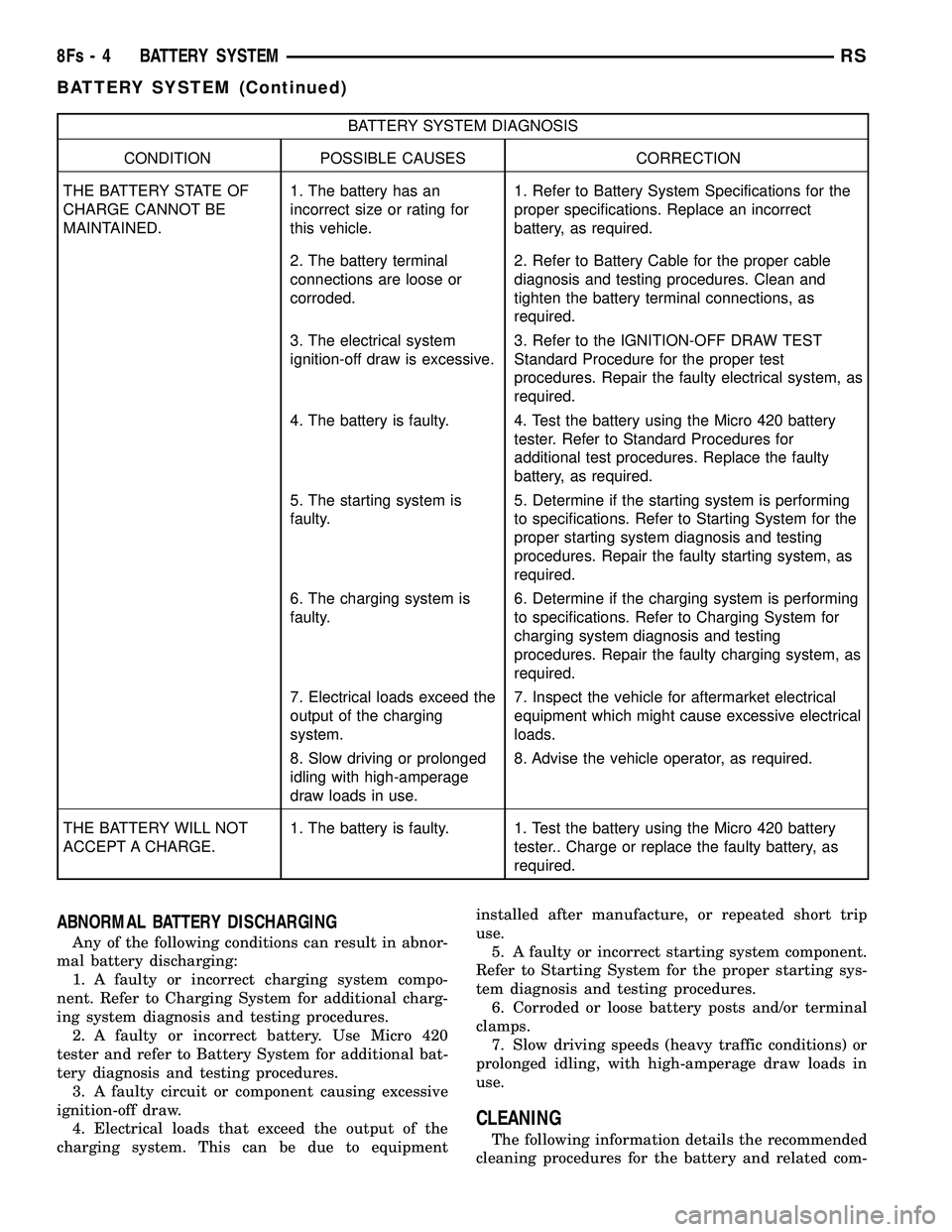

BATTERY SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

THE BATTERY STATE OF

CHARGE CANNOT BE

MAINTAINED. 1. The battery has an

incorrect size or rating for

this vehicle.1. Refer to Battery System Specifications for the

proper specifications. Replace an incorrect

battery, as required.

2. The battery terminal

connections are loose or

corroded. 2. Refer to Battery Cable for the proper cable

diagnosis and testing procedures. Clean and

tighten the battery terminal connections, as

required.

3. The electrical system

ignition-off draw is excessive. 3. Refer to the IGNITION-OFF DRAW TEST

Standard Procedure for the proper test

procedures. Repair the faulty electrical system, as

required.

4. The battery is faulty. 4. Test the battery using the Micro 420 battery tester. Refer to Standard Procedures for

additional test procedures. Replace the faulty

battery, as required.

5. The starting system is

faulty. 5. Determine if the starting system is performing

to specifications. Refer to Starting System for the

proper starting system diagnosis and testing

procedures. Repair the faulty starting system, as

required.

6. The charging system is

faulty. 6. Determine if the charging system is performing

to specifications. Refer to Charging System for

charging system diagnosis and testing

procedures. Repair the faulty charging system, as

required.

7. Electrical loads exceed the

output of the charging

system. 7. Inspect the vehicle for aftermarket electrical

equipment which might cause excessive electrical

loads.

8. Slow driving or prolonged

idling with high-amperage

draw loads in use. 8. Advise the vehicle operator, as required.

THE BATTERY WILL NOT

ACCEPT A CHARGE. 1. The battery is faulty. 1. Test the battery using the Micro 420 battery

tester.. Charge or replace the faulty battery, as

required.

ABNORMAL BATTERY DISCHARGING

Any of the following conditions can result in abnor-

mal battery discharging: 1. A faulty or incorrect charging system compo-

nent. Refer to Charging System for additional charg-

ing system diagnosis and testing procedures. 2. A faulty or incorrect battery. Use Micro 420

tester and refer to Battery System for additional bat-

tery diagnosis and testing procedures. 3. A faulty circuit or component causing excessive

ignition-off draw. 4. Electrical loads that exceed the output of the

charging system. This can be due to equipment installed after manufacture, or repeated short trip

use.

5. A faulty or incorrect starting system component.

Refer to Starting System for the proper starting sys-

tem diagnosis and testing procedures. 6. Corroded or loose battery posts and/or terminal

clamps. 7. Slow driving speeds (heavy traffic conditions) or

prolonged idling, with high-amperage draw loads in

use.

CLEANING

The following information details the recommended

cleaning procedures for the battery and related com-

8Fs - 4 BATTERY SYSTEMRS

BATTERY SYSTEM (Continued)

Page 463 of 2585

INSPECTION

The following information details the recommended

inspection procedures for the battery and related

components. In addition to the maintenance sched-

ules found in this service manual and the owner's

manual, it is recommended that these procedures be

performed any time the battery or related compo-

nents must be removed for vehicle service. (1) Inspect the battery cable terminal clamps for

damage. Replace any battery cable that has a dam-

aged or deformed terminal clamp. (2) Inspect the battery tray and battery holddown

hardware for damage. Replace any damaged parts. (3) Slide the thermowrap off of the battery case.

Inspect the battery case for cracks or other damage

that could result in electrolyte leaks. Also, check the

battery terminal posts for looseness. Batteries with

damaged cases or loose terminal posts must be

replaced. (4) Inspect the battery thermowrap for tears,

cracks, deformation or other damage. Replace any

battery thermal guard that has been damaged. (5) Inspect the battery built-in test indicator sight

glass(if equipped) for an indication of the battery con-

dition. If the battery is discharged, charge as

required. Refer to Standard Procedures for the

proper battery built-in indicator test procedures. Also

refer to Standard Procedures for the proper battery

charging procedures.

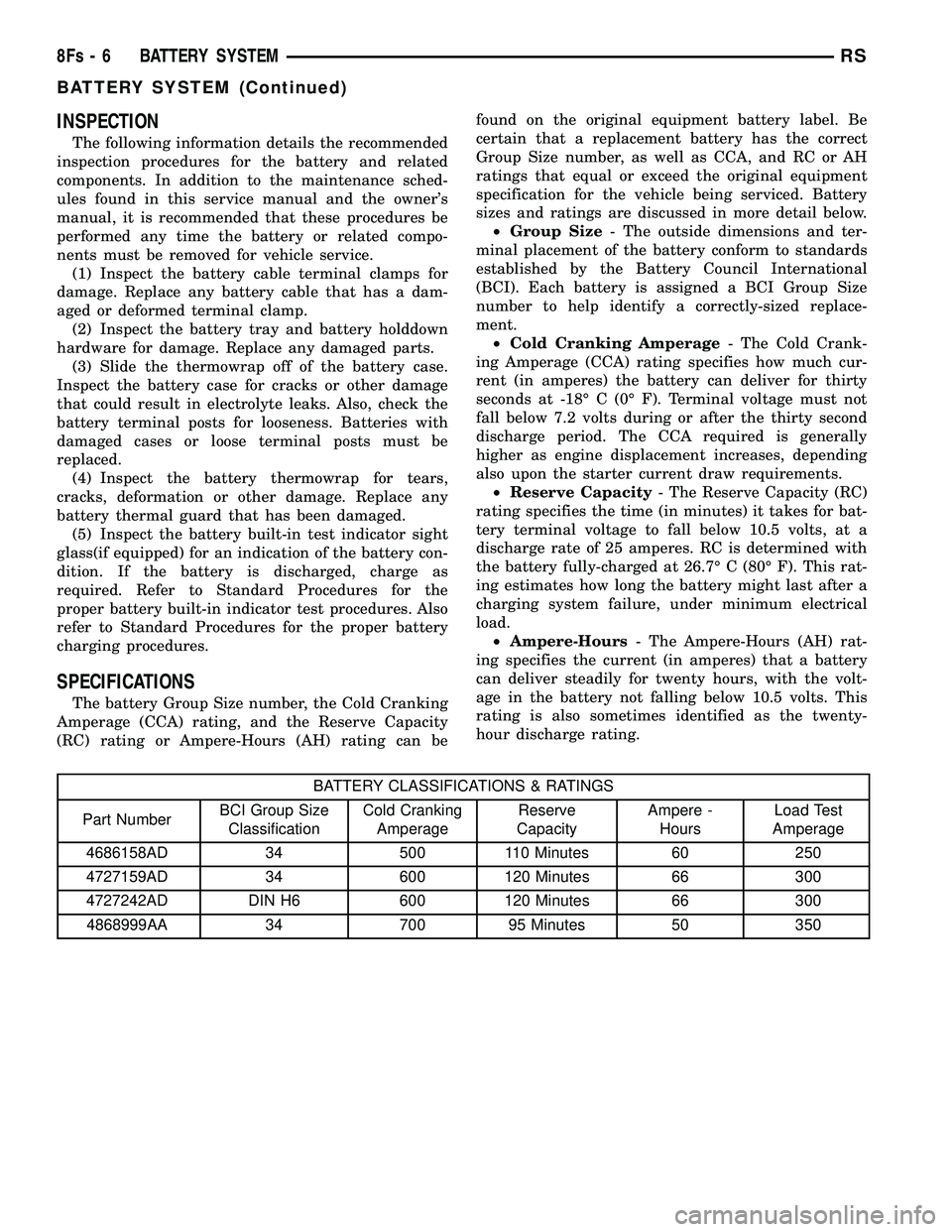

SPECIFICATIONS

The battery Group Size number, the Cold Cranking

Amperage (CCA) rating, and the Reserve Capacity

(RC) rating or Ampere-Hours (AH) rating can be found on the original equipment battery label. Be

certain that a replacement battery has the correct

Group Size number, as well as CCA, and RC or AH

ratings that equal or exceed the original equipment

specification for the vehicle being serviced. Battery

sizes and ratings are discussed in more detail below.

² Group Size - The outside dimensions and ter-

minal placement of the battery conform to standards

established by the Battery Council International

(BCI). Each battery is assigned a BCI Group Size

number to help identify a correctly-sized replace-

ment. ² Cold Cranking Amperage - The Cold Crank-

ing Amperage (CCA) rating specifies how much cur-

rent (in amperes) the battery can deliver for thirty

seconds at -18É C (0É F). Terminal voltage must not

fall below 7.2 volts during or after the thirty second

discharge period. The CCA required is generally

higher as engine displacement increases, depending

also upon the starter current draw requirements. ² Reserve Capacity - The Reserve Capacity (RC)

rating specifies the time (in minutes) it takes for bat-

tery terminal voltage to fall below 10.5 volts, at a

discharge rate of 25 amperes. RC is determined with

the battery fully-charged at 26.7É C (80É F). This rat-

ing estimates how long the battery might last after a

charging system failure, under minimum electrical

load. ² Ampere-Hours - The Ampere-Hours (AH) rat-

ing specifies the current (in amperes) that a battery

can deliver steadily for twenty hours, with the volt-

age in the battery not falling below 10.5 volts. This

rating is also sometimes identified as the twenty-

hour discharge rating.

BATTERY CLASSIFICATIONS & RATINGS

Part Number BCI Group Size

Classification Cold Cranking

Amperage Reserve

Capacity Ampere -

Hours Load Test

Amperage

4686158AD 34 500 110 Minutes 60 250

4727159AD 34 600 120 Minutes 66 300

4727242AD DIN H6 600 120 Minutes 66 300 4868999AA 34 700 95 Minutes 50 350

8Fs - 6 BATTERY SYSTEMRS

BATTERY SYSTEM (Continued)

Page 465 of 2585

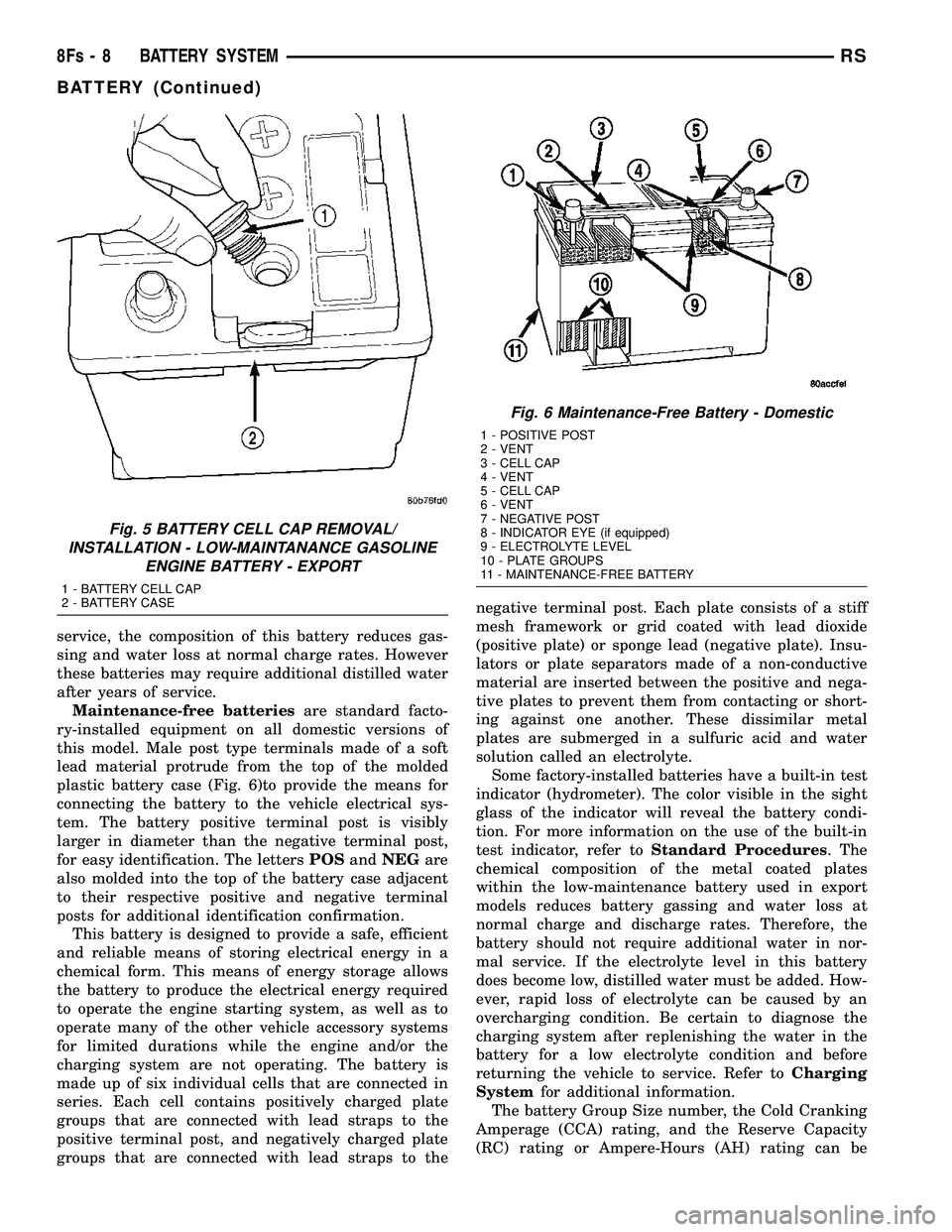

service, the composition of this battery reduces gas-

sing and water loss at normal charge rates. However

these batteries may require additional distilled water

after years of service.Maintenance-free batteries are standard facto-

ry-installed equipment on all domestic versions of

this model. Male post type terminals made of a soft

lead material protrude from the top of the molded

plastic battery case (Fig. 6)to provide the means for

connecting the battery to the vehicle electrical sys-

tem. The battery positive terminal post is visibly

larger in diameter than the negative terminal post,

for easy identification. The letters POSandNEG are

also molded into the top of the battery case adjacent

to their respective positive and negative terminal

posts for additional identification confirmation. This battery is designed to provide a safe, efficient

and reliable means of storing electrical energy in a

chemical form. This means of energy storage allows

the battery to produce the electrical energy required

to operate the engine starting system, as well as to

operate many of the other vehicle accessory systems

for limited durations while the engine and/or the

charging system are not operating. The battery is

made up of six individual cells that are connected in

series. Each cell contains positively charged plate

groups that are connected with lead straps to the

positive terminal post, and negatively charged plate

groups that are connected with lead straps to the negative terminal post. Each plate consists of a stiff

mesh framework or grid coated with lead dioxide

(positive plate) or sponge lead (negative plate). Insu-

lators or plate separators made of a non-conductive

material are inserted between the positive and nega-

tive plates to prevent them from contacting or short-

ing against one another. These dissimilar metal

plates are submerged in a sulfuric acid and water

solution called an electrolyte.

Some factory-installed batteries have a built-in test

indicator (hydrometer). The color visible in the sight

glass of the indicator will reveal the battery condi-

tion. For more information on the use of the built-in

test indicator, refer to Standard Procedures . The

chemical composition of the metal coated plates

within the low-maintenance battery used in export

models reduces battery gassing and water loss at

normal charge and discharge rates. Therefore, the

battery should not require additional water in nor-

mal service. If the electrolyte level in this battery

does become low, distilled water must be added. How-

ever, rapid loss of electrolyte can be caused by an

overcharging condition. Be certain to diagnose the

charging system after replenishing the water in the

battery for a low electrolyte condition and before

returning the vehicle to service. Refer to Charging

System for additional information.

The battery Group Size number, the Cold Cranking

Amperage (CCA) rating, and the Reserve Capacity

(RC) rating or Ampere-Hours (AH) rating can be

Fig. 5 BATTERY CELL CAP REMOVAL/

INSTALLATION - LOW-MAINTANANCE GASOLINE ENGINE BATTERY - EXPORT

1 - BATTERY CELL CAP

2 - BATTERY CASE

Fig. 6 Maintenance-Free Battery - Domestic

1 - POSITIVE POST

2 - VENT

3 - CELL CAP

4 - VENT

5 - CELL CAP

6 - VENT

7 - NEGATIVE POST

8 - INDICATOR EYE (if equipped)

9 - ELECTROLYTE LEVEL

10 - PLATE GROUPS

11 - MAINTENANCE-FREE BATTERY

8Fs - 8 BATTERY SYSTEMRS

BATTERY (Continued)

Page 466 of 2585

found on the original equipment battery label. Be

certain that a replacement battery has the correct

Group Size number, as well as CCA, and RC or AH

ratings that equal or exceed the original equipment

specification for the vehicle being serviced. Refer to

Battery Specificationsin this group for the loca-

tion of the proper factory-installed battery specifica-

tions.

OPERATION

The battery is designed to store electrical energy in

a chemical form. When an electrical load is applied to

the terminals of the battery, an electrochemical reac-

tion occurs. This reaction causes the battery to dis-

charge electrical current from its terminals. As the

battery discharges, a gradual chemical change takes

place within each cell. The sulfuric acid in the elec-

trolyte combines with the plate materials, causing

both plates to slowly change to lead sulfate. At the

same time, oxygen from the positive plate material

combines with hydrogen from the sulfuric acid, caus-

ing the electrolyte to become mainly water. The

chemical changes within the battery are caused by

the movement of excess or free electrons between the

positive and negative plate groups. This movement of

electrons produces a flow of electrical current

through the load device attached to the battery ter-

minals. As the plate materials become more similar chem-

ically, and the electrolyte becomes less acid, the volt-

age potential of each cell is reduced. However, by

charging the battery with a voltage higher than that

of the battery itself, the battery discharging process

is reversed. Charging the battery gradually changes

the sulfated lead plates back into sponge lead and

lead dioxide, and the water back into sulfuric acid.

This action restores the difference in the electron

charges deposited on the plates, and the voltage

potential of the battery cells. For a battery to remain

useful, it must be able to produce high-amperage cur-

rent over an extended period. A battery must also be

able to accept a charge, so that its voltage potential

may be restored. The battery is vented to release excess hydrogen

gas that is created when the battery is being charged

or discharged. However, even with these vents,

hydrogen gas can collect in or around the battery. If

hydrogen gas is exposed to flame or sparks, it may

ignite. If the electrolyte level is low, the battery may

arc internally and explode. If the battery is equipped

with removable cell caps, add distilled water when-

ever the electrolyte level is below the top of the

plates. If the battery cell caps cannot be removed, the

battery must be replaced if the electrolyte level

becomes low.

DIAGNOSIS AND TESTING - BATTERY

The battery must be completely charged and the

terminals should be properly cleaned and inspected

before diagnostic procedures are performed. Refer to

Battery System Cleaning for the proper cleaning pro-

cedures, and Battery System Inspection for the

proper battery inspection procedures. Refer to Stan-

dard Procedures for the proper battery charging pro-

cedures.

MICRO 420 BATTERY TESTER

The Micro 420 automotive battery tester is

designed to help the dealership technicians diagnose

the cause of a defective battery. Follow the instruc-

tion manual supplied with the tester to properly

diagnose a vehicle. If the instruction manual is not

available refer to the standard procedure in this sec-

tion, which includes the directions for using the

Micro 420 battery tester.

WARNING: IF THE BATTERY SHOWS SIGNS OF

FREEZING, LEAKING OR LOOSE POSTS, DO NOT

TEST, ASSIST-BOOST, OR CHARGE. THE BATTERY

MAY ARC INTERNALLY AND EXPLODE. PERSONAL

INJURY AND/OR VEHICLE DAMAGE MAY RESULT.

WARNING: EXPLOSIVE HYDROGEN GAS FORMS IN

AND AROUND THE BATTERY. DO NOT SMOKE,

USE FLAME, OR CREATE SPARKS NEAR THE BAT-

TERY. PERSONAL INJURY AND/OR VEHICLE DAM-

AGE MAY RESULT.

WARNING: THE BATTERY CONTAINS SULFURIC

ACID, WHICH IS POISONOUS AND CAUSTIC. AVOID

CONTACT WITH THE SKIN, EYES, OR CLOTHING.

IN THE EVENT OF CONTACT, FLUSH WITH WATER

AND CALL A PHYSICIAN IMMEDIATELY. KEEP OUT

OF THE REACH OF CHILDREN.

A battery that will not accept a charge is faulty,

and must be replaced. Further testing is not

required. A fully-charged battery must be tested to

determine its cranking capacity. A battery that is ful-

ly-charged, but does not pass the Micro 420 or load

test, is faulty and must be replaced.

NOTE: Completely discharged batteries may take

several hours to accept a charge. Refer to Standard

Procedures for the proper battery charging proce-

dures.

RS BATTERY SYSTEM8Fs-9

BATTERY (Continued)

Page 468 of 2585

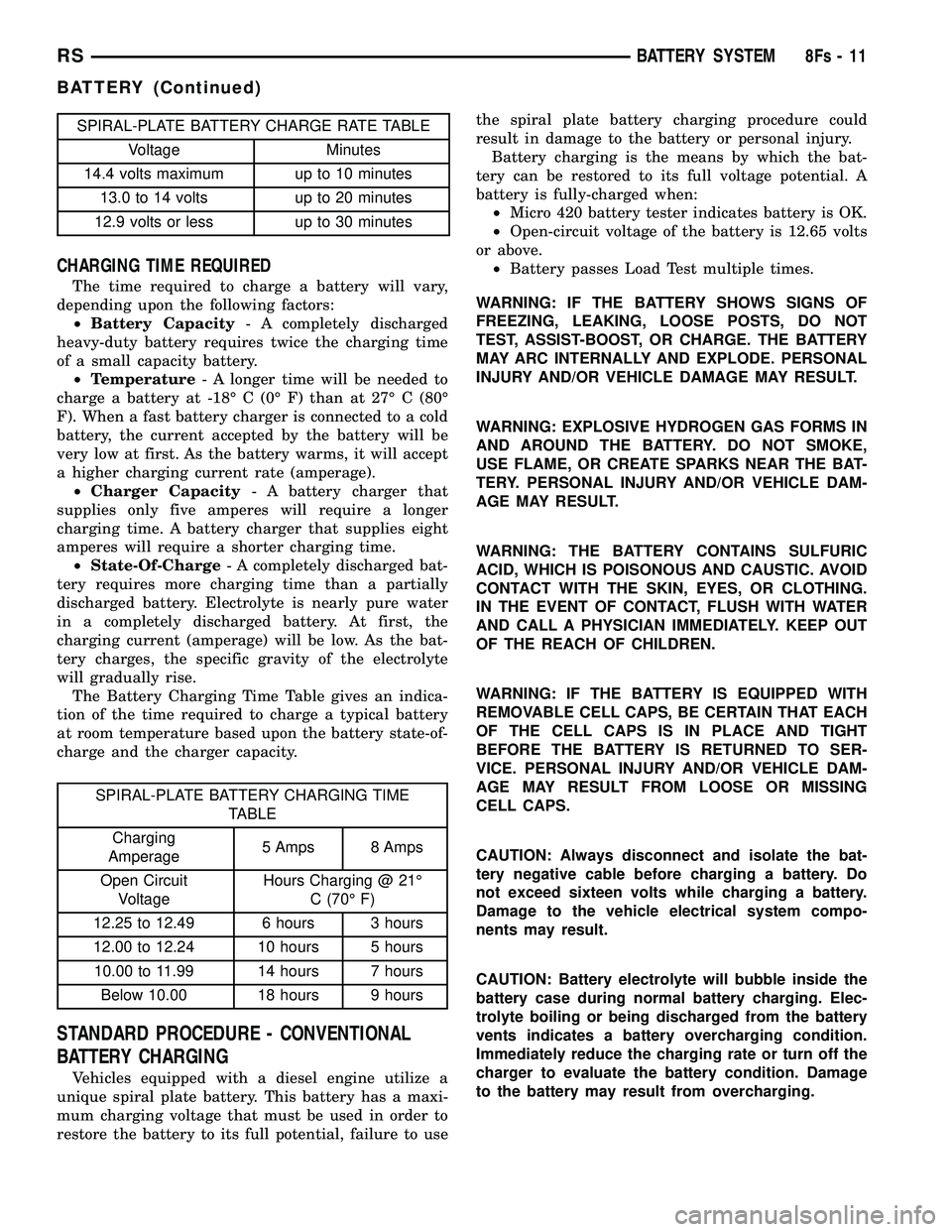

SPIRAL-PLATE BATTERY CHARGE RATE TABLEVoltage Minutes

14.4 volts maximum up to 10 minutes 13.0 to 14 volts up to 20 minutes

12.9 volts or less up to 30 minutes

CHARGING TIME REQUIRED

The time required to charge a battery will vary,

depending upon the following factors: ² Battery Capacity - A completely discharged

heavy-duty battery requires twice the charging time

of a small capacity battery. ² Temperature - A longer time will be needed to

charge a battery at -18É C (0É F) than at 27É C (80É

F). When a fast battery charger is connected to a cold

battery, the current accepted by the battery will be

very low at first. As the battery warms, it will accept

a higher charging current rate (amperage). ² Charger Capacity - A battery charger that

supplies only five amperes will require a longer

charging time. A battery charger that supplies eight

amperes will require a shorter charging time. ² State-Of-Charge - A completely discharged bat-

tery requires more charging time than a partially

discharged battery. Electrolyte is nearly pure water

in a completely discharged battery. At first, the

charging current (amperage) will be low. As the bat-

tery charges, the specific gravity of the electrolyte

will gradually rise. The Battery Charging Time Table gives an indica-

tion of the time required to charge a typical battery

at room temperature based upon the battery state-of-

charge and the charger capacity.

SPIRAL-PLATE BATTERY CHARGING TIME TABLE

Charging

Amperage 5 Amps 8 Amps

Open Circuit Voltage Hours Charging @ 21É

C (70É F)

12.25 to 12.49 6 hours 3 hours

12.00 to 12.24 10 hours 5 hours 10.00 to 11.99 14 hours 7 hours Below 10.00 18 hours 9 hours

STANDARD PROCEDURE - CONVENTIONAL

BATTERY CHARGING

Vehicles equipped with a diesel engine utilize a

unique spiral plate battery. This battery has a maxi-

mum charging voltage that must be used in order to

restore the battery to its full potential, failure to use the spiral plate battery charging procedure could

result in damage to the battery or personal injury.

Battery charging is the means by which the bat-

tery can be restored to its full voltage potential. A

battery is fully-charged when: ² Micro 420 battery tester indicates battery is OK.

² Open-circuit voltage of the battery is 12.65 volts

or above. ² Battery passes Load Test multiple times.

WARNING: IF THE BATTERY SHOWS SIGNS OF

FREEZING, LEAKING, LOOSE POSTS, DO NOT

TEST, ASSIST-BOOST, OR CHARGE. THE BATTERY

MAY ARC INTERNALLY AND EXPLODE. PERSONAL

INJURY AND/OR VEHICLE DAMAGE MAY RESULT.

WARNING: EXPLOSIVE HYDROGEN GAS FORMS IN

AND AROUND THE BATTERY. DO NOT SMOKE,

USE FLAME, OR CREATE SPARKS NEAR THE BAT-

TERY. PERSONAL INJURY AND/OR VEHICLE DAM-

AGE MAY RESULT.

WARNING: THE BATTERY CONTAINS SULFURIC

ACID, WHICH IS POISONOUS AND CAUSTIC. AVOID

CONTACT WITH THE SKIN, EYES, OR CLOTHING.

IN THE EVENT OF CONTACT, FLUSH WITH WATER

AND CALL A PHYSICIAN IMMEDIATELY. KEEP OUT

OF THE REACH OF CHILDREN.

WARNING: IF THE BATTERY IS EQUIPPED WITH

REMOVABLE CELL CAPS, BE CERTAIN THAT EACH

OF THE CELL CAPS IS IN PLACE AND TIGHT

BEFORE THE BATTERY IS RETURNED TO SER-

VICE. PERSONAL INJURY AND/OR VEHICLE DAM-

AGE MAY RESULT FROM LOOSE OR MISSING

CELL CAPS.

CAUTION: Always disconnect and isolate the bat-

tery negative cable before charging a battery. Do

not exceed sixteen volts while charging a battery.

Damage to the vehicle electrical system compo-

nents may result.

CAUTION: Battery electrolyte will bubble inside the

battery case during normal battery charging. Elec-

trolyte boiling or being discharged from the battery

vents indicates a battery overcharging condition.

Immediately reduce the charging rate or turn off the

charger to evaluate the battery condition. Damage

to the battery may result from overcharging.

RS BATTERY SYSTEM8Fs-11

BATTERY (Continued)

Page 470 of 2585

CONVENTIONAL BATTERY CHARGING TIME TABLECharging

Amperage 5 Amps10

Amps 20 Amps

Open Circuit Voltage Hours Charging @ 21É C (70É

F)

12.25 to 12.49 6 hours 3 hours 1.5 hours

12.00 to 12.24 10 hours 5 hours 2.5 hours

10.00 to 11.99 14 hours 7 hours 3.5 hours

Below 10.00 18 hours 9 hours 4.5 hours

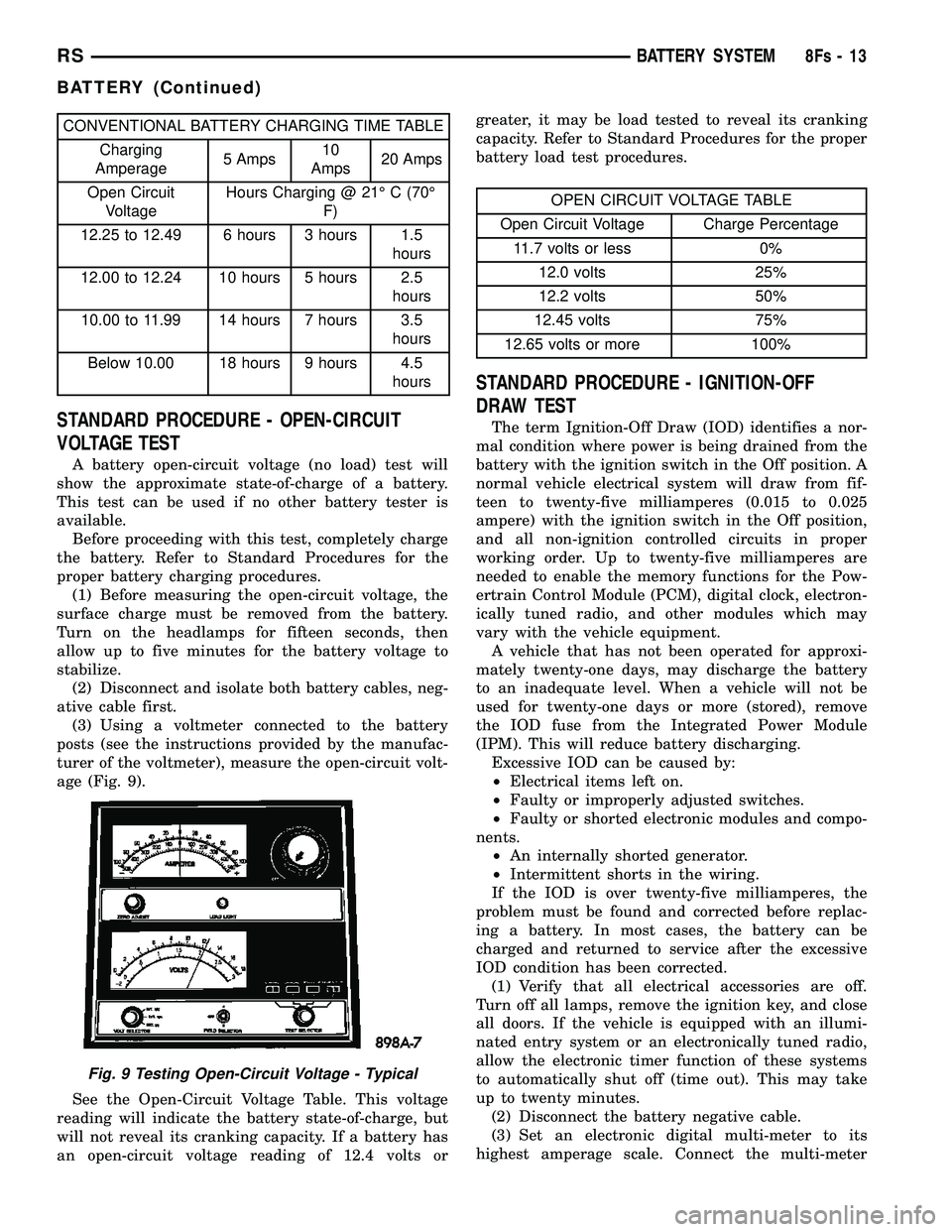

STANDARD PROCEDURE - OPEN-CIRCUIT

VOLTAGE TEST

A battery open-circuit voltage (no load) test will

show the approximate state-of-charge of a battery.

This test can be used if no other battery tester is

available. Before proceeding with this test, completely charge

the battery. Refer to Standard Procedures for the

proper battery charging procedures. (1) Before measuring the open-circuit voltage, the

surface charge must be removed from the battery.

Turn on the headlamps for fifteen seconds, then

allow up to five minutes for the battery voltage to

stabilize. (2) Disconnect and isolate both battery cables, neg-

ative cable first. (3) Using a voltmeter connected to the battery

posts (see the instructions provided by the manufac-

turer of the voltmeter), measure the open-circuit volt-

age (Fig. 9).

See the Open-Circuit Voltage Table. This voltage

reading will indicate the battery state-of-charge, but

will not reveal its cranking capacity. If a battery has

an open-circuit voltage reading of 12.4 volts or greater, it may be load tested to reveal its cranking

capacity. Refer to Standard Procedures for the proper

battery load test procedures.

OPEN CIRCUIT VOLTAGE TABLE

Open Circuit Voltage Charge Percentage 11.7 volts or less 0% 12.0 volts 25%

12.2 volts 50%

12.45 volts 75%

12.65 volts or more 100%

STANDARD PROCEDURE - IGNITION-OFF

DRAW TEST

The term Ignition-Off Draw (IOD) identifies a nor-

mal condition where power is being drained from the

battery with the ignition switch in the Off position. A

normal vehicle electrical system will draw from fif-

teen to twenty-five milliamperes (0.015 to 0.025

ampere) with the ignition switch in the Off position,

and all non-ignition controlled circuits in proper

working order. Up to twenty-five milliamperes are

needed to enable the memory functions for the Pow-

ertrain Control Module (PCM), digital clock, electron-

ically tuned radio, and other modules which may

vary with the vehicle equipment. A vehicle that has not been operated for approxi-

mately twenty-one days, may discharge the battery

to an inadequate level. When a vehicle will not be

used for twenty-one days or more (stored), remove

the IOD fuse from the Integrated Power Module

(IPM). This will reduce battery discharging. Excessive IOD can be caused by:

² Electrical items left on.

² Faulty or improperly adjusted switches.

² Faulty or shorted electronic modules and compo-

nents. ² An internally shorted generator.

² Intermittent shorts in the wiring.

If the IOD is over twenty-five milliamperes, the

problem must be found and corrected before replac-

ing a battery. In most cases, the battery can be

charged and returned to service after the excessive

IOD condition has been corrected. (1) Verify that all electrical accessories are off.

Turn off all lamps, remove the ignition key, and close

all doors. If the vehicle is equipped with an illumi-

nated entry system or an electronically tuned radio,

allow the electronic timer function of these systems

to automatically shut off (time out). This may take

up to twenty minutes. (2) Disconnect the battery negative cable.

(3) Set an electronic digital multi-meter to its

highest amperage scale. Connect the multi-meter

Fig. 9 Testing Open-Circuit Voltage - Typical

RS BATTERY SYSTEM8Fs-13

BATTERY (Continued)

Page 471 of 2585

between the disconnected battery negative cable ter-

minal clamp and the battery negative terminal post.

Make sure that the doors remain closed so that the

illuminated entry system is not activated. The multi-

meter amperage reading may remain high for up to

three minutes, or may not give any reading at all

while set in the highest amperage scale, depending

upon the electrical equipment in the vehicle. The

multi-meter leads must be securely clamped to the

battery negative cable terminal clamp and the bat-

tery negative terminal post. If continuity between the

battery negative terminal post and the negative cable

terminal clamp is lost during any part of the IOD

test, the electronic timer function will be activated

and all of the tests will have to be repeated.(4) After about three minutes, the high-amperage

IOD reading on the multi-meter should become very

low or nonexistent, depending upon the electrical

equipment in the vehicle. If the amperage reading

remains high, remove and replace each fuse or circuit

breaker in the Integrated Power Module (IPM), one

at a time until the amperage reading becomes very

low, or nonexistent. Refer to the appropriate wiring

information in this service manual for complete Inte-

grated Power Module fuse, circuit breaker, and cir-

cuit identification. This will isolate each circuit and

identify the circuit that is the source of the high-am-

perage IOD. If the amperage reading remains high

after removing and replacing each fuse and circuit

breaker, disconnect the wire harness from the gener-

ator. If the amperage reading now becomes very low

or nonexistent, refer to Charging System for the

proper charging system diagnosis and testing proce-

dures. After the high-amperage IOD has been cor-

rected, switch the multi-meter to progressively lower

amperage scales and, if necessary, repeat the fuse

and circuit breaker remove-and-replace process to

identify and correct all sources of excessive IOD. It is

now safe to select the lowest milliampere scale of the

multi-meter to check the low-amperage IOD.

CAUTION: Do not open any doors, or turn on any

electrical accessories with the lowest milliampere

scale selected, or the multi-meter may be damaged.

(5) Allow twenty minutes for the IOD to stabilize

and observe the multi-meter reading. The low-amper-

age IOD should not exceed twenty-five milliamperes

(0.025 ampere). If the current draw exceeds twenty-

five milliamperes, isolate each circuit using the fuse

and circuit breaker remove-and-replace process in

Step 4. The multi-meter reading will drop to within

the acceptable limit when the source of the excessive

current draw is disconnected. Repair this circuit as

required; whether a wiring short, incorrect switch

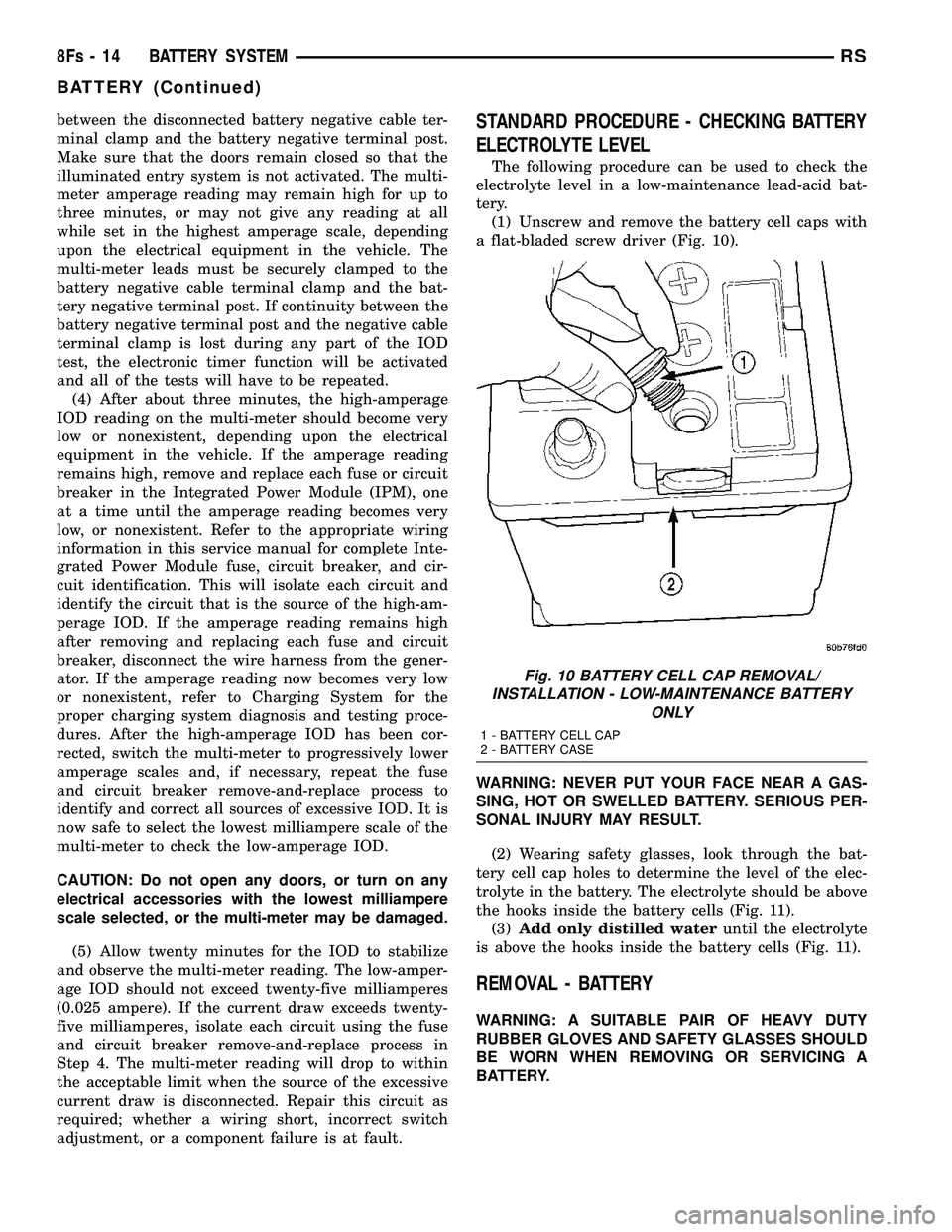

adjustment, or a component failure is at fault.STANDARD PROCEDURE - CHECKING BATTERY

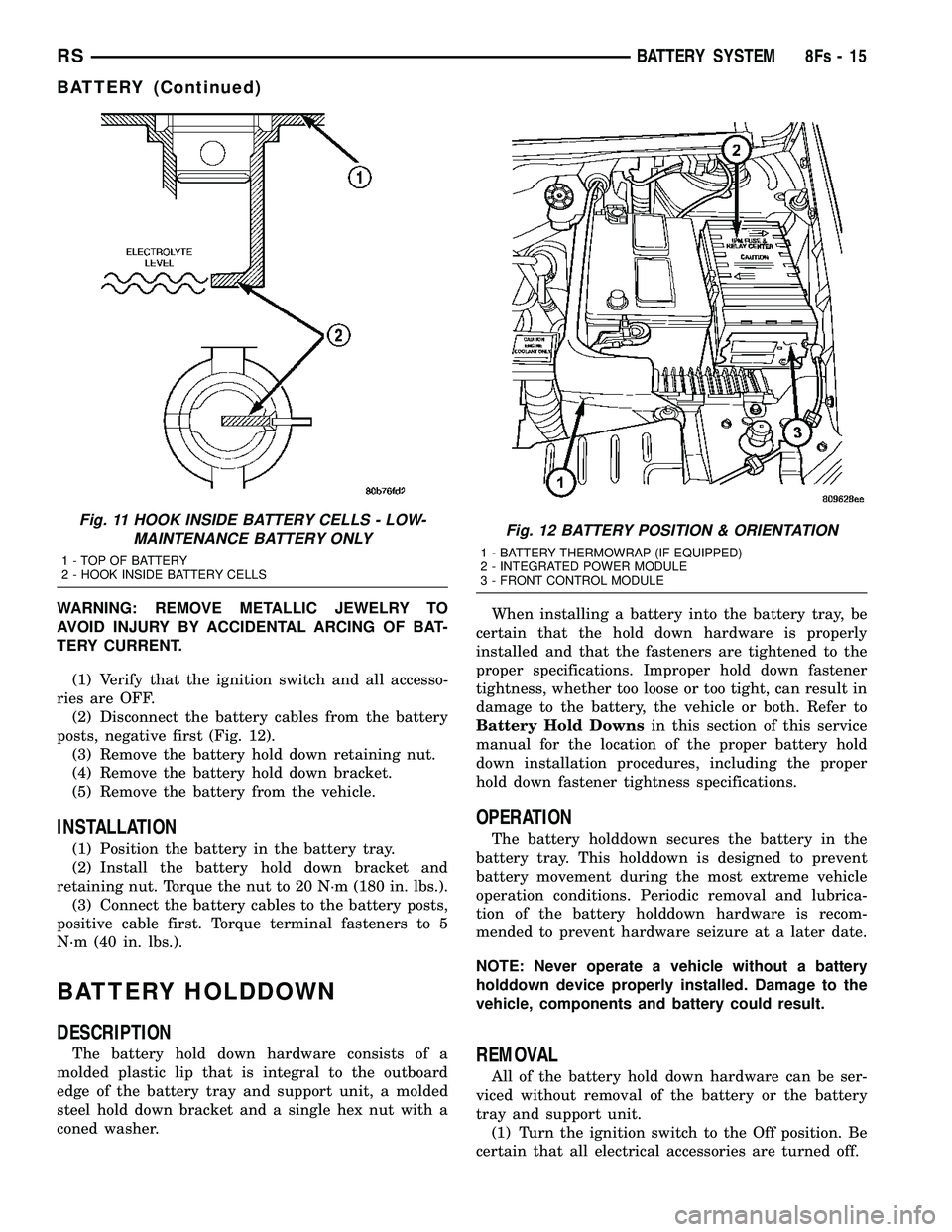

ELECTROLYTE LEVEL

The following procedure can be used to check the

electrolyte level in a low-maintenance lead-acid bat-

tery. (1) Unscrew and remove the battery cell caps with

a flat-bladed screw driver (Fig. 10).

WARNING: NEVER PUT YOUR FACE NEAR A GAS-

SING, HOT OR SWELLED BATTERY. SERIOUS PER-

SONAL INJURY MAY RESULT.

(2) Wearing safety glasses, look through the bat-

tery cell cap holes to determine the level of the elec-

trolyte in the battery. The electrolyte should be above

the hooks inside the battery cells (Fig. 11). (3) Add only distilled water until the electrolyte

is above the hooks inside the battery cells (Fig. 11).

REMOVAL - BATTERY

WARNING: A SUITABLE PAIR OF HEAVY DUTY

RUBBER GLOVES AND SAFETY GLASSES SHOULD

BE WORN WHEN REMOVING OR SERVICING A

BATTERY.

Fig. 10 BATTERY CELL CAP REMOVAL/

INSTALLATION - LOW-MAINTENANCE BATTERY ONLY

1 - BATTERY CELL CAP

2 - BATTERY CASE

8Fs - 14 BATTERY SYSTEMRS

BATTERY (Continued)

Page 472 of 2585

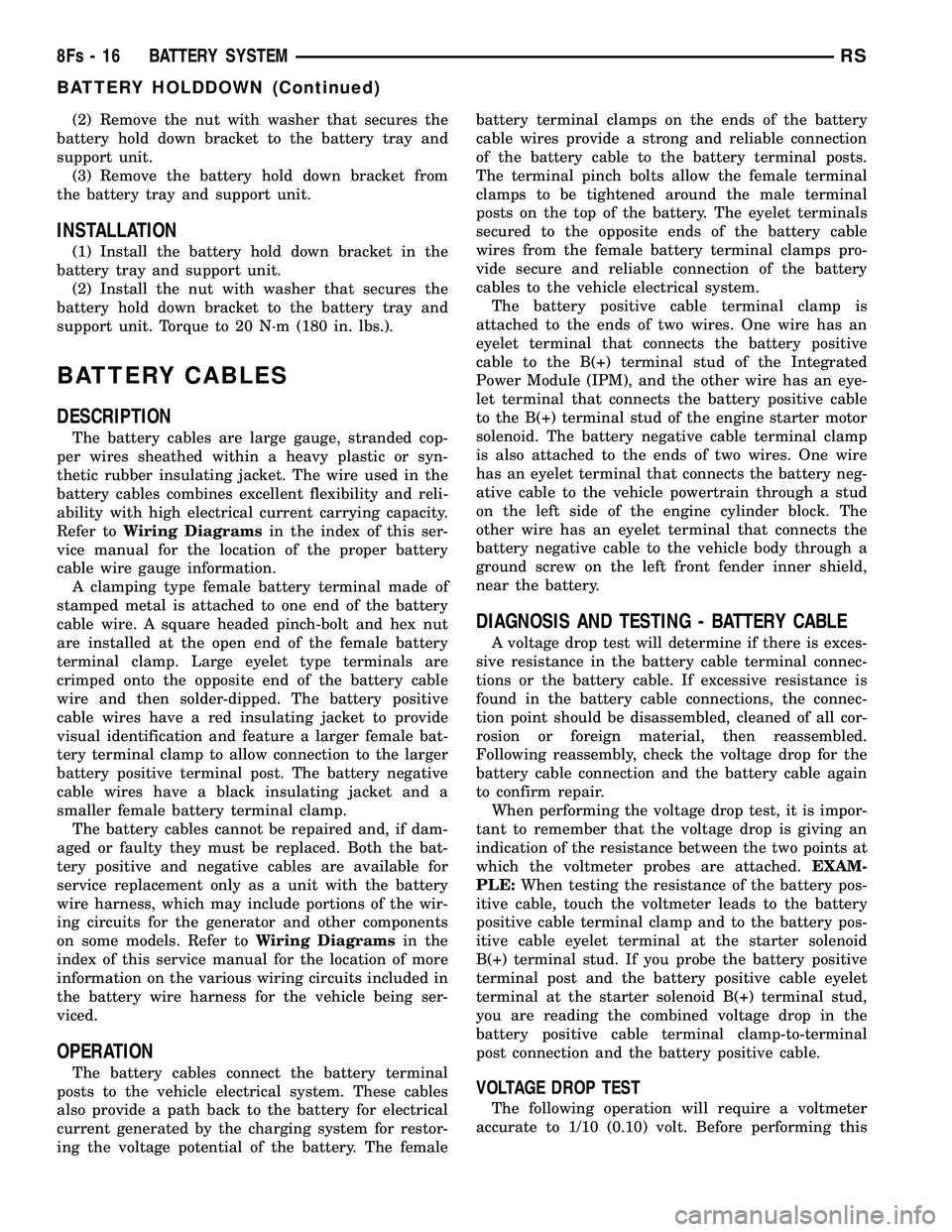

WARNING: REMOVE METALLIC JEWELRY TO

AVOID INJURY BY ACCIDENTAL ARCING OF BAT-

TERY CURRENT.(1) Verify that the ignition switch and all accesso-

ries are OFF. (2) Disconnect the battery cables from the battery

posts, negative first (Fig. 12). (3) Remove the battery hold down retaining nut.

(4) Remove the battery hold down bracket.

(5) Remove the battery from the vehicle.

INSTALLATION

(1) Position the battery in the battery tray.

(2) Install the battery hold down bracket and

retaining nut. Torque the nut to 20 N´m (180 in. lbs.). (3) Connect the battery cables to the battery posts,

positive cable first. Torque terminal fasteners to 5

N´m (40 in. lbs.).

BATTERY HOLDDOWN

DESCRIPTION

The battery hold down hardware consists of a

molded plastic lip that is integral to the outboard

edge of the battery tray and support unit, a molded

steel hold down bracket and a single hex nut with a

coned washer. When installing a battery into the battery tray, be

certain that the hold down hardware is properly

installed and that the fasteners are tightened to the

proper specifications. Improper hold down fastener

tightness, whether too loose or too tight, can result in

damage to the battery, the vehicle or both. Refer to

Battery Hold Downs in this section of this service

manual for the location of the proper battery hold

down installation procedures, including the proper

hold down fastener tightness specifications.

OPERATION

The battery holddown secures the battery in the

battery tray. This holddown is designed to prevent

battery movement during the most extreme vehicle

operation conditions. Periodic removal and lubrica-

tion of the battery holddown hardware is recom-

mended to prevent hardware seizure at a later date.

NOTE: Never operate a vehicle without a battery

holddown device properly installed. Damage to the

vehicle, components and battery could result.

REMOVAL

All of the battery hold down hardware can be ser-

viced without removal of the battery or the battery

tray and support unit. (1) Turn the ignition switch to the Off position. Be

certain that all electrical accessories are turned off.

Fig. 11 HOOK INSIDE BATTERY CELLS - LOW- MAINTENANCE BATTERY ONLY

1 - TOP OF BATTERY

2 - HOOK INSIDE BATTERY CELLS

Fig. 12 BATTERY POSITION & ORIENTATION

1 - BATTERY THERMOWRAP (IF EQUIPPED)

2 - INTEGRATED POWER MODULE

3 - FRONT CONTROL MODULE

RS BATTERY SYSTEM8Fs-15

BATTERY (Continued)

Page 473 of 2585

(2) Remove the nut with washer that secures the

battery hold down bracket to the battery tray and

support unit. (3) Remove the battery hold down bracket from

the battery tray and support unit.

INSTALLATION

(1) Install the battery hold down bracket in the

battery tray and support unit. (2) Install the nut with washer that secures the

battery hold down bracket to the battery tray and

support unit. Torque to 20 N´m (180 in. lbs.).

BATTERY CABLES

DESCRIPTION

The battery cables are large gauge, stranded cop-

per wires sheathed within a heavy plastic or syn-

thetic rubber insulating jacket. The wire used in the

battery cables combines excellent flexibility and reli-

ability with high electrical current carrying capacity.

Refer to Wiring Diagrams in the index of this ser-

vice manual for the location of the proper battery

cable wire gauge information. A clamping type female battery terminal made of

stamped metal is attached to one end of the battery

cable wire. A square headed pinch-bolt and hex nut

are installed at the open end of the female battery

terminal clamp. Large eyelet type terminals are

crimped onto the opposite end of the battery cable

wire and then solder-dipped. The battery positive

cable wires have a red insulating jacket to provide

visual identification and feature a larger female bat-

tery terminal clamp to allow connection to the larger

battery positive terminal post. The battery negative

cable wires have a black insulating jacket and a

smaller female battery terminal clamp. The battery cables cannot be repaired and, if dam-

aged or faulty they must be replaced. Both the bat-

tery positive and negative cables are available for

service replacement only as a unit with the battery

wire harness, which may include portions of the wir-

ing circuits for the generator and other components

on some models. Refer to Wiring Diagramsin the

index of this service manual for the location of more

information on the various wiring circuits included in

the battery wire harness for the vehicle being ser-

viced.

OPERATION

The battery cables connect the battery terminal

posts to the vehicle electrical system. These cables

also provide a path back to the battery for electrical

current generated by the charging system for restor-

ing the voltage potential of the battery. The female battery terminal clamps on the ends of the battery

cable wires provide a strong and reliable connection

of the battery cable to the battery terminal posts.

The terminal pinch bolts allow the female terminal

clamps to be tightened around the male terminal

posts on the top of the battery. The eyelet terminals

secured to the opposite ends of the battery cable

wires from the female battery terminal clamps pro-

vide secure and reliable connection of the battery

cables to the vehicle electrical system.

The battery positive cable terminal clamp is

attached to the ends of two wires. One wire has an

eyelet terminal that connects the battery positive

cable to the B(+) terminal stud of the Integrated

Power Module (IPM), and the other wire has an eye-

let terminal that connects the battery positive cable

to the B(+) terminal stud of the engine starter motor

solenoid. The battery negative cable terminal clamp

is also attached to the ends of two wires. One wire

has an eyelet terminal that connects the battery neg-

ative cable to the vehicle powertrain through a stud

on the left side of the engine cylinder block. The

other wire has an eyelet terminal that connects the

battery negative cable to the vehicle body through a

ground screw on the left front fender inner shield,

near the battery.

DIAGNOSIS AND TESTING - BATTERY CABLE

A voltage drop test will determine if there is exces-

sive resistance in the battery cable terminal connec-

tions or the battery cable. If excessive resistance is

found in the battery cable connections, the connec-

tion point should be disassembled, cleaned of all cor-

rosion or foreign material, then reassembled.

Following reassembly, check the voltage drop for the

battery cable connection and the battery cable again

to confirm repair. When performing the voltage drop test, it is impor-

tant to remember that the voltage drop is giving an

indication of the resistance between the two points at

which the voltmeter probes are attached. EXAM-

PLE: When testing the resistance of the battery pos-

itive cable, touch the voltmeter leads to the battery

positive cable terminal clamp and to the battery pos-

itive cable eyelet terminal at the starter solenoid

B(+) terminal stud. If you probe the battery positive

terminal post and the battery positive cable eyelet

terminal at the starter solenoid B(+) terminal stud,

you are reading the combined voltage drop in the

battery positive cable terminal clamp-to-terminal

post connection and the battery positive cable.

VOLTAGE DROP TEST

The following operation will require a voltmeter

accurate to 1/10 (0.10) volt. Before performing this

8Fs - 16 BATTERY SYSTEMRS

BATTERY HOLDDOWN (Continued)