8e electrical CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 520 of 2585

REMOVAL

REMOVAL - 2.4L

The camshaft position sensor is mounted to the

rear of the cylinder head.

(1) Remove the negative battery cable.

(2) Disconnect electrical connectors from the cam-

shaft position sensor (Fig. 3).

(3) Remove camshaft position sensor mounting

screws. Remove sensor.

(4) Loosen screw attaching target magnet to rear

of camshaft and remove magnet (Fig. 4).

REMOVAL - 3.3/3.8L

(1) Disconnect the negative battery cable.

(2)

Remove the air box cover and inlet tube (Fig. 5).

(3) Disconnect camshaft position sensor electrical

connector from the wiring harness connector (Fig. 6).

(4) Remove bolt holding sensor.

(5) Rotate sensor away from block.

(6) Pull sensor up out of the chain case cover.Do

not pull on the sensor wiring.There is an O-ring

on the body of the sensor. The O-ring may make

removal difficult. A light tap to top of sensor prior to

removal may reduce force needed for removal.

Fig. 3 EGR/CAM SENSOR 2.4L

Fig. 4 Target Magnet Removal/Installation

1 - TARGET MAGNET

2 - MOUNTING BOLT

3 - REAR OF CYLINDER HEAD

Fig. 5 AIR BOX COVER

Fig. 6 CAMSHAFT POSITION SENSOR

RSIGNITION CONTROL8I-5

CAMSHAFT POSITION SENSOR (Continued)

Page 521 of 2585

INSTALLATION

INSTALLATION - 2.4L

The target magnet has locating dowels that fit into

machined locating holes in the end of the camshaft

(Fig. 7).

(1) Install target magnet in end of camshaft.

Tighten mounting screw to 3 N´m (30 in. lbs.) torque.

Over torqueing could cause cracks in magnet. If mag-

net cracks replace it.

(2) Install camshaft position sensor. Tighten sensor

mounting screws to 12.9 N´m (115 in. lbs.) torque.

(3) Carefully attach electrical connector to cam-

shaft position sensor.

(4) Connect the negative battery cable.

INSTALLATION - 3.3/3.8L

If the removed sensor is reinstalled, clean off

the old spacer on the sensor face. A NEW SPACER

must be attached to the face before installation.

Inspect O-ring for damage, replace if necessary. If the

sensor is being replaced, confirm that the paper

spacer is attached to the face and O-ring is posi-

tioned in groove of the new sensor (Fig. 8).

(1) Apply a couple drops of clean engine oil to the

O-ring prior to installation.

(2) Install sensor in the chain case cover and

rotate into position.

(3) Push sensor down until contact is made with

the camshaft gear. While holding the sensor in this

position, install and tighten the retaining bolt 14

N´m (125 in. lbs.) torque.

(4) Connect camshaft position sensor electrical

connector to harness connector.

(5) Install the air box cover and inlet hose (Fig. 5).

(6) Connect the negative battery cable.

IGNITION COIL

DESCRIPTION

The ignition coil assembly consists of 2 or 3 inde-

pendent coils molded together (Fig. 9) or (Fig. 10).

The coil assembly for the 3.3/3.8L is mounted on the

intake manifold. The coil assembly for the 2.4L is

mounted on the cylinder head cover. Spark plug

cables route to each cylinder from the coil.

Fig. 7 Target Magnet Installation

1 - LOCATING DOWELS

2 - LOCATING HOLES (2)

Fig. 8 Camshaft Position Sensor and Spacer

1 - ELECTRICAL CONNECTOR

2 - O-RING

3 - PAPER SPACER

Fig. 9 IGNITION COIL - 2.4L

8I - 6 IGNITION CONTROLRS

CAMSHAFT POSITION SENSOR (Continued)

Page 522 of 2585

OPERATION

The coil fires two spark plugs every power stroke.

One plug is the cylinder under compression, the

other cylinder fires on the exhaust stroke. The Pow-

ertrain Control Module (PCM) determines which of

the coils to charge and fire at the correct time.

The Auto Shutdown (ASD) relay provides battery

voltage to the ignition coil. The PCM provides a

ground contact (circuit) for energizing the coil. When

the PCM breaks the contact, the magnetic energy in

the coil transfers to the secondary causing the spark.

The PCM will de-energize the ASD relay if it does

not receive the crankshaft position sensor and cam-

shaft position sensor inputs. Refer to Auto Shutdown

(ASD) RelayÐPCM Output, in this section for relay

operation.

REMOVAL

REMOVAL - 2.4L

The electronic ignition coil pack attaches directly

to the valve cover.

(1) Diconnect the negative battery cable.

(2) Disconnect electrical connector from coil pack.

(3) Remove coil pack mounting bolts.

(4) Remove coil pack and heat shield (Fig. 9).

REMOVAL - 3.3/3.8L

(1) Disconnect the negative battery cable.(2) Remove the throttle and speed control cables

from clip.

(3) Remove 2 bolts from the Power steering reser-

voir to intake manifold.

(4) Loosen the lower nut for the power steering

reservoir from stud on ignition coil bracket.

(5) Reposition the Power steering reservoir (Fig.

11).

(6) Remove the ignition cables from the ignition

coil.

(7) Disconnect the electrical connector from the

ignition coil.

(8) Remove 2 nuts from the ignition coil studs.

INSTALLATION

INSTALLATION - 2.4L

(1) Install ignition coil and heat shield to valve

cover and tighten bolts.

(2) Connect the electrical connector to the ignition

coil.

(3) Transfer spark plug cables to new coil pack.

The coil pack towers are numbered with the cylinder

identification. Be sure the ignition cables are fully

seated onto the towers.

(4) Connect the negative battery cable.

INSTALLATION - 3.3/3.8L

(1) Install coil over studs on bracket.

(2) Install 2 nuts to the ignition coil studs. Tighten

nuts and bolts.

Fig. 10 IGNITION COIL - 3.3/3.8L

1 -Ignition Coil

Fig. 11 IGNITION COIL BRACKET 3.3/3.8L

RSIGNITION CONTROL8I-7

IGNITION COIL (Continued)

Page 523 of 2585

(3) Connect the electrical connector to the ignition

coil.

(4) Install the ignition cables to the ignition coil.

(5) Reposition the Power steering reservoir. Slide

bracket over the mounting stud (Fig. 11).

(6) Install 2 bolts to the Power steering reservoir

to intake manifold.

(7) Tighten the lower nut to stud on ignition coil

bracket.

(8) Install the throttle and speed control cables to

clip.

(9) Connect the negative battery cable.

KNOCK SENSOR

DESCRIPTION

The knock sensor threads into the cylinder block.

The knock sensor is designed to detect engine vibra-

tion that is caused by detonation.

OPERATION

When the knock sensor detects a knock in one of

the cylinders, it sends an input signal to the PCM. In

response, the PCM retards ignition timing for all cyl-

inders by a scheduled amount.

Knock sensors contain a piezoelectric material

which constantly vibrates and sends an input voltage

(signal) to the PCM while the engine operates. As the

intensity of the crystal's vibration increases, the

knock sensor output voltage also increases.

The voltage signal produced by the knock sensor

increases with the amplitude of vibration. The PCM

receives as an input the knock sensor voltage signal.

If the signal rises above a predetermined level, the

PCM will store that value in memory and retard

ignition timing to reduce engine knock. If the knock

sensor voltage exceeds a preset value, the PCM

retards ignition timing for all cylinders. It is not a

selective cylinder retard.

The PCM ignores knock sensor input during engine

idle conditions. Once the engine speed exceeds a

specified value, knock retard is allowed.Knock retard uses its own short term and long

term memory program.

Long term memory stores previous detonation

information in its battery-backed RAM. The maxi-

mum authority that long term memory has over tim-

ing retard can be calibrated.

Short term memory is allowed to retard timing up

to a preset amount under all operating conditions (as

long as rpm is above the minimum rpm) except WOT.

The PCM, using short term memory, can respond

quickly to retard timing when engine knock is

detected. Short term memory is lost any time the

ignition key is turned off.

NOTE: Over or under tightening affects knock sen-

sor performance, possibly causing improper spark

control.

REMOVAL

REMOVAL - 2.4L

The knock sensor threads into the side of the cyl-

inder block in front of the starter (Fig. 12).

(1) Disconnect electrical connector from knock sen-

sor.

(2) Use a crow foot socket to remove the knock

sensors.

REMOVAL - 3.8L

The knock sensor threads into the side of the cyl-

inder block in the rear.

(1) Disconnect the negative battery cable.

(2) Raise vehicle and support.

(3) On All Wheel Drive vehicles remove the PTU

(Power Transfer Unit), refer to the Transmission sec-

tion for more information.

(4) Disconnect electrical connector from knock sen-

sor.

(5) Use a crow foot socket to remove the knock

sensor.

8I - 8 IGNITION CONTROLRS

IGNITION COIL (Continued)

Page 524 of 2585

INSTALLATION

INSTALLATION - 2.4L

The knock sensor threads into the side of the cyl-

inder block in front of the starter (Fig. 12).

(1) Install knock sensor. Tighten knock sensor to

10 N´m (7 ft. lbs.) torque.Over or under tighten-

ing effects knock sensor performance, possibly

causing improper spark control.

(2) Attach electrical connector to knock sensor.

INSTALLATION - 3.8L

The knock sensor threads into the side of the cyl-

inder block in the rear.

(1) Install knock sensor. Tighten knock sensor to

10 N´m (7 ft. lbs.) torque.Over or under tighten-

ing effects knock sensor performance, possibly

causing improper spark control.

(2) Attach electrical connector to knock sensor.

(3) On All Wheel Drive vehicles install the PTU

(Power Transfer Unit) for the rear wheels, refer to

the Transmission section for more information.

(4) Lower vehicle.

(5) Connect the negative cable.

SPARK PLUG

DESCRIPTION

DESCRIPTION - STANDARD 4 CYLINDER

All engines use resistor spark plugs. They have

resistance values ranging from 6,000 to 20,000 ohms

when checked with at least a 1000 volt spark plug

tester.

Do not use an ohm meter to check the resis-

tance of the spark plugs. This will give an inac-

curate reading.

Refer to the Specifications section for gap and type

of spark plug.

DESCRIPTION - PLATINUM PLUGS

The V6 engines use platinum resistor spark plugs.

They have resistance values of 6,000 to 20,000 ohms

when checked with at least a 1000 volt tester. For

spark plug identification and specifications, Refer to

the Specifications section.

Do not use an ohm meter to check the resis-

tance of the spark plugs. This will give an inac-

curate reading.

When the spark plugs use a single or double plat-

inum tips and they have a recommended service life

of 100,000 miles for normal driving conditions per

schedule A in this manual. The spark plugs have a

recommended service life of 75,000 miles for severe

driving conditions per schedule B in this manual. A

thin platinum pad is welded to both or just the cen-

ter electrode end(s) as shown in (Fig. 13). Extreme

care must be used to prevent spark plug cross

threading, mis-gapping (Fig. 14) and ceramic insula-

tor damage during plug removal and installation.

Fig. 12 Knock Sensor

1 - GENERATOR

2 - INTAKE MANIFOLD

3 - KNOCK SENSOR

4-STARTER

Fig. 13 Platinum Pads

1 - APPLY ANTI-SEIZE COMPOUND HERE ONLY

2 - PLATINUM SPARK SURFACE

RSIGNITION CONTROL8I-9

KNOCK SENSOR (Continued)

Page 537 of 2585

LAMPS/LIGHTING - EXTERIOR

DESCRIPTION

LAMP SYSTEMS

Lighting circuits are protected by fuses. Lighting

circuits require an overload protected power and high

side drivers source, ON/OFF device, lamps and body

grounds to operate properly. Plastic lamps require a

wire in the harness to supply body ground to the

lamp socket. Replace sockets and bulbs that are cor-

roded.

Some of the interior and exterior lighting functions

are governed by the Body Control Module (BCM).

The headlamp, dome, and the door ajar switches pro-

vide signals to the BCM. The BCM in turn sends a

Programmable Communication Interface (PCI) bus

message to the Front Control Module (FCM) to

enable the necessary drivers to set the required illu-

mination configuration.

Wire connectors can make intermittent contact or

become corroded. Before coupling wire connectors,

inspect the terminals inside the connector. Male ter-

minals should not be bent or disengaged from the

insulator. Female terminals should not be sprung

open or disengaged from the insulator. Bent and

sprung terminals can be repaired using needle nose

pliers and pick tool. Corroded terminals appear

chalky or green. Corroded terminals should be

replaced to avoid recurrence of the problem symp-

toms.

Begin electrical system failure diagnosis by testing

related fuses in the fuse block and intelligent power

module. Verify that bulbs are in good condition and

test continuity of the circuit ground. Refer to the

appropriate wiring information.

AUTOMATIC HEADLAMP SYSTEM

The Automatic Headlamp system turns the instru-

mentation and exterior illumination lamps ON when

the ambient light levels are Night and the engine

RPM is 450 or above, and OFF when light levels are

Day.

DAYTIME RUNNING LAMPS

Operating the high-beam headlamps at reduced

power provides daytime running lamps, which are

required on all new Canadian vehicles. Daytime run-

ning lamps are functional when 450 rpm's are

reached.

HEADLAMPS ON WITH WINDSHIELD WIPERS

For vehicles equipped with the Automatic Head-

lamp System, the instrumentation and exterior illu-

mination lamps will be turned ON when the

headlamp switch is in the AUTO position, RPM >450 and the windshield wipers have been in the

intermittent, low or high mode of operation for more

than ten seconds. When the windshield wipers are

turned OFF the Body Control Module will determine

if the instrumentation and exterior illumination

lamps should remain ON base upon the current

ambient light level.

HEADLAMP SYSTEM

The configuration of the headlamp system of head-

lamps, park lamps and fog lamps is determined by

the BCM. The BCM determines the lighting configu-

ration as a result of the inputs from the ignition

switch, headlamp switch and multi-function switch. A

PCI bus is transmitted from the BCM to the FCM to

enable the necessary drivers to set the illumination

configuration. Four wires are connected between the

headlamp switch and the BCM. The first wire con-

tains information regarding the position of the head-

lamp switch (Off, Automatic Headlamps, Automatic

Headlamp switch fog, Park with Fog, Head, or Head

with Fog Lamps). The second wire contains informa-

tion regarding the position of the dimmer switch

(Dome Lamp, Daytime Brightness, Dimming Level or

Off). The third wire is a dedicated signal return

(ground) wire. The fourth wire provides power to the

front fog lamp indicator.

HEADLAMP TIME DELAY SYSTEM

The headlamp time delay system is controlled by

the Body Control Module (BCM) via a PCI bus mes-

sage transmitted by the BCM to the FCM to turn off

the headlamps.

OPERATION

AUTOMATIC HEADLAMP SYSTEM

Automatic headlamps are controlled by the Body

Control Module (BCM). With the headlamp switch in

the AUTO position, the BCM will control the head-

lamp, parking, side marker, tail and instrumentation

lamps based on ambient light levels. Ambient light

levels are monitored by the BCM using the Day/

Night signal and Electrochromatic Mirror (ECM)

present from the Compass Mini Trip (CMTC) located

on the front windshield in front of the rear view mir-

ror ECM. Ambient light readings are averaged to

limit cycling the lamps ON and OFF when passing

through areas with varying light levels. The auto-

matic headlamps will only function when the engine

is running with RPM > 450. When the headlamp

switch is in the AUTO position (Automatic mode), the

Headlamp Time Delay system will function when the

ignition switch is placed in any position other than

run/start.

8L - 2 LAMPS/LIGHTING - EXTERIORRS

Page 539 of 2585

LAMP BULB

FRONT FOG 9040

HEADLAMP 9007

LICENSE 168

TAIL, STOP 3057

TURN SIGNAL 3057

BULB APPLICATION TABLE - EXPORT

LAMP BULB

HEADLAMP LOW/HIGH BEAM H7

FRONT FOG H3

FRONT POSITION W5W

FRONT TURN SIGNAL PY21W

SIDE REPEATER T4W

LICENSE PLATE W5W/168

REAR TAIL AND STOP P21/5W

REAR TURN SIGNAL PY21W

BACK-UP P21W

REAR FOG P21W

CHMSL W16W/921

BRAKE LAMP SWITCH

DESCRIPTION

The brake lamp switch is located under the instru-

ment panel, at the brake pedal arm (Fig. 3). It has

three internal switches controlling various functions

of the vehicle. It's main function is to control opera-

tion of the vehicle's brake lamps via a brake switch

input to the BCM. The BCM will then activate the

stop lamps. Other functions include speed control

deactivation, brake sense for the antilock brake sys-

tem and brake sense for the brake transmission shift

interlock.

CAUTION: The switch can only be adjusted once.

That is during initial installation of the switch. If the

switch is not adjusted properly or has been

removed for some service, a new switch must be

installed and adjusted.

OPERATION

When the brake pedal is pressed, the plunger on

the outside of the brake lamp switch extends out-

ward. This action opens or closes the contacts of the

three switches inside the brake lamp switch.

With the brake pedal pressed down (plunger

extended), the switch for terminals 1 and 2 is closedcompleting the circuit. The switch for terminals 3

and 4 is open and so is the switch for terminals 5

and 6.

When the brake pedal is released (plunger pushed

in), the three switches assume the opposite positions.

The switch for terminals 1 and 2 is now open while

the other two switches are now closed, completing

their circuits.

A lever on the back of the switch is used to set the

switch into the ªadjustedº position. A non-adjusted

switch will have the lever set to the diagonal position

in relation to the switch housing. The plunger can be

moved in and out, but the states of the internal

switches will not change.

CAUTION: Never move the adjustment lever of the

new brake lamp switch without it being properly

installed in the vehicle first. Such action will render

the switch unusable and the switch must be dis-

carded.

Once installed in the vehicle as described in the

brake lamp switch installation procedure (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

BRAKE LAMP SWITCH - INSTALLATION), the new

switch's adjustment lever is rotated to the adjusted

position as indicated (Fig. 4). This action locks the

plunger to the internal switches.Once in this posi-

tion the switch is permanently adjusted (or

locked) and cannot be readjusted or released

even if the lever is moved back.

DIAGNOSIS AND TESTING - BRAKE LAMP

SWITCH

NOTE: Before proceeding with this diagnostic test,

verify the adjustment lever on the back of the

switch is in the adjusted position. If the lever is in

the non-adjusted (diagonal) position it may have

never been adjusted (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - OPERATION). For adjustment, (Refer to 8

- ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

BRAKE LAMP SWITCH - INSTALLATION)

If the electrical circuit has been tested and the

brake lamp switch is suspected of being faulty, it can

be tested using the following method.

(1) Remove the switch from the vehicle. (Refer to 8

- ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

BRAKE LAMP SWITCH - REMOVAL)

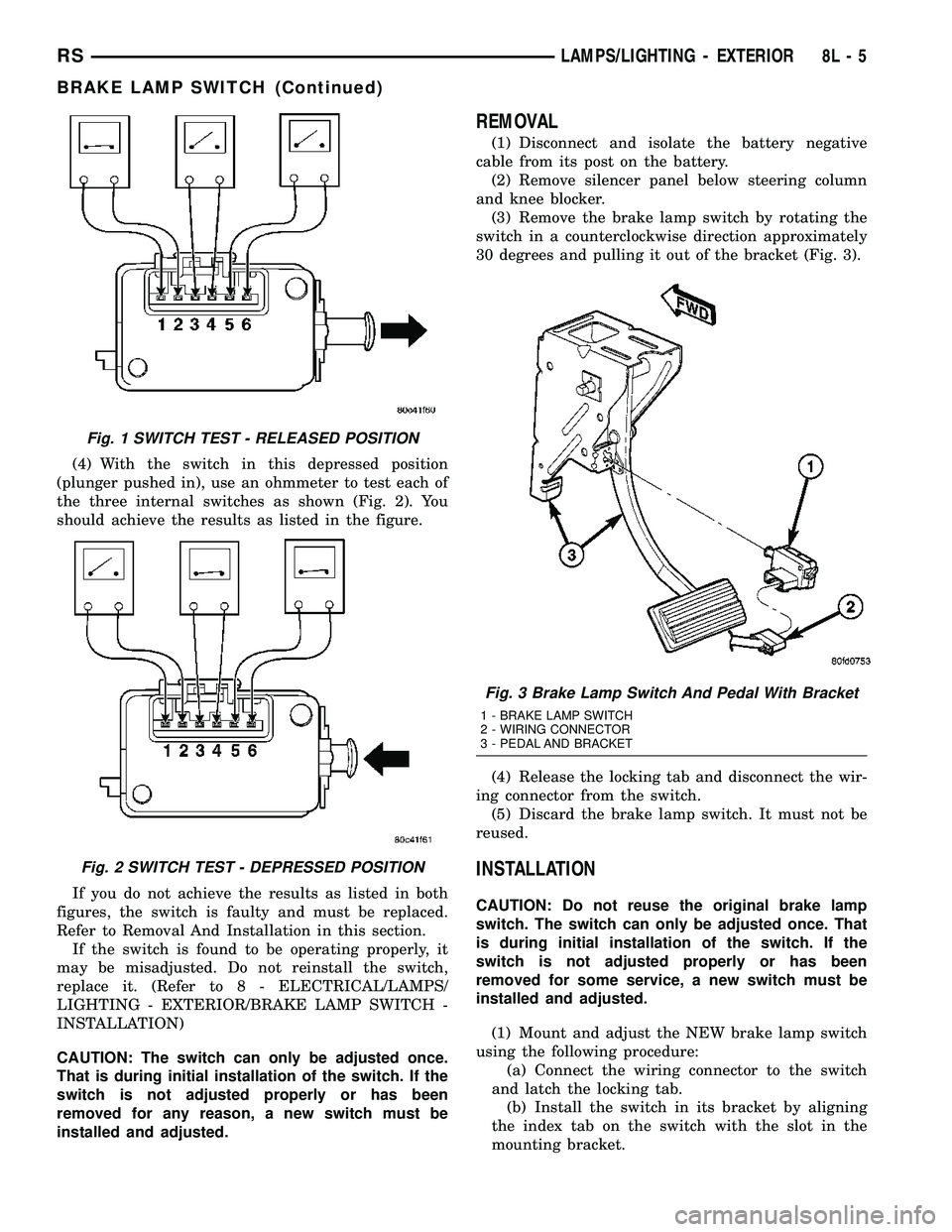

(2) With the switch in the released position

(plunger extended), use an ohmmeter to test each of

the three internal switches as shown (Fig. 1). You

should achieve the results as listed in the figure.

(3) Gently push the plunger on the brake lamp

switch in until it stops.

8L - 4 LAMPS/LIGHTING - EXTERIORRS

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 540 of 2585

(4) With the switch in this depressed position

(plunger pushed in), use an ohmmeter to test each of

the three internal switches as shown (Fig. 2). You

should achieve the results as listed in the figure.

If you do not achieve the results as listed in both

figures, the switch is faulty and must be replaced.

Refer to Removal And Installation in this section.

If the switch is found to be operating properly, it

may be misadjusted. Do not reinstall the switch,

replace it. (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/BRAKE LAMP SWITCH -

INSTALLATION)

CAUTION: The switch can only be adjusted once.

That is during initial installation of the switch. If the

switch is not adjusted properly or has been

removed for any reason, a new switch must be

installed and adjusted.

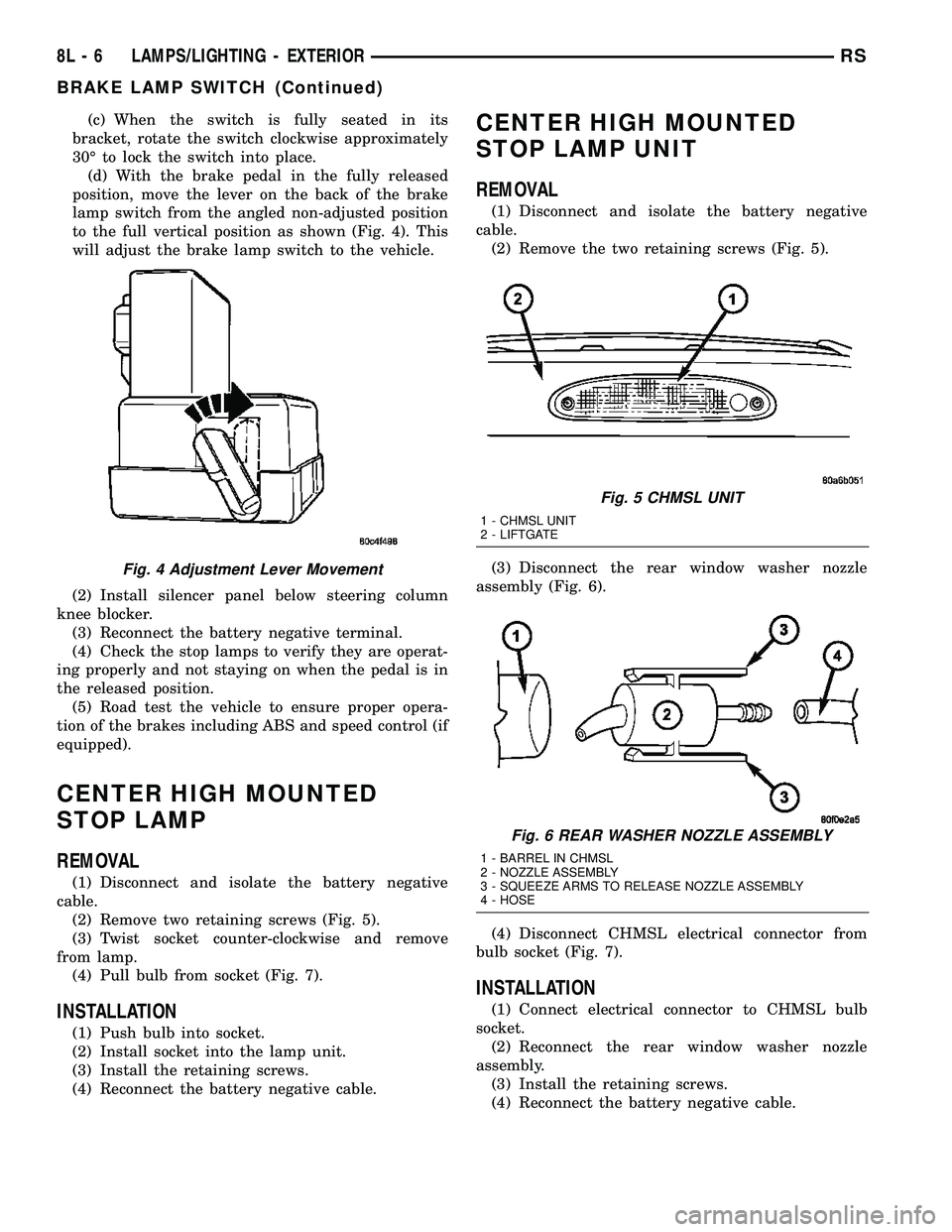

REMOVAL

(1) Disconnect and isolate the battery negative

cable from its post on the battery.

(2) Remove silencer panel below steering column

and knee blocker.

(3) Remove the brake lamp switch by rotating the

switch in a counterclockwise direction approximately

30 degrees and pulling it out of the bracket (Fig. 3).

(4) Release the locking tab and disconnect the wir-

ing connector from the switch.

(5) Discard the brake lamp switch. It must not be

reused.

INSTALLATION

CAUTION: Do not reuse the original brake lamp

switch. The switch can only be adjusted once. That

is during initial installation of the switch. If the

switch is not adjusted properly or has been

removed for some service, a new switch must be

installed and adjusted.

(1) Mount and adjust the NEW brake lamp switch

using the following procedure:

(a) Connect the wiring connector to the switch

and latch the locking tab.

(b) Install the switch in its bracket by aligning

the index tab on the switch with the slot in the

mounting bracket.

Fig. 1 SWITCH TEST - RELEASED POSITION

Fig. 2 SWITCH TEST - DEPRESSED POSITION

Fig. 3 Brake Lamp Switch And Pedal With Bracket

1 - BRAKE LAMP SWITCH

2 - WIRING CONNECTOR

3 - PEDAL AND BRACKET

RSLAMPS/LIGHTING - EXTERIOR8L-5

BRAKE LAMP SWITCH (Continued)

Page 541 of 2585

(c) When the switch is fully seated in its

bracket, rotate the switch clockwise approximately

30É to lock the switch into place.

(d) With the brake pedal in the fully released

position, move the lever on the back of the brake

lamp switch from the angled non-adjusted position

to the full vertical position as shown (Fig. 4). This

will adjust the brake lamp switch to the vehicle.

(2) Install silencer panel below steering column

knee blocker.

(3) Reconnect the battery negative terminal.

(4) Check the stop lamps to verify they are operat-

ing properly and not staying on when the pedal is in

the released position.

(5) Road test the vehicle to ensure proper opera-

tion of the brakes including ABS and speed control (if

equipped).

CENTER HIGH MOUNTED

STOP LAMP

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove two retaining screws (Fig. 5).

(3) Twist socket counter-clockwise and remove

from lamp.

(4) Pull bulb from socket (Fig. 7).

INSTALLATION

(1) Push bulb into socket.

(2) Install socket into the lamp unit.

(3) Install the retaining screws.

(4) Reconnect the battery negative cable.

CENTER HIGH MOUNTED

STOP LAMP UNIT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the two retaining screws (Fig. 5).

(3) Disconnect the rear window washer nozzle

assembly (Fig. 6).

(4) Disconnect CHMSL electrical connector from

bulb socket (Fig. 7).

INSTALLATION

(1) Connect electrical connector to CHMSL bulb

socket.

(2) Reconnect the rear window washer nozzle

assembly.

(3) Install the retaining screws.

(4) Reconnect the battery negative cable.

Fig. 4 Adjustment Lever Movement

Fig. 5 CHMSL UNIT

1 - CHMSL UNIT

2 - LIFTGATE

Fig. 6 REAR WASHER NOZZLE ASSEMBLY

1 - BARREL IN CHMSL

2 - NOZZLE ASSEMBLY

3 - SQUEEZE ARMS TO RELEASE NOZZLE ASSEMBLY

4 - HOSE

8L - 6 LAMPS/LIGHTING - EXTERIORRS

BRAKE LAMP SWITCH (Continued)

Page 542 of 2585

FRONT FOG LAMP

DIAGNOSIS AND TESTING - FRONT FOG LAMP

When a vehicle experiences problems with the

front fog lamp system, verify the condition of the bat-

tery connections, fuses, charging system, fog lamp

bulbs, wire connectors, relay, high beam switch, and

headlamp switch. Refer to the appropriate wiring

information.

Each vehicle is equipped with various lamp assem-

blies. A good ground is necessary for proper lighting

operation. Grounding is provided by the lamp socket

when it comes in contact with the metal body, or

through a separate ground wire.

When changing lamp bulbs check the socket for

corrosion. If corrosion is present, clean it with a wire

brush.

When it is necessary to remove components to ser-

vice another, it should not be necessary to apply

excessive force or bend a component to remove it.

Before damaging a trim component, verify hidden

fasteners or captured edges are not holding the com-

ponent in place.

FRONT FOG LAMP DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

FOG LAMPS ARE DIM

WITH ENGINE IDLING

OR IGNITION TURNED

OFF.1. Loose or corroded battery

cables.1. Clean and secure battery cable clamps and

posts.

2. Loose or worn generator drive

belt.2. Adjust or replace generator drive belt.

3. Charging system output too low. 3. Test and repair charging system. Refer to

Electrical, Charging,

4. Battery has insufficient charge. 4. Test battery state-of-charge. Refer to

Electrical, Battery System.

5. Battery is sulfated or shorted. 5. Load test battery. Refer to Electrical, Battery

System.

6. Poor lighting circuit Z349/Z248

ground.6. Test for voltage drop across Z349/248

ground locations. Refer to Electrical, Wiring

Information.

FOG LAMP BULBS

BURN OUT

FREQUENTLY1. Charging system output too

high.1. Test and repair charging system. Refer to

Electrical, Charging.

2. Loose or corroded terminals or

splices in circuit.2. Inspect and repair all connectors and splices.

Refer to Electrical, Wiring Information.

FOG LAMPS ARE DIM

WITH ENGINE

RUNNING ABOVE IDLE1. Charging system output too low. 1. Test and repair charging system. Refer to

Electrical, Charging.

2. Poor lighting circuit Z349/Z248

ground.2. Test for voltage drop across Z349/Z248

ground locations. Refer to Electrical, Wiring

Information.

3. High resistance in fog lamp

circuit.3. Test amperage draw of fog lamp circuit.

Fig. 7 CHMSL ELECTRICAL CONNECTOR

1 - CHMSL UNIT

2 - CHMSL ELECTRICAL CONNECTOR

RSLAMPS/LIGHTING - EXTERIOR8L-7

CENTER HIGH MOUNTED STOP LAMP UNIT (Continued)