instrument panel CHRYSLER VOYAGER 2004 Manual Online

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 658 of 2585

(2) Turn the ignition key to the ON position. Exit

vehicle with the scan tool.

(3) After checking that no one is inside the vehicle,

connect the battery negative remote terminal.

(4) Read and record theACTIVEDiagnostic Trou-

ble Code (DTC) data.

(5) Read and record anySTOREDDTC's.

(6) Refer to the proper Body Diagnostic Procedures

manual if any DTC's are found in Step 4 and Step 5.

(7) If the airbag warning lamp either fails to light,

or goes ON and stays ON, there is a system malfunc-

tion. To test the airbag warning lamp (bulb) opera-

tion in the cluster, refer to Electrical, Instrument

Cluster, Diagnosis and Testing - Instrument Cluster.

Refer to the proper Body Diagnostic Procedures man-

ual for any other system problems.

STANDARD PROCEDURE

STANDARD PROCEDURE - HANDLING

AIRBAGS

DEPLOYED AIRBAG

The vehicle interior may contain a very small

amount of sodium hydroxide powder, a by-product of

airbag deployment. Sodium hydroxide powder can

irritate the skin, eyes, nose and throat. Wear safety

glasses, rubber gloves, and long sleeved clothing

when cleaning any of the powder residue from the

vehicle.

If you find that the cleanup is irritating your skin,

run cool water over the affected area. Also, if you

experience nasal or throat irritation, exit the vehicle

for fresh air until the irritation ceases. If irritation

continues, see a physician.

UNDEPLOYED AIRBAG

The airbags must be stored in its original special

container until used for service. At no time should a

source of electricity be permitted near the inflator on

the back of an airbag module. When carrying or han-

dling an undeployed airbag module, the trim side of

the airbag should be pointing away from the body to

minimize possibility of injury if accidental deploy-

ment occurs. Do not place undeployed airbag face

down on a solid surface, the airbag will propel into

the air if accidental deployment occurs.

STANDARD PROCEDURE - SERVICE AFTER AN

AIRBAG DEPLOYMENT

DRIVER AIRBAG

After a Driver Airbag has been deployed due to a

collision, the followingMUSTbe replaced:

²Driver Airbag²Clock Spring Assembly

²Steering Wheel

²Complete Steering Column Assembly w/Lower

Steering Column Coupler

All other airbag and vehicle components should be

closely inspected following any airbag deployment,

and should be replaced when visible damage is

incurred.

PASSENGER AIRBAG

After a Passenger Airbag has been deployed due to

a collision. the followingMUSTbe replaced:

²Passenger Airbag

²Instrument Panel and Pad Assembly

All other airbag and vehicle components should be

closely inspected following any airbag deployment,

and should be replaced when visible damage is

incurred.

SEAT AIRBAG

After a Seat Airbag has been deployed due to a col-

lision. the followingMUSTbe replaced:

²Complete Seat Back Assembly

All other airbag and vehicle components should be

closely inspected following any airbag deployment,

and should be replaced when visible damage is

incurred.

SEAT BELTS AND TENSIONERS

After a frontal impact where an airbag has been

deployed due to a collision. the followingMUSTbe

replaced:

²Front Seat Belt Buckle (driver and passenger)

with integral Tensioners.

All other seat belts should be closely inspected for

cuts, tears, fraying, or damage in any way following

any frontal impact or airbag deployment. The other

seat belts are to be replaced when visible damage is

incurred. Inspect the Lower Anchors and Tether for

CHildren (LATCH) child restraint anchors for dam-

age after an impact event and replace as needed.

CLEAN UP PROCEDURE

Roll or fold the airbag towards its mounting point

(i.e. instrument panel, steering wheel, or seat back).

Then tape the ripped cover over the deployed airbag

if applicable.

Use a vacuum cleaner to remove any residual pow-

der from the vehicle interior. Work from the outside

in to avoid kneeling or sitting in a contaminated

area. Vacuum the heater and A/C outlets as well (Fig.

1). If the heater or air conditioner was in RECIRC

mode at time of airbag deployment, operate blower

motor on low speed and vacuum powder residue

expelled from the heater and A/C outlets. Multiple

RSRESTRAINTS8O-3

RESTRAINTS (Continued)

Page 660 of 2585

STANDARD PROCEDURE - CLOCK SPRING

CENTERING

If the rotating tape (wire coil) in the clock spring is

not positioned properly with the steering wheel and

the front wheels, the clock spring may fail. The fol-

lowing procedure MUST BE USED to center the

clock spring if it is not known to be properly posi-

tioned, or if the front wheels were moved from the

straight ahead position.

(1) Position steering wheel and front wheels

straight ahead.

(2) Release hood latch and open hood.

(3) Disconnect and isolate the battery negative

cable.

(4) Wait two minutes for the system reserve capac-

itor to discharge before beginning any airbag compo-

nent service.

(5) Remove driver airbag from steering wheel

(Refer to 8 - ELECTRICAL/RESTRAINTS/DRIVER

AIRBAG - REMOVAL).

(6) Disconnect wire connectors from back of driver

airbag.

(7) Disconnect the 2±way connector from remote

radio control harness.

(8) Disconnect the 4±way harness connector from

the speed control/horn harness to the clock spring.

(9) Remove steering wheel (Refer to 19 - STEER-

ING/COLUMN/STEERING WHEEL - REMOVAL).

(10) Rotate the clock spring rotor clockwise until

the rotor stops. Do not apply excessive force.

(11) From the end of travel, rotate the rotor two

turns counterclockwise until the wires end up at the

top.

(12) Install the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

INSTALLATION).

(13) Connect the 4±way harness connector to the

speed control/horn harness to the clock spring.

(14) Connect the 2±way connector to the remote

radio control harness.

(15) Install the driver airbag (Refer to 8 - ELEC-

TRICAL/RESTRAINTS/DRIVER AIRBAG - INSTAL-

LATION). Torque the two screws to 10 N´m (90 in.

lbs.).

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE (Refer to 8 - ELECTRICAL/RE-

STRAINTS - DIAGNOSIS AND TESTING).

PERSONAL INJURY OR DEATH MAY RESULT IF

THE SYSTEM TEST IS NOT PERFORMED PROP-

ERLY.

REMOVAL

(1) Position steering wheel and front wheels

straight ahead.(2) Release hood latch and open hood.

(3) Disconnect and isolate the battery negative

cable.

(4) Wait two minutes for the system reserve capac-

itor to discharge before beginning any airbag compo-

nent service.

(5) Remove driver airbag from steering wheel

(Refer to 8 - ELECTRICAL/RESTRAINTS/DRIVER

AIRBAG - REMOVAL).

(6) Disconnect wire connectors from back of driver

airbag.

(7) Disconnect the 2±way connector from remote

radio control harness.

(8) Disconnect the 4±way harness connector from

the speed control/horn harness to the clock spring.

(9) Remove steering wheel (Refer to 19 - STEER-

ING/COLUMN/STEERING WHEEL - REMOVAL).

(10) Remove steering column shrouds and discon-

nect traction control wire connector (if equipped)

(Refer to 19 - STEERING/COLUMN/LOWER

SHROUD - REMOVAL).

(11) Disconnect 4-way and 6-way connectors

between the clock spring and the instrument panel

wiring harness.

(12) Remove clock spring from column assembly by

removing the two retaining screws that attach the

clock spring to the column.

INSTALLATION

(1) Install the clock spring on the column.

(2) Connect the 4-way and 6-way connectors

between the clock spring and the instrument panel

wiring harness.

(3) Install the steering column shrouds and con-

nect traction control wire connector (if equipped)

(Refer to 19 - STEERING/COLUMN/LOWER

SHROUD - INSTALLATION).

(4) Install the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

INSTALLATION).

(5) Connect the 4±way harness connector to the

speed control/horn harness to the clock spring.

(6) Connect the 2±way connector to the remote

radio control harness.

(7) Install the driver airbag (Refer to 8 - ELEC-

TRICAL/RESTRAINTS/DRIVER AIRBAG - INSTAL-

LATION). Torque the two screws to 10 N´m (90 in.

lbs.).

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE (Refer to 8 - ELECTRICAL/RE-

STRAINTS - DIAGNOSIS AND TESTING).

PERSONAL INJURY OR DEATH MAY RESULT IF

THE SYSTEM TEST IS NOT PERFORMED PROP-

ERLY.

RSRESTRAINTS8O-5

CLOCK SPRING (Continued)

Page 661 of 2585

DRIVER AIRBAG

DESCRIPTION

The Driver Airbag is located in the center of the

steering wheel. The most visible part of the airbag is

the cover/horn switch. The Driver Airbag and Driver

Airbag Cover/Horn Pad are serviced separately from

each other.

OPERATION

The Driver Airbag cover contains the horn switch,

inflator device, and a fabric bag. The airbag cover/

horn switch is serviced separately from the inflator

and bag components.

When the front airbag system is deployed, the fol-

lowingMUSTbe replaced:

²Complete Steering Column Assembly.

²Lower Steering Column Coupler.

²Steering Wheel.

²Clock Spring.

²Driver Airbag

²Passenger Airbag

²Upper Instrument Panel with Pad.

CARE OF UNDEPLOYED AIRBAGS

Airbags must be stored in their original special

container until used for service. At no time should a

source of electricity be permitted near the inflator on

the back of an airbag. When carrying or handling an

undeployed airbag, the trim side of the airbag should

be pointing away from the body to minimize possibil-

ity of injury if accidental deployment occurs. Do not

place undeployed airbag face down on a solid surface,

the airbag will propel into the air if accidental

deployment occurs.

REMOVAL

DEPLOYED AIRBAG

(1) Clean powder residue from interior of vehicle

(Fig. 1).

(2) Position steering wheel and front wheels

straight ahead.

(3) Release hood latch and open hood.

(4) Disconnect and isolate the battery negative

cable.

(5) Wait two minutes for the system reserve capac-

itor to discharge before beginning any airbag compo-

nent service.

(6) Remove two screws retaining driver airbag to

steering wheel.

(7) Disconnect wire connectors from back of driver

airbag.

(8) Disconnect the 2±way connector from remote

radio control harness.(9) Disconnect the 4±way harness connector from

the speed control/horn harness to the clock spring.

(10) Remove steering wheel (Refer to 19 - STEER-

ING/COLUMN/STEERING WHEEL - REMOVAL).

(11) Remove steering column shrouds and discon-

nect traction control wire connector (if equipped)

(Refer to 19 - STEERING/COLUMN/LOWER

SHROUD - REMOVAL).

(12) Disconnect 4-way and 6-way connectors

between the clock spring and the instrument panel

wiring harness.

(13) Remove clock spring from column assembly by

removing the two retaining screws that attach the

clock spring to the column.

NOTE: The clock spring, steering wheel, and com-

plete steering column assembly w/lower steering

column coupler must be replaced also in the event

of a driver airbag deployment

UNDEPLOYED AIRBAG

(1) Release hood latch and open hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Wait two minutes for the system reserve capac-

itor to discharge before beginning any airbag compo-

nent service.

(4) Remove two screws retaining driver airbag to

steering wheel.

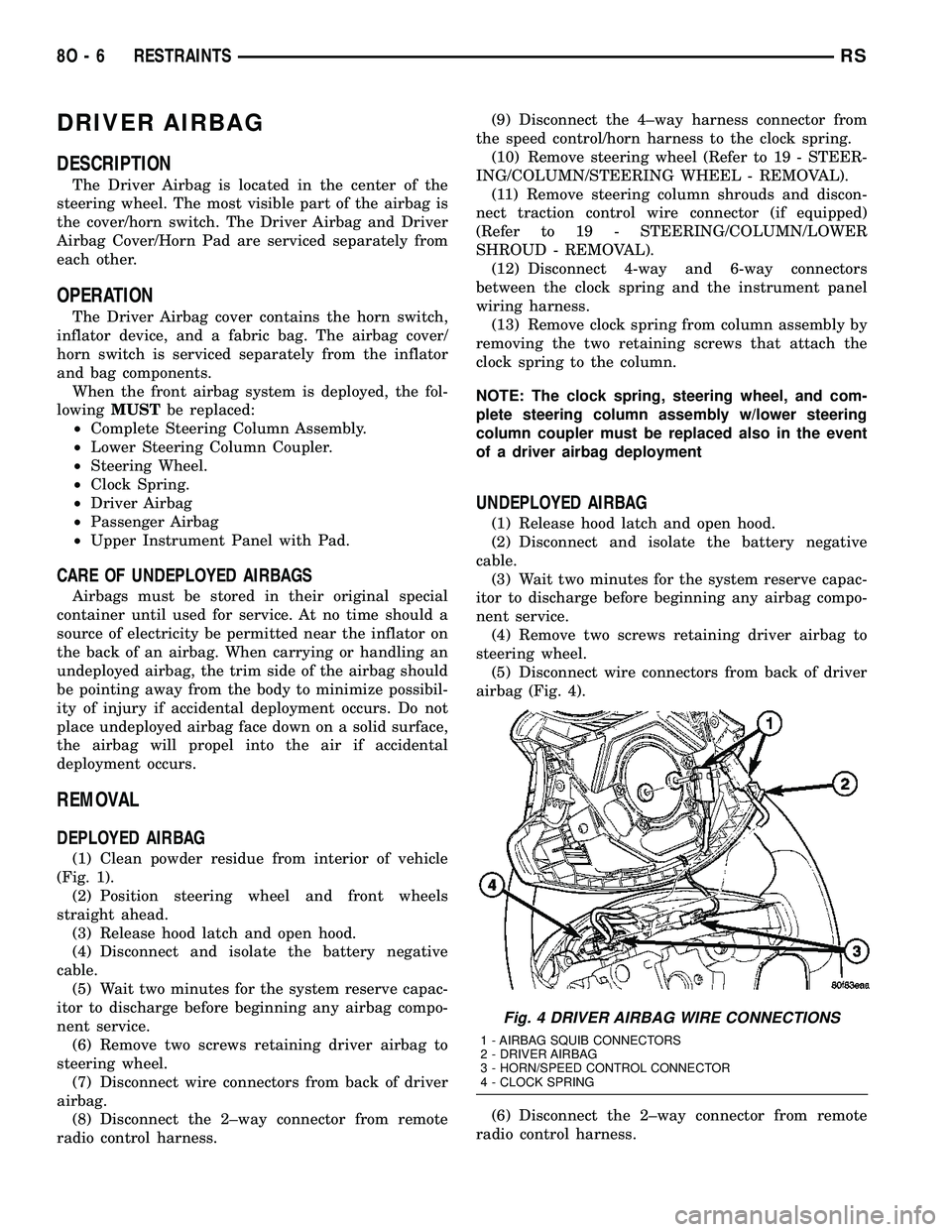

(5) Disconnect wire connectors from back of driver

airbag (Fig. 4).

(6) Disconnect the 2±way connector from remote

radio control harness.

Fig. 4 DRIVER AIRBAG WIRE CONNECTIONS

1 - AIRBAG SQUIB CONNECTORS

2 - DRIVER AIRBAG

3 - HORN/SPEED CONTROL CONNECTOR

4 - CLOCK SPRING

8O - 6 RESTRAINTSRS

Page 662 of 2585

(7) Disconnect the 4±way harness connector from

the speed control/horn harness to the clock spring.

INSTALLATION

DEPLOYED AIRBAG

(1) Perform clean up procedure (Refer to 8 - ELEC-

TRICAL/RESTRAINTS - STANDARD PROCEDURE

- SERVICE AFTER AN AIRBAG DEPLOYMENT).

(2) Install a new steering column assembly and

lower steering column coupler (Refer to 19 - STEER-

ING/COLUMN - INSTALLATION).

(3) Install the new clock spring.

(4) Connect the 4-way and 6-way connectors

between the clock spring and the instrument panel

wiring harness.

(5) Install the steering column shrouds and con-

nect traction control wire connector (if equipped)

(Refer to 19 - STEERING/COLUMN/LOWER

SHROUD - INSTALLATION).

(6) Install the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

INSTALLATION).

(7) Connect the 4±way harness connector to the

speed control/horn harness to the clock spring.

(8) Connect the 2±way connector to the remote

radio control harness.

(9) Install the driver airbag and the two screws

retaining the airbag. Tighten screws to 10 N´m (90

in. lbs.)

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE (Refer to 8 - ELECTRICAL/RE-

STRAINTS - DIAGNOSIS AND TESTING).

PERSONAL INJURY OR DEATH MAY RESULT IF

THE SYSTEM TEST IS NOT PERFORMED PROP-

ERLY.

UNDEPLOYED AIRBAG

(1) Connect the harness connector on the DAB

cover (horn, speed controls) to the clock spring.

(2) Connect the squib connectors to the DAB.

(3) Position a new airbag into the airbag cavity.

(4) Install the two screws retaining the airbag.

Tighten screws to 10 N´m (90 in. lbs.)

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE (Refer to 8 - ELECTRICAL/RE-

STRAINTS - DIAGNOSIS AND TESTING).

PERSONAL INJURY OR DEATH MAY RESULT IF

THE SYSTEM TEST IS NOT PERFORMED PROP-

ERLY.

DRIVER AIRBAG TRIM COVER

REMOVAL

The horn switch is integral to the driver airbag

trim cover. If either component is faulty or damaged,

the entire driver airbag trim cover and horn switch

unit must be replaced.

(1) Disconnect and isolate the battery negative

cable. Wait two minutes for the system capacitor to

discharge.

(2) Remove the driver airbag from the steering

wheel (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - REMOVAL).

(3) Remove the plastic wire retainer that captures

the horn switch feed pigtail wire between the upper

left inflator stud and the inflator on the back of the

driver airbag housing and disconnect the speed con-

trol switches (if equipped).

(4) Remove the four nuts that secure the trim

cover retainer to the studs on the back of the driver

airbag housing.

(5) Remove the horn switch ground pigtail wire

eyelet terminal from the upper left airbag housing

stud.

(6) Remove the trim cover retainer from the airbag

housing studs.

(7) Disengage the six trim cover locking blocks

from the lip around the outside edge of the driver

airbag housing and remove the housing from the

cover.

INSTALLATION

(1) Install the housing into the cover. Engage the

six trim cover locking blocks to the lip around the

outside edge of the driver airbag housing.

(2) Install the trim cover retainer to the airbag

housing studs.

(3) Install the horn switch ground pigtail wire eye-

let terminal to the upper left airbag housing stud.

(4) Install the four nuts that secure the upper and

lower trim cover retainers to the studs on the back of

the driver airbag housing. Torque nuts to 6.8 N´m (60

in. lbs.).

(5) Install the plastic wire retainer that captures

the horn switch feed pigtail wire between the upper

left inflator stud and the inflator on the back of the

driver airbag housing.

(6) Connect speed control switches (if equipped).

(7) Install the driver airbag onto the steering

wheel (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - INSTALLATION).

RSRESTRAINTS8O-7

DRIVER AIRBAG (Continued)

Page 663 of 2585

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE (Refer to 8 - ELECTRICAL/RE-

STRAINTS - DIAGNOSIS AND TESTING).

PERSONAL INJURY OR DEATH MAY RESULT IF

THE SYSTEM TEST IS NOT PERFORMED PROP-

ERLY.

OCCUPANT RESTRAINT

CONTROLLER

DESCRIPTION

The front driver and passenger airbag system is

designed to reduce the risk of fatality or serious

injury, caused by a frontal impact of the vehicle.

The Occupant Restraint Controller (ORC) is also

sometimes referred to as the Airbag Control Module

(ACM). The ORC contains the impact sensor and

energy reserve capacitor. It is mounted on a bracket,

under the instrument panel, just forward of the stor-

age bin. The ORC monitors the system to determine

the system readiness. The ORC contains on-board

diagnostics and will light the AIRBAG warning lamp

in the message center when a problem occurs.

OPERATION

The impact sensor provides verification of the

direction and severity of the impact. One impact sen-

sor is used. It is located inside the Occupant

Restraint Controller (ORC). The impact sensor is an

accelerometer that senses deceleration. The decelera-

tion pulses are sent to a microprocessor which con-

tains a decision algorithm. When an impact is severe

enough to require airbag protection, the ORC micro-

processor sends a signal that completes the electrical

circuit to the driver and passenger airbags. The

impact sensor is calibrated for the specific vehicle

and reacts to the severity and direction of an impact.

REMOVAL

NOTE: Diagnose the ORC using the service/diag-

nostic manual.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove storage bin from instrument panel.

Refer to Body, Instrument Panel, Storage Bin,

Removal.

(3) Remove three bolts holding ORC to floor

bracket.

(4) Disconnect the wire connector from ORC.

(5) Remove the ORC assembly from vehicle.

INSTALLATION

WARNING: DO NOT INSTALL ORC IF MOUNTING

LOCATION IS DEFORMED OR DAMAGED. THIS

WILL CAUSE THE ORC TO BE IMPROPERLY

LOCATED AND COULD RESULT IN OCCUPANT

PERSONAL INJURY OR DEATH.

CAUTION: Use correct screws when installing the

ORC.

(1) Install the ORC assembly into vehicle.

(2) Connect the wire connector to the ORC.

(3) Install three bolts holding ORC to floor

bracket. Torque bolts to 7.3 - 9.6 N´m (65 to 85 in.

lbs.)

(4) Install the storage bin onto the instrument

panel. Refer to Body, Instrument Panel, Storage Bin,

Installation.

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE (Refer to 8 - ELECTRICAL/RE-

STRAINTS - DIAGNOSIS AND TESTING).

PERSONAL INJURY OR DEATH MAY RESULT IF

THE SYSTEM TEST IS NOT PERFORMED PROP-

ERLY.

PASSENGER AIRBAG

DESCRIPTION

WARNING: NEVER DISASSEMBLE THE PASSEN-

GER AIRBAG, THE PASSENGER AIRBAG HAS NO

SERVICEABLE PARTS. IF TAMPERED WITH INTER-

NALLY, THE AIRBAG COULD DEPLOY AND RESULT

IN PERSONAL INJURY OR DEATH.

The Passenger Airbag is located beneath the

instrument panel and pad assembly. The airbag is

mounted to the back side of the instrument panel

reinforcement.

The instrument panel top pad is the most visible

part of the passenger airbag system. Located under

the instrument panel top pad are the airbag door, the

passenger airbag cushion and the airbag cushion

supporting components.

The passenger airbag includes a magnesium hous-

ing within which the cushion and inflator are

mounted and sealed.

Following a passenger airbag deployment, the pas-

senger airbag and the instrument panel must be

replaced. The passenger airbag cannot be repaired,

and must be replaced if deployed or damaged in any

way.

8O - 8 RESTRAINTSRS

DRIVER AIRBAG TRIM COVER (Continued)

Page 664 of 2585

OPERATION

The passenger airbag is equipped with two infla-

tors, each with three levels of pressure output. The

inflators seal the hole in the airbag cushion so it can

discharge the gas it produces directly into the cush-

ion when supplied with the proper electrical signal.

Following an airbag deployment, the airbag cushion

quickly deflates by venting this gas through the

cushion material towards the instrument panel.

The passenger airbag is secured with screws to the

instrument panel beneath the instrument panel top

pad and above the glove box opening. The instrument

panel top pad above the glove box opening conceals

the airbag door and a predetermined hinge line

beneath its decorative cover. Upon airbag deploy-

ment, the top pad will bend at the hinge line and the

door will fold back out of the way onto the top of the

instrument panel.

When the front airbag system is deployed, the fol-

lowingMUSTbe replaced:

²Complete Steering Column Assembly.

²Lower Steering Column Coupler.

²Steering Wheel.

²Clock Spring.

²Driver Airbag.

²Passenger Airbag.

²Upper Instrument Panel with Pad.

CARE OF UNDEPLOYED AIRBAGS

Airbags must be stored in their original special

container until used for service. At no time should a

source of electricity be permitted near the inflator on

the back of an airbag. When carrying or handling an

undeployed airbag, the trim side of the airbag should

be pointing away from the body to minimize possibil-

ity of injury if accidental deployment occurs. Do not

place undeployed airbag face down on a solid surface,

the airbag will propel into the air if accidental

deployment occurs.

REMOVAL

DEPLOYED AIRBAG

(1) Clean powder residue from interior of vehicle

(Refer to 8 - ELECTRICAL/RESTRAINTS - STAN-

DARD PROCEDURE - SERVICE AFTER AN AIR-

BAG DEPLOYMENT).

(2) Remove instrument panel (Refer to 23 - BODY/

INSTRUMENT PANEL/INSTRUMENT PANEL

ASSEMBLY - REMOVAL).

(3) Remove all reusable components from the

upper instrument panel and transfer to the new

instrument panel.

UNDEPLOYED AIRBAG

(1) Open hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Wait two minutes for the airbag system reserve

capacitor to discharge before attempting any airbag

or instrument panel service.

(4) Remove center console bin between front seats.

(5) Remove left front door sill plate using a trim

stick (special tool #C-4755) or equivalent, and gently

prying up on sill plate.

(6) Remove left cowl panel using a trim stick or

equivalent, and gently prying out on cowl panel.

(7) Remove four screws to lower steering column

cover and remove cover.

(8) Unsnap parking brake lever from knee blocker

reinforcement.

(9) Remove Data Link Connector (DLC) from knee

blocker.

(10) Remove screws to knee blocker.

(11) Unsnap left A-pillar lower extension trim

using a trim stick or equivalent.

(12) Remove three left side instrument panel A-pil-

lar retaining bolts and loosen the instrument panel

roll down bolt.

(13) Remove four nuts at brake pedal support

bracket to instrument panel.

(14) Using a trim stick or equivalent, gently pry

off left side upper A-pillar trim.

(15) Remove six screws and two wiring connectors

to lower instrument panel cubby bin at bottom of

center stack.

(16) Remove two left side nuts at instrument panel

center stack support to floor.

(17) Remove two right side nuts at instrument

panel center stack support to floor.

(18) Remove right front door sill plate using a trim

stick or equivalent, and gently prying up on sill

plate.

(19) Remove right cowl panel using a trim stick or

equivalent, and gently prying out on cowl panel.

(20) Using a trim stick or equivalent, gently pry

out on right instrument panel end cap.

(21) Unsnap right A-pillar lower extension trim

using a trim stick or equivalent.

(22) Remove three right side instrument panel

A-pillar retaining bolts and loosen the instrument

panel roll down bolt.

(23) Using a trim stick or equivalent, gently pry

off right side upper A-pillar trim.

(24) Open glove box, pinch in sides and roll down

towards floor. With a firm pull, snap glove box door

off hinges and remove.

(25) Using a trim stick or equivalent, gently pry

up on rear of instrument panel top cover and then

pull rearward and out.

RSRESTRAINTS8O-9

PASSENGER AIRBAG (Continued)

Page 665 of 2585

(26) Using a trim stick or equivalent, gently pry

off the filler bezel just above the cup holder to expose

the lower screws to center bezel.

(27) Remove two screws and then using a trim

stick or equivalent, gently pry off instrument panel

center bezel.

(28) Remove center bezel wiring connectors to

HVAC control and switch assembly (hazard, rear

wiper/washer, heated seats) and remove bezel.

(29) Slide cup holder assembly from instrument

panel.

(30) Remove nineteen screws to right lower instru-

ment panel trim (glove box surround), unplug glove

box lamp wire connector, and remove panel.

(31) Remove four screws and wiring connectors to

radio and remove radio.

(32) Remove one far left instrument panel speaker

retaining screw.

(33) Remove four screws along top front edge of

instrument panel cover/pad.

(34) Remove seven lower instrument panel cover/

pad retaining screws starting from right of vehicle

and only removing these seven, not all of them.

(35) Remove six upper fence line instrument panel

retaining bolts.

(36) Roll back instrument panel just enough to

increase access to the passenger airbag retaining

bolts at the reinforcement. Lift the instrument panel

up slightly so as not to damage the air distribution to

HVAC unit seal.

(37) Disconnect the passenger airbag electrical

connector. Using a trim stick or equivalent, gently

pry electrical connector off of instrument panel rein-

forcement.

(38) Remove the two passenger airbag to instru-

ment panel cover/pad retaining screws.

(39) Remove the three passenger airbag to instru-

ment panel reinforcement retaining bolts.

(40) Pull rearward slightly on the instrument

panel cover/pad to maneuver passenger airbag out

from reinforcement and instrument panel.

INSTALLATION

DEPLOYED AIRBAG

Transfer all reusable components to the new

instrument panel.

(1) Install new Passenger Airbag into instrument

panel.

(2) Install airbag attaching bolts to the instrument

panel.

(a) Torque the two bolts at instrument panel

retainer bosses to 2.7 .5 N´m (24 5 in. lbs.).

(b) Torque the three bolts that attach the pas-

senger airbag to cross-car beam to 10 2 N´m (90

15 in. lbs.).(3) Connect yellow wire connector to passenger air-

bag and affix connector to instrument panel rein-

forcement with push pins.

(4) Install Instrument panel (Refer to 23 - BODY/

INSTRUMENT PANEL/INSTRUMENT PANEL

ASSEMBLY - INSTALLATION).

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE (Refer to 8 - ELECTRICAL/RE-

STRAINTS - DIAGNOSIS AND TESTING).

PERSONAL INJURY OR DEATH MAY RESULT IF

THE SYSTEM TEST IS NOT PERFORMED PROP-

ERLY.

UNDEPLOYED AIRBAG

(1) Pull rearward slightly on the instrument panel

cover/pad to maneuver passenger airbag up onto

reinforcement and instrument panel.

(2) Install the three passenger airbag to instru-

ment panel reinforcement retaining bolts but leave

loose. This will help align the passenger airbag for

the cover/pad fit.

(3) Install the two passenger airbag to instrument

panel cover/pad retaining screws. Torque screws to

2.7 .5 N´m (24 5 in. lbs.).

NOTE: Insure that the instrument panel cover/pad

locator pins are indexed properly at center stack

area prior to reassembly.

(4) Tighten the three passenger airbag to instru-

ment panel reinforcement retaining bolts. Torque

bolts to 10 2 N´m (90 15 in. lbs.).

(5) Connect the passenger airbag electrical connec-

tor. Install the connector onto the instrument panel

reinforcement with the push-pin fasteners.

(6) Roll the instrument panel forward lifting

slightly so as to seat the instrument panel air distri-

bution duct on top of the HVAC unit properly to

avoid any leaks or damage to the seal.

(7) Install six upper fence line instrument panel

retaining bolts.

(8) Install three right side instrument panel A-pil-

lar retaining bolts and tighten the right instrument

panel roll down bolt. Install the smaller 10 mm bolt

first to align the instrument panel properly.

(9) Install three left side instrument panel A-pillar

retaining bolts and tighten the left instrument panel

roll down bolt. Install the smaller 10 mm bolt first to

align the instrument panel properly.

(10) Install seven lower instrument panel cover/

pad retaining screws.

(11) Install four screws along top front edge of

instrument panel cover/pad.

(12) Install one far left instrument panel speaker

retaining screw.

8O - 10 RESTRAINTSRS

PASSENGER AIRBAG (Continued)

Page 666 of 2585

(13) Install wiring connectors to radio. Install

radio and four retaining screws.

(14) Connect glove box lamp wiring connector and

place right lower instrument panel trim (glove box

surround) into position.

(15) Install nineteen right lower instrument panel

trim (glove box surround) and install panel screws.

(16) Slide cup holder assembly into instrument

panel.

(17) Install center bezel wiring connectors to

HVAC control and switch assembly (hazard, rear

wiper/washer, heated seats).

(18) Install instrument panel center bezel by align-

ing slots and firmly snapping into place.

(19) Install two screws to instrument panel center

bezel.

(20) Align filler bezel above cup holder over retain-

ing slots and firmly snap into place.

(21) Place instrument panel top cover into position

and firmly snap down rear edge of top cover.

(22) Install glove box. Align hinges, snap into

place, roll glove box upwards and push in sides to

fully install.

(23) Align right side upper A-pillar trim over

retaining slots and firmly snap into place.

(24) Align right A-pillar lower extension trim over

retaining slots and firmly snap into place.

(25) Align right instrument panel end cap over

retaining slots and firmly snap into place.

(26) Align right cowl panel over retaining slots and

firmly snap into place.

(27) Align right front door sill plate over retaining

slots and firmly snap into place.

(28) Install two right side nuts at instrument

panel center stack support to floor.

(29) Install two left side nuts at instrument panel

center stack support to floor.

(30) Connect the two wiring connectors to lower

instrument panel cubby bin at bottom of center stack

and install six screws.

(31) Align left side upper A-pillar trim over retain-

ing slots and firmly snap into place.

(32) Install four nuts at brake pedal support

bracket to instrument panel.

(33) Align left A-pillar lower extension trim over

retaining slots and firmly snap into place.

(34) Install knee blocker and retaining screws.

(35) Install Data Link Connector (DLC) into bot-

tom of knee blocker.

(36) Align parking brake lever and snap into place

on knee blocker reinforcement.

(37) Install lower steering column cover and four

retaining screws

(38) Align left cowl panel over retaining slots and

firmly snap into place.(39) Align left front door sill plate over retaining

slots and firmly snap into place.

(40) Install center console bin between front seats.

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE (Refer to 8 - ELECTRICAL/RE-

STRAINTS - DIAGNOSIS AND TESTING).

PERSONAL INJURY OR DEATH MAY RESULT IF

THE SYSTEM TEST IS NOT PERFORMED PROP-

ERLY.

(41) Close hood.

(42) Verify system and vehicle operation.

SEAT AIRBAG

DESCRIPTION

The side impact airbag system Seat Airbags are

located in the outboard side of the front seat backs.

One in each front seat. The seat airbag inflator

assembly is within the airbag housing (Fig. 5). Each

airbag is mounted to the seat back frame. If deployed

or defective, the entire seat back assembly must be

replaced.

OPERATION

Only the Side Impact Airbag Control Module

(SIACM) can deploy the side airbags. When supplied

with the proper electrical signal, the seat airbag

inflator will produce a gas and discharge the bag

directly between the occupant and the side of the

vehicle, protecting the occupant. Upon deployment,

Fig. 5 SEAT AIRBAG - TYPICAL

RSRESTRAINTS8O-11

PASSENGER AIRBAG (Continued)

Page 684 of 2585

sends a9valid key9message to the Powertrain Con-

trol Module (PCM) over the Programmable Commu-

nication Interface (PCI) data bus. If the response

received identifies the key as invalid or no response

is received from the transponder in the ignition key,

the SKREEM sends an9invalid key9message to the

PCM. The PCM will enable or disable engine opera-

tion based upon the status of the SKREEM mes-

sages. It is important to note that the default

condition in the PCM is9invalid key.9Therefore, if no

response is received by the PCM, the engine will be

immobilized after two (2) seconds of running.

The SKREEM also sends indicator light status

messages to the Mechanical Instrument Cluster

(MIC) to operate the light. This is the method used to

turn the light ON solid or to flash it after the indi-

cator light test is complete to signify a fault in the

SKREES. If the light comes ON and stays ON solid

after the indicator light test, this signifies that the

SKREEM has detected a system malfunction and/or

that the SKREES has become inoperative. If the

SKREEM detects an invalid keyORa key-related

fault exists, the indicator light will flash following

the indicator light test. The SKREEM may also

request an audible chime if the customer key pro-

gramming feature is available and the procedure is

being utilized (Refer to 8 - ELECTRICAL/VEHICLE

THEFT SECURITY/TRANSPONDER KEY - STAN-

DARD PROCEDURE).

REMOTE KEYLESS ENTRY (RKE)

After pressing the lock button on the RKE trans-

mitter, all of the door locks will lock, the illuminated

entry will turn off (providing all doors are closed),

and the VTSS (if equipped) will arm. After pressing

the unlock button, on the RKE transmitter, one time,

the driver door lock will unlock, the illuminated

entry will turn on the courtesy lamps, and the VTSS

(if equipped) will disarm. After pressing the unlock

button a second time, the remaining door locks will

unlock. The Electronic Vehicle Information Center

(EVIC) or the DRBIIItscan tool can reprogram this

feature to unlock all of the door locks with one press

of the unlock button. If the vehicle is equipped with

the memory system, the memory message will iden-

tify which transmitter (1 or 2) sent the signal.

The SKREEM is capable of retaining up to 8 indi-

vidual access codes (8 transmitters). If the PRNDL is

in any position except park, the SKREEM will dis-

able the RKE. The 4 button transmitter uses

1-CR2032 battery. The minimum battery life is

approximately 4.7 years based on 20 transmissions a

day at 84ÉF (25ÉC). Use the DRBIIItscan tool or the

Miller Tool 9001 RF Detector to test the RKE trans-

mitter. Use the DRBIIItor the customer program-

ming method to program the RKE system. However,the SKREEM will only allow RKE programming

when the ignition is in the ON position, the PRNDL

is in park position, and the VTSS (if equipped) is dis-

armed.

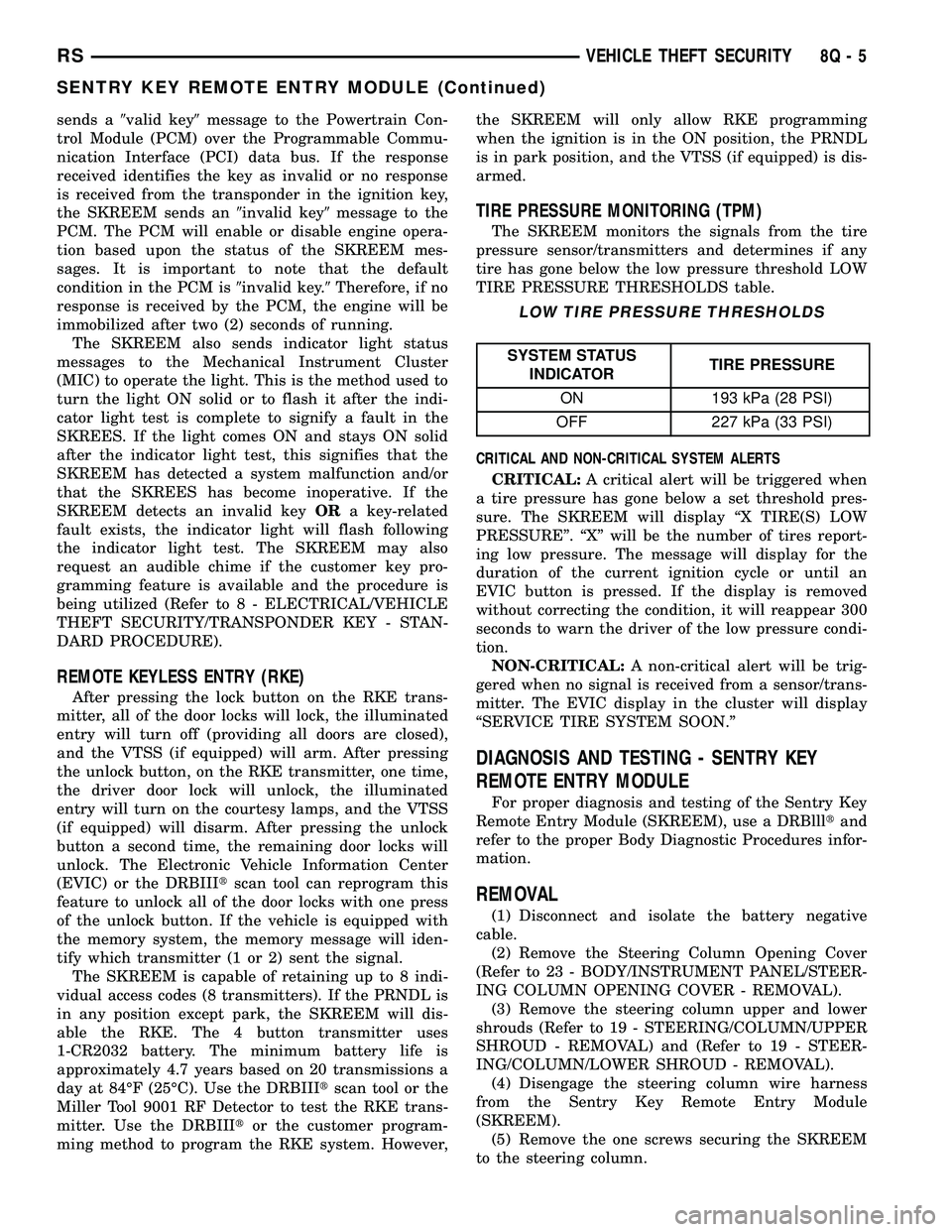

TIRE PRESSURE MONITORING (TPM)

The SKREEM monitors the signals from the tire

pressure sensor/transmitters and determines if any

tire has gone below the low pressure threshold LOW

TIRE PRESSURE THRESHOLDS table.

LOW TIRE PRESSURE THRESHOLDS

SYSTEM STATUS

INDICATORTIRE PRESSURE

ON 193 kPa (28 PSI)

OFF 227 kPa (33 PSI)

CRITICAL AND NON-CRITICAL SYSTEM ALERTS

CRITICAL:A critical alert will be triggered when

a tire pressure has gone below a set threshold pres-

sure. The SKREEM will display ªX TIRE(S) LOW

PRESSUREº. ªXº will be the number of tires report-

ing low pressure. The message will display for the

duration of the current ignition cycle or until an

EVIC button is pressed. If the display is removed

without correcting the condition, it will reappear 300

seconds to warn the driver of the low pressure condi-

tion.

NON-CRITICAL:A non-critical alert will be trig-

gered when no signal is received from a sensor/trans-

mitter. The EVIC display in the cluster will display

ªSERVICE TIRE SYSTEM SOON.º

DIAGNOSIS AND TESTING - SENTRY KEY

REMOTE ENTRY MODULE

For proper diagnosis and testing of the Sentry Key

Remote Entry Module (SKREEM), use a DRBllltand

refer to the proper Body Diagnostic Procedures infor-

mation.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the Steering Column Opening Cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - REMOVAL).

(3) Remove the steering column upper and lower

shrouds (Refer to 19 - STEERING/COLUMN/UPPER

SHROUD - REMOVAL) and (Refer to 19 - STEER-

ING/COLUMN/LOWER SHROUD - REMOVAL).

(4) Disengage the steering column wire harness

from the Sentry Key Remote Entry Module

(SKREEM).

(5) Remove the one screws securing the SKREEM

to the steering column.

RSVEHICLE THEFT SECURITY8Q-5

SENTRY KEY REMOTE ENTRY MODULE (Continued)

Page 685 of 2585

(6) Rotate the SKREEM upwards and then to the

side away from the steering column to slide the

SKREEM antenna ring from around the ignition

switch lock cylinder housing.

(7) Remove the SKREEM from the vehicle.

INSTALLATION

(1) Slip the Sentry Key Remote Entry Module

(SKREEM) antenna ring around the ignition switch

lock cylinder housing. Rotate the SKREEM down-

wards and then towards the steering column.

(2) Install the one screws securing the SKREEM to

the steering column.

(3) Connect the steering column wire harness to

the SKREEM.

(4) Install the steering column upper and lower

shrouds (Refer to 19 - STEERING/COLUMN/UPPER

SHROUD - INSTALLATION) and (Refer to 19 -

STEERING/COLUMN/LOWER SHROUD - INSTAL-

LATION).

(5) Install the Steering Column Opening Cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - INSTALLA-

TION)

(6) Connect the battery negative cable.

TRANSPONDER KEY

DESCRIPTION

The Sentry Key Remote Entry System (SKREES)

uses a transponder chip that is integral to each igni-

tion key to communicate with the Sentry Key Remote

Entry Module (SKREEM). Ignition keys are supplied

with the vehicle when it is shipped from the factory.

The transponder chip is undermolded within the

head of the key.

OPERATION

Each Sentry Key has a unique transponder identi-

fication code permanently programmed into it by the

manufacturer. Likewise, the Sentry Key Remote

Entry Module (SKREEM) has a unique9Secret Key9

code programmed into it by the manufacturer as

well. When a Sentry Key is programmed into the

memory of the SKREEM, the SKREEM stores the

transponder identification code from the Sentry Key,

and the Sentry Key learns the9Secret Key9code from

the SKREEM. Once the Sentry Key learns the

9Secret Key9code of the SKREEM, it is also perma-

nently programmed into the transponder's memory.

Therefore, blank keys for the Sentry Key Remote

Entry System (SKREES) must be programmed by

the SKREEM in addition to being cut to match the

mechanical coding of the ignition lock cylinder. Refer

to Electrical, Vehicle Theft Security, TransponderKey, Standard Procedure - Transponder Program-

ming.

The Sentry Key's transponder is within the range

of the SKREEM's transceiver antenna ring when it is

inserted into the ignition lock cylinder. When the

ignition switch is turned to the ON position, the

SKREEM communicates with the Sentry Key via a

radio frequency (RF) signal. The SKREEM deter-

mines if a valid key is present based on the informa-

tion it receives from the Sentry Key. If a valid key is

detected, that fact is communicated to the PCM via

the PCI bus and the vehicle is allowed to continue

running. If an invalid key is received by the PCM or

no status at all is communicated, the vehicle will

stall after two (2) seconds of running. The indicator

light will be flashing at this point. The Sentry Key's

transponder can not be repaired. If it is faulty or

damaged, it must be replaced.

Common communication problems:

²Two transponder keys too close together.

²Speed Pass too close to transponder key.

Solid indicator that there is a system failure.

²Loss of PCM communication.

²Failed antenna circuit.

STANDARD PROCEDURE - TRANSPONDER

PROGRAMMING

USING A DRBIIITSCAN TOOL

All Sentry Keys included with the vehicle are pre-

programmed to work with the Sentry Key Remote

Entry System (SKREES) when it is shipped from the

factory. The Sentry Key Remote Entry Module

(SKREEM) can be programmed to recognize up to a

total of eight Sentry Keys. When programming a

blank Sentry Key transponder, the key must first be

cut to match the ignition lock cylinder of the vehicle

for which it will be used. The vehicle's four digit PIN

code will be required to complete this task since you

will need it to enter the Secured Access Mode in the

SKREEM. The following steps must be completed

using a DRBIIItscan tool:

(1) Insert the blank key into the ignition and turn

it to the RUN position.

(2) Using a DRBIIItscan tool, select9Theft

Alarm,99SKREEM,99Miscellaneous,9and then9Pro-

gram New Key.9

(3) Enter the four digit PIN code using the

DRBIIItscan tool. When programming is completed,

the SKREEM will exit Secured Access Mode and the

DRBIIItscan tool will display the results of your

attempt to program the key. One of five distinct

results may be displayed. All five are listed below:

²(Programming Successful(is displayed if the

Sentry Key programming is successful.

8Q - 6 VEHICLE THEFT SECURITYRS

SENTRY KEY REMOTE ENTRY MODULE (Continued)