instrument panel CHRYSLER VOYAGER 2004 Repair Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 497 of 2585

OPERATION

When the rear window defogger button is

depressed to the On position, current is directed to

the rear defogger grid lines and the heated power

mirrors (if equipped). The heated grid lines heat the

glass to help clear the rear window and side mirror

surfaces of fog or frost.

The defogger system is controlled by a momentary

switch located in the A/C-heater control on the

instrument panel. A yellow indicator in the switch

will illuminate to indicate when the defogger system

is turned on. The integrated power module (IPM)

contains the defogger system control circuitry.

NOTE:

The rear window defogger turns off automat-

ically after approximately 10 minutes of initial opera-

tion. Each following activation cycle of the defogger

system will last approximately five minutes.

The defogger system will be automatically turned

off after a programmed time interval of about ten

minutes. After the initial time interval has expired, if

the defogger switch is turned on again during the

same ignition cycle, the defogger system will auto-

matically turn off after about five minutes.

The defogger system will automatically shut off if

the ignition switch is turned to the Off position, or it

can be turned off manually by depressing the defog-

ger switch a second time.

DIAGNOSIS AND TESTING - REAR WINDOW

DEFOGGER SYSTEM

The electrically heated rear window defogger oper-

ation can be checked on the vehicle in the following

manner:

(1) Turn the ignition switch to the On position.

(2) Make sure that the defogger switch is Off.

(3) Using a ammeter on the battery, turn the rear

defogger control switch to the On position, a distinct

increase in amperage draw should be noted.

(4) The rear window defogger operation can be

checked by feeling the glass. A distinct difference in

temperature between the grid lines and adjacent

clear glass should be detected in three to four min-

utes of operation.

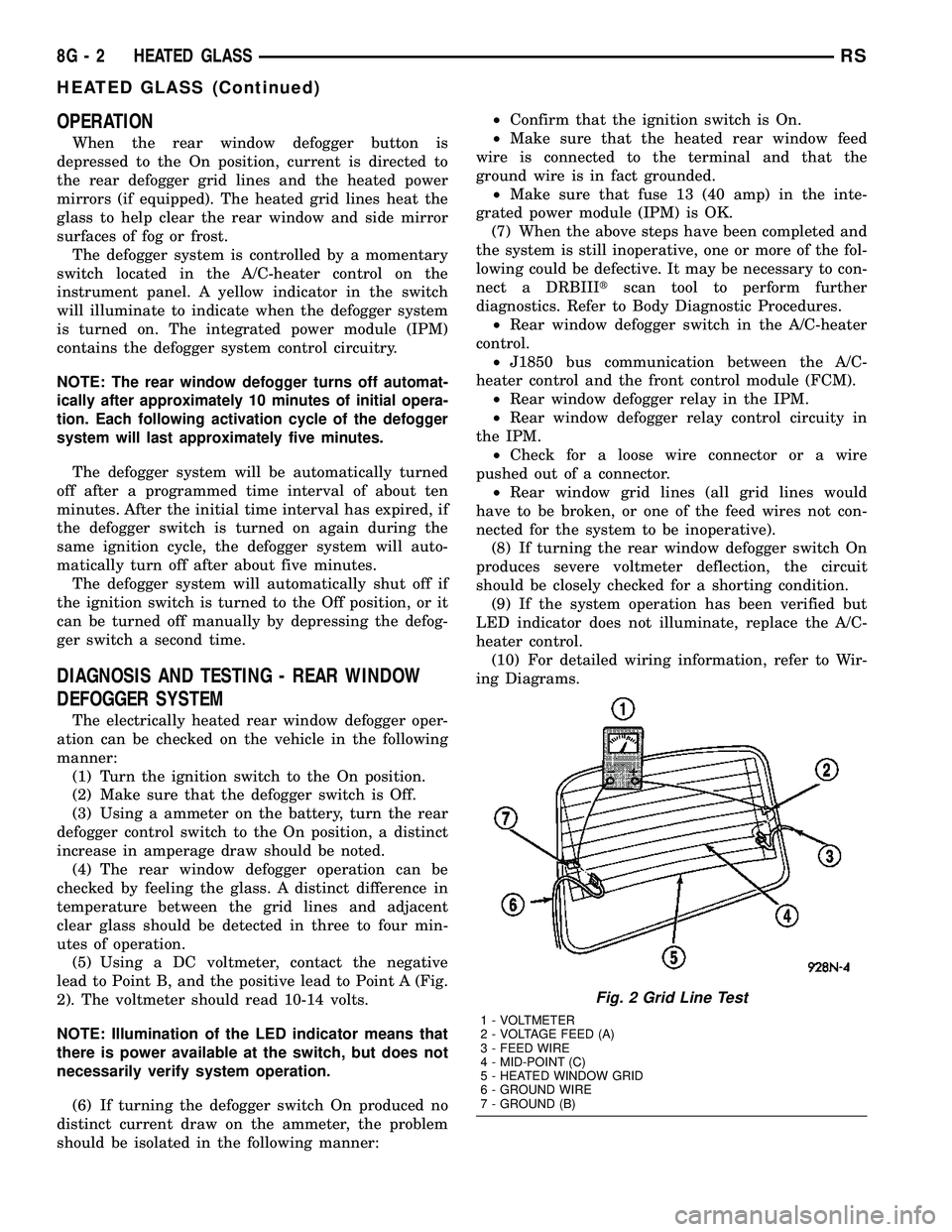

(5) Using a DC voltmeter, contact the negative

lead to Point B, and the positive lead to Point A (Fig.

2). The voltmeter should read 10-14 volts.

NOTE: Illumination of the LED indicator means that

there is power available at the switch, but does not

necessarily verify system operation.

(6) If turning the defogger switch On produced no

distinct current draw on the ammeter, the problem

should be isolated in the following manner:²Confirm that the ignition switch is On.

²Make sure that the heated rear window feed

wire is connected to the terminal and that the

ground wire is in fact grounded.

²Make sure that fuse 13 (40 amp) in the inte-

grated power module (IPM) is OK.

(7) When the above steps have been completed and

the system is still inoperative, one or more of the fol-

lowing could be defective. It may be necessary to con-

nect a DRBIIItscan tool to perform further

diagnostics. Refer to Body Diagnostic Procedures.

²Rear window defogger switch in the A/C-heater

control.

²J1850 bus communication between the A/C-

heater control and the front control module (FCM).

²Rear window defogger relay in the IPM.

²Rear window defogger relay control circuity in

the IPM.

²Check for a loose wire connector or a wire

pushed out of a connector.

²Rear window grid lines (all grid lines would

have to be broken, or one of the feed wires not con-

nected for the system to be inoperative).

(8) If turning the rear window defogger switch On

produces severe voltmeter deflection, the circuit

should be closely checked for a shorting condition.

(9) If the system operation has been verified but

LED indicator does not illuminate, replace the A/C-

heater control.

(10) For detailed wiring information, refer to Wir-

ing Diagrams.

Fig. 2 Grid Line Test

1 - VOLTMETER

2 - VOLTAGE FEED (A)

3 - FEED WIRE

4 - MID-POINT (C)

5 - HEATED WINDOW GRID

6 - GROUND WIRE

7 - GROUND (B)

8G - 2 HEATED GLASSRS

HEATED GLASS (Continued)

Page 499 of 2585

(2) Position the rear window defogger relay into

the proper receptacle in the IPM.

(3) Align the rear window defogger relay terminals

with the terminal cavities in the IPM receptacle.

(4) Push down firmly on the rear window defogger

relay until the terminals are fully seated in the ter-

minal cavities in the IPM receptacle.

(5) Install the cover onto the IPM.

(6) Reconnect the battery negative cable.

REAR WINDOW DEFOGGER

SWITCH

DESCRIPTION

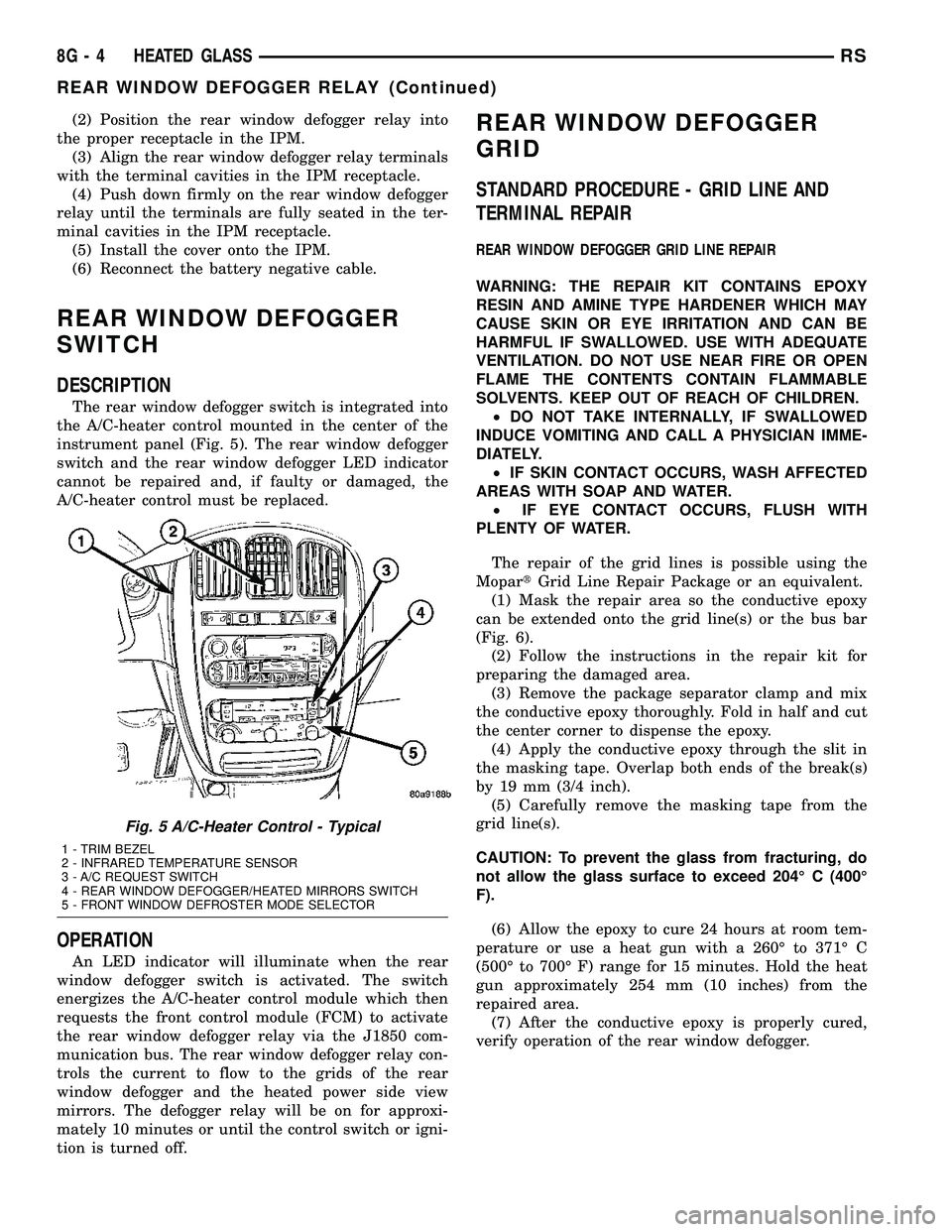

The rear window defogger switch is integrated into

the A/C-heater control mounted in the center of the

instrument panel (Fig. 5). The rear window defogger

switch and the rear window defogger LED indicator

cannot be repaired and, if faulty or damaged, the

A/C-heater control must be replaced.

OPERATION

An LED indicator will illuminate when the rear

window defogger switch is activated. The switch

energizes the A/C-heater control module which then

requests the front control module (FCM) to activate

the rear window defogger relay via the J1850 com-

munication bus. The rear window defogger relay con-

trols the current to flow to the grids of the rear

window defogger and the heated power side view

mirrors. The defogger relay will be on for approxi-

mately 10 minutes or until the control switch or igni-

tion is turned off.

REAR WINDOW DEFOGGER

GRID

STANDARD PROCEDURE - GRID LINE AND

TERMINAL REPAIR

REAR WINDOW DEFOGGER GRID LINE REPAIR

WARNING: THE REPAIR KIT CONTAINS EPOXY

RESIN AND AMINE TYPE HARDENER WHICH MAY

CAUSE SKIN OR EYE IRRITATION AND CAN BE

HARMFUL IF SWALLOWED. USE WITH ADEQUATE

VENTILATION. DO NOT USE NEAR FIRE OR OPEN

FLAME THE CONTENTS CONTAIN FLAMMABLE

SOLVENTS. KEEP OUT OF REACH OF CHILDREN.

²DO NOT TAKE INTERNALLY, IF SWALLOWED

INDUCE VOMITING AND CALL A PHYSICIAN IMME-

DIATELY.

²IF SKIN CONTACT OCCURS, WASH AFFECTED

AREAS WITH SOAP AND WATER.

²IF EYE CONTACT OCCURS, FLUSH WITH

PLENTY OF WATER.

The repair of the grid lines is possible using the

MopartGrid Line Repair Package or an equivalent.

(1) Mask the repair area so the conductive epoxy

can be extended onto the grid line(s) or the bus bar

(Fig. 6).

(2) Follow the instructions in the repair kit for

preparing the damaged area.

(3) Remove the package separator clamp and mix

the conductive epoxy thoroughly. Fold in half and cut

the center corner to dispense the epoxy.

(4) Apply the conductive epoxy through the slit in

the masking tape. Overlap both ends of the break(s)

by 19 mm (3/4 inch).

(5) Carefully remove the masking tape from the

grid line(s).

CAUTION: To prevent the glass from fracturing, do

not allow the glass surface to exceed 204É C (400É

F).

(6) Allow the epoxy to cure 24 hours at room tem-

perature or use a heat gun with a 260É to 371É C

(500É to 700É F) range for 15 minutes. Hold the heat

gun approximately 254 mm (10 inches) from the

repaired area.

(7) After the conductive epoxy is properly cured,

verify operation of the rear window defogger.

Fig. 5 A/C-Heater Control - Typical

1 - TRIM BEZEL

2 - INFRARED TEMPERATURE SENSOR

3 - A/C REQUEST SWITCH

4 - REAR WINDOW DEFOGGER/HEATED MIRRORS SWITCH

5 - FRONT WINDOW DEFROSTER MODE SELECTOR

8G - 4 HEATED GLASSRS

REAR WINDOW DEFOGGER RELAY (Continued)

Page 502 of 2585

HEATED SEAT SYSTEM

TABLE OF CONTENTS

page page

HEATED SEAT SYSTEM

DESCRIPTION..........................7

OPERATION............................8

DIAGNOSIS AND TESTING - HEATED SEAT

SYSTEM.............................8

DRIVER HEATED SEAT SWITCH

DESCRIPTION..........................8

OPERATION............................8

DIAGNOSIS AND TESTING - DRIVER HEATED

SEAT SWITCH.........................9

REMOVAL.............................10

INSTALLATION.........................10

HEATED SEAT ELEMENTS

DESCRIPTION.........................10

OPERATION...........................10

DIAGNOSIS AND TESTING - HEATED SEAT

ELEMENTS..........................10REMOVAL.............................11

INSTALLATION.........................11

HEATED SEAT SENSOR

DESCRIPTION.........................12

OPERATION...........................12

DIAGNOSIS AND TESTING - HEATED SEAT

SENSOR............................12

PASSENGER HEATED SEAT SWITCH

DESCRIPTION.........................12

OPERATION...........................12

DIAGNOSIS AND TESTING - PASSENGER

HEATED SEAT SWITCH.................13

REMOVAL.............................14

INSTALLATION.........................14

HEATED SEAT SYSTEM

DESCRIPTION

Vehicles with the heated seat option can be visu-

ally identified by the two separate heated seatswitches located in the instrument panel center

stack, just above the radio (Fig. 1). The heated seat

system allows the front seat driver and passenger to

select from two different levels of supplemental elec-

trical seat heating (HI/LO), or no seat heating to suit

their individual comfort requirements. The heated

seat system for this vehicle includes the following

major components, which are described in further

detail later in this section:

²Heated Seat Elements- Four heated seat ele-

ments are used per vehicle, two for each front seat.

One heated seat element is integral to each front

seat trim cover, one in the seat back and one in the

seat bottom (cushion). Service replacement heating

elements are available, refer to heated seat elements

later in this section for additional information.

²Heated Seat Modules- Two heated seat mod-

ules are used per vehicle. One module is mounted to

each of the seat cushion pans, located under the for-

ward edge of each front seat. Refer to heated seat

module in the electronic control modules section of

the service manual for additional information.

²Heated Seat Sensors- Two heated seat sen-

sors are used per vehicle, one for each front seat. The

heated seat sensors are integral to each of the heated

seat bottoms (cushions).

²Heated Seat Switch- Two heated seat

switches are used per vehicle, one for the driver and

one for the passenger side front seats. The switches

are mounted in the instrument panel center stack.

Fig. 1 HEATED SEAT SWITCH LOCATIONS

1 - HEATED SEAT SWITCHES

RSHEATED SEAT SYSTEM8G-7

Page 503 of 2585

Refer to the description of the heated seat switch

later in this section for additional information.

Hard wired circuitry connects the heated seat sys-

tem components to each other through the electrical

system of the vehicle. These hard wired circuits are

integral to several wire harnesses, which are routed

throughout the vehicle and retained by many differ-

ent methods. These circuits may be connected to each

other, to the vehicle electrical system and to the

heated seat system components through the use of a

combination of soldered splices and splice block con-

nectors. Refer to Wiring for complete system wiring

schematics. The wiring information also includes the

proper wire and connector repair procedures, further

details on wire harness routing and retention, as well

as pin-out and location views for the various wire

harness connectors, splices and grounds.

OPERATION

The heated seat system components operate on

battery current received through a fuse in the Inte-

grated Power Module (IPM) on a fused ignition

switch output (run) circuit from the Body Control

Module. The system will only operate when the igni-

tion switch is in the On position. The heated seat

system will be turned Off automatically whenever

the ignition switch is turned to any position except

On. Also, the heated seat system will not operate

when the surface temperature of the seat cushion

cover at either heated seat sensor is above the

designed temperature set points of the system. See

the owner's manual in the vehicle glove box for more

information on the features, use and operation of the

heated seat system.

DIAGNOSIS AND TESTING - HEATED SEAT

SYSTEM

The most reliable, efficient, and accurate means to

diagnose the heated seat system requires the use of a

DRBIIItscan tool and the proper Diagnostic Proce-

dures manual. The DRBIIItscan tool can provide

confirmation that the PCI data bus is functional, that

all of the electronic modules are sending and receiv-

ing the proper messages on the PCI data bus, and

that the heated seat modules are receiving the

proper hard wired inputs from and relaying the

proper hard wired outputs to the Body Control Mod-

ule in order to perform its functions. Refer toWiring

Diagramsfor complete wiring schematics. The wir-

ing information also includes the proper wire and

connector repair procedures, further details on wire

harness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.

DRIVER HEATED SEAT

SWITCH

DESCRIPTION

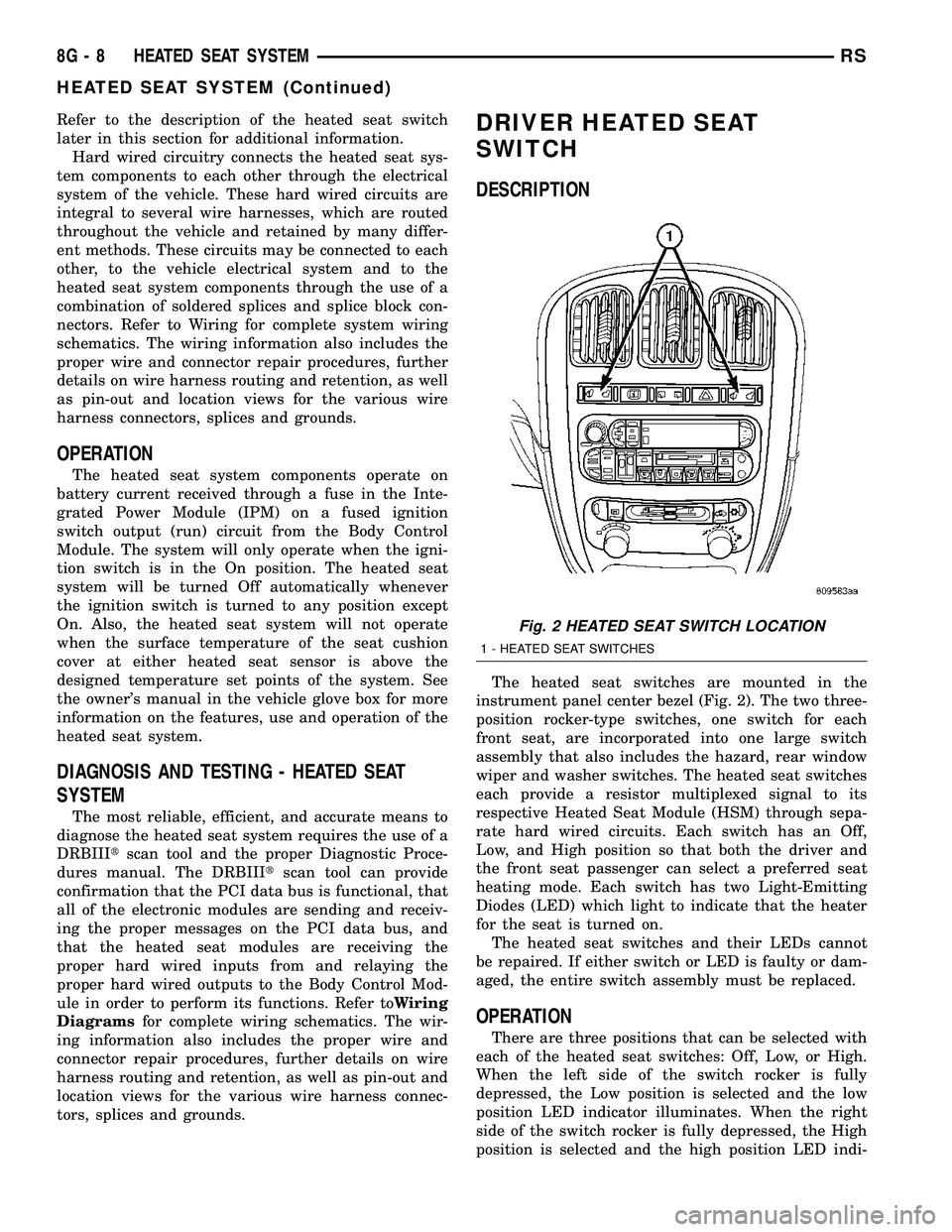

The heated seat switches are mounted in the

instrument panel center bezel (Fig. 2). The two three-

position rocker-type switches, one switch for each

front seat, are incorporated into one large switch

assembly that also includes the hazard, rear window

wiper and washer switches. The heated seat switches

each provide a resistor multiplexed signal to its

respective Heated Seat Module (HSM) through sepa-

rate hard wired circuits. Each switch has an Off,

Low, and High position so that both the driver and

the front seat passenger can select a preferred seat

heating mode. Each switch has two Light-Emitting

Diodes (LED) which light to indicate that the heater

for the seat is turned on.

The heated seat switches and their LEDs cannot

be repaired. If either switch or LED is faulty or dam-

aged, the entire switch assembly must be replaced.

OPERATION

There are three positions that can be selected with

each of the heated seat switches: Off, Low, or High.

When the left side of the switch rocker is fully

depressed, the Low position is selected and the low

position LED indicator illuminates. When the right

side of the switch rocker is fully depressed, the High

position is selected and the high position LED indi-

Fig. 2 HEATED SEAT SWITCH LOCATION

1 - HEATED SEAT SWITCHES

8G - 8 HEATED SEAT SYSTEMRS

HEATED SEAT SYSTEM (Continued)

Page 504 of 2585

cator illuminates. When the switch rocker is moved

to its neutral position (middle), Off is selected and

both LED indicators are extinguished.

Each switch provides separate resistor multiplexed

hard wire inputs to its respective Heated Seat Mod-

ule (HSM) to indicate the selected switch position.

The heated seat module responds to the heated seat

switch status messages by controlling the output to

the seat heater elements of the selected seat. The

Low heat position set point is about 36É C (97É F),

and the High heat position set point is about 41É C

(105É F).

DIAGNOSIS AND TESTING - DRIVER HEATED

SEAT SWITCH

For complete circuit diagrams, refer toWiring

Diagrams.

WARNING: REFER TO THE RESTRAINTS SECTION

OF THIS MANUAL BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, SEAT OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

CHECKING SWITCH SIGNAL AND WIRING AT THE

MODULE

(1) Disconnect and isolate the battery negative

cable.

(2) Access and disconnect the gray 4-way connector

from the heated seat module. Visually inspect wiring

terminals for damage that would prevent positive

connection. If not OK, repair or replace the necessary

components.

(3) Place the heated seat switch in the LO posi-

tion. Using an Ohmmeter, check the resistance

between cavities 2 and 3 of the gray connector noted

above. Resistance should be about 3.5 kilohms (3500

ohms). If not OK, check resistance directly at switch,

as noted below. If OK, proceed to the next step. If not

OK, replace the faulty switch.

(4) Place the heated seat switch in the HI position.

Using an ohmmeter, check the resistance between

cavities 2 and 3 of the gray connector noted above.

Resistance should be about 1.4 kilohms (1400 ohms).

If not OK, check resistance directly at switch, as

noted below. If OK, proceed. If not OK replace the

faulty switch.

(5) With the system ON in the HI position, check

for battery voltage and ground at cavities 4 and 1. If

OK, proceed with testing remaining components. If

not OK, repair open or shorted wiring.

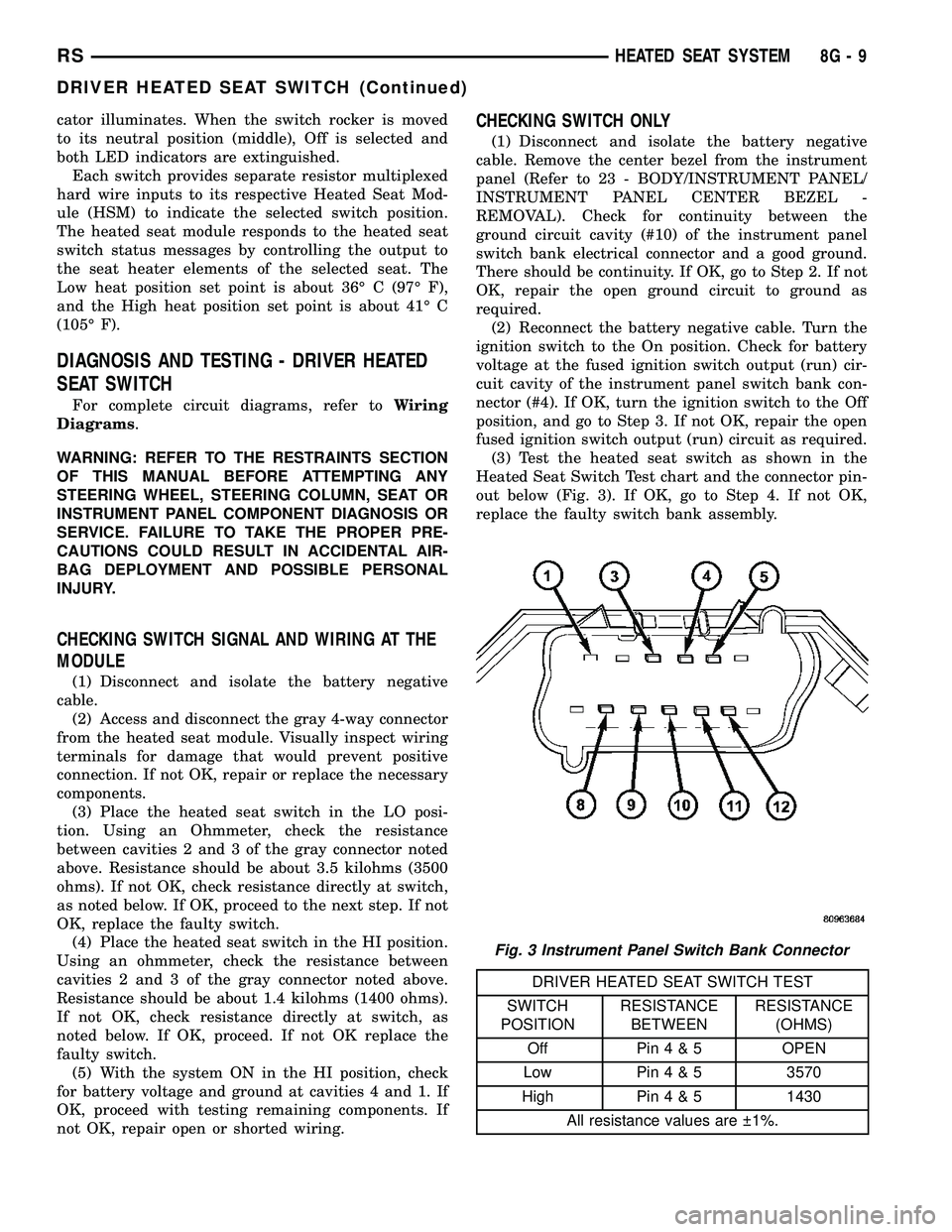

CHECKING SWITCH ONLY

(1) Disconnect and isolate the battery negative

cable. Remove the center bezel from the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL -

REMOVAL). Check for continuity between the

ground circuit cavity (#10) of the instrument panel

switch bank electrical connector and a good ground.

There should be continuity. If OK, go to Step 2. If not

OK, repair the open ground circuit to ground as

required.

(2) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Check for battery

voltage at the fused ignition switch output (run) cir-

cuit cavity of the instrument panel switch bank con-

nector (#4). If OK, turn the ignition switch to the Off

position, and go to Step 3. If not OK, repair the open

fused ignition switch output (run) circuit as required.

(3) Test the heated seat switch as shown in the

Heated Seat Switch Test chart and the connector pin-

out below (Fig. 3). If OK, go to Step 4. If not OK,

replace the faulty switch bank assembly.

DRIVER HEATED SEAT SWITCH TEST

SWITCH

POSITIONRESISTANCE

BETWEENRESISTANCE

(OHMS)

Off Pin4&5OPEN

Low Pin4&53570

High Pin4&51430

All resistance values are 1%.

Fig. 3 Instrument Panel Switch Bank Connector

RSHEATED SEAT SYSTEM8G-9

DRIVER HEATED SEAT SWITCH (Continued)

Page 505 of 2585

(4) Reconnect the instrument panel switch bank

and test the heated seat system for proper operation.

If the system is still inoperative proceed with check-

ing remaining components.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO THE RESTRAINTS SECTION OF

THIS MANUAL BEFORE ATTEMPTING ANY STEER-

ING WHEEL, STEERING COLUMN, SEAT OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel center bezel.

Refer toInstrument Panel Center Bezelin the

Body section for the procedure.

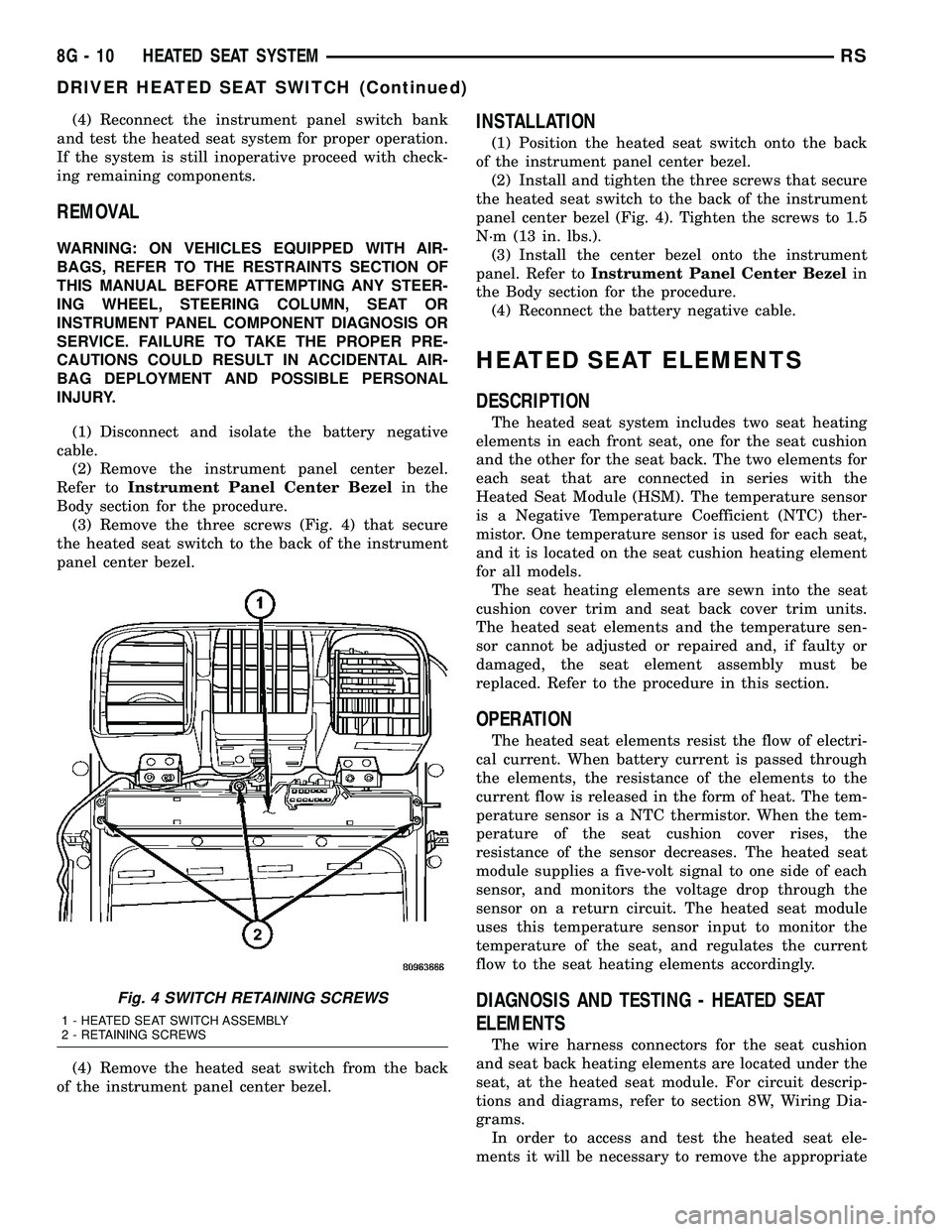

(3) Remove the three screws (Fig. 4) that secure

the heated seat switch to the back of the instrument

panel center bezel.

(4) Remove the heated seat switch from the back

of the instrument panel center bezel.

INSTALLATION

(1) Position the heated seat switch onto the back

of the instrument panel center bezel.

(2) Install and tighten the three screws that secure

the heated seat switch to the back of the instrument

panel center bezel (Fig. 4). Tighten the screws to 1.5

N´m (13 in. lbs.).

(3) Install the center bezel onto the instrument

panel. Refer toInstrument Panel Center Bezelin

the Body section for the procedure.

(4) Reconnect the battery negative cable.

HEATED SEAT ELEMENTS

DESCRIPTION

The heated seat system includes two seat heating

elements in each front seat, one for the seat cushion

and the other for the seat back. The two elements for

each seat that are connected in series with the

Heated Seat Module (HSM). The temperature sensor

is a Negative Temperature Coefficient (NTC) ther-

mistor. One temperature sensor is used for each seat,

and it is located on the seat cushion heating element

for all models.

The seat heating elements are sewn into the seat

cushion cover trim and seat back cover trim units.

The heated seat elements and the temperature sen-

sor cannot be adjusted or repaired and, if faulty or

damaged, the seat element assembly must be

replaced. Refer to the procedure in this section.

OPERATION

The heated seat elements resist the flow of electri-

cal current. When battery current is passed through

the elements, the resistance of the elements to the

current flow is released in the form of heat. The tem-

perature sensor is a NTC thermistor. When the tem-

perature of the seat cushion cover rises, the

resistance of the sensor decreases. The heated seat

module supplies a five-volt signal to one side of each

sensor, and monitors the voltage drop through the

sensor on a return circuit. The heated seat module

uses this temperature sensor input to monitor the

temperature of the seat, and regulates the current

flow to the seat heating elements accordingly.

DIAGNOSIS AND TESTING - HEATED SEAT

ELEMENTS

The wire harness connectors for the seat cushion

and seat back heating elements are located under the

seat, at the heated seat module. For circuit descrip-

tions and diagrams, refer to section 8W, Wiring Dia-

grams.

In order to access and test the heated seat ele-

ments it will be necessary to remove the appropriate

Fig. 4 SWITCH RETAINING SCREWS

1 - HEATED SEAT SWITCH ASSEMBLY

2 - RETAINING SCREWS

8G - 10 HEATED SEAT SYSTEMRS

DRIVER HEATED SEAT SWITCH (Continued)

Page 507 of 2585

(3) Connect the negative battery cable.

(4) Verify heated seat system operation.

(5) Install the appropriate seat cushion or seat

back trim cover. Make certain the seat wire harness

is correctly routed through the seat and seat back.

The excess wire between the cushion and back ele-

ments should be securely tucked between the rear of

the cushion foam and the rear carpet flap of the trim

cover.

HEATED SEAT SENSOR

DESCRIPTION

Two heated seat sensors are used per vehicle, one

in each front seat cushion heating element. The

heated seat temperature sensor is a Negative Tem-

perature Coefficient (NTC) thermistor.

The heated seat sensors cannot be repaired or

adjusted and if found to be faulty, the complete

heated seat cushion element must be replaced.

OPERATION

The temperature sensor is a NTC thermistor.

When the temperature of the seat cushion cover

rises, the resistance of the sensor decreases. The

heated seat module supplies a five-volt current to one

side of each sensor, and monitors the voltage drop

through the sensor on a return circuit. The heated

seat module uses this temperature sensor input to

monitor the temperature of the seat, and regulates

the current flow to the seat heating elements accord-

ingly.

DIAGNOSIS AND TESTING - HEATED SEAT

SENSOR

For complete circuit diagrams, refer toWiring

Diagrams.

(1) Disconnect and isolate the battery negative

cable. Disconnect the green 4-way heated seat mod-

ule wire harness connector.

(2) Using an ohmmeter, check the resistance

between cavities 2 and 3. The sensor resistance

should be between 50 kilohms at 15É C (60É F) and 2

kilohms at 30É C (85É F). If not OK, replace the

faulty seat element and sensor assembly.

PASSENGER HEATED SEAT

SWITCH

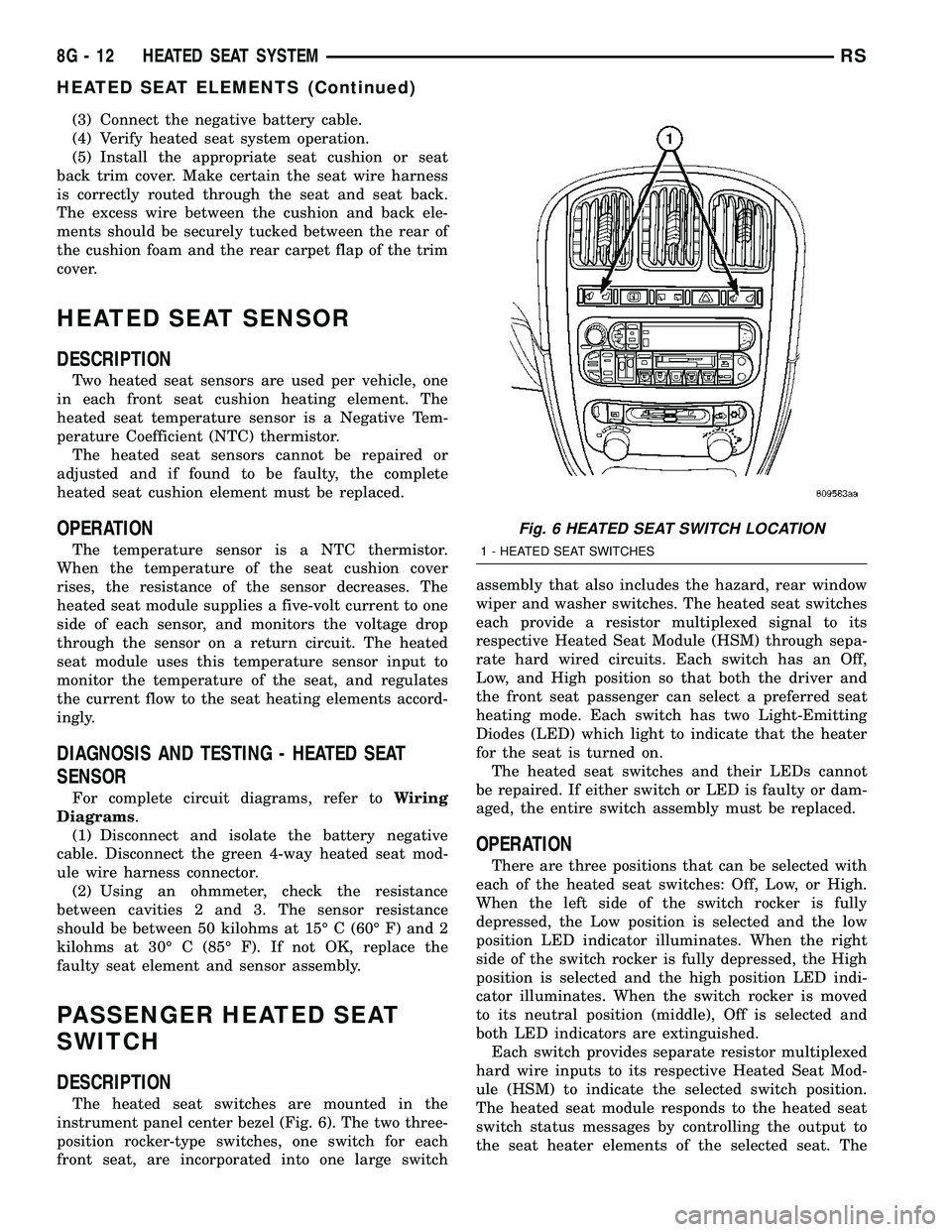

DESCRIPTION

The heated seat switches are mounted in the

instrument panel center bezel (Fig. 6). The two three-

position rocker-type switches, one switch for each

front seat, are incorporated into one large switchassembly that also includes the hazard, rear window

wiper and washer switches. The heated seat switches

each provide a resistor multiplexed signal to its

respective Heated Seat Module (HSM) through sepa-

rate hard wired circuits. Each switch has an Off,

Low, and High position so that both the driver and

the front seat passenger can select a preferred seat

heating mode. Each switch has two Light-Emitting

Diodes (LED) which light to indicate that the heater

for the seat is turned on.

The heated seat switches and their LEDs cannot

be repaired. If either switch or LED is faulty or dam-

aged, the entire switch assembly must be replaced.

OPERATION

There are three positions that can be selected with

each of the heated seat switches: Off, Low, or High.

When the left side of the switch rocker is fully

depressed, the Low position is selected and the low

position LED indicator illuminates. When the right

side of the switch rocker is fully depressed, the High

position is selected and the high position LED indi-

cator illuminates. When the switch rocker is moved

to its neutral position (middle), Off is selected and

both LED indicators are extinguished.

Each switch provides separate resistor multiplexed

hard wire inputs to its respective Heated Seat Mod-

ule (HSM) to indicate the selected switch position.

The heated seat module responds to the heated seat

switch status messages by controlling the output to

the seat heater elements of the selected seat. The

Fig. 6 HEATED SEAT SWITCH LOCATION

1 - HEATED SEAT SWITCHES

8G - 12 HEATED SEAT SYSTEMRS

HEATED SEAT ELEMENTS (Continued)

Page 508 of 2585

Low heat position set point is about 36É C (97É F),

and the High heat position set point is about 41É C

(105É F).

DIAGNOSIS AND TESTING - PASSENGER

HEATED SEAT SWITCH

For complete circuit diagrams, refer toWiring

Diagrams.

WARNING: REFER TO THE RESTRAINTS SECTION

OF THIS MANUAL BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, SEAT OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

CHECKING SWITCH SIGNAL AND WIRING AT THE

MODULE

(1) Disconnect and isolate the battery negative

cable.

(2) Access and disconnect the gray 4-way connector

from the heated seat module. Visually inspect wiring

terminals for damage that would prevent positive

connection. If not OK, repair or replace the necessary

components.

(3) Reconnect the negative battery cable and Turn

heated seat ON in the LO position. Using an Ohm-

meter, check the resistance between cavities 2 and 3

of the gray connector noted above. Resistance should

be about 3.5 kiloohms (3500 ohms). If not OK, check

resistance directly at switch, as noted below. If OK,

proceed. If NOT OK replace the switch or faulty wir-

ing.

(4) Turn heated seat ON in the HI position. Using

an Ohmmeter, check the resistance between cavities

2 and 3 of the gray connector noted above. Resistance

should be about 1.4 kiloohms (1400 ohms). If not OK,

check resistance directly at switch, as noted below. If

OK, proceed. If NOT OK replace the switch or faulty

wiring.

(5) With the system ON in the HI position, Check

for battery voltage and ground at cavities 4 and 1. If

OK, proceed with testing remaining components. If

NOT OK, repair open or wiring short.

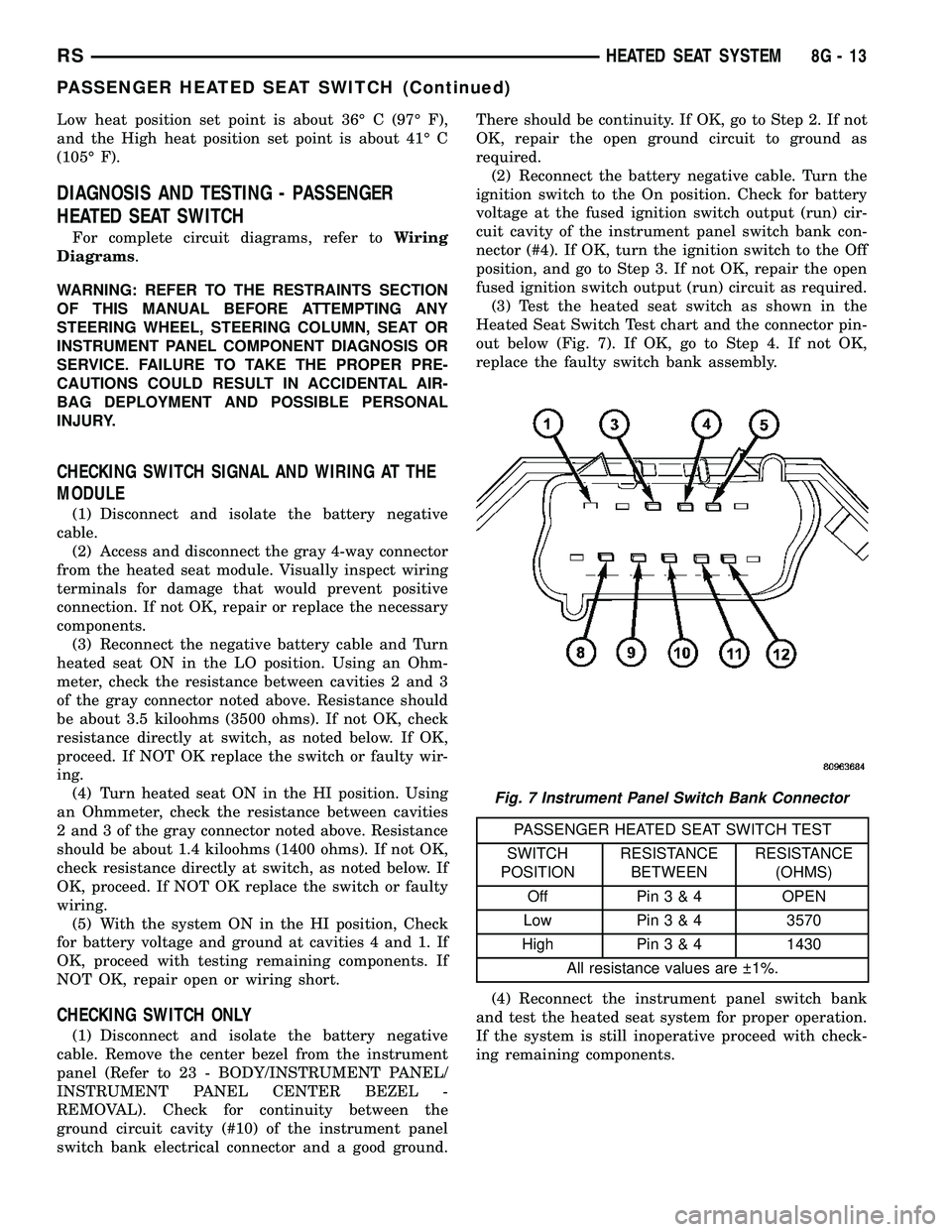

CHECKING SWITCH ONLY

(1) Disconnect and isolate the battery negative

cable. Remove the center bezel from the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL -

REMOVAL). Check for continuity between the

ground circuit cavity (#10) of the instrument panel

switch bank electrical connector and a good ground.There should be continuity. If OK, go to Step 2. If not

OK, repair the open ground circuit to ground as

required.

(2) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Check for battery

voltage at the fused ignition switch output (run) cir-

cuit cavity of the instrument panel switch bank con-

nector (#4). If OK, turn the ignition switch to the Off

position, and go to Step 3. If not OK, repair the open

fused ignition switch output (run) circuit as required.

(3) Test the heated seat switch as shown in the

Heated Seat Switch Test chart and the connector pin-

out below (Fig. 7). If OK, go to Step 4. If not OK,

replace the faulty switch bank assembly.

PASSENGER HEATED SEAT SWITCH TEST

SWITCH

POSITIONRESISTANCE

BETWEENRESISTANCE

(OHMS)

Off Pin3&4OPEN

Low Pin3&43570

High Pin3&41430

All resistance values are 1%.

(4) Reconnect the instrument panel switch bank

and test the heated seat system for proper operation.

If the system is still inoperative proceed with check-

ing remaining components.

Fig. 7 Instrument Panel Switch Bank Connector

RSHEATED SEAT SYSTEM8G-13

PASSENGER HEATED SEAT SWITCH (Continued)

Page 509 of 2585

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO THE RESTRAINTS SECTION OF

THIS MANUAL BEFORE ATTEMPTING ANY STEER-

ING WHEEL, STEERING COLUMN, SEAT OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel center bezel.

Refer toInstrument Panel Center Bezelin the

Body section for the procedure.

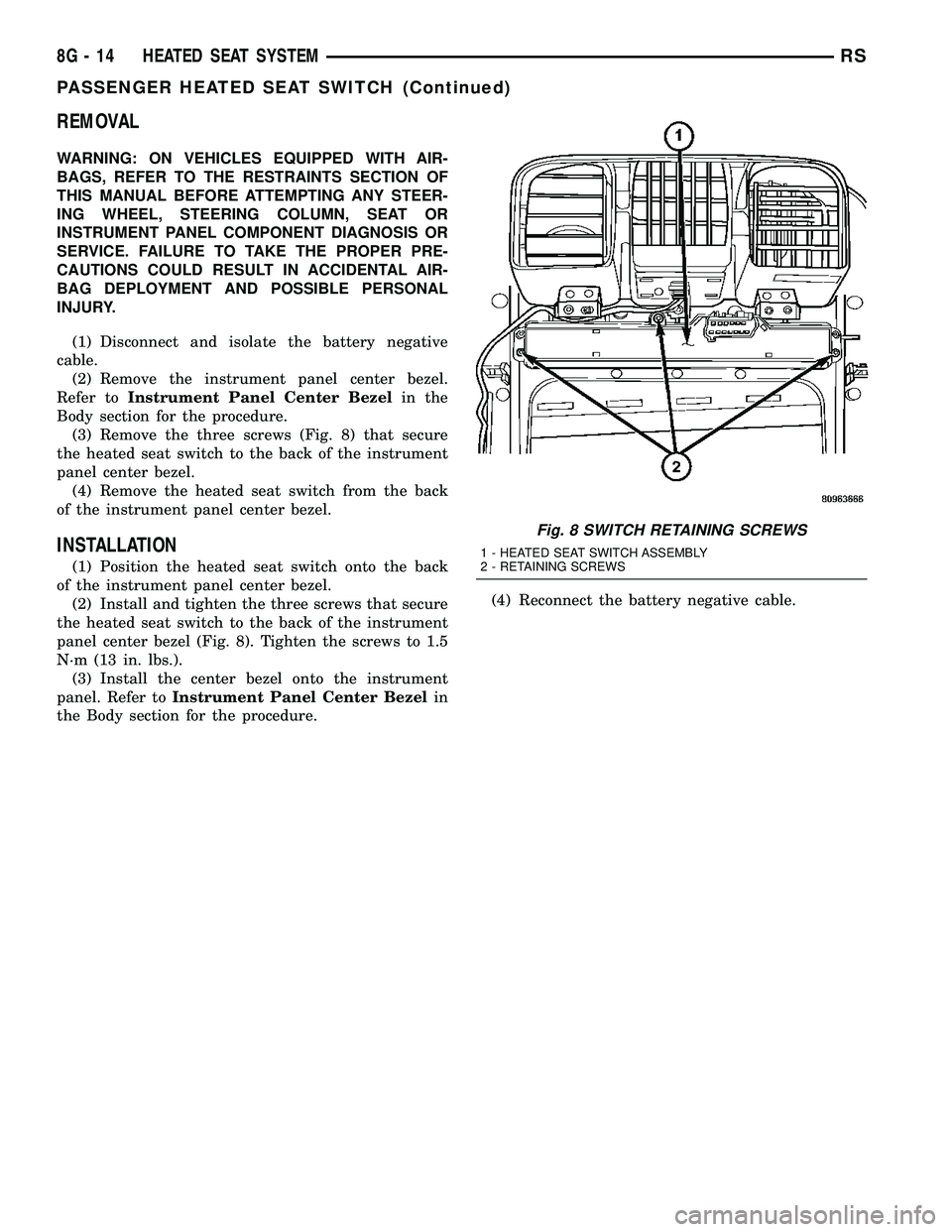

(3) Remove the three screws (Fig. 8) that secure

the heated seat switch to the back of the instrument

panel center bezel.

(4) Remove the heated seat switch from the back

of the instrument panel center bezel.

INSTALLATION

(1) Position the heated seat switch onto the back

of the instrument panel center bezel.

(2) Install and tighten the three screws that secure

the heated seat switch to the back of the instrument

panel center bezel (Fig. 8). Tighten the screws to 1.5

N´m (13 in. lbs.).

(3) Install the center bezel onto the instrument

panel. Refer toInstrument Panel Center Bezelin

the Body section for the procedure.(4) Reconnect the battery negative cable.

Fig. 8 SWITCH RETAINING SCREWS

1 - HEATED SEAT SWITCH ASSEMBLY

2 - RETAINING SCREWS

8G - 14 HEATED SEAT SYSTEMRS

PASSENGER HEATED SEAT SWITCH (Continued)

Page 510 of 2585

HORN

TABLE OF CONTENTS

page page

HORN SYSTEM

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING - HORN SYSTEM . . . 1

HORN

DIAGNOSIS AND TESTING - HORN..........3REMOVAL.............................4

INSTALLATION..........................5

HORN SWITCH

DESCRIPTION..........................5

HORN SYSTEM

DESCRIPTION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, REFER TO ELECTRICAL, RESTRAINTS FOR

SAFETY PRECAUTIONS. DISCONNECT THE NEGA-

TIVE CABLE FROM THE BATTERY BEFORE SER-

VICING COMPONENTS INVOLVING THE AIRBAG

SYSTEM. ACCIDENTAL DEPLOYMENT OF AIRBAG

AND PERSONAL INJURY CAN RESULT.

The horn circuit consists of a horn switch, clock-

spring, horn relay, horns and Integrated Power Mod-

ule (IPM). The horn switch is a membrane switch

located in the airbag trim cover. The horns are

located forward of the left front wheel behind the

bumper fascia.

OPERATION

The horn relay plugs into the Integrated Power

Module (IPM) which is located in the engine com-

partment. For circuit information and component

locations, refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, details

of wire harness routing and retention, connector pin-

out information and location views for the various

wire harness connectors, splices and grounds.

The horns will not function if the switch is

ªCLOSEDº for more than 30 seconds. Once the

switch is ªOPENº, a 20±30 second delay will occur

before the horns are functional again.

DIAGNOSIS AND TESTING - HORN SYSTEM

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Refer to Horn System Test below. If the horn does

not sound, check horn fuse located in the Integrated

Power Module (IPM). If the fuse is blown, replace

with the correct fuse. If the horns fail to sound and

the new fuse blows when depressing the horn switch,

a short circuit in the horn or the horn wiring

between the fuse terminal and the horn is responsi-

ble, or a defective horn switch allowed the horn to

burn out is responsible.

If the fuse is OK, test horn relay (Refer to 8 -

ELECTRICAL/HORN/HORN RELAY - DIAGNOSIS

AND TESTING).

If the relay is OK, test horn. Refer to Horn System

Test.

CAUTION: Continuous sounding of horn may

cause horn failure.

Should the horn sound continuously:

²Unplug the horn relay from IPM.

²Refer to (Refer to 8 - ELECTRICAL/HORN/

HORN RELAY - DIAGNOSIS AND TESTING).

Refer to the appropriate wiring information.

RSHORN8H-1