AUX CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 19 of 2585

NOTE: Intentional tampering with emissions control

systems can result in civil penalties being assessed

against you.

DESCRIPTION - FUEL REQUIREMENTS -

DIESEL ENGINE

WARNING: DO NOT USE ALCOHOL OR GASOLINE

AS A FUEL BLENDING AGENT. THEY CAN BE

UNSTABLE UNDER CERTAIN CONDITIONS AND

HAZARDOUS OR EXPLOSIVE WHEN MIXED WITH

DIESEL FUEL.

Use good quality diesel fuel from a reputable sup-

plier. For most year-round service, number 2 diesel

fuel meeting DIN EN 590 (Class0-4)will provide

good performance. If the vehicle is exposed to

extreme cold (below -18ÉC/0ÉF) or is required to oper-

ate at colder than normal conditions for prolonged

periods, use climatize No. 2 diesel fuel or dilute the

No. 2 diesel fuel with 50% No. 1 diesel fuel as long as

it meets ASTM D 975: 1D and 2D and the quality of

lubrication behavior is in accordance with DIN EN

590. This will provide better protection from fuel gel-

ling or wax plugging of the fuel filters.

Diesel fuel is seldom completely free of water. To

prevent fuel system trouble, including fuel line freez-

ing in winter, drain the accumulated water from the

fuel/water separator using the fuel/water separator

drain provided. If you buy good quality fuel and fol-

low the cold weather advice above, fuel conditioners

should not be required in your vehicle. If available in

your area, a high cetane ªpremiumº diesel fuel may

offer improved cold starting and warm up perfor-

mance.

DESCRIPTION - ENGINE OIL - DIESEL

ENGINES

Use only Diesel Engine Oil meeting standardMIL-

2104Cor API ClassificationCD or higherorCCML

D4, D5.

SAE VISCOSITY GRADE

CAUTION: Low viscosity oils must have the proper

API quality or the CCMC G5 designation.

To assure of properly formulated engine oils, it is

recommended that SAE Grade 10W-40 engine oils

that meet Chrysler material standard MS-6395, be

used in accordance to ACEA B3, B4 specification.

European Grade 10W-40 oils are also acceptable.

Oils of the SAE 5W-40 grade number are preferred

when minimum temperatures consistently fall below

-15ÉC.

DESCRIPTION - AWD REAR DRIVELINE

MODULE FLUIDS

The AWD Rear Driveline Module Assembly consists

of two subassemblies, the Overrunning Clutch Hous-

ing (front) and the Differential Carrier (rear).

The recommended lubricant for the Overrunning

Clutch Housing is MopartATF+4. The recommended

lubricant for the Differential Carrier is Mopart

80W-90 Gear and Axle Lubricant.

DESCRIPTION - AWD POWER TRANSFER UNIT

FLUID

The recommended lubricant for the AWD Power

Transfer Unit is MopartGear and Axle Lubricant

80W-90.

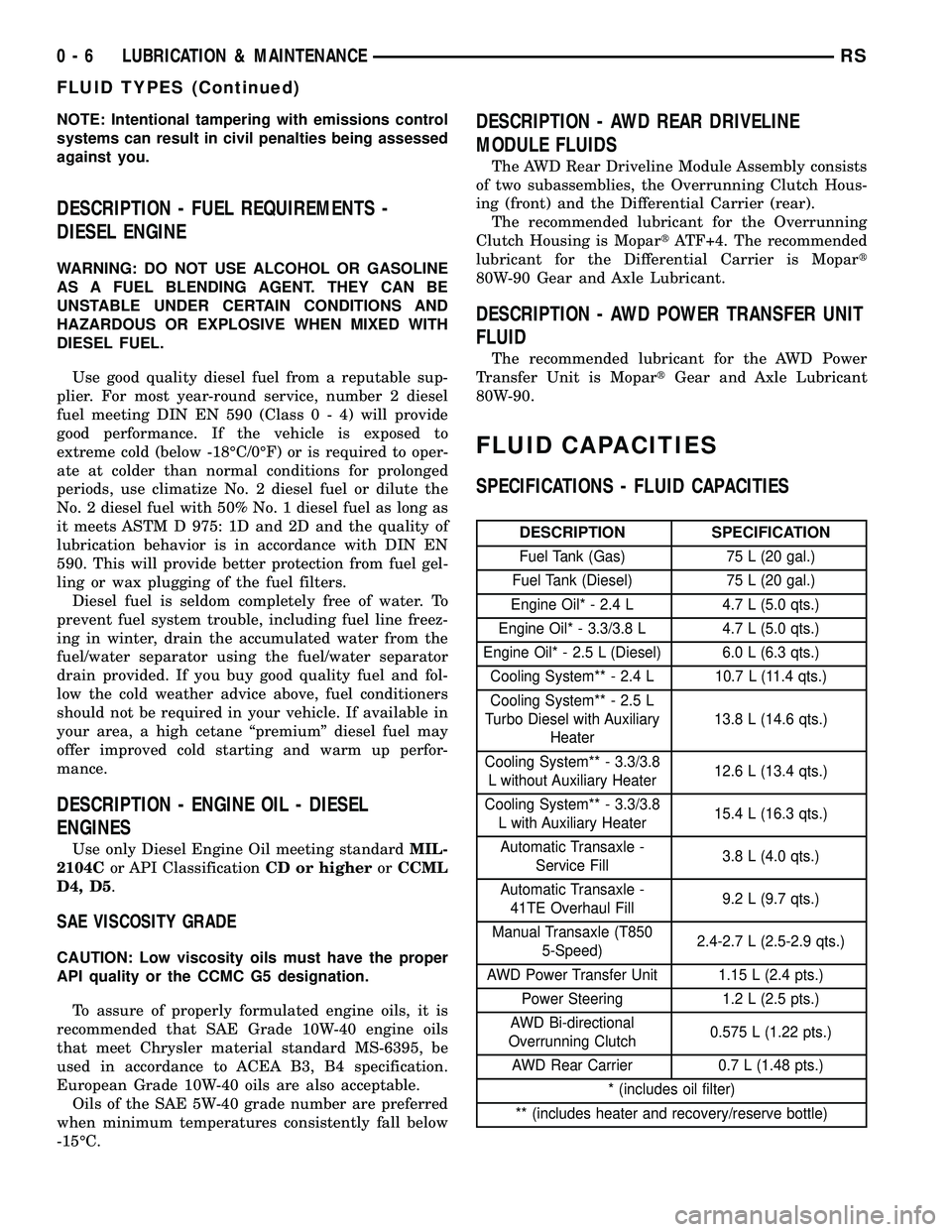

FLUID CAPACITIES

SPECIFICATIONS - FLUID CAPACITIES

DESCRIPTION SPECIFICATION

Fuel Tank (Gas) 75 L (20 gal.)

Fuel Tank (Diesel) 75 L (20 gal.)

Engine Oil* - 2.4 L 4.7 L (5.0 qts.)

Engine Oil* - 3.3/3.8 L 4.7 L (5.0 qts.)

Engine Oil* - 2.5 L (Diesel) 6.0 L (6.3 qts.)

Cooling System** - 2.4 L 10.7 L (11.4 qts.)

Cooling System** - 2.5 L

Turbo Diesel with Auxiliary

Heater13.8 L (14.6 qts.)

Cooling System** - 3.3/3.8

L without Auxiliary Heater12.6 L (13.4 qts.)

Cooling System** - 3.3/3.8

L with Auxiliary Heater15.4 L (16.3 qts.)

Automatic Transaxle -

Service Fill3.8 L (4.0 qts.)

Automatic Transaxle -

41TE Overhaul Fill9.2 L (9.7 qts.)

Manual Transaxle (T850

5-Speed)2.4-2.7 L (2.5-2.9 qts.)

AWD Power Transfer Unit 1.15 L (2.4 pts.)

Power Steering 1.2 L (2.5 pts.)

AWD Bi-directional

Overrunning Clutch0.575 L (1.22 pts.)

AWD Rear Carrier 0.7 L (1.48 pts.)

* (includes oil filter)

** (includes heater and recovery/reserve bottle)

0 - 6 LUBRICATION & MAINTENANCERS

FLUID TYPES (Continued)

Page 1515 of 2585

FUEL PUMP

DESCRIPTION

The electric fuel pump is located in and is part of

the fuel pump module. It is a positive displacement,

gerotor type, immersible pump with a permanent

magnet electric motor. The fuel pump module is sus-

pended in fuel in the fuel tank.

OPERATION

The pump draws fuel through a strainer and

pushes it through the motor to the outlet. The pump

contains a check valve. The valve, in the pump out-

let, maintains pump pressure during engine off con-

ditions, for a short while. It is normal for fuel

pressure to drop to zero after cooldown. The fuel

pump relay provides voltage to the fuel pump. The

fuel pump has a maximum deadheaded pressure out-

put of approximately 880 kPa (130 psi). The regula-

tor adjusts fuel system pressure to approximately

400 kpa 34 kpa (58 psi 5 psi).

FUEL PUMP MODULE

DESCRIPTION

The fuel pump module is installed in the top of the

fuel tank (Fig. 9).

The fuel pump module contains the following:

²Electric fuel pump²Fuel pump reservoir

²Inlet strainer

²Fuel pressure regulator

²Fuel gauge sending unit

²Fuel supply line connection

The inlet strainer, fuel pressure regulator

and fuel level sensor are the only serviceable

items. If the fuel pump or electrical wiring har-

ness requires service, replace the fuel pump

module.

The electric fuel pump is located in and is part of

the fuel pump module. It is a positive displacement,

gerotor type, immersible pump with a permanent

magnet electric motor.

OPERATION

The pump draws fuel through a strainer and

pushes it through the motor to the outlet. The pump

contains one check valve. The check valve, in the

pump outlet, maintains pump pressure during engine

off conditions. The fuel pump relay provides voltage

to the fuel pump.

The fuel pump has a maximum deadheaded pres-

sure output of approximately 880 kPa (130 psi). The

regulator adjusts fuel system pressure to approxi-

mately 400 34 kPa (58 5 psi).

FUEL PUMP ELECTRICAL CONTROL

Voltage to operate the electric pump is supplied

through the fuel pump relay. For an electrical opera-

tional description of the fuel pump refer to fuel Pump

RelayÐPCM Output.

ELECTRICAL PUMP REPLACEMENT

The electric fuel pump is not serviceable. If the

fuel pump or electrical wiring harness needs replace-

ment, the complete fuel pump module must be

replaced. Perform the Fuel System Pressure Release

procedure before servicing the fuel pump.

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

(1) Remove fuel filler cap and perform Fuel Sys-

tem Pressure Release procedure.

(2) Disconnect negative cable from auxiliary

jumper terminal.

(3) Drain fuel tank, refer to the Fuel Tank proce-

dure in the Fuel Delivery section.

(4) Remove fuel tank, refer to the Fuel Tank

removal section.

Fig. 9 Fuel Pump Module

1 - INLET STRAINER

2 - FUEL RESERVOIR

3 - FUEL PRESSURE REGULATOR

4 - FUEL LEVEL SENSOR

5 - FILTER

6 - GROUND STRAPS

14 - 8 FUEL DELIVERYRS

Page 1521 of 2585

QUICK CONNECT FITTING

STANDARD PROCEDURE - QUICK-CONNECT

FITTINGS

REMOVAL

When disconnecting a quick-connect fitting, the

retainer will remain on the fuel tube nipple.

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE DISCONNECTING A QUICK-CONNECT FIT-

TINGS. REFER TO THE FUEL PRESSURE RELEASE

PROCEDURE. THIS MAY RESULT IN PERSONAL

INJURY OR DEATH.

(1) Perform Fuel Pressure Release Procedure.

Refer to the Fuel Pressure Release Procedure in this

section.

(2) Disconnect negative cable from battery or aux-

iliary jumper terminal.

(3) Squeeze retainer tabs together and pull fuel

tube/quick-connect fitting assembly off of fuel tube

nipple. The retainer will remain on fuel tube.

INSTALLATION

CAUTION: Make sure that the o-ring in installed in

fitting. Never install a quick-connect fitting without

the retainer being either on the fuel tube or already

in the quick-connect fitting. In either case, ensure

the retainer locks securely into the quick-connect

fitting by firmly push-pulling-push on fuel tube and

fitting to ensure it is secured.

(1) Using a clean lint free cloth, clean the fuel tube

nipple and retainer.

(2) Prior to connecting the fitting to the fuel tube,

coat the fuel tube nipple with clean engine oil.

(3) Push the quick-connect fitting over the fuel

tube until theretainer seats and a click is heard.

(4) The plastic quick-connect fitting has windows

in the sides of the casing. When the fitting com-

pletely attaches to the fuel tube, the retainer locking

ears and the fuel tube shoulder are visible in the

windows. If they are not visible, the retainer was not

properly installed (Fig. 22).Do not rely upon the

audible click to confirm a secure connection.

(5) Connect negative cable to battery or auxiliary

jumper terminal.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for several minutes, until the test is stopped, or

until the ignition switch is turned to the Off posi-

tion.(6) Use the DRB IIItscan tool ASD Fuel System

Test to pressurize the fuel system. Check for leaks.

TWO-TAB TYPE FITTING

This type of fitting is equipped with tabs located on

both sides of the fitting (Fig. 23). These tabs are sup-

plied for disconnecting the quick-connect fitting from

component being serviced.

CAUTION: The interior components (O-rings, spac-

ers) of this type of quick-connect fitting are not ser-

viced separately, but new plastic retainers are

available. Do not attempt to repair damaged fittings

or fuel lines/tubes. If repair is necessary, replace

the complete fuel tube assembly.

Fig. 22 Plastic Quick-Connect Fitting/Fuel Tube

Connection

1 - WINDOW

2-TAB(2)

3 - EAR

4 - SHOULDER (ON TUBE)

Fig. 23 Typical Two-Tab Type Quick-Connect Fitting

1 - TAB(S)

2 - QUICK-CONNECT FITTING

14 - 14 FUEL DELIVERYRS

Page 1522 of 2585

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES,

FITTINGS OR LINES, THE FUEL SYSTEM PRES-

SURE MUST BE RELEASED. REFER TO THE FUEL

PRESSURE RELEASE PROCEDURE IN THIS

GROUP. THIS MAY RESULT IN PERSONAL INJURY

OR DEATH.

DISCONNECTION/CONNECTION

(1) Perform fuel pressure release procedure. Refer

to Fuel Pressure Release Procedure in this group.

(2) Disconnect negative battery cable from battery

or auxiliary jumper terminal.

(3) Clean fitting of any foreign material before dis-

assembly.

(4) To disconnect quick-connect fitting, squeeze

plastic retainer tabs (Fig. 23) against sides of quick-

connect fitting with your fingers. Tool use is not

required for removal and may damage plastic

retainer. Pull fitting from fuel system component

being serviced. The plastic retainer will remain on

component being serviced after fitting is discon-

nected. The O-rings and spacer will remain in quick-

connect fitting connector body.

(5) Inspect quick-connect fitting body and compo-

nent for damage. Replace as necessary.

CAUTION: When the quick-connect fitting was dis-

connected, the plastic retainer will remain on the

component being serviced. If this retainer must be

removed, very carefully release the retainer from

the component with two small screwdrivers. After

removal, inspect the retainer for cracks or any dam-

age.

(6) Prior to connecting quick-connect fitting to

component being serviced, check condition of fitting

and component. Clean parts with a lint-free cloth.

Lubricate with clean engine oil.

(7) Insert quick-connect fitting to component being

serviced and into plastic retainer. When a connection

is made, a click will be heard.

(8) Verify a locked condition by firmly push-pull-

ing-push on fuel tube and fitting (15-30 lbs.).

(9) Connect negative cable to battery or auxiliary

jumper terminal.

(10) Use the DRB IIItscan tool ASD Fuel System

Test to pressurize the fuel system. Check for leaks.

PLASTIC RETAINER RING TYPE FITTING

This type of fitting can be identified by the use of a

full-round plastic retainer ring (Fig. 24) usually black

in color.CAUTION: The interior components (O-rings, spac-

ers, retainers) of this type of quick-connect fitting

are not serviced separately. Do not attempt to repair

damaged fittings or fuel lines/tubes. If repair is nec-

essary, replace the complete fuel tube assembly.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES,

FITTINGS OR LINES, THE FUEL SYSTEM PRES-

SURE MUST BE RELEASED. REFER TO THE FUEL

SYSTEM PRESSURE RELEASE PROCEDURE IN

THIS GROUP. THIS MAY RESULT IN PERSONAL

INJURY OR DEATH.

DISCONNECTION/CONNECTION

(1) Perform fuel pressure release procedure. Refer

to Fuel Pressure Release Procedure in this section.

(2) Disconnect negative battery cable from battery

or auxiliary jumper terminal.

(3) Clean fitting of any foreign material before dis-

assembly.

(4) To release fuel system component from quick-

connect fitting, firmly push fitting towards compo-

nent being serviced while firmly pushing plastic

Fig. 24 Plastic Retainer Ring Type Fitting

1 - FUEL TUBE

2 - QUICK CONNECT FITTING

3 - PUSH

4 - PLASTIC RETAINER

5 - PUSH

6 - PUSH

7 - PUSH

8 - PUSH

RSFUEL DELIVERY14-15

QUICK CONNECT FITTING (Continued)

Page 1523 of 2585

retainer ring into fitting (Fig. 24). With plastic ring

depressed, pull fitting from component.The plastic

retainer ring must be pressed squarely into fit-

ting body. If this retainer is cocked during

removal, it may be difficult to disconnect fit-

ting. Use an open-end wrench on shoulder of

plastic retainer ring to aid in disconnection.

(5) After disconnection, plastic retainer ring will

remain with quick-connect fitting connector body.

(6) Inspect fitting connector body, plastic retainer

ring and fuel system component for damage. Replace

as necessary.(7) Prior to connecting quick-connect fitting to

component being serviced, check condition of fitting

and component. Clean parts with a lint-free cloth.

Lubricate with clean engine oil.

(8) Insert quick-connect fitting into component

being serviced until a click is felt.

(9) Verify a locked condition by firmly push-pull-

ing-push on fuel tube and fitting (15-30 lbs.).

(10) Connect negative battery cable to battery or

auxiliary jumper terminal.

(11) Use the DRB IIItscan tool ASD Fuel System

Test to pressurize the fuel system. Check for leaks.

14 - 16 FUEL DELIVERYRS

QUICK CONNECT FITTING (Continued)

Page 2176 of 2585

INSTRUMENT PANEL

ASSEMBLY

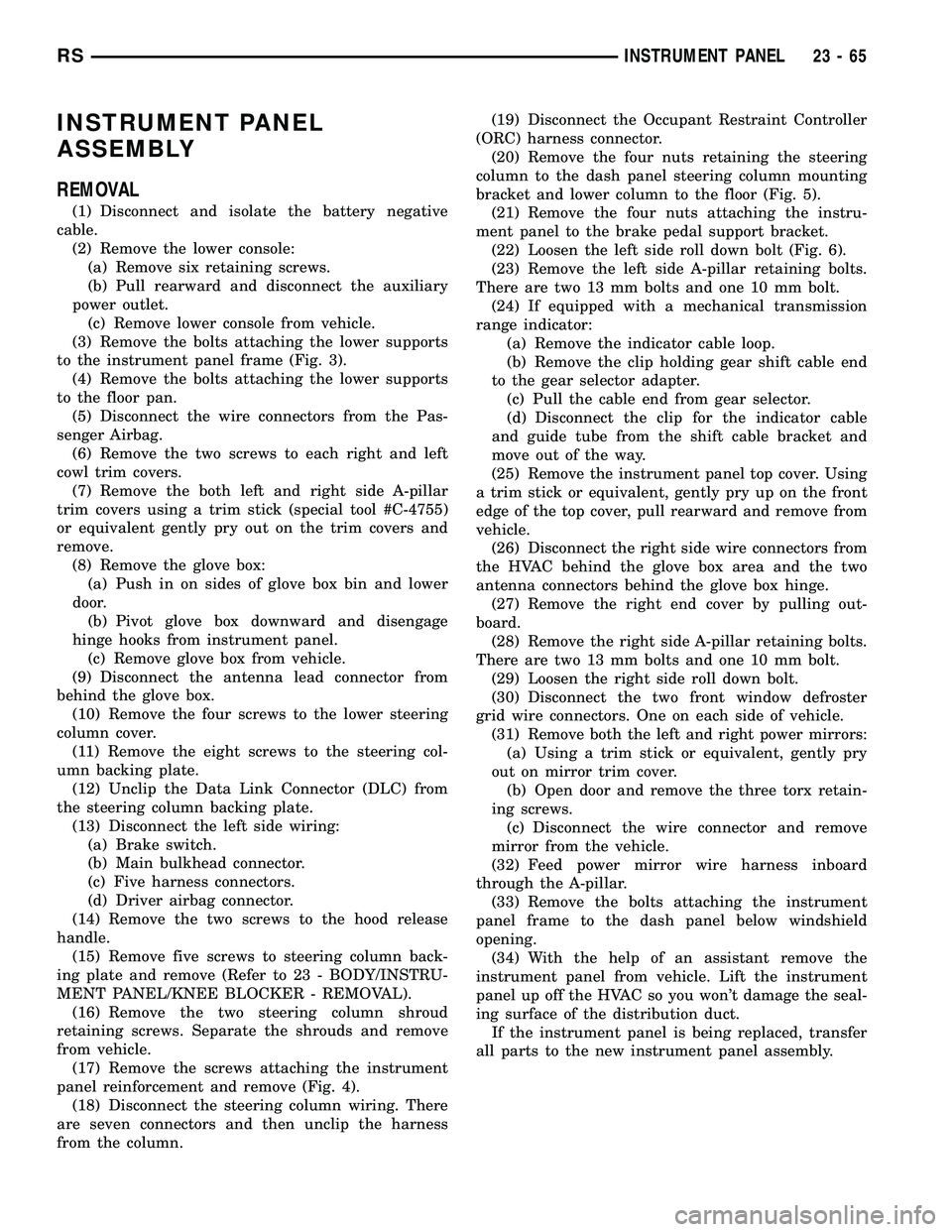

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the lower console:

(a) Remove six retaining screws.

(b) Pull rearward and disconnect the auxiliary

power outlet.

(c) Remove lower console from vehicle.

(3) Remove the bolts attaching the lower supports

to the instrument panel frame (Fig. 3).

(4) Remove the bolts attaching the lower supports

to the floor pan.

(5) Disconnect the wire connectors from the Pas-

senger Airbag.

(6) Remove the two screws to each right and left

cowl trim covers.

(7) Remove the both left and right side A-pillar

trim covers using a trim stick (special tool #C-4755)

or equivalent gently pry out on the trim covers and

remove.

(8) Remove the glove box:

(a) Push in on sides of glove box bin and lower

door.

(b) Pivot glove box downward and disengage

hinge hooks from instrument panel.

(c) Remove glove box from vehicle.

(9) Disconnect the antenna lead connector from

behind the glove box.

(10) Remove the four screws to the lower steering

column cover.

(11) Remove the eight screws to the steering col-

umn backing plate.

(12) Unclip the Data Link Connector (DLC) from

the steering column backing plate.

(13) Disconnect the left side wiring:

(a) Brake switch.

(b) Main bulkhead connector.

(c) Five harness connectors.

(d) Driver airbag connector.

(14) Remove the two screws to the hood release

handle.

(15) Remove five screws to steering column back-

ing plate and remove (Refer to 23 - BODY/INSTRU-

MENT PANEL/KNEE BLOCKER - REMOVAL).

(16) Remove the two steering column shroud

retaining screws. Separate the shrouds and remove

from vehicle.

(17) Remove the screws attaching the instrument

panel reinforcement and remove (Fig. 4).

(18) Disconnect the steering column wiring. There

are seven connectors and then unclip the harness

from the column.(19) Disconnect the Occupant Restraint Controller

(ORC) harness connector.

(20) Remove the four nuts retaining the steering

column to the dash panel steering column mounting

bracket and lower column to the floor (Fig. 5).

(21) Remove the four nuts attaching the instru-

ment panel to the brake pedal support bracket.

(22) Loosen the left side roll down bolt (Fig. 6).

(23) Remove the left side A-pillar retaining bolts.

There are two 13 mm bolts and one 10 mm bolt.

(24) If equipped with a mechanical transmission

range indicator:

(a) Remove the indicator cable loop.

(b) Remove the clip holding gear shift cable end

to the gear selector adapter.

(c) Pull the cable end from gear selector.

(d) Disconnect the clip for the indicator cable

and guide tube from the shift cable bracket and

move out of the way.

(25) Remove the instrument panel top cover. Using

a trim stick or equivalent, gently pry up on the front

edge of the top cover, pull rearward and remove from

vehicle.

(26) Disconnect the right side wire connectors from

the HVAC behind the glove box area and the two

antenna connectors behind the glove box hinge.

(27) Remove the right end cover by pulling out-

board.

(28) Remove the right side A-pillar retaining bolts.

There are two 13 mm bolts and one 10 mm bolt.

(29) Loosen the right side roll down bolt.

(30) Disconnect the two front window defroster

grid wire connectors. One on each side of vehicle.

(31) Remove both the left and right power mirrors:

(a) Using a trim stick or equivalent, gently pry

out on mirror trim cover.

(b) Open door and remove the three torx retain-

ing screws.

(c) Disconnect the wire connector and remove

mirror from the vehicle.

(32) Feed power mirror wire harness inboard

through the A-pillar.

(33) Remove the bolts attaching the instrument

panel frame to the dash panel below windshield

opening.

(34) With the help of an assistant remove the

instrument panel from vehicle. Lift the instrument

panel up off the HVAC so you won't damage the seal-

ing surface of the distribution duct.

If the instrument panel is being replaced, transfer

all parts to the new instrument panel assembly.

RSINSTRUMENT PANEL23-65

Page 2178 of 2585

(14) Install the four nuts retaining the steering

column and lower to the floor (Fig. 5).

(15) Connect the Occupant Restraint Controller

(ORC) harness connector.

(16) Connect the steering column wiring. There

are seven connectors and then clip the harness to the

column.

(17) Install the screws attaching the instrument

panel reinforcement (Fig. 4).

(18) Connect the shrouds and install the two steer-

ing column shroud retaining screws.

(19) Install five screws to the left under column

instrument panel reinforcement brace.

(20) Install the two screws to the hood release

handle.

(21) Connect the left side wiring:

(a) Brake switch.

(b) Main bulkhead connector.

(c) Five harness connectors.

(d) Driver airbag connector.

(22) Clip the Data Link Connector (DLC) to the

steering column backing plate.

(23) Install the eight screws to the steering column

backing plate.(24) Install the four screws to the lower steering

column cover.

(25) Install the glove box:

(a) Install glove box into the vehicle. Line up the

hinges and firmly snap together.

(b) Push in on sides of glove box bin and raise

door.

(26) Install the both left and right side A-pillar

trim covers. Position trim cover over slots and firmly

snap into place.

(27) Install the two screws to each right and left

cowl trim covers.

(28) Connect the wire connectors to the Passenger

Airbag.

(29) Install the bolts attaching the lower supports

to the floor pan.

(30) Install the bolts attaching the lower supports

to the instrument panel frame (Fig. 3).

(31) Install the lower console:

(a) Install lower console to vehicle.

(b) Connect the auxiliary power outlet.

(c) Install the six retaining screws.

(32) Connect the battery negative cable.

Fig. 6 INSTRUMENT PANEL REMOVAL

1 - INSTRUMENT PANEL

2 - FIVE ATTACHING SCREWS

3 - 13 mm BOLT - TWO ON EACH SIDE4 - ROLL DOWN BRACKET

5 - 10 mm BOLT - STARTING BOLT ONE EACH SIDE

RSINSTRUMENT PANEL23-67

INSTRUMENT PANEL ASSEMBLY (Continued)

Page 2180 of 2585

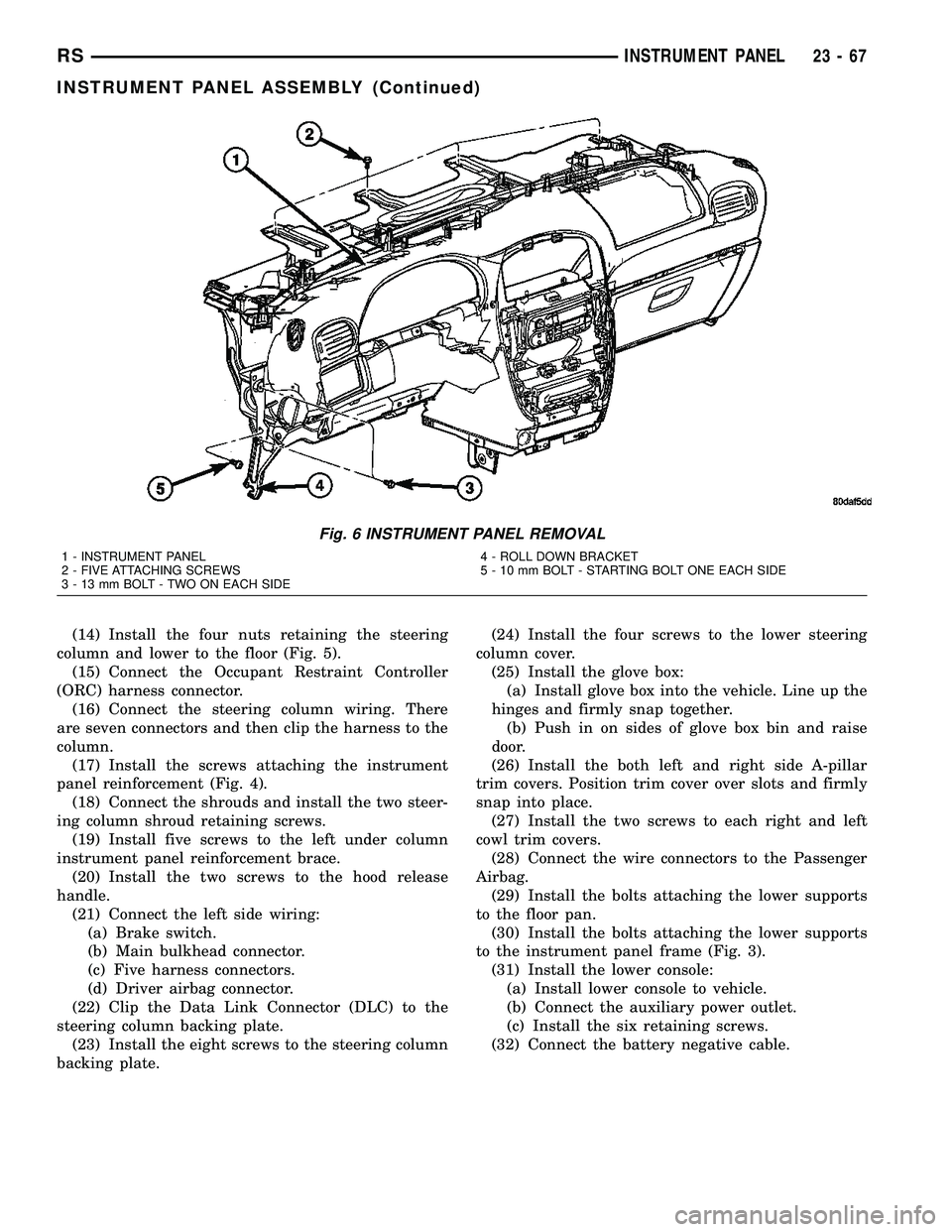

INSTALLATION

(1) Place instrument panel top cover in position on

vehicle (Fig. 9).

(2) Push top cover forward to engage hooks attach-

ing front of top cover to instrument panel.

(3) Engage clips attaching rear edge of top cover to

instrument panel.

(4) Pull top cover rearward.

(5) Install A-pillar trim.

LOWER CONSOLE

REMOVAL

(1) Remove screws attaching the lower console to

floor bracket and instrument panel (Fig. 10).

(2) Slide lower console rearward from around

instrument panel supports.

(3) Disconnect the auxiliary power outlet wire con-

nector (if equipped).

(4) Remove lower console from vehicle.

INSTALLATION

(1) Connect the auxiliary power outlet wire con-

nector (if equipped).

(2) Install the lower console into the vehicle (Fig.

10).

(3) Slide console forward around instrument panel

supports.

(4) Install the screws attaching lower console to

floor bracket and instrument panel.

LOWER INSTRUMENT PANEL

REMOVAL

When servicing the lower instrument panel, refer

to Body, Instrument Panel, and then the appropriate

removal procedure.

(1) Remove the right end cover.

(2) Remove the lower steering column cover.

(3) Remove the center bezel.

(4) Remove the lower console.

(5) Remove the cup holder and track.

(6) Remove the glove box.

(7) Remove the glove box latch striker.

(8) Remove the glove box lamp.

(9) Remove the eighteen screws holding the lower

instrument panel to the reinforcement frame (Fig.

11).

(10) Remove the lower instrument panel from

vehicle.

INSTALLATION

When servicing the lower instrument panel, refer

to Body, Instrument Panel, and then the appropriate

removal procedure.

(1) Install the lower instrument panel into the

vehicle (Fig. 11).

(2) Install the eighteen screws holding the lower

instrument panel to the reinforcement frame.

(3) Install the glove box lamp.

(4) Install the glove box latch striker.

(5) Install the glove box.

(6) Install the cup holder and track.

(7) Install the lower console.

Fig. 9 INSTRUMENT PANEL TOP COVER

1 - INSTRUMENT PANEL TOP COVER

2 - INSTRUMENT PANEL

Fig. 10 INSTRUMENT PANEL FLOOR CONSOLE

1 - INSTRUMENT PANEL

2 - INSTRUMENT PANEL FLOOR CONSOLE

RSINSTRUMENT PANEL23-69

INSTRUMENT PANEL TOP COVER (Continued)