lock diagram CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 230 of 2585

HYDRAULIC/MECHANICAL

OPERATION - HYDRAULIC CIRCUITS AND

VALVES

The hydraulic fluid control valves control the flow

of pressurized brake fluid to the wheel brakes during

the different modes of ABS braking. The following

paragraphs explain how this works. For purposes of

explanation only, it is assumed that only the right

front wheel is experiencing antilock braking; the fol-

lowing diagrams show only the right front wheel in

an antilock braking operation.

NORMAL BRAKING HYDRAULIC CIRCUIT AND

SOLENOID VALVE FUNCTION

The hydraulic diagram (Fig. 6) shows the vehicle in

the normal braking mode of the base brake hydraulic

system. The diagram shows no wheel spin or slip

occurring relative to the speed of the vehicle. The

driver is applying the brake pedal which builds pres-

sure in the brake hydraulic system to engage the

brakes and stop the vehicle.

Fig. 6 Normal Braking Hydraulic Circuit

1 - OUTLET VALVE

2 - PUMP PISTON

3 - PUMP MOTOR (OFF)

4 - LOW PRESSURE ACCUMULATOR

5 - NORMALLY CLOSED VALVE (OFF)6 - TO RIGHT FRONT WHEEL

7 - NORMALLY OPEN VALVE (OFF)

8 - MASTER CYLINDER PRESSURE

9 - FROM MASTER CYLINDER

10 - NOISE DAMPER CHAMBER

RSBRAKES - ABS5-83

Page 377 of 2585

dures, further details on wire harness routing and

retention, as well as pin-out and location views for

the various wire harness connectors, splices, and

grounds.

OPERATION

Operating instructions for the factory installed

audio systems can be found in the Owner's Manual

provided with this vehicle.

DIAGNOSIS AND TESTING - AUDIO

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

AUDIO SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

NO AUDIO. 1. FUSE FAULTY. 1. CHECK RADIO FUSES IN FUSE BLOCK MODULE.

REPLACE FUSES, IF REQUIRED.

2. RADIO CONNECTOR

FAULTY.2. CHECK FOR LOOSE OR CORRODED RADIO CONNECTOR.

REPAIR, IF REQUIRED.

3. WIRING FAULTY. 3. CHECK FOR BATTERY VOLTAGE AT RADIO CONNECTOR.

REPAIR WIRING, IF REQUIRED.

4. GROUND FAULTY. 4. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED.

5. RADIO FAULTY. 5. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

6. SPEAKERS FAULTY. 6. SEE SPEAKER DIAGNOSIS, IN THIS GROUP.

NO DISPLAY. 1. FUSE FAULTY. 1. CHECK RADIO FUSES IN FUSE BLOCK MODULE.

REPLACE FUSES, IF REQUIRED.

2. RADIO CONNECTOR

FAULTY.2. CHECK FOR LOOSE OR CORRODED RADIO CONNECTOR.

REPAIR, IF REQUIRED.

3. WIRING FAULTY. 3. CHECK FOR BATTERY VOLTAGE AT RADIO CONNECTOR.

REPAIR WIRING, IF REQUIRED.

4. GROUND FAULTY. 4. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED.

5. RADIO FAULTY. 5. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

8A - 2 AUDIORS

AUDIO/VIDEO (Continued)

Page 384 of 2585

(1) Disconnect and isolate the battery negative

cable.

(2) Remove glove box (Refer to 23 - BODY/IN-

STRUMENT PANEL/GLOVE BOX - REMOVAL).

(3) Disconnect extension cable end from antenna

cable end.

(4) Disconnect cable hanger clip from HVAC unit.

(5) Remove radio as necessary to gain access to

extension cable (Refer to 8 - ELECTRICAL/AUDIO/

RADIO - REMOVAL).

CAUTION: Pulling the antenna cable straight out of

the radio without pulling on the locking antenna

connector could damage the cable or radio.

(6) Disconnect the antenna cable by pulling the

locking antenna connector away from the radio (Fig.

8).

(7) Remove cable from vehicle.

INSTALLATION

(1) Install extension cable to vehicle.

(2) Connect extension cable to back of radio.

(3) Install radio (Refer to 8 - ELECTRICAL/AU-

DIO/RADIO - INSTALLATION).

(4) Connect cable hanger clip to HVAC unit.

(5) Connect extension cable end to antenna cable

end.

(6) Install glove box (Refer to 23 - BODY/INSTRU-

MENT PANEL/GLOVE BOX - INSTALLATION).

(7) Connect the battery negative cable.

QUARTER GLASS INTEGRAL

ANTENNA - EXPORT

DESCRIPTION

The quarter glass integral antenna element is

bonded to the right rear quarter glass and is replaced

with the glass assembly only (Fig. 9).

OPERATION

The integral antenna receives radio frequencies

and sends them to the antenna module for amplifica-

tion.

DIAGNOSIS AND TESTING - QUARTER GLASS

INTEGRAL ANTENNA - EXPORT

The antenna grid pattern is divided into two sepa-

rate patterns. Each terminal connects to a separate

grid pattern, one for AM and the other for FM.

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds. To detect breaks in the

integral antenna elements, the following procedure is

required:

(1) Disconnect the antenna module connector from

the antenna terminals on the glass.

(2) Using an ohmmeter, place a lead on one of the

terminals and check each end of the grid pattern con-

nected to this terminal for continuity. If continuity is

not present, move one lead through the grid in pro-

gression starting at the terminal with the other lead

on the terminal until continuity is lost. Repeat pro-

cedure for the other terminal. A break in the antenna

Fig. 8 ANTENNA TO RADIO

1 - RADIO

2 - LOCKING ANTENNA CONNECTOR

3 - INSTRUMENT PANEL ANTENNA CABLE

Fig. 9 QUARTER GLASS INTEGRAL ANTENNA

1 - REAR QUARTER GLASS

2 - ANTENNA

RSAUDIO8A-9

INSTRUMENT PANEL ANTENNA CABLE (Continued)

Page 385 of 2585

grid can be repaired using a Mopar Rear Window

Defogger Repair Kit (Part Number 4267922) or

equivalent. (Refer to 8 - ELECTRICAL/HEATED

GLASS/WINDSHIELD GRID - STANDARD PROCE-

DURE).

RADIO

DESCRIPTION

Available factory-installed radio receivers for this

model include:

²AM/FM/cassette/CD (RAZ sales code)

²AM/FM/CD with CD changer control (RBK sales

code)

²AM/FM/cassette with CD changer control fea-

ture (RBB sales code)

²AM/FM/cassette/CD with rear audio (RBU sales

code)

All factory-installed radio receivers can communi-

cate on the Programmable Communications Interface

(PCI) data bus network. All factory-installed receiv-

ers are stereo Electronically Tuned Radios (ETR) and

include an electronic digital clock function.

These radio receivers can only be serviced by an

authorized radio repair station. See the latest War-

ranty Policies and Procedures manual for a current

listing of authorized radio repair stations.

OPERATION

The radio receiver operates on ignition switched

battery current that is available only when the igni-

tion switch is in the On or Accessory/Accessory Delay

positions. The electronic digital clock function of the

radio operates on fused battery current supplied

through the IOD fuse, regardless of the ignition

switch position.

For more information on the features, setting pro-

cedures, and control functions for each of the avail-

able factory-installed radio receivers, refer to the

owner's manual. For complete circuit diagrams, refer

to the appropriate wiring information. The wiring

information includes wiring diagrams, proper wire

and connector repair procedures, details of wire har-

ness routing and retention, connector pin-out infor-

mation and location views for the various wire

harness connectors, splices and grounds.

DIAGNOSIS AND TESTING - RADIO

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULDRESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

If the vehicle is equipped with remote radio

switches located on the back of the steering wheel

spokes, and the problem being diagnosed is related to

one of the symptoms listed below, be certain to check

the remote radio switches and circuits as described

in this group, prior to attempting radio diagnosis or

repair.

²Stations changing with no remote radio switch

input

²Radio memory presets not working properly

²Volume changes with no remote radio switch

input

²Remote radio switch buttons taking on other

functions

²CD player skipping tracks

²Remote radio switch inoperative.

CAUTION: The speaker output of the radio is a

ªfloating groundº system. Do not allow any speaker

lead to short to ground, as damage to the radio

may result.

(1) Check the fuse(s) in the junction block and the

Integrated Power Module (IPM). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse(s).

(2) Check for battery voltage at the fuse in the

(IPM). If OK, go to Step 3. If not OK, repair the open

circuit to the battery as required.

(3) Turn the ignition switch to the ON position.

Check for battery voltage at the fuse in the junction

block. If OK, go to Step 4. If not OK, repair the open

circuit to the ignition switch as required.

(4) Turn the ignition switch to the OFF position.

Remove the radio, but do not unplug the wire har-

ness connectors. Check for continuity between the

radio chassis and a good ground. There should be

continuity. If OK, go to Step 5. If not OK, repair the

open radio chassis ground circuit as required.

(5) Connect the battery negative cable. Turn the

ignition switch to the ON position. Check for battery

voltage at the fused ignition switch output circuit

cavity of the radio wire harness connector. If OK, go

8A - 10 AUDIORS

QUARTER GLASS INTEGRAL ANTENNA - EXPORT (Continued)

Page 387 of 2585

motors, and fuel pumps that have been found to be

potential sources of RFI or EMI.

OPERATION

There are two common strategies that can be used

to suppress Radio Frequency Interference (RFI) and

ElectroMagnetic Interference (EMI) radio noise. The

first suppression strategy involves preventing the

production of RFI and EMI electromagnetic signals

at their sources. The second suppression strategy

involves preventing the reception of RFI and EMI

electromagnetic signals by the audio system compo-

nents.

The use of braided ground straps in key locations

is part of the RFI and EMI prevention strategy.

These ground straps ensure adequate ground paths,

particularly for high current components such as

many of those found in the starting, charging, igni-

tion, engine control and transmission control sys-

tems. An insufficient ground path for any of these

high current components may result in radio noise

caused by induced voltages created as the high cur-

rent seeks alternative ground paths through compo-

nents or circuits intended for use by, or in close

proximity to the audio system components or circuits.

Preventing the reception of RFI and EMI is accom-

plished by ensuring that the audio system compo-

nents are correctly installed in the vehicle. Loose,

corroded or improperly soldered wire harness connec-

tions, improperly routed wiring and inadequate audio

system component grounding can all contribute to

the reception of RFI and EMI. A properly grounded

antenna body and radio chassis, as well as a shielded

antenna coaxial cable with clean and tight connec-

tions will each help reduce the potential for reception

of RFI and EMI.

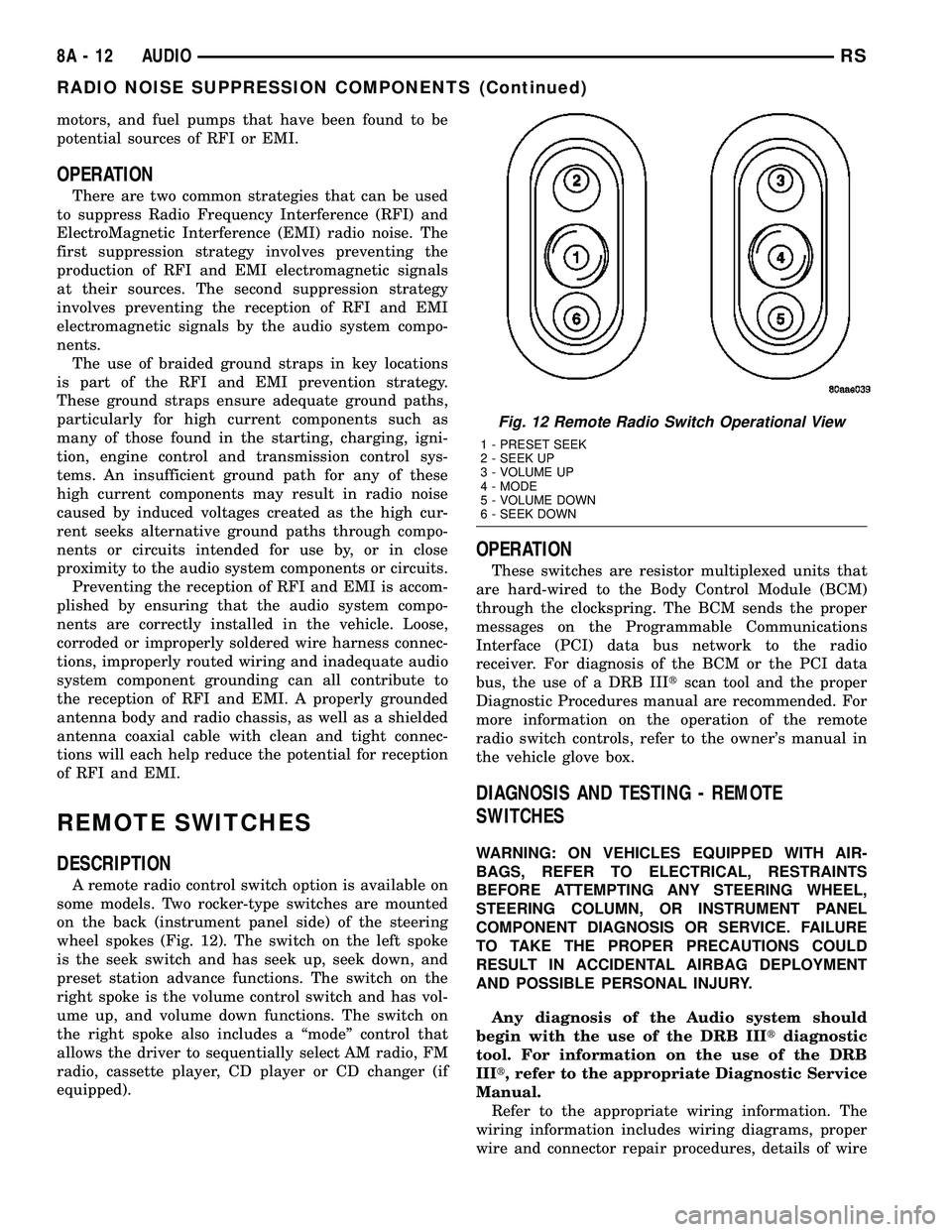

REMOTE SWITCHES

DESCRIPTION

A remote radio control switch option is available on

some models. Two rocker-type switches are mounted

on the back (instrument panel side) of the steering

wheel spokes (Fig. 12). The switch on the left spoke

is the seek switch and has seek up, seek down, and

preset station advance functions. The switch on the

right spoke is the volume control switch and has vol-

ume up, and volume down functions. The switch on

the right spoke also includes a ªmodeº control that

allows the driver to sequentially select AM radio, FM

radio, cassette player, CD player or CD changer (if

equipped).

OPERATION

These switches are resistor multiplexed units that

are hard-wired to the Body Control Module (BCM)

through the clockspring. The BCM sends the proper

messages on the Programmable Communications

Interface (PCI) data bus network to the radio

receiver. For diagnosis of the BCM or the PCI data

bus, the use of a DRB IIItscan tool and the proper

Diagnostic Procedures manual are recommended. For

more information on the operation of the remote

radio switch controls, refer to the owner's manual in

the vehicle glove box.

DIAGNOSIS AND TESTING - REMOTE

SWITCHES

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

Fig. 12 Remote Radio Switch Operational View

1 - PRESET SEEK

2 - SEEK UP

3 - VOLUME UP

4 - MODE

5 - VOLUME DOWN

6 - SEEK DOWN

8A - 12 AUDIORS

RADIO NOISE SUPPRESSION COMPONENTS (Continued)

Page 389 of 2585

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Install remote radio switch to the steering

wheel.

(2) Install three screws securing steering wheel

rear cover.

(3) Connect the wire harness to the remote radio

switch.

(4) Install the steering wheel. Refer to STEERING/

COLUMN/STEERING WHEEL.

(5) Install the driver side airbag module. Refer to

ELECTRICAL/RESTRAINTS/DRIVER AIRBAG.

(6) Connect the battery negative cable.

SPEAKER

DIAGNOSIS AND TESTING - SPEAKER

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

CAUTION: The speaker output of the radio is a

ªfloating groundº system. Do not allow any speakerlead to short to ground, as damage to the radio

may result.

(1) If all speakers are inoperative, check the radio

fuses in the junction block. If OK, go to Step 2. If not

OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the ON position.

Turn the radio receiver ON. Adjust the balance and

fader control controls to check the performance of

each individual speaker. Note the speaker locations

that are not performing correctly. Go to Step 3.

(3) Turn the radio receiver OFF. Turn the ignition

OFF. Disconnect and isolate the battery negative

cable. Remove the radio receiver.

(4) Check both the speaker feed (+) circuit and

return (-) circuit cavities for the inoperative speaker

at the radio receiver wire harness connector for con-

tinuity to ground. There should be no continuity. If

OK, go to Step 5. If not OK, repair the shorted

speaker feed (+) and/or return (-) circuits(s) to the

speaker as required.

(5) Disconnect wire harness connector at the inop-

erative speaker. Check for continuity between the

speaker feed (+) circuit cavities of the radio receiver

wire harness connector and the speaker wire harness

connector. Repeat the check between the speaker

return (-) circuit cavities of the radio receiver wire

harness connector and the speaker wire harness con-

nector. In each case, there should be continuity. If

OK, replace the faulty speaker. If not OK, repair the

open speaker feed (+) and/or return (-) circuits(s) as

required.

REMOVAL

D-PILLAR SPEAKER

(1) Disconnect and isolate the battery negative

cable.

(2) Remove rear header trim (right side speaker).

(3) Remove jack cover (left side speaker).

(4) Remove liftgate scuff plate.

(5) Remove upper seat belt bolt. (Refer to 8 -

ELECTRICAL/RESTRAINTS/SEAT BELT OUT-

BOARD FRONT - REMOVAL).

(6) Partially remove quarter trim panel to access

the D-pillar speaker.

(7) Slide the speaker from the retainer (Fig. 14).

(8) Disconnect the wire harness connector from the

speaker.

FRONT DOOR SPEAKER

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the front door trim panel. (Refer to 23

- BODY/DOOR - FRONT/TRIM PANEL - REMOV-

AL).

8A - 14 AUDIORS

REMOTE SWITCHES (Continued)

Page 437 of 2585

NOTE: Never operate a vehicle without a battery

holddown device properly installed. Damage to the

vehicle, components and battery could result.

REMOVAL

All of the battery hold down hardware can be ser-

viced without removal of the battery or the battery

tray and support unit.

(1) Turn the ignition switch to the Off position. Be

certain that all electrical accessories are turned off.

(2) Remove the nut with washer that secures the

battery hold down bracket to the battery tray and

support unit.

(3) Remove the battery hold down bracket from

the battery tray and support unit.

INSTALLATION

(1) Install the battery hold down bracket in the

battery tray and support unit.

(2) Install the nut with washer that secures the

battery hold down bracket to the battery tray and

support unit. Torque to 20 N´m (180 in. lbs.).

BATTERY CABLES

DESCRIPTION

The battery cables are large gauge, stranded cop-

per wires sheathed within a heavy plastic or syn-

thetic rubber insulating jacket. The wire used in the

battery cables combines excellent flexibility and reli-

ability with high electrical current carrying capacity.

Refer toWiring Diagramsin the index of this ser-

vice manual for the location of the proper battery

cable wire gauge information.

A clamping type female battery terminal made of

stamped metal is attached to one end of the battery

cable wire. A square headed pinch-bolt and hex nut

are installed at the open end of the female battery

terminal clamp. Large eyelet type terminals are

crimped onto the opposite end of the battery cable

wire and then solder-dipped. The battery positive

cable wires have a red insulating jacket to provide

visual identification and feature a larger female bat-

tery terminal clamp to allow connection to the larger

battery positive terminal post. The battery negative

cable wires have a black insulating jacket and a

smaller female battery terminal clamp.

The battery cables cannot be repaired and, if dam-

aged or faulty they must be replaced. Both the bat-

tery positive and negative cables are available for

service replacement only as a unit with the battery

wire harness, which may include portions of the wir-

ing circuits for the generator and other components

on some models. Refer toWiring Diagramsin theindex of this service manual for the location of more

information on the various wiring circuits included in

the battery wire harness for the vehicle being ser-

viced.

OPERATION

The battery cables connect the battery terminal

posts to the vehicle electrical system. These cables

also provide a path back to the battery for electrical

current generated by the charging system for restor-

ing the voltage potential of the battery. The female

battery terminal clamps on the ends of the battery

cable wires provide a strong and reliable connection

of the battery cable to the battery terminal posts.

The terminal pinch bolts allow the female terminal

clamps to be tightened around the male terminal

posts on the top of the battery. The eyelet terminals

secured to the opposite ends of the battery cable

wires from the female battery terminal clamps pro-

vide secure and reliable connection of the battery

cables to the vehicle electrical system.

The battery positive cable terminal clamp is

attached to the ends of two wires. One wire has an

eyelet terminal that connects the battery positive

cable to the B(+) terminal stud of the Integrated

Power Module (IPM), and the other wire has an eye-

let terminal that connects the battery positive cable

to the B(+) terminal stud of the engine starter motor

solenoid. The battery negative cable terminal clamp

is also attached to the ends of two wires. One wire

has an eyelet terminal that connects the battery neg-

ative cable to the vehicle powertrain through a stud

on the left side of the engine cylinder block. The

other wire has an eyelet terminal that connects the

battery negative cable to the vehicle body through a

ground screw on the left front fender inner shield,

near the battery.

DIAGNOSIS AND TESTING - BATTERY CABLE

A voltage drop test will determine if there is exces-

sive resistance in the battery cable terminal connec-

tions or the battery cable. If excessive resistance is

found in the battery cable connections, the connec-

tion point should be disassembled, cleaned of all cor-

rosion or foreign material, then reassembled.

Following reassembly, check the voltage drop for the

battery cable connection and the battery cable again

to confirm repair.

When performing the voltage drop test, it is impor-

tant to remember that the voltage drop is giving an

indication of the resistance between the two points at

which the voltmeter probes are attached.EXAM-

PLE:When testing the resistance of the battery pos-

itive cable, touch the voltmeter leads to the battery

positive cable terminal clamp and to the battery pos-

itive cable eyelet terminal at the starter solenoid

8F - 16 BATTERY SYSTEMRS

BATTERY HOLDDOWN (Continued)

Page 449 of 2585

STARTING

TABLE OF CONTENTS

page page

STARTING

DESCRIPTION.........................28

OPERATION...........................28

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - STARTING

SYSTEM TEST.......................28

DIAGNOSIS AND TESTING - CONTROL

CIRCUIT TEST........................30

DIAGNOSIS AND TESTING - FEED CIRCUIT

RESISTANCE TEST....................32

DIAGNOSIS AND TESTING - FEED CIRCUIT

TEST...............................33SPECIFICATIONS

Torques.............................33

STARTER ...........................34

STARTER MOTOR

REMOVAL

REMOVAL - 2.4L......................34

REMOVAL - 3.3/3.8L...................35

INSTALLATION

INSTALLATION - 2.4L..................35

INSTALLATION - 3.3/3.8L................36

STARTING

DESCRIPTION

The starting system consists of:

²Starter relay

²Starter motor (including an integral starter sole-

noid)

Other components to be considered as part of start-

ing system are:

²Battery

²Battery cables

²Ignition switch and key lock cylinder

²Clutch pedal position switch (manual transmis-

sion)

²Park/neutral position switch (automatic trans-

mission)

²Wire harnesses and connections.

The Battery, Starting, and Charging systems oper-

ate in conjunction with one another, and must be

tested as a complete system. For correct operation of

starting/charging systems, all components used in

these 3 systems must perform within specifications.

When attempting to diagnose any of these systems, it

is important that you keep their interdependency in

mind.

The diagnostic procedures used in each of these

groups include the most basic conventional diagnostic

methods, to the more sophisticated On-Board Diag-

nostics (OBD) built into the Powertrain Control Mod-

ule (PCM). Use of an induction-type milliampere

ammeter, volt/ohmmeter, battery charger, carbon pile

rheostat (load tester), and 12-volt test lamp may be

required.

OPERATION

These components form two separate circuits. A

high amperage circuit that feeds the starter motor up

to 300+ amps, and a control circuit that operates on

less than 20 amps.

The PCM controls a double start over-ride safety

that does not allow the starter to be engaged if the

engine is already running.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - STARTING

SYSTEM TEST

For circuit descriptions and diagrams, refer to the

Wiring Diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO THE PASSIVE RESTRAINT SYS-

TEMS BEFORE ATTEMPTING STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

INSPECTION

Before removing any unit from the starting system

for repair or diagnosis, perform the following inspec-

tions:

²Battery- Visually inspect the battery for indi-

cations of physical damage and loose or corroded

cable connections. Determine the state-of-charge and

cranking capacity of the battery. Charge or replace

8F - 28 STARTINGRS

Page 450 of 2585

the battery, if required. Refer to the Battery section

for more information.

²Ignition Switch- Visually inspect the ignition

switch for indications of physical damage and loose

or corroded wire harness connections.

²Transmission Range Sensor or Park/Neu-

tral Switch- Visually inspect the transmission

range sensor for indications of physical damage and

loose or corroded wire harness connections.

²Starter Relay- Visually inspect the starter

relay for indications of physical damage and loose or

corroded wire harness connections.

²Starter Motor- Visually inspect the starter

motor for indications of physical damage and loose or

corroded wire harness connections.²Starter Solenoid- Visually inspect the starter

solenoid for indications of physical damage and loose

or corroded wire harness connections.

²Wiring- Visually inspect the wire harness for

damage. Repair or replace any faulty wiring, as

required. Check for loose or corroded wire harness

connections at main engine ground and remote jump

post.

²Power Distribution Center (PDC)- Visually

inspect the B+ connections at the PDC for physical

damage and loose or corroded harness connections.

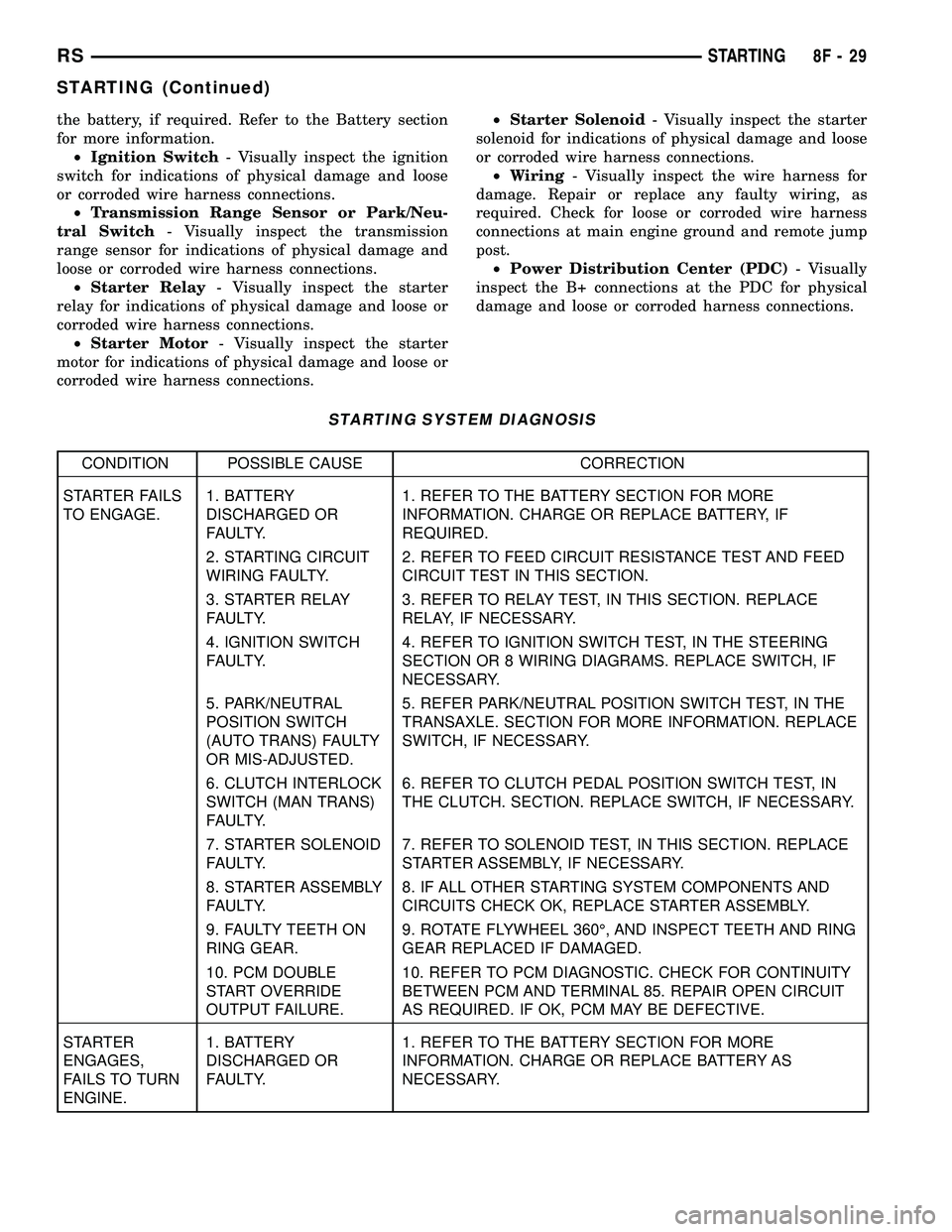

STARTING SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

STARTER FAILS

TO ENGAGE.1. BATTERY

DISCHARGED OR

FAULTY.1. REFER TO THE BATTERY SECTION FOR MORE

INFORMATION. CHARGE OR REPLACE BATTERY, IF

REQUIRED.

2. STARTING CIRCUIT

WIRING FAULTY.2. REFER TO FEED CIRCUIT RESISTANCE TEST AND FEED

CIRCUIT TEST IN THIS SECTION.

3. STARTER RELAY

FAULTY.3. REFER TO RELAY TEST, IN THIS SECTION. REPLACE

RELAY, IF NECESSARY.

4. IGNITION SWITCH

FAULTY.4. REFER TO IGNITION SWITCH TEST, IN THE STEERING

SECTION OR 8 WIRING DIAGRAMS. REPLACE SWITCH, IF

NECESSARY.

5. PARK/NEUTRAL

POSITION SWITCH

(AUTO TRANS) FAULTY

OR MIS-ADJUSTED.5. REFER PARK/NEUTRAL POSITION SWITCH TEST, IN THE

TRANSAXLE. SECTION FOR MORE INFORMATION. REPLACE

SWITCH, IF NECESSARY.

6. CLUTCH INTERLOCK

SWITCH (MAN TRANS)

FAULTY.6. REFER TO CLUTCH PEDAL POSITION SWITCH TEST, IN

THE CLUTCH. SECTION. REPLACE SWITCH, IF NECESSARY.

7. STARTER SOLENOID

FAULTY.7. REFER TO SOLENOID TEST, IN THIS SECTION. REPLACE

STARTER ASSEMBLY, IF NECESSARY.

8. STARTER ASSEMBLY

FAULTY.8. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

9. FAULTY TEETH ON

RING GEAR.9. ROTATE FLYWHEEL 360É, AND INSPECT TEETH AND RING

GEAR REPLACED IF DAMAGED.

10. PCM DOUBLE

START OVERRIDE

OUTPUT FAILURE.10. REFER TO PCM DIAGNOSTIC. CHECK FOR CONTINUITY

BETWEEN PCM AND TERMINAL 85. REPAIR OPEN CIRCUIT

AS REQUIRED. IF OK, PCM MAY BE DEFECTIVE.

STARTER

ENGAGES,

FAILS TO TURN

ENGINE.1. BATTERY

DISCHARGED OR

FAULTY.1. REFER TO THE BATTERY SECTION FOR MORE

INFORMATION. CHARGE OR REPLACE BATTERY AS

NECESSARY.

RSSTARTING8F-29

STARTING (Continued)

Page 453 of 2585

RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) is

connected to battery voltage and should be hot at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the PDC fuse as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is con-

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage

to the starter solenoid field coils. There should be

continuity between the cavity for relay terminal 87

and the starter solenoid terminal at all times. If OK,

go to Step 4. If not OK, repair the open circuit to the

starter solenoid as required.

(4) The coil battery terminal (85) is connected to

the electromagnet in the relay. It is energized when

the ignition switch is held in the Start position and

the clutch pedal is depressed (manual trans). Check

for battery voltage at the cavity for relay terminal 86

with the ignition switch in the Start position and the

clutch pedal is depressed (manual trans), and no

voltage when the ignition switch is released to the

On position. If OK, go to Step 5. If not OK, check for

an open or short circuit to the ignition switch and

repair, if required. If the circuit to the ignition switch

is OK, see the Ignition Switch Test procedure in this

group.

(5) The coil ground terminal (86) is connected to

the electromagnet in the relay. It is grounded by the

PCM if the conditions are right to start the car. For

automatic trans. cars the PCM must see Park Neu-

tral switch low and near zero engine speed (rpm).

For manual trans. cars the PCM only needs to see

near zero engine speed (rpm) and low clutch inter-

lock input and see near zero engine speed (rpm). To

diagnose the Park Neutral switch of the trans range

sensor refer to the transaxle section. Check for conti-

nuity to ground while the ignition switch is in the

start position and if equipped the clutch pedal

depressed. If not OK and the vehicle has an auto-

matic trans. verify Park Neutral switch operation. If

that checks OK check for continuity between PCM

and the terminal 86. Repair open circuit as required.

Also check the clutch interlock switch operation if

equipped with a manual transmission. If OK, the

PCM may be defective.

SAFETY SWITCHES

For diagnostics of the Transmission Range Sensor,

refer to the Transaxle section for more information.

If equipped with Clutch Interlock/Upstop Switch,

refer to Diagnosis and Testing in the Clutch section.

IGNITION SWITCH

After testing starter solenoid and relay, test igni-

tion switch and wiring. Refer to the Ignition Section

or Wiring Diagrams for more information. Check all

wiring for opens or shorts, and all connectors for

being loose or corroded.

BATTERY

For battery diagnosis and testing, refer to the Bat-

tery section for procedures.

ALL RELATED WIRING AND CONNECTORS

Refer to Wiring Diagrams for more information.

DIAGNOSIS AND TESTING - FEED CIRCUIT

RESISTANCE TEST

Before proceeding with this operation, review Diag-

nostic Preparation and Starter Feed Circuit Tests.

The following operation will require a voltmeter,

accurate to 1/10 of a volt.

CAUTION: Ignition and Fuel systems must be dis-

abled to prevent engine start while performing the

following tests.

(1) To disable the Ignition and Fuel systems, dis-

connect the Automatic Shutdown Relay (ASD). The

ASD relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for proper relay

location.

(2) Gain access to battery terminals.

(3) With all wiring harnesses and components

properly connected, perform the following:

(a) Connect the negative lead of the voltmeter to

the battery negative post, and positive lead to the

battery negative cable clamp. Rotate and hold the

ignition switch in the START position. Observe the

voltmeter. If voltage is detected, correct poor con-

tact between cable clamp and post.

(b) Connect positive lead of the voltmeter to the

battery positive post, and negative lead to the bat-

tery positive cable clamp. Rotate and hold the igni-

tion switch key in the START position. Observe the

voltmeter. If voltage is detected, correct poor con-

tact between the cable clamp and post.

(c) Connect negative lead of voltmeter to battery

negative terminal, and positive lead to engine

block near the battery cable attaching point.

Rotate and hold the ignition switch in the START

position. If voltage reads above 0.2 volt, correct

poor contact at ground cable attaching point. If

voltage reading is still above 0.2 volt after correct-

ing poor contacts, replace ground cable.

(4) Connect positive voltmeter lead to the starter

motor housing and the negative lead to the battery

negative terminal. Hold the ignition switch key in

8F - 32 STARTINGRS

STARTING (Continued)