service interval CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 15 of 2585

²Society of Automotive Engineers (SAE)

²American Petroleum Institute (API)

²National Lubricating Grease Institute (NLGI)

API SERVICE GRADE CERTIFIED

Use an engine oil that is API Certified (GF-3).

Mopartprovides engine oils, meeting Material Stan-

dard MS-6395, that meet or exceed this requirement.

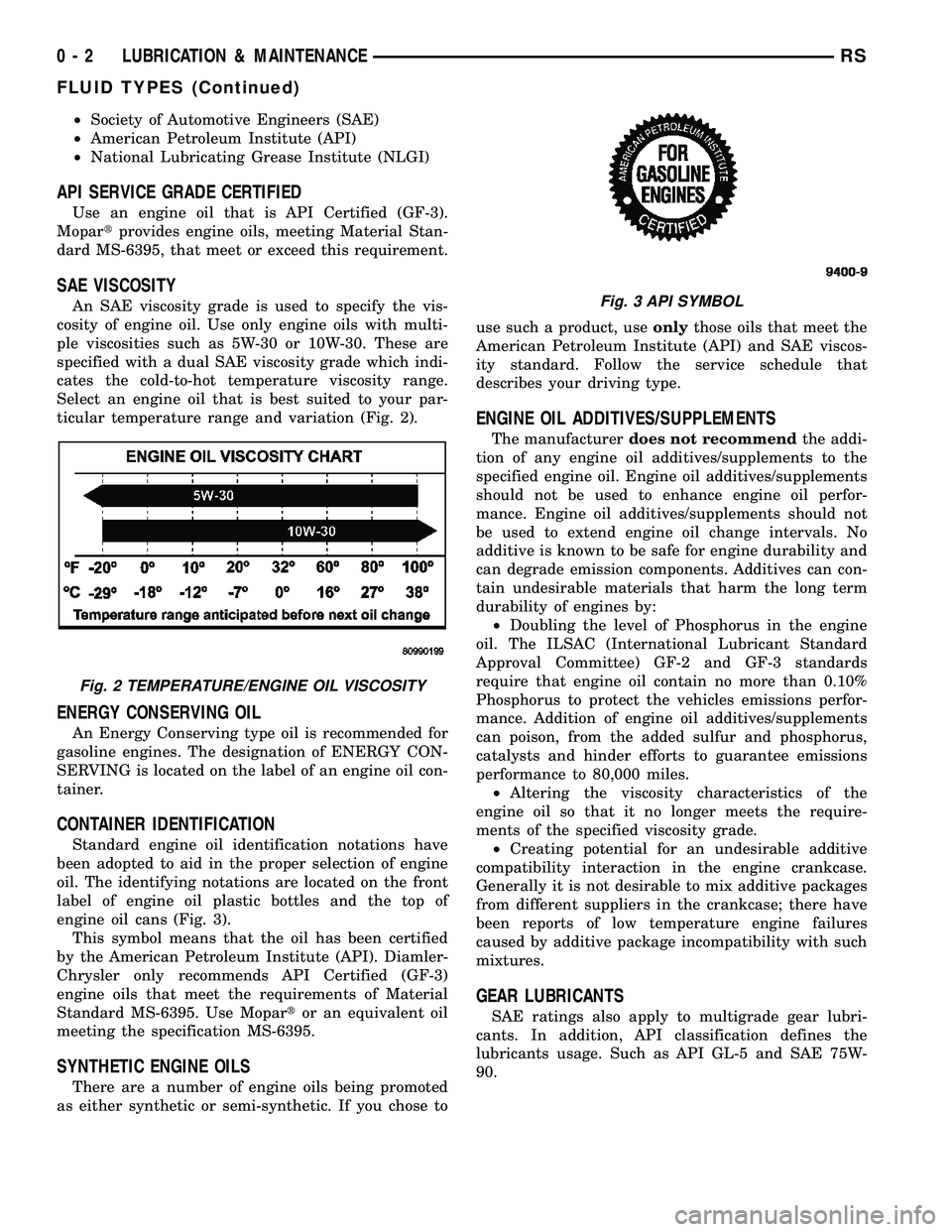

SAE VISCOSITY

An SAE viscosity grade is used to specify the vis-

cosity of engine oil. Use only engine oils with multi-

ple viscosities such as 5W-30 or 10W-30. These are

specified with a dual SAE viscosity grade which indi-

cates the cold-to-hot temperature viscosity range.

Select an engine oil that is best suited to your par-

ticular temperature range and variation (Fig. 2).

ENERGY CONSERVING OIL

An Energy Conserving type oil is recommended for

gasoline engines. The designation of ENERGY CON-

SERVING is located on the label of an engine oil con-

tainer.

CONTAINER IDENTIFICATION

Standard engine oil identification notations have

been adopted to aid in the proper selection of engine

oil. The identifying notations are located on the front

label of engine oil plastic bottles and the top of

engine oil cans (Fig. 3).

This symbol means that the oil has been certified

by the American Petroleum Institute (API). Diamler-

Chrysler only recommends API Certified (GF-3)

engine oils that meet the requirements of Material

Standard MS-6395. Use Mopartor an equivalent oil

meeting the specification MS-6395.

SYNTHETIC ENGINE OILS

There are a number of engine oils being promoted

as either synthetic or semi-synthetic. If you chose touse such a product, useonlythose oils that meet the

American Petroleum Institute (API) and SAE viscos-

ity standard. Follow the service schedule that

describes your driving type.

ENGINE OIL ADDITIVES/SUPPLEMENTS

The manufacturerdoes not recommendthe addi-

tion of any engine oil additives/supplements to the

specified engine oil. Engine oil additives/supplements

should not be used to enhance engine oil perfor-

mance. Engine oil additives/supplements should not

be used to extend engine oil change intervals. No

additive is known to be safe for engine durability and

can degrade emission components. Additives can con-

tain undesirable materials that harm the long term

durability of engines by:

²Doubling the level of Phosphorus in the engine

oil. The ILSAC (International Lubricant Standard

Approval Committee) GF-2 and GF-3 standards

require that engine oil contain no more than 0.10%

Phosphorus to protect the vehicles emissions perfor-

mance. Addition of engine oil additives/supplements

can poison, from the added sulfur and phosphorus,

catalysts and hinder efforts to guarantee emissions

performance to 80,000 miles.

²Altering the viscosity characteristics of the

engine oil so that it no longer meets the require-

ments of the specified viscosity grade.

²Creating potential for an undesirable additive

compatibility interaction in the engine crankcase.

Generally it is not desirable to mix additive packages

from different suppliers in the crankcase; there have

been reports of low temperature engine failures

caused by additive package incompatibility with such

mixtures.

GEAR LUBRICANTS

SAE ratings also apply to multigrade gear lubri-

cants. In addition, API classification defines the

lubricants usage. Such as API GL-5 and SAE 75W-

90.

Fig. 2 TEMPERATURE/ENGINE OIL VISCOSITY

Fig. 3 API SYMBOL

0 - 2 LUBRICATION & MAINTENANCERS

FLUID TYPES (Continued)

Page 17 of 2585

FUEL REQUIREMENTS

The vehicle will operate on both unleaded gasoline

with an octane rating of 87, or E-85 fuel, or any mix-

ture of these two.

For best results, a refueling pattern that alternates

between E-85 and unleaded gasoline should be

avoided. When you do switch fuels, it is recom-

mended that

²you do not switch when the fuel gauge indicates

less than 1/4 full

²you do not add less than 5 gallons when refuel-

ing

²you operate the vehicle immediately after refuel-

ing for a period of at least 5 minutes

Observing these precautions will avoid possible

hard starting and/or significant deterioration in

driveability during warm up.

FFV STARTING

The characteristics of E-85 fuel make it unsuitable

for use when ambient temperatures fall below 0ÉF. In

the range of 0ÉF to 32ÉF, you may experience an

increase in the time it takes for your engine to start,

and a deterioration in driveability (sags and/or hesi-

tations) until the engine is fully warmed up.

Engine Operating on E-85 Fuel

If vehicle operates on E-85 fuel either full or part-

time, use only MopartFlexible Fuel 5W-30 engine oil

or an equivalent that meets DaimlerChrysler Stan-

dard MS-9214. Equivalent commercial Flexible Fuel

engine oils may be labeled as Multi-Fuel, Variable

Fuel, Flexible Fuel, etc. These engine oils may be

satisfactory if they meet the DaimlerChrysler Stan-

dard.

SAE 5W-30 engine oil is preferred for use in Flex-

ible Fuel engines.

CAUTION: If Flexible Fuel engine oil is not used

when using E-85 fuel, engine wear or damage may

result.

CRUISING RANGE

Because E-85 fuel contains less energy per gallon

than gasoline, you will experience an increase in fuel

consumption. You can expect your MPG and your

driving range to decrease by about 30% compared to

gasoline operation.

DESCRIPTION - AUTOMATIC/MANUAL

TRANSAXLE FLUID

NOTE: Refer to the maintenance schedules for the

recommended maintenance (fluid/filter change)

intervals for these transaxles.NOTE: All transaxles have a common transmission

and differential sump. Filling the transaxle accom-

modates the differential as well.

TRANSMISSION FLUID

MopartATF+4 (Automatic Transmission Fluid) is

required in the 41TE automatic and T850 manual

transaxles. Substitute fluids can induce transmission

problems and/or failure.

MopartATF+4 (Automatic Transmission Fluid)

when new is red in color. The ATF is dyed red so it

can be identified from other fluids used in the vehicle

such as engine oil or antifreeze. The red color is not

permanent and is not an indicator of fluid condition.

As the vehicle is driven, the ATF will begin to look

darker in color and may eventually become brown.

This is normal.ATF+4 also has a unique odor that

may change with age. Consequently,odor and color

cannot be used to indicate the fluid condition

or the need for a fluid change.

FLUID ADDITIVES

DaimlerChrysler strongly recommends against the

addition of any fluids to the transmission, other than

those automatic transmission fluids listed above.

Exceptions to this policy are the use of special dyes

to aid in detecting fluid leaks.

Various ªspecialº additives and supplements exist

that claim to improve shift feel and/or quality. These

additives and others also claim to improve converter

clutch operation and inhibit overheating, oxidation,

varnish, and sludge. These claims have not been sup-

ported to the satisfaction of DaimlerChrysler and

these additivesmust not be used.The use of trans-

mission ªsealersº should also be avoided, since they

may adversely affect the integrity of transmission

seals.

DESCRIPTION - FUEL REQUIREMENTS

Your engine is designed to meet all emissions reg-

ulations and provide excellent fuel economy and per-

formance when using high quality unleaded gasoline

having an octane rating of 87. The use of premium

gasoline is not recommended. The use of premium

gasoline will provide no benefit over high quality reg-

ular gasoline, and in some circumstances may result

in poorer performance.

Light spark knock at low engine speeds is not

harmful to your engine. However, continued heavy

spark knock at high speeds can cause damage and

immediate service is required. Engine damage result-

ing from operation with a heavy spark knock may

not be covered by the new vehicle warranty.

Poor quality gasoline can cause problems such as

hard starting, stalling and hesitations. If you experi-

0 - 4 LUBRICATION & MAINTENANCERS

FLUID TYPES (Continued)

Page 20 of 2585

FLUID FILL/CHECK

LOCATIONS

DESCRIPTION

The fluid check/fill point locations are located in

each applicable service manual section.

LUBRICATION POINTS

DESCRIPTION

Lubrication point locations are located in each

applicable Sections.

MAINTENANCE SCHEDULES

DESCRIPTION

DESCRIPTION

There are two maintenance schedules that show

therequiredservice for your vehicle.

First is ScheduleªBº. It is for vehicles that are

operated under the conditions that are listed below

and at the beginning of the schedule.

²Day or night temperatures are below 32É F (0É

C).

²Stop and go driving.

²Extensive engine idling.

²Driving in dusty conditions.

²Short trips of less than 10 miles (16 km).

²More than 50% of your driving is at sustained

high speeds during hot weather, above 90É F (32É C).

²Trailer towing.L

²Taxi, police, or delivery service (commercial ser-

vice).L

²Off-road or desert operation.

NOTE: Most vehicles are operated under the condi-

tions listed for Schedule(B(.

Second is ScheduleªAº. It is for vehicles that are

not operated under any of the conditions listed under

Schedule9B9.

Use the schedule that best describes your driving

conditions. Where time and mileage are listed, follow

the interval that occurs first.

CAUTION: Failure to perform the required mainte-

nance items may result in damage to the vehicle.

At Each Stop for Fuel

²Check the engine oil level about 5 minutes after

a fully warmed engine is shut off. Checking the oil

level while the vehicle is on level ground will

improve the accuracy of the oil level reading. Add oil

only when the level is at or below the ADD or MIN

mark.

²Check the windshield washer solvent and add if

required.

Once a Month

²Check tire pressure and look for unusual wear

or damage.

²Inspect the battery and clean and tighten the

terminals as required.

²Check the fluid levels of coolant reservoir, brake

master cylinder and transmission; add as needed.

²Check all lights and all other electrical items for

correct operation.

At Each Oil Change

²Change the engine oil filter.

²Inspect the exhaust system.

²Inspect the brake hoses.

²Inspect the CV joints and front suspension com-

ponents.

²Check the automatic transmission fluid level.

²Check the coolant level, hoses, and clamps.

Tire Rotation

²Rotate the tires at 6,000 miles (10 000 km).

SCHEDULE B

Follow schedule ªBº if you usually operate your

vehicle under one or more of the following conditions.

Change the automatic transmission fluid and filter

every 60,000 miles (96 000 km) if the vehicle is usu-

ally operated under one or more of the conditions

marked with anL.

²Day or night temperatures are below 32É F (0É

C).

²Stop and go driving.

²Extensive engine idling.

²Driving in dusty conditions.

²Short trips of less than 10 miles (16 km).

²More than 50% of your driving is at sustained

high speeds during hot weather, above 90É F (32É C).

²Trailer towing.L

²Taxi, police, or delivery service (commercial ser-

vice).L

²Off-road or desert operation.

RSLUBRICATION & MAINTENANCE0-7

Page 25 of 2585

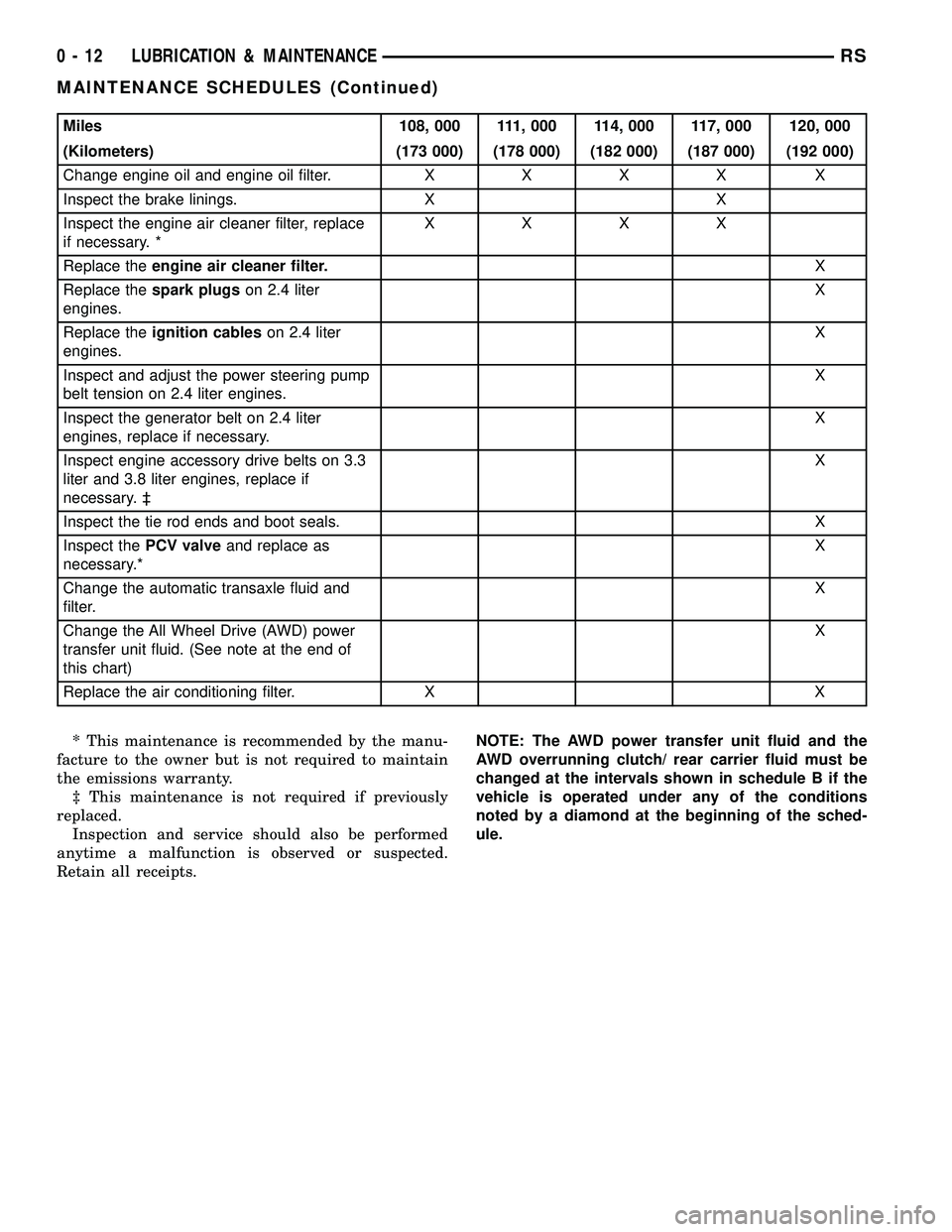

Miles 108, 000 111, 000 114, 000 117, 000 120, 000

(Kilometers) (173 000) (178 000) (182 000) (187 000) (192 000)

Change engine oil and engine oil filter.XXXX X

Inspect the brake linings. X X

Inspect the engine air cleaner filter, replace

if necessary. *XXXX

Replace theengine air cleaner filter.X

Replace thespark plugson 2.4 liter

engines.X

Replace theignition cableson 2.4 liter

engines.X

Inspect and adjust the power steering pump

belt tension on 2.4 liter engines.X

Inspect the generator belt on 2.4 liter

engines, replace if necessary.X

Inspect engine accessory drive belts on 3.3

liter and 3.8 liter engines, replace if

necessary. ³X

Inspect the tie rod ends and boot seals. X

Inspect thePCV valveand replace as

necessary.*X

Change the automatic transaxle fluid and

filter.X

Change the All Wheel Drive (AWD) power

transfer unit fluid. (See note at the end of

this chart)X

Replace the air conditioning filter. X X

* This maintenance is recommended by the manu-

facture to the owner but is not required to maintain

the emissions warranty.

³ This maintenance is not required if previously

replaced.

Inspection and service should also be performed

anytime a malfunction is observed or suspected.

Retain all receipts.NOTE: The AWD power transfer unit fluid and the

AWD overrunning clutch/ rear carrier fluid must be

changed at the intervals shown in schedule B if the

vehicle is operated under any of the conditions

noted by a diamond at the beginning of the sched-

ule.

0 - 12 LUBRICATION & MAINTENANCERS

MAINTENANCE SCHEDULES (Continued)

Page 28 of 2585

* This maintenance is recommended by the manu-

facture to the owner but is not required to maintain

the emissions warranty.

³ This maintenance is not required if previously

replaced.

Inspection and service should also be performed

anytime a malfunction is observed or suspected.

Retain all receipts.

WARNING: You can be badly injured working on or

around a motor vehicle. Do only that service work

for which you have the knowledge and the right

equipment. If you have any doubt about your ability

to perform a service job, take your vehicle to a

competent mechanic.

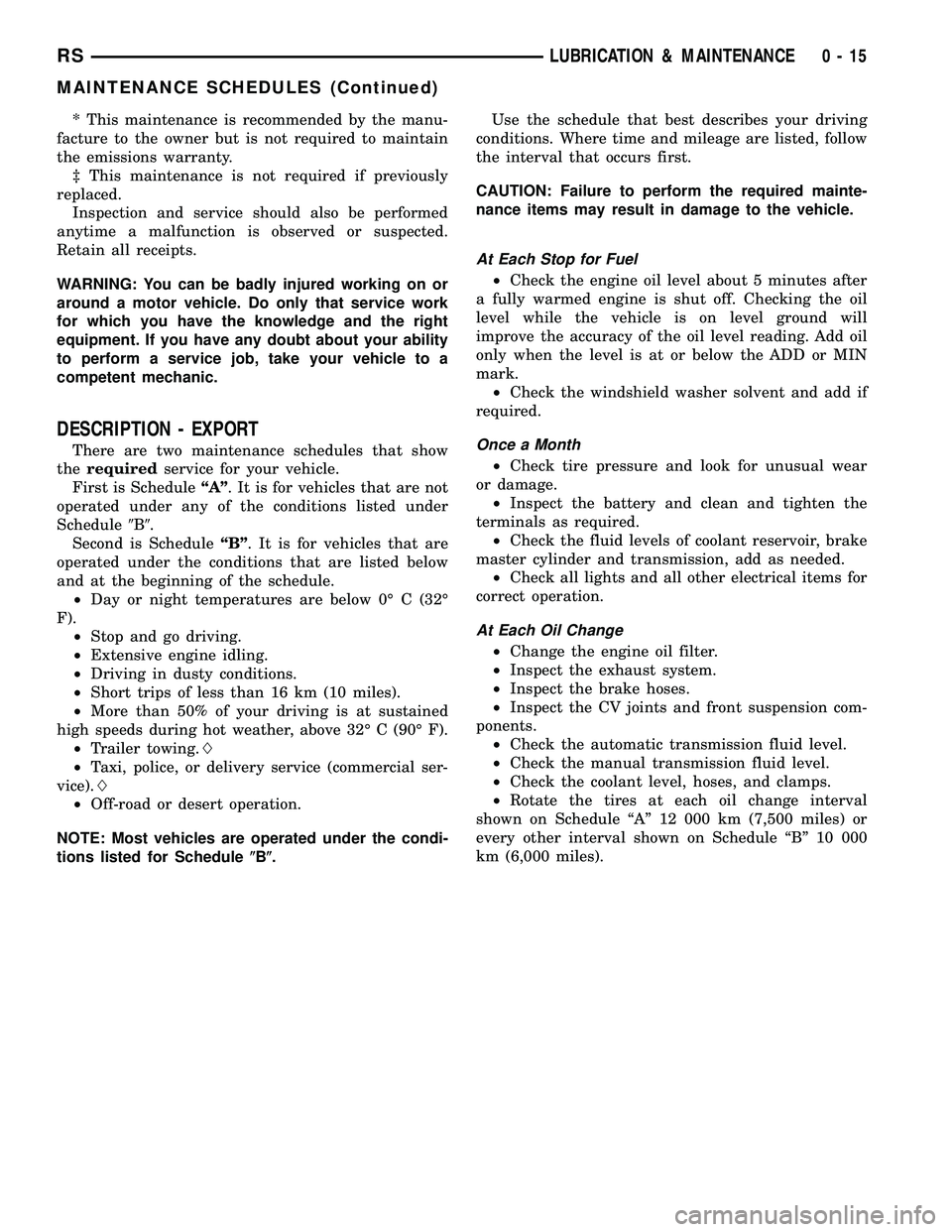

DESCRIPTION - EXPORT

There are two maintenance schedules that show

therequiredservice for your vehicle.

First is ScheduleªAº. It is for vehicles that are not

operated under any of the conditions listed under

Schedule9B9.

Second is ScheduleªBº. It is for vehicles that are

operated under the conditions that are listed below

and at the beginning of the schedule.

²Day or night temperatures are below 0É C (32É

F).

²Stop and go driving.

²Extensive engine idling.

²Driving in dusty conditions.

²Short trips of less than 16 km (10 miles).

²More than 50% of your driving is at sustained

high speeds during hot weather, above 32É C (90É F).

²Trailer towing.L

²Taxi, police, or delivery service (commercial ser-

vice).L

²Off-road or desert operation.

NOTE: Most vehicles are operated under the condi-

tions listed for Schedule(B(.Use the schedule that best describes your driving

conditions. Where time and mileage are listed, follow

the interval that occurs first.

CAUTION: Failure to perform the required mainte-

nance items may result in damage to the vehicle.

At Each Stop for Fuel

²Check the engine oil level about 5 minutes after

a fully warmed engine is shut off. Checking the oil

level while the vehicle is on level ground will

improve the accuracy of the oil level reading. Add oil

only when the level is at or below the ADD or MIN

mark.

²Check the windshield washer solvent and add if

required.

Once a Month

²Check tire pressure and look for unusual wear

or damage.

²Inspect the battery and clean and tighten the

terminals as required.

²Check the fluid levels of coolant reservoir, brake

master cylinder and transmission, add as needed.

²Check all lights and all other electrical items for

correct operation.

At Each Oil Change

²Change the engine oil filter.

²Inspect the exhaust system.

²Inspect the brake hoses.

²Inspect the CV joints and front suspension com-

ponents.

²Check the automatic transmission fluid level.

²Check the manual transmission fluid level.

²Check the coolant level, hoses, and clamps.

²Rotate the tires at each oil change interval

shown on Schedule ªAº 12 000 km (7,500 miles) or

every other interval shown on Schedule ªBº 10 000

km (6,000 miles).

RSLUBRICATION & MAINTENANCE0-15

MAINTENANCE SCHEDULES (Continued)

Page 36 of 2585

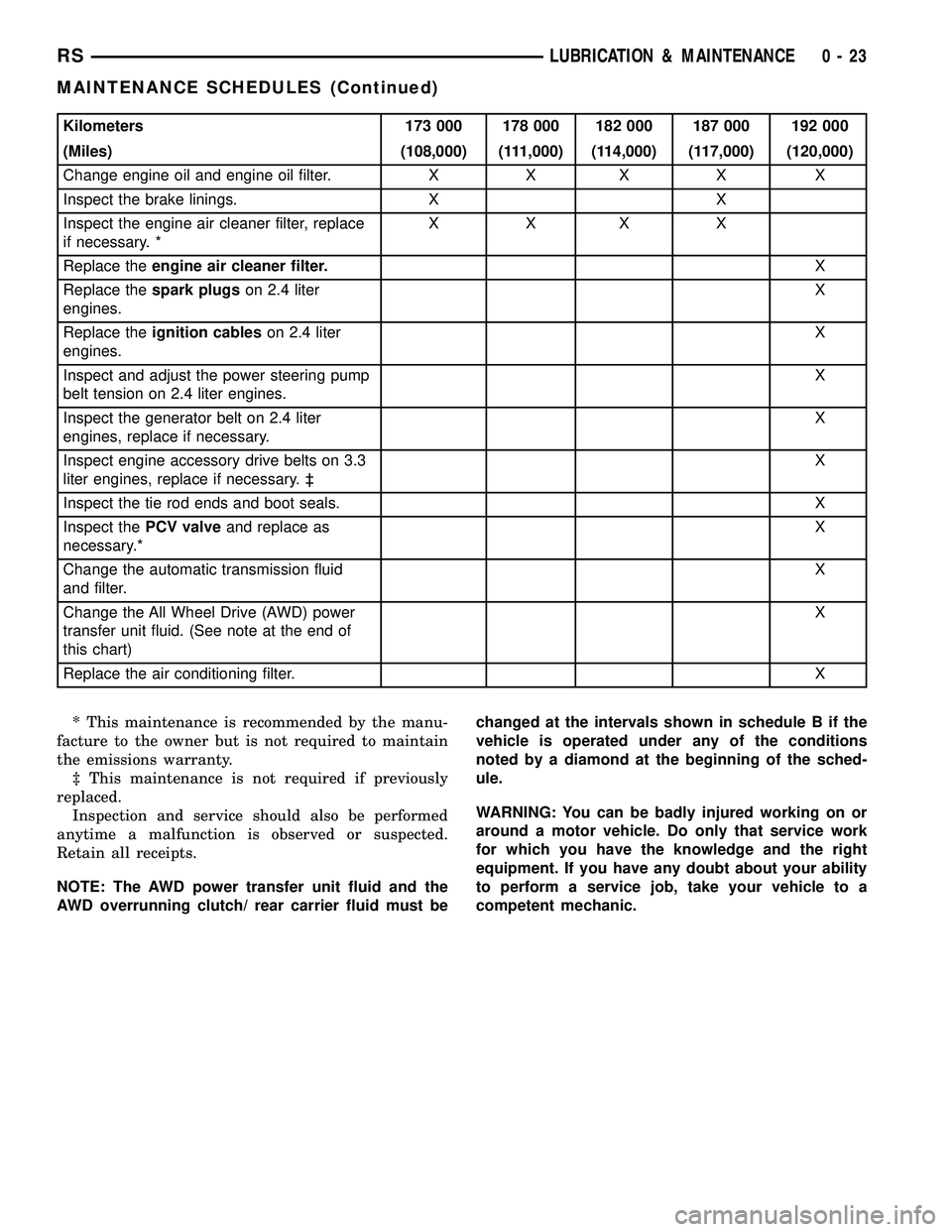

Kilometers 173 000 178 000 182 000 187 000 192 000

(Miles) (108,000) (111,000) (114,000) (117,000) (120,000)

Change engine oil and engine oil filter. X X X X X

Inspect the brake linings. X X

Inspect the engine air cleaner filter, replace

if necessary. *XXXX

Replace theengine air cleaner filter.X

Replace thespark plugson 2.4 liter

engines.X

Replace theignition cableson 2.4 liter

engines.X

Inspect and adjust the power steering pump

belt tension on 2.4 liter engines.X

Inspect the generator belt on 2.4 liter

engines, replace if necessary.X

Inspect engine accessory drive belts on 3.3

liter engines, replace if necessary. ³X

Inspect the tie rod ends and boot seals. X

Inspect thePCV valveand replace as

necessary.*X

Change the automatic transmission fluid

and filter.X

Change the All Wheel Drive (AWD) power

transfer unit fluid. (See note at the end of

this chart)X

Replace the air conditioning filter.X

* This maintenance is recommended by the manu-

facture to the owner but is not required to maintain

the emissions warranty.

³ This maintenance is not required if previously

replaced.

Inspection and service should also be performed

anytime a malfunction is observed or suspected.

Retain all receipts.

NOTE: The AWD power transfer unit fluid and the

AWD overrunning clutch/ rear carrier fluid must bechanged at the intervals shown in schedule B if the

vehicle is operated under any of the conditions

noted by a diamond at the beginning of the sched-

ule.

WARNING: You can be badly injured working on or

around a motor vehicle. Do only that service work

for which you have the knowledge and the right

equipment. If you have any doubt about your ability

to perform a service job, take your vehicle to a

competent mechanic.

RSLUBRICATION & MAINTENANCE0-23

MAINTENANCE SCHEDULES (Continued)

Page 37 of 2585

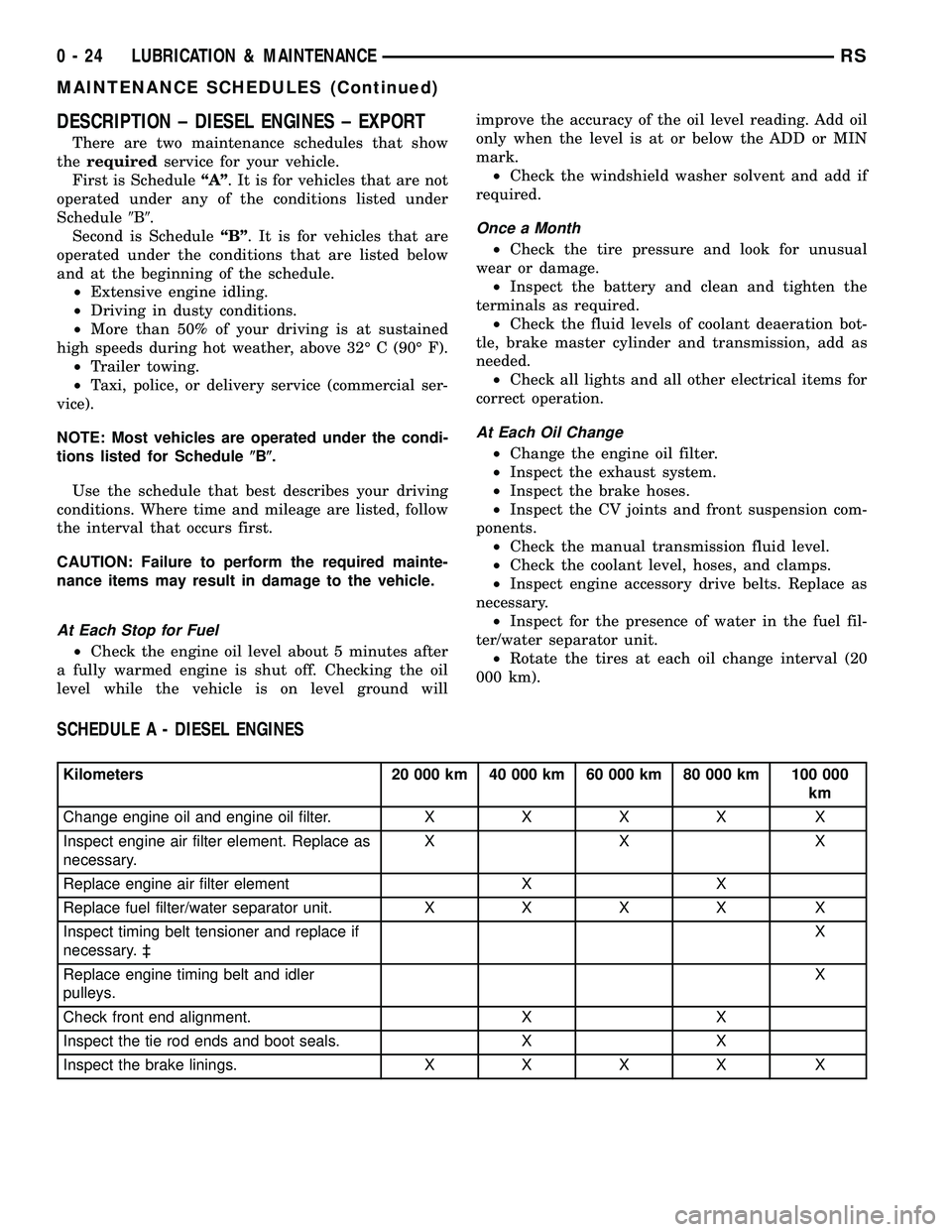

DESCRIPTION ± DIESEL ENGINES ± EXPORT

There are two maintenance schedules that show

therequiredservice for your vehicle.

First is ScheduleªAº. It is for vehicles that are not

operated under any of the conditions listed under

Schedule9B9.

Second is ScheduleªBº. It is for vehicles that are

operated under the conditions that are listed below

and at the beginning of the schedule.

²Extensive engine idling.

²Driving in dusty conditions.

²More than 50% of your driving is at sustained

high speeds during hot weather, above 32É C (90É F).

²Trailer towing.

²Taxi, police, or delivery service (commercial ser-

vice).

NOTE: Most vehicles are operated under the condi-

tions listed for Schedule(B(.

Use the schedule that best describes your driving

conditions. Where time and mileage are listed, follow

the interval that occurs first.

CAUTION: Failure to perform the required mainte-

nance items may result in damage to the vehicle.

At Each Stop for Fuel

²Check the engine oil level about 5 minutes after

a fully warmed engine is shut off. Checking the oil

level while the vehicle is on level ground willimprove the accuracy of the oil level reading. Add oil

only when the level is at or below the ADD or MIN

mark.

²Check the windshield washer solvent and add if

required.

Once a Month

²Check the tire pressure and look for unusual

wear or damage.

²Inspect the battery and clean and tighten the

terminals as required.

²Check the fluid levels of coolant deaeration bot-

tle, brake master cylinder and transmission, add as

needed.

²Check all lights and all other electrical items for

correct operation.

At Each Oil Change

²Change the engine oil filter.

²Inspect the exhaust system.

²Inspect the brake hoses.

²Inspect the CV joints and front suspension com-

ponents.

²Check the manual transmission fluid level.

²Check the coolant level, hoses, and clamps.

²Inspect engine accessory drive belts. Replace as

necessary.

²Inspect for the presence of water in the fuel fil-

ter/water separator unit.

²Rotate the tires at each oil change interval (20

000 km).

SCHEDULE A - DIESEL ENGINES

Kilometers 20 000 km 40 000 km 60 000 km 80 000 km 100 000

km

Change engine oil and engine oil filter.XXXX X

Inspect engine air filter element. Replace as

necessary.XX X

Replace engine air filter element X X

Replace fuel filter/water separator unit.XXXX X

Inspect timing belt tensioner and replace if

necessary. ³X

Replace engine timing belt and idler

pulleys.X

Check front end alignment. X X

Inspect the tie rod ends and boot seals. X X

Inspect the brake linings.XXXX X

0 - 24 LUBRICATION & MAINTENANCERS

MAINTENANCE SCHEDULES (Continued)

Page 566 of 2585

sive, the use of a DRBIIItscan tool and the proper

Diagnostic Procedures manual are recommended for

further testing of the EVIC module and the J1850

PCI data bus circuit.

The EVIC module cannot be repaired, and is avail-

able for service only as a unit. This unit includes the

plastic module and display lens. If any of these com-

ponents is faulty or damaged, the complete EVIC

module must be replaced.

OPERATION

The EVIC has access to both non-switched and

ignition switched sources of battery current so that

some of its features remain operational at any time,

while others may only operate with the ignition

switch in the On position. When the ignition switch

is turned to the On position, the EVIC module VFD

will return to the last function being displayed before

the ignition was turned to the Off position.

The compass/thermometer display is the normal

EVIC display. With the ignition switch in the On

position, momentarily depressing and releasing the

C/T (compass/thermometer) push button switch will

cause the EVIC to return to the compass/thermome-

ter/trip computer display mode from any other mode.

While in the compass/thermometer/trip computer dis-

play mode, momentarily depressing and releasing the

Step push button will step through the available trip

computer display options.

The EVIC trip computer features several functions

that can be reset. The functions that can be reset

are: average fuel economy, trip odometer and elapsed

time. With the ignition switch in the On position and

with one of the functions of the trip computer that

can be reset currently displayed, depressing the

Reset push button twice within three seconds will

perform a global reset, and all of the trip computer

information that can be reset will be reset to zero.

With the ignition switch in the On position and the

function that is to be reset currently displayed,

momentarily depressing and releasing the Reset

push button once will perform a local reset, and only

the value of the displayed function will be reset to

zero. A global or local reset will only occur if the

function currently displayed is a function that can be

reset. The distance to service function can also be

reset using the local reset method, but it will reset

back to the Service Interval distance that is set in

the EVIC programmable features mode. Refer to

ELECTRONIC VEHICLE INFORMATION CEN-

TER PROGRAMMINGin the Standard Procedures

section of this group for more information on setting

the Service Interval.

For more information on the features, control func-

tions and setting procedures for the EVIC module,

see the owner's manual in the vehicle glove box.

DIAGNOSIS AND TESTING - ELECTRONIC

VEHICLE INFORMATION CENTER

Electronic Vehicle Information Center (EVIC) data

is obtained from the Body Control Module (BCM) on

the J1850 Data Bus circuit. The EVIC will display

dashes (- -) for any of the screens it did not receive

the bus messages. The label corresponding to the

missing information will be lit. If no EVIC data is

displayed, check the J1850 Data Bus circuit commu-

nications and the BCM. If the brightness level is

improper check the J1850 Data Bus circuit.

The DRB IIItis recommended for checking the

J1850 Data Bus circuit and the BCM. Perform the

EVIC self diagnosis before replacing the EVIC mod-

ule.

STANDARD PROCEDURE - ELECTRONIC

VEHICLE INFORMATION CENTER

PROGRAMMING

EVIC PROGRAMMING MODE

Some vehicles are equipped with a Electronic Vehi-

cle Information Center (EVIC) equipped overhead

console. The Electronic Vehicle Information Center

(EVIC) provides the vehicle operator with a user

interface, which allows the selection of several

optional customer programmable electronic features

to suit individual preferences. The EVIC must be

placed into its programming mode in order to view or

change the programmable features. To enter the

EVIC programming mode and to view or change the

selected programmable features options, proceed as

follows:

(1) Turn the ignition switch to the On position.

(2) Depress and release the Menu push button.

The first item in the programmable features menu

list will appear in the EVIC display.

(3) Momentarily depress and release the Menu

push button to step through the programmable fea-

tures list. Each programmable feature and its cur-

rently selected option will appear on the EVIC

display in the sequence shown in the Programmable

Features list that follows.

(4) Momentarily depress and release the Step push

button to step through the available options for the

programmable feature being displayed.

(5) The option that last appears in the display

with a programmable feature before exiting the pro-

gramming mode, becomes the newly selected pro-

grammable feature option.

(6) The EVIC exits the programming mode and

returns to its normal operating mode when the C/T

push button is depressed or when the end of the pro-

grammable features menu list is reached, whichever

occurs first.

RSMESSAGE SYSTEMS8M-7

ELECTRONIC VEHICLE INFO CENTER (Continued)

Page 567 of 2585

PROGRAMMABLE FEATURES

NOTE: Tire pressure monitoring (TPM) system infor-

mation is not covered in this section of the service

manual. Refer to the tires/wheels section of this

manual for detailed tire pressure monitoring system

information.

²LANGUAGE?- The options include English,

Francaise, Deutsch, Italiana, or Espanol. The default

is English. All EVIC display nomenclature, including

the trip computer functions, warning messages and

the programmable features appear in the selected

language.

²DISPLAY U.S. OR METRIC?- The options

include U.S. and M. The default is U.S. This feature

toggles the trip computer temperature, fuel economy

and odometer display readings between U.S. and

metric units of measure. It also changes the odome-

ter display in the instrument cluster.

²SERVICE INTV. =- The options include from

1000 to 12000 kilometers in 1000 kilometer incre-

ments (2000 to 7500 miles in 500 mile increments).

The default is 12000 kilometers (7500 miles). The

selected distance becomes the interval at which the

Perform Service warning message will be displayed

by the EVIC. If a new distance is selected, a second

programmable feature appears,RESET SERVICE

DISTANCE?- The options include No and Yes. The

default is Yes. When Yes is selected, the accumulated

distance since the last previous Perform Service

warning message will be reset to zero because the

service interval has been changed. When No is

selected, the distance until the next Perform Service

warning message is reduced by the accumulated dis-

tance since the last previous message.

²USE FACTORY SETTINGS?- The options

include Yes and No. The default is Yes. When yes is

selected all the programmable features will return to

there defaults and the rest of the programmable fea-

tures will not be displayed. If No is selected the rest

of the programmable features will be displayed at

there default values. This feature will automatically

return to the Yes default under two conditions. First,

if no programmable features are changed from there

defaults. Second, if all the programmable features

equal there defaults.

²AUTO DOOR LOCKS?- The options include

Yes and No. The default is Yes. When Yes is selected,

all doors and the liftgate lock automatically when

vehicle speed reaches 25 kilometers-per-hour (15

miles-per-hour). If YES is selected, a second program-

mable feature appears,AUTO UNLOCK ON EXIT?

- The options again include Yes and No. The default

is No. When Yes is selected, following each Auto Door

Lock event all doors and the liftgate will automati-

cally unlock when the driver door is opened, if thevehicle is stopped and the transmission gear selector

is in Park or Neutral. The Auto Door Unlock event

will only occur once following each Auto Door Lock

event.

²REMOTE UNLOCK- The options include

Driver Door 1st and All Doors. The default is Driver

Door 1st. When Diver Door 1st is selected, only the

driver door unlocks when the Unlock button of the

Remote Keyless Entry (RKE) transmitter is

depressed once. The Unlock button of the RKE trans-

mitter must be depressed twice to unlock all doors.

When All Doors is selected, all doors unlock when the

Unlock button of the RKE transmitter is depressed

once.

²REMOTE LINKED TO MEMORY?- This pro-

grammable feature only applies to vehicles equipped

with the optional memory / heated system. The

options include Yes and No. The default is No. When

Yes is selected, the memory system will recall the

Driver 1 or Driver 2 memory settings assigned to the

RKE transmitter being used to unlock the vehicle.

When No is selected, the memory system will only

recall memory settings when the Driver 1 or Driver 2

push buttons of the memory switch on the driver side

front door trim panel are depressed.

²SOUND HORN ON LOCK?- The options

include Yes and No. The default is No. When Yes is

selected, a short horn chirp will provide an audible

confirmation when the RKE receiver recognizes a

valid Lock signal from an RKE transmitter. When No

is selected, no horn chirp will occur with the RKE

Lock event. This feature may be selected indepen-

dent of theFLASH LIGHTS WITH LOCKS?pro-

grammable feature.

²FLASH LIGHTS WITH LOCKS?- The options

include Yes and No. The default is Yes. When Yes is

selected, a single flash of the hazard warning lamps

will provide an optical confirmation when the RKE

receiver recognizes a valid Lock signal from an RKE

transmitter, and two flashes of the same lamps will

occur when the RKE receiver recognizes a valid

Unlock signal from an RKE transmitter. When No is

selected, no lamp flash will occur with the RKE Lock

or Unlock event. This feature may be selected inde-

pendent of theSOUND HORN ON LOCK?pro-

grammable feature.

²HEADLAMP DELAY =- The options include

Off, 30 Sec, 60 Sec, and 90 Sec. The default is 90 Sec.

When a time interval is selected, the headlamps will

remain on for that length of time when the head-

lamps are turned off after the ignition is turned off,

or if the Auto mode is selected on vehicles with the

Auto Headlamps option. When Off is selected, the

headlamp delay feature is disabled.

²HEADLAMPS ON WITH WIPERS?- This pro-

grammable feature only applies to vehicles equipped

8M - 8 MESSAGE SYSTEMSRS

ELECTRONIC VEHICLE INFO CENTER (Continued)

Page 1294 of 2585

INSTALLATION

(1) Snap the left side of the Integrated Power Mod-

ule (IPM) housing in its mounting bracket and con-

nect the various electrical connectors. Care must be

taken that the Connector Positive Assurance (CPA)

on the five-pin B+ connector is positively engaged to

prevent generating a Diagnostic Trouble Code (DTC).

NOTE: IPM electrical connectors are color coded to

ease location reference.

(2) Being certain no wires are stressed or pinched,

rotate the IPM clock-wise until secured in mounting

bracket. An audible click may be heard.

(3) Install the battery in the vehicle. Refer to the

Battery section for the procedure.

(4) Install the battery thermal guard in the vehi-

cle. Refer to the Battery section for the procedure.

(5)

Connect the negative and positive battery cables.

(6) Using a diagnostic scan tool, check for any

stored diagnostic trouble codes and correct, check

that all vehicle options are operational before return-

ing the vehicle to service.

IOD FUSE

DESCRIPTION

All vehicles are equipped with an Ignition-Off

Draw (IOD) fuse that is removed from its normal

cavity in the Integrated Power Module (IPM) whenthe vehicle is shipped from the factory. Dealer per-

sonnel are to remove the IOD fuse from the storage

location and install it into the IPM fuse cavity

marked IOD as part of the preparation procedures

performed just prior to new vehicle delivery.

The IPM has a molded plastic cover that can be

removed to provide service access to all of the fuses

and relays in the IPM. An integral latch and hinges

are molded into the IPM cover for easy removal. A

fuse layout map is integral to the underside of the

IPM cover to ensure proper fuse and relay identifica-

tion. The IOD fuse is a 20 ampere blade-type mini

fuse and, when removed, it is stored in a fuse cavity

adjacent to the washer fuse within the IPM.

OPERATION

The term ignition-off draw identifies a normal condi-

tion where power is being drained from the battery with

the ignition switch in the Off position. The IOD fuse

feeds the memory and sleep mode functions for some of

the electronic modules in the vehicle as well as various

other accessories that require battery current when the

ignition switch is in the Off position, including the

clock. The only reason the IOD fuse is removed is to

reduce the normal IOD of the vehicle electrical system

during new vehicle transportation and pre-delivery stor-

age to reduce battery depletion, while still allowing

vehicle operation so that the vehicle can be loaded,

unloaded and moved as needed by both vehicle trans-

portation company and dealer personnel.

The IOD fuse is removed from the IPM fuse cavity

when the vehicle is shipped from the assembly plant.

Dealer personnel must install the IOD fuse when the

vehicle is being prepared for delivery in order to

restore full electrical system operation. Once the

vehicle is prepared for delivery, the IOD function of

this fuse becomes transparent and the fuse that has

been assigned the IOD designation becomes only

another Fused B(+) circuit fuse. The IOD fuse serves

no useful purpose to the dealer technician in the ser-

vice or diagnosis of any vehicle system or condition,

other than the same purpose as that of any other

standard circuit protection device.

The IOD fuse can be used by the vehicle owner as

a convenient means of reducing battery depletion

when a vehicle is to be stored for periods not to

exceed about thirty days. However, it must be

remembered that removing the IOD fuse will not

eliminate IOD, but only reduce this normal condition.

If a vehicle will be stored for more than about thirty

days, the battery negative cable should be discon-

nected to eliminate normal IOD; and, the battery

should be tested and recharged at regular intervals

during the vehicle storage period to prevent the bat-

tery from becoming discharged or damaged. Refer to

Battery Systemfor additional service information.

Fig. 3 DISCONNECTING IPM

1 - INTEGRATED POWER MODULE FUSE & RELAY CENTER

RS8W-97 POWER DISTRIBUTION SYSTEM8W-97-3

INTEGRATED POWER MODULE (Continued)