power modul CHRYSLER VOYAGER 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 469 of 2339

CONDITION POSSIBLE CAUSES CORRECTION

Inoperative fuel filler door lockout

mechanismCheck operation of fuel filler door lockout

mechanism.

Inoperative sliding door control module

or BCMDisconnect then reconnect battery negative

cable to reset module. Cycle door, if no

function exists check for loose wire

connections, see Body Diagnostic Manual for

detailed procedures

Inoperative striker Striker misaligned or loose

Striker damaged

Replace striker if necessary

Cables worn and stretched Replace cables as necessary

Binding or sticking of components Establish location of binding and replace

necessary components

Key fob, B-pillar or overhead

console switch does not

operate power sliding doorBlown Fuse Check fuse and replace

Battery voltage low Charge or replace battery

Inoperative latch assembly Check for foreign matter preventing the

operation of latch assembly

Check wire connection

Pawl and/or ratchet switch inoperative

Replace latch if necessary

Wiring problems (system or vehicle) Troubleshoot using the appropriate wiring

information

Inoperative BCM Check electrical connections

Refer to the body diagnostic manual for

additional checks

Replace BCM if necessary

Inoperative key fob Verify inoperative key fob by trying other key

fob functions

Replace key fob battery

Reprogram key fob

Replace key fob if necessary

Inoperative sliding door control module Disconnect then reconnect battery negative

cable to reset module. Cycle door, if no

function exists check for loose wire

connections, see Body Diagnostic Manual for

detailed procedures

Inoperative door motor assembly Check for foreign matter preventing the

operation of gear motor assembly

Check wire connections

Gear motor clutch does not engage, replace

assembly

8N - 46 POWER SLIDING DOOR SYSTEMRS

POWER SLIDING DOOR SYSTEM (Continued)

Page 470 of 2339

CONDITION POSSIBLE CAUSES CORRECTION

Full open switch inoperative, replace hold

open latch assembly

Replace motor assembly. if necessary

Door does not stay open Inoperative hold open latch assembly Check wire/cable connections

Replace hold open latch, if necessary

Inoperative hold open latch striker Replace hold open latch striker, if necessary

High inside/outside opening

effortInoperative latch assembly Check wire connections and for blown fuse

Check cable connections

Check for foreign matter preventing the

operation of latch assembly

Troubleshoot using body diagnostic manual

Replace latch assembly, if necessary

Inoperative inside/outside handle

assemblyGo to that9POSSIBLE CAUSE9and review

9CORRECTIONS9

Binding or sticking of components Establish location of binding and replace

necessary components

Door continues to cinch

closed during power modeInoperative latch assembly Check wire connections and for blown fuse

Check for foreign matter preventing the

operation of latch assembly

Troubleshoot using body diagnostic manual

Replace latch assembly, if necessary

Inoperative sliding door control module

or BCMDisconnect then reconnect battery negative

cable to reset module. Cycle door, if no

function exists check for loose wire

connections, see Body Diagnostic Manual for

detailed procedures

Wiring problems (system or vehicle) Troubleshoot using the appropriate wiring

information

Door continues to open

during power mode (runaway

motor)Inoperative sliding door control module

or BCMDisconnect then reconnect battery negative

cable to reset module. Cycle door, if no

function exists check for loose wire

connections, see Body Diagnostic Manual for

detailed procedures

Inoperative hold open latch assembly Check wire/cable connections

Replace hold open latch, if necessary

Inoperative drive assembly Remove lower drive unit and check for no

drive condition

Wiring problems (system or vehicle) Troubleshoot using electrical schematics.

Refer to wiring diagrams

Door opens very slowly Inoperative door motor assembly Check wire/cable connections

Replace motor assembly, if necessary

RSPOWER SLIDING DOOR SYSTEM8N-47

POWER SLIDING DOOR SYSTEM (Continued)

Page 471 of 2339

CONDITION POSSIBLE CAUSES CORRECTION

Binding or sticking of components Establish location of binding and replace

necessary components

Squeaks, Noises and rattles Foreign material in door compartment Remove foreign material

Loose components Check and tighten loose components

Missing stabilizers, bumpers or

anti-rattle componentsCheck to ensure components are present.

Replace as necessary

Misadjusted stabilizers, bumpers or

anti-rattle componentsAdjust components as necessary

Poor door track lubrication Lubricate the front portions of the side door

tracks with9Door EaseT9or equivalent

STANDARD PROCEDURE

POWER SLIDING DOOR LEARN CYCLE

Any time a power sliding door component is removed,

replaced, door adjustment is performed or diagnostic

trouble codes are addressed and erased, a learn cycle

mustbe performed. This learn cycle enables the power

sliding door control module to learn or relearn its critical

information (travel limits, resistance to door travel, etc.)

which allows it to perform properly and safely. To per-

form a power sliding door learn cycle do the following:

(1)Obtain a DRB IIIt, or equivalent scan tool.

Connect the scan tool to the vehicle and check for

any power sliding door system stored diagnostic trou-

ble codes, erase any stored codes. Operate the system

and check to see if any trouble codes return. If any

diagnostic trouble codes return, diagnose, correct and

erase the codes before performing the learn cycle. If a

DRB IIIt, or equivalent scan tool is not available, the

learn cycle can be performed by opening and closing

the power sliding door using any of the normal open/

close command switches. Be certain to cycle the

power sliding door through a complete openand

close cycle or the procedure will not be complete.

(2) Using the scan tool, Go into Test Routine Menu

and select a power open command.

(3) Select a power close command.

(4) The power side door learn cycle is complete.

NOTE: If the power sliding door will not complete a

full cycle, a problem exists with the power sliding door

system. (Refer to 8 - ELECTRICAL/POWER DOORS -

DIAGNOSIS AND TESTING) for additional information.

PUSH-PIN GROMMET REPLACEMENT

Push-pin grommets are used to hold and isolate

the power sliding door motor to and from the door

inner panel. This secures the door motor assembly to

the inner panel and keeps the audible motor vibra-

tions to a minimum. If a push-pin grommet showssigns of wear, it must be replaced. Follow the proce-

dure below if replacement is necessary.

(1) Remove the door motor from the door inner

panel. (Refer to 8 - ELECTRICAL/POWER DOORS/

MOTOR - REMOVAL).

(2) Using a trim panel tool (special tool #C-4755)

or equivalent, remove the push-pin grommets from

the inner panel by pulling them straight out (Fig. 2).

(3) Install the replacement push-pin grommets in

the inner panel and install the door motor(Refer to 8

- ELECTRICAL/POWER DOORS/MOTOR - INSTAL-

LATION).

Fig. 2 SIDE DOOR MOTOR PUSH-PIN GROMMETS

1 - PUSH-PIN GROMMETS

2 - SIDE DOOR INNER PANEL

8N - 48 POWER SLIDING DOOR SYSTEMRS

POWER SLIDING DOOR SYSTEM (Continued)

Page 472 of 2339

POWER SLIDING DOOR ADJUSTMENT

In order for the power sliding door system to func-

tion properly the door must move freely and

smoothly. The power sliding door system can accom-

modate for some minor changes in the effort required

to move the door. However, in extreme conditions the

door may need to be mechanically adjusted for proper

fit. (Refer to 23 - BODY/DOORS - SLIDING/SLID-

ING DOOR - ADJUSTMENTS).

If a problem exists with the power sliding door and

it is suspected to be extreme effort, check for proper

door alignment and adjustment first, then check the

door tracks and drive unit for free manual operation.

(Refer to 23 - BODY/DOORS - SLIDING/SLIDING

DOOR - ADJUSTMENTS) for detailed instructions.

LATCH

DESCRIPTION

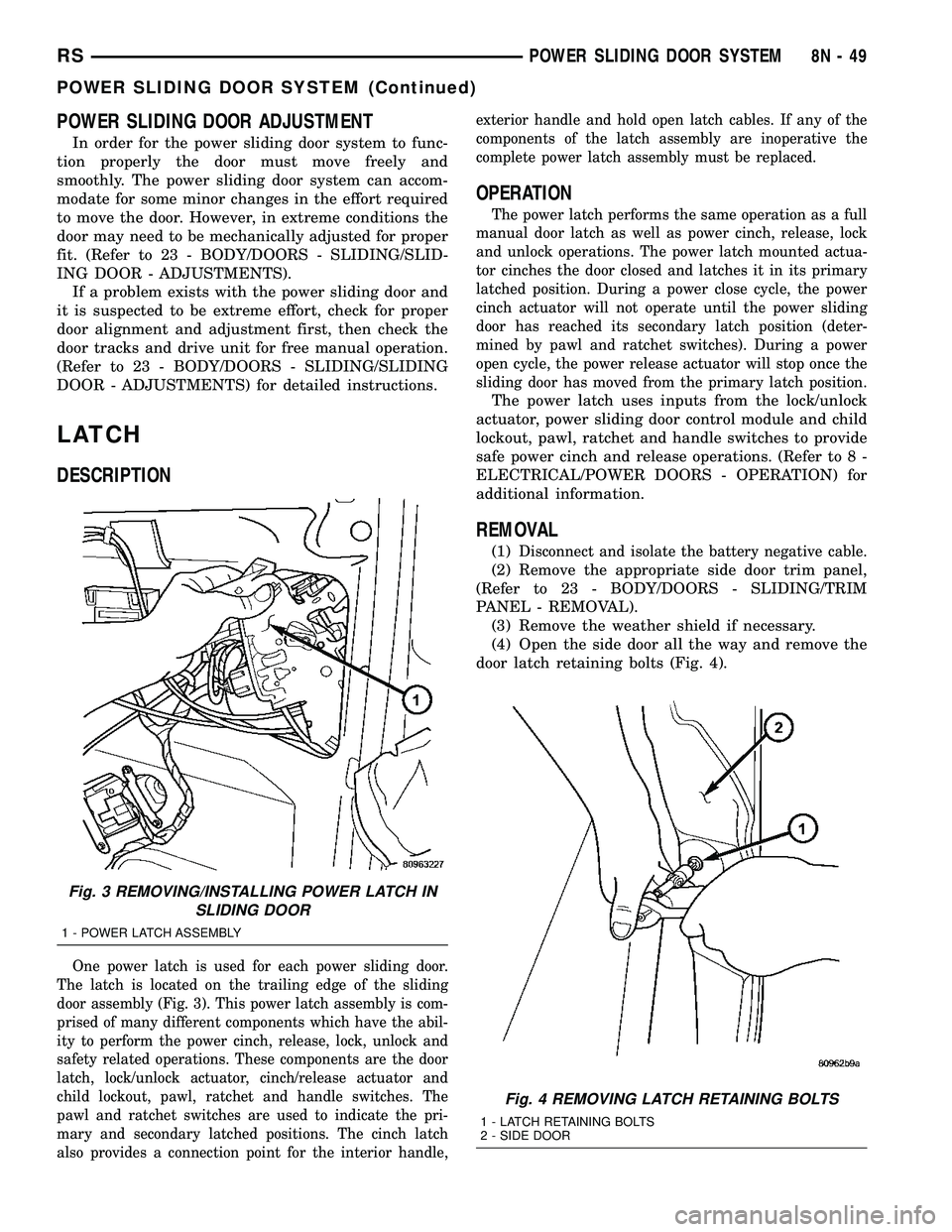

One power latch is used for each power sliding door.

The latch is located on the trailing edge of the sliding

door assembly (Fig. 3). This power latch assembly is com-

prised of many different components which have the abil-

ity to perform the power cinch, release, lock, unlock and

safety related operations. These components are the door

latch, lock/unlock actuator, cinch/release actuator and

child lockout, pawl, ratchet and handle switches. The

pawl and ratchet switches are used to indicate the pri-

mary and secondary latched positions. The cinch latch

also provides a connection point for the interior handle,exterior handle and hold open latch cables. If any of the

components of the latch assembly are inoperative the

complete power latch assembly must be replaced.

OPERATION

The power latch performs the same operation as a full

manual door latch as well as power cinch, release, lock

and unlock operations. The power latch mounted actua-

tor cinches the door closed and latches it in its primary

latched position. During a power close cycle, the power

cinch actuator will not operate until the power sliding

door has reached its secondary latch position (deter-

mined by pawl and ratchet switches). During a power

open cycle, the power release actuator will stop once the

sliding door has moved from the primary latch position.

The power latch uses inputs from the lock/unlock

actuator, power sliding door control module and child

lockout, pawl, ratchet and handle switches to provide

safe power cinch and release operations. (Refer to 8 -

ELECTRICAL/POWER DOORS - OPERATION) for

additional information.

REMOVAL

(1)Disconnect and isolate the battery negative cable.

(2) Remove the appropriate side door trim panel,

(Refer to 23 - BODY/DOORS - SLIDING/TRIM

PANEL - REMOVAL).

(3) Remove the weather shield if necessary.

(4) Open the side door all the way and remove the

door latch retaining bolts (Fig. 4).

Fig. 3 REMOVING/INSTALLING POWER LATCH IN

SLIDING DOOR

1 - POWER LATCH ASSEMBLY

Fig. 4 REMOVING LATCH RETAINING BOLTS

1 - LATCH RETAINING BOLTS

2 - SIDE DOOR

RSPOWER SLIDING DOOR SYSTEM8N-49

POWER SLIDING DOOR SYSTEM (Continued)

Page 474 of 2339

SLIDING DOOR MOTOR

DESCRIPTION

The door motor is located in the center of the

power sliding door (Fig. 8) and is comprised of three

parts. The three parts of the door motor assembly are

the motor, gear reduction and clutch assembly. The

door motor assembly provides the power and torque

to move the sliding door from the open/closed posi-

tion to full closed/open position, after the power

latching mechanism has released.

The door motor is replaced as a complete assembly,

which includes the DC motor, gear reduction and

clutch assemblies.

OPERATION

With the push of a power sliding door command

switch, the power sliding door control module will

signal the latch assembly to release the door from its

primary locked position. The door motor will then

take over to provide the power to open the door to its

full open or closed position. The gear reduction por-

tion of the motor assembly reduces the speed of the

motor from 5800 to 260 rpm and also increases the

torque to the lower drive unit. The clutch portion of

the motor assembly engages the motor to drive thedoor under power and disengages it so the door can

be moved easily under manual operation.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the door trim panel from the appropri-

ate door, (Refer to 23 - BODY/DOORS - SLIDING/

TRIM PANEL - REMOVAL).

(3) Remove the water shield as necessary to gain

access to motor assembly.

(4) Remove retaining clip holding flex drive assem-

bly to the motor (Fig. 9). Pull flex drive cable straight

out of the motor assembly.

(5) Disconnect door motor electrical connector.

(6) Using a trim stick (special tool #C-4755) or

equivalent, gently pry out push-pin fasteners retain-

ing the door motor.

(7) Remove the door motor assembly from the

vehicle.

INSTALLATION

(1) Position the door motor assembly on the door

inner panel.

(2) Install the push-pin fasteners retaining the

motor assembly to the power sliding door.

Fig. 8 POWER SLIDING DOOR COMPONENTS

1 - POWER SLIDING DOOR CONTROL MODULE

2 - MODULE RETAINING SCREW

3 - MODULE ELECTRICAL CONNECTORS

4 - DOOR MOTOR ASSEMBLY

5 - FLEX DRIVE ASSEMBLY

6 - DOOR MOTOR RETAINING FASTENERS

7 - DOOR MOTOR ELECTRICAL CONNECTOR

Fig. 9 FLEX DRIVE RETAINING CLIP

1 - FLEX DRIVE CABLE RETAINING CLIP

2 - FLEX DRIVE CABLE

3 - DOOR MOTOR ASSEMBLY

RSPOWER SLIDING DOOR SYSTEM8N-51

Page 475 of 2339

NOTE: Push in on the push-pins at the clutch hous-

ing (plastic side) until you hear one click. Push in

on the push-pin fasteners at the motor mount

(sheet metal side) until you hear two clicks. This

assures proper installation/attachment of the motor

to the sliding door.

(3) Install the flex shaft by lining up the square

shaped drive shaft with the corresponding hole in the

door motor drive unit and push straight in.

(4) Install the E-clip to secure flex-shaft.

(5) Install the weather shield as necessary.

(6) Install the door trim panel on the sliding door,

(Refer to 23 - BODY/DOORS - SLIDING/TRIM

PANEL - INSTALLATION) for the procedure.

(7) Connect the battery negative cable.

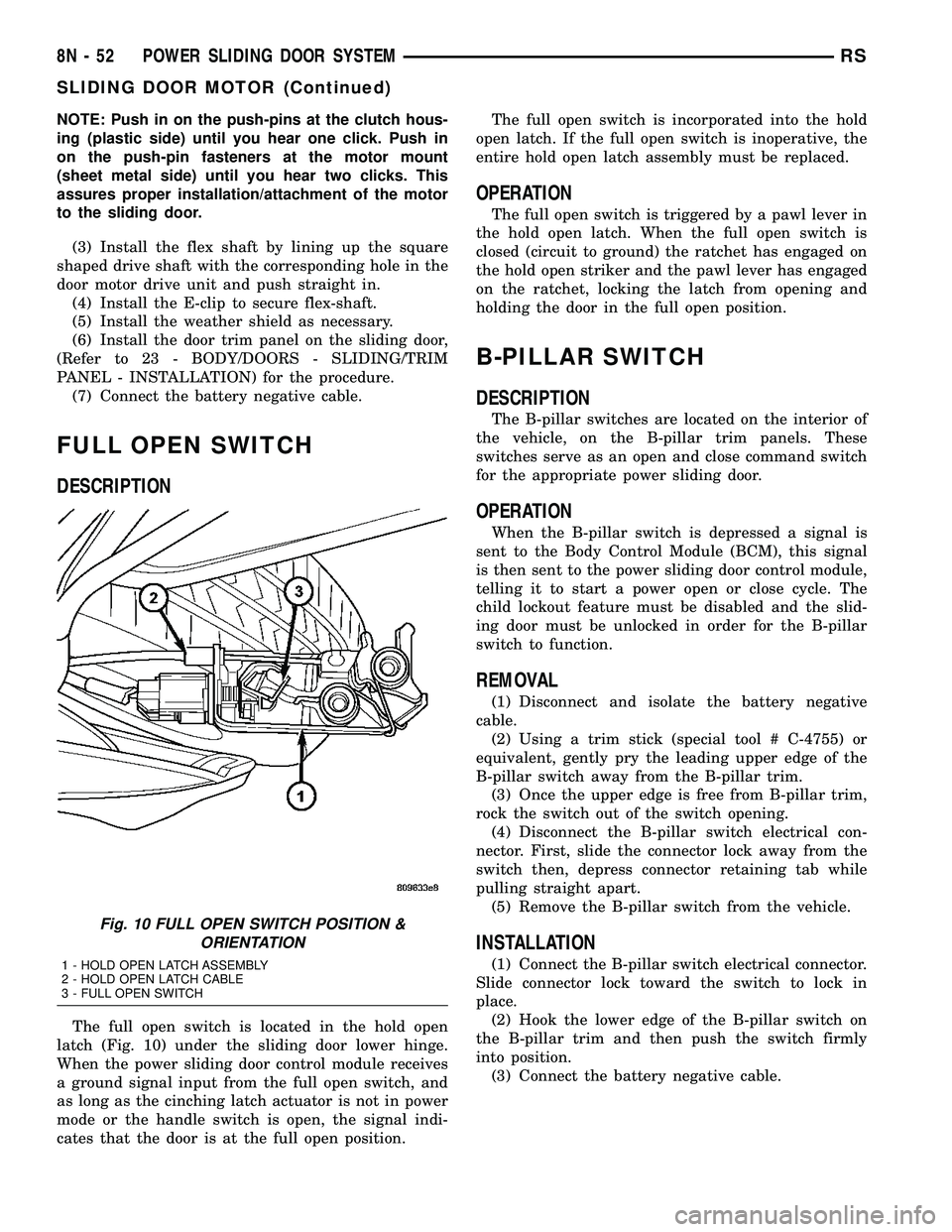

FULL OPEN SWITCH

DESCRIPTION

The full open switch is located in the hold open

latch (Fig. 10) under the sliding door lower hinge.

When the power sliding door control module receives

a ground signal input from the full open switch, and

as long as the cinching latch actuator is not in power

mode or the handle switch is open, the signal indi-

cates that the door is at the full open position.The full open switch is incorporated into the hold

open latch. If the full open switch is inoperative, the

entire hold open latch assembly must be replaced.

OPERATION

The full open switch is triggered by a pawl lever in

the hold open latch. When the full open switch is

closed (circuit to ground) the ratchet has engaged on

the hold open striker and the pawl lever has engaged

on the ratchet, locking the latch from opening and

holding the door in the full open position.

B-PILLAR SWITCH

DESCRIPTION

The B-pillar switches are located on the interior of

the vehicle, on the B-pillar trim panels. These

switches serve as an open and close command switch

for the appropriate power sliding door.

OPERATION

When the B-pillar switch is depressed a signal is

sent to the Body Control Module (BCM), this signal

is then sent to the power sliding door control module,

telling it to start a power open or close cycle. The

child lockout feature must be disabled and the slid-

ing door must be unlocked in order for the B-pillar

switch to function.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Using a trim stick (special tool # C-4755) or

equivalent, gently pry the leading upper edge of the

B-pillar switch away from the B-pillar trim.

(3) Once the upper edge is free from B-pillar trim,

rock the switch out of the switch opening.

(4) Disconnect the B-pillar switch electrical con-

nector. First, slide the connector lock away from the

switch then, depress connector retaining tab while

pulling straight apart.

(5) Remove the B-pillar switch from the vehicle.

INSTALLATION

(1) Connect the B-pillar switch electrical connector.

Slide connector lock toward the switch to lock in

place.

(2) Hook the lower edge of the B-pillar switch on

the B-pillar trim and then push the switch firmly

into position.

(3) Connect the battery negative cable.

Fig. 10 FULL OPEN SWITCH POSITION &

ORIENTATION

1 - HOLD OPEN LATCH ASSEMBLY

2 - HOLD OPEN LATCH CABLE

3 - FULL OPEN SWITCH

8N - 52 POWER SLIDING DOOR SYSTEMRS

SLIDING DOOR MOTOR (Continued)

Page 478 of 2339

FLEX DRIVE

DESCRIPTION

The flex drive assembly is located in the lower por-

tion of the power sliding door (Fig. 17) and is used to

connect the door motor to the lower drive unit. An

E-clip is used to secure the flex drive to the motor

assembly, while the flex drive collar is used to secure

the drive to the lower drive unit. The flex drive

assembly is basically a flexible drive shaft for the

power sliding door system. The flex drive assembly is

a replaceable component.

OPERATION

With one end of the flex drive attached to the door

motor and the other attached to the lower drive unit,the flex drive transfers the power and torque from

the motor to the drive unit. A square shaped drive

cable, inside the flex drive assembly engages the

motor drive and rotates to move the door accordingly.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the appropriate sliding door trim

panel, (Refer to 23 - BODY/DOORS - SLIDING/TRIM

PANEL - REMOVAL).

(3) Position the weathershield aside to gain access

to the flex drive assembly.

(4) Remove the E-clip from the flex drive assembly

(Fig. 18).

(5) Pull the flex drive straight out of the motor

assembly.

Fig. 17 POWER SLIDING DOOR COMPONENTS

1 - POWER SLIDING DOOR CONTROL MODULE

2 - MODULE RETAINING SCREW

3 - MODULE ELECTRICAL CONNECTORS

4 - DOOR MOTOR ASSEMBLY

5 - FLEX DRIVE ASSEMBLY

6 - DOOR MOTOR RETAINING FASTENERS

7 - DOOR MOTOR ELECTRICAL CONNECTOR

Fig. 18 FLEX DRIVE E-CLIP

1 - FLEX DRIVE CABLE RETAINING CLIP

2 - FLEX DRIVE CABLE

3 - DOOR MOTOR ASSEMBLY

RSPOWER SLIDING DOOR SYSTEM8N-55

Page 485 of 2339

(3) Switch ignition ON position.

(4) Connect the clip end of a 12 volt test light to

Pin 13 in door harness connector at the window

switch. Touch the test light probe to Pin 9 and then

to Pin 11.

²If the test light illuminates, the wiring circuit

between the battery and switch is OK.

²If the lamp does not illuminate, first check the

25 amp circuit breaker attached to the electrical dis-

tribution wiring bracket. If the circuit breaker is OK,

then check the 40 amp fuse (#28) in the Integrated

Power Module (IPM). If both components are OK,

then check for a broken wire.

VENT WINDOW MOTOR

DIAGNOSIS AND TESTING

VENT WINDOW MOTOR

If the power vent window motor is receiving proper

current and ground and does not operate proceed

with motor test. Refer to the appropriate wiring

information.

(1) Remove D-pillar trim panel necessary to gain

access to power vent window motor wire connector,

(Refer to 23 - BODY/INTERIOR/LEFT D-PILLAR

TRIM PANEL - REMOVAL) or (Refer to 23 - BODY/

INTERIOR/RIGHT D-PILLAR TRIM PANEL -

REMOVAL).

(2) Disconnect power vent window motor wire con-

nector from body harness.

(3) Using two jumper wires, connect one to a bat-

tery (+) source and the other to a good ground (-).

(4) Connect the Negative (-) jumper probe to one of

the motor connector terminals.

(5) Momentarily touch the Positive (+) jumper

probe to the other motor connector terminal.

When positive probe is connected the motor should

rotate in one direction to either move window open or

closed. If window is all the way open or closed the

motor will grunt and the crank system will flex when

actuated in that one direction.

Reverse jumper probes at the motor connector ter-

minals and window should now move in opposite

direction. If window does not move or grunt, replace

the motor.

If window moved completely open or closed, reverse

the jumper probes and cycle window to the opposite

position to verify full operation.

If motor grunts and does not move, verify that

crank system is not binding.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.(2) Remove D-pillar trim panel. (Refer to 23 -

BODY/INTERIOR/LEFT D-PILLAR TRIM PANEL -

REMOVAL) or (Refer to 23 - BODY/INTERIOR/

RIGHT D-PILLAR TRIM PANEL - REMOVAL).

(3) Disconnect wire connector from power vent

motor.

(4) Using a flat bladed tool, carefully lift the circu-

lar actuator link tab. Remove link from window ball

socket.

(5) Remove bolts holding power vent motor to

D-pillar (Fig. 1).

(6) Remove power vent motor.

INSTALLATION

(1) Obtain new vent window motor.

(2) Snap the actuator link socket onto the quarter

window ball socket. Using a soft rubber mallet, push

the circular link tab flush with link surface.

(3) Install bolts holding power vent motor to D-pil-

lar.

(4) Reconnect wire connector to power vent motor.

(5) Reconnect the battery negative cable.

(6) Cycle quarter window open/close to verify func-

tion.

(7) Install D-pillar trim panel.

WINDOW MOTOR

REMOVAL

The window motor is incorporated into the window

regulator assembly. If the window motor requires

replacement, the window regulator must be replaced.

(Refer to 23 - BODY/DOOR - FRONT/WINDOW

REGULATOR - REMOVAL).

Fig. 1 VENT WINDOW MOTOR

1 - VENT WINDOW MOTOR

2 - WIRE HARNESS CONNECTOR

3 - BOLT

4 - VENT WINDOW

8N - 62 POWER WINDOWSRS

POWER WINDOWS (Continued)

Page 532 of 2339

SPEED CONTROL

TABLE OF CONTENTS

page page

SPEED CONTROL

DESCRIPTION..........................1

OPERATION

OPERATION..........................1

OPERATION - INTERACTIVE SPEED

CONTROL (4 Speed EATX Only)...........2

DIAGNOSIS AND TESTING - ROAD TEST.....3

SPECIFICATIONS - TORQUE...............3

CABLE

DESCRIPTION..........................4

OPERATION............................4

REMOVAL.............................4

INSTALLATION..........................4

SERVO

DESCRIPTION..........................4OPERATION............................4

REMOVAL.............................4

INSTALLATION..........................4

SWITCH

DESCRIPTION..........................5

OPERATION............................5

REMOVAL.............................5

INSTALLATION..........................6

VACUUM RESERVOIR

DESCRIPTION..........................6

OPERATION............................6

REMOVAL.............................6

INSTALLATION..........................6

SPEED CONTROL

DESCRIPTION

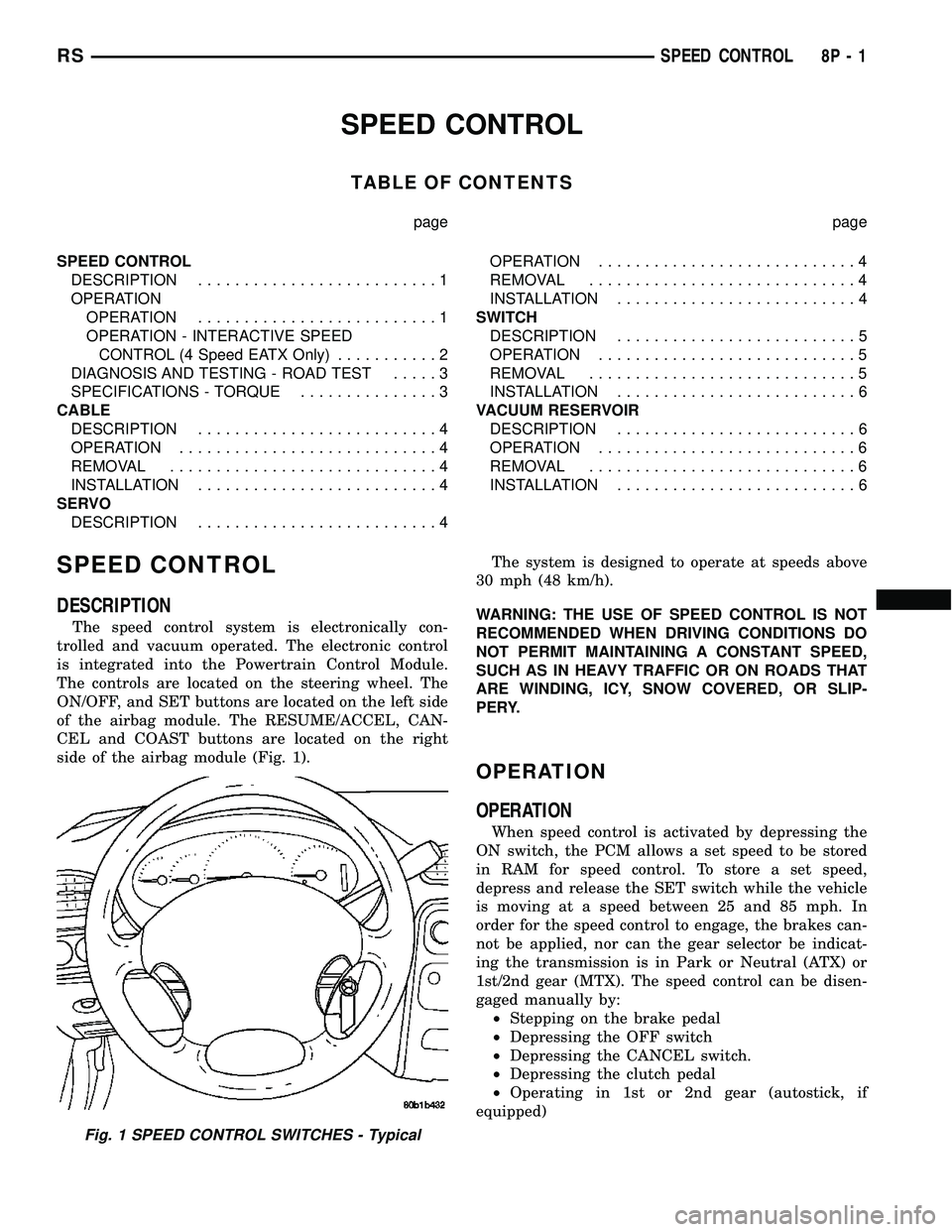

The speed control system is electronically con-

trolled and vacuum operated. The electronic control

is integrated into the Powertrain Control Module.

The controls are located on the steering wheel. The

ON/OFF, and SET buttons are located on the left side

of the airbag module. The RESUME/ACCEL, CAN-

CEL and COAST buttons are located on the right

side of the airbag module (Fig. 1).The system is designed to operate at speeds above

30 mph (48 km/h).

WARNING: THE USE OF SPEED CONTROL IS NOT

RECOMMENDED WHEN DRIVING CONDITIONS DO

NOT PERMIT MAINTAINING A CONSTANT SPEED,

SUCH AS IN HEAVY TRAFFIC OR ON ROADS THAT

ARE WINDING, ICY, SNOW COVERED, OR SLIP-

PERY.

OPERATION

OPERATION

When speed control is activated by depressing the

ON switch, the PCM allows a set speed to be stored

in RAM for speed control. To store a set speed,

depress and release the SET switch while the vehicle

is moving at a speed between 25 and 85 mph. In

order for the speed control to engage, the brakes can-

not be applied, nor can the gear selector be indicat-

ing the transmission is in Park or Neutral (ATX) or

1st/2nd gear (MTX). The speed control can be disen-

gaged manually by:

²Stepping on the brake pedal

²Depressing the OFF switch

²Depressing the CANCEL switch.

²Depressing the clutch pedal

²Operating in 1st or 2nd gear (autostick, if

equipped)

Fig. 1 SPEED CONTROL SWITCHES - Typical

RSSPEED CONTROL8P-1

Page 536 of 2339

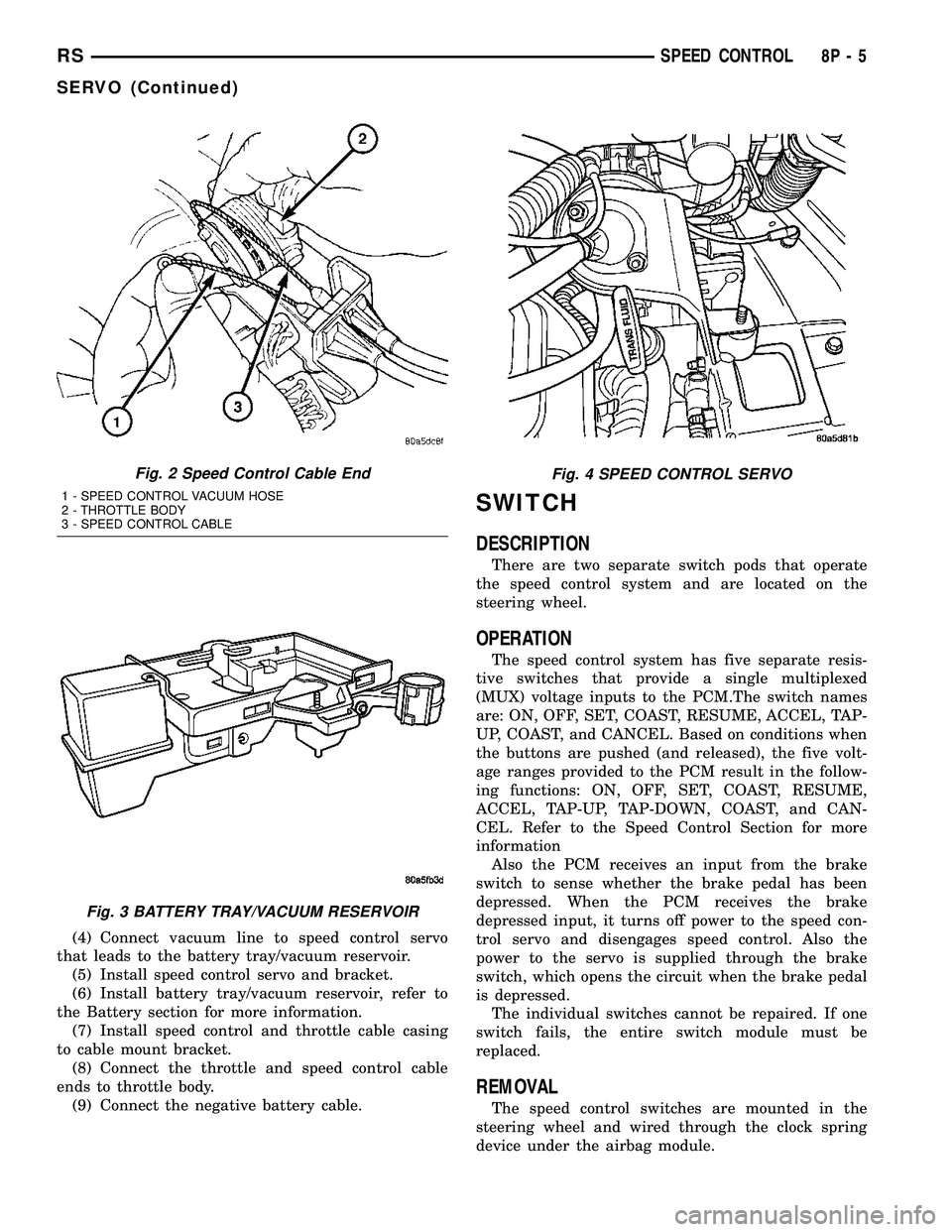

(4) Connect vacuum line to speed control servo

that leads to the battery tray/vacuum reservoir.

(5) Install speed control servo and bracket.

(6) Install battery tray/vacuum reservoir, refer to

the Battery section for more information.

(7) Install speed control and throttle cable casing

to cable mount bracket.

(8) Connect the throttle and speed control cable

ends to throttle body.

(9) Connect the negative battery cable.

SWITCH

DESCRIPTION

There are two separate switch pods that operate

the speed control system and are located on the

steering wheel.

OPERATION

The speed control system has five separate resis-

tive switches that provide a single multiplexed

(MUX) voltage inputs to the PCM.The switch names

are: ON, OFF, SET, COAST, RESUME, ACCEL, TAP-

UP, COAST, and CANCEL. Based on conditions when

the buttons are pushed (and released), the five volt-

age ranges provided to the PCM result in the follow-

ing functions: ON, OFF, SET, COAST, RESUME,

ACCEL, TAP-UP, TAP-DOWN, COAST, and CAN-

CEL. Refer to the Speed Control Section for more

information

Also the PCM receives an input from the brake

switch to sense whether the brake pedal has been

depressed. When the PCM receives the brake

depressed input, it turns off power to the speed con-

trol servo and disengages speed control. Also the

power to the servo is supplied through the brake

switch, which opens the circuit when the brake pedal

is depressed.

The individual switches cannot be repaired. If one

switch fails, the entire switch module must be

replaced.

REMOVAL

The speed control switches are mounted in the

steering wheel and wired through the clock spring

device under the airbag module.

Fig. 2 Speed Control Cable End

1 - SPEED CONTROL VACUUM HOSE

2 - THROTTLE BODY

3 - SPEED CONTROL CABLE

Fig. 3 BATTERY TRAY/VACUUM RESERVOIR

Fig. 4 SPEED CONTROL SERVO

RSSPEED CONTROL8P-5

SERVO (Continued)