lock CHRYSLER VOYAGER 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 291 of 2339

(5) Remove the battery tray (Refer to 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - REMOVAL).

(6) Pull up on the CAB connector lock and discon-

nect the 24±way electrical connector (Fig. 2).

(7) Disconnect the pump/motor connector from the

CAB.

(8) Remove the screws securing the CAB to the

HCU (Fig. 3)

(9) Pull CAB straight forward off HCU.

INSTALLATION

(1) Slide the CAB onto the HCU (Fig. 3).(2) Install screws securing the CAB to the HCU

(Fig. 3) Tighten the mounting screws to 2 N´m (17 in

lbs).

(3) Reconnect the 24±way wiring connector and

the pump/motor wiring connector. (Fig. 2)

(4) Install the battery tray (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/TRAY - INSTALLATION).

(5) Install the screw securing the coolant filler

neck to the battery tray.

(6) Reconnect the vacuum hose to the coolant tank

built into the battery tray.

(7) Install the battery (Refer to 8 - ELECTRICAL/

BATTERY SYSTEM/BATTERY - INSTALLATION).

(8) Reconnect the battery cables.

(9) Connect a DRBIIItto the vehicle. Check and

clear any faults, and initialize the system.

DATA LINK CONNECTOR

DESCRIPTION

The data link connector is located inside the vehi-

cle, below instrument panel next to the center col-

umn (Fig. 4).

OPERATION

The data link connector (diagnostic connector)

links the DRB scan tool with the Powertrain Control

Module (PCM). Refer to On-Board Diagnostics in the

General Diagnosis section of this group.

Fig. 2 CAB Connector Lock

1 - CONNECTOR LOCK

2 - CAB

Fig. 3 CAB Mounting Screws

1 - HCU

2 - MOUNTING SCREWS

3 - CAB

Fig. 4 DATA LINK CONNECTOR

8E - 6 ELECTRONIC CONTROL MODULESRS

CONTROLLER ANTILOCK BRAKE (Continued)

Page 292 of 2339

FRONT CONTROL MODULE

DESCRIPTION

The Front Control Module (FCM) is a micro con-

troller based module located in the engine compart-

ment. The FCM mates to the Power Distribution

Center (PDC) to form the Integrated Power Module

(IPM). The IPM connects directly to the battery and

provides the primary means of circuit protection and

power distribution for all vehicle electrical systems.

The FCM controls power to some of these vehicle sys-

tems electrical and electromechanical loads based on

inputs received from hard wired switch inputs and

data received on the Programmable Communications

Interface (PCI) data bus.

For information on the IPM, (Refer to 8 - ELEC-

TRICAL/POWER DISTRIBUTION/INTEGRATED

POWER MODULE - DESCRIPTION)

OPERATION

As messages are sent over the Programmable Com-

munications Interface (PCI) data bus, the Front Con-

trol Module (FCM) reads these messages and controls

power to some of the vehicles electrical systems by

completing the circuit to ground (low side driver) or

completing the circuit to 12 volt power (high side

driver).

The following functions arecontrolledby the

Front Control Module:

²Accessory Relay Actuation

²Brake Transmission Shift Interlock Functions

(BTSI - gas engine only)

²Diesel Cabin Heater (Diesel Engine Vehicles)

²Electronic Back Light (EBL) Rear Defogger

²Front and Rear Blower Motor Relay Actuation

²Front Fog Lamp Relay Actuation

²Washer Motor (front and rear)

²Front Windshield Wiper ªHIº & ªLOº Relay

Actuation

²Front Windshield Wiper ªONº Relay Actuation

²Headlamp Power with Voltage Regulation

²Horn Relay Actuation

²Headlamp Washer Relay Actuation (IF

EQUIPPED - EXPORT ONLY)

²Name Brand Speaker (NBS) Relay Actuation

²Park Lamp Relay Actuation

The following inputs areReceived/Monitoredby

the Front Control Module:

²Ambient Temperature Sensing

²Back-Up switch

²Brake Fluid Level

²B+ Connection Detection

²Engine Crank Signal (Diesel Engine Vehicles)

²Horn Input

²Ignition Switch Start Only

²Ignition Switch Run and Start Only²Stop Lamp Sense

²Washer Fluid Level

²Windshield Wiper Park

DIAGNOSIS AND TESTING

FRONT CONTROL MODULE

The Front Control Module (FCM) is a printed cir-

cuit board based module with a on-board micro-pro-

cessor. The FCM interfaces with other electronic

modules in the vehicle via the Programmable Com-

munications Interface (PCI) data bus. In order to

obtain conclusive testing the PCI data bus and all of

the electronic modules that provide inputs to, or

receive outputs from the FCM must be checked. All

PCI communication faults must be resolved prior to

further diagnosing any front control module related

issues.

The FCM was designed to be diagnosed with an

appropriate diagnostic scan tool, such as the DRB

IIIt. The most reliable, efficient, and accurate means

to diagnose the front control module requires the use

of a DRB IIItscan tool and the proper Body Diag-

nostic Procedures manual.

Before any testing of the FCM is attempted, the

battery should be fully charged and all wire harness

and ground connections inspected around the affected

areas on the vehicle.

REMOVAL

(1) Disconnect and isolate the negative and posi-

tive battery cables from the battery.

(2) Remove the battery (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - REMOVAL).

(3) Using a long flat-bladed screwdriver, gently

twist the Integrated Power Module (IPM) retaining

clip outboard to free the IPM from its mounting

bracket (Fig. 5). Rotate IPM upward to access the

Front Control Module (FCM) retaining screws.

(4) Remove the front control module retaining

screws.

(5) Pull the FCM straight from the IPM assembly

to disconnect the electrical connector (Fig. 6) and

remove the FCM from the vehicle.

INSTALLATION

NOTE: Front Control Module must be programmed

to the correct radio EQ curve using the DRB IIIT.

This will ensure that the audio system is operating

correctly.

(1) Install the Front Control Module (FCM) in the

Integrated Power Module (IPM) assembly by pushing

the 49-way electrical connector straight in.

RSELECTRONIC CONTROL MODULES8E-7

Page 295 of 2339

Inspect the related wiring harness connectors for

broken, bent, pushed out, or corroded terminals.

Refer to the appropriate wiring information.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the driver side front bucket seat

retaining nuts from under the vehicle (Refer to 23 -

BODY/SEATS/SEAT - REMOVAL).

(3) Lift the drivers seat up and out of the mount-

ing holes in the floor pan and lay the seat rearward

to access the module located under the seat.

(4) Disconnect the memory seat/mirror module

electrical connectors. Depress the retaining tab and

pull straight apart.

(5) Remove the module retaining bolts and remove

the module from the bracket.

INSTALLATION

(1) Position and install the module retaining bolts.

(2) Connect the memory seat/mirror module elec-

trical connectors.

(3) Position the drivers seat in the mounting holes

in the floor pan.

(4) Install the driver side front bucket seat retain-

ing nuts from under the vehicle (Refer to 23 - BODY/

SEATS/SEAT - INSTALLATION).

(5) Connect the battery negative cable.

POWER LIFTGATE CONTROL

MODULE

DESCRIPTION

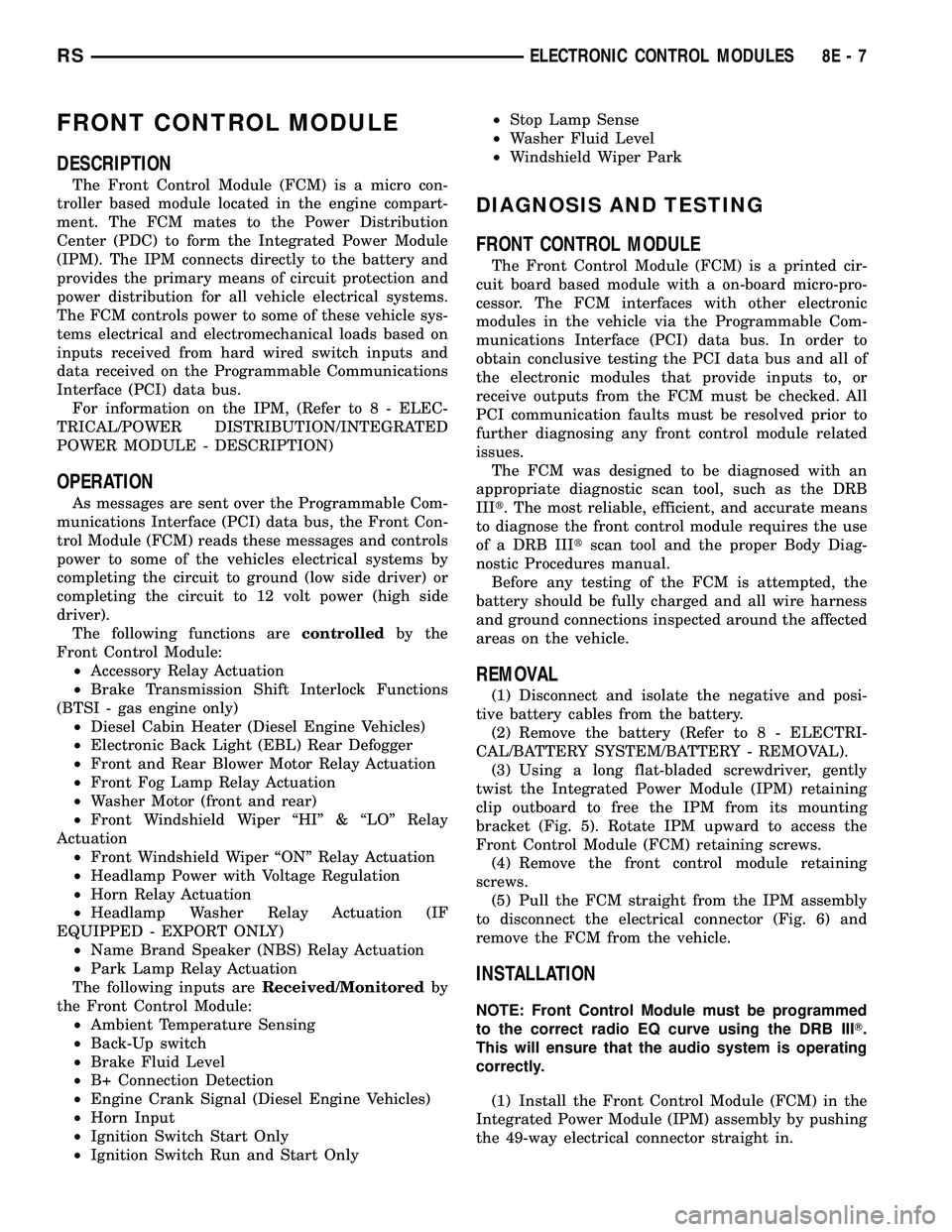

Vehicles equipped with a power liftgate (PLG) uti-

lize a PLG control module. This module is located on

the vehicles left side D-pillar just below the motor

assembly (Fig. 7) and contains a microprocessor,

which is used to communicate to the vehicles body

control module. The PLG control module receives and

monitors logic inputs from all the PLG system

switches except for the outside handle switch. This

module also contains the software technology to

detect liftgate obstructions and stop and/or reverse

the door accordingly.

OPERATION

The power liftgate control module contains the

electronic circuitry and software used to control the

sequence of events for the power liftgate system. This

module communicates on the Programmable Commu-

nications Interface (PCI) bus circuit with the vehicles

Body Control Module (BCM) to monitor many differ-

ent inputs and outputs such as door lock status,

transmission gear selector position and vehicle speed.(Refer to 8 - ELECTRICAL/POWER DOORS - OPER-

ATION) for more information.

DIAGNOSIS AND TESTING

POWER LIFTGATE CONTROL MODULE

Any diagnosis of the Power Liftgate system

should begin with the use of the DRB IIItdiag-

nostic tool. For information on the use of the

DRB IIIt, refer to the appropriate Diagnostic

Procedures information.

Inspect the related wiring harness connectors for

broken, bent, pushed out, or corroded terminals.

Refer to the appropriate wiring information.

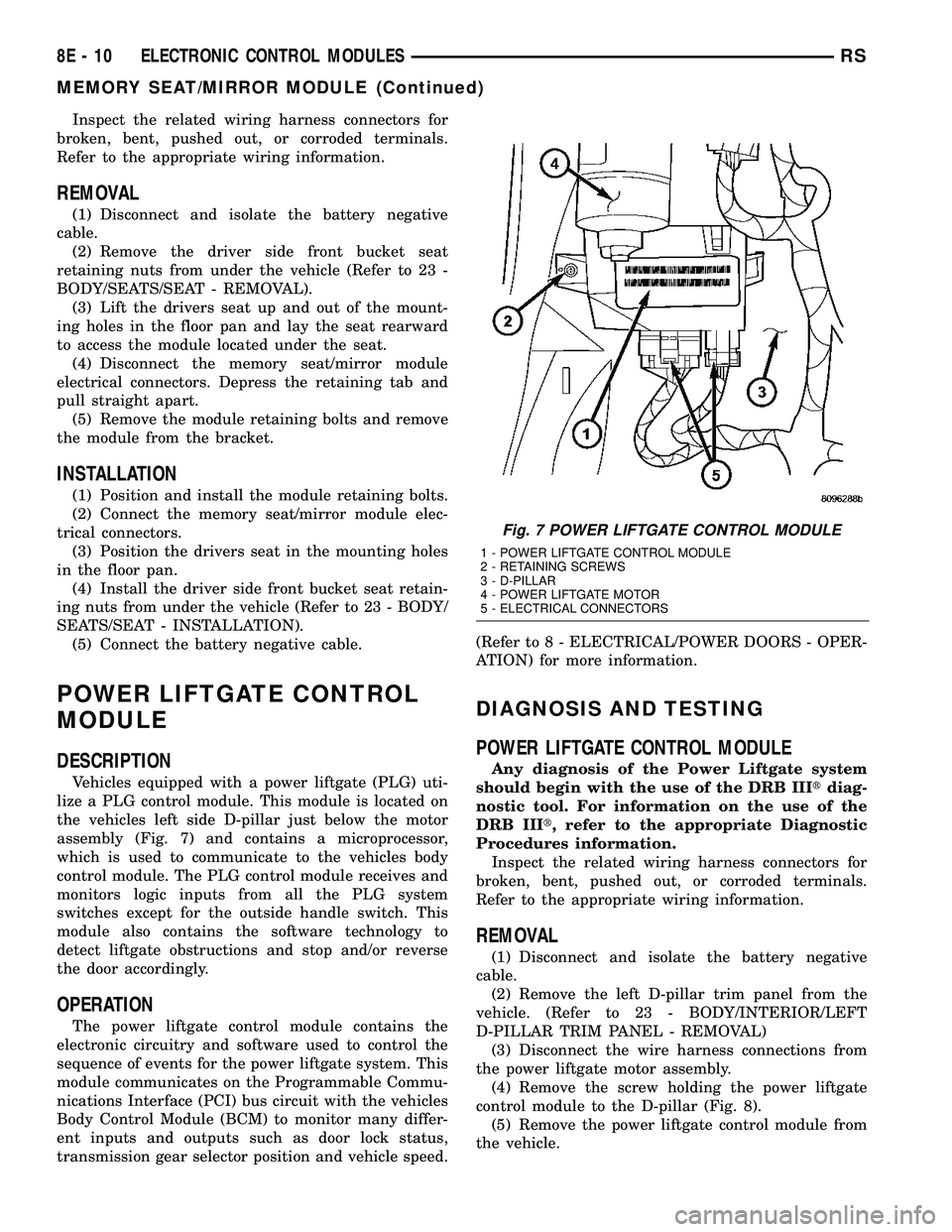

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the left D-pillar trim panel from the

vehicle. (Refer to 23 - BODY/INTERIOR/LEFT

D-PILLAR TRIM PANEL - REMOVAL)

(3) Disconnect the wire harness connections from

the power liftgate motor assembly.

(4) Remove the screw holding the power liftgate

control module to the D-pillar (Fig. 8).

(5) Remove the power liftgate control module from

the vehicle.

Fig. 7 POWER LIFTGATE CONTROL MODULE

1 - POWER LIFTGATE CONTROL MODULE

2 - RETAINING SCREWS

3 - D-PILLAR

4 - POWER LIFTGATE MOTOR

5 - ELECTRICAL CONNECTORS

8E - 10 ELECTRONIC CONTROL MODULESRS

MEMORY SEAT/MIRROR MODULE (Continued)

Page 296 of 2339

INSTALLATION

(1) Install the Power Liftgate (PLG) control mod-

ule on the D-pillar and install retaining screw.

(2) Connect the wire harness connections to the

PLG control module. Be certain to slide connector

locks to the locked position.

(3) Install the D-pillar trim panel on the vehicle.

(Refer to 23 - BODY/INTERIOR/LEFT D-PILLAR

TRIM PANEL - INSTALLATION)

(4) Connect the battery negative cable.

(5) Using an appropriate scan tool, check and

erase any PLG control module diagnostic trouble

codes.

(6) Verify PLG system operation. Cycle the PLG

through one complete open and close cycle, this will

allow the PLG control module to relearn its cycle

with the new components.

POWERTRAIN CONTROL

MODULE

DESCRIPTION

DESCRIPTION

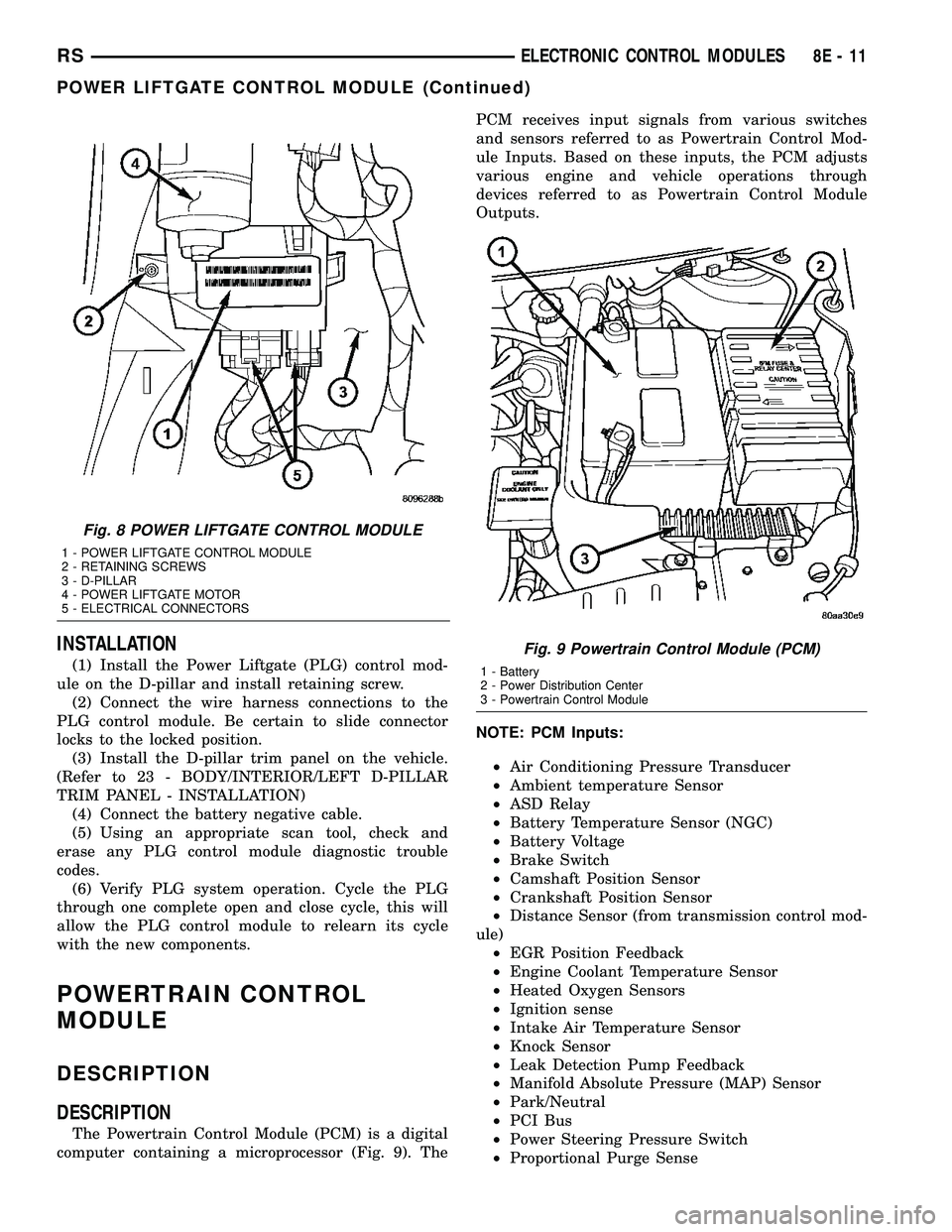

The Powertrain Control Module (PCM) is a digital

computer containing a microprocessor (Fig. 9). ThePCM receives input signals from various switches

and sensors referred to as Powertrain Control Mod-

ule Inputs. Based on these inputs, the PCM adjusts

various engine and vehicle operations through

devices referred to as Powertrain Control Module

Outputs.

NOTE: PCM Inputs:

²Air Conditioning Pressure Transducer

²Ambient temperature Sensor

²ASD Relay

²Battery Temperature Sensor (NGC)

²Battery Voltage

²Brake Switch

²Camshaft Position Sensor

²Crankshaft Position Sensor

²Distance Sensor (from transmission control mod-

ule)

²EGR Position Feedback

²Engine Coolant Temperature Sensor

²Heated Oxygen Sensors

²Ignition sense

²Intake Air Temperature Sensor

²Knock Sensor

²Leak Detection Pump Feedback

²Manifold Absolute Pressure (MAP) Sensor

²Park/Neutral

²PCI Bus

²Power Steering Pressure Switch

²Proportional Purge Sense

Fig. 8 POWER LIFTGATE CONTROL MODULE

1 - POWER LIFTGATE CONTROL MODULE

2 - RETAINING SCREWS

3 - D-PILLAR

4 - POWER LIFTGATE MOTOR

5 - ELECTRICAL CONNECTORS

Fig. 9 Powertrain Control Module (PCM)

1 - Battery

2 - Power Distribution Center

3 - Powertrain Control Module

RSELECTRONIC CONTROL MODULES8E-11

POWER LIFTGATE CONTROL MODULE (Continued)

Page 299 of 2339

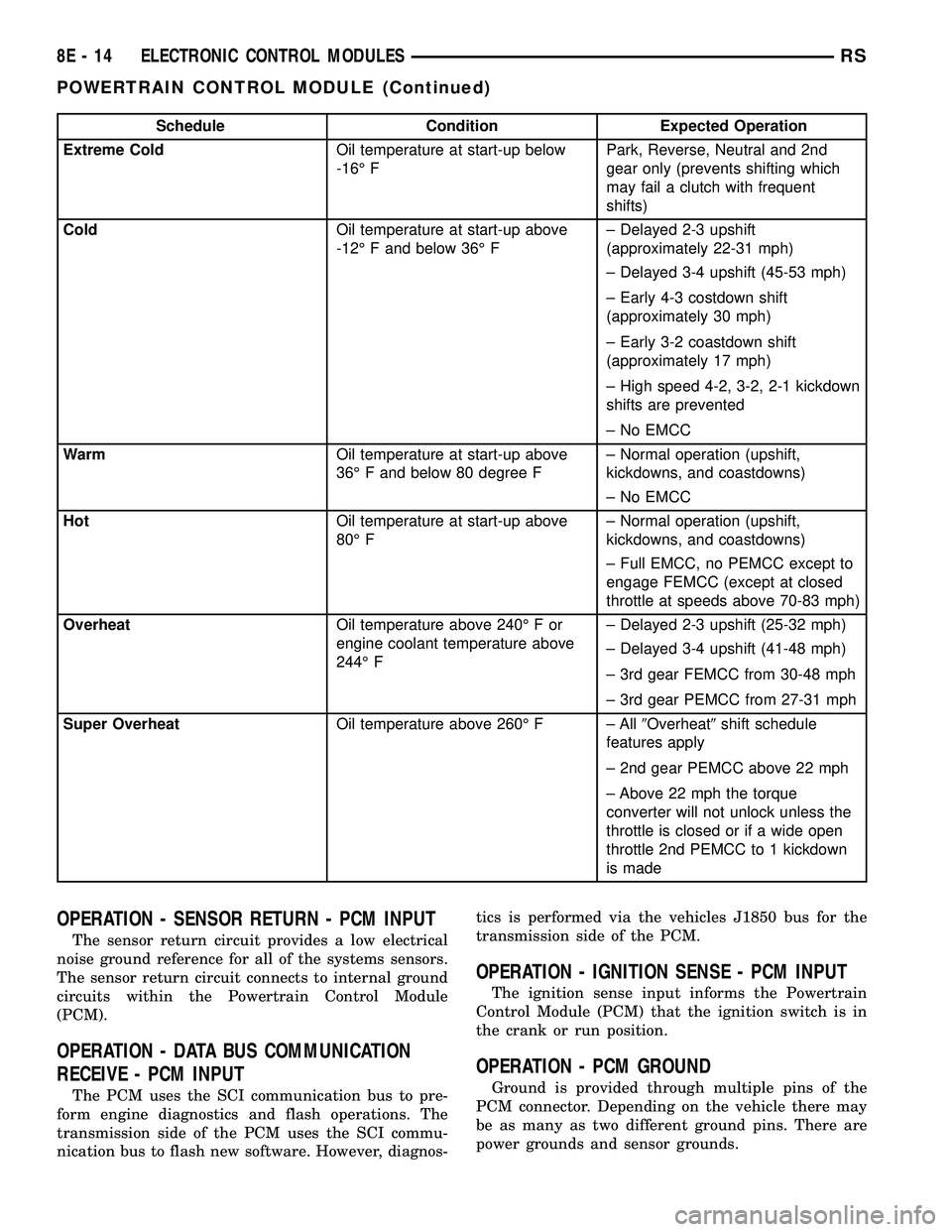

Schedule Condition Expected Operation

Extreme ColdOil temperature at start-up below

-16É FPark, Reverse, Neutral and 2nd

gear only (prevents shifting which

may fail a clutch with frequent

shifts)

ColdOil temperature at start-up above

-12É F and below 36É F± Delayed 2-3 upshift

(approximately 22-31 mph)

± Delayed 3-4 upshift (45-53 mph)

± Early 4-3 costdown shift

(approximately 30 mph)

± Early 3-2 coastdown shift

(approximately 17 mph)

± High speed 4-2, 3-2, 2-1 kickdown

shifts are prevented

± No EMCC

WarmOil temperature at start-up above

36É F and below 80 degree F± Normal operation (upshift,

kickdowns, and coastdowns)

± No EMCC

HotOil temperature at start-up above

80É F± Normal operation (upshift,

kickdowns, and coastdowns)

± Full EMCC, no PEMCC except to

engage FEMCC (except at closed

throttle at speeds above 70-83 mph)

OverheatOil temperature above 240É F or

engine coolant temperature above

244É F± Delayed 2-3 upshift (25-32 mph)

± Delayed 3-4 upshift (41-48 mph)

± 3rd gear FEMCC from 30-48 mph

± 3rd gear PEMCC from 27-31 mph

Super OverheatOil temperature above 260É F ± All9Overheat9shift schedule

features apply

± 2nd gear PEMCC above 22 mph

± Above 22 mph the torque

converter will not unlock unless the

throttle is closed or if a wide open

throttle 2nd PEMCC to 1 kickdown

is made

OPERATION - SENSOR RETURN - PCM INPUT

The sensor return circuit provides a low electrical

noise ground reference for all of the systems sensors.

The sensor return circuit connects to internal ground

circuits within the Powertrain Control Module

(PCM).

OPERATION - DATA BUS COMMUNICATION

RECEIVE - PCM INPUT

The PCM uses the SCI communication bus to pre-

form engine diagnostics and flash operations. The

transmission side of the PCM uses the SCI commu-

nication bus to flash new software. However, diagnos-tics is performed via the vehicles J1850 bus for the

transmission side of the PCM.

OPERATION - IGNITION SENSE - PCM INPUT

The ignition sense input informs the Powertrain

Control Module (PCM) that the ignition switch is in

the crank or run position.

OPERATION - PCM GROUND

Ground is provided through multiple pins of the

PCM connector. Depending on the vehicle there may

be as many as two different ground pins. There are

power grounds and sensor grounds.

8E - 14 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

Page 302 of 2339

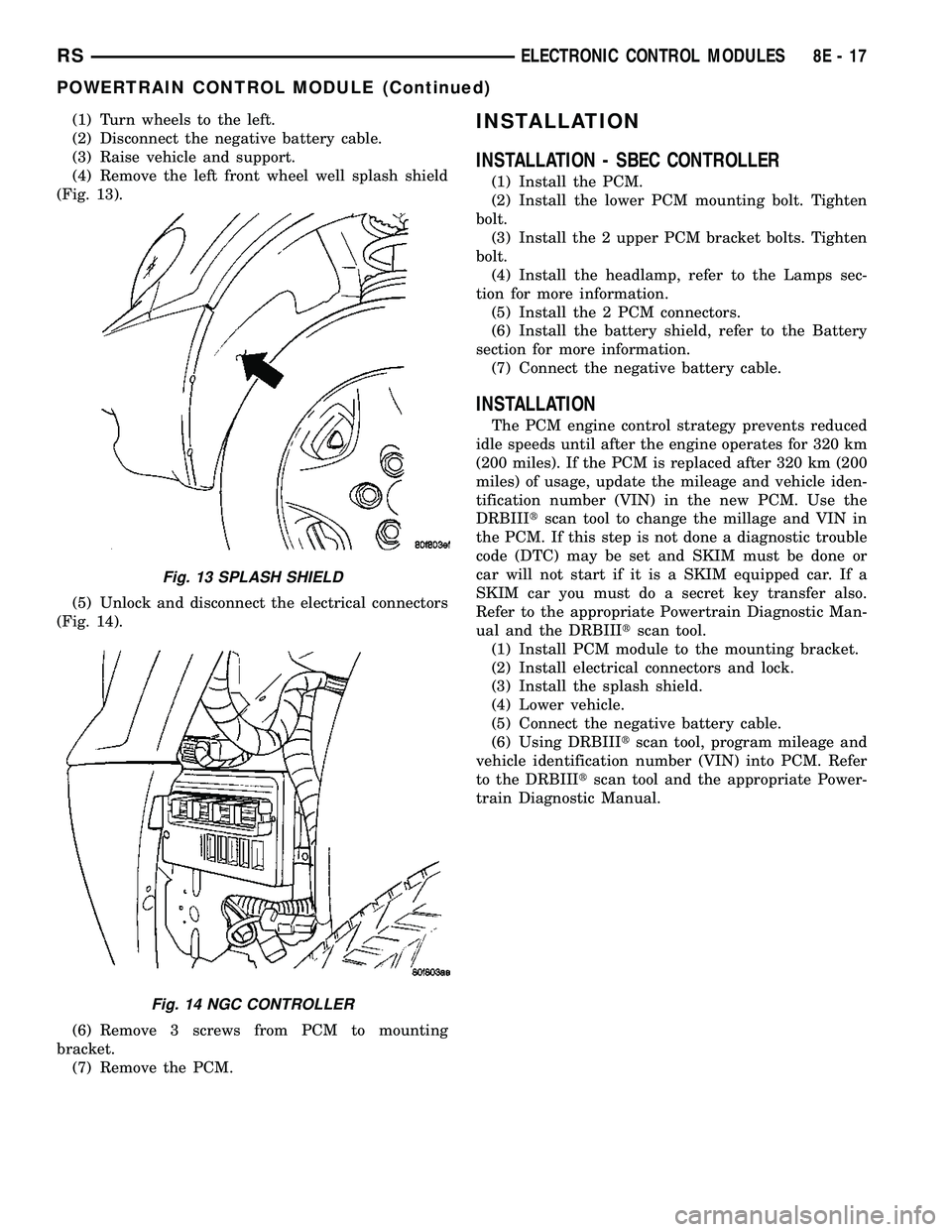

(1) Turn wheels to the left.

(2) Disconnect the negative battery cable.

(3) Raise vehicle and support.

(4) Remove the left front wheel well splash shield

(Fig. 13).

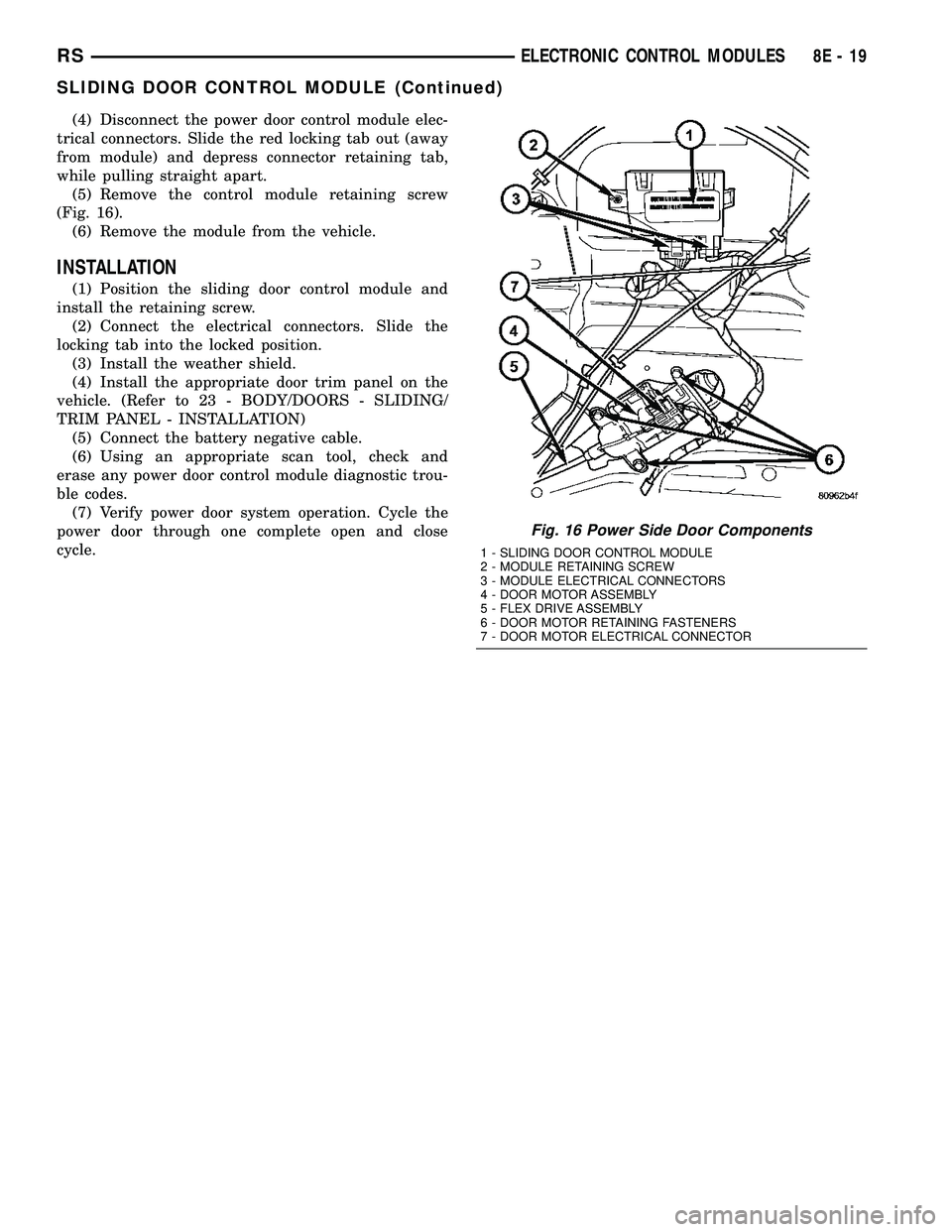

(5) Unlock and disconnect the electrical connectors

(Fig. 14).

(6) Remove 3 screws from PCM to mounting

bracket.

(7) Remove the PCM.INSTALLATION

INSTALLATION - SBEC CONTROLLER

(1) Install the PCM.

(2) Install the lower PCM mounting bolt. Tighten

bolt.

(3) Install the 2 upper PCM bracket bolts. Tighten

bolt.

(4) Install the headlamp, refer to the Lamps sec-

tion for more information.

(5) Install the 2 PCM connectors.

(6) Install the battery shield, refer to the Battery

section for more information.

(7) Connect the negative battery cable.

INSTALLATION

The PCM engine control strategy prevents reduced

idle speeds until after the engine operates for 320 km

(200 miles). If the PCM is replaced after 320 km (200

miles) of usage, update the mileage and vehicle iden-

tification number (VIN) in the new PCM. Use the

DRBIIItscan tool to change the millage and VIN in

the PCM. If this step is not done a diagnostic trouble

code (DTC) may be set and SKIM must be done or

car will not start if it is a SKIM equipped car. If a

SKIM car you must do a secret key transfer also.

Refer to the appropriate Powertrain Diagnostic Man-

ual and the DRBIIItscan tool.

(1) Install PCM module to the mounting bracket.

(2) Install electrical connectors and lock.

(3) Install the splash shield.

(4) Lower vehicle.

(5) Connect the negative battery cable.

(6) Using DRBIIItscan tool, program mileage and

vehicle identification number (VIN) into PCM. Refer

to the DRBIIItscan tool and the appropriate Power-

train Diagnostic Manual.

Fig. 13 SPLASH SHIELD

Fig. 14 NGC CONTROLLER

RSELECTRONIC CONTROL MODULES8E-17

POWERTRAIN CONTROL MODULE (Continued)

Page 304 of 2339

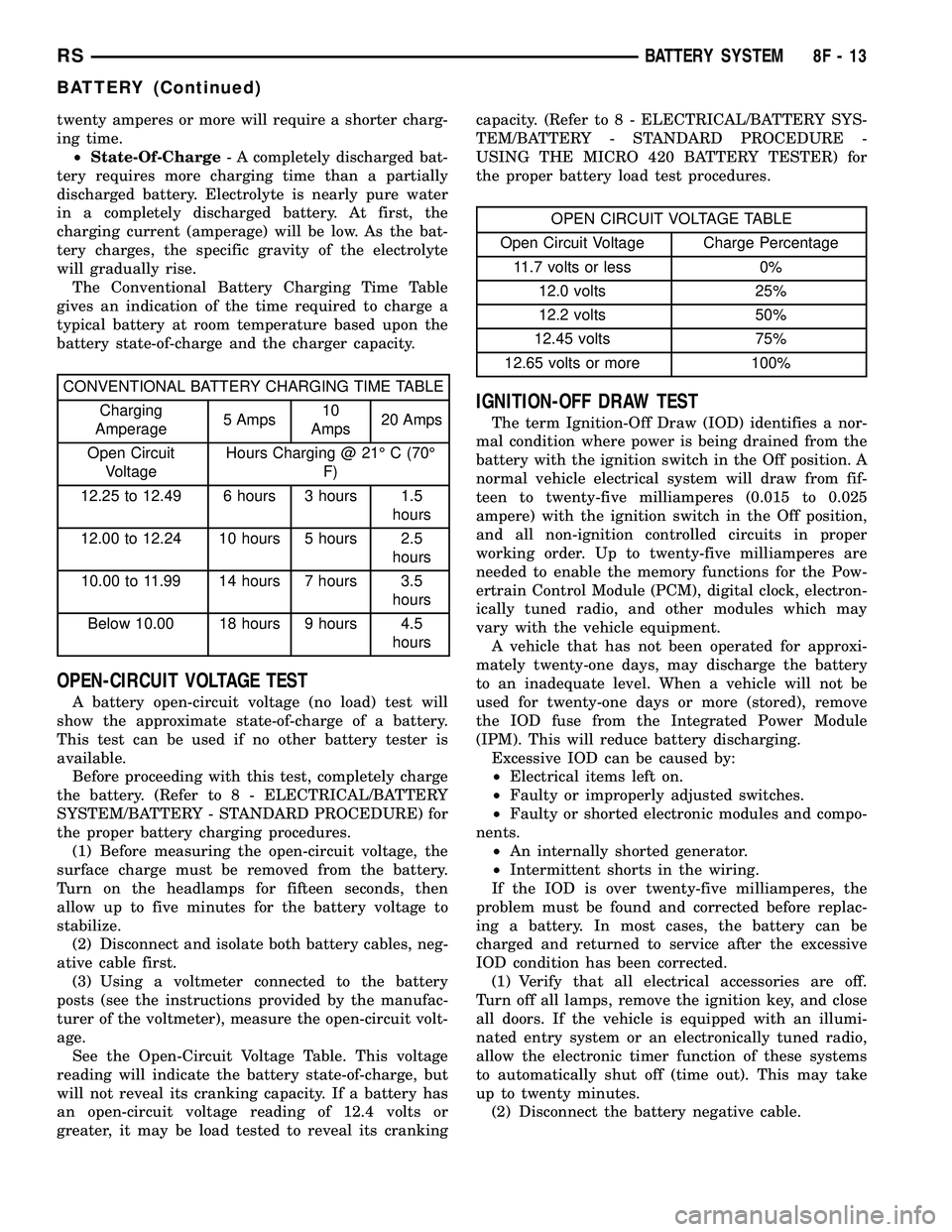

(4) Disconnect the power door control module elec-

trical connectors. Slide the red locking tab out (away

from module) and depress connector retaining tab,

while pulling straight apart.

(5) Remove the control module retaining screw

(Fig. 16).

(6) Remove the module from the vehicle.

INSTALLATION

(1) Position the sliding door control module and

install the retaining screw.

(2) Connect the electrical connectors. Slide the

locking tab into the locked position.

(3) Install the weather shield.

(4) Install the appropriate door trim panel on the

vehicle. (Refer to 23 - BODY/DOORS - SLIDING/

TRIM PANEL - INSTALLATION)

(5) Connect the battery negative cable.

(6) Using an appropriate scan tool, check and

erase any power door control module diagnostic trou-

ble codes.

(7) Verify power door system operation. Cycle the

power door through one complete open and close

cycle.

Fig. 16 Power Side Door Components

1 - SLIDING DOOR CONTROL MODULE

2 - MODULE RETAINING SCREW

3 - MODULE ELECTRICAL CONNECTORS

4 - DOOR MOTOR ASSEMBLY

5 - FLEX DRIVE ASSEMBLY

6 - DOOR MOTOR RETAINING FASTENERS

7 - DOOR MOTOR ELECTRICAL CONNECTOR

RSELECTRONIC CONTROL MODULES8E-19

SLIDING DOOR CONTROL MODULE (Continued)

Page 318 of 2339

twenty amperes or more will require a shorter charg-

ing time.

²State-Of-Charge- A completely discharged bat-

tery requires more charging time than a partially

discharged battery. Electrolyte is nearly pure water

in a completely discharged battery. At first, the

charging current (amperage) will be low. As the bat-

tery charges, the specific gravity of the electrolyte

will gradually rise.

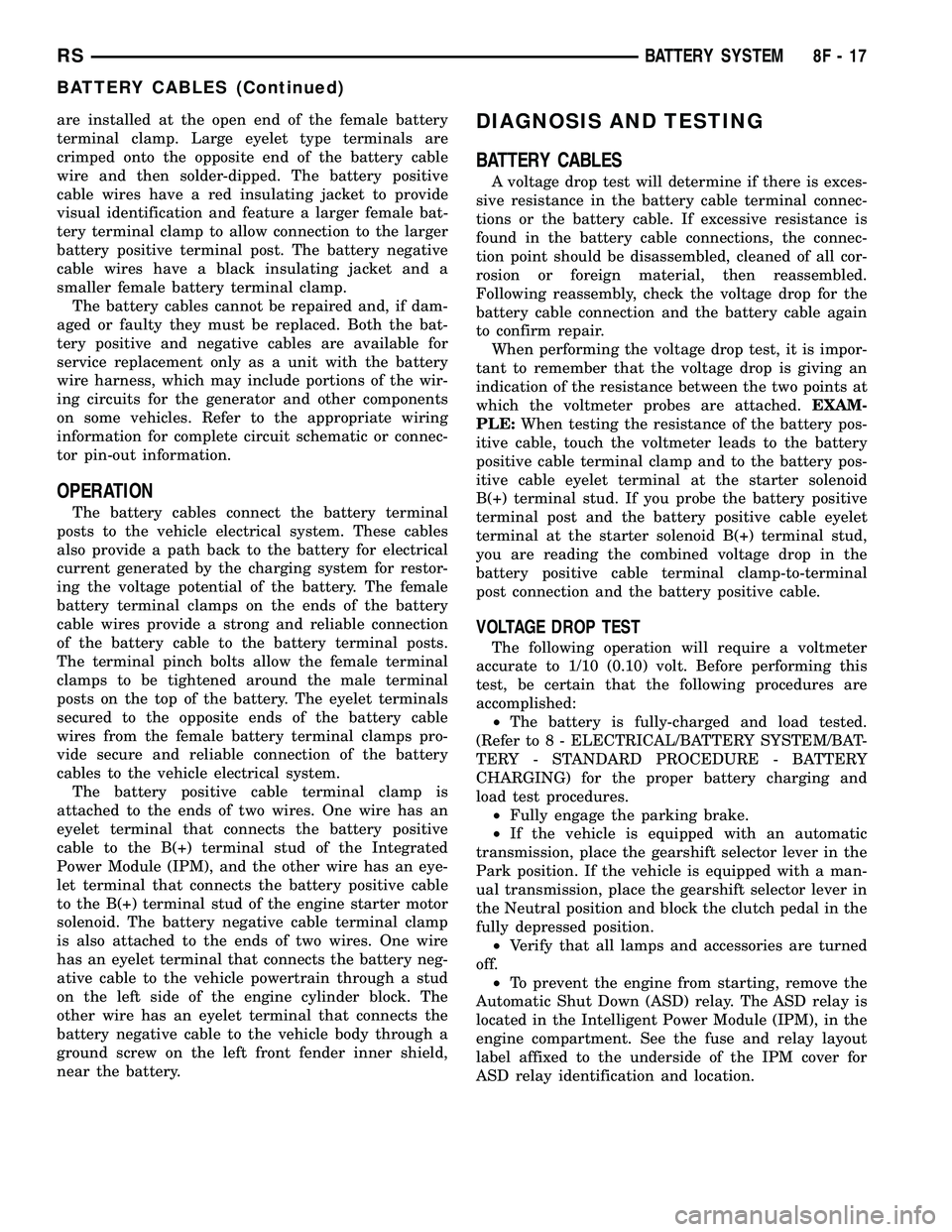

The Conventional Battery Charging Time Table

gives an indication of the time required to charge a

typical battery at room temperature based upon the

battery state-of-charge and the charger capacity.

CONVENTIONAL BATTERY CHARGING TIME TABLE

Charging

Amperage5 Amps10

Amps20 Amps

Open Circuit

VoltageHours Charging @ 21É C (70É

F)

12.25 to 12.49 6 hours 3 hours 1.5

hours

12.00 to 12.24 10 hours 5 hours 2.5

hours

10.00 to 11.99 14 hours 7 hours 3.5

hours

Below 10.00 18 hours 9 hours 4.5

hours

OPEN-CIRCUIT VOLTAGE TEST

A battery open-circuit voltage (no load) test will

show the approximate state-of-charge of a battery.

This test can be used if no other battery tester is

available.

Before proceeding with this test, completely charge

the battery. (Refer to 8 - ELECTRICAL/BATTERY

SYSTEM/BATTERY - STANDARD PROCEDURE) for

the proper battery charging procedures.

(1) Before measuring the open-circuit voltage, the

surface charge must be removed from the battery.

Turn on the headlamps for fifteen seconds, then

allow up to five minutes for the battery voltage to

stabilize.

(2) Disconnect and isolate both battery cables, neg-

ative cable first.

(3) Using a voltmeter connected to the battery

posts (see the instructions provided by the manufac-

turer of the voltmeter), measure the open-circuit volt-

age.

See the Open-Circuit Voltage Table. This voltage

reading will indicate the battery state-of-charge, but

will not reveal its cranking capacity. If a battery has

an open-circuit voltage reading of 12.4 volts or

greater, it may be load tested to reveal its crankingcapacity. (Refer to 8 - ELECTRICAL/BATTERY SYS-

TEM/BATTERY - STANDARD PROCEDURE -

USING THE MICRO 420 BATTERY TESTER) for

the proper battery load test procedures.

OPEN CIRCUIT VOLTAGE TABLE

Open Circuit Voltage Charge Percentage

11.7 volts or less 0%

12.0 volts 25%

12.2 volts 50%

12.45 volts 75%

12.65 volts or more 100%

IGNITION-OFF DRAW TEST

The term Ignition-Off Draw (IOD) identifies a nor-

mal condition where power is being drained from the

battery with the ignition switch in the Off position. A

normal vehicle electrical system will draw from fif-

teen to twenty-five milliamperes (0.015 to 0.025

ampere) with the ignition switch in the Off position,

and all non-ignition controlled circuits in proper

working order. Up to twenty-five milliamperes are

needed to enable the memory functions for the Pow-

ertrain Control Module (PCM), digital clock, electron-

ically tuned radio, and other modules which may

vary with the vehicle equipment.

A vehicle that has not been operated for approxi-

mately twenty-one days, may discharge the battery

to an inadequate level. When a vehicle will not be

used for twenty-one days or more (stored), remove

the IOD fuse from the Integrated Power Module

(IPM). This will reduce battery discharging.

Excessive IOD can be caused by:

²Electrical items left on.

²Faulty or improperly adjusted switches.

²Faulty or shorted electronic modules and compo-

nents.

²An internally shorted generator.

²Intermittent shorts in the wiring.

If the IOD is over twenty-five milliamperes, the

problem must be found and corrected before replac-

ing a battery. In most cases, the battery can be

charged and returned to service after the excessive

IOD condition has been corrected.

(1) Verify that all electrical accessories are off.

Turn off all lamps, remove the ignition key, and close

all doors. If the vehicle is equipped with an illumi-

nated entry system or an electronically tuned radio,

allow the electronic timer function of these systems

to automatically shut off (time out). This may take

up to twenty minutes.

(2) Disconnect the battery negative cable.

RSBATTERY SYSTEM8F-13

BATTERY (Continued)

Page 322 of 2339

are installed at the open end of the female battery

terminal clamp. Large eyelet type terminals are

crimped onto the opposite end of the battery cable

wire and then solder-dipped. The battery positive

cable wires have a red insulating jacket to provide

visual identification and feature a larger female bat-

tery terminal clamp to allow connection to the larger

battery positive terminal post. The battery negative

cable wires have a black insulating jacket and a

smaller female battery terminal clamp.

The battery cables cannot be repaired and, if dam-

aged or faulty they must be replaced. Both the bat-

tery positive and negative cables are available for

service replacement only as a unit with the battery

wire harness, which may include portions of the wir-

ing circuits for the generator and other components

on some vehicles. Refer to the appropriate wiring

information for complete circuit schematic or connec-

tor pin-out information.

OPERATION

The battery cables connect the battery terminal

posts to the vehicle electrical system. These cables

also provide a path back to the battery for electrical

current generated by the charging system for restor-

ing the voltage potential of the battery. The female

battery terminal clamps on the ends of the battery

cable wires provide a strong and reliable connection

of the battery cable to the battery terminal posts.

The terminal pinch bolts allow the female terminal

clamps to be tightened around the male terminal

posts on the top of the battery. The eyelet terminals

secured to the opposite ends of the battery cable

wires from the female battery terminal clamps pro-

vide secure and reliable connection of the battery

cables to the vehicle electrical system.

The battery positive cable terminal clamp is

attached to the ends of two wires. One wire has an

eyelet terminal that connects the battery positive

cable to the B(+) terminal stud of the Integrated

Power Module (IPM), and the other wire has an eye-

let terminal that connects the battery positive cable

to the B(+) terminal stud of the engine starter motor

solenoid. The battery negative cable terminal clamp

is also attached to the ends of two wires. One wire

has an eyelet terminal that connects the battery neg-

ative cable to the vehicle powertrain through a stud

on the left side of the engine cylinder block. The

other wire has an eyelet terminal that connects the

battery negative cable to the vehicle body through a

ground screw on the left front fender inner shield,

near the battery.

DIAGNOSIS AND TESTING

BATTERY CABLES

A voltage drop test will determine if there is exces-

sive resistance in the battery cable terminal connec-

tions or the battery cable. If excessive resistance is

found in the battery cable connections, the connec-

tion point should be disassembled, cleaned of all cor-

rosion or foreign material, then reassembled.

Following reassembly, check the voltage drop for the

battery cable connection and the battery cable again

to confirm repair.

When performing the voltage drop test, it is impor-

tant to remember that the voltage drop is giving an

indication of the resistance between the two points at

which the voltmeter probes are attached.EXAM-

PLE:When testing the resistance of the battery pos-

itive cable, touch the voltmeter leads to the battery

positive cable terminal clamp and to the battery pos-

itive cable eyelet terminal at the starter solenoid

B(+) terminal stud. If you probe the battery positive

terminal post and the battery positive cable eyelet

terminal at the starter solenoid B(+) terminal stud,

you are reading the combined voltage drop in the

battery positive cable terminal clamp-to-terminal

post connection and the battery positive cable.

VOLTAGE DROP TEST

The following operation will require a voltmeter

accurate to 1/10 (0.10) volt. Before performing this

test, be certain that the following procedures are

accomplished:

²The battery is fully-charged and load tested.

(Refer to 8 - ELECTRICAL/BATTERY SYSTEM/BAT-

TERY - STANDARD PROCEDURE - BATTERY

CHARGING) for the proper battery charging and

load test procedures.

²Fully engage the parking brake.

²If the vehicle is equipped with an automatic

transmission, place the gearshift selector lever in the

Park position. If the vehicle is equipped with a man-

ual transmission, place the gearshift selector lever in

the Neutral position and block the clutch pedal in the

fully depressed position.

²Verify that all lamps and accessories are turned

off.

²To prevent the engine from starting, remove the

Automatic Shut Down (ASD) relay. The ASD relay is

located in the Intelligent Power Module (IPM), in the

engine compartment. See the fuse and relay layout

label affixed to the underside of the IPM cover for

ASD relay identification and location.

RSBATTERY SYSTEM8F-17

BATTERY CABLES (Continued)

Page 323 of 2339

(1) Connect the positive lead of the voltmeter to

the battery negative terminal post. Connect the neg-

ative lead of the voltmeter to the battery negative

cable terminal clamp (Fig. 13). Rotate and hold the

ignition switch in the Start position. Observe the

voltmeter. If voltage is detected, correct the poor con-

nection between the battery negative cable terminal

clamp and the battery negative terminal post.

(2) Connect the positive lead of the voltmeter to

the battery positive terminal post. Connect the nega-

tive lead of the voltmeter to the battery positive cable

terminal clamp (Fig. 14). Rotate and hold the ignition

switch in the Start position. Observe the voltmeter. If

voltage is detected, correct the poor connection

between the battery positive cable terminal clamp

and the battery positive terminal post.(3) Connect the voltmeter to measure between the

battery positive cable terminal clamp and the starter

solenoid B(+) terminal stud (Fig. 15). Rotate and hold

the ignition switch in the Start position. Observe the

voltmeter. If the reading is above 0.2 volt, clean and

tighten the battery positive cable eyelet terminal con-

nection at the starter solenoid B(+) terminal stud.

Repeat the test. If the reading is still above 0.2 volt,

replace the inoperative battery positive cable.

(4) Connect the voltmeter to measure between the

battery negative cable terminal clamp and a good

clean ground on the engine block (Fig. 16). Rotate

and hold the ignition switch in the Start position.

Observe the voltmeter. If the reading is above 0.2

volt, clean and tighten the battery negative cable

eyelet terminal connection to the engine block.

Repeat the test. If the reading is still above 0.2 volt,

replace the inoperative battery negative cable.

Fig. 13 Test Battery Negative Connection

Resistance - Typical

1 - VOLTMETER

2 - BATTERY

Fig. 14 Test Battery Positive Connection Resistance

- Typical

1 - VOLTMETER

2 - BATTERY

Fig. 15 Test Battery Positive Cable Resistance - Typical

1 - BATTERY

2 - VOLTMETER

3 - STARTER MOTOR

Fig. 16 Test Ground Circuit Resistance - Typical

1 - VOLTMETER

2 - BATTERY

3 - ENGINE GROUND

8F - 18 BATTERY SYSTEMRS

BATTERY CABLES (Continued)