lock CHRYSLER VOYAGER 2005 Manual PDF

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 211 of 2339

ABS TRACTION CONTROL HYDRAULIC CIRCUIT,

SOLENOID VALVE, AND SHUTTLE VALVE

FUNCTION (ABS WITH TRACTION CONTROL)

The hydraulic diagram (Fig. 11) shows the vehicle

in the ABS braking mode. The diagram shows a drive

wheel is spinning and brake pressure is required to

reduce its speed.

²The normally open ASR valve is energized to iso-

late the brake fluid being pumped from the master

cylinder and to isolate the driven wheel.

²The normally open ASR valve bypasses the

pump output back to the master cylinder at a fixed

pressure setting.

²The normally open and normally closed valves

modulate (build/decay) the brake pressure as

required to the spinning wheel.

HCU (HYDRAULIC CONTROL

UNIT)

DESCRIPTION

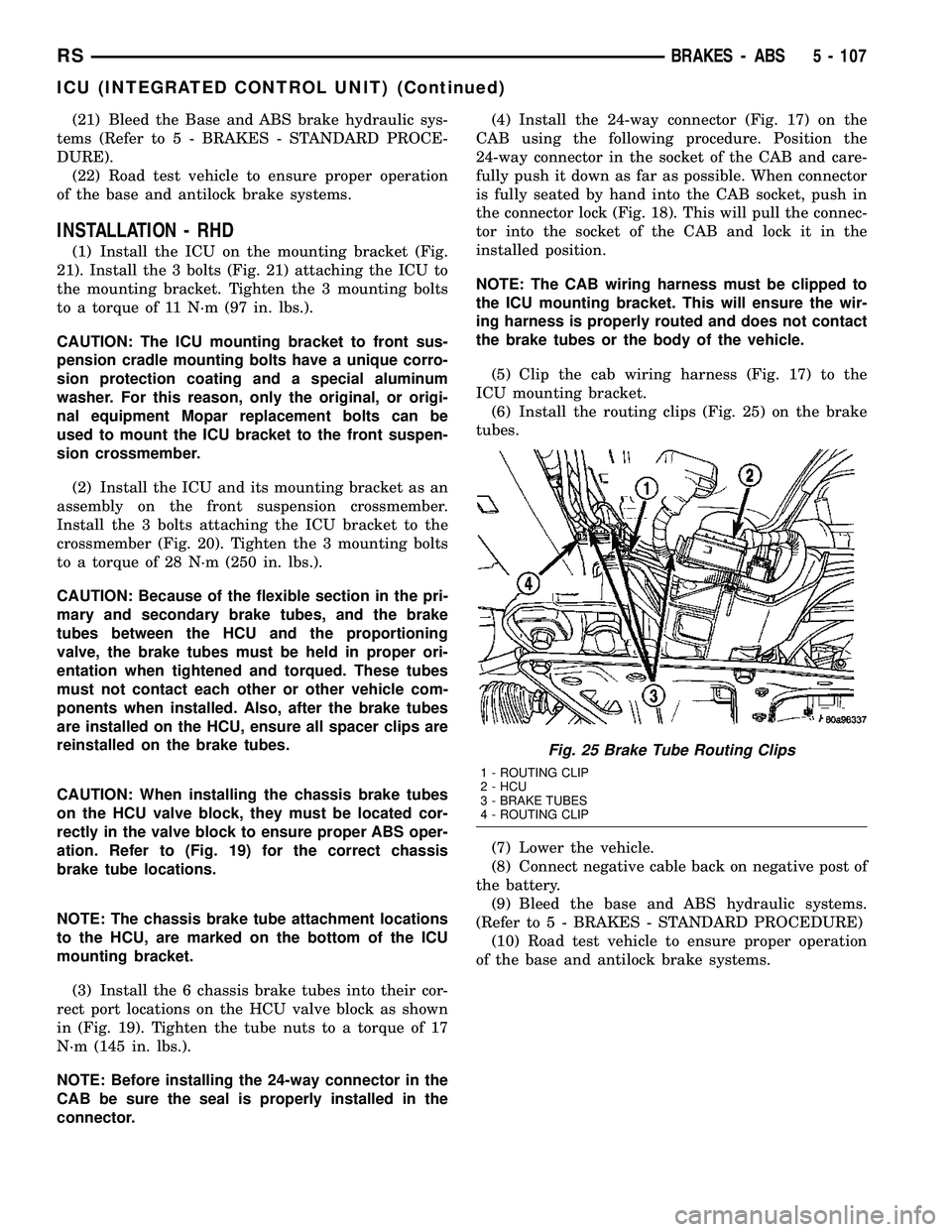

The hydraulic control unit (HCU) is mounted to

the CAB as part of the ICU (Fig. 22). The HCU con-

trols the flow of brake fluid to the brakes using a

series of valves and accumulators. A pump/motor is

mounted on the HCU to supply build pressure to the

brakes during an ABS stop.

The HCU on a vehicle equipped with ABS and

traction control has a valve block housing that is

approximately 1 inch longer on the low pressure fluid

accumulators side than a HCU on a vehicle that is

equipped with only ABS.

Fig. 11 Traction Control Hydraulic Circuit

1 - OUTLET VALVE

2 - PUMP PISTON

3 - PUMP MOTOR (ON)

4 - LOW PRESSURE ACCUMULATOR PRESSURE

5 - LOW PRESSURE ACCUMULATOR

6 - NORMALLY CLOSED VALVE (MODULATING)

7 - TO RIGHT FRONT WHEEL (SPINNING)

8 - NORMALLY OPEN VALVE (MODULATING)

9 - NORMALLY OPEN ASR VALVE ON (REGULATING)10 - FROM MASTER CYLINDER

11 - HYDRAULIC SHUTTLE VALVE

12 - CONTROLLED WHEEL PRESSURE

13 - SUCTION VALVE

14 - PUMP INTERSTAGE PRESSURE

15 - NOISE DAMPER CHAMBER

16 - MASTER CYLINDER PRESSURE

17 - PUMP PRESSURE

5 - 100 BRAKES - ABSRS

HYDRAULIC/MECHANICAL (Continued)

Page 212 of 2339

For more information, (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ICU (INTEGRATED CON-

TROL UNIT) - DESCRIPTION)

OPERATION

For information on the operation of the HCU as a

whole, refer to Hydraulic Circuits And Valve Opera-

tion which can be found elsewhere in this section.

For information on the operation of the components

within the HCU, refer to the following three topics.

VALVES AND SOLENOIDS

The valve block contains four inlet valves and four

outlet valves. The inlet valves are spring-loaded in

the open position and the outlet valves are spring-

loaded in the closed position during normal braking.

The fluid is allowed to flow from the master cylinder

to the wheel brakes.

During an ABS stop, these valves cycle to maintain

the proper slip ratio for each wheel. The inlet valve

closes preventing further pressure increase and the

outlet valve opens to provide a path from the wheel

brake to the HCU accumulators and pump/motor.

This releases (decays) pressure from the wheel brake,

thus releasing the wheel from excessive slippage.

Once the wheel is no longer slipping, the outlet valve

is closed and the inlet valve is opened to reapply

(build) pressure.

On vehicles with traction control, there is an extra

set of valves and solenoids. The ASR valves, mounted

in the HCU valve block, are normally in the open

position and close only when the traction control is

applied.

These isolator valves are used to isolate the rear

(non-driving) wheels of the vehicle from the hydraulic

pressure that the HCU pump/motor is sending to the

front (driving) wheels when traction control is being

applied. The rear brakes need to be isolated from the

master cylinder when traction control is being

applied so the rear wheels do not drag. For more

information, refer to Traction Control System in this

section.

BRAKE FLUID ACCUMULATORS

There are two fluid accumulators in the HCU±one

for the primary hydraulic circuit and one for the sec-

ondary hydraulic circuit. Each hydraulic circuit uses

a 5 cc accumulator.

The fluid accumulators temporarily store brake

fluid that is removed from the wheel brakes during

an ABS cycle. This stored fluid is used by the pump/

motor to provide build pressure for the brake hydrau-

lic system. When the antilock stop is complete, the

accumulators are drained by the pump/motor.

On ABS-only vehicles, there is a mini-accumulator

on the secondary hydraulic circuit that protects the

master cylinder seals during an ABS stop, and there

is a noise dampening chamber on the primary circuit.

On ABS with traction control vehicles, there are

two noise dampening chambers in the HCU.

PUMP/MOTOR

There are two pump assemblies in the HCUÐone

for the primary hydraulic circuit and one for the sec-

ondary hydraulic circuit. Both pumps are driven by a

common electric motor. This DC-type motor is inte-

gral to the HCU and is controlled by the CAB.

The pump/motor provides the extra amount of

brake fluid needed during antilock braking. Brake

fluid is released to the accumulators when the outlet

valve is opened during an antilock stop. The pump

mechanism consists of two opposing pistons operated

by an eccentric camshaft. In operation, one piston

draws fluid from the accumulators, and the opposing

piston pumps fluid to the master cylinder circuits.

When the antilock stop is complete, the pump/motor

drains the accumulators.

The CAB may turn on the pump/motor when an

antilock stop is detected. The pump/motor continues

to run during the antilock stop and is turned off after

the stop is complete. Under some conditions, the

pump/motor runs to drain the accumulators during

the next drive-off.

The pump/motor is not a serviceable item; if it

requires replacement, the HCU must be replaced.

RSBRAKES - ABS5 - 101

HCU (HYDRAULIC CONTROL UNIT) (Continued)

Page 213 of 2339

ICU (INTEGRATED CONTROL

UNIT)

DESCRIPTION

The hydraulic control unit (HCU) and the control-

ler antilock brake (CAB) used with this antilock

brake system are combined (integrated) into one

unit, which is called the integrated control unit (ICU)

(Fig. 12). The ICU is located below the master cylin-

der in the engine compartment (Fig. 13).

Two different ICU's (HCU and CAB) are used on

this vehicle depending on whether or not the vehicle

is equipped with traction control. The HCU on avehicle equipped with traction control has a valve

block that is approximately one inch longer than a

HCU on a vehicle that is equipped with ABS only.

The ABS-only ICU consists of the following compo-

nents: the CAB, eight (build/decay) solenoid valves

(four inlet valves and four outlet valves), valve block,

fluid accumulators, a pump, and an electric motor.

The ABS-with traction control ICU consists of the

following components: the CAB, eight (build/decay)

solenoid valves (four inlet valves and four outlet

valves), two traction control (ASR) valves, two

hydraulic shuttle valves, valve block, fluid accumula-

tors, a pump, and an electric motor.

The replaceable components of the ICU are the

HCU and the CAB. No attempt should be made to

service any individual components of the HCU or

CAB. For information on the CAB, (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/CONTROLLER ANTILOCK BRAKE -

DESCRIPTION).

OPERATION

For information of the ICU, refer to these individ-

ual components of the ICU:

²CONTROLLER ANTILOCK BRAKE (CAB)

(Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/CONTROLLER ANTILOCK

BRAKE - OPERATION)

²HYDRAULIC CONTROL UNIT (HCU) (Refer to

5 - BRAKES - ABS/HYDRAULIC/MECHANICAL/

HCU (HYDRAULIC CONTROL UNIT) - OPERA-

TION)

For information on the ICU's hydraulic circuits,

refer to HYDRAULIC CIRCUITS AND VALVE

OPERATION. (Refer to 5 - BRAKES - ABS/HY-

DRAULIC/MECHANICAL - OPERATION)

REMOVAL

REMOVAL - LHD

(1) Disconnect the negative (ground) cable from

the battery and isolate cable.

(2) Remove the battery shield.

(3) Remove the battery (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - REMOVAL).

(4) Disconnect the vacuum hose connector at the

tank built into the battery tray.

(5) Remove the screw securing the engine coolant

filler neck to the battery tray.

(6) Remove the battery tray (Refer to 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - REMOVAL).

(7) Using a brake pedal depressor, move and lock

the brake pedal to a position past the first inch of

pedal travel.This will prevent brake fluid from

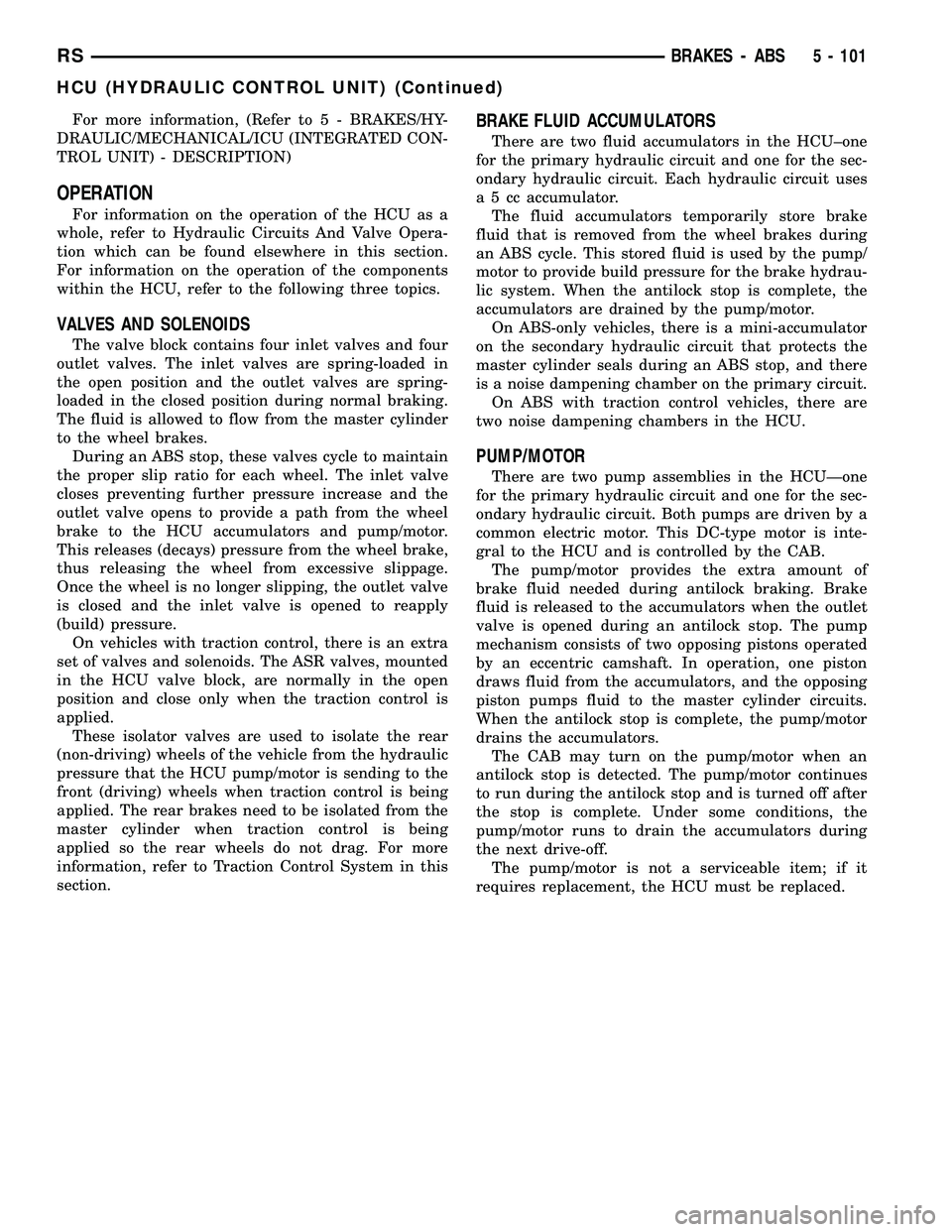

Fig. 12 INTEGRATED CONTROL UNIT (ICU)

1 - PUMP/MOTOR

2 - HCU

3 - PUMP/MOTOR CONNECTOR

4 - CAB

Fig. 13 ICU LOCATION IN VEHICLE

1 - POWER BRAKE BOOSTER

2 - MASTER CYLINDER

3 - ICU

5 - 102 BRAKES - ABSRS

Page 214 of 2339

draining out of the master cylinder once the

brake tubes are removed from the HCU.

CAUTION: Do not apply a 12±volt power source to

any terminals of the 24-way CAB connector when

disconnected.

(8) Disconnect the wiring harness connector from

the speed control servo.

(9) Remove the speed control servo mounting nuts

and move the servo out of the way.

(10) Disconnect the 24±way connector from the

CAB. To disconnect the 24±way connector, grasp the

lock on the 24±way connector and pull it as far up as

possible. This will unlock the 24±way connector from

the socket on the CAB.

CAUTION: Before removing the brake tubes from

the HCU, the HCU must be thoroughly cleaned. This

must be done to prevent dirt particles from falling

into the ports of HCU or entering the brake tubes.

(11) Thoroughly clean all surfaces of the ICU and

brake tube nuts. Use only a solvent such as Mopart

Brake Parts Cleaner or equivalent to clean the ICU.

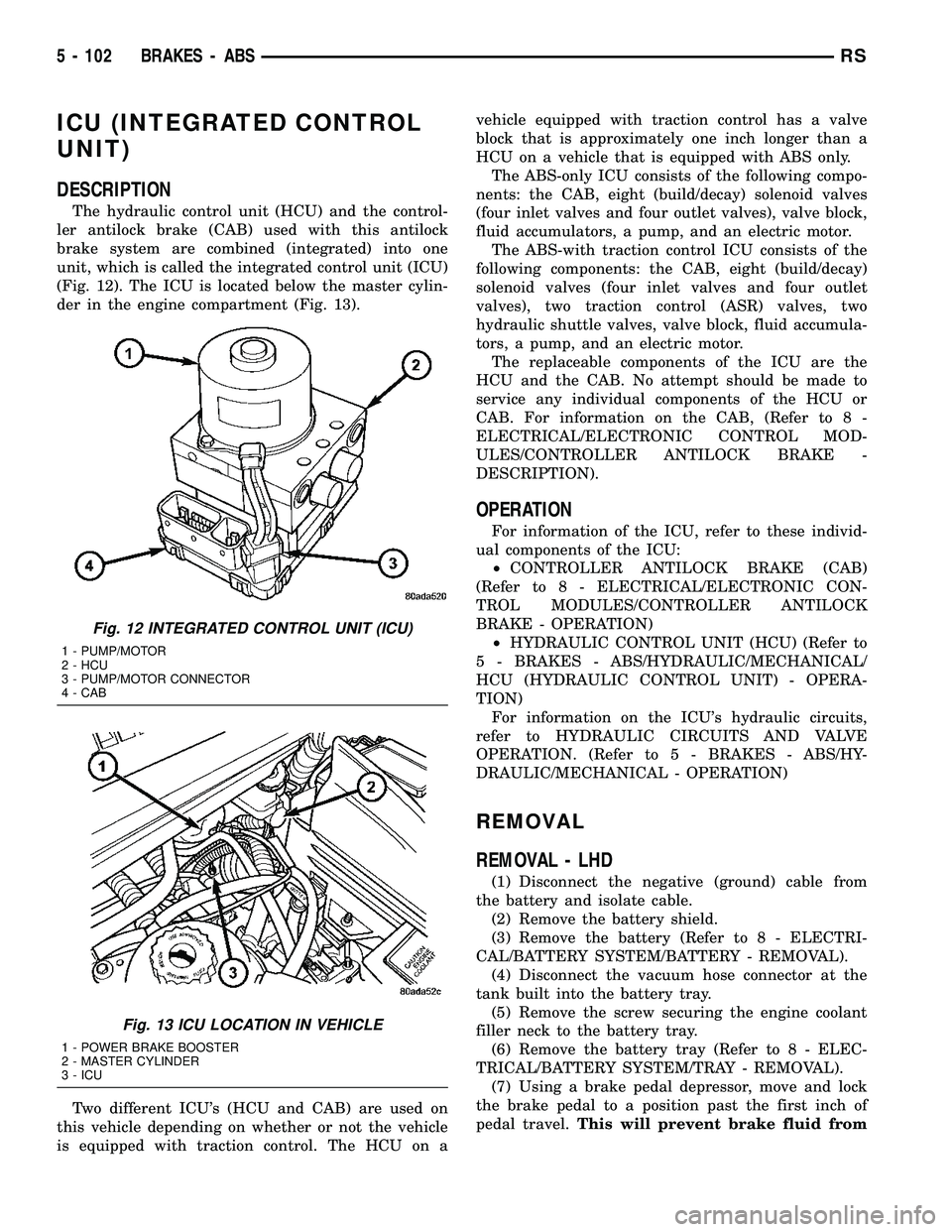

(12) Remove the brake tubes (4) from the outlet

ports on the HCU (Fig. 14).

(13) Remove the primary and secondary brake

tubes from the inlet ports on the HCU (Fig. 14).

(14) Center and prop the steering wheel.

(15) Remove the pinch bolt and disconnect the

steering shaft coupling.

(16) If equipped, remove the two clips securing

silencer to dash seal (Fig. 15). Remove silencer.

(17) Remove the three screws securing the dash

seal (Fig. 15). Remove seal.(18) Remove the 3 bolts attaching the ICU to its

mounting bracket (Fig. 16).

(19) Remove ICU from the vehicle through engine

compartment.

(20) If required, to separating the CAB from the

HCU, (Refer to 5 - BRAKES - ABS/HYDRAULIC/ME-

Fig. 14 Brake Tube Nuts At ICU

1 - PRIMARY BRAKE TUBE

2 - SECONDARY BRAKE TUBE

3 - CHASSIS BRAKE TUBES

Fig. 15 Lower Coupling And Dash Seal

1 - COUPLING

2 - DASH SEAL

3 - SILENCER

4 - MOUNTING SCREWS

5 - RETAINING CLIPS

6 - DASH

Fig. 16 ICU Mounting Bolts

1 - ICU MOUNTING BOLTS

2 - COUPLER

RSBRAKES - ABS5 - 103

ICU (INTEGRATED CONTROL UNIT) (Continued)

Page 215 of 2339

CHANICAL/ICU (INTEGRATED CONTROL UNIT) -

DISASSEMBLY).

REMOVAL - RHD

NOTE: Before proceeding, (Refer to 5 - BRAKES -

WARNING)(Refer to 5 - BRAKES - CAUTION)

(1) Disconnect the negative (ground) cable from

the battery and isolate cable.

(2) Using a brake pedal depressor, move and lock

the brake pedal to a position past the first inch of

pedal travel.This will prevent brake fluid from

draining out of the master cylinder when the

brake tubes are removed from the HCU.

(3) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

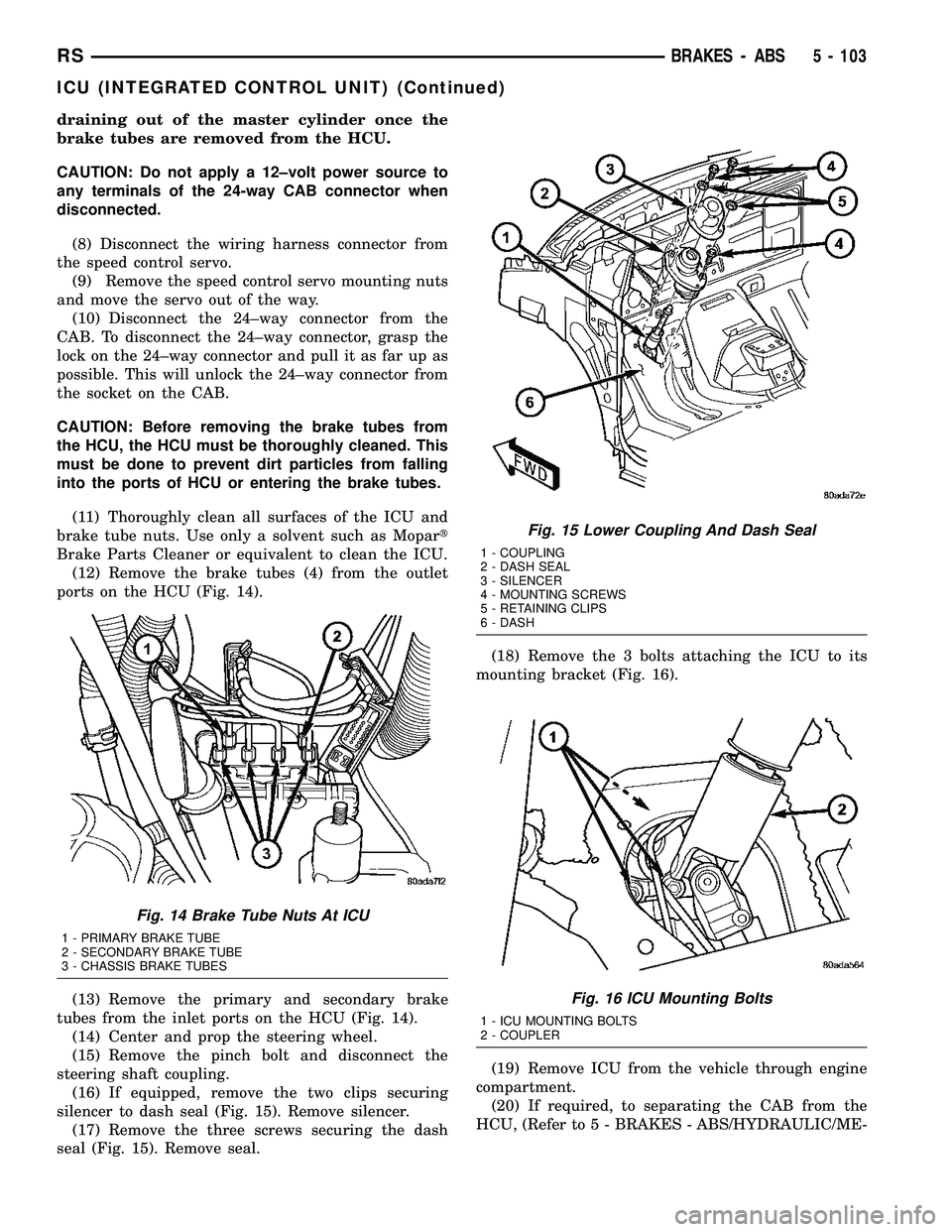

(4) Remove the routing clip attaching the ICU wir-

ing harness to the ICU mounting bracket (Fig. 17).

CAUTION: Do not apply a 12 volt power source to

any terminals of the HCU connector when discon-

nected.

(5) Remove the 24-way connector (Fig. 17) from

the CAB. The 24-way connector is removed from the

CAB using the following procedure. Grasp the lock

on the 24-way connector (Fig. 17) and pull it as far

out as possible (Fig. 18). This will raise and unlock

the 24-way connector from the socket on the CAB.

CAUTION: Before removing the brake tubes from

the HCU, the HCU must be thoroughly cleaned. Thismust be done to prevent dirt particles from falling

into the ports of HCU or entering the brake tubes.

(6) Thoroughly clean all surfaces of the HCU, and

all brake tube nuts located on the HCU. Use only a

solvent such as Mopar Brake Parts Cleaner or an

equivalent to clean the HCU.

(7) Remove the brake tubes (6) from the inlet and

outlet ports on the HCU. (Fig. 19).

Fig. 17 CAB 24-Way Connector

1 - CAB WIRING HARNESS

2 - 24±WAY CONNECTOR

3 - FLOOR PAN

4 - HCU

5 - CAB

6 - HCU MOUNTING BRACKET

7 - CONNECTOR LOCK

Fig. 18 Unlocked 24-Way CAB Connector

1 - HCU

2 - CAB

3 - 24±WAY CONNECTOR

4 - CONNECTOR LOCK (UNLOCKED)

Fig. 19 Brake Tube Connections To HCU

1 - LEFT REAR WHEEL BRAKE TUBE

2 - SECONDARY BRAKE TUBE FROM MASTER CYLINDER

3 - LEFT FRONT WHEEL BRAKE TUBE

4 - CAB

5 - RIGHT REAR WHEEL BRAKE TUBE

6 - HCU MOUNTING BRACKET

7 - BRAKE TUBE TO HCU CONNECTION LOCATION LEGEND

8 - RIGHT FRONT WHEEL BRAKE TUBE

9 - PRIMARY BRAKE TUBE FROM MASTER CYLINDER

5 - 104 BRAKES - ABSRS

ICU (INTEGRATED CONTROL UNIT) (Continued)

Page 216 of 2339

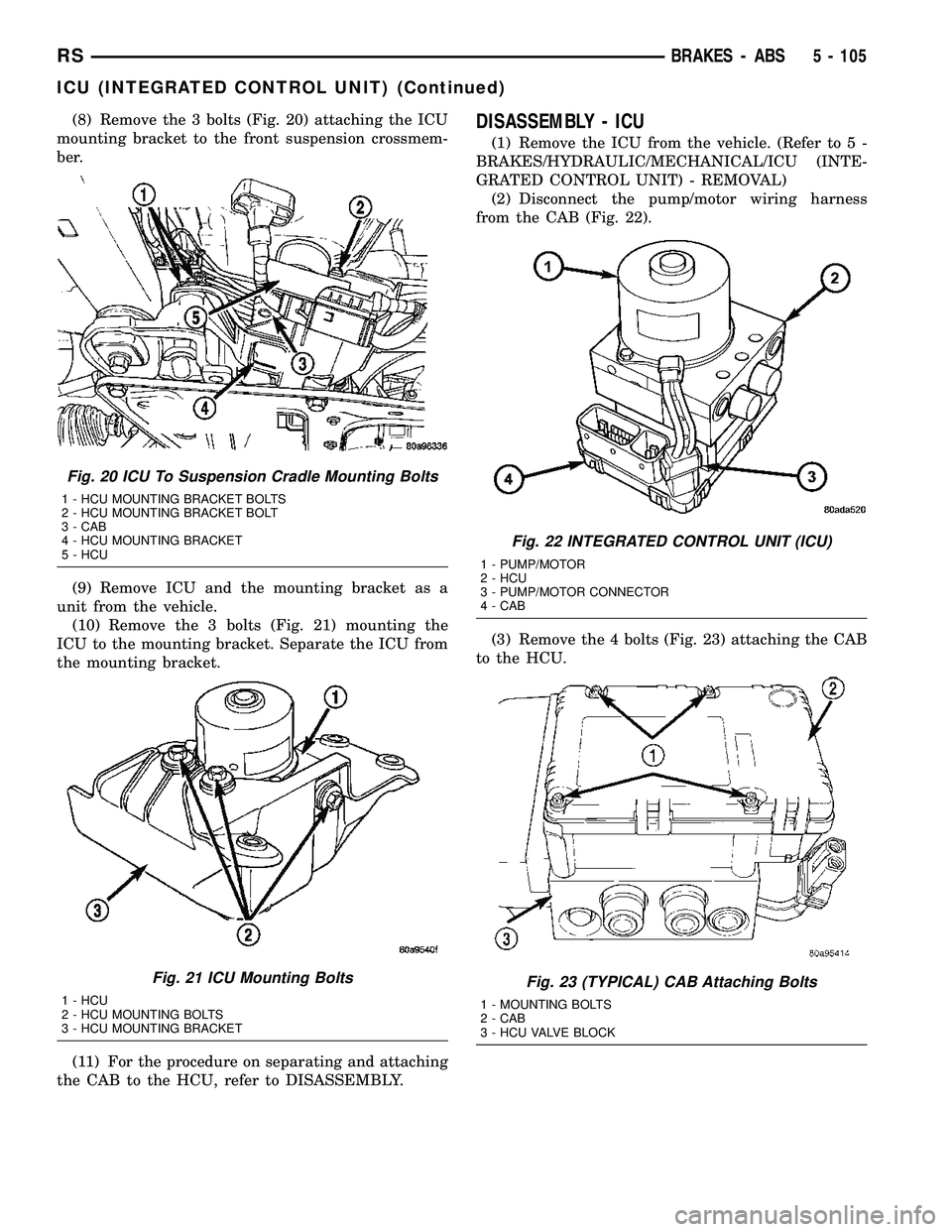

(8) Remove the 3 bolts (Fig. 20) attaching the ICU

mounting bracket to the front suspension crossmem-

ber.

(9) Remove ICU and the mounting bracket as a

unit from the vehicle.

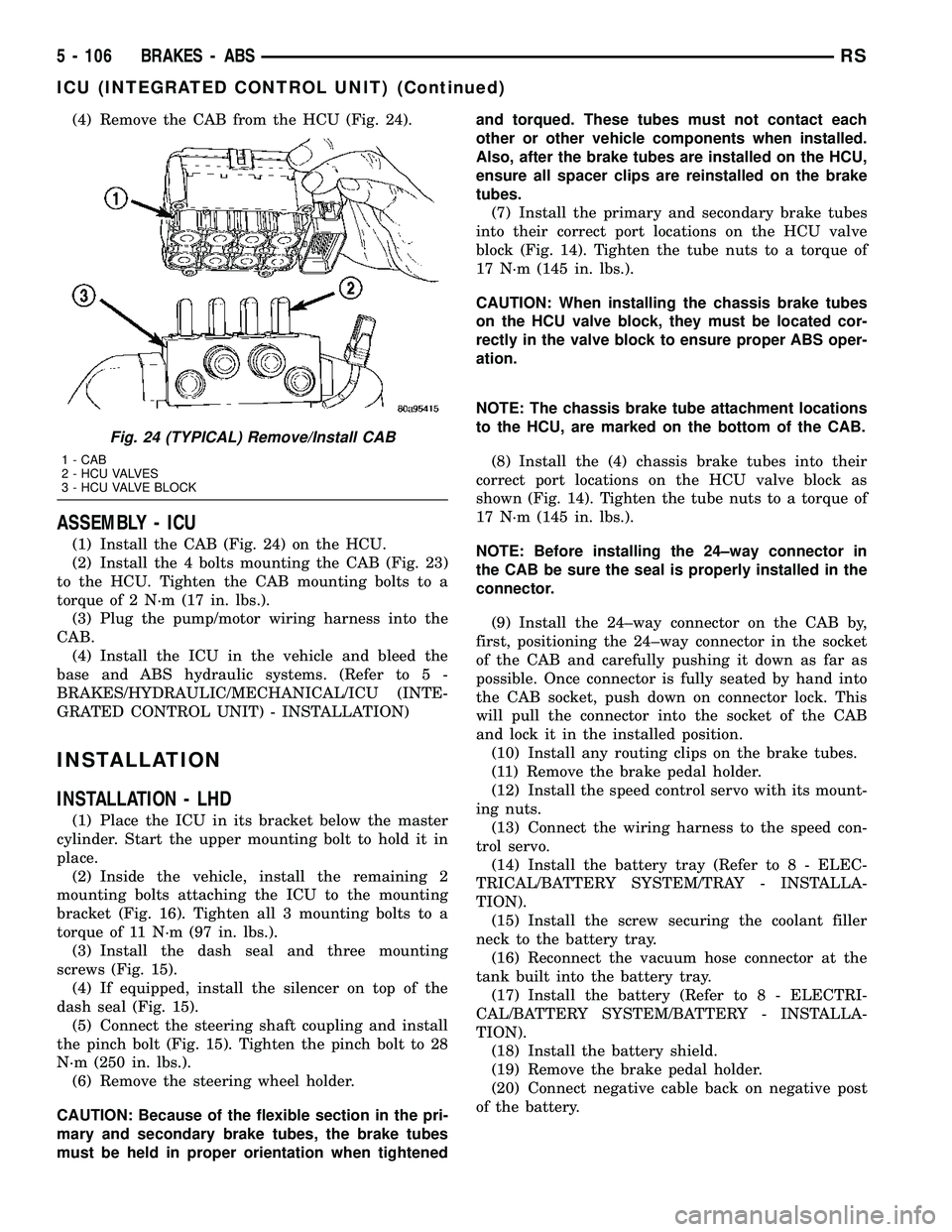

(10) Remove the 3 bolts (Fig. 21) mounting the

ICU to the mounting bracket. Separate the ICU from

the mounting bracket.

(11) For the procedure on separating and attaching

the CAB to the HCU, refer to DISASSEMBLY.DISASSEMBLY - ICU

(1) Remove the ICU from the vehicle. (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ICU (INTE-

GRATED CONTROL UNIT) - REMOVAL)

(2) Disconnect the pump/motor wiring harness

from the CAB (Fig. 22).

(3) Remove the 4 bolts (Fig. 23) attaching the CAB

to the HCU.

Fig. 20 ICU To Suspension Cradle Mounting Bolts

1 - HCU MOUNTING BRACKET BOLTS

2 - HCU MOUNTING BRACKET BOLT

3 - CAB

4 - HCU MOUNTING BRACKET

5 - HCU

Fig. 21 ICU Mounting Bolts

1 - HCU

2 - HCU MOUNTING BOLTS

3 - HCU MOUNTING BRACKET

Fig. 22 INTEGRATED CONTROL UNIT (ICU)

1 - PUMP/MOTOR

2 - HCU

3 - PUMP/MOTOR CONNECTOR

4 - CAB

Fig. 23 (TYPICAL) CAB Attaching Bolts

1 - MOUNTING BOLTS

2 - CAB

3 - HCU VALVE BLOCK

RSBRAKES - ABS5 - 105

ICU (INTEGRATED CONTROL UNIT) (Continued)

Page 217 of 2339

(4) Remove the CAB from the HCU (Fig. 24).

ASSEMBLY - ICU

(1) Install the CAB (Fig. 24) on the HCU.

(2) Install the 4 bolts mounting the CAB (Fig. 23)

to the HCU. Tighten the CAB mounting bolts to a

torque of 2 N´m (17 in. lbs.).

(3) Plug the pump/motor wiring harness into the

CAB.

(4) Install the ICU in the vehicle and bleed the

base and ABS hydraulic systems. (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ICU (INTE-

GRATED CONTROL UNIT) - INSTALLATION)

INSTALLATION

INSTALLATION - LHD

(1) Place the ICU in its bracket below the master

cylinder. Start the upper mounting bolt to hold it in

place.

(2) Inside the vehicle, install the remaining 2

mounting bolts attaching the ICU to the mounting

bracket (Fig. 16). Tighten all 3 mounting bolts to a

torque of 11 N´m (97 in. lbs.).

(3) Install the dash seal and three mounting

screws (Fig. 15).

(4) If equipped, install the silencer on top of the

dash seal (Fig. 15).

(5) Connect the steering shaft coupling and install

the pinch bolt (Fig. 15). Tighten the pinch bolt to 28

N´m (250 in. lbs.).

(6) Remove the steering wheel holder.

CAUTION: Because of the flexible section in the pri-

mary and secondary brake tubes, the brake tubes

must be held in proper orientation when tightenedand torqued. These tubes must not contact each

other or other vehicle components when installed.

Also, after the brake tubes are installed on the HCU,

ensure all spacer clips are reinstalled on the brake

tubes.

(7) Install the primary and secondary brake tubes

into their correct port locations on the HCU valve

block (Fig. 14). Tighten the tube nuts to a torque of

17 N´m (145 in. lbs.).

CAUTION: When installing the chassis brake tubes

on the HCU valve block, they must be located cor-

rectly in the valve block to ensure proper ABS oper-

ation.

NOTE: The chassis brake tube attachment locations

to the HCU, are marked on the bottom of the CAB.

(8) Install the (4) chassis brake tubes into their

correct port locations on the HCU valve block as

shown (Fig. 14). Tighten the tube nuts to a torque of

17 N´m (145 in. lbs.).

NOTE: Before installing the 24±way connector in

the CAB be sure the seal is properly installed in the

connector.

(9) Install the 24±way connector on the CAB by,

first, positioning the 24±way connector in the socket

of the CAB and carefully pushing it down as far as

possible. Once connector is fully seated by hand into

the CAB socket, push down on connector lock. This

will pull the connector into the socket of the CAB

and lock it in the installed position.

(10) Install any routing clips on the brake tubes.

(11) Remove the brake pedal holder.

(12) Install the speed control servo with its mount-

ing nuts.

(13) Connect the wiring harness to the speed con-

trol servo.

(14) Install the battery tray (Refer to 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - INSTALLA-

TION).

(15) Install the screw securing the coolant filler

neck to the battery tray.

(16) Reconnect the vacuum hose connector at the

tank built into the battery tray.

(17) Install the battery (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - INSTALLA-

TION).

(18) Install the battery shield.

(19) Remove the brake pedal holder.

(20) Connect negative cable back on negative post

of the battery.

Fig. 24 (TYPICAL) Remove/Install CAB

1 - CAB

2 - HCU VALVES

3 - HCU VALVE BLOCK

5 - 106 BRAKES - ABSRS

ICU (INTEGRATED CONTROL UNIT) (Continued)

Page 218 of 2339

(21) Bleed the Base and ABS brake hydraulic sys-

tems (Refer to 5 - BRAKES - STANDARD PROCE-

DURE).

(22) Road test vehicle to ensure proper operation

of the base and antilock brake systems.

INSTALLATION - RHD

(1) Install the ICU on the mounting bracket (Fig.

21). Install the 3 bolts (Fig. 21) attaching the ICU to

the mounting bracket. Tighten the 3 mounting bolts

to a torque of 11 N´m (97 in. lbs.).

CAUTION: The ICU mounting bracket to front sus-

pension cradle mounting bolts have a unique corro-

sion protection coating and a special aluminum

washer. For this reason, only the original, or origi-

nal equipment Mopar replacement bolts can be

used to mount the ICU bracket to the front suspen-

sion crossmember.

(2) Install the ICU and its mounting bracket as an

assembly on the front suspension crossmember.

Install the 3 bolts attaching the ICU bracket to the

crossmember (Fig. 20). Tighten the 3 mounting bolts

to a torque of 28 N´m (250 in. lbs.).

CAUTION: Because of the flexible section in the pri-

mary and secondary brake tubes, and the brake

tubes between the HCU and the proportioning

valve, the brake tubes must be held in proper ori-

entation when tightened and torqued. These tubes

must not contact each other or other vehicle com-

ponents when installed. Also, after the brake tubes

are installed on the HCU, ensure all spacer clips are

reinstalled on the brake tubes.

CAUTION: When installing the chassis brake tubes

on the HCU valve block, they must be located cor-

rectly in the valve block to ensure proper ABS oper-

ation. Refer to (Fig. 19) for the correct chassis

brake tube locations.

NOTE: The chassis brake tube attachment locations

to the HCU, are marked on the bottom of the ICU

mounting bracket.

(3) Install the 6 chassis brake tubes into their cor-

rect port locations on the HCU valve block as shown

in (Fig. 19). Tighten the tube nuts to a torque of 17

N´m (145 in. lbs.).

NOTE: Before installing the 24-way connector in the

CAB be sure the seal is properly installed in the

connector.(4) Install the 24-way connector (Fig. 17) on the

CAB using the following procedure. Position the

24-way connector in the socket of the CAB and care-

fully push it down as far as possible. When connector

is fully seated by hand into the CAB socket, push in

the connector lock (Fig. 18). This will pull the connec-

tor into the socket of the CAB and lock it in the

installed position.

NOTE: The CAB wiring harness must be clipped to

the ICU mounting bracket. This will ensure the wir-

ing harness is properly routed and does not contact

the brake tubes or the body of the vehicle.

(5) Clip the cab wiring harness (Fig. 17) to the

ICU mounting bracket.

(6) Install the routing clips (Fig. 25) on the brake

tubes.

(7) Lower the vehicle.

(8) Connect negative cable back on negative post of

the battery.

(9) Bleed the base and ABS hydraulic systems.

(Refer to 5 - BRAKES - STANDARD PROCEDURE)

(10) Road test vehicle to ensure proper operation

of the base and antilock brake systems.

Fig. 25 Brake Tube Routing Clips

1 - ROUTING CLIP

2 - HCU

3 - BRAKE TUBES

4 - ROUTING CLIP

RSBRAKES - ABS5 - 107

ICU (INTEGRATED CONTROL UNIT) (Continued)

Page 222 of 2339

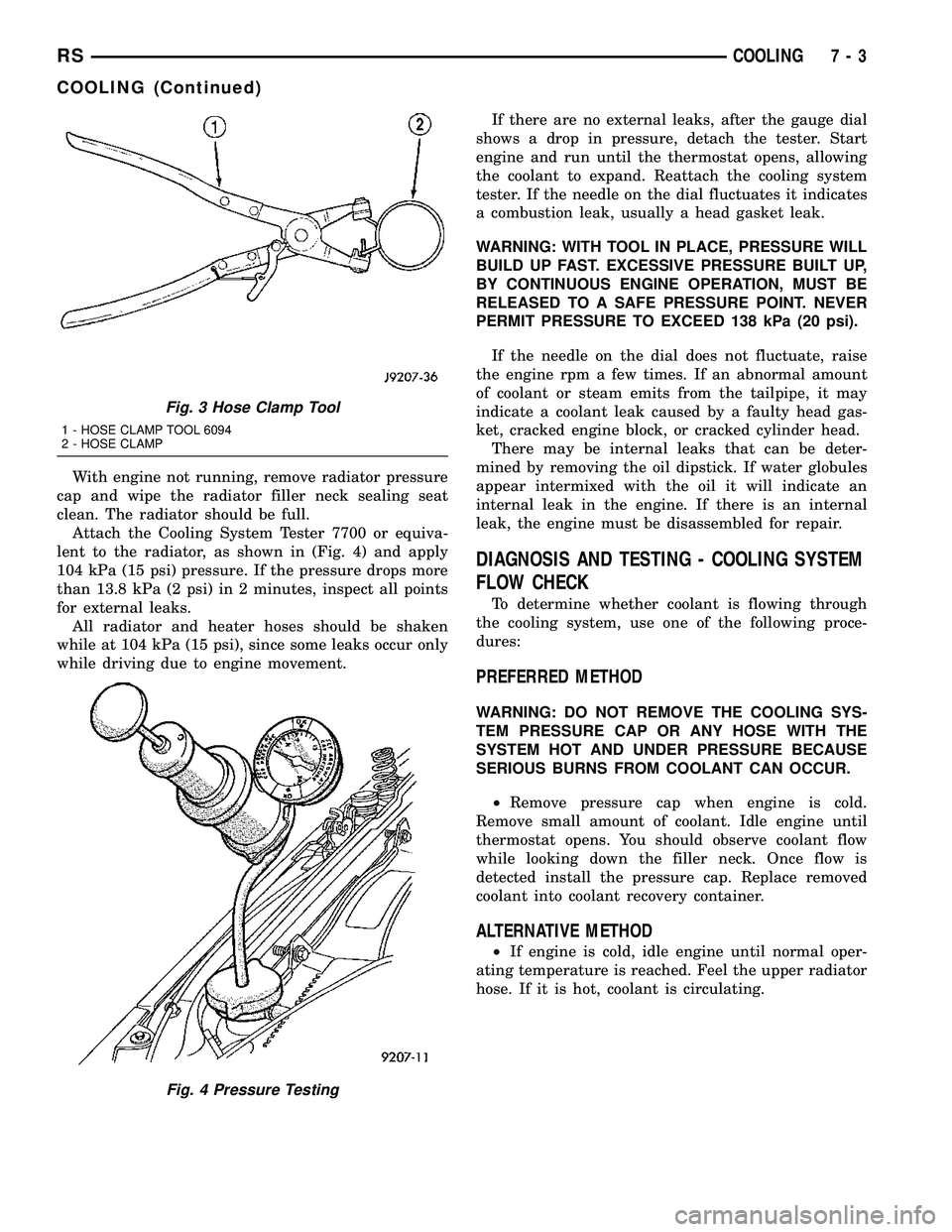

With engine not running, remove radiator pressure

cap and wipe the radiator filler neck sealing seat

clean. The radiator should be full.

Attach the Cooling System Tester 7700 or equiva-

lent to the radiator, as shown in (Fig. 4) and apply

104 kPa (15 psi) pressure. If the pressure drops more

than 13.8 kPa (2 psi) in 2 minutes, inspect all points

for external leaks.

All radiator and heater hoses should be shaken

while at 104 kPa (15 psi), since some leaks occur only

while driving due to engine movement.If there are no external leaks, after the gauge dial

shows a drop in pressure, detach the tester. Start

engine and run until the thermostat opens, allowing

the coolant to expand. Reattach the cooling system

tester. If the needle on the dial fluctuates it indicates

a combustion leak, usually a head gasket leak.

WARNING: WITH TOOL IN PLACE, PRESSURE WILL

BUILD UP FAST. EXCESSIVE PRESSURE BUILT UP,

BY CONTINUOUS ENGINE OPERATION, MUST BE

RELEASED TO A SAFE PRESSURE POINT. NEVER

PERMIT PRESSURE TO EXCEED 138 kPa (20 psi).

If the needle on the dial does not fluctuate, raise

the engine rpm a few times. If an abnormal amount

of coolant or steam emits from the tailpipe, it may

indicate a coolant leak caused by a faulty head gas-

ket, cracked engine block, or cracked cylinder head.

There may be internal leaks that can be deter-

mined by removing the oil dipstick. If water globules

appear intermixed with the oil it will indicate an

internal leak in the engine. If there is an internal

leak, the engine must be disassembled for repair.

DIAGNOSIS AND TESTING - COOLING SYSTEM

FLOW CHECK

To determine whether coolant is flowing through

the cooling system, use one of the following proce-

dures:

PREFERRED METHOD

WARNING: DO NOT REMOVE THE COOLING SYS-

TEM PRESSURE CAP OR ANY HOSE WITH THE

SYSTEM HOT AND UNDER PRESSURE BECAUSE

SERIOUS BURNS FROM COOLANT CAN OCCUR.

²Remove pressure cap when engine is cold.

Remove small amount of coolant. Idle engine until

thermostat opens. You should observe coolant flow

while looking down the filler neck. Once flow is

detected install the pressure cap. Replace removed

coolant into coolant recovery container.

ALTERNATIVE METHOD

²If engine is cold, idle engine until normal oper-

ating temperature is reached. Feel the upper radiator

hose. If it is hot, coolant is circulating.

Fig. 3 Hose Clamp Tool

1 - HOSE CLAMP TOOL 6094

2 - HOSE CLAMP

Fig. 4 Pressure Testing

RSCOOLING7-3

COOLING (Continued)

Page 223 of 2339

DIAGNOSIS AND TESTING - COOLING SYSTEM

AERATION

Low coolant level in a cross flow radiator will

equalize in both tanks with engine off. With engine

at running and at operating temperature, the high

pressure inlet tank runs full and the low pressure

outlet tank drops, resulting in cooling system aera-

tion. Aeration will draw air into the water pump

resulting in the following:

²High reading shown on the temperature gauge.

²Loss of coolant flow through the heater core.

²Corrosion in the cooling system.

²Water pump seal may run dry, increasing the

risk of premature seal failure.

²Combustion gas leaks into the coolant can also

cause the above problems.

DIAGNOSIS AND TESTING - COOLING SYSTEM

DEAERATION

Air can only be removed from the system by gath-

ering under the pressure cap. On the next heat up it

will be pushed past the pressure cap into the coolant

recovery bottle by thermal expansion of the coolant.

It then escapes to the atmosphere in the coolant

recovery bottle and is replaced with coolant on cool

down.

To effectively deaerate the system, multiple ther-

mal cycles of the system may be required.

NOTE: Deaeration does not occur at engine idleÐ

higher engine speeds are required. Normal driving

will deaerate cooling system.

STANDARD PROCEDURE

STANDARD PROCEDURE - COOLING SYSTEM

DRAINING

WARNING: DO NOT REMOVE OR LOOSEN THE

COOLANT PRESSURE CAP, CYLINDER BLOCK

DRAIN PLUGS, OR THE DRAINCOCK WHEN THE

SYSTEM IS HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM THE COOLANT

CAN OCCUR.

(1)Without removing radiator pressure cap

and with system not under pressure, using a

screwdriver, open the draincock. The draincock is

located on the lower left side of radiator.

(2) After the coolant recovery/reserve container is

empty, then remove coolant pressure cap (Fig. 5).

(3) Remove the cylinder block drain plug(s).

STANDARD PROCEDURE - COOLING SYSTEM

FILLING

Remove radiator pressure cap (Fig. 5) and fill sys-

tem, using a 50/50 mix of MopartAntifreeze/Coolant,

5 Year/100,000 Mile Formula and distilled water.

Continue filling system until full.Be careful not

to spill coolant on drive belts or the generator.

For cooling system capacity, (Refer to LUBRICATION

& MAINTENANCE/FLUID CAPACITIES - SPECIFI-

CATIONS).

Fill coolant recovery/reserve container (Fig. 5) to at

least the MAX mark with 50/50 solution. It may be

necessary to add coolant to the recovery/reserve con-

tainer after three or four warm up/cool down cycles

to maintain coolant level between the MAX and MIN

mark. This will allow trapped air to be removed from

the system.

STANDARD PROCEDURE - ADDING

ADDITIONAL COOLANT

The radiator cap should not be removed.

When additional coolant is needed to maintain this

level, it should be added to the coolant recovery/re-

serve container (Fig. 5). Use only 50/50 mix of ethyl-

ene glycol type antifreeze and distilled water. For the

recommeded antifreeze/coolant type (Refer to LUBRI-

CATION & MAINTENANCE/FLUID TYPES -

DESCRIPTION).

CAUTION: Do not use well water, or suspect water

supply in cooling system. A 50/50 ethylene glycol

and distilled water mix is recommended. For the

recommeded antifreeze/coolant type (Refer to

LUBRICATION & MAINTENANCE/FLUID TYPES -

DESCRIPTION).

STANDARD PROCEDURE - COOLANT LEVEL

CHECK

NOTE: Do not remove radiator cap for routine cool-

ant level inspections.

The coolant reserve system provides a quick visual

method for determining the coolant level without

removing the radiator cap.With the engine cold

and not running,simply observe the level of the

coolant in the recovery/reserve container (Fig. 5). The

coolant level should be between the MIN and MAX

marks.

7 - 4 COOLINGRS

COOLING (Continued)