heater CHRYSLER VOYAGER 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 2213 of 2339

INSTALLATION

NOTE: If the rear heater core or the rear HVAC

housing have been removed from the vehicle for

service, the rear heater core may be pre-filled with

the proper engine coolant mixture prior to recon-

necting the heater hoses to the heater core hose fit-

tings (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - REAR/HEATER CORE - STANDARD

PROCEDURE - HEATER CORE FILLING).

(1) Position the rear HVAC housing into the vehi-

cle with the evaporator extension line sealing plate

inserted into the rectangular hole in the rear floor

panel behind the right rear wheel house.

(2) Align the rear HVAC housing lower mounting

studs with the holes in the rear floor panel and lower

the rear HVAC housing to the floor.

(3) Install the screw that secures the front of the

rear HVAC housing to the right quarter inner panel.

Tighten the screw to 11 N´m (97 in. lbs.).(4) Install the screw that secures the back of the

rear HVAC housing to the right D-pillar. Tighten the

screw to 11 N´m (97 in. lbs.).

(5) Remove the plugs or tape from both heater core

fittings and both heater hoses.

(6) Reconnect the heater hoses to the rear heater

core (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - REAR/HEATER HOSE - INSTAL-

LATION).

(7) Reinstall the rear floor heat duct onto the right

quarter inner panel (Refer to 24 - HEATING & AIR

CONDITIONING/DISTRIBUTION/REAR FLOOR

HEAT DUCT - INSTALLATION).

(8) Install the two screws that secure the bottom

of the quarter trim panel attaching bracket to the

rear HVAC housing. Tighten the screws to 2 N´m (17

in. lbs.).

(9) Install and tighten the two screws that secure

the top of the quarter trim panel attaching bracket to

the quarter inner panel.

Fig. 8 Rear HVAC Housing ± Typical

1 - U-NUT (3)

2 - REAR HVAC HOUSING

3 - SCREW (3)

4 - EXPANSION VALVE5 - STUD (2 w/NSE, 3 wo/NSE)

6 - HEATER LINES

7 - NUT (5)

8 - STUD (2)

24 - 62 DISTRIBUTION - REARRS

HVAC HOUSING (Continued)

Page 2215 of 2339

PLUMBING - FRONT

TABLE OF CONTENTS

page page

PLUMBING - FRONT

DESCRIPTION.........................65

OPERATION...........................65

WARNING

ENGINE COOLING SYSTEM.............65

A/C SYSTEM.........................66

CAUTION - A/C SYSTEM.................66

DIAGNOSIS AND TESTING

REFRIGERANT SYSTEM LEAKS..........67

SYSTEM CHARGE LEVEL TEST..........67

STANDARD PROCEDURE

HANDLING TUBING AND FITTINGS.......69

REFRIGERANT SYSTEM SERVICE

EQUIPMENT.........................69

REFRIGERANT SYSTEM RECOVERY......70

REFRIGERANT SYSTEM EVACUATE......70

REFRIGERANT SYSTEM CHARGE........71

A/C COMPRESSOR

DESCRIPTION

A/C COMPRESSOR....................72

HIGH PRESSURE RELIEF VALVE.........72

OPERATION

A/C COMPRESSOR....................72

HIGH PRESSURE RELIEF VALVE.........72

DIAGNOSIS AND TESTING

A/C COMPRESSOR NOISE DIAGNOSIS....72

REMOVAL

A/C COMPRESSOR....................73

A/C COMPRESSOR MOUNTING BRACKET -

2.4L ENGINE.........................74

INSTALLATION

A/C COMPRESSOR....................74

A/C COMPRESSOR MOUNTING BRACKET -

2.4L ENGINE.........................75

A/C CONDENSER

DESCRIPTION.........................75

OPERATION...........................75

REMOVAL

2.4L/3.3L/3.8L ENGINES................76

2.5L/2.8L DIESEL ENGINES..............77

INSTALLATION

2.4L/3.3L/3.8L ENGINES................77

2.5L/2.8L DIESEL ENGINES..............78

A/C DISCHARGE LINE

REMOVAL.............................79

INSTALLATION.........................80

A/C EVAPORATOR

DESCRIPTION.........................80OPERATION...........................80

REMOVAL.............................81

INSTALLATION.........................81

EXPANSION VALVE

DESCRIPTION.........................81

OPERATION...........................81

DIAGNOSIS AND TESTING

FRONT A/C EXPANSION VALVE..........82

REMOVAL.............................82

INSTALLATION.........................83

HEATER CORE

DESCRIPTION.........................83

OPERATION...........................84

REMOVAL

FRONT HEATER CORE TUBES...........84

FRONT HEATER CORE.................85

INSTALLATION

FRONT HEATER CORE TUBES...........85

FRONT HEATER CORE.................86

HEATER INLET HOSE

REMOVAL.............................86

INSTALLATION.........................87

HEATER RETURN HOSE

REMOVAL.............................88

INSTALLATION.........................89

LIQUID LINE

REMOVAL.............................89

INSTALLATION.........................91

RECEIVER / DRIER

DESCRIPTION.........................92

OPERATION...........................92

REMOVAL.............................92

INSTALLATION.........................93

REFRIGERANT

DESCRIPTION.........................93

OPERATION...........................94

REFRIGERANT OIL

DESCRIPTION.........................94

OPERATION...........................94

STANDARD PROCEDURE

REFRIGERANT OIL LEVEL..............94

SERVICE PORT VALVE CORE

DESCRIPTION.........................95

REMOVAL.............................95

INSTALLATION.........................95

SUCTION LINE

REMOVAL.............................96

INSTALLATION.........................97

24 - 64 PLUMBING - FRONTRS

Page 2216 of 2339

PLUMBING - FRONT

DESCRIPTION

CAUTION: The system must be completely empty

before opening any fitting or connection in the

refrigeration system. Open fittings with caution

even after the system has been emptied. If any

pressure is noticed as a fitting is loosened,

retighten fitting and evacuate the system again.

The use of correct wrenches when making connec-

tions is very important. Improper wrenches or

improper use of wrenches can damage the fittings.

The internal parts of the A/C system will remain sta-

ble as long as moisture-free refrigerant and refrig-

erant oil is used. Abnormal amounts of dirt,

moisture or air can upset the chemical stability.

This may cause operational troubles or even seri-

ous damage if present in more than very small

quantities. Before disconnecting a refrigerant line

or hose, clean the outside of the fittings thoroughly

to prevent contamination from entering the refriger-

ant system.

When opening a refrigeration system, have every-

thing you will need to repair the system ready to

minimize the amount of time the system is opened.

Cap or plug all refrigerant line fittings as soon as

they are opened. This will help prevent the entrance

of dirt and moisture. All new lines and components

should be capped or sealed until they are ready to

be used. Before connecting a refrigerant line or

hose, clean the outside of the fittings thoroughly to

prevent contamination from entering the refrigerant

system.

All tools, including the refrigerant dispensing mani-

fold, manifold gauge set and test hoses should be

kept clean and dry.

The A/C refrigerant lines and hoses are used to

carry the refrigerant between the various A/C system

components. The refrigerant lines and hoses for the

R-134a system on this vehicle consist of a barrier-

hose design with a nylon tube sandwiched between

rubber layers. The nylon tube helps to contain the

R-134a refrigerant, which has a smaller molecular

structure than R-12 refrigerant. The ends of the

refrigerant lines are made from lightweight alumi-

num or steel, and commonly use braze-less fittings.Any kinks or sharp bends in the refrigerant lines

and hoses will reduce the capacity of the entire A/C

system and can reduce the flow of refrigerant in the

system. The radius of all bends in the flexible hose

refrigerant lines should be at least ten times the

diameter of the hose and the refrigerant lines should

be routed so they are at least 80 millimeters (3

inches) away from the exhaust manifold(s) and

exhaust pipe(s).

OPERATION

High pressures are produced in the refrigerant sys-

tem when the A/C compressor is operating. Extreme

care must be exercised to make sure that each of the

refrigerant system connections is pressure-tight and

leak free. It is a good practice to inspect all flexible

hose refrigerant lines at least once a year to make

sure they are in good condition and properly routed.

The refrigerant lines and hoses are coupled to

other A/C system components with block-type fit-

tings. An O-ring seal, or a flat steel gasket with an

integral O-ring (dual plane seal), is used to mate the

refrigerant line fittings with A/C system components

to ensure the integrity of the refrigerant system.

The refrigerant lines and hoses cannot be repaired

and, if faulty or damaged, they must be replaced.

WARNING

ENGINE COOLING SYSTEM

WARNING: THE ENGINE COOLING SYSTEM IS

DESIGNED TO DEVELOP INTERNAL PRESSURES

OF 97 TO 123 KILOPASCALS (14 TO 18 POUNDS

PER SQUARE INCH). DO NOT REMOVE OR

LOOSEN THE COOLANT PRESSURE CAP, CYLIN-

DER BLOCK DRAIN PLUGS, RADIATOR DRAIN,

RADIATOR HOSES, HEATER HOSES, OR HOSE

CLAMPS WHILE THE ENGINE COOLING SYSTEM IS

HOT AND UNDER PRESSURE. FAILURE TO

OBSERVE THIS WARNING CAN RESULT IN SERI-

OUS BURNS FROM THE HEATED ENGINE COOL-

ANT. ALLOW THE VEHICLE TO COOL FOR A

MINIMUM OF 15 MINUTES BEFORE OPENING THE

COOLING SYSTEM FOR SERVICE.

RSPLUMBING - FRONT24-65

Page 2219 of 2339

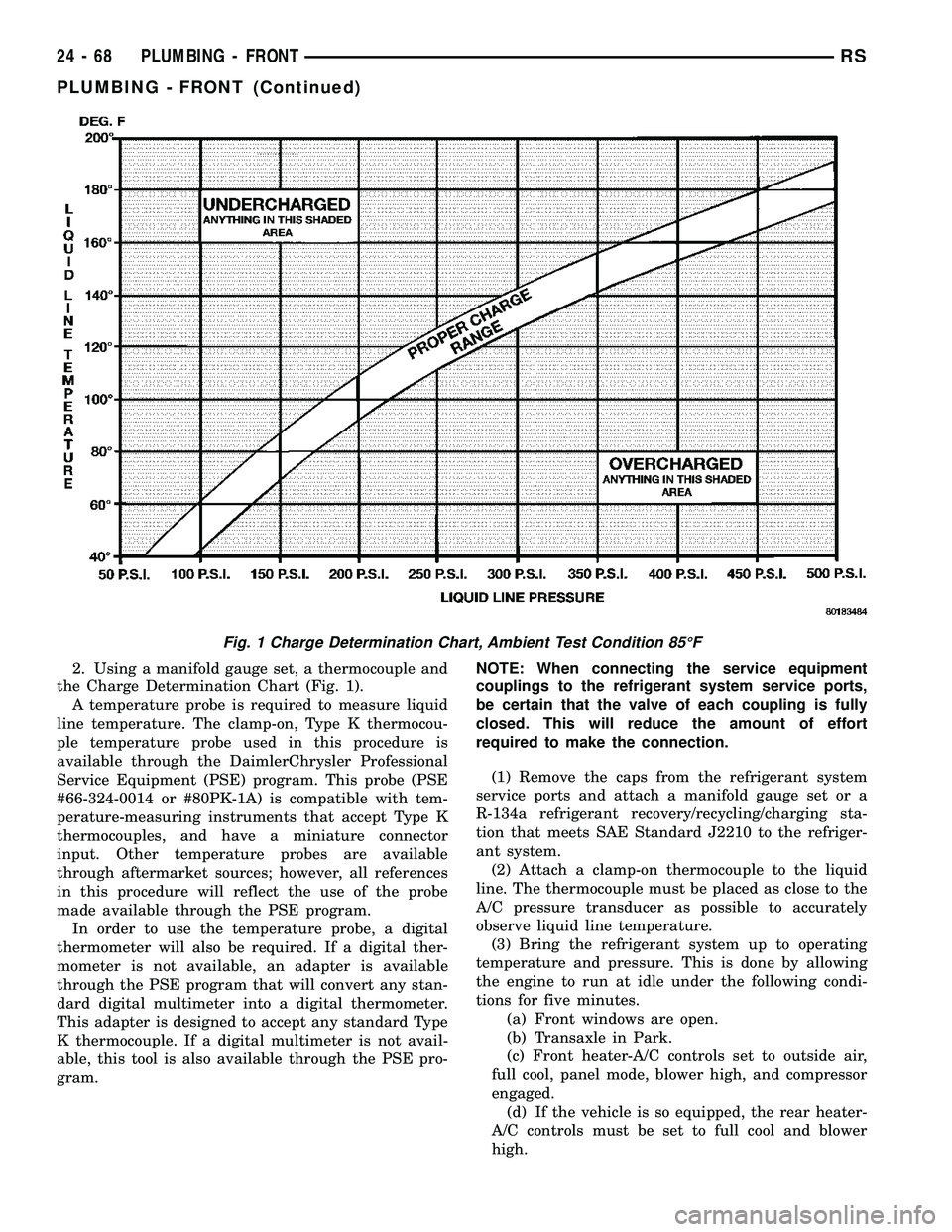

2. Using a manifold gauge set, a thermocouple and

the Charge Determination Chart (Fig. 1).

A temperature probe is required to measure liquid

line temperature. The clamp-on, Type K thermocou-

ple temperature probe used in this procedure is

available through the DaimlerChrysler Professional

Service Equipment (PSE) program. This probe (PSE

#66-324-0014 or #80PK-1A) is compatible with tem-

perature-measuring instruments that accept Type K

thermocouples, and have a miniature connector

input. Other temperature probes are available

through aftermarket sources; however, all references

in this procedure will reflect the use of the probe

made available through the PSE program.

In order to use the temperature probe, a digital

thermometer will also be required. If a digital ther-

mometer is not available, an adapter is available

through the PSE program that will convert any stan-

dard digital multimeter into a digital thermometer.

This adapter is designed to accept any standard Type

K thermocouple. If a digital multimeter is not avail-

able, this tool is also available through the PSE pro-

gram.NOTE: When connecting the service equipment

couplings to the refrigerant system service ports,

be certain that the valve of each coupling is fully

closed. This will reduce the amount of effort

required to make the connection.

(1) Remove the caps from the refrigerant system

service ports and attach a manifold gauge set or a

R-134a refrigerant recovery/recycling/charging sta-

tion that meets SAE Standard J2210 to the refriger-

ant system.

(2) Attach a clamp-on thermocouple to the liquid

line. The thermocouple must be placed as close to the

A/C pressure transducer as possible to accurately

observe liquid line temperature.

(3) Bring the refrigerant system up to operating

temperature and pressure. This is done by allowing

the engine to run at idle under the following condi-

tions for five minutes.

(a) Front windows are open.

(b) Transaxle in Park.

(c) Front heater-A/C controls set to outside air,

full cool, panel mode, blower high, and compressor

engaged.

(d) If the vehicle is so equipped, the rear heater-

A/C controls must be set to full cool and blower

high.

Fig. 1 Charge Determination Chart, Ambient Test Condition 85ÉF

24 - 68 PLUMBING - FRONTRS

PLUMBING - FRONT (Continued)

Page 2223 of 2339

(4) Open both the suction and discharge valves,

then open the charge valve to allow the heated

refrigerant to flow into the system.

(5) When the transfer of refrigerant has stopped,

close both the suction and discharge valves.

(6) If all of the refrigerant charge did not transfer

from the dispensing device, open all of the windows

in the vehicle and set the heater-air conditioner con-

trols so that the compressor is engaged and the

blower motor is operating at its lowest speed setting.

Run the engine at a steady high idle (about 1400

rpm). If the compressor will not engage, test the com-

pressor clutch control circuit and repair as required.

(7) Open the suction valve to allow the remaining

refrigerant to transfer to the refrigerant system.

WARNING: TAKE CARE NOT TO OPEN THE DIS-

CHARGE (HIGH PRESSURE) VALVE AT THIS TIME.

(8) Close the suction valve and test the system

performance. (Refer to 24 - HEATING & AIR CON-

DITIONING - STANDARD PROCEDURE - A/C PER-

FORMANCE TEST).

(9) Disconnect the charging station and manifold

gauge set from the refrigerant system service ports.

(10) Reinstall the caps onto the refrigerant system

service ports.

(11) Run the HVAC Control Cooldown test to ver-

ify proper operation(Refer to 24 - HEATING & AIR

CONDITIONING - DIAGNOSIS AND TESTING).

A/C COMPRESSOR

DESCRIPTION

A/C COMPRESSOR

Vehicles equipped with the 2.4L gasoline, 2.5L die-

sel, 2.8L diesel and 3.3L gasoline engines with the

front heating-A/C system only, use the Denso 10S17

A/C compressor. Vehicles equipped with the 3.3L and

the 3.8L gasoline engines with the optional rear heat-

ing-A/C system use the Denso 10S20 A/C compressor.

Both A/C compressors include an integral high pres-

sure relief valve. The A/C compressor is secured to a

mounting bracket on the 2.4L gasoline engine and

directly to the cylinder block on the 2.5L diesel, 2.8L

diesel, 3.3L gasoline and 3.8L gasoline engines.

HIGH PRESSURE RELIEF VALVE

A high pressure relief valve is located on the rear

of the A/C compressor. This mechanical valve is

designed to vent refrigerant from the A/C system to

protect against damage to the compressor and other

system components, caused by condenser air flow

restriction or an overcharge of refrigerant.

OPERATION

A/C COMPRESSOR

The A/C compressor is driven by the engine

through an electric clutch, drive pulley and belt

arrangement. The compressor is lubricated by refrig-

erant oil that is circulated throughout the refrigerant

system with the refrigerant.

The compressor draws in low-pressure refrigerant

vapor from the evaporator through its suction port. It

then compresses the refrigerant into a high-pressure,

high-temperature refrigerant vapor. The compressor

pumps the high-pressure refrigerant vapor to the

condenser through the compressor discharge port.

The compressor cannot be repaired. If faulty or

damaged, the entire compressor assembly must be

replaced. The compressor clutch, pulley and clutch

coil are available for service.

HIGH PRESSURE RELIEF VALVE

The high pressure relief valve vents the system

when a discharge pressure of 3445 to 4135 kPa (500

to 600 psi) or above is reached. The valve closes

when a minimum discharge pressure of 2756 kPa

(400 psi) is reached.

The high pressure relief valve vents only enough

refrigerant to reduce the system pressure, and then

re-seats itself. The majority of the refrigerant is con-

served in the system. If the valve vents refrigerant, it

does not mean that the valve is faulty.

The high pressure relief valve is a factory-cali-

brated unit. The valve cannot be adjusted or

repaired, and must not be removed or otherwise dis-

turbed. The valve is only serviced as a part of the

compressor assembly.

DIAGNOSIS AND TESTING

A/C COMPRESSOR NOISE DIAGNOSIS

Excessive noise while the air conditioning compres-

sor is operating can be caused by loose compressor

mounts, a loose compressor clutch, or high operating

pressures in the refrigerant system. Verify compres-

sor drive belt condition, proper compressor mounting,

correct refrigerant charge level, and compressor head

pressure before compressor repair is performed.

With the close tolerances within the compressor, it

is possible to experience a temporary lockup. The

longer the compressor is inactive, the more likely the

condition is to occur. This condition is the result of

normal refrigerant migration within the refrigerant

system caused by ambient temperature changes. The

refrigerant migration may wash the refrigerant oil

out of the compressor.

24 - 72 PLUMBING - FRONTRS

PLUMBING - FRONT (Continued)

Page 2233 of 2339

DIAGNOSIS AND TESTING

FRONT A/C EXPANSION VALVE

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - WARNING - A/C PLUMBING) and (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - CAUTION - A/C PLUMBING).

NOTE: The A/C expansion valve should only be

tested following testing of the A/C compressor.

NOTE: Liquid CO

2is required to test the A/C expan-

sion valve. This material is available from most

welding supply facilities. Liquid CO

2is also avail-

able from companies which service and sell fire

extinguishers.

When testing the A/C expansion valve, the work

area and the vehicle temperature must be 21É to 27É

C (70É to 85É F). To test the expansion valve:

(1) Connect a charging station or manifold gauge

set to the refrigerant system service ports. Verify the

refrigerant charge level.

(2) Close all doors, windows and vents to the pas-

senger compartment.

(3) Set the A/C-heater controls so that the A/C

compressor is operating, the temperature control is

in the highest temperature position, the mode door is

directing the output to the floor outlets, and the

blower motor is operating at the highest speed set-

ting.

(4) Start the engine and allow it to idle. After the

engine has reached normal operating temperature,

allow the passenger compartment to heat up. This

will create the need for maximum refrigerant flow

into the A/C evaporator.

(5) If the refrigerant charge is sufficient, the dis-

charge (high pressure) gauge should read 965 kPa to

1655 kPa (140 psi to 240 psi). The suction (low pres-

sure) gauge should read 138 kPa to 207 kPa (20 psi

to 30 psi). If OK, go to Step 6. If not OK, replace the

faulty A/C expansion valve.

WARNING:

PROTECT THE SKIN AND EYES FROM EXPOSURE

TO LIQUID CO

2OR PERSONAL INJURY CAN

RESULT.

(6) If the suction (low pressure) gauge reads

within the specified range, freeze the A/C expansion

valve for 30 seconds using liquid CO

2or another suit-able super-cold material.Do not spray R-134a or

R-12 refrigerant on the A/C expansion valve for

this test.The suction (low pressure) gauge reading

should drop by 69 kPa (10 psi). If OK, go to Step 7 If

not OK, replace the faulty A/C expansion valve.

(7) Allow the expansion valve control head to thaw.

The suction (low pressure) gauge reading should sta-

bilize at 138 kPa to 207 kPa (20 psi to 30 psi). If not

OK, replace the faulty A/C expansion valve.

(8) When expansion valve testing is complete, test

the overall A/C system performance (Refer to 24 -

HEATING & AIR CONDITIONING - DIAGNOSIS

AND TESTING - A/C PERFORMANCE TEST).

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - WARNING - A/C PLUMBING) and (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - CAUTION - A/C PLUMBING).

(1) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - FRONT/REFRIGERANT - STAN-

DARD PROCEDURE - REFRIGERANT

RECOVERY).

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the air cleaner housing from the right

side of the engine compartment.

(4) Disconnect the drain tube from the wiper mod-

ule drain on the right side of the engine compart-

ment.

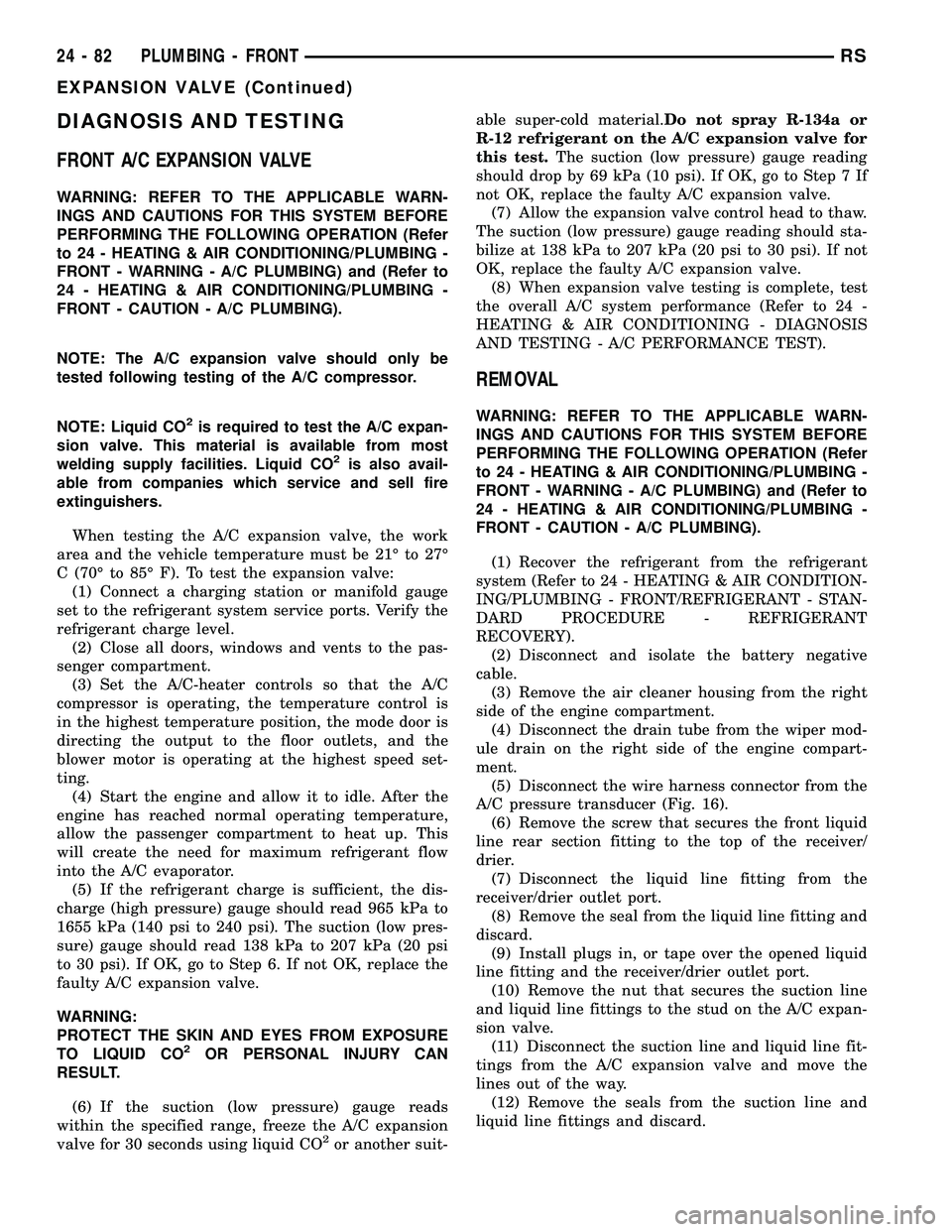

(5) Disconnect the wire harness connector from the

A/C pressure transducer (Fig. 16).

(6) Remove the screw that secures the front liquid

line rear section fitting to the top of the receiver/

drier.

(7) Disconnect the liquid line fitting from the

receiver/drier outlet port.

(8) Remove the seal from the liquid line fitting and

discard.

(9) Install plugs in, or tape over the opened liquid

line fitting and the receiver/drier outlet port.

(10) Remove the nut that secures the suction line

and liquid line fittings to the stud on the A/C expan-

sion valve.

(11) Disconnect the suction line and liquid line fit-

tings from the A/C expansion valve and move the

lines out of the way.

(12) Remove the seals from the suction line and

liquid line fittings and discard.

24 - 82 PLUMBING - FRONTRS

EXPANSION VALVE (Continued)

Page 2234 of 2339

(13) Install plugs in, or tape over the opened suc-

tion line and liquid line fittings and both expansion

valve ports.

(14) Remove the two screws that secure the A/C

expansion valve to the evaporator tube tapping plate.

(15) On RG models, disconnect the HVAC wire

harness connector from the evaporator temperature

sensor.

(16) Remove the A/C expansion valve from the

evaporator inlet and outlet tube fittings.

(17) Remove the seals from the evaporator inlet

and outlet tube fittings and discard.

(18) Install plugs in, or tape over the opened evap-

orator inlet and outlet tube fittings and both expan-

sion valve ports.

(19) On RG models, remove the evaporator tem-

perature sensor retainer and evaporator temperature

sensor from the A/C expansion valve, if required.

INSTALLATION

NOTE: Any grease removed with the evaporator

temperature sensor must be replaced. Failure to do

so could result in poor A/C performance.

(1) On RG models, install the evaporator tempera-

ture sensor and retainer onto the A/C expansion

valve, if removed.

(2) Remove the tape or plugs from the evaporator

inlet and outlet tube fittings and both ports on the

back of the A/C expansion valve.(3) Lubricate new rubber O-ring seals with clean

refrigerant oil and install them on the evaporator

inlet and outlet tube fittings.

(4) Position the A/C expansion valve onto the evap-

orator inlet and outlet tube fittings.

(5) Install the two screws that secure the A/C

expansion valve to the evaporator tube tapping plate

plate. Tighten the screws to 11 N´m (97 in. lbs.).

(6) On RG models, connect the HVAC wire harness

connector to the evaporator temperature sensor.

(7) Remove the tape or plugs from the front liquid

line rear section and suction line fittings for the

expansion valve and both ports on the front of the

expansion valve.

(8) Lubricate new rubber O-ring seals with clean

refrigerant oil and install them on the front liquid

line rear section and suction line fittings for the

expansion valve.

(9) Connect the liquid line and suction line fittings

to the expansion valve.

(10) Install the nut that secures the suction line

and liquid line fittings to the stud on the expansion

valve. Tighten the nut to 23 N´m (17 ft. lbs.).

(11) Remove the tape or plugs from the liquid line

rear section fitting and the receiver/drier outlet port.

(12) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

(13) Connect the liquid line fitting to the receiver/

drier outlet port.

(14) Install the screw that secures the liquid line

fitting to the receiver/drier. Tighten the screw to 11

N´m (97 in. lbs.).

(15) Connect the wire harness connector to the A/C

pressure transducer.

(16) Connect the drain tube to the wiper module

drain on the right side of the engine compartment.

(17) Install the air cleaner housing.

(18) Reconnect the battery negative cable.

(19) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(20) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).

HEATER CORE

DESCRIPTION

The heater core is located in the distribution hous-

ing, which is attached to the HVAC housing, behind

the instrument panel. It is a heat exchanger made of

rows of tubes and fins. One end of the core is fitted

with a molded plastic tank, which includes integral

Fig. 16 A/C Expansion Valve - LHD Shown, RHD

Typical

1 - A/C PRESSURE TRANSDUCER

2 - EVAPORATOR TEMPERATURE SENSOR (RG ONLY)

3 - A/C EXPANSION VALVE

4 - SUCTION LINE

5 - HIGH SIDE SERVICE PORT

6 - LIQUID LINE

RSPLUMBING - FRONT24-83

EXPANSION VALVE (Continued)

Page 2235 of 2339

heater core inlet and outlet ports. Removable heater

core tubes attach to the ports by use of a sealing

plate secured with a screw to the heater core tank.

This removable heater core tube arrangement allows

the heater core to be serviced without removing the

HVAC housing from the vehicle.

OPERATION

Engine coolant is circulated through heater hoses

to the heater core at all times. As the coolant flows

through the heater core, heat removed from the

engine is transferred to the heater core fins and

tubes. Air directed through the heater core picks up

the heat from the heater core fins. The blend door

allows control of the heater output air temperature

by regulating the amount of air that is flowing

through the heater core within the HVAC housing.

The heater core cannot be repaired and, if faulty or

damaged, it must be replaced.

REMOVAL

FRONT HEATER CORE TUBES

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Drain the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM DRAIN).

(2) Disconnect and isolate the battery negative

cable.

(3) Disconnect the heater hoses from the heater

core tubes (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/HEATER INLET HOSE -

REMOVAL) and (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING/HEATER RETURN

HOSE - REMOVAL).(4) Remove the silencer from beneath the driver

side end of the instrument panel.

NOTE: Take the proper precautions to protect the

carpeting below the heater core from spilled engine

coolant and have absorbent toweling readily avail-

able to clean up any spills.

(5) Remove the screw that secures the heater core

tube sealing plate to the heater core supply and

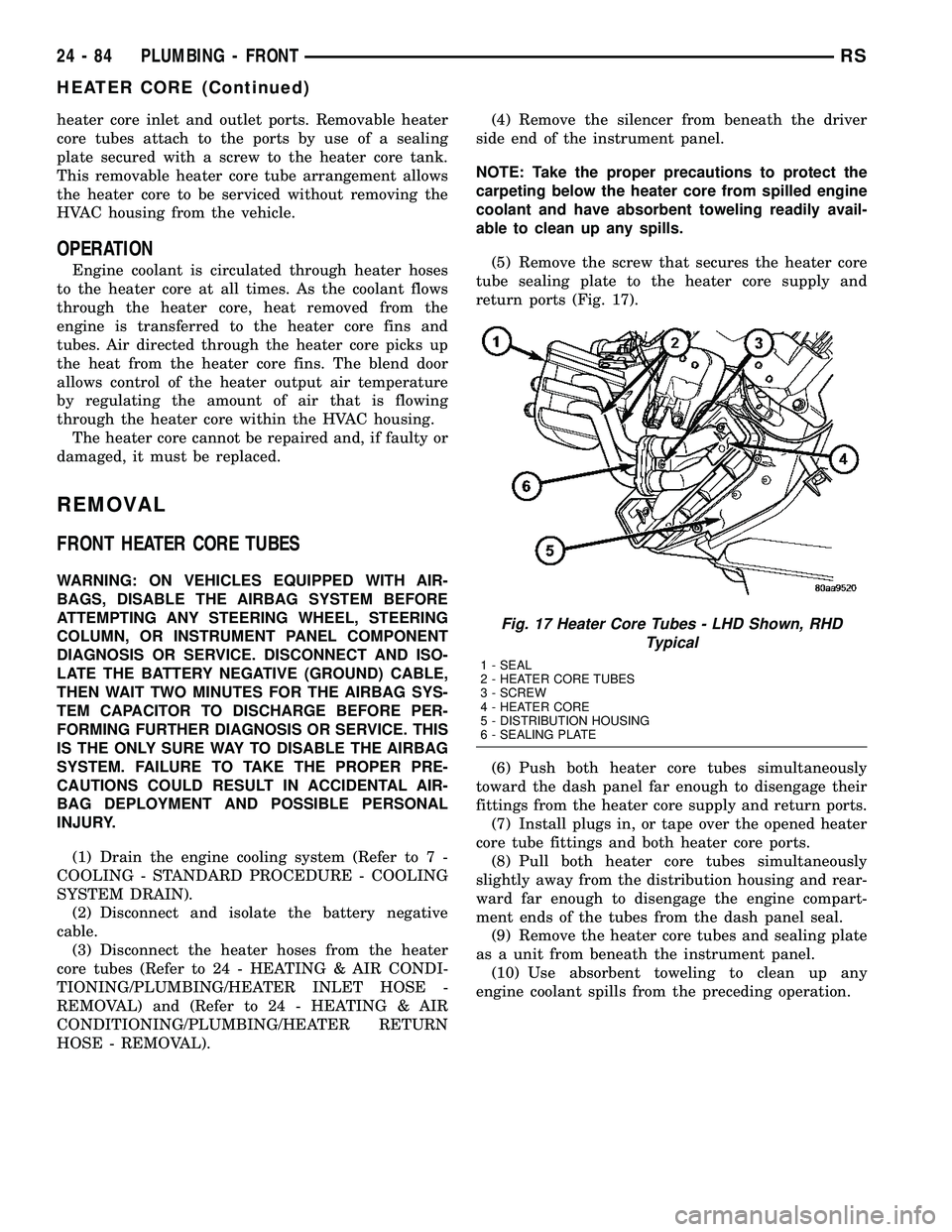

return ports (Fig. 17).

(6) Push both heater core tubes simultaneously

toward the dash panel far enough to disengage their

fittings from the heater core supply and return ports.

(7) Install plugs in, or tape over the opened heater

core tube fittings and both heater core ports.

(8) Pull both heater core tubes simultaneously

slightly away from the distribution housing and rear-

ward far enough to disengage the engine compart-

ment ends of the tubes from the dash panel seal.

(9) Remove the heater core tubes and sealing plate

as a unit from beneath the instrument panel.

(10) Use absorbent toweling to clean up any

engine coolant spills from the preceding operation.

Fig. 17 Heater Core Tubes - LHD Shown, RHD

Typical

1 - SEAL

2 - HEATER CORE TUBES

3 - SCREW

4 - HEATER CORE

5 - DISTRIBUTION HOUSING

6 - SEALING PLATE

24 - 84 PLUMBING - FRONTRS

HEATER CORE (Continued)

Page 2236 of 2339

FRONT HEATER CORE

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Remove the silencer boot fasteners located

around the base of the lower steering shaft from the

dash panel so that it may be pushed aside.

(2) Remove the brake lamp switch from its mount-

ing bracket (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/BRAKE LAMP SWITCH -

REMOVAL).

(3) Disconnect the power brake booster input rod

(push rod) from the pin on the brake pedal arm

(Refer to 5 - BRAKES - ABS/HYDRAULIC/ME-

CHANICAL/POWER BRAKE BOOSTER -

REMOVAL).

(4) Remove the heater core tubes (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/

HEATER CORE - REMOVAL).

(5) Remove the two screws that secure the heater

core mounting plate to the distribution housing.

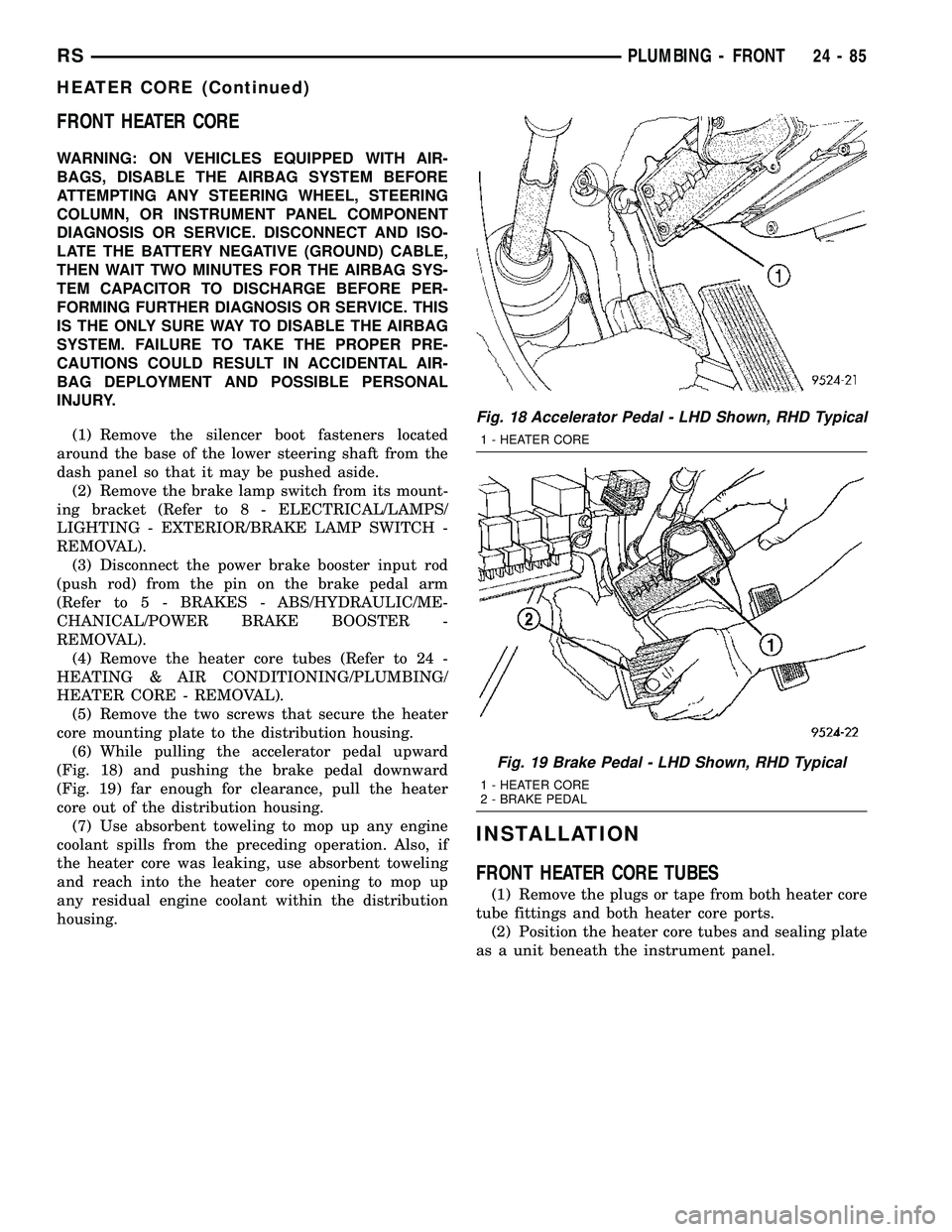

(6) While pulling the accelerator pedal upward

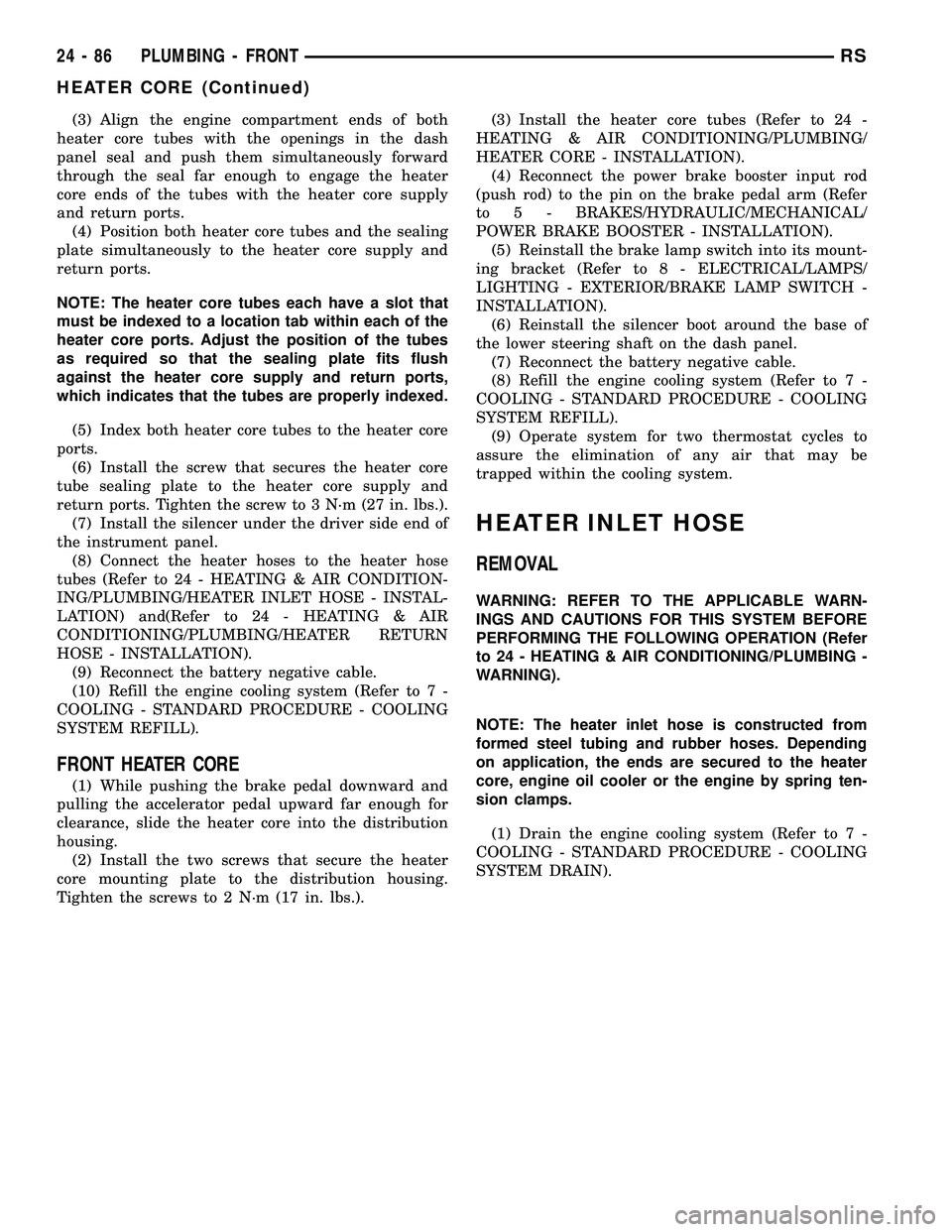

(Fig. 18) and pushing the brake pedal downward

(Fig. 19) far enough for clearance, pull the heater

core out of the distribution housing.

(7) Use absorbent toweling to mop up any engine

coolant spills from the preceding operation. Also, if

the heater core was leaking, use absorbent toweling

and reach into the heater core opening to mop up

any residual engine coolant within the distribution

housing.

INSTALLATION

FRONT HEATER CORE TUBES

(1) Remove the plugs or tape from both heater core

tube fittings and both heater core ports.

(2) Position the heater core tubes and sealing plate

as a unit beneath the instrument panel.

Fig. 18 Accelerator Pedal - LHD Shown, RHD Typical

1 - HEATER CORE

Fig. 19 Brake Pedal - LHD Shown, RHD Typical

1 - HEATER CORE

2 - BRAKE PEDAL

RSPLUMBING - FRONT24-85

HEATER CORE (Continued)

Page 2237 of 2339

(3) Align the engine compartment ends of both

heater core tubes with the openings in the dash

panel seal and push them simultaneously forward

through the seal far enough to engage the heater

core ends of the tubes with the heater core supply

and return ports.

(4) Position both heater core tubes and the sealing

plate simultaneously to the heater core supply and

return ports.

NOTE: The heater core tubes each have a slot that

must be indexed to a location tab within each of the

heater core ports. Adjust the position of the tubes

as required so that the sealing plate fits flush

against the heater core supply and return ports,

which indicates that the tubes are properly indexed.

(5) Index both heater core tubes to the heater core

ports.

(6) Install the screw that secures the heater core

tube sealing plate to the heater core supply and

return ports. Tighten the screw to 3 N´m (27 in. lbs.).

(7) Install the silencer under the driver side end of

the instrument panel.

(8) Connect the heater hoses to the heater hose

tubes (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING/HEATER INLET HOSE - INSTAL-

LATION) and(Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING/HEATER RETURN

HOSE - INSTALLATION).

(9) Reconnect the battery negative cable.

(10) Refill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM REFILL).

FRONT HEATER CORE

(1) While pushing the brake pedal downward and

pulling the accelerator pedal upward far enough for

clearance, slide the heater core into the distribution

housing.

(2) Install the two screws that secure the heater

core mounting plate to the distribution housing.

Tighten the screws to 2 N´m (17 in. lbs.).(3) Install the heater core tubes (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/

HEATER CORE - INSTALLATION).

(4) Reconnect the power brake booster input rod

(push rod) to the pin on the brake pedal arm (Refer

to 5 - BRAKES/HYDRAULIC/MECHANICAL/

POWER BRAKE BOOSTER - INSTALLATION).

(5) Reinstall the brake lamp switch into its mount-

ing bracket (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/BRAKE LAMP SWITCH -

INSTALLATION).

(6) Reinstall the silencer boot around the base of

the lower steering shaft on the dash panel.

(7) Reconnect the battery negative cable.

(8) Refill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM REFILL).

(9) Operate system for two thermostat cycles to

assure the elimination of any air that may be

trapped within the cooling system.

HEATER INLET HOSE

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING).

NOTE: The heater inlet hose is constructed from

formed steel tubing and rubber hoses. Depending

on application, the ends are secured to the heater

core, engine oil cooler or the engine by spring ten-

sion clamps.

(1) Drain the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM DRAIN).

24 - 86 PLUMBING - FRONTRS

HEATER CORE (Continued)