torque CHRYSLER VOYAGER 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 561 of 2339

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANELCOMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

TELECOMMUNICATION SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

Phone Not

Available1. Bluetooth phone not

paired to the system.1. Ensure that phone(s) are paired to the system.

2. Bluetooth phone not

present or turned OFF.2. Make sure paired phone is present, turned ON and that the

Bluetooth option is enabled on the phone.

3. Bluetooth phone has

low battery.3. At low battery levels, some phones will turn off Bluetooth

functionality. Ensure cellular phone is charged to an adequate

level.

Phone Pairing

Failed1. Phone does not

support Hands Free

Profile1. The Telecommunication system requires the cellular phone to

be BluetoothŸ enabled, as well as supporting the Hands Free

Profile. The customer will have to upgrade their phone to one

supporting Hands Free Profile. A list of suggested phones is

available at: http://www.chrysler.com/uconnect.

2. Phone not Bluetooth

enabled.2. The Telecommunication system requires the cellular phone to

be BluetoothŸ enabled. A list of suggested phones is available

at: http://www.chrysler.com/uconnect.

3. PIN entered on the

phone is not the same

as PIN spoken to the

system.3. The PIN spoken to the system must be the same PIN entered

into the phone.

4. Phone has reached

maximum number of

allowed devices paired.4. Remove one of the previously paired devices from it's list.

Poor Voice

Recognition1. Microphone failure 1. Using a scan tool, check for microphone fault codes.

2. Customer not waiting

for the beep before

speaking.2. Ensure customer is waiting for the system9beep9prior to

beginning the speech to be recognized.

3. Customer not

speaking in a smooth

normal manner.3. Verify that the customer is attempting to use the system with a

smooth consistent voice. The system is designed to accept

normal speech spoken at a normal tone, some people tend to

speak to a computer loud and slow, which results in reduced

performance.

4. Rear view mirror not

properly attached to

mounting.4. Mirror must be firmly mounted to the mounting location. Ensure

that mirror is tightened to the specified torque.

5. High levels of noise in

vehicle compartment5. System performance is increased when noise conditions in the

vehicle are lowered. Ideal conditions include windows closed.

6. Object interfering with

microphone input6. Verify that there is no object, hanging from the mirror, that

could be obstructing the microphone.

7. User not saying9send9

after a pager dialing

request7. User must say9send9at the end of a Pager Dialing request.

8T - 2 NAVIGATION/TELECOMMUNICATIONRS

NAVIGATION/TELECOMMUNICATION (Continued)

Page 562 of 2339

CONDITION POSSIBLE CAUSE CORRECTION

8. Other passengers

talking while customer is

attempting to use the

system8. Although designed for primary use by the driver, the

microphone will pick up passengers in any seat of the vehicle.

System performance is increased in low noise environments.

Phonebook

names not

recognized

consistently1. Phonebook names

recorded in high noise

conditions1. For increased system performance, it is recommended that the

phone book entries are recorded in a low noise environment. That

is, vehicle in park, with windows up.

2. Phonebook name(s)

short2. For increased performance it is recommended that the user

use both first and last name as a phonebook entry. Example9

Daniel James9as opposed to9Dan9.

3. Phonebook names

recorded by another user3. It is recommended that each user of the system record their

own phonebook entries. This will increase the recognition

performance.

4. Similar names in

phonebook4. For increased system performance it is recommended that the

user do not enter similar sounding names in the phonebook.

5. Object interfering with

microphone input5. Object interfering with microphone input.

Poor Phone

audio quality.1. Microphone failure 1. Use a scan tool, and check for Microphone faults.

2. Rear view mirror not

properly fixed to

mounting button2. Mirror must be firmly mounted to the mounting location. Tighten

mirror to the specified torque.

3. System being used in

high noise conditions3. System performance is increased when noise conditions in the

vehicle are lowered. Ideal conditions include windows closed.

No Phone Audio 1. Phone setting cause

phone audio to be routed

to handset.1. Route audio to9Hands free9device.

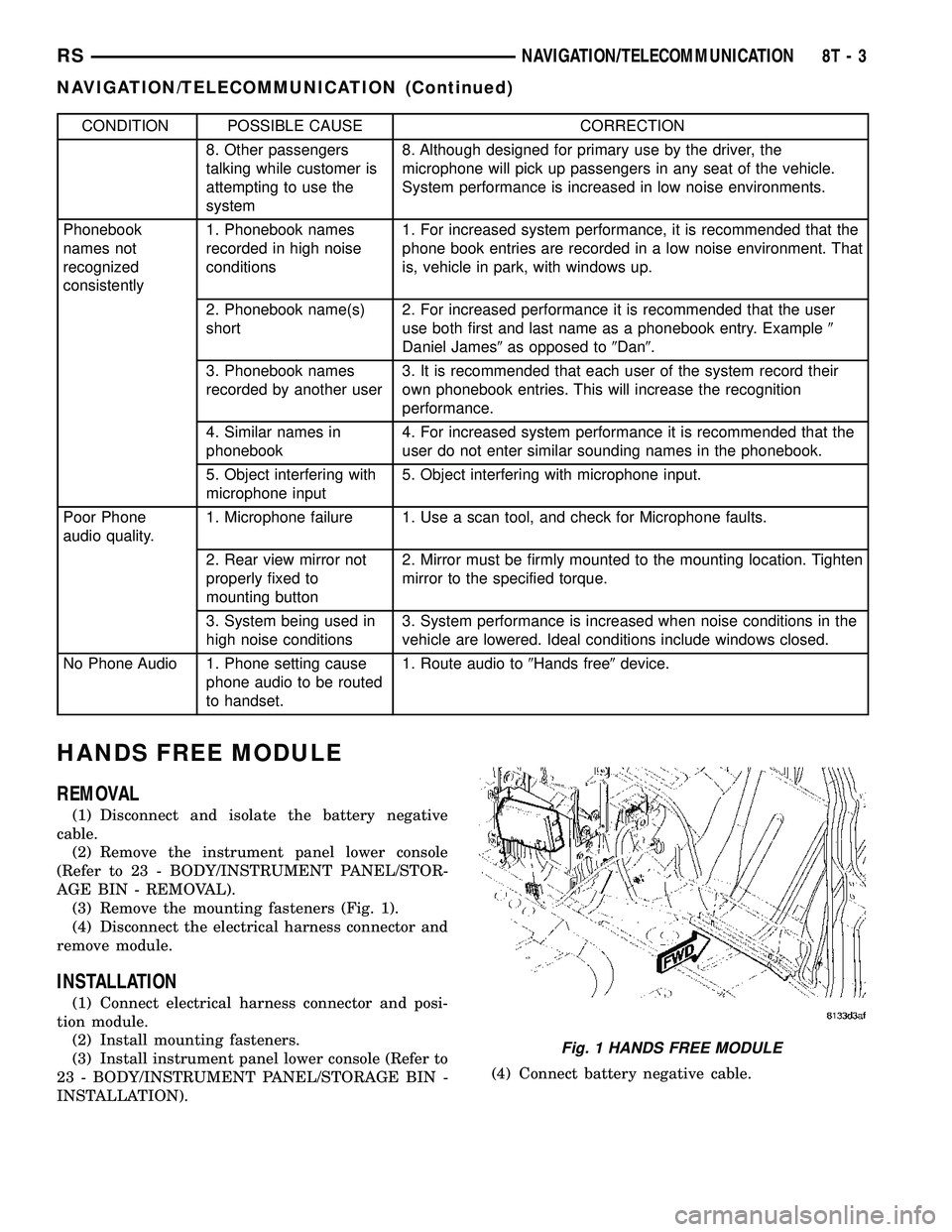

HANDS FREE MODULE

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel lower console

(Refer to 23 - BODY/INSTRUMENT PANEL/STOR-

AGE BIN - REMOVAL).

(3) Remove the mounting fasteners (Fig. 1).

(4) Disconnect the electrical harness connector and

remove module.

INSTALLATION

(1) Connect electrical harness connector and posi-

tion module.

(2) Install mounting fasteners.

(3) Install instrument panel lower console (Refer to

23 - BODY/INSTRUMENT PANEL/STORAGE BIN -

INSTALLATION).(4) Connect battery negative cable.

Fig. 1 HANDS FREE MODULE

RSNAVIGATION/TELECOMMUNICATION8T-3

NAVIGATION/TELECOMMUNICATION (Continued)

Page 1036 of 2339

ENGINE CONTROL MODULE C1 (DIESEL) - BLACK 81 WAY

CAV CIRCUIT FUNCTION

33 - -

34 K4 20BK/LB SENSOR GROUND

35 F852 20VT/PK ACCELERATOR PEDAL POSITION SENSOR 5 VOLT

SUPPLY

36 C18 20LB/BR A/C PRESSURE SENSOR SIGNAL

37 - -

38 V37 20VT/TN SPEED CONTROL SWITCH SIGNAL

39 - -

40 K2 20TN/BK ENGINE COOLANT TEMPERATURE SENSOR SIGNAL

41 K21 20DB/LG INTAKE AIR TEMPERATURE SENSOR SIGNAL

42 Z122 18WT GROUND (DRAIN)

43 K24 20BR/LB CRANKSHAFT POSITION SENSOR SIGNAL NO. 2

44 - -

45 - -

46 - -

47 L50 20WT/TN PRIMARY BRAKE SWITCH SIGNAL

48 B29 20DG/WT SECONDARY BRAKE SWITCH SIGNAL

49 T751 20YL FUSED IGNITION SWITCH OUTPUT (START)

50 F855 20PK/YL SENSOR REFERENCE VOLTAGE A

51 - -

52 K121 20DB BOOST PRESSURE SENSOR GROUND

53 - -

54 K957 20BK/OR MASS AIR FLOW SENSOR GROUND

55 N7 20DB/OR VEHICLE SPEED SENSOR SIGNAL

56 C918 20BK/LB A/C PRESSURE SENSOR GROUND

57 T10 20DG/LG (EATX) TORQUE MANAGEMENT REQUEST SENSE

58 - -

59 - -

60 K9 20LB FUEL PRESSURE SENSOR 5 VOLT SUPPLY

61 K51 20BR/WT ECM/PCM RELAY CONTROL

62 - -

63 D21 20WT/DG SCI TRANSMIT (ECM)

64 K151 20WT LOW IDLE POSITION SWITCH SENSE

65 - -

66 K936 20BR/YL ENGINE OIL PRESSURE SENSOR GROUND

67 - -

68 - -

69 C13 20LB/OR A/C COMPRESSOR CLUTCH RELAY CONTROL

70 N210 20DB/DG LOW SPEED RADIATOR FAN RELAY CONTROL

71 - -

72 N21 20DB/TN LIFT PUMP RELAY CONTROL

73 - -

74 T752 20DG/OR STARTER MOTOR RELAY CONTROL

75 - -

76 - -

77 K152 20DB/WT GLOW PLUG RELAY CONTROL

78 N122 20DB/YL HIGH SPEED RADIATOR FAN DUAL RELAY CONTROL

79 - -

80 K87 20BR FUEL PRESSURE SOLENOID CONTROL

81 K87 20BR FUEL PRESSURE SOLENOID CONTROL

RS8W-80 CONNECTOR PIN-OUTS8W-80-67

Page 1110 of 2339

THROTTLE POSITION SENSOR (GAS) - GRAY 3 WAY

CAV CIRCUIT FUNCTION

1 K900 18DB/DG SENSOR GROUND

2 K22 18BR/OR TP SIGNAL

3 F855 20PK/YL 5 VOLT SUPPLY

TRACTION CONTROL SWITCH - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 B27 20DG/WT TRACTION CONTROL SWITCH SENSE

2 Z427 20BK/WT GROUND

TRAILER TOW CONNECTOR (EXCEPT EXPORT)-4WAY

CAV CIRCUIT FUNCTION

1 L62 18LG RIGHT REAR TURN SIGNAL DRIVER

2 Z362 18WT GROUND

3 L77 18BR FUSED PARK LAMP RELAY OUTPUT (LEFT)

4 L63 18YL LEFT REAR TURN SIGNAL DRIVER

TRANSMISSION CONTROL MODULE (DIESEL) - BLACK

CAV CIRCUIT FUNCTION

1 T1 18DG/LB TRS T1 SENSE

2- -

3 T3 18DG/DB TRS T3 SENSE

4- -

5- -

6 K24 20BR/LB CRANKSHAFT POSITION SENSOR SIGNAL NO.2

7 D15 20DG/YL SCI TRANSMIT (TCM)

8 T751 20YL FUSED IGNITION SWITCH OUTPUT (START)

9 T9 18DG/TN OVERDRIVE PRESSURE SWITCH SENSE

10 T10 20DG/LG TORQUE MANAGEMENT REQUEST SENSE

11 F1 18PK/WT FCM OUTPUT (UNLOCK-RUN-START)

12 K23 20BR/OR ACCELERATOR PEDAL POSITION SENSOR SIGNAL

NO.2

13 T13 18DG/VT SPEED SENSOR GROUND

14 T14 18DG/BR OUTPUT SPEED SENSOR SIGNAL

15 T15 18YL/BR TRANSMISSION CONTROL RELAY CONTROL

16 T16 18YL/OR TRANSMISSION CONTROL RELAY OUTPUT

17 T16 18YL/OR TRANSMISSION CONTROL RELAY OUTPUT

18 - -

19 T19 18YL/DB 2-4 SOLENOID CONTROL

20 T20 18DG/WT L/R SOLENOID CONTROL

21 - -

22 - -

RS8W-80 CONNECTOR PIN-OUTS8W - 80 - 141

Page 1126 of 2339

SPLICES

SPLICE NUMBER LOCATION FIG.

S101 (Gas) Near T/O for Radiator Fan No.1 1

S103 (Diesel) Between T/O for Battery Temperature Sensor and T/O

for C10215

S106 (2.5L) Near T/O for Battery Temperature Sensor 15

S106 (3.3L/3.8L) Near T/O for G103 18

S107 (Gas) Near T/O for Integrated Power Module C3 11

S107 (Diesel) In T/O for Integrated Power Module C3 7

S111 (2.4L) Near T/O for C101 11

S111 (Diesel) In T/O for Battery (-) N/S

S111 (3.3L/3.8L) Near T/O for Battery Temperature Sensor N/S

S112 (Gas) Near T/O for Integrated Power Module - C3 19, 5, 11

S113 (2.4L) Near T/O for Park/Neutral Position Switch 11

S114 (2.4L) Near T/O for Powertrain Control Module C4 11

S114 (3.3L/3.8L) In T/O to Transmission Control Module N/S

S115 (2.4L) Near T/O for Powertrain Control Module C4 11

S115 (3.3L/3.8L) In T/O to Transmission Control Module N/S

S116 (2.4L) 180mm from T/O for Torque Converter Clutch Solenoid 11, 13

S116 (Diesel) Near T/O for Mass Air Flow Sensor 16

S116 (3.3L/3.8L) Near T/O for G103 18

S118 (2.4L) Near T/O for Knock Sensor 11, 13

S119 (Diesel) Near T/O for Engine Starter Motor 15

S121 (3.3L/3.8L) Near T/O for Output Speed Sensor 18

S122 (2.4L) In T/O to Engine Starter Motor 13

S122 (3.3L/3.8L) In T/O to Engine Starter Motor 18

S124 (2.4L) Near T/O for Fuel Injector No.2 N/S

S124 (3.3L/3.8L) Near T/O for Fuel Injector No.5 and No.6 N/S

S125 (2.4L) In T/O for Manifold Absolute Pressure Sensor N/S

S126 In Right Headlamp Leveling Assembly N/S

S127 (Diesel) In T/O for Engine Starter Motor N/S

S128 (Diesel) Near T/O for Engine Starter Motor N/S

S129 (Diesel) Near T/O for Battery (+) N/S

S130 (Diesel) Near T/O for Battery (+) N/S

S131 (2.4L) Near T/O for Transmission Control Module 11

S131 (3.3L/3.8L) Near T/O for C110 N/S

S132 (Diesel) Near T/O for Battery (+) N/S

S134 (Diesel) IN T/O for Engine Control Module N/S

S135 (Diesel) Near T/O for Glow Plug No.2 N/S

S136 (Diesel) In T/O for Radiator Fan Relays 2

S137 (Diesel) Above Starter 15

S138 (Diesel) Between T/O for Radiator Fan No.2 and T/O for G102 N/S

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-13

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1178 of 2339

ENGINE

TABLE OF CONTENTS

page page

ENGINE 2.4L.............................. 1ENGINE 3.3/3.8L......................... 76

ENGINE 2.4L

TABLE OF CONTENTS

page page

ENGINE 2.4L

DESCRIPTION..........................3

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - INTRODUCTION............3

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - PERFORMANCE............4

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - MECHANICAL..............6

DIAGNOSIS AND TESTING - ENGINE OIL

LEAK INSPECTION.....................8

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE TEST.........9

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE

TEST................................9

STANDARD PROCEDURE

STANDARD PROCEDURE - ENGINE CORE

AND OIL GALLERY PLUGS..............10

STANDARD PROCEDURE - REPAIR OF

DAMAGED OR WORN THREADS.........10

HYDROSTATIC LOCKED ENGINE.........10

FORM-IN-PLACE GASKETS AND SEALERS . 11

STANDARD PROCEDURE - ENGINE

GASKET SURFACE PREPARATION........11

STANDARD PROCEDURE - MEASURING

BEARING CLEARANCE USING

PLASTIGAGE........................12

REMOVAL - ENGINE ASSEMBLY...........12

INSTALLATION - ENGINE ASSEMBLY........14

SPECIFICATIONS

SPECIFICATIONS - 2.4L ENGINE.........16

SPECIFICATIONS - TORQUE............20

SPECIAL TOOLS

2.4L ENGINE.........................21

AIR CLEANER ELEMENT

REMOVAL.............................24INSTALLATION.........................24

AIR CLEANER HOUSING

REMOVAL.............................25

INSTALLATION.........................25

CYLINDER HEAD

DESCRIPTION.........................25

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET............................25

REMOVAL - CYLINDER HEAD.............26

CLEANING............................26

INSPECTION..........................27

INSTALLATION - CYLINDER HEAD..........27

CAMSHAFT OIL SEAL(S)

REMOVAL.............................28

INSTALLATION.........................29

CAMSHAFT(S)

DESCRIPTION.........................29

OPERATION...........................29

STANDARD PROCEDURE - MEASURING

CAMSHAFT END PLAY.................29

REMOVAL.............................30

CLEANING............................30

INSPECTION..........................30

INSTALLATION.........................31

CYLINDER HEAD COVER

REMOVAL.............................31

CLEANING............................31

INSPECTION..........................31

INSTALLATION.........................32

INTAKE/EXHAUST VALVES & SEATS

DESCRIPTION.........................33

CLEANING............................33

VALVE SPRINGS & SEALS

REMOVAL

REMOVAL - CYLINDER HEAD ON.........33

REMOVAL - CYLINDER HEAD OFF........33

INSPECTION..........................33

RSENGINE9-1

Page 1184 of 2339

CONDITION POSSIBLE CAUSES CORRECTION

MAIN BEARING NOISE 1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Thick oil 4. (a) Change engine oil and filter.

(b) Run engine to operating

temperature.

(c) Change engine oil and filter

again.

5. Excessive bearing clearance. 5. Measure bearings for correct

clearance. Repair as necessary.

6. Excessive end play. 6. Check thrust bearing for wear on

flanges.

7. Crankshaft journal out-of-round

or worn.7. Replace crankshaft or grind

journals.

8. Loose flywheel or torque

converter.8. Tighten to correct torque.

OIL PRESSURE DROP 1. Low oil level. 1. Check engine oil level.

2. Faulty oil pressure sensor/switch. 2. Replace oil pressure sensor/

switch.

3. Low oil pressure. 3. Check oil pressure sensor/switch

and main bearing oil clearance.

4. Clogged oil filter. 4. Install new oil filter.

5. Worn parts in oil pump. 5. Replace worn parts or pump.

6. Thin or diluted oil. 6. Change oil to correct viscosity.

7. Oil pump relief valve stuck. 7. Remove valve and inspect, clean,

or replace.

8. Oil pump suction tube loose. 8. Remove oil pan and install new

tube or clean, if necessary.

9. Oil pump cover warped or

cracked.9. Install new oil pump.

10. Excessive bearing clearance. 10. Measure bearings for correct

clearance.

OIL LEAKS 1. Misaligned or deteriorated

gaskets.1. Replace gasket(s).

2. Loose fastener, broken or porous

metal part.2. Tighten, repair or replace the

part.

3. Misaligned or deteriorated cup or

threaded plug.3. Replace as necessary.

RSENGINE 2.4L9-7

ENGINE 2.4L (Continued)

Page 1186 of 2339

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak. If a leak is

present in this area, remove transmission for further

inspection.

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, oil gallery cup

plug, bedplate to cylinder block mating surfaces

and seal bore. See proper repair procedures for

these items.

(4) If no leaks are detected, pressurize the crank-

case as previously described.

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

(7) After the oil leak root cause and appropriate

corrective action have been identified, replace compo-

nent(s) as necessary.

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Check engine oil level and add oil if necessary.

(2) Drive the vehicle until engine reaches normal

operating temperature. Select a route free from traf-

fic and other forms of congestion, observe all traffic

laws, and accelerate through the gears several times

briskly.

(3) Remove all spark plugs from engine. As spark

plugs are being removed, check electrodes for abnor-

mal firing indicators fouled, hot, oily, etc. Record cyl-

inder number of spark plug for future reference.(4) Remove the Auto Shutdown (ASD) relay from

the PDC.

(5) Be sure throttle blade is fully open during the

compression check.

(6) Insert compression gauge adaptor Special Tool

8116 or the equivalent, into the #1 spark plug hole in

cylinder head. Connect the 0±500 psi (Blue) pressure

transducer (Special Tool CH7059) with cable adap-

tors to the DRBIIIt. For Special Tool identification,

(Refer to 9 - ENGINE - SPECIAL TOOLS).

(7) Crank engine until maximum pressure is

reached on gauge. Record this pressure as #1 cylin-

der pressure.

(8) Repeat the previous step for all remaining cyl-

inders.

(9) Compression should not be less than 689 kPa

(100 psi) and not vary more than 25 percent from cyl-

inder to cylinder.

(10) If one or more cylinders have abnormally low

compression pressures, repeat the compression test.

(11) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.The recommended com-

pression pressures are to be used only as a

guide to diagnosing engine problems. An engine

should not be disassembled to determine the

cause of low compression unless some malfunc-

tion is present.

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

WARNING: DO NOT REMOVE THE PRESSURE CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the pressure cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF.

Clean spark plug recesses with compressed air.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

RSENGINE 2.4L9-9

ENGINE 2.4L (Continued)

Page 1188 of 2339

(11) Fill engine with specified amount of approved

oil.

(12) Connect negative battery cable.

(13) Start engine and check for any leaks.

FORM-IN-PLACE GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN IIis used to seal

components exposed to engine oil. This material is a

specially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTVis a specifically designed

black silicone rubber RTV that retains adhesion and

sealing properties to seal components exposed to

automatic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKERis an anaerobic type

gasket material. The material cures in the absence of

air when squeezed between two metallic surfaces. It

will not cure if left in the uncovered tube. The

anaerobic material is for use between two machined

surfaces. Do not use on flexible metal flanges.

MOPARtBED PLATE SEALANTis a unique

(green-in-color) anaerobic type gasket material that

is specially made to seal the area between the bed

plate and cylinder block without disturbing the bear-

ing clearance or alignment of these components. The

material cures slowly in the absence of air when

torqued between two metallic surfaces, and will rap-

idly cure when heat is applied.

MOPARtGASKET SEALANTis a slow drying,

permanently soft sealer. This material is recom-

mended for sealing threaded fittings and gasketsagainst leakage of oil and coolant. Can be used on

threaded and machined parts under all tempera-

tures. This material is used on engines with multi-

layer steel (MLS) cylinder head gaskets. This

material also will prevent corrosion. MopartGasket

Sealant is available in a 13 oz. aerosol can or 4oz./16

oz. can w/applicator.

SEALER APPLICATION

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

STANDARD PROCEDURE - ENGINE GASKET

SURFACE PREPARATION

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components and multi-layer

steel cylinder head gaskets.

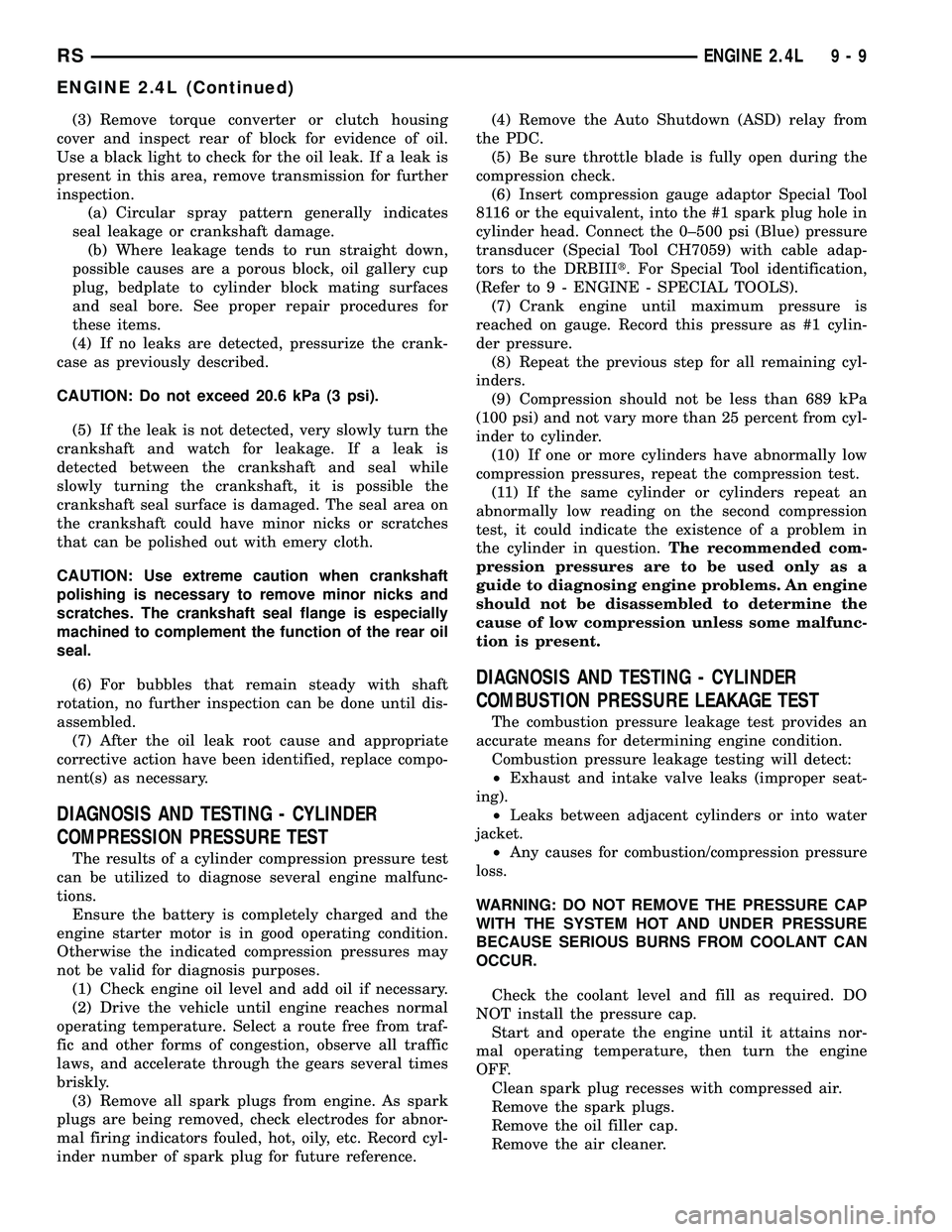

Neveruse the following to clean gasket surfaces:

²Metal scraper

²Abrasive pad or paper to clean cylinder block

and head

²High speed power tool with an abrasive pad or a

wire brush (Fig. 3)

NOTE: Multi-Layer Steel (MLS) head gaskets require

a scratch free sealing surface.

Only use the following for cleaning gasket surfaces:

²Solvent or a commercially available gasket

remover

²Plastic or wood scraper (Fig. 3)

RSENGINE 2.4L9-11

ENGINE 2.4L (Continued)

Page 1189 of 2339

²Drill motor with 3M RolocŸ Bristle Disc (white

or yellow) (Fig. 3)

CAUTION: Excessive pressure or high RPM (beyond

the recommended speed), can damage the sealing

surfaces. The mild (white, 120 grit) bristle disc is

recommended. If necessary, the medium (yellow, 80

grit) bristle disc may be used on cast iron surfaces

with care.

STANDARD PROCEDURE - MEASURING

BEARING CLEARANCE USING PLASTIGAGE

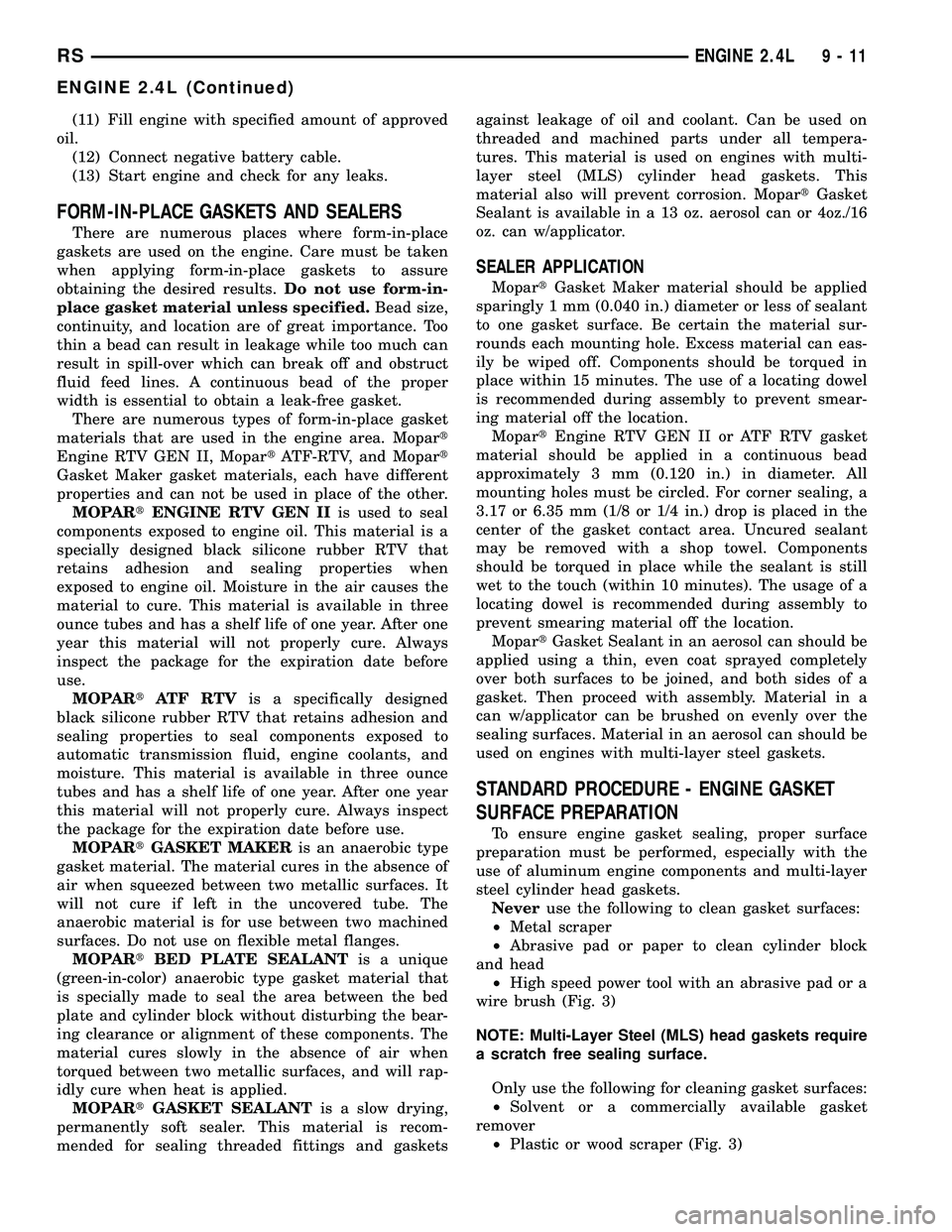

Engine crankshaft bearing clearances can be deter-

mined by use of Plastigage or equivalent. The follow-

ing is the recommended procedure for the use of

Plastigage:

(1) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(2) Place a piece of Plastigage across the entire

width of the bearing shell in the cap approximately

6.35 mm (1/4 in.) off center and away from the oil

holes (Fig. 4). (In addition, suspected areas can be

checked by placing the Plastigage in the suspected

area). Torque the bearing cap/bed plate bolts of the

bearing being checked to the proper specifications.

(3) Remove the bearing cap and compare the

width of the flattened Plastigage with the metric

scale provided on the package. Locate the band clos-

est to the same width. This band shows the amount

of clearance in thousandths of a millimeter. Differ-

ences in readings between the ends indicate the

amount of taper present. Record all readings taken.

Compare the clearance measurements to specsifica-

tions found in the engine specifications table(Refer to9 - ENGINE - SPECIFICATIONS).Plastigage gen-

erally is accompanied by two scales. One scale

is in inches, the other is a metric scale.

NOTE: Plastigage is available in a variety of clear-

ance ranges. Use the most appropriate range for

the specifications you are checking.

(4) Install the proper crankshaft bearings to

achieve the specified bearing clearances.

REMOVAL - ENGINE ASSEMBLY

(1) Perform fuel pressure release procedure (Refer

to 14 - FUEL SYSTEM/FUEL DELIVERY - STAN-

DARD PROCEDURE)

(2) Disconnect battery negative cable.

(3) Remove air cleaner housing and inlet tube.

(4) Disconnect the fuel line from fuel rail. (Refer to

14 - FUEL SYSTEM/FUEL DELIVERY/FUEL LINES

- STANDARD PROCEDURE)

(5) Disconnect all vacuum hoses.

(6) Drain cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(7) Remove radiator fans. (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - REMOVAL)

(8) Remove radiator upper and lower hoses.

NOTE: When the transaxle cooler lines are removed

from the rolled-groove type fittings at the transaxle,

damage to the inner wall of the hose will occur. To

prevent prevent potential leakage, the cooler hoses

must be cut off flush at the transaxle fitting, and a

service cooler hose splice kit must be installed

upon reassembly.

Fig. 3 Proper Tool Usage For Surface Preparation

1 - ABRASIVE PAD

2 - 3M ROLOCŸ BRISTLE DISC

3 - PLASTIC/WOOD SCRAPER

Fig. 4 Plastigage Placed in Lower ShellÐTypical

1 - PLASTIGAGE

9 - 12 ENGINE 2.4LRS

ENGINE 2.4L (Continued)