torque CHRYSLER VOYAGER 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 499 of 2339

(12) Install the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

INSTALLATION).

(13) Connect the 4±way harness connector to the

speed control/horn harness to the clockspring.

(14) Connect the 2±way connector to the remote

radio control harness.

(15) Install the driver airbag (Refer to 8 - ELEC-

TRICAL/RESTRAINTS/DRIVER AIRBAG - INSTAL-

LATION). Torque the two screws to 10 N´m (90 in.

lbs.).

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING). Personal injury or

death may result if the system test is not performed

properly.

REMOVAL

(1) Position steering wheel and front wheels

straight ahead.

(2) Release hood latch and open hood.

(3) Disconnect and isolate the battery negative

cable.

(4)

WARNING: Wait two minutes for the airbag system

reserve capacitor to discharge before beginning

any airbag system or component service. Failure to

do so may result in accidental airbag deployment,

personal injury or death.

(5) Remove driver airbag from steering wheel

(Refer to 8 - ELECTRICAL/RESTRAINTS/DRIVER

AIRBAG - REMOVAL).

(6) Disconnect wire connectors from back of driver

airbag.

(7) Disconnect the 2±way connector from remote

radio control harness.

(8) Disconnect the 4±way harness connector from

the speed control/horn harness to the clockspring.

(9) Remove steering wheel (Refer to 19 - STEER-

ING/COLUMN/STEERING WHEEL - REMOVAL).

(10) Remove steering column shrouds and discon-

nect traction control wire connector (if equipped)

(Refer to 19 - STEERING/COLUMN/LOWER

SHROUD - REMOVAL).

(11) Disconnect 4-way and 6-way connectors

between the clockspring and the instrument panel

wiring harness.

(12) Remove clockspring from column assembly by

removing the two retaining screws that attach the

clock spring to the column.

INSTALLATION

(1) Install the clockspring on the column.

(2) Connect the 4-way and 6-way connectors

between the clockspring and the instrument panel

wiring harness.

(3) Install the steering column shrouds and con-

nect traction control wire connector (if equipped)

(Refer to 19 - STEERING/COLUMN/LOWER

SHROUD - INSTALLATION).

(4) Install the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

INSTALLATION).

(5) Connect the 4±way harness connector to the

speed control/horn harness to the clockspring.

(6) Connect the 2±way connector to the remote

radio control harness (if equipped).

(7) Install the driver airbag (Refer to 8 - ELEC-

TRICAL/RESTRAINTS/DRIVER AIRBAG - INSTAL-

LATION). Torque the two screws to 10 N´m (90 in.

lbs.).

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

CURTAIN AIRBAG

DESCRIPTION

Curtain Airbags (Fig. 11) are available when it is

also equipped with dual front airbags. These airbags

are passive and inflatable, Supplemental Restraint

System (SRS) components, and vehicles with this

equipment can be readily identified by a molded

identification trim button with the ªSRS - AIRBAGº

logo (Fig. 12) located on the B-pillar and C-pillar

upper trim panels. This system is designed to reduce

injuries to the vehicle occupants in the event of a

side impact collision.

Curtain airbags have two individually controlled

curtain airbag units. These airbag units are con-

cealed and mounted above the headliner where they

are each secured to one of the roof side rails (Fig.

13). Each airbag cushion is contained within a fabric

wrap that extends along the roof rail from the A-pil-

lar at the front of the vehicle to just behind the

D-pillar at the rear of the vehicle. One tether extends

down the A-pillar from the front of the airbag cush-

ion, and a second tether extends to the roof rail at

the D-pillar. The end of the A-pillar tether is secured

to a slot in the sheet metal with a metal hook

retained by a bolt. The D-pillar tether is attached to

the d-pillar.

8O - 12 RESTRAINTSRS

CLOCKSPRING (Continued)

Page 505 of 2339

INSTALLATION

DEPLOYED AIRBAG

(1) Perform clean up procedure (Refer to 8 - ELEC-

TRICAL/RESTRAINTS - STANDARD PROCEDURE

- SERVICE AFTER AN AIRBAG DEPLOYMENT).

(2) Install a new steering column assembly and

lower steering column coupler (Refer to 19 - STEER-

ING/COLUMN - INSTALLATION).

(3) Install the new clockspring.

(4) Connect the 4-way and 6-way connectors

between the clockspring and the instrument panel

wiring harness.

(5) Install the steering column shrouds and con-

nect traction control wire connector (if equipped)

(Refer to 19 - STEERING/COLUMN/LOWER

SHROUD - INSTALLATION).

(6) Install the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

INSTALLATION).

(7) Connect the 4±way harness connector to the

speed control/horn harness to the clockspring.

(8) Connect the 2±way connector to the remote

radio control harness.

(9) Install the driver airbag and the two screws

retaining the airbag. Tighten screws to 10 N´m (90

in. lbs.)

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

UNDEPLOYED AIRBAG

(1) Connect the harness connector on the driver

airbag trim cover (horn, speed controls) to the clock-

spring.

(2) Connect the squib connectors to the driver air-

bag.

(3) Position the driver airbag into the steering

wheel.

(4) Install the two screws retaining the airbag.

Tighten screws to 10 N´m (90 in. lbs.)

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

IMPACT SENSOR

DESCRIPTION

FRONT IMPACT SENSORS

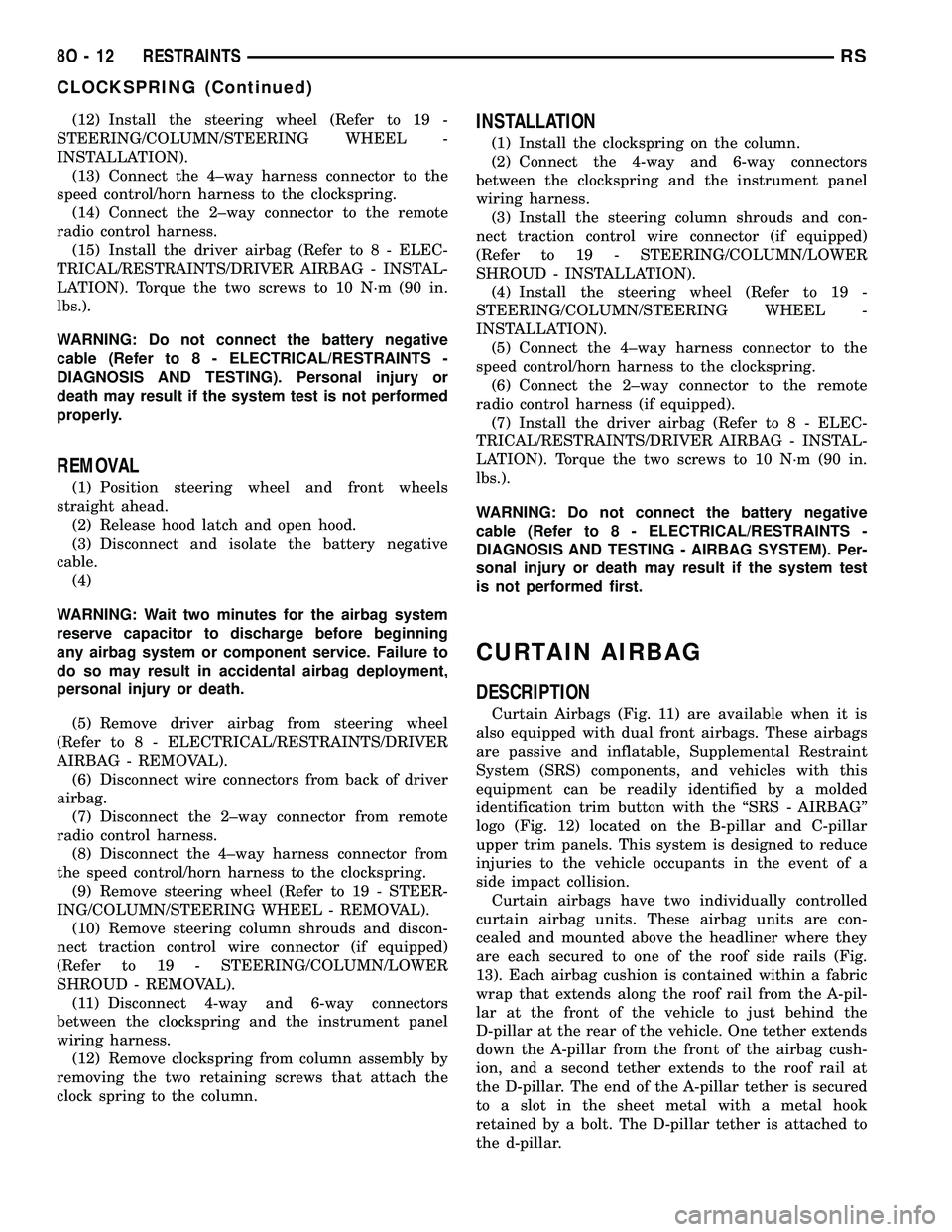

There are two front impact sensors (Fig. 21), one

on the left, and one on the right front sides of the

vehicle. These sensors are mounted remotely from

the impact sensor that is internal to the Occupant

Restraint Controller (ORC). The right and left front

and side impact sensors are identical in construction

and calibration and each front impact sensor is

secured with two screws. The front impact sensors

are secured with two screws to the outboard sides of

the right and left front rail tips.

The impact sensor housing has an integral connec-

tor and two mounting ears, each with a metal sleeve

to provide crush protection. A cavity in the center of

the molded black plastic impact sensor housing con-

tains the electronic circuitry of the sensor which

includes an electronic communication chip and an

electronic impact sensor. Potting material fills the

cavity to seal and protect the internal electronic cir-

cuitry and components. The front impact sensors are

each connected to the vehicle electrical system

through the headlamp to dash wire harness.

The front impact sensors cannot be repaired or

adjusted and, if damaged or faulty, they must be

replaced. If a front impact sensor is faulty, only the

sensor needs to be replaced. If the sensor is damaged

or faulty, or if proper tightening torque of the screws

that secure the sensor to the bracket cannot be

achieved, the sensor and bracket must be replaced.

Refer to the proper body diagnostic information for

diagnosis and testing.

Fig. 21 FRONT IMPACT SENSOR

8O - 18 RESTRAINTSRS

DRIVER AIRBAG (Continued)

Page 508 of 2339

WARNING: Wait two minutes for the system reserve

capacitor to discharge before beginning any airbag

component service. Personal injury or death may

result.

(3) Open sliding door to the fullest open position.

(4) Remove the two retaining screws to the impact

sensor (Fig. 27).

(5) Disconnect the electrical connector from the

impact sensor and remove from vehicle (Fig. 27).

QUARTER PANEL MOUNTED

(1) Open hood, disconnect and isolate the battery

negative cable.

(2)

WARNING: Wait two minutes for the system reserve

capacitor to discharge before beginning any airbag

component service. Personal injury or death may

result.

(3) Remove the quarter trim panel for the side of

the vehicle that you are replacing the side impact

sensor (Refer to 23 - BODY/INTERIOR/QUARTER

TRIM PANEL - REMOVAL).

(4) Remove the two retaining screws to the impact

sensor (Fig. 28).

(5) Disconnect the electrical connector from the

impact sensor and remove from vehicle (Fig. 28).

INSTALLATION

FRONT IMPACT SENSOR

(1) Position sensor in vehicle (Fig. 24).

(2) Install the two retaining screws to the impact

sensor (Fig. 24). Torque screws to 7 N´m (62 in. lbs.).

(3) Connect electrical connector (Fig. 24).

(4) Lower vehicle from hoist.

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

(5) Verify vehicle and system operation.

(6) Close hood.

SIDE IMPACT SENSORS

B-PILLAR MOUNTED

(1) Position sensor bracket in vehicle (Fig. 25).

(2) Install the four retaining screws to the impact

sensor bracket (Fig. 25). Torque screws to 7 N´m (62

in. lbs.).

(3) Connect the electrical connector (Fig. 25).

(4) Install the B-pillar lower trim for the side of

the vehicle that you are replacing the side impact

sensor (Refer to 23 - BODY/INTERIOR/B-PILLAR

LOWER TRIM - INSTALLATION).

Fig. 27 2ND ROW SIDE IMPACT SENSOR

1 - 2ND ROW SIDE IMPACT SENSOR ELECTRICAL CONNECTOR

2 - 2ND ROW SIDE IMPACT SENSOR RETAINING SCREWS

3 - SLIDING DOOR LOWER ROLLER ARM

Fig. 28 3RD ROW SIDE IMPACT SENSOR

1 - 3RD ROW SIDE IMPACT SENSOR

2 - 3RD ROW SIDE IMPACT SENSOR MOUNTING SCREWS

3 - REAR SPEAKER

4 - REAR WHEEL WELL

RSRESTRAINTS8O-21

IMPACT SENSOR (Continued)

Page 509 of 2339

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

(5) Verify vehicle and system operation.

(6) Close hood.

SLIDING DOOR OPENING MOUNTED

(1) Connect electrical connector (Fig. 27).

(2) Position sensor in vehicle (Fig. 27).

(3) Install the two retaining screws to the impact

sensor (Fig. 27). Torque screws to 7 N´m (62 in. lbs.).

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

(4) Verify vehicle and system operation.

(5) Close hood.

QUARTER PANEL MOUNTED

(1) Position sensor in vehicle (Fig. 28).

(2) Connect electrical connector (Fig. 28).

(3) Install the two retaining screws to the impact

sensor (Fig. 28). Torque screws to 7 N´m (62 in. lbs.).

(4) Install the quarter trim panel for the side of

the vehicle that you are replacing the side impact

sensor (Refer to 23 - BODY/INTERIOR/QUARTER

TRIM PANEL - INSTALLATION).

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

(5) Verify vehicle and system operation.

(6) Close hood.

KNEE BLOCKER AIRBAG

DESCRIPTION

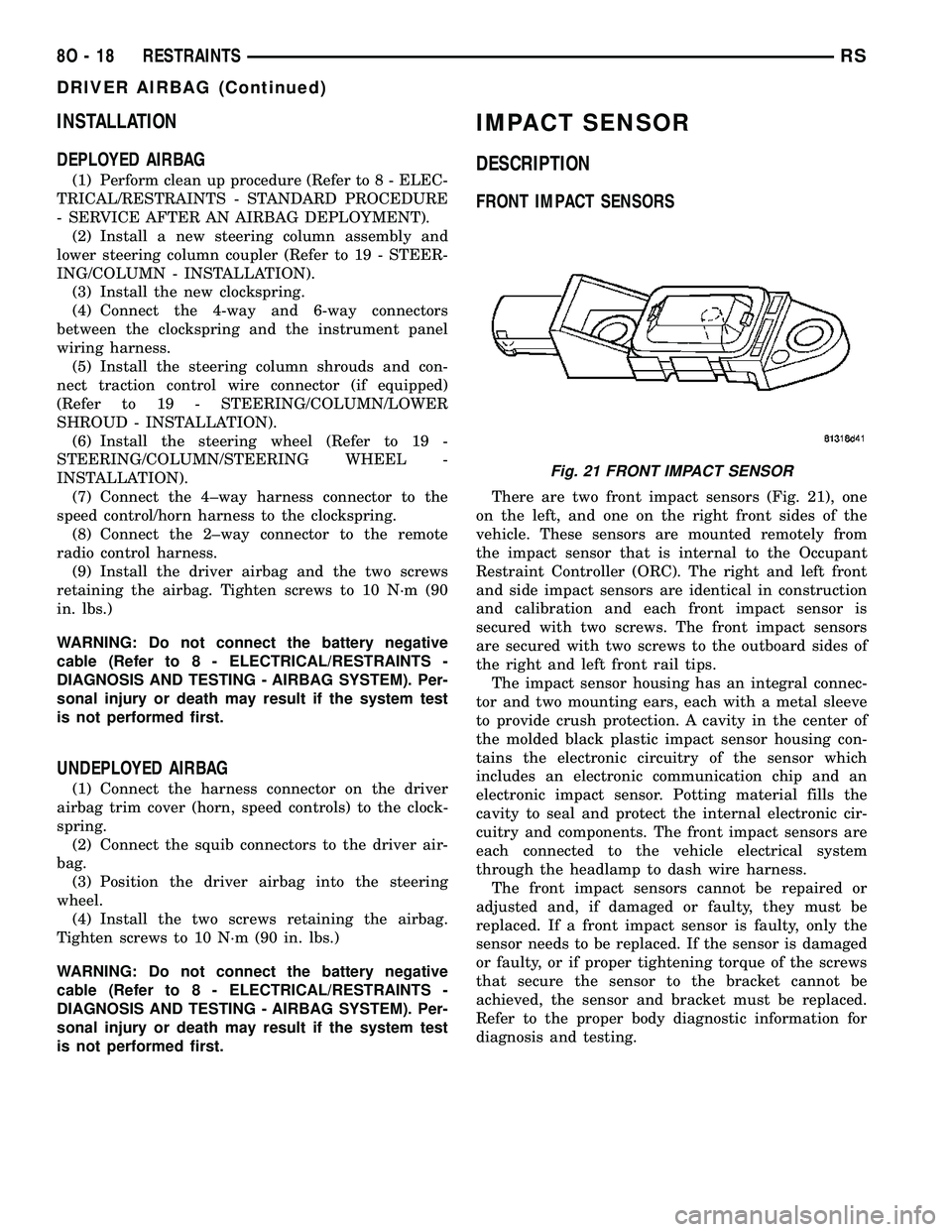

The Knee Blocker Airbag (Fig. 29) is located on the

driver side of the vehicle beneath the instrument

panel under steering column cover (Fig. 30).

The knee blocker airbag includes one reaction plate

and one load plate, within which the cushion and

inflator are mounted and sealed. Following a knee

blocker airbag deployment, the knee blocker airbag

and instrument panel assembly must be replaced.

Refer to the proper diagnostic information for diagno-

sis and testing.

OPERATION

The knee blocker airbag is equipped with a single

inflator. When the Occupant Restraint Controller

(ORC) sends the proper electrical signals to the initi-

ator, the electrical energy generates enough heat to

initiate a small pyrotechnic charge which, in turn

ignites chemical pellets within the inflator. Once

ignited, these chemical pellets burn rapidly and pro-

duce a large quantity of inert gas. The inflator is

sealed to the back of the airbag housing and a dif-

fuser in the inflator directs all of the inert gas into

the airbag cushion, causing the cushion to inflate. As

the cushion inflates, the knee blocker airbag trim

deploy. Following an airbag deployment, the airbag

cushion quickly deflates by venting the inert gas

towards the instrument panel through vent holes

within the fabric used to construct the back panel of

the airbag cushion.

Some of the chemicals used to create the inert gas

may be considered hazardous while in their solid

state before they are burned, but they are securely

sealed within the airbag inflator. Typically, the poten-

tially hazardous chemicals are burned during an air-

bag deployment event.

WARNING: The inert gas that is produced when the

chemicals are burned is harmless. However, a small

amount of residue from the burned chemicals may

cause some temporary discomfort if it contacts the

skin, eyes, or breathing passages. If skin or eye irri-

tation is noted, rinse the affected area with plenty

of cool, clean water. If breathing passages are irri-

tated, move to another area where there is plenty of

clean, fresh air to breath. If the irritation is not alle-

viated by these actions, contact a physician.

Fig. 29 KNEE BLOCKER AIRBAG

8O - 22 RESTRAINTSRS

IMPACT SENSOR (Continued)

Page 514 of 2339

ger side front seat cushion unit with another com-

plete service replacement package. (Refer to 23 -

BODY/SEATS/SEAT CUSHION - FRONT -

REMOVAL).

WARNING: Never replace both the Occupant

Restraint Controller (ORC) and the Occupant Clas-

sification Module (OCM) at the same time. If both

require replacement, replace one, then perform the

Airbag System test (Refer to 8 - ELECTRICAL/RE-

STRAINTS - DIAGNOSIS AND TESTING - AIRBAG

SYSTEM) before replacing the other. Both the ORC

and the OCM store Occupant Classification System

(OCS) calibration data, which they transfer to one

another when one of them is replaced. If both are

replaced at the same time, an irreversible fault will

be set in both modules and the OCS may malfunc-

tion may result in personal injury or death.

(1) Carefully position the Occupant Classification

Module (OCM) to the OCM bracket (Fig. 36). When

the OCM is correctly positioned, the connector on the

module will be pointed to right side of the vehicle.

(2) Install the two screws to the OCM. Torque the

screws to 2 N´m (20 in. lbs.).

(3) Connect the seat wire harness connector for the

OCM. Be certain that the latches on the connector

are each fully engaged.(4) Install the lock pin into the connector lock

tower on the OCM.

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

WARNING: Following successful completion of the

Airbag System test procedure, the Occupant Classi-

fication System Verification Test must be done

using a scan tool and the appropriate diagnostic

information.

(5) Verify vehicle and system operation.

(6) Close hood.

OCCUPANT RESTRAINT

CONTROLLER

DESCRIPTION

The Occupant Restraint Controller (ORC) (Fig. 37)

is also sometimes referred to as the Airbag Control

Module (ACM).

Fig. 36 OCM - REMOVE/INSTALL

1 - OCCUPANT CLASSIFICATION MODULE (OCM)

2 - LOCK TOWER

3 - LOCK PIN

4 - CONNECTOR

5 - SCREW (2)

6 - BRACKET

Fig. 37 OCCUPANT RESTRAINT CONTROLLER -

TYPICAL

1 - ORC

2 - ORIENTATION ARROW UPON INSTALLATION

3 - LABEL

4 - ORC ELECTRICAL CONNECTORS

RSRESTRAINTS8O-27

OCCUPANT CLASSIFICATION MODULE (Continued)

Page 517 of 2339

WARNING: Never replace both the Occupant

Restraint Controller (ORC) and the Occupant Clas-

sification Module (OCM) at the same time. If both

require replacement, replace one, then perform the

Airbag System test (Refer to 8 - ELECTRICAL/RE-

STRAINTS - DIAGNOSIS AND TESTING - AIRBAG

SYSTEM) before replacing the other. Both the ORC

and the OCM store Occupant Classification System

(OCS) calibration data, which they transfer to one

another when one of them is replaced. If both are

replaced at the same time, an irreversible fault will

be set in both modules and the OCS may malfunc-

tion and result in personal injury or death.

(1) Install the ORC into vehicle (Fig. 39).

(2) Connect the wire connector to the ORC (Fig.

39).

(3) Install three bolts holding ORC to floor bracket

(Fig. 39). Torque bolts to 7.3 - 9.6 N´m (65 to 85 in.

lbs.)

(4) Install the storage bin onto the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

STORAGE BIN - INSTALLATION).

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

(5) Verify vehicle and system operation.

(6) Close hood.

PASSENGER AIRBAG

DESCRIPTION

WARNING: Never disassemble the passenger air-

bag. The passenger airbag has no serviceable

parts. If tampered with internally, the airbag could

deploy and result in personal injury or death.

The Passenger Airbag is located beneath the

instrument panel and pad assembly. The airbag is

mounted to the back side of the instrument panel

reinforcement.

The instrument panel top pad is the most visible

part of the passenger airbag system. Located under

the instrument panel top pad are the airbag door, the

passenger airbag cushion and the airbag cushion

supporting components.

The passenger airbag includes a magnesium hous-

ing within which the cushion and inflator are

mounted and sealed.

Following a passenger airbag deployment, the pas-

senger airbag and the instrument panel must bereplaced. The passenger airbag cannot be repaired,

and must be replaced if deployed or damaged in any

way.

OPERATION

The passenger airbag is equipped with two infla-

tors, each with three levels of pressure output. The

inflators seal the hole in the airbag cushion so it can

discharge the gas it produces directly into the cush-

ion when supplied with the proper electrical signal.

Following an airbag deployment, the airbag cushion

quickly deflates by venting this gas through the

cushion material towards the instrument panel.

The passenger airbag is secured with screws to the

instrument panel beneath the instrument panel top

pad and above the glove box opening. The instrument

panel top pad above the glove box opening conceals

the airbag door and a predetermined hinge line

beneath its decorative cover. Upon airbag deploy-

ment, the top pad will bend at the hinge line and the

door will fold back out of the way onto the top of the

instrument panel.

When the front airbag system is deployed, the fol-

lowingMUSTbe replaced:

²Complete Steering Column Assembly.

²Lower Steering Column Coupler.

²Steering Wheel.

²Clock Spring.

²Driver Airbag.

²Passenger Airbag.

²Upper Instrument Panel with Pad.

CARE OF UNDEPLOYED AIRBAGS

Airbags must be stored in their original special

container until used for service. At no time should a

source of electricity be permitted near the inflator on

the back of an airbag. When carrying or handling an

undeployed airbag, the trim side of the airbag should

be pointing away from the body to minimize possibil-

ity of injury if accidental deployment occurs. Do not

place undeployed airbag face down on a solid surface,

the airbag will propel into the air if accidental

deployment occurs.

REMOVAL

DEPLOYED AIRBAG

(1) Open hood.

(2) Disconnect and isolate the battery negative

cable.

(3)

8O - 30 RESTRAINTSRS

OCCUPANT RESTRAINT CONTROLLER (Continued)

Page 519 of 2339

(38) Remove the two passenger airbag to instru-

ment panel cover/pad retaining screws.

(39) Remove the three passenger airbag to instru-

ment panel reinforcement retaining bolts.

(40) Pull rearward slightly on the instrument

panel cover/pad to maneuver passenger airbag out

from reinforcement and instrument panel.

INSTALLATION

DEPLOYED AIRBAG

Transfer all reusable components to the new

instrument panel.

(1) Install new Passenger Airbag into instrument

panel.

(2) Install airbag attaching bolts to the instrument

panel.

(a) Torque the two bolts at instrument panel

retainer bosses to 2.7 .5 N´m (24 5 in. lbs.).

(b) Torque the three bolts that attach the pas-

senger airbag to cross-car beam to 10 2 N´m (90

15 in. lbs.).

(3) Connect yellow wire connector to passenger air-

bag and affix connector to instrument panel rein-

forcement with push pins.

(4) Install Instrument panel (Refer to 23 - BODY/

INSTRUMENT PANEL/INSTRUMENT PANEL

ASSEMBLY - INSTALLATION).

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

UNDEPLOYED AIRBAG

(1) Pull rearward slightly on the instrument panel

cover/pad to maneuver passenger airbag up onto

reinforcement and instrument panel.

(2) Install the three passenger airbag to instru-

ment panel reinforcement retaining bolts but leave

loose. This will help align the passenger airbag for

the cover/pad fit.

(3) Install the two passenger airbag to instrument

panel cover/pad retaining screws. Torque screws to

2.7 .5 N´m (24 5 in. lbs.).

NOTE: Insure that the instrument panel cover/pad

locator pins are indexed properly at center stack

area prior to reassembly.

(4) Tighten the three passenger airbag to instru-

ment panel reinforcement retaining bolts. Torque

bolts to 10 2 N´m (90 15 in. lbs.).(5) Connect the passenger airbag electrical connec-

tor. Install the connector onto the instrument panel

reinforcement with the push-pin fasteners.

(6) Roll the instrument panel forward lifting

slightly so as to seat the instrument panel air distri-

bution duct on top of the HVAC unit properly to

avoid any leaks or damage to the seal.

(7) Install six upper fence line instrument panel

retaining bolts.

(8) Install three right side instrument panel A-pil-

lar retaining bolts and tighten the right instrument

panel roll down bolt. Install the smaller 10 mm bolt

first to align the instrument panel properly.

(9) Install three left side instrument panel A-pillar

retaining bolts and tighten the left instrument panel

roll down bolt. Install the smaller 10 mm bolt first to

align the instrument panel properly.

(10) Install seven lower instrument panel cover/

pad retaining screws.

(11) Install four screws along top front edge of

instrument panel cover/pad.

(12) Install one far left instrument panel speaker

retaining screw.

(13) Install wiring connectors to radio. Install

radio and four retaining screws.

(14) Connect glove box lamp wiring connector and

place right lower instrument panel trim (glove box

surround) into position.

(15) Install nineteen right lower instrument panel

trim (glove box surround) and install panel screws.

(16) Slide cup holder assembly into instrument

panel.

(17) Install center bezel wiring connectors to

HVAC control and switch assembly (hazard, rear

wiper/washer, heated seats).

(18) Install instrument panel center bezel by align-

ing slots and firmly snapping into place.

(19) Install two screws to instrument panel center

bezel.

(20) Align filler bezel above cup holder over retain-

ing slots and firmly snap into place.

(21) Place instrument panel top cover into position

and firmly snap down rear edge of top cover.

(22) Install glove box. Align hinges, snap into

place, roll glove box upwards and push in sides to

fully install.

(23) Align right side upper A-pillar trim over

retaining slots and firmly snap into place.

(24) Align right A-pillar lower extension trim over

retaining slots and firmly snap into place.

(25) Align right instrument panel end cap over

retaining slots and firmly snap into place.

(26) Align right cowl panel over retaining slots and

firmly snap into place.

(27) Align right front door sill plate over retaining

slots and firmly snap into place.

8O - 32 RESTRAINTSRS

PASSENGER AIRBAG (Continued)

Page 522 of 2339

SEAT BELT BUCKLE - FRONT

INBOARD

REMOVAL

The seat belt tensioners are integral to the front

seat belt buckles. They are not serviceable and must

be replaced after a frontal impact event. The entire

front seat belt buckle assembly must be replaced as

an assembly.

(1) Open hood.

(2) Disconnect and isolate the battery negative

cable.

(3)

WARNING: Wait two minutes for the airbag system

reserve capacitor to discharge before beginning

any airbag system or component service. Failure to

do so may result in accidental airbag deployment,

personal injury or death.

(4) Remove screws attaching front inboard side

cover to seat cushion frame.

(5) Remove side cover from front seat.

(6) Disconnect the tensioner wire connector from

seat belt buckle.

(7) Remove bolt attaching seat belt buckle to front

seat track.

(8) Remove buckle from seat.

INSTALLATION

The seat belt tensioners are integral to the front

seat belt buckles. They are not serviceable and must

be replaced after a frontal impact event. The entire

front seat belt buckle assembly must be replaced as

an assembly.

(1) Place buckle into position.

(2) Install bolt attaching seat belt buckle to front

seat track. Torque bolt to 39 N´m (29 ft. lbs.).

(3) Connect the seat belt tensioner electrical con-

nector.

(4) Install side cover into position.

(5) Install screws attaching front inboard side

cover to seat cushion frame.

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

WARNING: If equipped with the Occupant Classifi-

cation System (OCS) and replacing the passenger

front seat belt buckle: Following successful com-

pletion of the Airbag System test procedure, the

Occupant Classification System Verification Testmust be done using a scan tool and the appropriate

diagnostic information.

(6) Close hood.

(7) Verify system and vehicle operation.

SEAT BELT BUCKLE - FIRST

ROW INBOARD - QUAD

BUCKET

REMOVAL

QUAD BUCKET

(1) Remove seat from vehicle.

(2) Remove screws attaching inboard side cover to

seat cushion.

(3) Remove side cover from seat.

(4) Remove bolts attaching recliner bracket to seat

cushion.

(5) Remove recliner bracket from seat.

(6) Remove bolt attaching seat belt buckle to seat

track (Fig. 41).

(7) Remove buckle from vehicle.

QUAD BUCKET - FOLD IN FLOOR

(1) Fold in floor the seat not having the buckle

replaced.

(2) Remove the hinge cover retaining screw and

hinge cover.

Fig. 41 1ST ROW INBOARD BUCKLE - QUAD

BUCKET

1 - SEAT CUSHION

2 - SEAT BELT BUCKLE

3 - SEAT TRACK

RSRESTRAINTS8O-35

Page 523 of 2339

(3) Remove the hinge retaining bolts under the

cushion cover side panel (Fig. 42).

(4) Gently lift hinge upwards to free buckle from

between the cushion frame and the hinge itself (Fig.

43).(5) Remove buckle half from seat.

INSTALLATION

QUAD BUCKET

(1) Place buckle into position.

(2) Install bolt attaching seat belt buckle to seat

track. Torque bolt to 39 N´m (29 ft. lbs.).

(3) Install recliner bracket onto the seat.

(4) Install bolts attaching recliner bracket to seat

cushion.

(5) Install side cover from seat.

(6) Install screws attaching inboard side cover to

seat cushion.

(7) Install seat into position.

QUAD BUCKET - FOLD IN FLOOR

(1) Gently lift hinge upwards and place buckle in

between the cushion frame and the hinge itself (Fig.

43).

(2) Install the hinge retaining bolts under the

cushion cover side panel (Fig. 42).

(3) Install the hinge cover retaining screw and

hinge cover.

SEAT BELT BUCKLE - FIRST

ROW - BENCH

REMOVAL

(1) Remove seat from vehicle.

(2) Remove bolt attaching inboard seat belt buckle

to seat frame (Fig. 44).

(3) Remove belt from seat.

Fig. 42 1ST ROW INBOARD BUCKLE RETAINING

BOLTS - FOLD IN FLOOR

1 - SEAT BELT BUCKLE

2 - SEAT BACK INBOARD HINGE

3 - SEAT RISER

4 - INBOARD HINGE RETAINING BOLTS

5 - SEAT CUSHION COVER SIDE PANEL

Fig. 43 1ST ROW INBOARD BUCKLE - FOLD IN

FLOOR

1 - SEAT BACK HINGE

2 - SEAT BELT BUCKLE

3 - SEAT CUSHION FRAME

Fig. 44 SEAT BELT BUCKLE - FIRST ROW - BENCH

1 - ANCHOR BOLT

2 - TWO (2) PASS REAR SEAT BELT BUCKLE

3 - RISER

4 - REAR FRAME

8O - 36 RESTRAINTSRS

SEAT BELT BUCKLE - FIRST ROW INBOARD - QUAD BUCKET (Continued)

Page 524 of 2339

INSTALLATION

(1) Place seat belt into position to the seat.

(2) Install bolt attaching inboard seat belt buckle

to seat frame. Tighten all seat belt anchor bolts to 39

N´m (29 ft. lbs.) torque.

(3) Install seat into position.

SEAT BELT BUCKLE - SECOND

ROW INBOARD - 50/50 BENCH

REMOVAL

SECOND ROW 50/50 BENCH

(1) Open rear liftgate.

(2) Pull handle #1 and fold seat back forward.

(3) Pull handle #2, and lift seat bottom up.

(4) Pull #3 strap and remove seat from latching

area.

(5) While looking at the bottom of the seat, locate

retaining bolt on the left side of the seat riser.

Remove retaining bolt from seat riser (Fig. 45).

(6) Pull belt through seat cushion.

SECOND ROW - FOLD IN FLOOR

(1) Fold in floor the seat not having the buckle

replaced.(2) Remove the hinge cover retaining screw (Fig.

46).

(3) Pull hinge cover out just far enough to gain

access to buckle retaining nut (Fig. 47). Remove nut

and slide buckle out from under cushion cover side

panel.

Fig. 45 SEAT BELT BUCKLE - SECOND ROW

INBOARD - 50/50 BENCH

1 - SEAT BELT BUCKLE

2 - BUCKLE RETAINING BOLT

3 - 50/50 SPLIT BENCH RISER

4 - BOTTOM OF SEAT CUSHION

Fig. 46 FIRST ROW BUCKLE - INBOARD - COVER

RETAINING SCREW

1 - SEAT BELT BUCKLE

2 - HINGE COVER

3 - HINGE COVER RETAINING SCREW

4 - CUSHION COVER SIDE PANEL

Fig. 47 FIRST ROW BUCKLE - INBOARD -

RETAINING NUT

1 - SEAT BELT BUCKLE

2 - HINGE COVER

3 - SEAT BELT BUCKLE RETAINING NUT

4 - CUSHION COVER SIDE PANEL

RSRESTRAINTS8O-37

SEAT BELT BUCKLE - FIRST ROW - BENCH (Continued)