enter code CHRYSLER VOYAGER 2005 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 321 of 2339

press the ENTER button to view the SERVICE

CODE. Pressing the CODE button a second time will

return you to the test results.

BATTERY TEST RESULTS

GOOD BATTERY Return to service

GOOD - RECHARGE Fully charge battery and

return to service

CHARGE & RETEST Fully charge battery and

retest battery

REPLACE BATTERY Replace the battery and

retest complete system

BAD-CELL REPLACE Replace the battery and

retest complete system

NOTE: The SERVICE CODE is required on every

warranty claim submitted for battery replacement.

REMOVAL - BATTERY

WARNING: A SUITABLE PAIR OF HEAVY DUTY

RUBBER GLOVES AND SAFETY GLASSES SHOULD

BE WORN WHEN REMOVING OR SERVICING A

BATTERY.

WARNING: REMOVE METALLIC JEWELRY TO

AVOID INJURY BY ACCIDENTAL ARCING OF BAT-

TERY CURRENT.

(1) Verify that the ignition switch and all accesso-

ries are OFF.

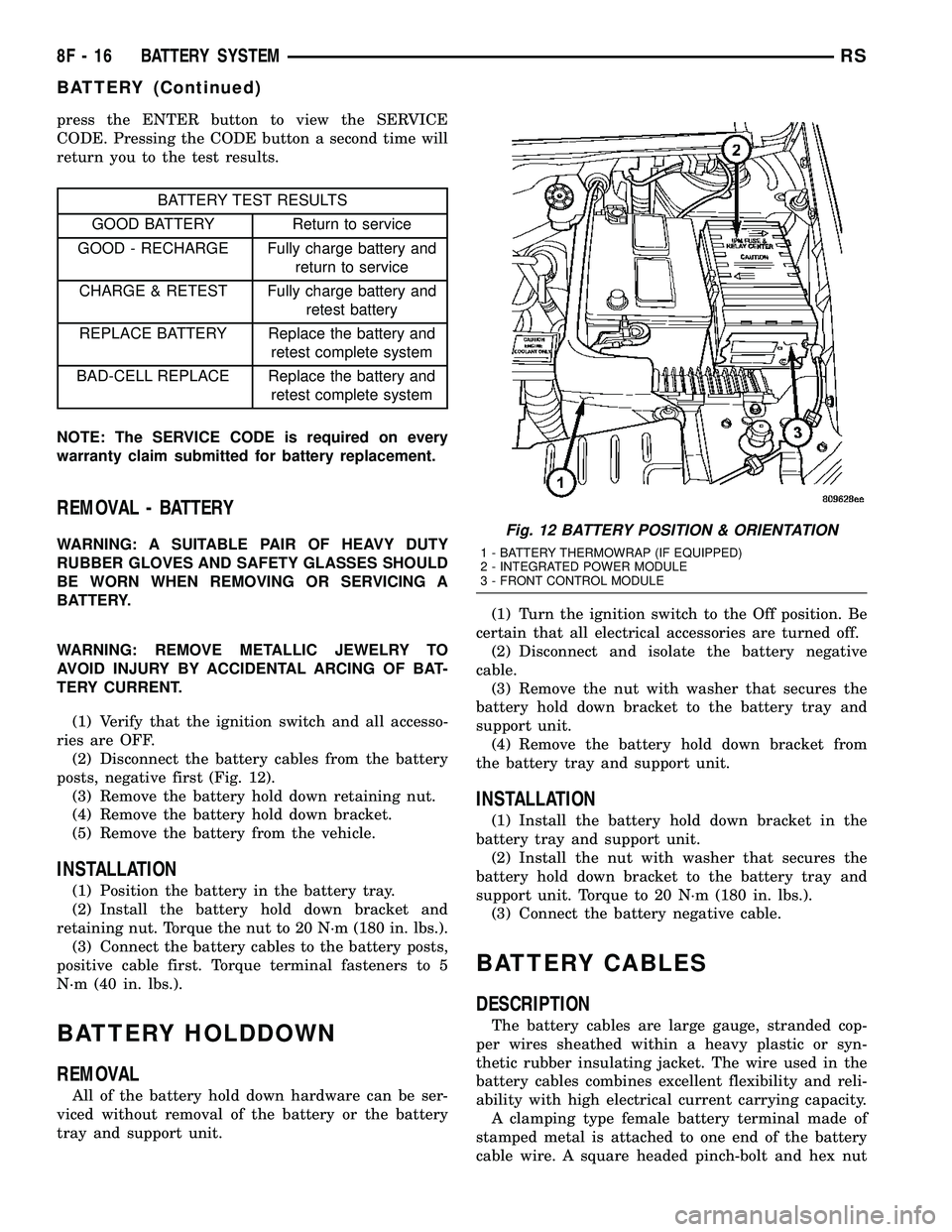

(2) Disconnect the battery cables from the battery

posts, negative first (Fig. 12).

(3) Remove the battery hold down retaining nut.

(4) Remove the battery hold down bracket.

(5) Remove the battery from the vehicle.

INSTALLATION

(1) Position the battery in the battery tray.

(2) Install the battery hold down bracket and

retaining nut. Torque the nut to 20 N´m (180 in. lbs.).

(3) Connect the battery cables to the battery posts,

positive cable first. Torque terminal fasteners to 5

N´m (40 in. lbs.).

BATTERY HOLDDOWN

REMOVAL

All of the battery hold down hardware can be ser-

viced without removal of the battery or the battery

tray and support unit.(1) Turn the ignition switch to the Off position. Be

certain that all electrical accessories are turned off.

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the nut with washer that secures the

battery hold down bracket to the battery tray and

support unit.

(4) Remove the battery hold down bracket from

the battery tray and support unit.

INSTALLATION

(1) Install the battery hold down bracket in the

battery tray and support unit.

(2) Install the nut with washer that secures the

battery hold down bracket to the battery tray and

support unit. Torque to 20 N´m (180 in. lbs.).

(3) Connect the battery negative cable.

BATTERY CABLES

DESCRIPTION

The battery cables are large gauge, stranded cop-

per wires sheathed within a heavy plastic or syn-

thetic rubber insulating jacket. The wire used in the

battery cables combines excellent flexibility and reli-

ability with high electrical current carrying capacity.

A clamping type female battery terminal made of

stamped metal is attached to one end of the battery

cable wire. A square headed pinch-bolt and hex nut

Fig. 12 BATTERY POSITION & ORIENTATION

1 - BATTERY THERMOWRAP (IF EQUIPPED)

2 - INTEGRATED POWER MODULE

3 - FRONT CONTROL MODULE

8F - 16 BATTERY SYSTEMRS

BATTERY (Continued)

Page 327 of 2339

ULES/POWERTRAIN CONTROL MODULE -

DESCRIPTION) section for more DTC information.

The Charging system ªBatteryº light indicates

problems with the charging system (voltage too high/

low, generator failure, etc.). If an extreme condition is

indicated, the lamp will be illuminated. The signal to

activate the lamp is sent via the PCI bus circuits.

The lamp is located on the instrument panel. Refer

to the Instrument Cluster section for additional infor-

mation.

The PCM uses the ambient air temperature sensor

to control the charge system voltage. This tempera-

ture, along with data from monitored line voltage, is

used by the PCM to vary the battery charging rate.

The system voltage is higher at cold temperatures

and is gradually reduced as the calculated battery

temperature increases.

The ambient temperature sensor is used to control

the battery voltage based upon ambient temperature

(approximation of battery temperature). The PCM

maintains the optimal output of the generator by

monitoring battery voltage and controlling it to a

range of 13.5 - 14.7 volts based on battery tempera-

ture.

DIAGNOSIS AND TESTING

ON-BOARD DIAGNOSTIC SYSTEM

The Powertrain Control Module (PCM) monitors

critical input and output circuits of the charging sys-

tem, making sure they are operational. A Diagnostic

Trouble Code (DTC) is assigned to each input and

output circuit monitored by the OBD system. Some

circuits are checked continuously and some are

checked only under certain conditions.

If the OBD system senses that a monitored circuit

is bad, it will put a DTC into electronic memory. The

DTC will stay in electronic memory as long as the

circuit continues to be bad. The PCM is programmed

to clear the memory after 40 good trip if the problem

does not occur again.

DIAGNOSTIC TROUBLE CODES

A DTC description can be read using the DRBIIIt

scan tool. Refer to the appropriate Powertrain Diag-

nostic Procedures manual for information.

A DTC does not identify which component in a cir-

cuit is bad. Thus, a DTC should be treated as a

symptom, not as the cause for the problem. In some

cases, because of the design of the diagnostic test

procedure, a DTC can be the reason for another DTC

to be set. Therefore, it is important that the test pro-

cedures be followed in sequence, to understand what

caused a DTC to be set.ERASING DIAGNOSTIC TROUBLE CODES

The DRBIIItScan Tool must be used to erase a

DTC.

The following procedures may be used to diagnose

the charging system if:

²the check gauges lamp or battery lamp is illumi-

nated with the engine running

²the voltmeter (if equipped) does not register

properly

²an undercharged or overcharged battery condi-

tion occurs.

Remember that an undercharged battery is often

caused by:

²accessories being left on with the engine not

running

²a faulty or improperly adjusted switch that

allows a lamp to stay on. Refer to Ignition-Off Draw

Test (Refer to 8 - ELECTRICAL/BATTERY SYSTEM/

BATTERY - STANDARD PROCEDURE)

²loose generator belt.

INSPECTION

The Powertrain Control Module (PCM) monitors

critical input and output circuits of the charging sys-

tem, making sure they are operational. A Diagnostic

Trouble Code (DTC) is assigned to each input and

output circuit monitored by the On-Board Diagnostic

(OBD) system. Some charging system circuits are

checked continuously, and some are checked only

under certain conditions.

Refer to Diagnostic Trouble Codes in; Powertrain

Diagnostic manual for more DTC information. This

will include a complete list of DTC's including DTC's

for the charging system.

To perform a complete test of the charging system,

refer to the appropriate Powertrain Diagnostic Proce-

dures service manual and the DRBIIItscan tool.

Perform the following inspections before attaching

the scan tool.

(1) Inspect the battery condition. Refer to the Bat-

tery section (Refer to 8 - ELECTRICAL/BATTERY

SYSTEM - DIAGNOSIS AND TESTING) for proce-

dures.

(2) Inspect condition of battery cable terminals,

battery posts, connections at engine block, starter

solenoid and relay. They should be clean and tight.

Repair as required.

(3) Inspect all fuses in both the fuseblock and

Power Distribution Center (PDC) or IPM (if

equipped) for tightness in receptacles. They should be

properly installed and tight. Repair or replace as

required.

(4) Inspect generator mounting bolts for tightness.

Replace or tighten bolts if required. Refer to the Gen-

erator Removal/Installation section of this group for

8F - 22 CHARGINGRS

CHARGING (Continued)

Page 411 of 2339

OVERHEAD CONSOLE

TABLE OF CONTENTS

page page

OVERHEAD CONSOLE

DESCRIPTION..........................2

DIAGNOSIS AND TESTING

OVERHEAD CONSOLE..................3

STANDARD PROCEDURE

COMPASS CALIBRATION................4

COMPASS DEMAGNETIZING.............5

COMPASS VARIATION ADJUSTMENT.......5

REMOVAL.............................6

INSTALLATION..........................6

SPECIAL TOOLS

OVERHEAD CONSOLE..................7

ELECTRONIC VEHICLE INFO CENTER

DESCRIPTION..........................7

OPERATION............................7

DIAGNOSIS AND TESTING

ELECTRONIC VEHICLE INFORMATION

CENTER.............................8

STANDARD PROCEDURE

ELECTRONIC VEHICLE INFORMATION

CENTER PROGRAMMING................8

REMOVAL.............................9

INSTALLATION.........................10

COMPASS/MINI-TRIP COMPUTER

DESCRIPTION.........................10OPERATION...........................10

DIAGNOSIS AND TESTING

COMPASS MINI-TRIP COMPUTER........10

REMOVAL.............................10

INSTALLATION.........................10

UNIVERSAL TRANSMITTER

DESCRIPTION.........................11

DIAGNOSIS AND TESTING

UNIVERSAL TRANSMITTER.............11

STANDARD PROCEDURE

SETTING TRANSMITTER CODES.........12

ERASING TRANSMITTER CODES.........12

REMOVAL.............................12

AMBIENT TEMP SENSOR

DESCRIPTION.........................12

OPERATION...........................12

DIAGNOSIS AND TESTING

AMBIENT TEMPERATURE SENSOR.......12

AMBIENT TEMPERATURE SENSOR

CIRCUIT............................12

REMOVAL.............................13

INSTALLATION.........................13

OVERHEAD CONSOLE

DESCRIPTION

Three overhead consoles options are available on

this vehicle. These options are:

²The Electronic Vehicle Information Center

(EVIC)

²The Compass Mini-Trip Computer (CMTC)

All consoles are equipped with two reading/cour-

tesy lamps and if the vehicle is equipped with a

power liftgate or power sliding door(s) the overhead

console will also include switches for these features.

The overhead console is mounted with one screw and

two snap clips to a molded plastic retainer bracket

located above the headliner.

DESCRIPTION - COMPASS

All overhead consoles include compass information.

While in the compass/temperature mode, the com-

pass will display the direction in which the vehicle is

pointed using the eight major compass headings

(Examples: north is N, northeast is NE). The self-cal-

ibrating compass unit requires no adjusting in nor-

mal use. The only calibration that may be necessary

is to drive the vehicle in three complete circles at 5

to 8 kilometers-per-hour (3 to 5 miles-per-hour), on

level ground, for a minimum of forty-eight seconds.

This will reorient the compass unit to its vehicle.

8M - 2 OVERHEAD CONSOLERS

Page 420 of 2339

NOTE: If a new CMTC module has been installed,

the compass will have to be calibrated and the vari-

ance set. (Refer to 8 - ELECTRICAL/OVERHEAD

CONSOLE - STANDARD PROCEDURE - COMPASS

CALIBRATION).

UNIVERSAL TRANSMITTER

DESCRIPTION

A Universal Transmitter transceiver is available on

some vehicles. The universal transmitter transceiver

is integral to the Electronic Vehicle Information Cen-

ter (EVIC) and the Compass Mini-Trip Computer

(CMTC) modules, which are located in the overhead

console. The only visible component of the universal

transmitter are the three transmitter push buttons

centered between the modules push buttons located

just rearward of the display screen in the overhead

console. The three universal transmitter push but-

tons are identified with one, two or three light indi-

cators so that they can be easily identified.

Each of the three universal transmitter push but-

tons controls an independent radio transmitter chan-

nel. Each of these three channels can be trained to

transmit a different radio frequency signal for the

remote operation of garage door openers, motorized

gate openers, home or office lighting, security sys-

tems or just about any other device that can be

equipped with a radio receiver in the 286 to 399

MegaHertz (MHz) frequency range for remote opera-

tion. The universal transmitter is capable of operat-

ing systems using either rolling code or non-rolling

code technology.

The electronics module displays messages and a

small house-shaped icon with one, two or three dots

corresponding to the three transmitter buttons to

indicate the status of the universal transmitter. The

EVIC messages are:

²Cleared Channels- Indicates that all of the

transmitter codes stored in the universal transmitter

have been successfully cleared.

²Training- Indicates that the universal trans-

mitter is in its transmitter learning mode.

²Trained- Indicates that the universal transmit-

ter has successfully acquired a new transmitter code.

²Transmit- Indicates that a trained universal

transmitter button has been depressed and that the

universal transmitter is transmitting.

The universal transmitter cannot be repaired, and

is available for service only as a unit with the EVIC

or CMTC modules. If any of these components is

faulty or damaged, the complete EVIC or CMTC

module must be replaced.

DIAGNOSIS AND TESTING

UNIVERSAL TRANSMITTER

If both the Universal Transmitter and the Elec-

tronic Vehicle Information Center (EVIC) are inoper-

ative, (Refer to 8 - ELECTRICAL/OVERHEAD

CONSOLE/ELECTRONIC VEHICLE INFO CENTER

- DIAGNOSIS AND TESTING). If the Universal

Transmitter is inoperative, but the EVIC is operating

normally, retrain the Transmitter with a known good

transmitter (Refer to 8 - ELECTRICAL/OVERHEAD

CONSOLE/UNIVERSAL TRANSMITTER - STAN-

DARD PROCEDURE - SETTING TRANSMITTER

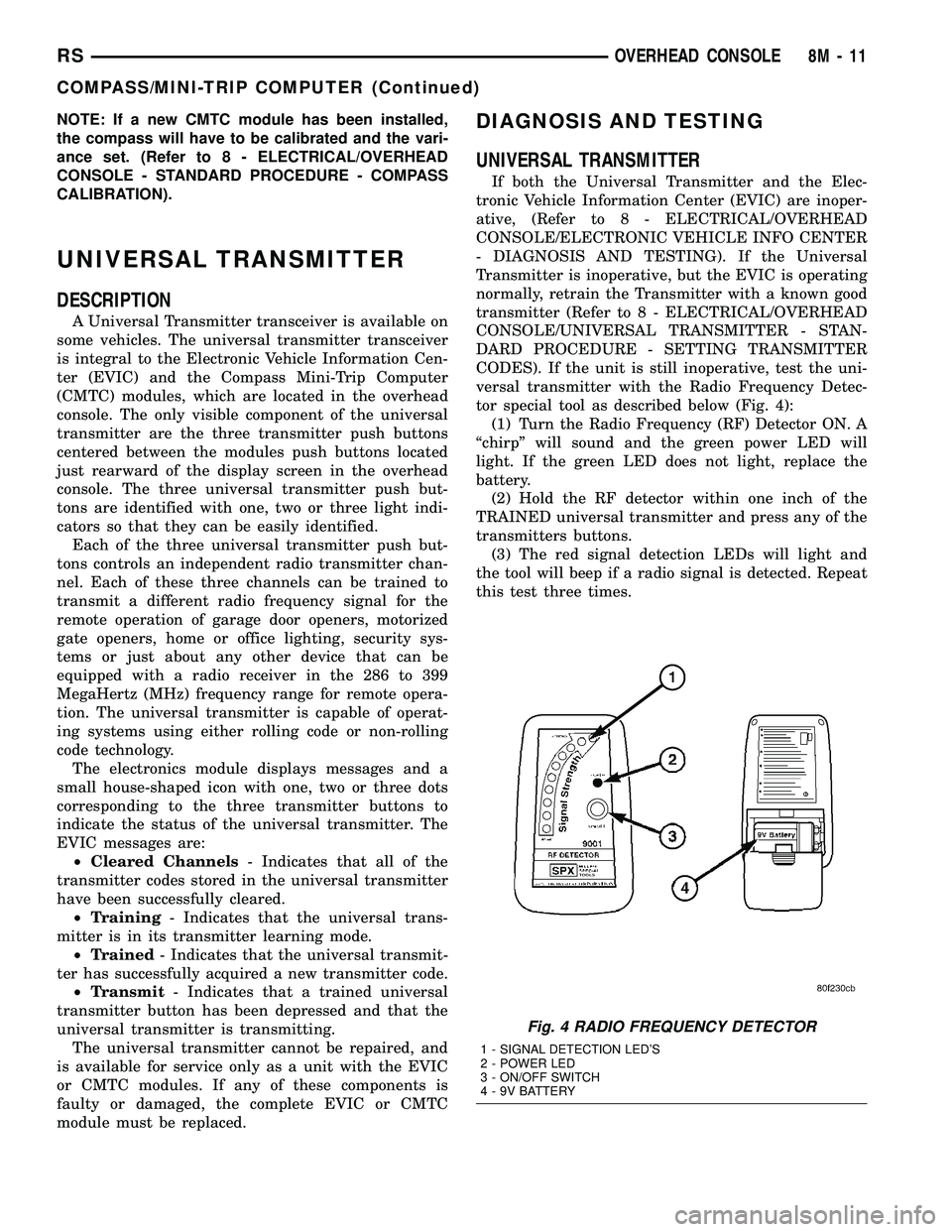

CODES). If the unit is still inoperative, test the uni-

versal transmitter with the Radio Frequency Detec-

tor special tool as described below (Fig. 4):

(1) Turn the Radio Frequency (RF) Detector ON. A

ªchirpº will sound and the green power LED will

light. If the green LED does not light, replace the

battery.

(2) Hold the RF detector within one inch of the

TRAINED universal transmitter and press any of the

transmitters buttons.

(3) The red signal detection LEDs will light and

the tool will beep if a radio signal is detected. Repeat

this test three times.

Fig. 4 RADIO FREQUENCY DETECTOR

1 - SIGNAL DETECTION LED'S

2 - POWER LED

3 - ON/OFF SWITCH

4 - 9V BATTERY

RSOVERHEAD CONSOLE8M-11

COMPASS/MINI-TRIP COMPUTER (Continued)

Page 421 of 2339

STANDARD PROCEDURE

SETTING TRANSMITTER CODES

(1) Turn off the engine.

(2) Erase the codes by pressing the two outside

buttons. Release the buttons when the display con-

firms the operation (about 20 seconds).

(3) Choose one of the three buttons to train. Place

the hand-held transmitter within one inch of the uni-

versal transmitter and push the buttons on both

transmitters.

(4) Release both buttons. Your universal transmit-

ter is now ªtrainedº. To train the other buttons,

repeat Step 3 and Step 4. Be sure to keep your hand-

held transmitter in case you need to retrain the uni-

versal transmitter.

ERASING TRANSMITTER CODES

To erase the universal transmitter codes, simply

hold down the two outside buttons until the display

confirms the operation.

NOTE: Individual channels cannot be erased. Eras-

ing the transmitter codes will erase ALL pro-

grammed codes.

REMOVAL

(1) For the universal transmitter removal proce-

dure, (Refer to 8 - ELECTRICAL/OVERHEAD CON-

SOLE/COMPASS/MINI-TRIP COMPUTER -

REMOVAL.

AMBIENT TEMP SENSOR

DESCRIPTION

Ambient air temperature is monitored by the over-

head console through ambient temperature messages

received from the Powertrain Control Module (PCM)

over the Programmable Communications Interface

(PCI) data bus circuit. The PCM receives a hard

wired input from the ambient temperature sensor.

The ambient temperature sensor is a variable resis-

tor mounted to a bracket that is secured with a screw

to the right side of the headlamp mounting module

grille opening, behind the radiator grille and in front

of the engine compartment.

For additional information on the PCM, (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/POWERTRAIN CONTROL MODULE -

DESCRIPTION).

OPERATION

The ambient temperature sensor is a variable

resistor that operates on a five-volt reference signal

sent by the Powertrain Control Module (PCM). The

resistance in the sensor changes as temperature

changes, changing the temperature sensor signal cir-

cuit voltage to the PCM. Based upon the resistance

in the sensor, the PCM senses a specific voltage on

the temperature sensor signal circuit, which it is pro-

grammed to correspond to a specific temperature.

The PCM then sends the proper ambient tempera-

ture messages to the Electronic Vehicle Information

Center (EVIC)/Compass Mini-Trip Computer (CMTC)

over the Programmable Communication Interface

(PCI) data bus.

The thermometer function is supported by the

ambient temperature sensor, a wiring circuit, the

PCM, the PCI data bus, and the Electronics module.

If any portion of the ambient temperature sensor cir-

cuit fails, the PCM will self-diagnose the circuit.

The ambient temperature sensor circuit can also be

diagnosed manually (Refer to 8 - ELECTRICAL/

OVERHEAD CONSOLE/AMBIENT TEMP SENSOR

- DIAGNOSIS AND TESTING - AMBIENT TEM-

PERATURE SENSOR CIRCUIT). If the temperature

sensor and circuit are confirmed to be OK, but the

temperature display is inoperative or incorrect,

(Refer to 8 - ELECTRICAL/OVERHEAD CONSOLE -

DIAGNOSIS AND TESTING) to determine the cause.

For complete circuit diagrams, refer to the appropri-

ate wiring information.

DIAGNOSIS AND TESTING

AMBIENT TEMPERATURE SENSOR

(1) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the ambient temperature sensor wire har-

ness connector.

(2) Measure the resistance of the ambient temper-

ature sensor. At room temperature (approx. 68ÉF),

the sensor resistance should be between 10-13 Kilo-

hms. The sensor resistance should be between these

two values at 68ÉF. If the resistance is out of range

replace the ambient temperature sensor.

AMBIENT TEMPERATURE SENSOR CIRCUIT

(1) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the ambient temperature sensor wire har-

ness connector and the Powertrain Control Module

(PCM) wire harness connector.

8M - 12 OVERHEAD CONSOLERS

UNIVERSAL TRANSMITTER (Continued)

Page 425 of 2339

POWER LIFTGATE SYSTEM

DESCRIPTION

the components of the power liftgate system are:

²Liftgate gear motor assembly

²Latch assembly

²Lift gear and rod

²Power liftgate control module

²Chime/thermistor

²Full open switch

²Engage actuator

²Pinch sensor

²Liftgate handle switch

²Overhead console switch

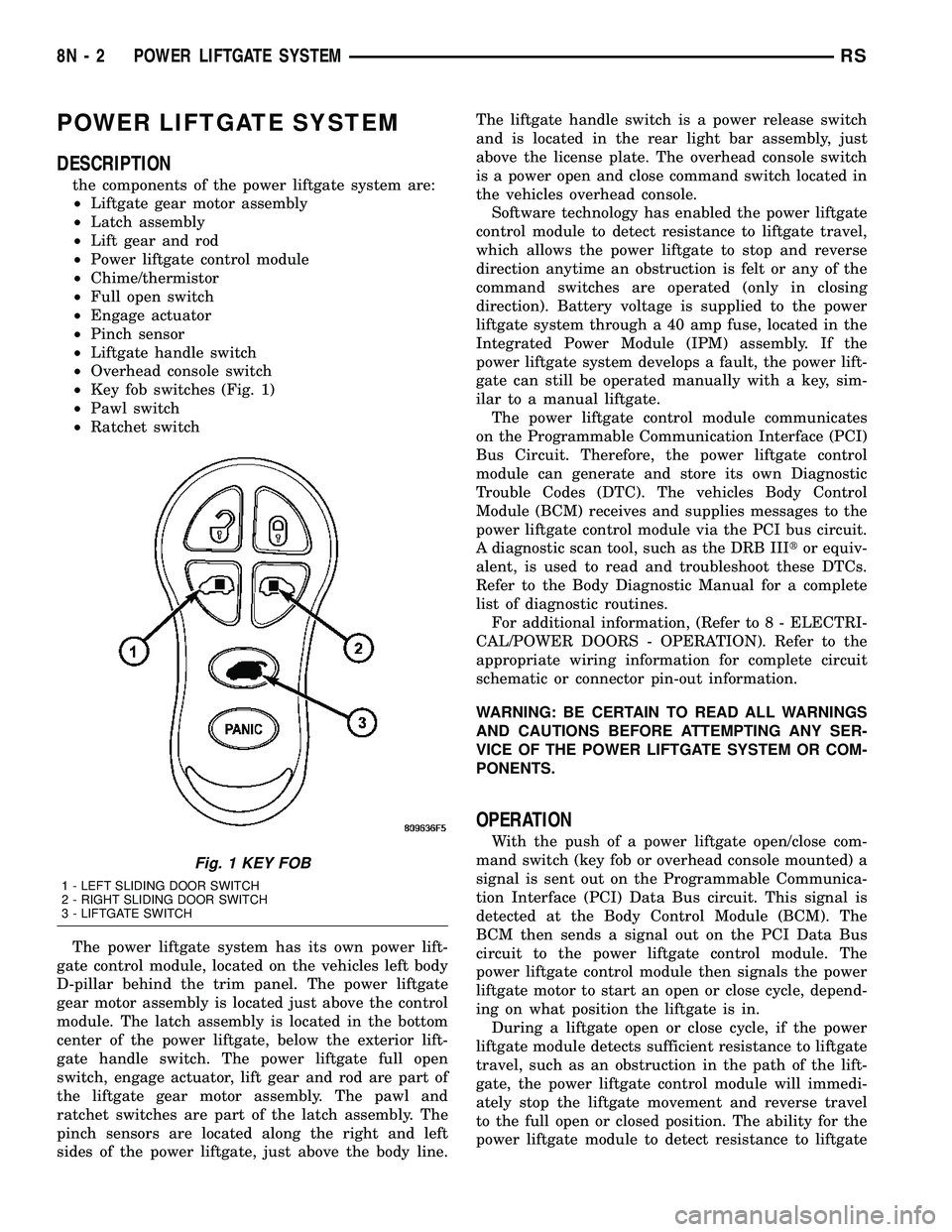

²Key fob switches (Fig. 1)

²Pawl switch

²Ratchet switch

The power liftgate system has its own power lift-

gate control module, located on the vehicles left body

D-pillar behind the trim panel. The power liftgate

gear motor assembly is located just above the control

module. The latch assembly is located in the bottom

center of the power liftgate, below the exterior lift-

gate handle switch. The power liftgate full open

switch, engage actuator, lift gear and rod are part of

the liftgate gear motor assembly. The pawl and

ratchet switches are part of the latch assembly. The

pinch sensors are located along the right and left

sides of the power liftgate, just above the body line.The liftgate handle switch is a power release switch

and is located in the rear light bar assembly, just

above the license plate. The overhead console switch

is a power open and close command switch located in

the vehicles overhead console.

Software technology has enabled the power liftgate

control module to detect resistance to liftgate travel,

which allows the power liftgate to stop and reverse

direction anytime an obstruction is felt or any of the

command switches are operated (only in closing

direction). Battery voltage is supplied to the power

liftgate system through a 40 amp fuse, located in the

Integrated Power Module (IPM) assembly. If the

power liftgate system develops a fault, the power lift-

gate can still be operated manually with a key, sim-

ilar to a manual liftgate.

The power liftgate control module communicates

on the Programmable Communication Interface (PCI)

Bus Circuit. Therefore, the power liftgate control

module can generate and store its own Diagnostic

Trouble Codes (DTC). The vehicles Body Control

Module (BCM) receives and supplies messages to the

power liftgate control module via the PCI bus circuit.

A diagnostic scan tool, such as the DRB IIItor equiv-

alent, is used to read and troubleshoot these DTCs.

Refer to the Body Diagnostic Manual for a complete

list of diagnostic routines.

For additional information, (Refer to 8 - ELECTRI-

CAL/POWER DOORS - OPERATION). Refer to the

appropriate wiring information for complete circuit

schematic or connector pin-out information.

WARNING: BE CERTAIN TO READ ALL WARNINGS

AND CAUTIONS BEFORE ATTEMPTING ANY SER-

VICE OF THE POWER LIFTGATE SYSTEM OR COM-

PONENTS.

OPERATION

With the push of a power liftgate open/close com-

mand switch (key fob or overhead console mounted) a

signal is sent out on the Programmable Communica-

tion Interface (PCI) Data Bus circuit. This signal is

detected at the Body Control Module (BCM). The

BCM then sends a signal out on the PCI Data Bus

circuit to the power liftgate control module. The

power liftgate control module then signals the power

liftgate motor to start an open or close cycle, depend-

ing on what position the liftgate is in.

During a liftgate open or close cycle, if the power

liftgate module detects sufficient resistance to liftgate

travel, such as an obstruction in the path of the lift-

gate, the power liftgate control module will immedi-

ately stop the liftgate movement and reverse travel

to the full open or closed position. The ability for the

power liftgate module to detect resistance to liftgate

Fig. 1 KEY FOB

1 - LEFT SLIDING DOOR SWITCH

2 - RIGHT SLIDING DOOR SWITCH

3 - LIFTGATE SWITCH

8N - 2 POWER LIFTGATE SYSTEMRS

Page 426 of 2339

travel is accomplished by hall effect sensors, drive

motor speed and pinch sensors (tape switches).

Anytime the liftgate is opened or closed using the

power liftgate system the power liftgate control mod-

ule learns from the cycle. If a replacement power lift-

gate component is installed or a liftgate adjustment

is made, the module will relearn the effort and/or

time required to open or close the liftgate. This learn

cycle can be performed with a DRB IIIt, or equiva-

lent scan tool, or with a complete cycle of the liftgate,

using any one of the command switches. (Refer to 8 -

ELECTRICAL/POWER DOORS - STANDARD PRO-

CEDURE) for detailed instructions.

The power liftgate system is designed with a num-

ber of system inhibitors. These inhibitors are neces-

sary for safety and / or feasibility of the power

liftgate system. The power liftgate system inhibitors

are:

²The Power Liftgate may not operate in extreme

temperatures. These extreme temperatures will be

approximately less than -12É F (-24.4É C) or greater

than 143É F (61.6É C). A chime/thermister assembly

in the rear light bar assembly monitors the outside

temperature.

²The vehicle transmission must be in Park or

Neutral for the power liftgate to start a cycle.

²If multiple obstacles are detected during the

same power open or close cycle, the liftgate goes into

manual operation.

²If severe problems occur, Diagnostic Trouble

Codes (DTC) are stored in the power liftgate control

module.

POWER LIFTGATE SYSTEM CAUTIONS AND

WARNINGS

WARNING: ALWAYS DISCONNECT THE BATTERY

NEGATIVE CABLE BEFORE ATTEMPTING ANY

POWER LIFTGATE SYSTEM SERVICE.

WARNING: THERE IS A SMALL AREA ON BOTH

SIDES OF THE LOWER POWER LIFTGATE WHICH

IS NOT PROTECTED BY PINCH SENSORS.

EXTREME CARE MUST BE TAKEN TO PREVENT

OBJECTS FROM ENTERING THIS AREA ONCE THELIFTGATE REACHES THE SECONDARY LATCH

CONTACT (APPROXIMATELY 1/2 INCH BEFORE

FULLY CLOSED).

WARNING: NEVER ATTEMPT TO ENTER OR EXIT

THE VEHICLE WITH THE LIFTGATE IN MOTION.

YOU COULD DAMAGE THE POWER LIFTGATE SYS-

TEM AND/OR COMPONENTS AND/OR CAUSE PER-

SONAL INJURY.

WARNING: NEVER STICK OBJECTS IN THE POWER

LIFTGATE WHEN CINCHING CLOSED. YOU COULD

DAMAGE THE VEHICLE, POWER LIFTGATE SYS-

TEM COMPONENTS AND/OR CAUSE PERSONAL

INJURY.

DIAGNOSIS AND TESTING

POWER LIFTGATE SYSTEM

The power liftgate system contains many compo-

nents and modules. In order to obtain conclusive

testing the Programmable Communications Interface

(PCI) data bus network and all of the electronic mod-

ules that provide inputs to, or receive outputs from

the power liftgate system must be checked.

The power liftgate system can be diagnosed with

an appropriate scan tool, such as the DRB IIItor

equivalent. The DRB IIItcan be used to observe var-

ious switch statuses throughout the power liftgate

system to help diagnose an inoperative switch or

component. The DRB IIItcan also be used to actuate

various components throughout the power liftgate

system to help diagnose an inoperative component.

Before any testing of the power liftgate system is

attempted, the battery should be fully charged, all

built-in power liftgate system inhibitors read and

understood, and all wire harness and ground connec-

tions inspected around the affected areas on the vehi-

cle.

The following are quick reference diagnostic tables

to help when diagnosing and testing the power lift-

gate system.

RSPOWER LIFTGATE SYSTEM8N-3

POWER LIFTGATE SYSTEM (Continued)

Page 465 of 2339

²If multiple obstacles are detected during the

same power open or close cycle the power sliding

door may go into full manual mode.

²If severe Diagnostic Trouble Codes (DTC) are

stored in the power sliding door control module the

power sliding door may go into full manual mode.

²Due to the high pressure created in the passen-

ger compartment with the blower motor on high, the

power sliding door may not complete a power close

cycle unless a window is cracked, allowing the pres-

sure to escape. This situation will only be experi-

enced on some vehicles, or vehicles with brand new

side door weather seals installed.

²The fuel tank filler door must be in the closed

position. Due to the sliding door interference with

the open fuel tank filler door, a mechanical linkage

prevents the side door from opening and striking the

fuel door. Refer to the Body section of this manual for

detailed information on the fuel door lockout feature.

POWER SLIDING DOOR SYSTEM WARNINGS

WARNING: ALWAYS DISCONNECT THE NEGATIVE

BATTERY CABLE BEFORE ATTEMPTING ANY

POWER SLIDING DOOR SYSTEM SERVICE.

WARNING: EXTREME CARE MUST BE TAKEN TO

PREVENT OBJECTS FROM ENTERING THE DOORS

PATH ONCE THE DOOR REACHES THE CINCH

MOTOR CONTACT (APPROXIMATELY 1 INCH

BEFORE FULLY CLOSED). NEVER PLACE

OBJECTS IN THE POWER SLIDING DOOR WHEN

CINCHING CLOSED. THE OBSTACLE DETECTION

FUNCTION IS INOPERATIVE DURING THE CINCH

PHASE AND DAMAGE TO THE VEHICLE, POWER

SLIDING DOOR SYSTEM OR COMPONENTS

AND/OR PERSONAL INJURY MAY OCCUR.

WARNING: NEVER ATTEMPT TO ENTER OR EXIT

THE VEHICLE WHILE THE POWER SLIDING DOOR

IS IN MOTION. YOU COULD DAMAGE THE POWER

SLIDING DOOR SYSTEM OR COMPONENTS

AND/OR CAUSE PERSONAL INJURY.WARNING: NEVER ATTEMPT TO DRIVE AWAY WITH

THE POWER SLIDING DOOR IN MOTION. YOU

COULD DAMAGE THE POWER SLIDING DOOR SYS-

TEM OR COMPONENTS AND/OR CAUSE PER-

SONAL INJURY.

DIAGNOSIS AND TESTING

POWER SLIDING DOOR SYSTEM

The power sliding door system contains many com-

ponents and modules. In order to obtain conclusive

testing, the Programmable Communications Interface

(PCI) data bus network and all of the electronic mod-

ules that provide inputs to, or receive outputs from

the power sliding door system must be checked.

The power sliding door system was designed to be

diagnosed with an appropriate diagnostic scan tool,

such as the DRB IIIt. The most reliable, efficient,

and accurate means to diagnose the power sliding

door system requires the use of a DRB IIItscan tool

and the proper Body Diagnostic Procedures manual.

The DRB IIItcan be used to observe various switch

statuses throughout the power sliding door system to

help the technician diagnose a defective switch or

component. The DRB IIItcan also be used to actuate

various components throughout the power sliding

door system to help the technician diagnose a defec-

tive component.

Before any testing of the power sliding door system

is attempted, the battery should be fully charged, all

built-in power sliding door system inhibitors read

and understood (Refer to 8 - ELECTRICAL/POWER

DOORS - OPERATION) and all wire harness and

ground connections inspected around the affected

areas on the vehicle.

The following are quick reference diagnostic tables

to help when diagnosing and testing the power slid-

ing door system.

8N - 42 POWER SLIDING DOOR SYSTEMRS

POWER SLIDING DOOR SYSTEM (Continued)

Page 492 of 2339

driver and the front seat passenger to the structure

of the instrument panel (Refer to 8 - ELECTRICAL/

RESTRAINTS/KNEE BLOCKER AIRBAG -

DESCRIPTION). The seat belt tensioners remove the

slack from the front seat belts to provide further

assurance that the driver and front seat passenger

are properly positioned and restrained for an airbag

deployment.

When the ORC monitors a problem in any of the

dual front airbag system circuits or components,

including the seat belt tensioners, it stores a Diag-

nostic Trouble Code (DTC) in its memory and sends

an electronic message to the EMIC to turn on the

airbag indicator. Proper testing of the supplemental

restraint system components, the Programmable

Communications Interface (PCI) data bus, the elec-

tronic message inputs to and outputs from the EMIC

or the ORC, as well as the retrieval or erasure of a

DTC from the ORC or the EMIC requires the use of

a scan tool. Refer to the appropriate diagnostic infor-

mation.

OCCUPANT CLASSIFICATION SYSTEM

The Occupant Classification System (OCS) auto-

matically suppresses or enables passenger airbag and

seat belt tensioner operation based upon whether or

not the passenger side front seat is occupied and, if

the seat is occupied, classifies the size of the occu-

pant and whether the seat is occupied by a child

seat.

The OCS has an Occupant Classification Module

(OCM) that monitors inputs from the seat weight

bladder pressure sensor under the passenger side

front seat cushion and from the belt tension sensor

on the passenger side front seat belt lower anchor.

Based upon those inputs the microprocessor within

the OCM classifies the occupant of the passenger

side front seat. The OCM then sends electronic occu-

pant classification messages to the ORC. The micro-

processor and programming of the ORC uses these

occupant classification messages to determine

whether to enable or disable the deployment circuits

for the passenger airbag and seat belt tensioner.

The OCS electrical circuits and components are

continuously monitored by the OCM, and the OCM is

continuously monitored by the ORC. A passenger air-

bag ON/OFF indicator is located in the instrument

panel center stack area. This indicator receives bat-

tery current whenever the ignition switch is in the

ON or START positions, and illuminates only when

the ORC pulls the indicator control circuit to ground.

The indicator illuminates for about seven seconds as

a bulb test each time the ignition switch is turned to

the ON or START positions. Following the bulb test,

the indicator is turned ON or OFF by the ORC based

upon the electronic occupant classification messagesreceived from the OCM. This indicator is illuminated

whenever the passenger airbag and seat belt ten-

sioner operation has been suppressed, and is turned

OFF whenever they are enabled or when the passen-

ger seat is classified as empty.

When the OCM monitors a problem in any of the

OCS circuits or components, it stores a fault code or

DTC in its memory circuit and sends an electronic

message to the ORC. The ORC then sends an elec-

tronic message to the EMIC to turn ON the airbag

indicator. If for any reason the OCM is unable to

classify the occupant it sends an electronic message

to the ORC, and the ORC suppresses passenger air-

bag and seat belt tensioner operation. Proper testing

of the OCS components, the Programmable Commu-

nications Interface (PCI) data bus, the electronic

message inputs to and outputs from the OCM, the

EMIC or the ORC, as well as the retrieval or erasure

of a DTC's, requires the use of a scan tool. Refer to

the appropriate diagnostic information.

WARNING

WARNINGS

Disconnect and isolate the battery negative

cable before beginning any airbag system com-

ponent diagnosis, testing, removal, or installa-

tion procedures. Allow system capacitor to

discharge for two minutes before beginning any

component testing or service. This will disable

the airbag system. Failure to disconnect the

battery negative cable may result in accidental

airbag deployment, personal injury, or death.

Do not place an intact undeployed airbag

face down on a solid surface. The airbag will

propel into the air if accidentally deployed and

may result in personal injury or death.

When carrying or handling an undeployed

airbag, the trim side (face) of the airbag should

be pointing towards the body to minimize pos-

sibility of injury if accidental deployment

occurs. Failure to do this may result in per-

sonal injury or death.

Replace airbag system components with

Mopartreplacement parts. Substitute parts

may appear interchangeable, but internal dif-

ferences may result in inferior occupant protec-

tion. Failure to do so may result in occupant

personal injury or death.

Wear safety glasses, rubber gloves, and long

sleeved clothing when cleaning powder residue

from vehicle after airbag deployment. Sodium

hydroxide powder residue emitted from a

deployed airbag can cause skin irritation.

Flush affected area with cool water if irritation

is experienced. If nasal or throat irritation is

RSRESTRAINTS8O-5

RESTRAINTS (Continued)

Page 513 of 2339

anchor. The OCM then monitors the return voltage

from each of the sensors. The bladder pressure sen-

sor input allows the OCM to determine whether the

passenger front seat is occupied and the relative size

of the occupant by providing a weight-sensing refer-

ence to the load on the seat cushion. The belt tension

sensor provides an additional logic input to the OCM

microprocessor that allows it to distinguish between

the lower seat belt cinch loads of a belted occupant

and the higher loads associated with a belted child

seat.

Pre-programmed decision algorithms and OCS cal-

ibration allow the OCM microprocessor to determine

when the seat cushion load as signaled by the blad-

der pressure sensor and the seat belt cinch load as

signaled by the belt tension sensor indicate that pas-

senger airbag protection is appropriate. When the

programmed conditions are met, the OCM sends the

proper electronic occupant classification messages

over the PCI data bus to the Occupant Restraint

Controller (ORC), and the ORC enables or disables

the deployment circuits for the passenger front sup-

plemental restraints. The ORC also provides a con-

trol output for the Passenger Airbag Disabled (PAD)

indicator in the instrument panel center stack, based

upon the electronic occupant classification messages

it receives from the OCM.

The OCM microprocessor continuously monitors all

of the OCS electrical circuits and components to

determine the system readiness. If the OCM detects

a monitored system fault, it sets an active and stored

Diagnostic Trouble Code (DTC) and sends the appro-

priate electronic messages to the ORC over the PCI

data bus. Then the ORC sets a DTC and sends mes-

sages to control the airbag indicator operation

accordingly. An active fault only remains for the

duration of the fault, or in some cases for the dura-

tion of the current ignition switch cycle, while a

stored fault causes a DTC to be stored in memory by

the OCM and the ORC. For some DTC's, if a fault

does not recur for a number of ignition cycles, the

OCM will automatically erase the stored DTC. For

other internal faults, the stored DTC is latched for-

ever.

The OCM receives battery current from an IPM

high side driver (Run/Start). The OCM receives

ground through a ground circuit of the body wire

harness, which it shares with the ORC. These con-

nections allow the OCM to be operational whenever

the ignition switch is in the Start or ON positions.

To diagnose and test the OCS, use a scan tool and

the appropriate diagnostic information.

REMOVAL

Once any of the original factory-installed compo-

nents except the Occupant Classification Module(OCM) have been replaced with the service replace-

ment package components, the OCM can only be ser-

viced by replacing the entire passenger front seat

cushion unit with another complete service replace-

ment package (Refer to 23 - BODY/SEATS/SEAT

CUSHION - FRONT - REMOVAL).

WARNING: Never replace both the Occupant

Restraint Controller (ORC) and the Occupant Clas-

sification Module (OCM) at the same time. If both

require replacement, replace one, then perform the

Airbag System test (Refer to 8 - ELECTRICAL/RE-

STRAINTS - DIAGNOSIS AND TESTING - AIRBAG

SYSTEM) before replacing the other. Both the ORC

and the OCM store Occupant Classification System

(OCS) calibration data, which they transfer to one

another when one of them is replaced. If both are

replaced at the same time, an irreversible fault will

be set in both modules and the OCS may malfunc-

tion and result in personal injury or death.

(1) Disconnect and isolate the battery negative

cable.

(2)

WARNING: Wait two minutes for the airbag system

reserve capacitor to discharge before beginning

any airbag system or component service. Failure to

do so may result in accidental airbag deployment,

personal injury or death.

(3) Reach under the front edge of the passenger

side front seat cushion to access and remove the lock

pin from the connector lock tower on the Occupant

Classification Module (OCM) (Fig. 36).

(4) Disconnect the passenger front seat wire har-

ness connector for the OCM.

(5) Remove the two screws that secure the OCM to

the OCM bracket.

(6) Remove the OCM from under the passenger

front seat.

INSTALLATION

WARNING: To avoid personal injury or death on

vehicles equipped with the Occupant Classification

System (OCS), only the Occupant Classification

Module (OCM) and the seat cushion trim may be

serviced separately. All other components of the

passenger front seat cushion must be serviced only

as a complete factory-calibrated, assembled and

tamper-evident service replacement package.

Once any of the original factory-installed compo-

nents except the OCM have been replaced with the

service replacement package components, the OCM

can only be serviced by replacing the entire passen-

8O - 26 RESTRAINTSRS

OCCUPANT CLASSIFICATION MODULE (Continued)