power modul CHRYSLER VOYAGER 2005 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 249 of 2339

DIAGNOSIS AND TESTING - RADIATOR FAN MOTOR

RADIATOR FAN DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

NOISY RADIATOR FAN 1. Fan blade loose. 1. Replace fan assembly. (Refer to

7 - COOLING/ENGINE/RADIATOR

FAN - REMOVAL)

2. Fan blade striking a surrounding

object.2. Locate point of fan blade contact

and repair as necessary.

3. Air obstructions at radiator or A/C

condenser.3. Remove obstructions and/or

clean debris.

4. Electric fan motor defective. 4. Replace fan assembly. (Refer to

7 - COOLING/ENGINE/RADIATOR

FAN - REMOVAL)

ELECTRIC FAN MOTOR DOES

NOT OPERATE1. Fan relay, powertrain control

module (PCM), coolant temperature

sensor, or wiring defective.1. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

2. Defective A/C pressure

transducer.2. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

ELECTRIC RADIATOR FAN

OPERATES ALL THE TIME1. Fan relay, powertrain control

module (PCM), coolant temperature

sensor or wiring defective.1. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

2. Check for low coolant level. 2. Add coolant as necessary.

3. Defective A/C pressure

transducer.3. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

REMOVAL

There are no repairs to be made to the fan or

shroud assembly. If the fan is warped, cracked, or

otherwise damaged, it must be replaced as an assem-

bly (Fig. 20).

(1) Remove the radiator upper crossmember. (Refer

to 23 - BODY/EXTERIOR/GRILLE OPENING REIN-

FORCEMENT - REMOVAL)

(2) Disconnect the radiator fan electrical connec-

tors.

(3) Remove radiator fan(s) retaining screw (Fig.

20).

(4) Remove the radiator fan(s) by lifting upward to

release from mounts.

INSTALLATION

(1) Install the radiator fan(s) into mounts and

attaching clips on the radiator.

(2) Install radiator fan(s) attaching screws (Fig.

20). Tighten to 5 N´m (45 in. lbs.).

(3) Connect the radiator fan(s) electrical connec-

tors.(4) Install the radiator upper support crossmem-

ber. (Refer to 23 - BODY/EXTERIOR/GRILLE OPEN-

ING REINFORCEMENT - INSTALLATION)

Fig. 20 Radiator Fans

1 - SCREWS - RADIATOR FAN ATTACHING

2 - RADIATOR FAN - RIGHT

3 - MOUNT - RIGHT RADIATOR FAN

4 - CLIPS - RADIATOR FAN LOWER

5 - MOUNT - LEFT RADIATOR FAN

6 - RADIATOR FAN - LEFT

7 - 30 ENGINERS

RADIATOR FAN (Continued)

Page 250 of 2339

(5) Install the upper radiator mounts to the cross-

member bolts, if removed. Tighten to 8 N´m (70 in.

lbs.).

(6) Install the radiator upper hose to the support

clip (2.4L engine).

RADIATOR FAN RELAY

DESCRIPTION

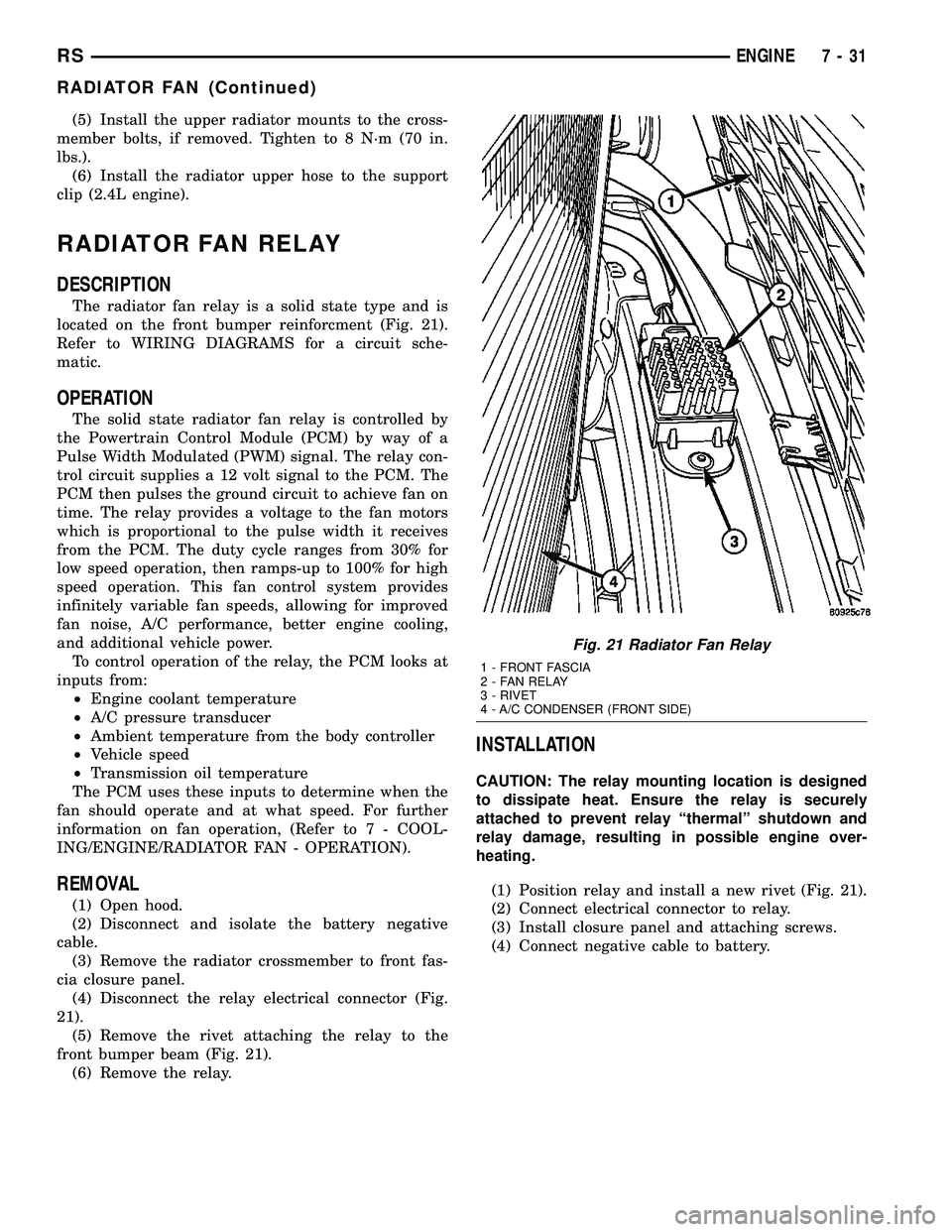

The radiator fan relay is a solid state type and is

located on the front bumper reinforcment (Fig. 21).

Refer to WIRING DIAGRAMS for a circuit sche-

matic.

OPERATION

The solid state radiator fan relay is controlled by

the Powertrain Control Module (PCM) by way of a

Pulse Width Modulated (PWM) signal. The relay con-

trol circuit supplies a 12 volt signal to the PCM. The

PCM then pulses the ground circuit to achieve fan on

time. The relay provides a voltage to the fan motors

which is proportional to the pulse width it receives

from the PCM. The duty cycle ranges from 30% for

low speed operation, then ramps-up to 100% for high

speed operation. This fan control system provides

infinitely variable fan speeds, allowing for improved

fan noise, A/C performance, better engine cooling,

and additional vehicle power.

To control operation of the relay, the PCM looks at

inputs from:

²Engine coolant temperature

²A/C pressure transducer

²Ambient temperature from the body controller

²Vehicle speed

²Transmission oil temperature

The PCM uses these inputs to determine when the

fan should operate and at what speed. For further

information on fan operation, (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - OPERATION).

REMOVAL

(1) Open hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the radiator crossmember to front fas-

cia closure panel.

(4) Disconnect the relay electrical connector (Fig.

21).

(5) Remove the rivet attaching the relay to the

front bumper beam (Fig. 21).

(6) Remove the relay.

INSTALLATION

CAUTION: The relay mounting location is designed

to dissipate heat. Ensure the relay is securely

attached to prevent relay ªthermalº shutdown and

relay damage, resulting in possible engine over-

heating.

(1) Position relay and install a new rivet (Fig. 21).

(2) Connect electrical connector to relay.

(3) Install closure panel and attaching screws.

(4) Connect negative cable to battery.

Fig. 21 Radiator Fan Relay

1 - FRONT FASCIA

2 - FAN RELAY

3 - RIVET

4 - A/C CONDENSER (FRONT SIDE)

RSENGINE7-31

RADIATOR FAN (Continued)

Page 269 of 2339

ANTENNA MODULE - EXPORT

DESCRIPTION

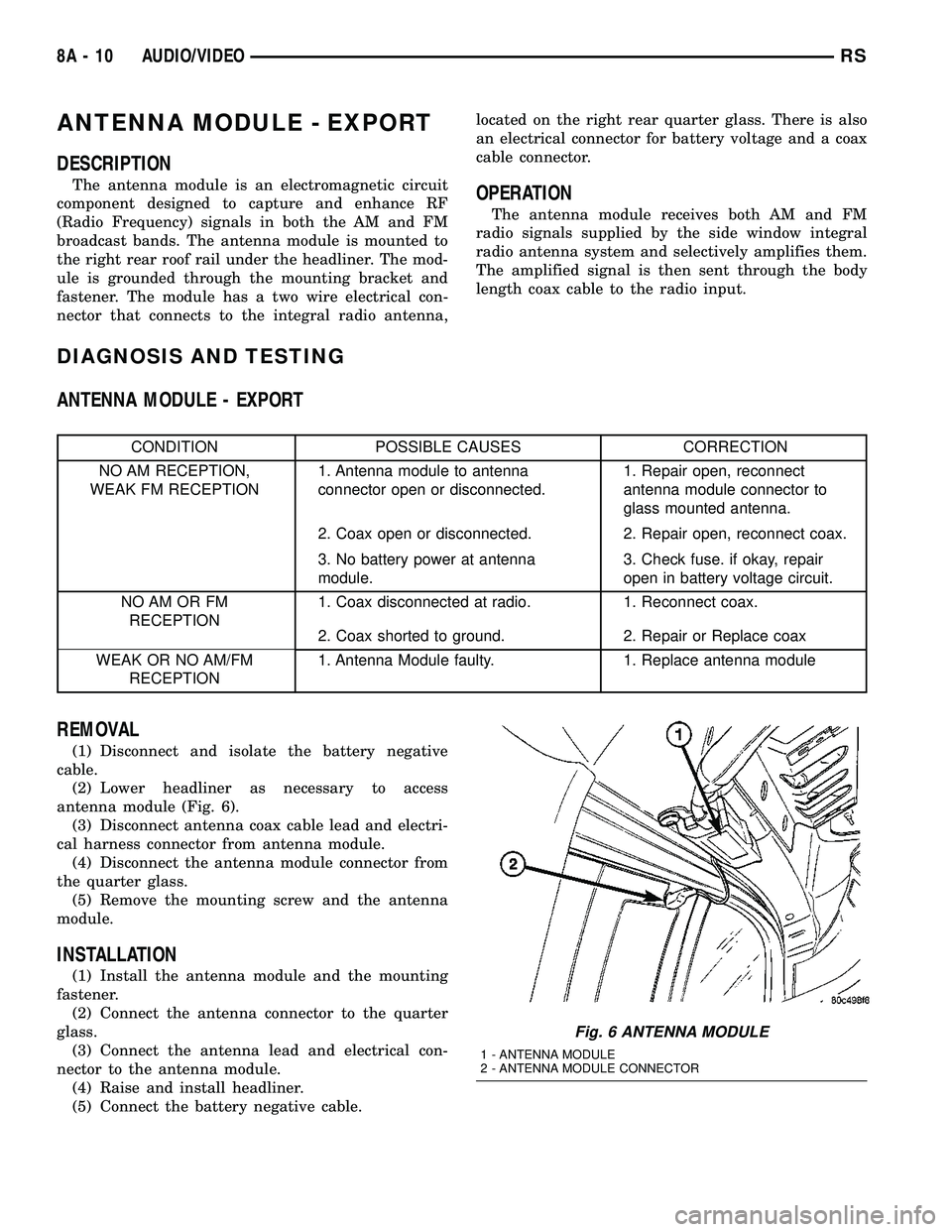

The antenna module is an electromagnetic circuit

component designed to capture and enhance RF

(Radio Frequency) signals in both the AM and FM

broadcast bands. The antenna module is mounted to

the right rear roof rail under the headliner. The mod-

ule is grounded through the mounting bracket and

fastener. The module has a two wire electrical con-

nector that connects to the integral radio antenna,located on the right rear quarter glass. There is also

an electrical connector for battery voltage and a coax

cable connector.OPERATION

The antenna module receives both AM and FM

radio signals supplied by the side window integral

radio antenna system and selectively amplifies them.

The amplified signal is then sent through the body

length coax cable to the radio input.

DIAGNOSIS AND TESTING

ANTENNA MODULE - EXPORT

CONDITION POSSIBLE CAUSES CORRECTION

NO AM RECEPTION,

WEAK FM RECEPTION1. Antenna module to antenna

connector open or disconnected.1. Repair open, reconnect

antenna module connector to

glass mounted antenna.

2. Coax open or disconnected. 2. Repair open, reconnect coax.

3. No battery power at antenna

module.3. Check fuse. if okay, repair

open in battery voltage circuit.

NO AM OR FM

RECEPTION1. Coax disconnected at radio. 1. Reconnect coax.

2. Coax shorted to ground. 2. Repair or Replace coax

WEAK OR NO AM/FM

RECEPTION1. Antenna Module faulty. 1. Replace antenna module

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Lower headliner as necessary to access

antenna module (Fig. 6).

(3) Disconnect antenna coax cable lead and electri-

cal harness connector from antenna module.

(4) Disconnect the antenna module connector from

the quarter glass.

(5) Remove the mounting screw and the antenna

module.

INSTALLATION

(1) Install the antenna module and the mounting

fastener.

(2) Connect the antenna connector to the quarter

glass.

(3) Connect the antenna lead and electrical con-

nector to the antenna module.

(4) Raise and install headliner.

(5) Connect the battery negative cable.

Fig. 6 ANTENNA MODULE

1 - ANTENNA MODULE

2 - ANTENNA MODULE CONNECTOR

8A - 10 AUDIO/VIDEORS

Page 273 of 2339

OPERATION

The radio receiver operates on ignition switched

battery current that is available only when the igni-

tion switch is in the On or Accessory/Accessory Delay

positions. The electronic digital clock function of the

radio operates on fused battery current supplied

through the IOD fuse, regardless of the ignition

switch position.

For complete circuit diagrams, refer to the appro-

priate wiring information.

DIAGNOSIS AND TESTING

RADIO

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information.

If the vehicle is equipped with remote radio

switches located on the back of the steering wheel

spokes, and the problem being diagnosed is related to

one of the symptoms listed below, be certain to check

the remote radio switches and circuits as described

in this group, prior to attempting radio diagnosis or

repair.

²Stations changing with no remote radio switch

input

²Radio memory presets not working properly

²Volume changes with no remote radio switch

input

²Remote radio switch buttons taking on other

functions

²CD player skipping tracks

²Remote radio switch inoperative.

CAUTION: The speaker output of the radio is a

ªfloating groundº system. Do not allow any speaker

lead to short to ground, as damage to the radio

may result.

(1) Check the fuse(s) in the junction block and the

Integrated Power Module (IPM). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse(s).(2) Check for battery voltage at the fuse in the

(IPM). If OK, go to Step 3. If not OK, repair the open

circuit to the battery as required.

(3) Turn the ignition switch to the ON position.

Check for battery voltage at the fuse in the junction

block. If OK, go to Step 4. If not OK, repair the open

circuit to the ignition switch as required.

(4) Turn the ignition switch to the OFF position.

Remove the radio, but do not unplug the wire har-

ness connectors. Check for continuity between the

radio chassis and a good ground. There should be

continuity. If OK, go to Step 5. If not OK, repair the

open radio chassis ground circuit as required.

(5) Connect the battery negative cable. Turn the

ignition switch to the ON position. Check for battery

voltage at the fused ignition switch output circuit

cavity of the radio wire harness connector. If OK, go

to Step 6. If not OK, repair the open circuit as

required.

(6) Turn the ignition switch to the OFF position.

Check for battery voltage at the fused B(+) circuit

cavity of the radio wire harness connector. If OK,

replace the faulty radio. If not OK, repair the open

circuit to the Ignition-Off Draw (IOD) fuse as

required.

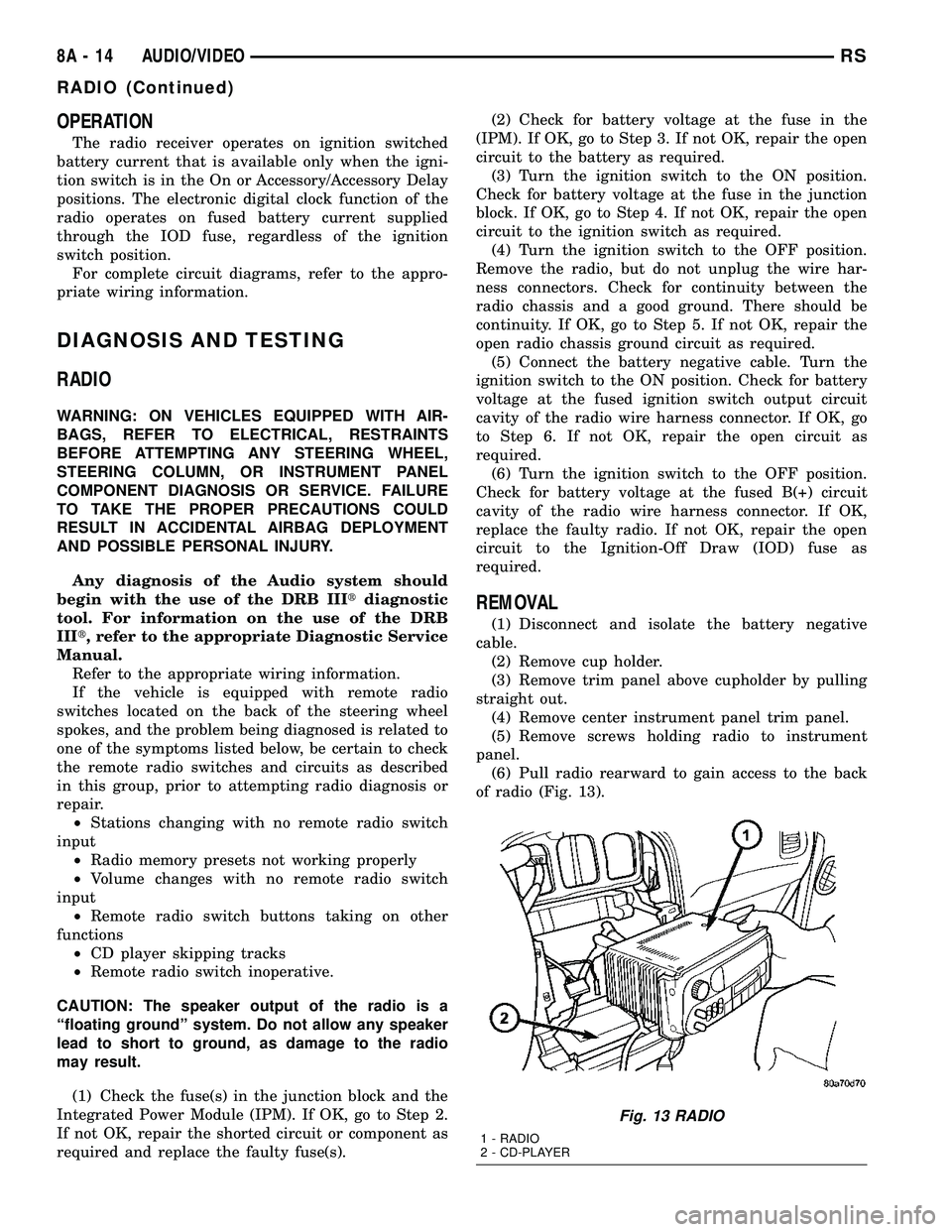

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove cup holder.

(3) Remove trim panel above cupholder by pulling

straight out.

(4) Remove center instrument panel trim panel.

(5) Remove screws holding radio to instrument

panel.

(6) Pull radio rearward to gain access to the back

of radio (Fig. 13).

Fig. 13 RADIO

1 - RADIO

2 - CD-PLAYER

8A - 14 AUDIO/VIDEORS

RADIO (Continued)

Page 285 of 2339

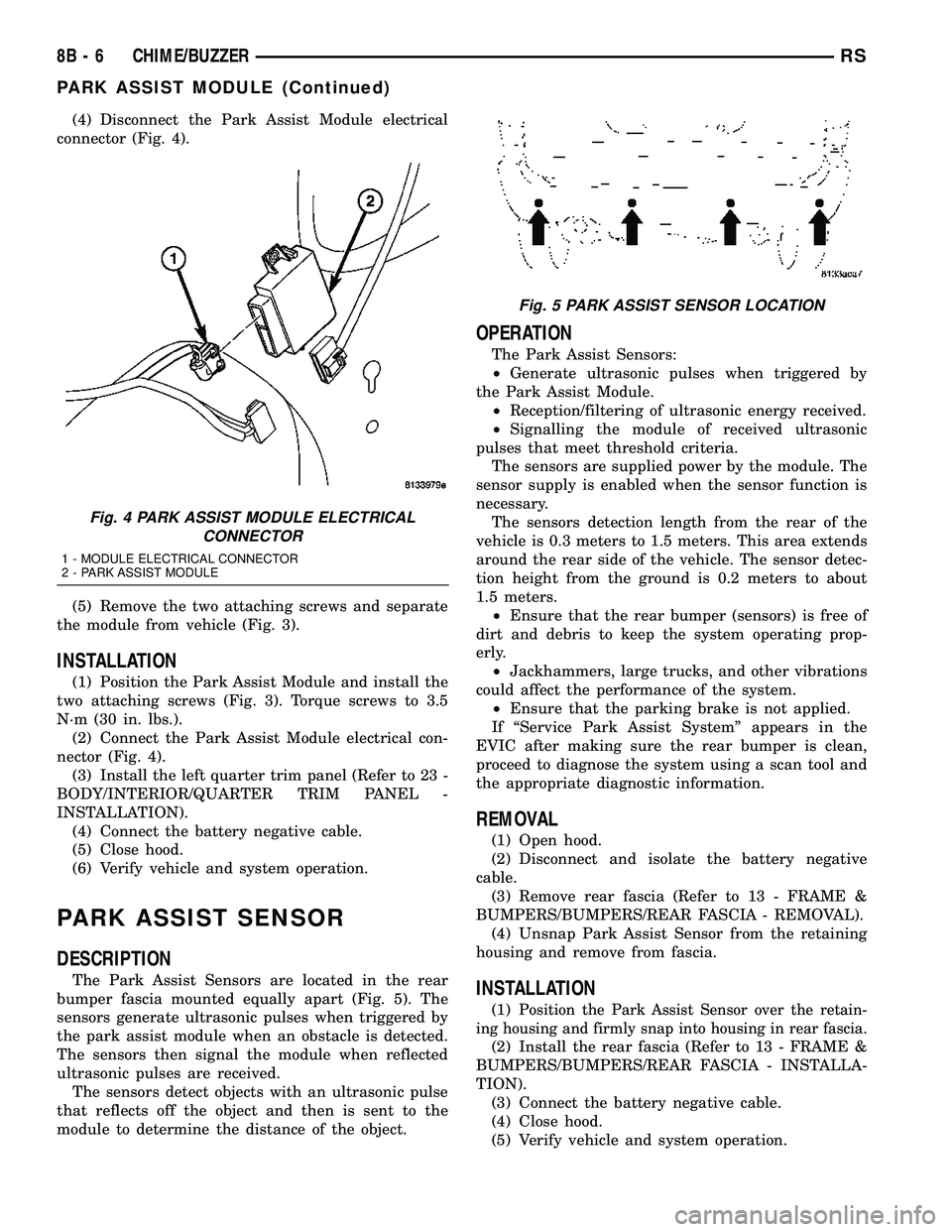

(4) Disconnect the Park Assist Module electrical

connector (Fig. 4).

(5) Remove the two attaching screws and separate

the module from vehicle (Fig. 3).

INSTALLATION

(1) Position the Park Assist Module and install the

two attaching screws (Fig. 3). Torque screws to 3.5

N´m (30 in. lbs.).

(2) Connect the Park Assist Module electrical con-

nector (Fig. 4).

(3) Install the left quarter trim panel (Refer to 23 -

BODY/INTERIOR/QUARTER TRIM PANEL -

INSTALLATION).

(4) Connect the battery negative cable.

(5) Close hood.

(6) Verify vehicle and system operation.

PARK ASSIST SENSOR

DESCRIPTION

The Park Assist Sensors are located in the rear

bumper fascia mounted equally apart (Fig. 5). The

sensors generate ultrasonic pulses when triggered by

the park assist module when an obstacle is detected.

The sensors then signal the module when reflected

ultrasonic pulses are received.

The sensors detect objects with an ultrasonic pulse

that reflects off the object and then is sent to the

module to determine the distance of the object.

OPERATION

The Park Assist Sensors:

²Generate ultrasonic pulses when triggered by

the Park Assist Module.

²Reception/filtering of ultrasonic energy received.

²Signalling the module of received ultrasonic

pulses that meet threshold criteria.

The sensors are supplied power by the module. The

sensor supply is enabled when the sensor function is

necessary.

The sensors detection length from the rear of the

vehicle is 0.3 meters to 1.5 meters. This area extends

around the rear side of the vehicle. The sensor detec-

tion height from the ground is 0.2 meters to about

1.5 meters.

²Ensure that the rear bumper (sensors) is free of

dirt and debris to keep the system operating prop-

erly.

²Jackhammers, large trucks, and other vibrations

could affect the performance of the system.

²Ensure that the parking brake is not applied.

If ªService Park Assist Systemº appears in the

EVIC after making sure the rear bumper is clean,

proceed to diagnose the system using a scan tool and

the appropriate diagnostic information.

REMOVAL

(1) Open hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Remove rear fascia (Refer to 13 - FRAME &

BUMPERS/BUMPERS/REAR FASCIA - REMOVAL).

(4) Unsnap Park Assist Sensor from the retaining

housing and remove from fascia.

INSTALLATION

(1)Position the Park Assist Sensor over the retain-

ing housing and firmly snap into housing in rear fascia.

(2) Install the rear fascia (Refer to 13 - FRAME &

BUMPERS/BUMPERS/REAR FASCIA - INSTALLA-

TION).

(3) Connect the battery negative cable.

(4) Close hood.

(5) Verify vehicle and system operation.

Fig. 4 PARK ASSIST MODULE ELECTRICAL

CONNECTOR

1 - MODULE ELECTRICAL CONNECTOR

2 - PARK ASSIST MODULE

Fig. 5 PARK ASSIST SENSOR LOCATION

8B - 6 CHIME/BUZZERRS

PARK ASSIST MODULE (Continued)

Page 286 of 2339

ELECTRONIC CONTROL MODULES

TABLE OF CONTENTS

page page

ELECTRONIC CONTROL MODULES

STANDARD PROCEDURE - PCM/SKIM

PROGRAMMING.......................1

BODY CONTROL MODULE

DESCRIPTION..........................2

OPERATION............................3

REMOVAL.............................4

INSTALLATION..........................4

CONTROLLER ANTILOCK BRAKE

DESCRIPTION..........................4

OPERATION............................5

REMOVAL.............................5

INSTALLATION..........................6

DATA LINK CONNECTOR

DESCRIPTION..........................6

OPERATION............................6

FRONT CONTROL MODULE

DESCRIPTION..........................7

OPERATION............................7

DIAGNOSIS AND TESTING

FRONT CONTROL MODULE..............7

REMOVAL.............................7

INSTALLATION..........................7

HEATED SEAT MODULE

DESCRIPTION..........................8

OPERATION............................8

DIAGNOSIS AND TESTING

HEATED SEAT MODULE.................9

REMOVAL.............................9

INSTALLATION..........................9

MEMORY SEAT/MIRROR MODULE

DESCRIPTION..........................9

OPERATION............................9

DIAGNOSIS AND TESTING

MEMORY SEAT/MIRROR MODULE.........9

REMOVAL.............................10

INSTALLATION.........................10

POWER LIFTGATE CONTROL MODULE

DESCRIPTION.........................10OPERATION...........................10

DIAGNOSIS AND TESTING

POWER LIFTGATE CONTROL MODULE....10

REMOVAL.............................10

INSTALLATION.........................11

POWERTRAIN CONTROL MODULE

DESCRIPTION

DESCRIPTION........................11

OPERATION - SENSOR RETURN - PCM

INPUT..............................14

OPERATION - DATA BUS COMMUNICATION

RECEIVE - PCM INPUT.................14

OPERATION - IGNITION SENSE - PCM

INPUT..............................14

OPERATION - PCM GROUND............14

OPERATION - 5 VOLT SUPPLY - PCM

OUTPUT............................15

STANDARD PROCEDURE

STANDARD PROCEDURE - OBTAINING

DIAGNOSTIC TROUBLE CODES..........15

STANDARD PROCEDURE - PINION

FACTOR SETTING.....................15

STANDARD PROCEDURE - QUICK LEARN

PROCEDURE........................15

REMOVAL

REMOVAL - SBEC CONTROLLER.........16

REMOVAL - NGC CONTROLLER..........16

INSTALLATION

INSTALLATION - SBEC CONTROLLER.....17

INSTALLATION.......................17

SLIDING DOOR CONTROL MODULE

DESCRIPTION.........................18

OPERATION...........................18

DIAGNOSIS AND TESTING

SLIDING DOOR CONTROL MODULE......18

REMOVAL.............................18

INSTALLATION.........................19

ELECTRONIC CONTROL

MODULES

STANDARD PROCEDURE - PCM/SKIM

PROGRAMMING

NOTE: Before replacing the PCM for a failed driver,

control circuit or ground circuit, be sure to checkthe related component/circuit integrity for failures

not detected due to a double fault in the circuit.

Most PCM driver/control circuit failures are caused

by internal component failures (i.e. relay and sole-

noids) and shorted circuits (i.e. pull-ups, drivers

and switched circuits). These failures are difficult to

detect when a double fault has occurred and only

one DTC has set.

RSELECTRONIC CONTROL MODULES8E-1

Page 288 of 2339

The BCM utilizes integrated circuitry and informa-

tion carried on the Programmable Communications

Interface (PCI) data bus network along with many

hard wired inputs to monitor many sensor and

switch inputs throughout the vehicle. In response to

those inputs, the internal circuitry and programming

of the BCM allow it to control and integrate many

electronic functions and features of the vehicle

through both hard wired outputs and the transmis-

sion of electronic message outputs to other electronic

modules in the vehicle over the PCI data bus.

OPERATION

The Body Control Module (BCM) supplies vehicle

occupants with visual and audible information and

controls various vehicle functions. To provide and

receive information, the BCM is interfaced to the

vehicle's serial bus communications network, referred

to as the Programmable Communications Interface

(PCI) bus.

This network consists of the;

²Powertrain Control Module (PCM)

²Transmission Control Module (TCM)

²Mechanical Instrument Cluster (MIC)

²Occupant Restraint Controller (ORC)

²Compass/Mini-Trip Computer (CMTC)

²Electronic Vehicle Information Center (EVIC)

²Controller Antilock Brake (CAB)

²HVAC Control Module

²Sliding Door Control Modules (driver and pas-

senger side doors)

²Power Liftgate Module (PLG)

²Audio system equipped with RAZ, RBU, RBK,

and RBB radios.

²Sentry Key Remote Entry Module (SKREEM).

²Side Impact Airbag Control Module (SIACM)²Memory Seat Module (MSM)

²Sentry Key Immobilizer Module (SKIM)

The BCM is operational when battery power is

supplied to the module.

The BCM provides the following features:

²Power Door Locks

²Automatic Door Locks

²Battery Protection - The BCM will automatically

turn off all exterior lamps after 3 minutes, and all

interior lamps after 15 minutes after the ignition is

turned off, if they are not turned off by the driver.

²Chime Control

²Compass/Mini-Trip support.

²Interior Lighting (Courtesy/Reading Lamps)

²BCM Diagnostic Reporting

²Electronic Liftgate Release (with Power Door

Locks)

²Exterior Lighting

²Headlamp Time Delay (with/without Automatic

Headlamps)

²Illuminated Entry

²Fade to Off Interior Lamps - This feature dims

the interior lighting (courtesy lamps) gradually if the

BCM does not receive any new inputs that would

cause the interior lamps to remain on.

²Pulse Width Modulated Instrument Panel Dim-

ming

²Door Lock Inhibit - This feature disables the

door lock functions if the key is in the ignition and

either front door is ajar. Pressing the Remote Keyless

Entry (RKE) lock/unlock button under these condi-

tions result in normal lock/unlock activation.

The BCM has the ability to LEARN additional fea-

tures in the vehicle, provided the appropriate switch

input and PCI data bus messages are received. Refer

to the LEARNED FEATURES table.

LEARNED FEATURES

FEATURE LEARNING KEY

REAR WIPER CONTROL ON HVAC CONTROL ON

INSTRUMENT PANELPCI BUS MESSAGE RECEIVED FROM HVAC

CONTROL

AUTOMATIC HEADLAMPS PCI MESSAGE FROM OVERHEAD OR HEADLAMP

SWITCH POSITION (AUTO)

REMOTE KEYLESS ENTRY SKREEM MESSAGE RECEIVED FROM MODULE

FRONT FOG LAMPS HEADLAMP SWITCH POSITION (PARK W/FRONT

FOG LAMPS)

POWER SLIDING DOOR PCI IFR RECEIVED FROM MODULE

THE BCM HAS FOUR SWITCH INPUTS FOR THE POWER SLIDING DOOR FEATURE; LOCATED IN THE

OVERHEAD CONSOLE ARE THE LEFT AND RIGHT SIDE SLIDING DOOR SWITCHES TO ACTIVATE EITHER

OR BOTH SLIDING DOORS UNDER THE PROPER CONDITIONS. ALSO ARE B-PILLAR SWITCHES LOCATED

ON THE LEFT AND RIGHT B-PILLAR POSTS.

POWER LIFTGATE PCI IFR RECEIVED FROM MODULE

RSELECTRONIC CONTROL MODULES8E-3

BODY CONTROL MODULE (Continued)

Page 289 of 2339

FEATURE LEARNING KEY

THE BCM HAS ONE LIFTGATE INPUT LOCATED IN THE OVERHEAD CONSOLE.

POWER LOCKOUT SWITCH INPUT

THE BCM HAS ONE LOCKOUT SWITCH INPUT THAT WHEN ENABLED WILL DISABLE THE B-PILLAR

SLIDING DOOR SWITCHES FROM ACTIVATING EITHER SLIDING DOOR WHEN DEPRESSED.

PCI AUDIO SYSTEM PCI MESSAGE RECEIVED FROM MODULE

REMOTE RADIO CONTROLS REMOTE RADIO SWITCHES PRESENT

VEHICLE THEFT SECURITY SKREEM MESSAGE RECEIVED, VALID KEY

RECEIVED, & DIAGNOSTIC PID RECEIVED.

MEMORY SEAT AND MIRRORS MEMORY SEAT SWITCH PRESENT AND OR PCI

MESSAGE RECEIVED FROM MEMORY MODULE

ABS W/TRACTION CONTROL PCI MESSAGE RECEIVED FROM CAB

SENTRY KEY IMMOBILIZER SYSTEM PCI MESSAGE RECEIVED FROM SKIM OR VTSS

PRESENT

ADJUSTABLE PEDAL MODULE PCI MESSAGE RECEIVED FROM ADJUSTABLE

PEDAL MODULE (APM)

When replacing a BCM there are three modules

available:

²Base

²Midline

²RG - Export

The Midline controller is used on vehicles that

have Power Door Locks. If a vehicle is equipped with

the Vehicle Theft Security System, the Midline con-

troller becomes a Premium when the theft feature is

enabled.

CAUTION: Do not swap Body Control Modules

between vehicles or body controller's off the shelf.

The BCM has internal diagnostic capability that

assists in diagnosing the system error. When an

OPEN or a SHORT circuit exists, the diagnostic tool

can be used to read the BCM faults. The faults are

very descriptive in identifying the appropriate fea-

ture that has faulted.

The only two faults that the BCM logs that con-

clude the replacement of a BCM are faults;

²# 01 - Internal BCM failure (replace BCM)

²# 1F - J1850 Internal Hardware Failure (replace

BCM)

Otherwise the appropriate diagnostic procedures

for each of the features should be taken when the

BCM logs a fault.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the lower instrument panel silencer.(3) Remove the knee blocker and reinforcement

(Refer to 23 - BODY/INSTRUMENT PANEL/KNEE

BLOCKER REINFORCEMENT - REMOVAL).

(4) Disconnect the five wire connectors from the

bottom of the Body Control Module (BCM).

(5) Move bulkhead wiring aside.

(6) Remove the screws holding the BCM to the

bulkhead.

(7) Remove the BCM from the mounting bracket.

INSTALLATION

(1) Install the BCM to the mounting bracket.

(2) Install the screws holding the BCM to the

bulkhead.

(3) Connect the five wire connectors to the bottom

of the Body Control Module (BCM).

(4) Install the knee blocker and reinforcement

(Refer to 23 - BODY/INSTRUMENT PANEL/KNEE

BLOCKER REINFORCEMENT - INSTALLATION).

(5) Install the lower instrument panel silencer.

(6) Connect the battery negative cable.

(7) Verify proper operation of BCM and its func-

tions.

CONTROLLER ANTILOCK

BRAKE

DESCRIPTION

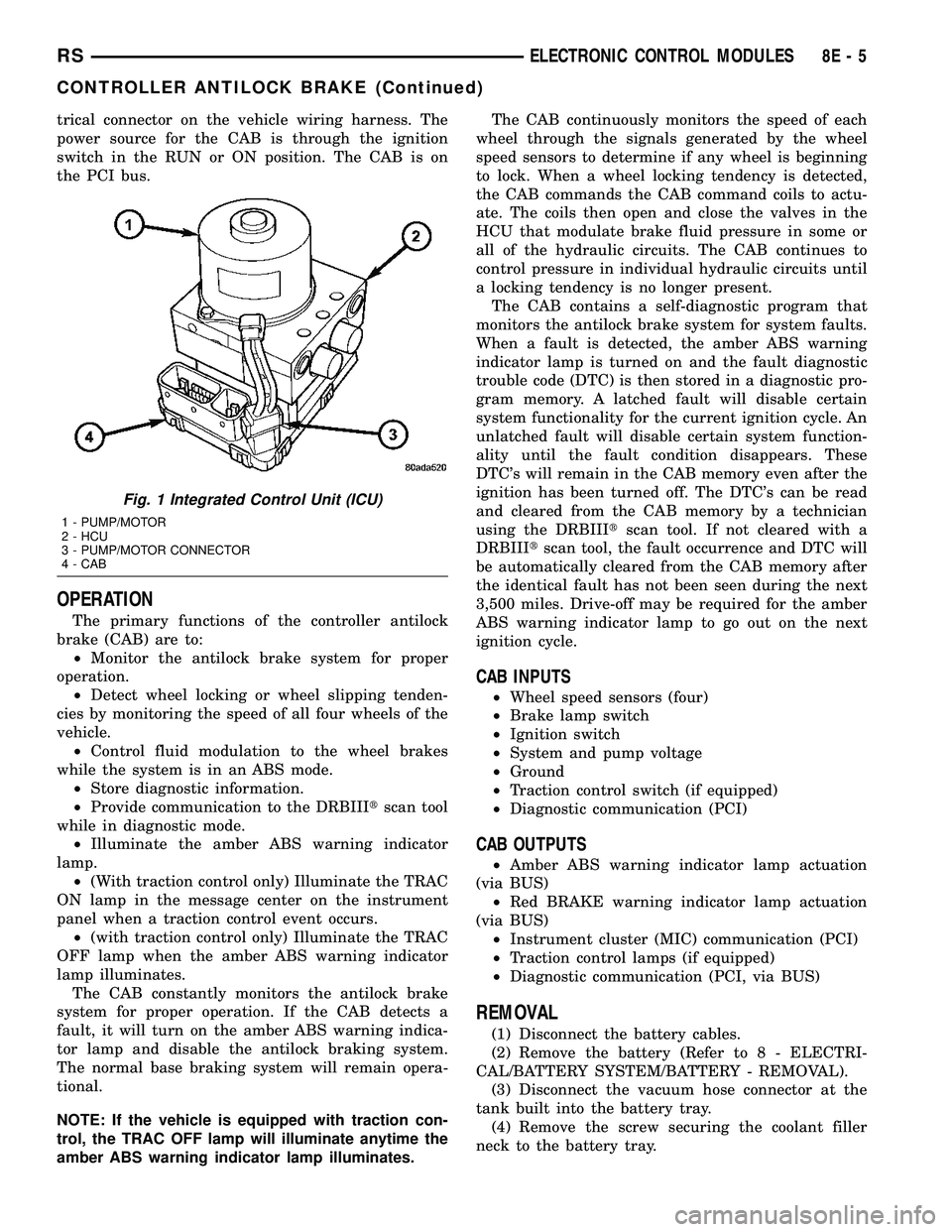

The controller antilock brake (CAB) is a micropro-

cessor-based device which monitors the antilock

brake system (ABS) during normal braking and con-

trols it when the vehicle is in an ABS stop. The CAB

is mounted to the HCU as part of the integrated con-

trol unit (ICU) (Fig. 1). The CAB uses a 24-way elec-

8E - 4 ELECTRONIC CONTROL MODULESRS

BODY CONTROL MODULE (Continued)

Page 290 of 2339

trical connector on the vehicle wiring harness. The

power source for the CAB is through the ignition

switch in the RUN or ON position. The CAB is on

the PCI bus.

OPERATION

The primary functions of the controller antilock

brake (CAB) are to:

²Monitor the antilock brake system for proper

operation.

²Detect wheel locking or wheel slipping tenden-

cies by monitoring the speed of all four wheels of the

vehicle.

²Control fluid modulation to the wheel brakes

while the system is in an ABS mode.

²Store diagnostic information.

²Provide communication to the DRBIIItscan tool

while in diagnostic mode.

²Illuminate the amber ABS warning indicator

lamp.

²(With traction control only) Illuminate the TRAC

ON lamp in the message center on the instrument

panel when a traction control event occurs.

²(with traction control only) Illuminate the TRAC

OFF lamp when the amber ABS warning indicator

lamp illuminates.

The CAB constantly monitors the antilock brake

system for proper operation. If the CAB detects a

fault, it will turn on the amber ABS warning indica-

tor lamp and disable the antilock braking system.

The normal base braking system will remain opera-

tional.

NOTE: If the vehicle is equipped with traction con-

trol, the TRAC OFF lamp will illuminate anytime the

amber ABS warning indicator lamp illuminates.The CAB continuously monitors the speed of each

wheel through the signals generated by the wheel

speed sensors to determine if any wheel is beginning

to lock. When a wheel locking tendency is detected,

the CAB commands the CAB command coils to actu-

ate. The coils then open and close the valves in the

HCU that modulate brake fluid pressure in some or

all of the hydraulic circuits. The CAB continues to

control pressure in individual hydraulic circuits until

a locking tendency is no longer present.

The CAB contains a self-diagnostic program that

monitors the antilock brake system for system faults.

When a fault is detected, the amber ABS warning

indicator lamp is turned on and the fault diagnostic

trouble code (DTC) is then stored in a diagnostic pro-

gram memory. A latched fault will disable certain

system functionality for the current ignition cycle. An

unlatched fault will disable certain system function-

ality until the fault condition disappears. These

DTC's will remain in the CAB memory even after the

ignition has been turned off. The DTC's can be read

and cleared from the CAB memory by a technician

using the DRBIIItscan tool. If not cleared with a

DRBIIItscan tool, the fault occurrence and DTC will

be automatically cleared from the CAB memory after

the identical fault has not been seen during the next

3,500 miles. Drive-off may be required for the amber

ABS warning indicator lamp to go out on the next

ignition cycle.

CAB INPUTS

²Wheel speed sensors (four)

²Brake lamp switch

²Ignition switch

²System and pump voltage

²Ground

²Traction control switch (if equipped)

²Diagnostic communication (PCI)

CAB OUTPUTS

²Amber ABS warning indicator lamp actuation

(via BUS)

²Red BRAKE warning indicator lamp actuation

(via BUS)

²Instrument cluster (MIC) communication (PCI)

²Traction control lamps (if equipped)

²Diagnostic communication (PCI, via BUS)

REMOVAL

(1) Disconnect the battery cables.

(2) Remove the battery (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - REMOVAL).

(3) Disconnect the vacuum hose connector at the

tank built into the battery tray.

(4) Remove the screw securing the coolant filler

neck to the battery tray.

Fig. 1 Integrated Control Unit (ICU)

1 - PUMP/MOTOR

2 - HCU

3 - PUMP/MOTOR CONNECTOR

4 - CAB

RSELECTRONIC CONTROL MODULES8E-5

CONTROLLER ANTILOCK BRAKE (Continued)

Page 291 of 2339

(5) Remove the battery tray (Refer to 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - REMOVAL).

(6) Pull up on the CAB connector lock and discon-

nect the 24±way electrical connector (Fig. 2).

(7) Disconnect the pump/motor connector from the

CAB.

(8) Remove the screws securing the CAB to the

HCU (Fig. 3)

(9) Pull CAB straight forward off HCU.

INSTALLATION

(1) Slide the CAB onto the HCU (Fig. 3).(2) Install screws securing the CAB to the HCU

(Fig. 3) Tighten the mounting screws to 2 N´m (17 in

lbs).

(3) Reconnect the 24±way wiring connector and

the pump/motor wiring connector. (Fig. 2)

(4) Install the battery tray (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/TRAY - INSTALLATION).

(5) Install the screw securing the coolant filler

neck to the battery tray.

(6) Reconnect the vacuum hose to the coolant tank

built into the battery tray.

(7) Install the battery (Refer to 8 - ELECTRICAL/

BATTERY SYSTEM/BATTERY - INSTALLATION).

(8) Reconnect the battery cables.

(9) Connect a DRBIIItto the vehicle. Check and

clear any faults, and initialize the system.

DATA LINK CONNECTOR

DESCRIPTION

The data link connector is located inside the vehi-

cle, below instrument panel next to the center col-

umn (Fig. 4).

OPERATION

The data link connector (diagnostic connector)

links the DRB scan tool with the Powertrain Control

Module (PCM). Refer to On-Board Diagnostics in the

General Diagnosis section of this group.

Fig. 2 CAB Connector Lock

1 - CONNECTOR LOCK

2 - CAB

Fig. 3 CAB Mounting Screws

1 - HCU

2 - MOUNTING SCREWS

3 - CAB

Fig. 4 DATA LINK CONNECTOR

8E - 6 ELECTRONIC CONTROL MODULESRS

CONTROLLER ANTILOCK BRAKE (Continued)