CHRYSLER VOYAGER 2005 Service Manual

Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 2281 of 2339

tion occurs such that the PCM cannot maintain the

optimum A/F ratio, then the MIL will be illuminated.

CATALYST MONITOR

To comply with clean air regulations, vehicles are

equipped with catalytic converters. These converters

reduce the emission of hydrocarbons, oxides of nitro-

gen and carbon monoxide.

Normal vehicle miles or engine misfire can cause a

catalyst to decay. A meltdown of the ceramic core can

cause a reduction of the exhaust passage. This can

increase vehicle emissions and deteriorate engine

performance, driveability and fuel economy.

The catalyst monitor uses dual oxygen sensors

(O2S's) to monitor the efficiency of the converter. The

dual O2S's strategy is based on the fact that as a cat-

alyst deteriorates, its oxygen storage capacity and its

efficiency are both reduced. By monitoring the oxy-

gen storage capacity of a catalyst, its efficiency can

be indirectly calculated. The upstream O2S is used to

detect the amount of oxygen in the exhaust gas

before the gas enters the catalytic converter. The

PCM calculates the A/F mixture from the output of

the O2S. A low voltage indicates high oxygen content

(lean mixture). A high voltage indicates a low content

of oxygen (rich mixture).

When the upstream O2S detects a lean condition,

there is an abundance of oxygen in the exhaust gas.

A functioning converter would store this oxygen so it

can use it for the oxidation of HC and CO. As the

converter absorbs the oxygen, there will be a lack of

oxygen downstream of the converter. The output of

the downstream O2S will indicate limited activity in

this condition.

As the converter loses the ability to store oxygen,

the condition can be detected from the behavior of

the downstream O2S. When the efficiency drops, no

chemical reaction takes place. This means the con-

centration of oxygen will be the same downstream as

upstream. The output voltage of the downstream

O2S copies the voltage of the upstream sensor. The

only difference is a time lag (seen by the PCM)

between the switching of the O2S's.

To monitor the system, the number of lean-to-rich

switches of upstream and downstream O2S's is

counted. The ratio of downstream switches to

upstream switches is used to determine whether the

catalyst is operating properly. An effective catalyst

will have fewer downstream switches than it has

upstream switches i.e., a ratio closer to zero. For a

totally ineffective catalyst, this ratio will be one-to-

one, indicating that no oxidation occurs in the device.

The system must be monitored so that when cata-

lyst efficiency deteriorates and exhaust emissions

increase to over the legal limit, the MIL (Check

Engine lamp) will be illuminated.NATURAL VACUUM LEAK DETECTION (NVLD) (if equipped)

The Natural Vacuum Leak Detection (NVLD) sys-

tem is the next generation evaporative leak detection

system that will first be used on vehicles equipped

with the Next Generation Controller (NGC). This

new system replaces the leak detection pump as the

method of evaporative system leak detection. This is

to detect a leak equivalent to a 0.0209(0.5 mm) hole.

This system has the capability to detect holes of this

size very dependably.

The basic leak detection theory employed with

NVLD is the9Gas Law9. This is to say that the pres-

sure in a sealed vessel will change if the temperature

of the gas in the vessel changes. The vessel will only

see this effect if it is indeed sealed. Even small leaks

will allow the pressure in the vessel to come to equi-

librium with the ambient pressure. In addition to the

detection of very small leaks, this system has the

capability of detecting medium as well as large evap-

orative system leaks.

The NVLD seals the canister vent during engine

off conditions. If the EVAP system has a leak of less

than the failure threshold, the evaporative system

will be pulled into a vacuum, either due to the cool

down from operating temperature or diurnal ambient

temperature cycling. The diurnal effect is considered

one of the primary contributors to the leak determi-

nation by this diagnostic. When the vacuum in the

system exceeds about 19H2O (0.25 KPA), a vacuum

switch closes. The switch closure sends a signal to

the NGC. The NGC, via appropriate logic strategies

(described below), utilizes the switch signal, or lack

thereof, to make a determination of whether a leak is

present.

The NVLD device is designed with a normally open

vacuum switch, a normally closed solenoid, and a

seal, which is actuated by both the solenoid and a

diaphragm. The NVLD is located on the atmospheric

vent side of the canister. The NVLD assembly may

be mounted on top of the canister outlet, or in-line

between the canister and atmospheric vent filter. The

normally open vacuum switch will close with about 19

H2O (0.25 KPA) vacuum in the evaporative system.

The diaphragm actuates the switch. This is above the

opening point of the fuel inlet check valve in the fill

tube so cap off leaks can be detected. Submerged fill

systems must have recirculation lines that do not

have the in-line normally closed check valve that pro-

tects the system from failed nozzle liquid ingestion,

in order to detect cap off conditions.

The normally closed valve in the NVLD is intended

to maintain the seal on the evaporative system dur-

ing the engine off condition. If vacuum in the evapo-

rative system exceeds 39to 69H2O (0.75 to 1.5 KPA),

the valve will be pulled off the seat, opening the seal.

This will protect the system from excessive vacuum

25 - 8 EMISSIONS CONTROLRS

EMISSIONS CONTROL (Continued)

Page 2282 of 2339

as well as allowing sufficient purge flow in the event

that the solenoid was to become inoperative.

The solenoid actuates the valve to unseal the can-

ister vent while the engine is running. It also will be

used to close the vent during the medium and large

leak tests and during the purge flow check. This sole-

noid requires initial 1.5 amps of current to pull the

valve open but after 100 ms. will be duty cycled down

to an average of about 150 mA for the remainder of

the drive cycle.

Another feature in the device is a diaphragm that

will open the seal in the NVLD with pressure in the

evaporative system. The device will9blow off9at

about 0.59H2O (0.12 KPA) pressure to permit the

venting of vapors during refueling. An added benefit

to this is that it will also allow the tank to9breathe9

during increasing temperatures, thus limiting the

pressure in the tank to this low level. This is benefi-

cial because the induced vacuum during a subse-

quent declining temperature will achieve the switch

closed (pass threshold) sooner than if the tank had to

decay from a built up pressure.

The device itself has 3 wires: Switch sense, sole-

noid driver and ground. It also includes a resistor to

protect the switch from a short to battery or a short

to ground. The NGC utilizes a high-side driver to

energize and duty-cycle the solenoid.

HIGH AND LOW LIMITS

The PCM compares input signal voltages from each

input device with established high and low limits for

the device. If the input voltage is not within limits

and other criteria are met, the PCM stores a diagnos-

tic trouble code in memory. Other diagnostic trouble

code criteria might include engine RPM limits or

input voltages from other sensors or switches that

must be present before verifying a diagnostic trouble

code condition.

OPERATION

SYSTEM

The Powertrain Control Module (PCM) monitors

many different circuits in the fuel injection, ignition,

emission and engine systems. If the PCM senses a

problem with a monitored circuit often enough to

indicate an actual problem, it stores a Diagnostic

Trouble Code (DTC) in the PCM's memory. If the

code applies to a non-emissions related component or

system, and the problem is repaired or ceases to

exist, the PCM cancels the code after 40 warmup

cycles. Diagnostic trouble codes that affect vehicle

emissions illuminate the Malfunction Indicator Lamp

(MIL). Refer to Malfunction Indicator Lamp in this

section.Certain criteria must be met before the PCM

stores a DTC in memory. The criteria may be a spe-

cific range of engine RPM, engine temperature,

and/or input voltage to the PCM.

The PCM might not store a DTC for a monitored

circuit even though a malfunction has occurred. This

may happen because one of the DTC criteria for the

circuit has not been met.For example, assume the

diagnostic trouble code criteria requires the PCM to

monitor the circuit only when the engine operates

between 750 and 2000 RPM. Suppose the sensor's

output circuit shorts to ground when engine operates

above 2400 RPM (resulting in 0 volt input to the

PCM). Because the condition happens at an engine

speed above the maximum threshold (2000 rpm), the

PCM will not store a DTC.

There are several operating conditions for which

the PCM monitors and sets DTC's. Refer to Moni-

tored Systems, Components, and Non-Monitored Cir-

cuits in this section.

NOTE: Various diagnostic procedures may actually

cause a diagnostic monitor to set a DTC. For

instance, pulling a spark plug wire to perform a

spark test may set the misfire code. When a repair

is completed and verified, use the scan tool to

erase all DTC's and extinguish the MIL.

Technicians can display stored DTC's. For obtain-

ing the DTC information, use the Data Link Connec-

tor with the scan tool (Fig. 1).

Fig. 1 Data Link Connector

RSEMISSIONS CONTROL25-9

EMISSIONS CONTROL (Continued)

Page 2283 of 2339

DRB IIITSTATE DISPLAY TEST MODE

OPERATION

The switch inputs to the Powertrain Control Mod-

ule (PCM) have two recognized states; HIGH and

LOW. For this reason, the PCM cannot recognize the

difference between a selected switch position versusan open circuit, a short circuit, or a defective switch.

If the State Display screen shows the change from

HIGH to LOW or LOW to HIGH, assume the entire

switch circuit to the PCM functions properly. From

the state display screen, access either State Display

Inputs and Outputs or State Display Sensors.

25 - 10 EMISSIONS CONTROLRS

EMISSIONS CONTROL (Continued)

Page 2284 of 2339

EVAPORATIVE EMISSIONS

TABLE OF CONTENTS

page page

EVAPORATIVE EMISSIONS

OPERATION - EVAPORATION CONTROL

SYSTEM............................11

SPECIFICATIONS

TORQUE............................12

EVAP/PURGE SOLENOID

DESCRIPTION.........................13

OPERATION...........................13

REMOVAL.............................13

INSTALLATION.........................13

FUEL FILLER CAP

DESCRIPTION.........................13

OPERATION...........................13

NATURAL VAC LEAK DETECTION ASSY

REMOVAL.............................14

INSTALLATION.........................14

LEAK DETECTION PUMP

REMOVAL.............................15

INSTALLATION.........................15

ORVR

OPERATION...........................15DIAGNOSIS AND TESTING - VEHICLE DOES

NOT FILL............................17

P C V VA LV E

DESCRIPTION.........................18

OPERATION...........................18

DIAGNOSIS AND TESTING - PCV SYSTEM . . . 18

VAPOR CANISTER

DESCRIPTION.........................19

OPERATION...........................19

REMOVAL

REMOVAL...........................19

REMOVAL - WITH NVLD - FOLD-IN-FLOOR . 20

REMOVAL - REAR EVAP CANISTER.......20

INSTALLATION

INSTALLATION.......................20

INSTALLATION - WITH NVLD - FOLD-IN-

FLOOR.............................20

INSTALLATION - REAR EVAP CANISTER . . . 21

EVAPORATIVE EMISSIONS

OPERATION - EVAPORATION CONTROL

SYSTEM

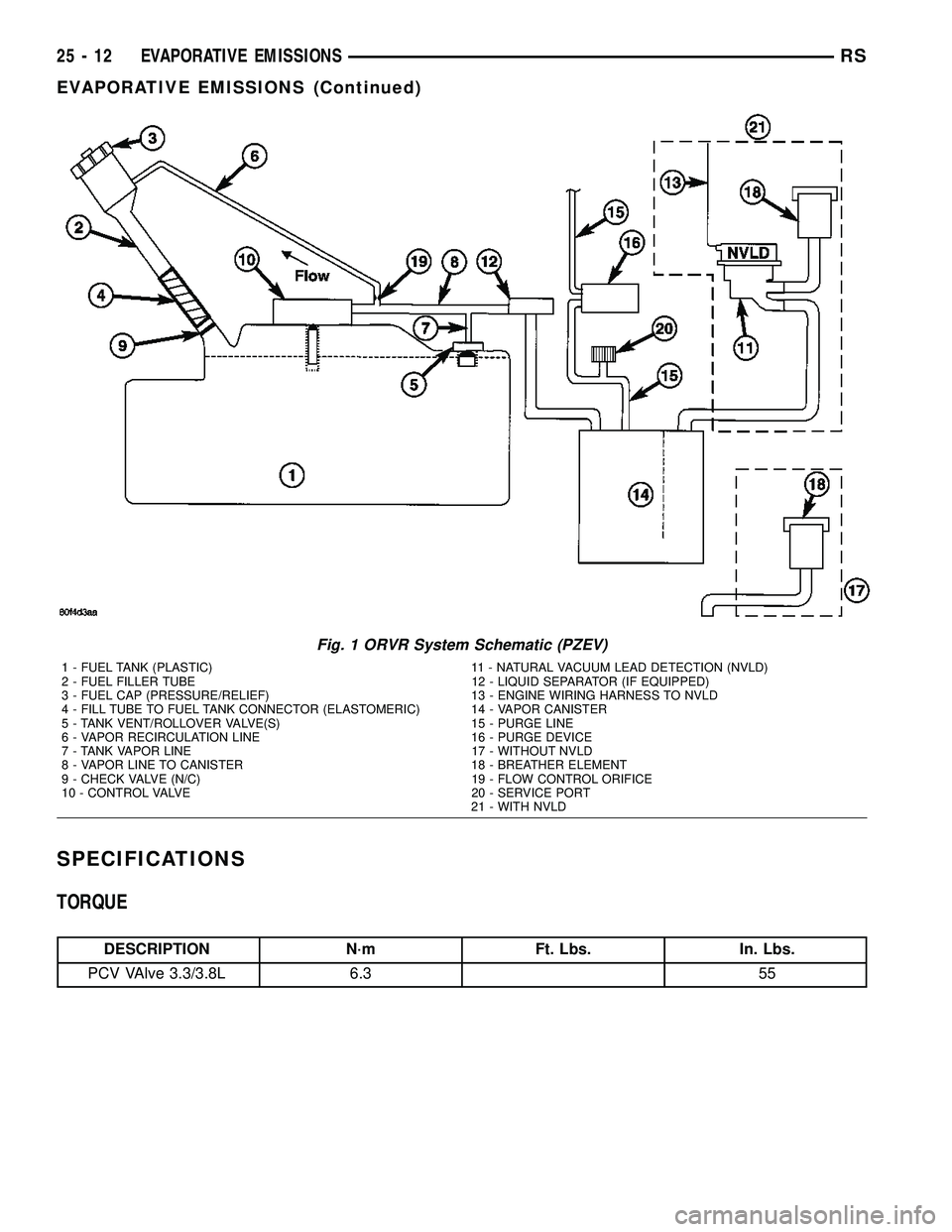

The evaporation control system prevents the emis-

sion of fuel tank vapors into the atmosphere. When

fuel evaporates in the fuel tank, the vapors pass

through vent hoses or tubes to an activated carbon

filled evaporative canister. The canister temporarily

holds the vapors. The Powertrain Control Module

(PCM) allows intake manifold vacuum to draw

vapors into the combustion chambers during certain

operating conditions (Fig. 1).All engines use a proportional purge solenoid sys-

tem. The PCM controls vapor flow by operating the

purge solenoid. Refer to Proportional Purge Solenoid

in this section.

NOTE: The evaporative system uses specially man-

ufactured hoses. If they need replacement, only use

fuel resistant hose. Also the hoses must be able to

pass an Ozone compliance test.

NOTE: For more information on Onboard Refueling

Vapor Recovery (ORVR), refer to the Fuel Delivery

section.

RSEVAPORATIVE EMISSIONS25-11

Page 2285 of 2339

SPECIFICATIONS

TORQUE

DESCRIPTION N´m Ft. Lbs. In. Lbs.

PCV VAlve 3.3/3.8L 6.3 55

Fig. 1 ORVR System Schematic (PZEV)

1 - FUEL TANK (PLASTIC) 11 - NATURAL VACUUM LEAD DETECTION (NVLD)

2 - FUEL FILLER TUBE 12 - LIQUID SEPARATOR (IF EQUIPPED)

3 - FUEL CAP (PRESSURE/RELIEF) 13 - ENGINE WIRING HARNESS TO NVLD

4 - FILL TUBE TO FUEL TANK CONNECTOR (ELASTOMERIC) 14 - VAPOR CANISTER

5 - TANK VENT/ROLLOVER VALVE(S) 15 - PURGE LINE

6 - VAPOR RECIRCULATION LINE 16 - PURGE DEVICE

7 - TANK VAPOR LINE 17 - WITHOUT NVLD

8 - VAPOR LINE TO CANISTER 18 - BREATHER ELEMENT

9 - CHECK VALVE (N/C) 19 - FLOW CONTROL ORIFICE

10 - CONTROL VALVE 20 - SERVICE PORT

21 - WITH NVLD

25 - 12 EVAPORATIVE EMISSIONSRS

EVAPORATIVE EMISSIONS (Continued)

Page 2286 of 2339

EVAP/PURGE SOLENOID

DESCRIPTION

All vehicles use a proportional purge solenoid (Fig.

2). The solenoid regulates the rate of vapor flow from

the EVAP canister to the throttle body. The PCM

operates the solenoid.

OPERATION

During the cold start warm-up period and the hot

start time delay, the PCM does not energize the sole-

noid. When de-energized, no vapors are purged.

The proportional purge solenoid operates at a fre-

quency of 200 hz and is controlled by an engine con-

troller circuit that senses the current being applied

to the proportional purge solenoid and then adjusts

that current to achieve the desired purge flow. The

proportional purge solenoid controls the purge rate of

fuel vapors from the vapor canister and fuel tank to

the engine intake manifold.

REMOVAL

The solenoid attaches to a bracket near the radia-

tor on the passenger side of vehicle (Fig. 3). The sole-

noid will not operate unless it is installed correctly.

(1) Disconnect electrical connector from solenoid.

(2) Disconnect vacuum tubes from solenoid.

(3) Remove solenoid from bracket.

INSTALLATION

The solenoid attaches to a bracket near the radia-

tor on the passenger side of vehicle. The solenoid will

not operate unless it is installed correctly.The top of the solenoid has TOP printed on it. The

solenoid will not operate unless it is installed cor-

rectly.

(1) Install solenoid on bracket.

(2) Connect vacuum tube to solenoid.

(3) Connect electrical connector to solenoid.

FUEL FILLER CAP

DESCRIPTION

The plastic fuel fill cap is threaded/quarter turn

onto the end of the fuel filler tube. It's purpose is to

retain vapors and fuel in the fuel tank.

OPERATION

The fuel filler cap incorporates a two-way relief

valve that is closed to atmosphere during normal

operating conditions. The relief valve is calibrated to

open when a pressure of 17 kPa (2.5 psi) or vacuum

of 2 kPa (0.6 in. Hg) occurs in the fuel tank. When

the pressure or vacuum is relieved, the valve returns

to the normally closed position.

CAUTION: Remove the fuel filler cap to release fuel

tank pressure before disconnecting any fuel system

component.

Fig. 2 Proportional Purge Solenoid

Fig. 3 EVAP PURGE SOLENOID

1 - EVAP Purge Solenoid

2 - EGR VAlve

3 - Generator

RSEVAPORATIVE EMISSIONS25-13

Page 2287 of 2339

NATURAL VAC LEAK

DETECTION ASSY

REMOVAL

(1) Disconnect thew negative battery cable.

(2) Raise vehicle and support (Fig. 4).

(3) Unlock and disconnect the electrical connector.

(4) Remove the hoses from the NVLD valve.

(5) Remove the 2 fasteners.

(6) Remove the valve and bracket from vehicle

(Fig. 5).

(7) Remove valve from bracket (Fig. 6).

INSTALLATION

(1) Install NVLD valve to the bracket (Fig. 6).

(2) Install valve and bracket to the vehicle (Fig. 5).

(3) Install the 2 mounting bolts and tighten.

(4) Install the electrical connector and lock.

(5) Install the 2 hoses and lock the clamps.

(6) Lower vehicle.

Fig. 4 NVLD LOCATION

Fig. 5 NVLD REMOVAL/INSTALLATION

Fig. 6 NVLD VALVE AND BRACKET

25 - 14 EVAPORATIVE EMISSIONSRS

Page 2288 of 2339

LEAK DETECTION PUMP

REMOVAL

(1) Disconnect the negative battery cable.

(2) Raise and support the vehicle.

(3) Remove 3 hoses (Fig. 7).

(4) Remove the electrical connector (Fig. 8).

(5) Remove the 3 screws and remove LDP pump.

INSTALLATION

(1) Install LDP.

(2) Install the 3 screws and tighten (Fig. 8).

(3) Install the electrical connector.

(4) Install the 3 hoses (Fig. 7).

(5) Lower vehicle.

(6) Connect the negative battery cable.

ORVR

OPERATION

The emission control principle used in the ORVR

system is that the fuel flowing into the filler tube

(appx. 1º I.D.) creates an aspiration effect which

draws air into the fill tube (Fig. 9). During refueling,

the fuel tank is vented to the vapor canister to cap-

ture escaping vapors. With air flowing into the filler

tube, there are no fuel vapors escaping to the atmo-

sphere. Once the refueling vapors are captured by

the canister, the vehicle's computer controlled purge

system draws vapor out of the canister for the engine

to burn. The vapors flow is metered by the purge

solenoid so that there is no or minimal impact on

driveability or tailpipe emissions.

As fuel starts to flow through the fill tube, it opens

the normally closed check valve and enters the fuel

tank. Vapor or air is expelled from the tank through

the control valve to the vapor canister. Vapor is

absorbed in the canister until vapor flow in the lines

stops, either following shut-off or by having the fuel

level in the tank rise high enough to close the control

valve. The control valve(Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/FUEL TANK - OPERATION)

contains a float that rises to seal the large diameter

vent path to the canister. At this point in the fueling

of the vehicle, the tank pressure increases, the check

valve closes (preventing tank fuel from spitting back

at the operator), and fuel then rises up the filler tube

to shut-off the dispensing nozzle.

If the engine is shut-off while the On-Board diag-

nostics test is running, low level tank pressure can

be trapped in the fuel tank and fuel can not be added

to the tank until the pressure is relieved. This is due

to the leak detection pump closing the vapor outlet

from the top of the tank and the one-way check valve

not allowing the tank to vent through the fill tube to

atmosphere. Therefore, when fuel is added, it will

back-up in the fill tube and shut off the dispensing

nozzle. The pressure can be eliminated in two ways:

1. Vehicle purge must be activated and for a long

enough period to eliminate the pressure. 2. Removing

the fuel cap and allowing enough time for the system

to vent thru the recirulation tube.

Fig. 7 LDP LOCATION

Fig. 8 LDP REMOVAL/INSTALLATION

RSEVAPORATIVE EMISSIONS25-15

Page 2289 of 2339

Fig. 9 ORVR System Schematic

1 - FUEL TANK (PLASTIC) 11 - NATURAL VACUUM LEAD DETECTION (NVLD)

2 - FUEL FILLER TUBE 12 - LIQUID SEPARATOR (IF EQUIPPED)

3 - FUEL CAP (PRESSURE/RELIEF) 13 - ENGINE WIRING HARNESS TO NVLD

4 - FILL TUBE TO FUEL TANK CONNECTOR (ELASTOMERIC) 14 - VAPOR CANISTER

5 - TANK VENT/ROLLOVER VALVE(S) 15 - PURGE LINE

6 - VAPOR RECIRCULATION LINE 16 - PURGE DEVICE

7 - TANK VAPOR LINE 17 - WITHOUT NVLD

8 - VAPOR LINE TO CANISTER 18 - BREATHER ELEMENT

9 - CHECK VALVE (N/C) 19 - FLOW CONTROL ORIFICE

10 - CONTROL VALVE 20 - SERVICE PORT

21 - WITH NVLD

25 - 16 EVAPORATIVE EMISSIONSRS

ORVR (Continued)

Page 2290 of 2339

DIAGNOSIS AND TESTING - VEHICLE DOES

NOT FILL

CONDITION POSSIBLE CAUSES CORRECTION

Pre-Mature Nozzle Shut-Off Defective fuel tank assembly

components.Fill tube improperly installed

(sump)

Fill tube hose pinched.

Check valve stuck shut.

Control valve stuck shut.

Defective vapor/vent components. Vent line from control valve to

canister pinched.

Vent line from canister to vent

filter pinched.

Canister vent valve failure

(requires double failure,

plugged to NVLD and

atmosphere).

Leak detection pump failed

closed.

Leak detection pump filter

plugged.

On-Board diagnostics evaporative

system leak test just conducted.Canister vent valve vent

plugged to atmosphere.

Engine still running when

attempting to fill (System

designed not to fill).

Defective fill nozzle. Try another nozzle.

Fuel Spits Out Of Filler

Tube.During fill. See Pre-Mature Shut-Off.

At conclusion of fill. Defective fuel handling

component. (Check valve stuck

open).

Defective vapor/vent handling

component.

Defective fill nozzle.

RSEVAPORATIVE EMISSIONS25-17

ORVR (Continued)