lock CHRYSLER VOYAGER 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 1174 of 2339

8W-97 POWER DISTRIBUTION SYSTEM

TABLE OF CONTENTS

page page

POWER DISTRIBUTION SYSTEM

DESCRIPTION..........................1

OPERATION............................1

SPECIAL TOOLS

POWER DISTRIBUTION SYSTEMS.........1

INTEGRATED POWER MODULE

DESCRIPTION..........................1

OPERATION............................2

REMOVAL.............................2

INSTALLATION..........................2IOD FUSE

DESCRIPTION..........................3

OPERATION............................3

POWER OUTLET

DESCRIPTION..........................3

OPERATION............................3

DIAGNOSIS AND TESTING

DIAGNOSIS & TESTING - POWER OUTLET . . 3

REMOVAL.............................4

INSTALLATION..........................4

POWER DISTRIBUTION

SYSTEM

DESCRIPTION

The power distribution system for this vehicle con-

sists of the following components:

²Integrated Power Module (IPM)

²Front Control Module (FCM)

²Power Outlets

Refer to Wiring Diagrams for complete circuit sche-

matics.

The power distribution system also incorporates

various types of circuit control and protection fea-

tures, including:

²Automatic resetting circuit breakers

²Blade-type fuses

²Bus bars

²Cartridge fuses

²Circuit splice blocks

²Flashers

²Fusible links

²Relays

OPERATION

The power distribution system for this vehicle is

designed to provide safe, reliable, and centralized dis-

tribution points for the electrical current required to

operate all of the many standard and optional facto-

ry-installed electrical and electronic powertrain,

chassis, safety, security, comfort and convenience sys-

tems. At the same time, the power distribution sys-

tem was designed to provide ready access to these

electrical distribution points for the vehicle techni-

cian to use when conducting diagnosis and repair of

faulty circuits. The power distribution system can

also prove useful for the sourcing of additional elec-

trical circuits that may be required to provide theelectrical current needed to operate many accessories

that the vehicle owner may choose to have installed.

SPECIAL TOOLS

POWER DISTRIBUTION SYSTEMS

INTEGRATED POWER MODULE

DESCRIPTION

The Integrated Power Module (IPM) is a combina-

tion of the Power Distribution Center (PDC) and the

Front Control Module (FCM). The IPM is located in

the engine compartment, next to the battery. (Fig. 1).

The PDC mates directly with the FCM to form the

IPM. The PDC is a printed circuit board based mod-

ule that contains fuses and relays, while the FCM

contains the electronics controlling the IPM and

other functions. This IPM connects directly to the

battery positive through a four pin connector. The

ground connection is through two other connectors.

Terminal Pick Kit 6680

RS8W-97 POWER DISTRIBUTION SYSTEM8W-97-1

Page 1175 of 2339

The IPM provides the primary means of voltage dis-

tribution and protection for the entire vehicle.

OPERATION

All of the current from the battery and the gener-

ator output enters the Integrated Power Module

(IPM) through a four- pin connector on the bottom of

the module. Internal connections of all of the power

distribution center circuits is accomplished by a com-

bination of bus bars and a printed circuit board.

REMOVAL

(1) Disconnect the negative and positive battery

cables.

(2) Remove the battery thermal guard.

(3) Remove the battery (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - REMOVAL).

(4) Using a flat-bladed screwdriver, twist the Inte-

grated Power Module (IPM) bracket retaining latch

outward to free the IPM from its mounting bracket

(Fig. 2).

(5) Rotate the IPM counter-clockwise to access and

disconnect the electrical connectors (Fig. 3).

(6) Remove the IPM bracket clips from the hinge.

INSTALLATION

(1) Snap the left side of the Integrated Power Mod-

ule (IPM) housing in its mounting bracket and con-

nect the various electrical connectors.NOTE: Ensure that the Connector Positive Assur-

ance (CPA) on the five-pin B+ connector is posi-

tively engaged to prevent generating a Diagnostic

Trouble Code (DTC).

(2) Rotate the IPM clock-wise until secured in

mounting bracket. An audible click may be heard.

(3) Install the battery (Refer to 8 - ELECTRICAL/

BATTERY SYSTEM/BATTERY - INSTALLATION).

(4) Install the battery thermal guard.

Fig. 1 INTEGRATED POWER MODULE

1 - BATTERY THERMAL GUARD

2 - INTEGRATED POWER MODULE

3 - FRONT CONTROL MODULE

Fig. 2 INTEGRATED POWER MODULE

Fig. 3 DISCONNECTING IPM

1 - INTEGRATED POWER MODULE

8W - 97 - 2 8W-97 POWER DISTRIBUTION SYSTEMRS

INTEGRATED POWER MODULE (Continued)

Page 1176 of 2339

(5) Connect the negative and positive battery

cables.

(6) Using a scan tool, check for any stored diagnos-

tic trouble codes. Ensure that all vehicle options are

operational.

IOD FUSE

DESCRIPTION

All vehicles are equipped with an Ignition-Off

Draw (IOD) fuse that is removed from its normal

cavity in the Integrated Power Module (IPM) when

the vehicle is shipped from the factory. Dealer per-

sonnel are to remove the IOD fuse from the storage

location and install it into the IPM fuse cavity

marked IOD as part of the preparation procedures

performed just prior to new vehicle delivery.

The IOD fuse is a 20 ampere blade-type mini fuse

and, when removed, it is stored in a fuse cavity adja-

cent to the washer fuse within the IPM.

OPERATION

The term ignition-off draw (IOD) identifies a nor-

mal condition where power is being drained from the

battery with the ignition switch in the Off position.

The IOD fuse feeds the memory and sleep mode func-

tions for some of the electronic modules in the vehicle

as well as various other accessories that require bat-

tery current when the ignition switch is in the Off

position, including the clock. The only reason the

IOD fuse is removed is to reduce the normal IOD of

the vehicle electrical system during new vehicle

transportation and pre-delivery storage to reduce

battery depletion, while still allowing vehicle opera-

tion so that the vehicle can be loaded, unloaded and

moved as needed by both vehicle transportation com-

pany and dealer personnel.

The IOD fuse is removed from the Integrated

Power Module (IPM) fuse cavity when the vehicle is

shipped from the assembly plant. Dealer personnel

must install the IOD fuse when the vehicle is being

prepared for delivery in order to restore full electrical

system operation. Once the vehicle is prepared for

delivery, the IOD function of this fuse becomes trans-

parent and the fuse that has been assigned the IOD

designation becomes only another Fused B(+) circuit

fuse. The IOD fuse serves no useful purpose to the

dealer technician in the service or diagnosis of any

vehicle system or condition, other than the same pur-

pose as that of any other standard circuit protection

device.

The IOD fuse can be used by the vehicle owner as

a convenient means of reducing battery depletion

when a vehicle is to be stored for periods not to

exceed approximately thirty days. However, it mustbe remembered that removing the IOD fuse will not

eliminate IOD, but only reduce this normal condition.

If a vehicle will be stored for more than thirty days,

the battery negative cable should be disconnected to

eliminate normal IOD; and, the battery should be

tested and recharged at regular intervals during the

vehicle storage period to prevent the battery from

becoming discharged or damaged.

POWER OUTLET

DESCRIPTION

Two power outlets are installed in the instrument

panel center lower bezel. Two additional power out-

lets are incorporated into the left rear C-pillar and

the center console (if equipped). The power outlets

bases are secured by a snap fit. A hinged plug flips

closed to conceal and protect the power outlet base

when not in use.

OPERATION

The power outlet base or receptacle shell is con-

nected to ground, and an insulated contact in the

bottom of the shell is connected to battery current.

The power outlet on the instrument panel marked

with a battery receives battery voltage from a fuse in

the Integrated Power Module (IPM) at all times. The

other power outlet on the instrument panel marked

with a key receives battery voltage only when the

key is in the on position.

The power outlet located in the center console

receives battery voltage all the time when positioned

between thefront seatsand key-on voltage when

positioned between therear seats. The power outlet

located on the C-pillar receives battery voltage only

when the key is in the ON position.

DIAGNOSIS AND TESTING

DIAGNOSIS & TESTING - POWER OUTLET

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO RESTRAINTS BEFORE ATTEMPT-

ING ANY STEERING WHEEL, STEERING COLUMN,

SEAT OR INSTRUMENT PANEL COMPONENT DIAG-

NOSIS OR SERVICE. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Check the fused B(+) fuse in the Integrated

Power Module (IPM). If OK, go to Step 2. If not OK,

repair the shorted circuit or component as required

and replace the faulty fuse.

RS8W-97 POWER DISTRIBUTION SYSTEM8W-97-3

INTEGRATED POWER MODULE (Continued)

Page 1177 of 2339

(2) Check for battery voltage at the fused B(+) fuse

in the IPM. If OK, go to Step 3. If not OK, repair the

open fused B(+) circuit to the IPM fuse as required.

(3) Open the power outlet door. Check for continu-

ity between the inside circumference of the power

outlet receptacle and a good ground. There should be

continuity. If OK, go to Step 4. If not OK, go to Step

5.

(4) Check for battery voltage at the insulated con-

tact located at the back of the power outlet recepta-

cle. If not OK, go to Step 5.

(5) Disconnect and isolate the battery negative

cable. Remove the appropriate bezel. Check for conti-

nuity between the ground circuit cavity of the power

outlet wire harness connector and a good ground.

There should be continuity. If OK, go to Step 6. If not

OK, repair the open ground circuit to ground as

required.

(6) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

power outlet wire harness connector. If OK, replace

the faulty power outlet receptacle. If not OK, repair

the open fused B(+) circuit to the IPM fuse as

required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Note position of the retaining bosses (Fig. 4).

(3) Using external snap ring pliers with 90 degree

tips. Insert pliers with tips against bosses and

squeeze forcing bosses out of base.

(4) Pull out the base through mounting ring by

gently rocking pliers.

(5) Disconnect the base wires.

(6) Remove light ring and disconnect wire.

INSTALLATION

(1) Position the mounting ring on the instrument

panel and feed the wires through the ring. Index thecap and the mounting ring with the index tab at the

9 o'clock position to the key in the instrument panel.

Install the ring.

(2) Connect the wires to the base. Orientate the

base alignment rib at the 11 o'clock position to mate

the groove in the mounting ring to the base.

(3) Push the base into the bezel until it locks in

place.

(4) Check operation of outlet or element and

install the outlet cap.

Fig. 4 POWER OUTLET

1 - RETAINING BOSSES-ENGAGE PLIERS HERE

2 - PARTIALLY REMOVED

3 - EXTERNAL SNAP-RING PLIERS

4 - PULL BASE OUT-THROUGH MOUNTING RING

8W - 97 - 4 8W-97 POWER DISTRIBUTION SYSTEMRS

POWER OUTLET (Continued)

Page 1178 of 2339

ENGINE

TABLE OF CONTENTS

page page

ENGINE 2.4L.............................. 1ENGINE 3.3/3.8L......................... 76

ENGINE 2.4L

TABLE OF CONTENTS

page page

ENGINE 2.4L

DESCRIPTION..........................3

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - INTRODUCTION............3

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - PERFORMANCE............4

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - MECHANICAL..............6

DIAGNOSIS AND TESTING - ENGINE OIL

LEAK INSPECTION.....................8

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE TEST.........9

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE

TEST................................9

STANDARD PROCEDURE

STANDARD PROCEDURE - ENGINE CORE

AND OIL GALLERY PLUGS..............10

STANDARD PROCEDURE - REPAIR OF

DAMAGED OR WORN THREADS.........10

HYDROSTATIC LOCKED ENGINE.........10

FORM-IN-PLACE GASKETS AND SEALERS . 11

STANDARD PROCEDURE - ENGINE

GASKET SURFACE PREPARATION........11

STANDARD PROCEDURE - MEASURING

BEARING CLEARANCE USING

PLASTIGAGE........................12

REMOVAL - ENGINE ASSEMBLY...........12

INSTALLATION - ENGINE ASSEMBLY........14

SPECIFICATIONS

SPECIFICATIONS - 2.4L ENGINE.........16

SPECIFICATIONS - TORQUE............20

SPECIAL TOOLS

2.4L ENGINE.........................21

AIR CLEANER ELEMENT

REMOVAL.............................24INSTALLATION.........................24

AIR CLEANER HOUSING

REMOVAL.............................25

INSTALLATION.........................25

CYLINDER HEAD

DESCRIPTION.........................25

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET............................25

REMOVAL - CYLINDER HEAD.............26

CLEANING............................26

INSPECTION..........................27

INSTALLATION - CYLINDER HEAD..........27

CAMSHAFT OIL SEAL(S)

REMOVAL.............................28

INSTALLATION.........................29

CAMSHAFT(S)

DESCRIPTION.........................29

OPERATION...........................29

STANDARD PROCEDURE - MEASURING

CAMSHAFT END PLAY.................29

REMOVAL.............................30

CLEANING............................30

INSPECTION..........................30

INSTALLATION.........................31

CYLINDER HEAD COVER

REMOVAL.............................31

CLEANING............................31

INSPECTION..........................31

INSTALLATION.........................32

INTAKE/EXHAUST VALVES & SEATS

DESCRIPTION.........................33

CLEANING............................33

VALVE SPRINGS & SEALS

REMOVAL

REMOVAL - CYLINDER HEAD ON.........33

REMOVAL - CYLINDER HEAD OFF........33

INSPECTION..........................33

RSENGINE9-1

Page 1179 of 2339

INSTALLATION

INSTALLATION - CYLINDER HEAD ON.....33

INSTALLATION - CYLINDER HEAD OFF....33

HYDRAULIC LASH ADJUSTERS

DIAGNOSIS AND TESTING - HYDRAULIC

LASH ADJUSTER NOISE DIAGNOSIS......34

REMOVAL.............................35

INSTALLATION.........................35

ROCKER ARMS

REMOVAL.............................35

INSPECTION..........................35

INSTALLATION.........................35

ENGINE BLOCK

DESCRIPTION.........................36

STANDARD PROCEDURE - CYLINDER BORE

HONING............................36

CLEANING............................37

INSPECTION..........................37

CRANKSHAFT

STANDARD PROCEDURE - CRANKSHAFT

ENDPLAY ...........................37

REMOVAL - CRANKSHAFT................37

INSPECTION..........................38

INSTALLATION - CRANKSHAFT............39

CRANKSHAFT OIL SEAL - FRONT

REMOVAL.............................41

INSTALLATION.........................42

CRANKSHAFT OIL SEAL - REAR

REMOVAL.............................42

INSTALLATION.........................42

PISTON & CONNECTING ROD

DESCRIPTION.........................44

STANDARD PROCEDURE - PISTON TO

CYLINDER BORE FITTING..............44

REMOVAL.............................44

INSTALLATION.........................45

CONNECTING ROD BEARINGS

STANDARD PROCEDURE

CONNECTING ROD - FITTING...........46

PISTON RINGS

STANDARD PROCEDURE

PISTON RING - FITTING................47

REMOVAL.............................47

INSTALLATION.........................47

VIBRATION DAMPER

REMOVAL.............................48

INSTALLATION.........................49

STRUCTURAL COLLAR

REMOVAL.............................49

INSTALLATION.........................49

ENGINE MOUNTING

DESCRIPTION.........................50

FRONT MOUNT

REMOVAL.............................50

INSTALLATION.........................50

LEFT MOUNT

REMOVAL.............................50INSTALLATION.........................50

REAR MOUNT

REMOVAL.............................51

INSTALLATION.........................52

RIGHT MOUNT

REMOVAL.............................52

INSTALLATION.........................52

LUBRICATION

DESCRIPTION.........................53

OPERATION...........................53

DIAGNOSIS AND TESTING - CHECKING

ENGINE OIL PRESSURE................53

OIL

STANDARD PROCEDURE

ENGINE OIL LEVEL CHECK.............54

STANDARD PROCEDURE - ENGINE OIL

AND FILTER CHANGE..................54

OIL FILTER

DESCRIPTION.........................54

REMOVAL.............................54

INSTALLATION.........................54

OIL PAN

REMOVAL.............................55

INSTALLATION.........................55

OIL PRESSURE SWITCH

REMOVAL.............................56

INSTALLATION.........................56

OIL PUMP

REMOVAL.............................56

DISASSEMBLY.........................57

CLEANING............................57

INSPECTION..........................58

ASSEMBLY............................58

INSTALLATION.........................59

INTAKE MANIFOLD

DESCRIPTION.........................60

DIAGNOSIS AND TESTING - INTAKE

MANIFOLD LEAKS.....................60

INTAKE MANIFOLD - UPPER

REMOVAL.............................60

INSPECTION..........................61

INSTALLATION.........................61

INTAKE MANIFOLD - LOWER

REMOVAL.............................62

INSPECTION..........................62

INSTALLATION.........................62

EXHAUST MANIFOLD

REMOVAL.............................63

CLEANING............................63

INSPECTION..........................63

INSTALLATION.........................63

TIMING BELT COVER(S)

REMOVAL.............................63

INSTALLATION.........................64

TIMING BELT AND SPROCKET(S)

REMOVAL

REMOVAL - TIMING BELT...............65

9 - 2 ENGINE 2.4LRS

Page 1180 of 2339

REMOVAL - CAMSHAFT SPROCKETS.....66

REMOVAL - CRANKSHAFT SPROCKET....66

CLEANING............................67

INSTALLATION

INSTALLATION - CRANKSHAFT SPROCKET . 67

INSTALLATION - CAMSHAFT SPROCKETS . . 67

INSTALLATION - TIMING BELT...........67

TIMING BELT TENSIONER & PULLEY

REMOVAL.............................69INSTALLATION.........................70

BALANCE SHAFTS AND CARRIER ASSEMBLY

DESCRIPTION.........................71

OPERATION...........................71

REMOVAL.............................71

INSTALLATION.........................73

ENGINE 2.4L

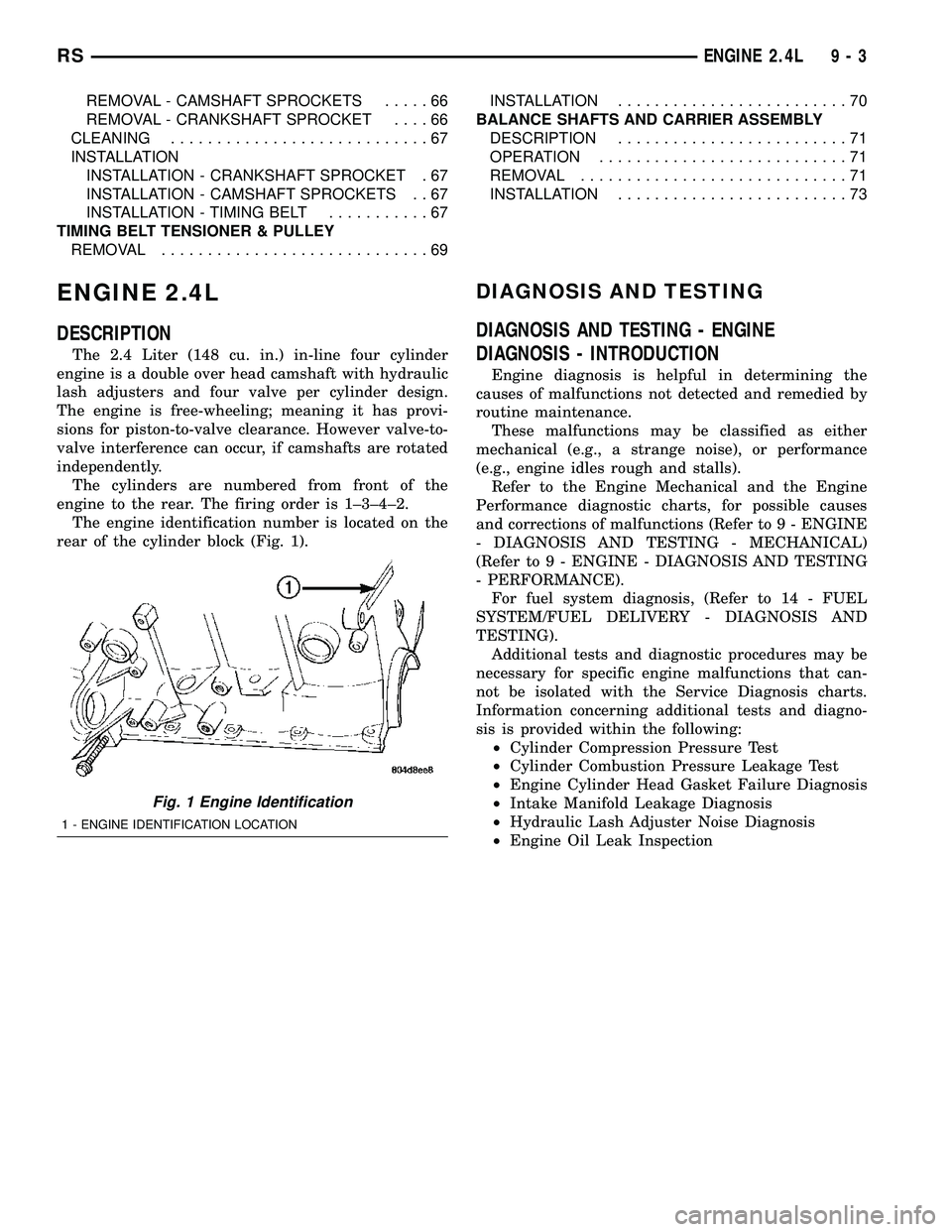

DESCRIPTION

The 2.4 Liter (148 cu. in.) in-line four cylinder

engine is a double over head camshaft with hydraulic

lash adjusters and four valve per cylinder design.

The engine is free-wheeling; meaning it has provi-

sions for piston-to-valve clearance. However valve-to-

valve interference can occur, if camshafts are rotated

independently.

The cylinders are numbered from front of the

engine to the rear. The firing order is 1±3±4±2.

The engine identification number is located on the

rear of the cylinder block (Fig. 1).

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - INTRODUCTION

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

Refer to the Engine Mechanical and the Engine

Performance diagnostic charts, for possible causes

and corrections of malfunctions (Refer to 9 - ENGINE

- DIAGNOSIS AND TESTING - MECHANICAL)

(Refer to 9 - ENGINE - DIAGNOSIS AND TESTING

- PERFORMANCE).

For fuel system diagnosis, (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY - DIAGNOSIS AND

TESTING).

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test

²Cylinder Combustion Pressure Leakage Test

²Engine Cylinder Head Gasket Failure Diagnosis

²Intake Manifold Leakage Diagnosis

²Hydraulic Lash Adjuster Noise Diagnosis

²Engine Oil Leak Inspection

Fig. 1 Engine Identification

1 - ENGINE IDENTIFICATION LOCATION

RSENGINE 2.4L9-3

Page 1185 of 2339

CONDITION POSSIBLE CAUSES CORRECTION

OIL CONSUMPTION OR SPARK

PLUGS FOULED1. PCV system malfunction. 1. Check system and repair as

necessary. (Refer to 25 -

EMISSIONS CONTROL/

EVAPORATIVE EMISSIONS/PCV

VALVE - DIAGNOSIS AND

TESTING)

2. Worn, scuffed or broken rings. 2. Hone cylinder bores. Install new

rings.

3. Carbon in oil ring slots. 3. Install new rings.

4. Rings fitted too tightly in grooves. 4. Remove rings and check

grooves. If groove is not proper

width, replace piston.

5. Worn valve guide(s). 5. Replace cylinder head assembly.

6. Valve stem seal(s) worn or

damaged.6. Replace seal(s).

DIAGNOSIS AND TESTING - ENGINE OIL LEAK

INSPECTION

Begin with a thorough visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair as necessary.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24 km (15 miles), and

repeat inspection.

(5)If the oil leak source is not positively

identified at this time, proceed with the air leak

detection test method as follows:

²Disconnect the fresh air hose (make-up air) at

the cylinder head cover and plug or cap the outlet on

the cover.

²Remove the PCV valve hose from the cylinder

head cover. Cap or plug the PCV valve outlet on the

cover.

²Attach an air hose with pressure gauge and reg-

ulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.²Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provides the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

²If the leakage occurs at the crankshaft rear oil

seal area, refer to the section, Inspection for Rear

Seal Area Leak.

(6) If no leaks are detected, turn off the air supply.

Remove the air hose, all plugs, and caps. Install the

PCV valve and fresh air hose (make-up air). Proceed

to next step.

(7) Clean the oil off the suspect oil leak area using

a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

NOTE: If oil leakage is observed at the dipstick tube

to block location; remove the tube, clean and reseal

using MoparTStud & Bearing Mount (press fit tube

applications only), and for O-ring style tubes,

remove tube and replace the O-ring seal.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

9 - 8 ENGINE 2.4LRS

ENGINE 2.4L (Continued)

Page 1186 of 2339

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak. If a leak is

present in this area, remove transmission for further

inspection.

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, oil gallery cup

plug, bedplate to cylinder block mating surfaces

and seal bore. See proper repair procedures for

these items.

(4) If no leaks are detected, pressurize the crank-

case as previously described.

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

(7) After the oil leak root cause and appropriate

corrective action have been identified, replace compo-

nent(s) as necessary.

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Check engine oil level and add oil if necessary.

(2) Drive the vehicle until engine reaches normal

operating temperature. Select a route free from traf-

fic and other forms of congestion, observe all traffic

laws, and accelerate through the gears several times

briskly.

(3) Remove all spark plugs from engine. As spark

plugs are being removed, check electrodes for abnor-

mal firing indicators fouled, hot, oily, etc. Record cyl-

inder number of spark plug for future reference.(4) Remove the Auto Shutdown (ASD) relay from

the PDC.

(5) Be sure throttle blade is fully open during the

compression check.

(6) Insert compression gauge adaptor Special Tool

8116 or the equivalent, into the #1 spark plug hole in

cylinder head. Connect the 0±500 psi (Blue) pressure

transducer (Special Tool CH7059) with cable adap-

tors to the DRBIIIt. For Special Tool identification,

(Refer to 9 - ENGINE - SPECIAL TOOLS).

(7) Crank engine until maximum pressure is

reached on gauge. Record this pressure as #1 cylin-

der pressure.

(8) Repeat the previous step for all remaining cyl-

inders.

(9) Compression should not be less than 689 kPa

(100 psi) and not vary more than 25 percent from cyl-

inder to cylinder.

(10) If one or more cylinders have abnormally low

compression pressures, repeat the compression test.

(11) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.The recommended com-

pression pressures are to be used only as a

guide to diagnosing engine problems. An engine

should not be disassembled to determine the

cause of low compression unless some malfunc-

tion is present.

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

WARNING: DO NOT REMOVE THE PRESSURE CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the pressure cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF.

Clean spark plug recesses with compressed air.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

RSENGINE 2.4L9-9

ENGINE 2.4L (Continued)

Page 1187 of 2339

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1,379

kPa (200 psi) maximum, with 552 kPa (80 psi) rec-

ommended.

Perform the test procedures on each cylinder

according to the tester manufacturer's instructions.

While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage per cylinder.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

STANDARD PROCEDURE

STANDARD PROCEDURE - ENGINE CORE AND

OIL GALLERY PLUGS

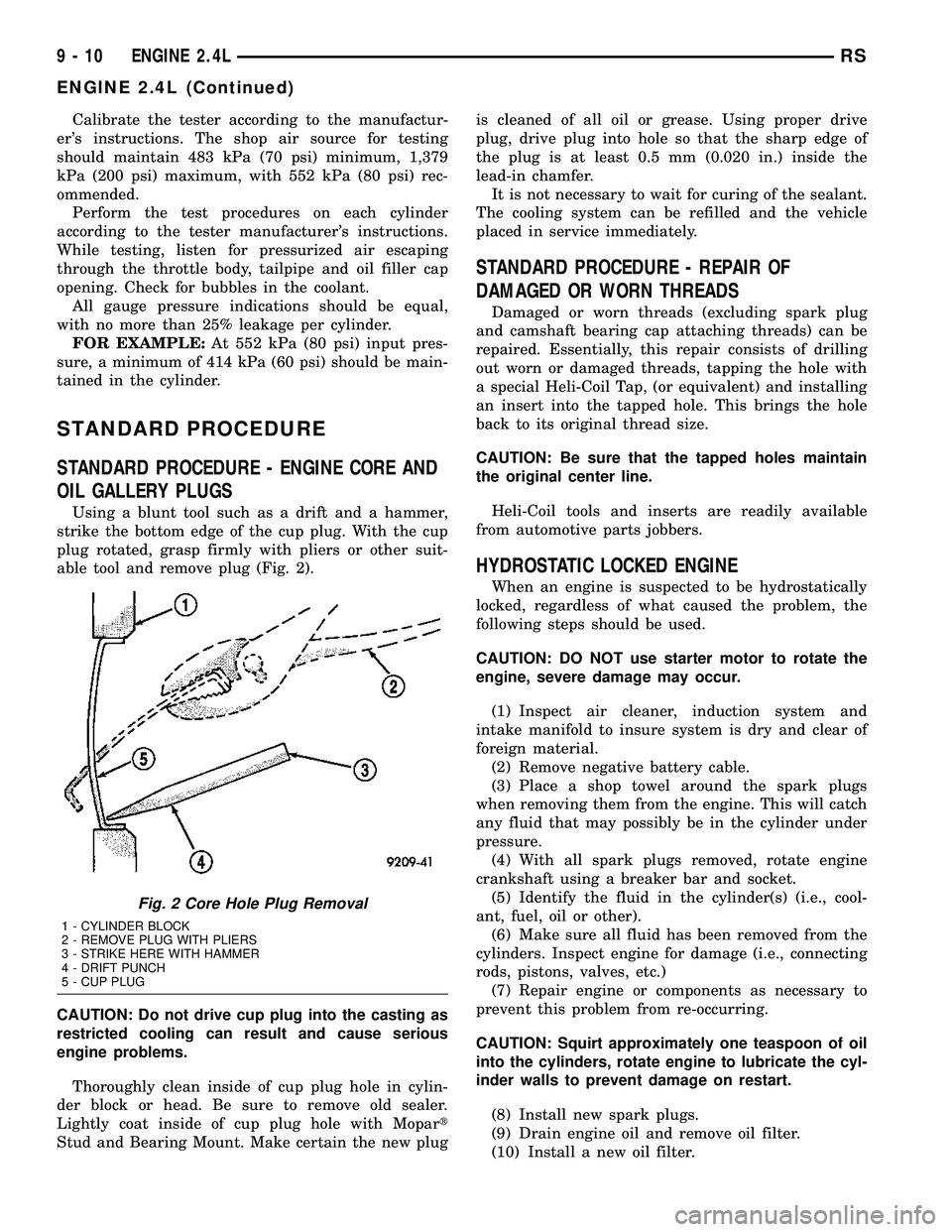

Using a blunt tool such as a drift and a hammer,

strike the bottom edge of the cup plug. With the cup

plug rotated, grasp firmly with pliers or other suit-

able tool and remove plug (Fig. 2).

CAUTION: Do not drive cup plug into the casting as

restricted cooling can result and cause serious

engine problems.

Thoroughly clean inside of cup plug hole in cylin-

der block or head. Be sure to remove old sealer.

Lightly coat inside of cup plug hole with Mopart

Stud and Bearing Mount. Make certain the new plugis cleaned of all oil or grease. Using proper drive

plug, drive plug into hole so that the sharp edge of

the plug is at least 0.5 mm (0.020 in.) inside the

lead-in chamfer.

It is not necessary to wait for curing of the sealant.

The cooling system can be refilled and the vehicle

placed in service immediately.

STANDARD PROCEDURE - REPAIR OF

DAMAGED OR WORN THREADS

Damaged or worn threads (excluding spark plug

and camshaft bearing cap attaching threads) can be

repaired. Essentially, this repair consists of drilling

out worn or damaged threads, tapping the hole with

a special Heli-Coil Tap, (or equivalent) and installing

an insert into the tapped hole. This brings the hole

back to its original thread size.

CAUTION: Be sure that the tapped holes maintain

the original center line.

Heli-Coil tools and inserts are readily available

from automotive parts jobbers.

HYDROSTATIC LOCKED ENGINE

When an engine is suspected to be hydrostatically

locked, regardless of what caused the problem, the

following steps should be used.

CAUTION: DO NOT use starter motor to rotate the

engine, severe damage may occur.

(1) Inspect air cleaner, induction system and

intake manifold to insure system is dry and clear of

foreign material.

(2) Remove negative battery cable.

(3) Place a shop towel around the spark plugs

when removing them from the engine. This will catch

any fluid that may possibly be in the cylinder under

pressure.

(4) With all spark plugs removed, rotate engine

crankshaft using a breaker bar and socket.

(5) Identify the fluid in the cylinder(s) (i.e., cool-

ant, fuel, oil or other).

(6) Make sure all fluid has been removed from the

cylinders. Inspect engine for damage (i.e., connecting

rods, pistons, valves, etc.)

(7) Repair engine or components as necessary to

prevent this problem from re-occurring.

CAUTION: Squirt approximately one teaspoon of oil

into the cylinders, rotate engine to lubricate the cyl-

inder walls to prevent damage on restart.

(8) Install new spark plugs.

(9) Drain engine oil and remove oil filter.

(10) Install a new oil filter.

Fig. 2 Core Hole Plug Removal

1 - CYLINDER BLOCK

2 - REMOVE PLUG WITH PLIERS

3 - STRIKE HERE WITH HAMMER

4 - DRIFT PUNCH

5 - CUP PLUG

9 - 10 ENGINE 2.4LRS

ENGINE 2.4L (Continued)