TCM CHRYSLER VOYAGER 2005 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 1581 of 2339

SPEED SENSOR - INPUT

DESCRIPTION

The Input Speed Sensor is a two-wire magnetic

pickup device that generates AC signals as rotation

occurs. It is threaded into the transaxle case (Fig.

285), sealed with an o-ring (Fig. 286), and is consid-

ered a primary input to the Powertrain/Transmission

Control Module.

OPERATION

The Input Speed Sensor provides information on

how fast the input shaft is rotating. As the teeth of

the input clutch hub pass by the sensor coil (Fig.

287), an AC voltage is generated and sent to the

PCM/TCM. The PCM/TCM interprets this informa-

tion as input shaft rpm.

The PCM/TCM compares the input speed signal

with output speed signal to determine the following:

²Transmission gear ratio

²Speed ratio error detection

²CVI calculation

The PCM/TCM also compares the input speed sig-

nal and the engine speed signal to determine the fol-

lowing:

²Torque converter clutch slippage

²Torque converter element speed ratio

Fig. 285 Input Speed Sensor Location

1 - INPUT SPEED SENSOR

Fig. 286 O-Ring Location

1 - INPUT SPEED SENSOR

2 - O-RING

Fig. 287 Sensor Relation to Input Clutch Hub

1 - INPUT SPEED SENSOR

2 - TRANSAXLE CASE

3 - INPUT CLUTCH HUB

21 - 120 40TE AUTOMATIC TRANSAXLERS

Page 1583 of 2339

SPEED SENSOR - OUTPUT

DESCRIPTION

The Output Speed Sensor is a two-wire magnetic

pickup device that generates an AC signal as rotation

occurs. It is threaded into the transaxle case (Fig.

291), sealed with an o-ring (Fig. 292), and is consid-

ered a primary input to the Powetrain/Transmission

Control Module.

OPERATION

The Output Speed Sensor provides information on

how fast the output shaft is rotating. As the rear

planetary carrier park pawl lugs pass by the sensor

coil (Fig. 293), an AC voltage is generated and sent to

the PCM/TCM. The PCM/TCM interprets this infor-

mation as output shaft rpm.

The PCM/TCM compares the input and output

speed signals to determine the following:

²Transmission gear ratio

²Speed ratio error detection

²CVI calculation

Fig. 291 Output Speed Sensor

1 - OUTPUT SPEED SENSOR

Fig. 292 O-Ring Location

1 - OUTPUT SPEED SENSOR

2 - O-RING

Fig. 293 Sensor Relation to Planet Carrier Park Pawl

1 - OUTPUT SPEED SENSOR

2 - REAR PLANET CARRIER/OUTPUT SHAFT ASSEMBLY

3 - TRANSAXLE CASE

21 - 122 40TE AUTOMATIC TRANSAXLERS

Page 1591 of 2339

TRANSMISSION CONTROL

RELAY

DESCRIPTION

The transmission control relay (Fig. 306) is located

in the Intelligent Power Module (IPM), which is

located on the left side of the engine compartment

between the battery and left fender.

OPERATION

The relay is supplied fused B+ voltage, energized by

the PCM/TCM, and is used to supply power to the sole-

noid pack when the transmission is in normal operating

mode. When the relay is ªoffº, no power is supplied to

the solenoid pack and the transmission is in ªlimp-inº

mode. After a controller reset (ignition key turned to the

ªrunº position or after cranking engine), the PCM/TCM

energizes the relay. Prior to this, the PCM/TCM verifies

that the contacts are open by checking for no voltage at

the switched battery terminals. After this is verified,

the voltage at the solenoid pack pressure switches is

checked. After the relay is energized, the PCM/TCM

monitors the terminals to verify that the voltage is

greater than 3 volts.

TRANSMISSION RANGE

SENSOR

DESCRIPTION

The Transmission Range Sensor (TRS) is mounted

to the top of the valve body inside the transaxle andcan only be serviced by removing the valve body. The

electrical connector extends through the transaxle

case (Fig. 307).

The Transmission Range Sensor (TRS) has four

switch contacts that monitor shift lever position and

send the information to the PCM/TCM.

The TRS also has an integrated temperature sen-

sor (thermistor) that communicates transaxle tem-

perature to the TCM and PCM (Fig. 308).

Fig. 306 Transmission Control Relay Location

1 - TRANSMISSION CONTROL RELAY

2 - LEFT FENDER

3 - INTELLIGENT POWER MODULE (IPM)

4 - BATTERY

Fig. 307 Transmission Range Sensor (TRS)

Location

1 - TRANSMISSION RANGE SENSOR

Fig. 308 Transmission Temperature Sensor

1 - TRANSMISSION RANGE SENSOR

2 - TEMPERATURE SENSOR

21 - 130 40TE AUTOMATIC TRANSAXLERS

Page 1592 of 2339

OPERATION

The Transmission Range Sensor (TRS) (Fig. 307)

communicates shift lever position (SLP) to the PCM/

TCM as a combination of open and closed switches.

Each shift lever position has an assigned combina-

tion of switch states (open/closed) that the PCM/TCM

receives from four sense circuits. The PCM/TCM

interprets this information and determines the

appropriate transaxle gear position and shift sched-

ule.

Since there are four switches, there are 16 possible

combinations of open and closed switches (codes).

Seven of these codes are related to gear position and

three are recognized as ªbetween gearº codes. This

results in six codes which should never occur. These

are called ªinvalidº codes. An invalid code will result

in a DTC, and the PCM/TCM will then determine the

shift lever position based on pressure switch data.

This allows reasonably normal transmission opera-

tion with a TRS failure.

TRS SWITCH STATES

SLP T42 T41 T3 T1

PCL CL CL OP

RCL OP OP OP

NCL CL OP CL

ODOP OP OP CL

3OP OP CL OP

LCL OP CL CL

TRANSMISSION TEMPERATURE SENSOR

The TRS has an integrated thermistor (Fig. 308)

that the PCM/TCM uses to monitor the transmis-

sion's sump temperature. Since fluid temperature

can affect transmission shift quality and convertor

lock up, the PCM/TCM requires this information to

determine which shift schedule to operate in. The

PCM also monitors this temperature data so it can

energize the vehicle cooling fan(s) when a transmis-

sion ªoverheatº condition exists. If the thermistor cir-

cuit fails, the PCM/TCM will revert to calculated oil

temperature usage.

CALCULATED TEMPERATURE

A failure in the temperature sensor or circuit will

result in calculated temperature being substituted for

actual temperature. Calculated temperature is a pre-dicted fluid temperature which is calculated from a

combination of inputs:

²Battery (ambient) temperature

²Engine coolant temperature

²In-gear run time since start-up

REMOVAL

(1) Remove valve body assembly from transaxle.

(Refer to 21 - TRANSMISSION/TRANSAXLE/AUTO-

MATIC - 41TE/VALVE BODY - REMOVAL)

(2) Remove transmission range sensor retaining

screw and remove sensor from valve body (Fig. 309).

(3) Remove TRS from manual shaft.

INSTALLATION

(1) Install transmission range sensor (TRS) to the

valve body and torque retaining screw (Fig. 309) to 5

N´m (45 in. lbs.).

(2) Install valve body to transaxle. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

41TE/VALVE BODY - INSTALLATION)

Fig. 309 Remove Transmission Range Sensor

1 - TRANSMISSION RANGE SENSOR

2 - MANUAL VALVE CONTROL PIN

3 - RETAINING SCREW

RS40TE AUTOMATIC TRANSAXLE21 - 131

TRANSMISSION RANGE SENSOR (Continued)

Page 1594 of 2339

MANUAL VALVE

The manual valve is operated by the mechanical

shift linkage. Its primary responsibility is to send

line pressure to the appropriate hydraulic circuits

and solenoids. The valve has three operating ranges

or positions.

CONVERTER CLUTCH SWITCH VALVE

The main responsibility of the converter clutch

switch valve is to control hydraulic pressure applied

to the front (off) side of the converter clutch piston.

Line pressure from the regulator valve is fed to the

torque converter regulator valve, where it passes

through the valve, and is slightly regulated. The

pressure is then directed to the converter clutch

switch valve and to the front side of the converter

clutch piston. This pressure pushes the piston back

and disengages the converter clutch.

CONVERTER CLUTCH CONTROL VALVE

The converter clutch control valve controls the

back (on) side of the torque converter clutch. When

the PCM/TCM energizes or modulates the LR/CC

solenoid to apply the converter clutch piston, both

the converter clutch control valve and the converter

control valve move, allowing pressure to be applied to

the back side of the clutch.

T/C REGULATOR VALVE

The torque converter regulator valve slightly regu-

lates the flow of fluid to the torque converter.

LOW/REVERSE SWITCH VALVE

The low/reverse clutch is applied from different

sources, depending on whether low (1st) gear or

reverse is selected. The low/reverse switch valve

alternates positions depending on from which direc-

tion fluid pressure is applied. By design, when the

valve is shifted by fluid pressure from one channel,

the opposing channel is blocked. The switch valve

alienates the possibility of a sticking ball check, thus

providing consistent application of the low/reverse

clutch under all operating conditions.

REMOVAL

NOTE: If valve body is replaced or reconditioned,

the ªQuick-Learnº Procedure must be performed.

(Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/TRANSMISSION CONTROL MODULE -

STANDARD PROCEDURE)

(1) Disconnect battery negative cable.

(2) Disconnect gearshift cable from manual valve

lever.

(3) Remove manual valve lever from manual shaft.

(4) Raise vehicle on hoist.

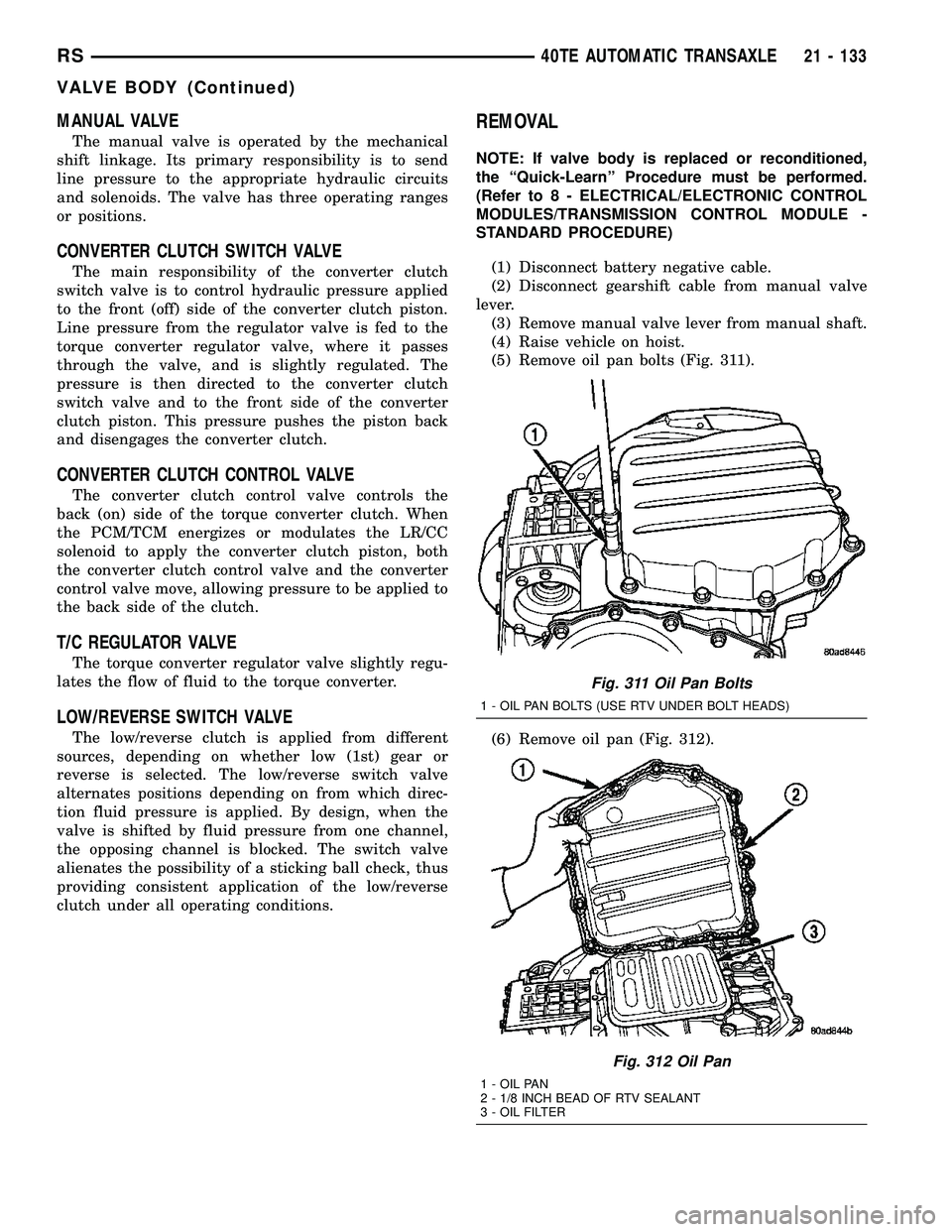

(5) Remove oil pan bolts (Fig. 311).

(6) Remove oil pan (Fig. 312).

Fig. 311 Oil Pan Bolts

1 - OIL PAN BOLTS (USE RTV UNDER BOLT HEADS)

Fig. 312 Oil Pan

1 - OIL PAN

2 - 1/8 INCH BEAD OF RTV SEALANT

3 - OIL FILTER

RS40TE AUTOMATIC TRANSAXLE21 - 133

VALVE BODY (Continued)

Page 1596 of 2339

DISASSEMBLY

NOTE: If valve body assembly is being recondi-

tioned, the PCM/TCM Quick Learn Procedure must

be performed. (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/TRANSMISSION

CONTROL MODULE - STANDARD PROCEDURE)

(1) Remove manual shaft seal (Fig. 317).

(2) Remove Transmission Range Sensor retaining

screw (Fig. 318).(3) Remove Manual Shaft/Rooster Comb and

Transmission Range Sensor (Fig. 319).

(4) Remove 2/4 Accumulator Retaining Plate (Fig.

320).

Fig. 317 Manual Shaft Seal

1 - SEAL

2 - MANUAL SHAFT

Fig. 318 Remove Transmission Range Sensor

1 - TRANSMISSION RANGE SENSOR

2 - MANUAL VALVE CONTROL PIN

3 - RETAINING SCREW

Fig. 319 Manual Shaft/Rooster Comb and

Transmission Range Sensor

1 - TRANSMISSION RANGE SENSOR

2 - MANUAL SHAFT

3 - ROOSTER COMB

Fig. 320 2/4 Accumulator Retaining Plate

1 - 2±4 ACCUMULATOR RETAINING PLATE

2 - DETENT SPRING

RS40TE AUTOMATIC TRANSAXLE21 - 135

VALVE BODY (Continued)

Page 1600 of 2339

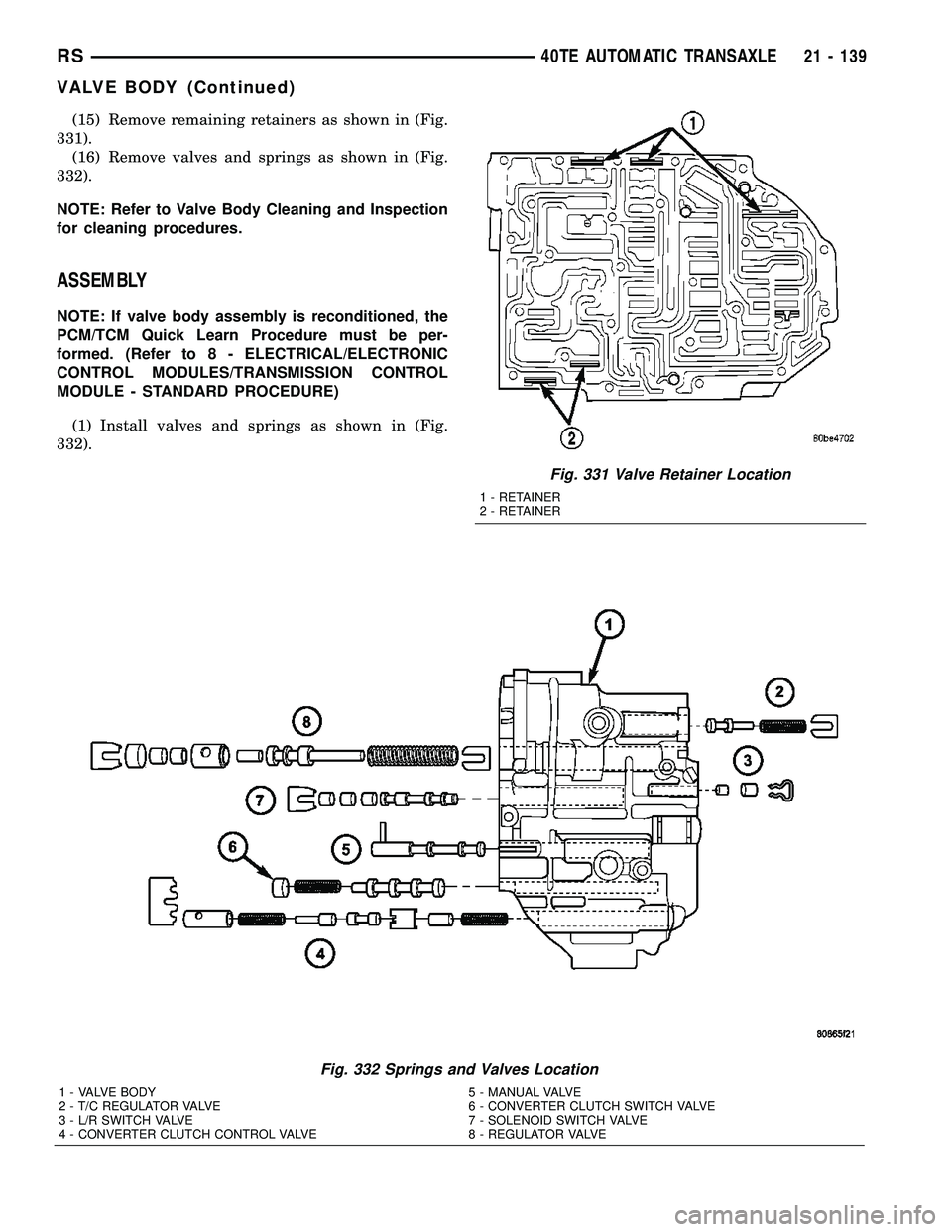

(15) Remove remaining retainers as shown in (Fig.

331).

(16) Remove valves and springs as shown in (Fig.

332).

NOTE: Refer to Valve Body Cleaning and Inspection

for cleaning procedures.

ASSEMBLY

NOTE: If valve body assembly is reconditioned, the

PCM/TCM Quick Learn Procedure must be per-

formed. (Refer to 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES/TRANSMISSION CONTROL

MODULE - STANDARD PROCEDURE)

(1) Install valves and springs as shown in (Fig.

332).

Fig. 331 Valve Retainer Location

1 - RETAINER

2 - RETAINER

Fig. 332 Springs and Valves Location

1 - VALVE BODY 5 - MANUAL VALVE

2 - T/C REGULATOR VALVE 6 - CONVERTER CLUTCH SWITCH VALVE

3 - L/R SWITCH VALVE 7 - SOLENOID SWITCH VALVE

4 - CONVERTER CLUTCH CONTROL VALVE 8 - REGULATOR VALVE

RS40TE AUTOMATIC TRANSAXLE21 - 139

VALVE BODY (Continued)

Page 1608 of 2339

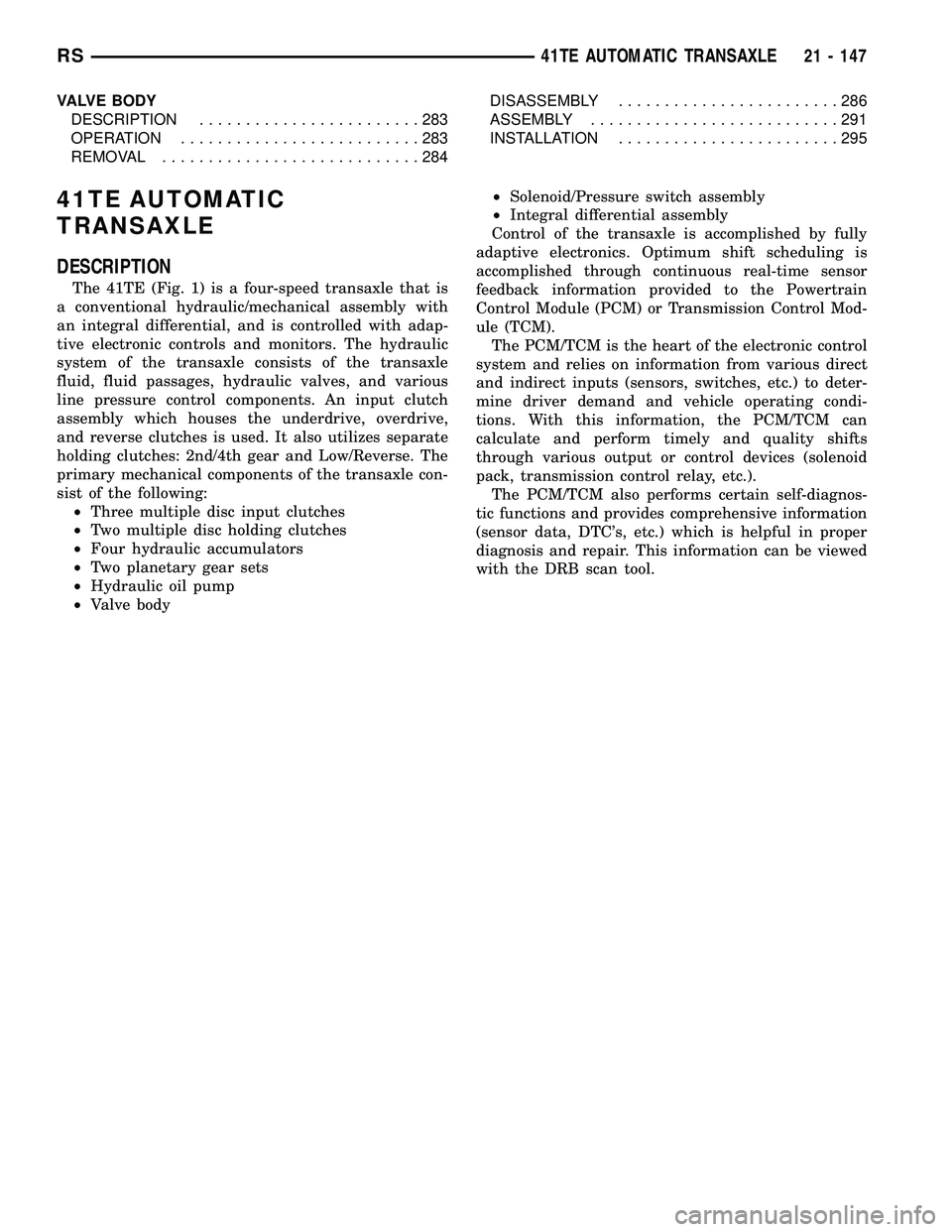

VALVE BODY

DESCRIPTION........................283

OPERATION..........................283

REMOVAL............................284DISASSEMBLY........................286

ASSEMBLY...........................291

INSTALLATION........................295

41TE AUTOMATIC

TRANSAXLE

DESCRIPTION

The 41TE (Fig. 1) is a four-speed transaxle that is

a conventional hydraulic/mechanical assembly with

an integral differential, and is controlled with adap-

tive electronic controls and monitors. The hydraulic

system of the transaxle consists of the transaxle

fluid, fluid passages, hydraulic valves, and various

line pressure control components. An input clutch

assembly which houses the underdrive, overdrive,

and reverse clutches is used. It also utilizes separate

holding clutches: 2nd/4th gear and Low/Reverse. The

primary mechanical components of the transaxle con-

sist of the following:

²Three multiple disc input clutches

²Two multiple disc holding clutches

²Four hydraulic accumulators

²Two planetary gear sets

²Hydraulic oil pump

²Valve body²Solenoid/Pressure switch assembly

²Integral differential assembly

Control of the transaxle is accomplished by fully

adaptive electronics. Optimum shift scheduling is

accomplished through continuous real-time sensor

feedback information provided to the Powertrain

Control Module (PCM) or Transmission Control Mod-

ule (TCM).

The PCM/TCM is the heart of the electronic control

system and relies on information from various direct

and indirect inputs (sensors, switches, etc.) to deter-

mine driver demand and vehicle operating condi-

tions. With this information, the PCM/TCM can

calculate and perform timely and quality shifts

through various output or control devices (solenoid

pack, transmission control relay, etc.).

The PCM/TCM also performs certain self-diagnos-

tic functions and provides comprehensive information

(sensor data, DTC's, etc.) which is helpful in proper

diagnosis and repair. This information can be viewed

with the DRB scan tool.

RS41TE AUTOMATIC TRANSAXLE21 - 147

Page 1612 of 2339

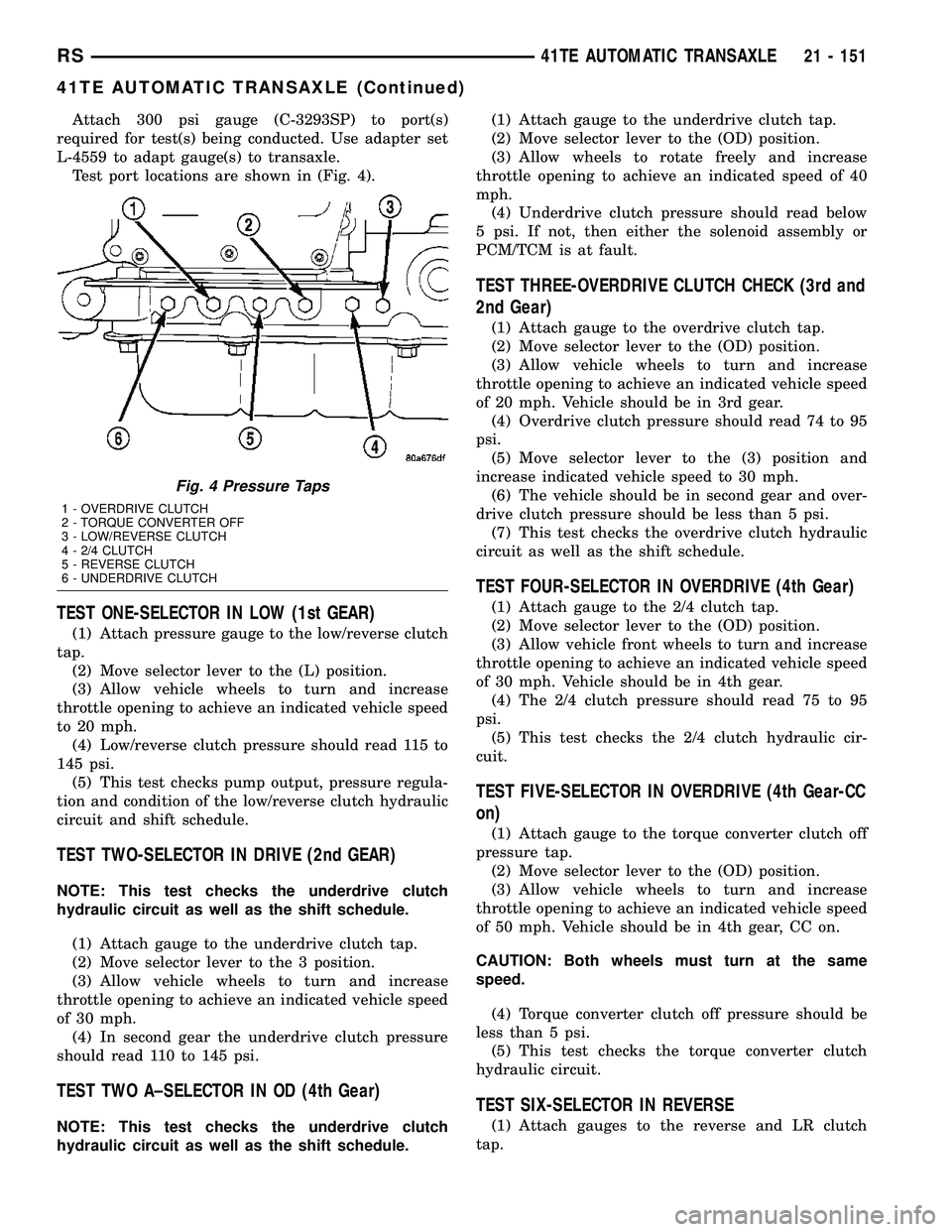

Attach 300 psi gauge (C-3293SP) to port(s)

required for test(s) being conducted. Use adapter set

L-4559 to adapt gauge(s) to transaxle.

Test port locations are shown in (Fig. 4).

TEST ONE-SELECTOR IN LOW (1st GEAR)

(1) Attach pressure gauge to the low/reverse clutch

tap.

(2) Move selector lever to the (L) position.

(3) Allow vehicle wheels to turn and increase

throttle opening to achieve an indicated vehicle speed

to 20 mph.

(4) Low/reverse clutch pressure should read 115 to

145 psi.

(5) This test checks pump output, pressure regula-

tion and condition of the low/reverse clutch hydraulic

circuit and shift schedule.

TEST TWO-SELECTOR IN DRIVE (2nd GEAR)

NOTE: This test checks the underdrive clutch

hydraulic circuit as well as the shift schedule.

(1) Attach gauge to the underdrive clutch tap.

(2) Move selector lever to the 3 position.

(3) Allow vehicle wheels to turn and increase

throttle opening to achieve an indicated vehicle speed

of 30 mph.

(4) In second gear the underdrive clutch pressure

should read 110 to 145 psi.

TEST TWO A±SELECTOR IN OD (4th Gear)

NOTE: This test checks the underdrive clutch

hydraulic circuit as well as the shift schedule.(1) Attach gauge to the underdrive clutch tap.

(2) Move selector lever to the (OD) position.

(3) Allow wheels to rotate freely and increase

throttle opening to achieve an indicated speed of 40

mph.

(4) Underdrive clutch pressure should read below

5 psi. If not, then either the solenoid assembly or

PCM/TCM is at fault.

TEST THREE-OVERDRIVE CLUTCH CHECK (3rd and

2nd Gear)

(1) Attach gauge to the overdrive clutch tap.

(2) Move selector lever to the (OD) position.

(3) Allow vehicle wheels to turn and increase

throttle opening to achieve an indicated vehicle speed

of 20 mph. Vehicle should be in 3rd gear.

(4) Overdrive clutch pressure should read 74 to 95

psi.

(5) Move selector lever to the (3) position and

increase indicated vehicle speed to 30 mph.

(6) The vehicle should be in second gear and over-

drive clutch pressure should be less than 5 psi.

(7) This test checks the overdrive clutch hydraulic

circuit as well as the shift schedule.

TEST FOUR-SELECTOR IN OVERDRIVE (4th Gear)

(1) Attach gauge to the 2/4 clutch tap.

(2) Move selector lever to the (OD) position.

(3) Allow vehicle front wheels to turn and increase

throttle opening to achieve an indicated vehicle speed

of 30 mph. Vehicle should be in 4th gear.

(4) The 2/4 clutch pressure should read 75 to 95

psi.

(5) This test checks the 2/4 clutch hydraulic cir-

cuit.

TEST FIVE-SELECTOR IN OVERDRIVE (4th Gear-CC

on)

(1) Attach gauge to the torque converter clutch off

pressure tap.

(2) Move selector lever to the (OD) position.

(3) Allow vehicle wheels to turn and increase

throttle opening to achieve an indicated vehicle speed

of 50 mph. Vehicle should be in 4th gear, CC on.

CAUTION: Both wheels must turn at the same

speed.

(4) Torque converter clutch off pressure should be

less than 5 psi.

(5) This test checks the torque converter clutch

hydraulic circuit.

TEST SIX-SELECTOR IN REVERSE

(1) Attach gauges to the reverse and LR clutch

tap.

Fig. 4 Pressure Taps

1 - OVERDRIVE CLUTCH

2 - TORQUE CONVERTER OFF

3 - LOW/REVERSE CLUTCH

4 - 2/4 CLUTCH

5 - REVERSE CLUTCH

6 - UNDERDRIVE CLUTCH

RS41TE AUTOMATIC TRANSAXLE21 - 151

41TE AUTOMATIC TRANSAXLE (Continued)

Page 1613 of 2339

(2) Move selector lever to the (R) position.

(3) Read reverse clutch pressure with output sta-

tionary (foot on brake) and throttle opened to achieve

1500 rpm.

(4) Reverse and LR clutch pressure should read

165 to 235 psi.

(5) This test checks the reverse clutch hydraulic

circuit.

TEST RESULT INDICATIONS

(1) If proper line pressure is found in any one test,

the pump and pressure regulator are working prop-

erly.(2) Low pressure in all positions indicates a defec-

tive pump, a clogged filter, or a stuck pressure regu-

lator valve.

(3) Clutch circuit leaks are indicated if pressures

do not fall within the specified pressure range.

(4) If the overdrive clutch pressure is greater than

5 psi in Step 4 of Test Three, a worn reaction shaft

seal ring or a defective solenoid assembly is indi-

cated.

(5) If the underdrive clutch pressure is greater

than 5 psi in Step 4 of Test Two A, a defective sole-

noid assembly or PCM/TCM is the cause.

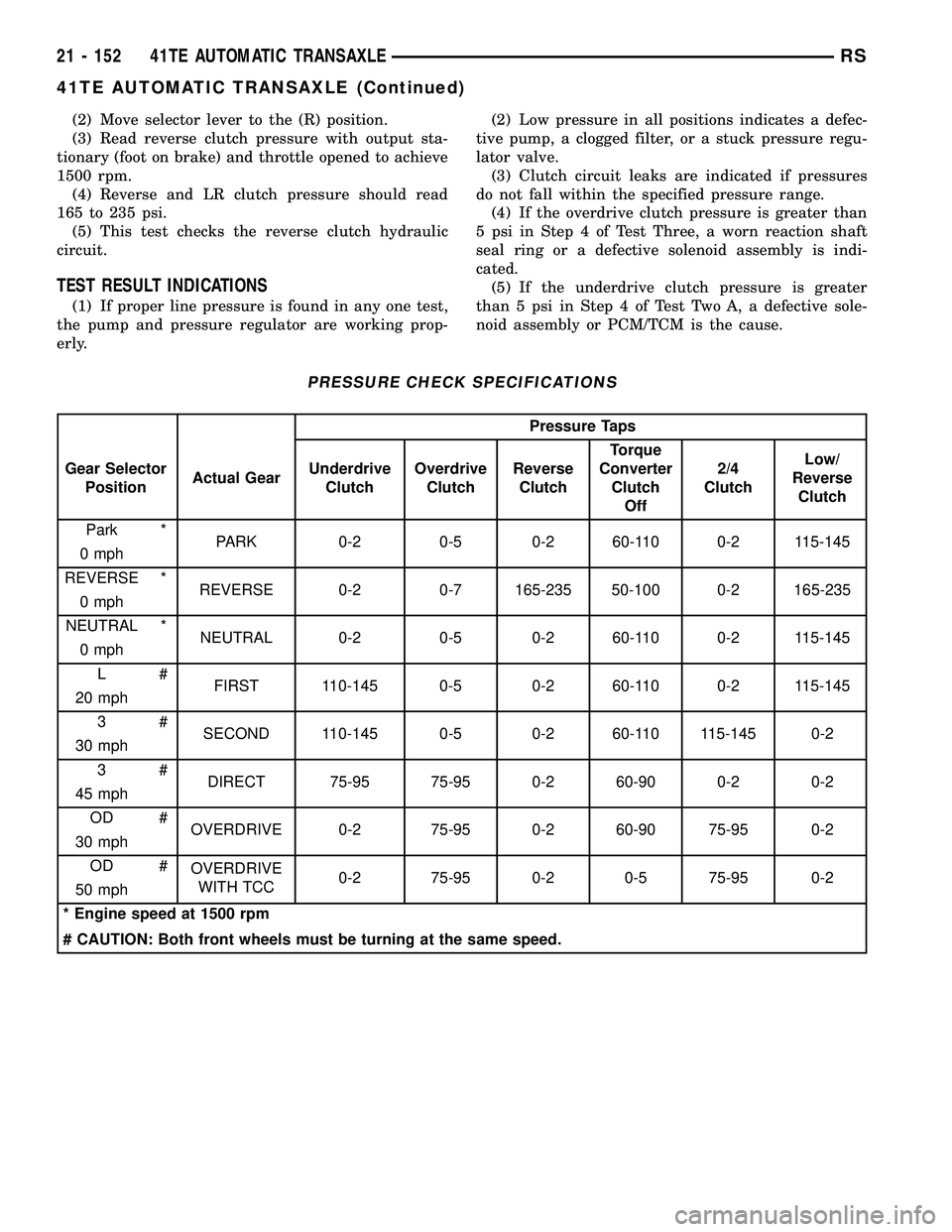

PRESSURE CHECK SPECIFICATIONS

Pressure Taps

Gear Selector

PositionActual GearUnderdrive

ClutchOverdrive

ClutchReverse

ClutchTorque

Converter

Clutch

Off2/4

ClutchLow/

Reverse

Clutch

Park *

PARK 0-2 0-5 0-2 60-110 0-2 115-145

0 mph

REVERSE *

REVERSE 0-2 0-7 165-235 50-100 0-2 165-235

0 mph

NEUTRAL *

NEUTRAL 0-2 0-5 0-2 60-110 0-2 115-145

0 mph

L#

FIRST 110-145 0-5 0-2 60-110 0-2 115-145

20 mph

3#

SECOND 110-145 0-5 0-2 60-110 115-145 0-2

30 mph

3#

DIRECT 75-95 75-95 0-2 60-90 0-2 0-2

45 mph

OD #

OVERDRIVE 0-2 75-95 0-2 60-90 75-95 0-2

30 mph

OD #

OVERDRIVE

WITH TCC0-2 75-95 0-2 0-5 75-95 0-2

50 mph

* Engine speed at 1500 rpm

# CAUTION: Both front wheels must be turning at the same speed.

21 - 152 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)