Water CHRYSLER VOYAGER 2005 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 509 of 2339

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

(5) Verify vehicle and system operation.

(6) Close hood.

SLIDING DOOR OPENING MOUNTED

(1) Connect electrical connector (Fig. 27).

(2) Position sensor in vehicle (Fig. 27).

(3) Install the two retaining screws to the impact

sensor (Fig. 27). Torque screws to 7 N´m (62 in. lbs.).

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

(4) Verify vehicle and system operation.

(5) Close hood.

QUARTER PANEL MOUNTED

(1) Position sensor in vehicle (Fig. 28).

(2) Connect electrical connector (Fig. 28).

(3) Install the two retaining screws to the impact

sensor (Fig. 28). Torque screws to 7 N´m (62 in. lbs.).

(4) Install the quarter trim panel for the side of

the vehicle that you are replacing the side impact

sensor (Refer to 23 - BODY/INTERIOR/QUARTER

TRIM PANEL - INSTALLATION).

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

(5) Verify vehicle and system operation.

(6) Close hood.

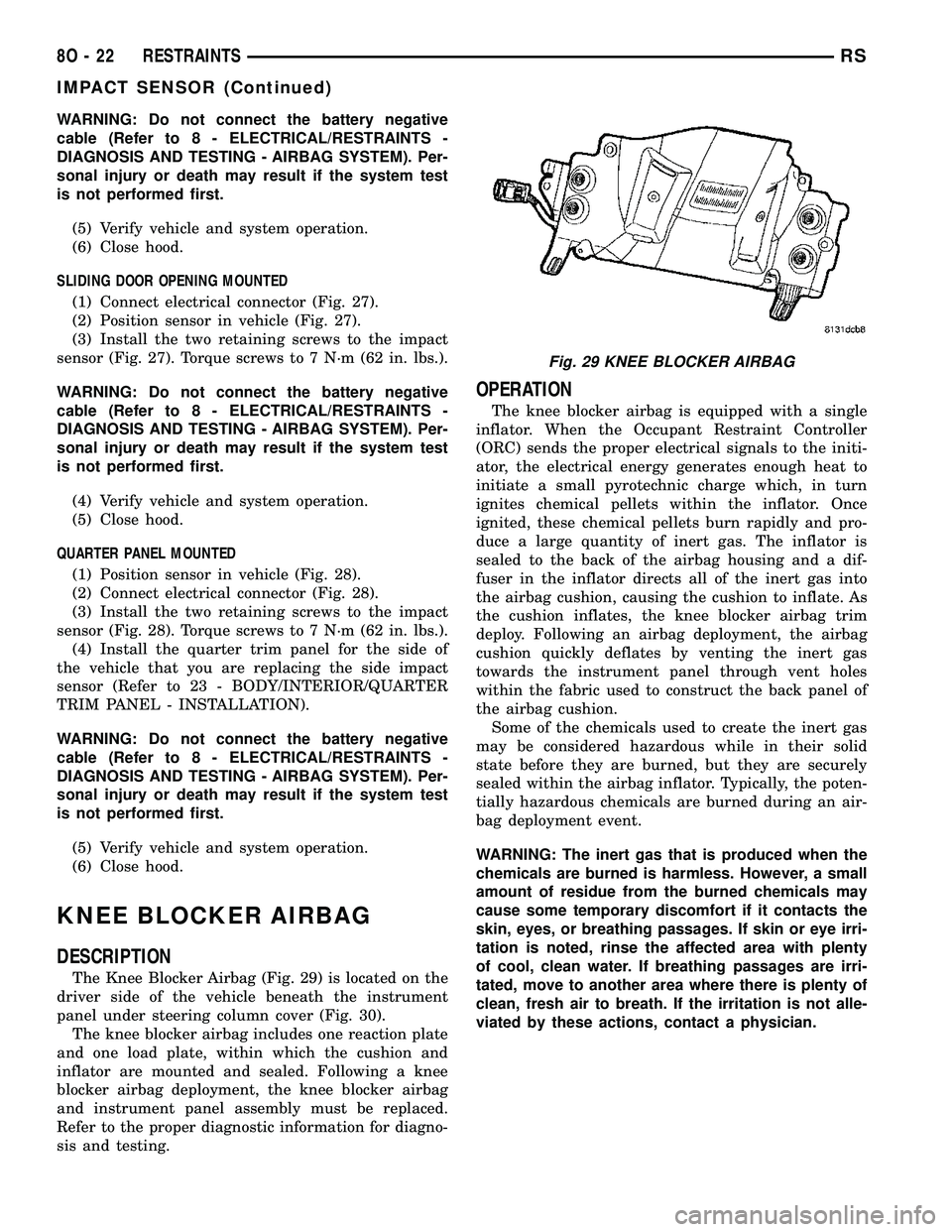

KNEE BLOCKER AIRBAG

DESCRIPTION

The Knee Blocker Airbag (Fig. 29) is located on the

driver side of the vehicle beneath the instrument

panel under steering column cover (Fig. 30).

The knee blocker airbag includes one reaction plate

and one load plate, within which the cushion and

inflator are mounted and sealed. Following a knee

blocker airbag deployment, the knee blocker airbag

and instrument panel assembly must be replaced.

Refer to the proper diagnostic information for diagno-

sis and testing.

OPERATION

The knee blocker airbag is equipped with a single

inflator. When the Occupant Restraint Controller

(ORC) sends the proper electrical signals to the initi-

ator, the electrical energy generates enough heat to

initiate a small pyrotechnic charge which, in turn

ignites chemical pellets within the inflator. Once

ignited, these chemical pellets burn rapidly and pro-

duce a large quantity of inert gas. The inflator is

sealed to the back of the airbag housing and a dif-

fuser in the inflator directs all of the inert gas into

the airbag cushion, causing the cushion to inflate. As

the cushion inflates, the knee blocker airbag trim

deploy. Following an airbag deployment, the airbag

cushion quickly deflates by venting the inert gas

towards the instrument panel through vent holes

within the fabric used to construct the back panel of

the airbag cushion.

Some of the chemicals used to create the inert gas

may be considered hazardous while in their solid

state before they are burned, but they are securely

sealed within the airbag inflator. Typically, the poten-

tially hazardous chemicals are burned during an air-

bag deployment event.

WARNING: The inert gas that is produced when the

chemicals are burned is harmless. However, a small

amount of residue from the burned chemicals may

cause some temporary discomfort if it contacts the

skin, eyes, or breathing passages. If skin or eye irri-

tation is noted, rinse the affected area with plenty

of cool, clean water. If breathing passages are irri-

tated, move to another area where there is plenty of

clean, fresh air to breath. If the irritation is not alle-

viated by these actions, contact a physician.

Fig. 29 KNEE BLOCKER AIRBAG

8O - 22 RESTRAINTSRS

IMPACT SENSOR (Continued)

Page 554 of 2339

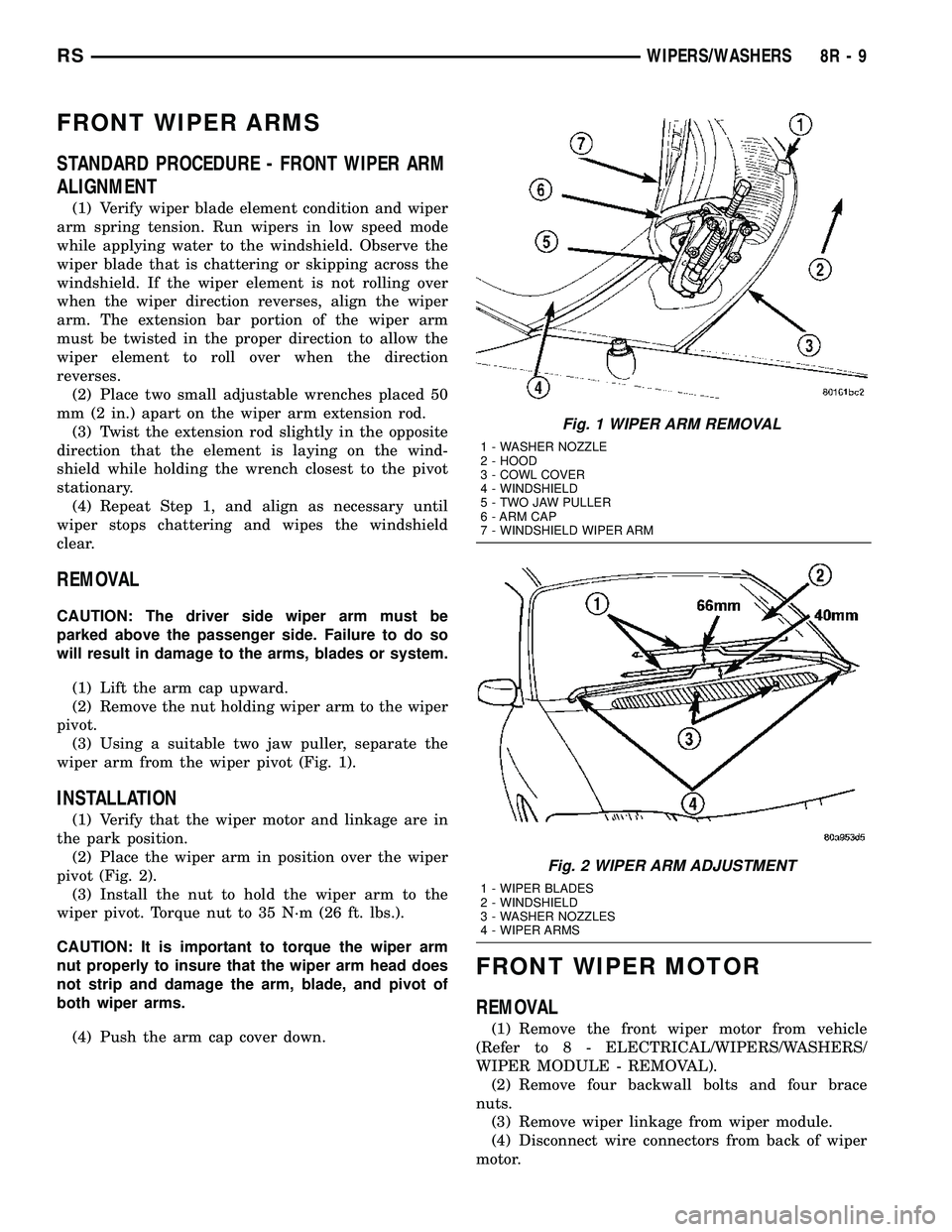

FRONT WIPER ARMS

STANDARD PROCEDURE - FRONT WIPER ARM

ALIGNMENT

(1) Verify wiper blade element condition and wiper

arm spring tension. Run wipers in low speed mode

while applying water to the windshield. Observe the

wiper blade that is chattering or skipping across the

windshield. If the wiper element is not rolling over

when the wiper direction reverses, align the wiper

arm. The extension bar portion of the wiper arm

must be twisted in the proper direction to allow the

wiper element to roll over when the direction

reverses.

(2) Place two small adjustable wrenches placed 50

mm (2 in.) apart on the wiper arm extension rod.

(3) Twist the extension rod slightly in the opposite

direction that the element is laying on the wind-

shield while holding the wrench closest to the pivot

stationary.

(4) Repeat Step 1, and align as necessary until

wiper stops chattering and wipes the windshield

clear.

REMOVAL

CAUTION: The driver side wiper arm must be

parked above the passenger side. Failure to do so

will result in damage to the arms, blades or system.

(1) Lift the arm cap upward.

(2) Remove the nut holding wiper arm to the wiper

pivot.

(3) Using a suitable two jaw puller, separate the

wiper arm from the wiper pivot (Fig. 1).

INSTALLATION

(1) Verify that the wiper motor and linkage are in

the park position.

(2) Place the wiper arm in position over the wiper

pivot (Fig. 2).

(3) Install the nut to hold the wiper arm to the

wiper pivot. Torque nut to 35 N´m (26 ft. lbs.).

CAUTION: It is important to torque the wiper arm

nut properly to insure that the wiper arm head does

not strip and damage the arm, blade, and pivot of

both wiper arms.

(4) Push the arm cap cover down.

FRONT WIPER MOTOR

REMOVAL

(1) Remove the front wiper motor from vehicle

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER MODULE - REMOVAL).

(2) Remove four backwall bolts and four brace

nuts.

(3) Remove wiper linkage from wiper module.

(4) Disconnect wire connectors from back of wiper

motor.

Fig. 1 WIPER ARM REMOVAL

1 - WASHER NOZZLE

2 - HOOD

3 - COWL COVER

4 - WINDSHIELD

5 - TWO JAW PULLER

6 - ARM CAP

7 - WINDSHIELD WIPER ARM

Fig. 2 WIPER ARM ADJUSTMENT

1 - WIPER BLADES

2 - WINDSHIELD

3 - WASHER NOZZLES

4 - WIPER ARMS

RSWIPERS/WASHERS8R-9

Page 583 of 2339

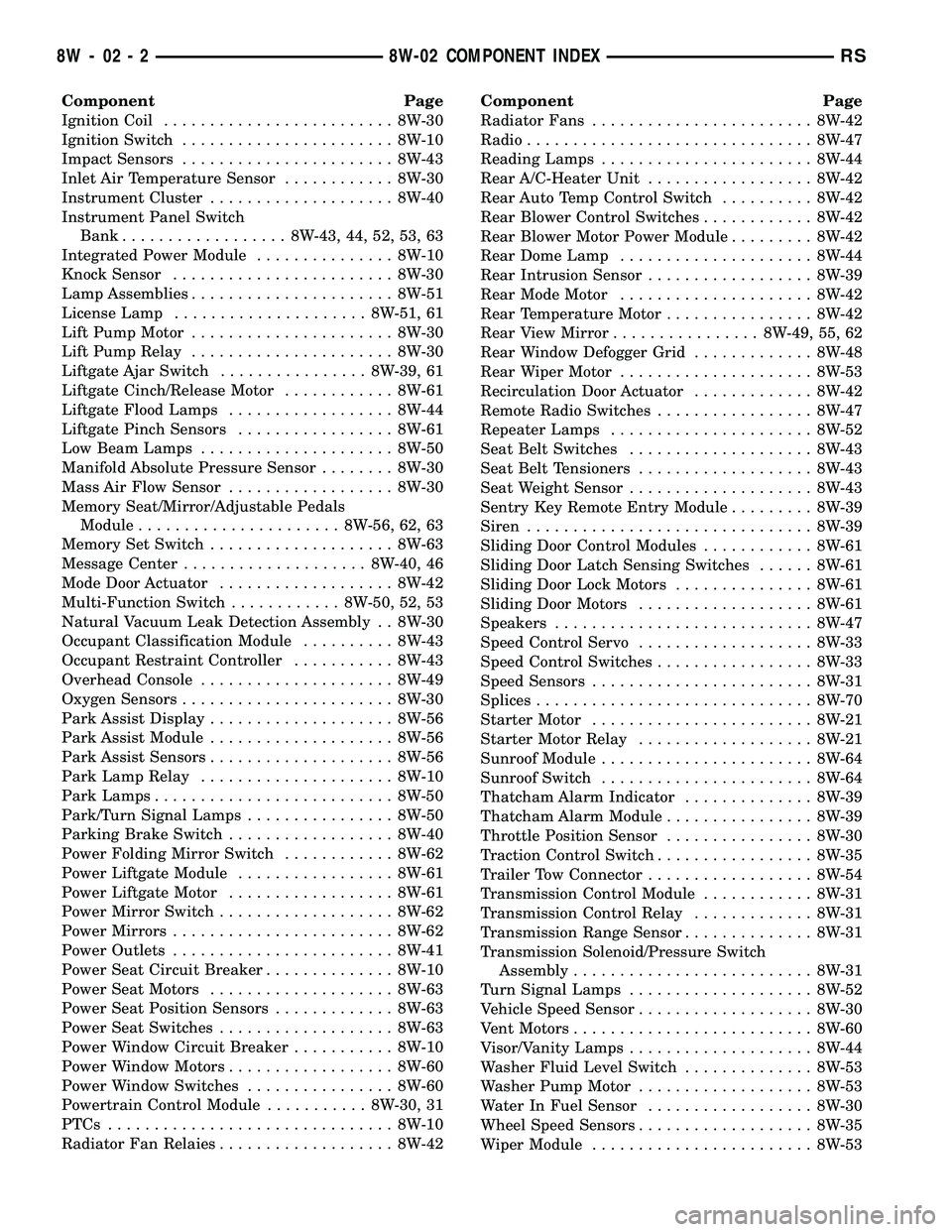

Component Page

Ignition Coil......................... 8W-30

Ignition Switch....................... 8W-10

Impact Sensors....................... 8W-43

Inlet Air Temperature Sensor............ 8W-30

Instrument Cluster.................... 8W-40

Instrument Panel Switch

Bank.................. 8W-43, 44, 52, 53, 63

Integrated Power Module............... 8W-10

Knock Sensor........................ 8W-30

Lamp Assemblies...................... 8W-51

License Lamp..................... 8W-51, 61

Lift Pump Motor...................... 8W-30

Lift Pump Relay...................... 8W-30

Liftgate Ajar Switch................ 8W-39, 61

Liftgate Cinch/Release Motor............ 8W-61

Liftgate Flood Lamps.................. 8W-44

Liftgate Pinch Sensors................. 8W-61

Low Beam Lamps..................... 8W-50

Manifold Absolute Pressure Sensor........ 8W-30

Mass Air Flow Sensor.................. 8W-30

Memory Seat/Mirror/Adjustable Pedals

Module...................... 8W-56, 62, 63

Memory Set Switch.................... 8W-63

Message Center.................... 8W-40, 46

Mode Door Actuator................... 8W-42

Multi-Function Switch............ 8W-50, 52, 53

Natural Vacuum Leak Detection Assembly . . 8W-30

Occupant Classification Module.......... 8W-43

Occupant Restraint Controller........... 8W-43

Overhead Console..................... 8W-49

Oxygen Sensors....................... 8W-30

Park Assist Display.................... 8W-56

Park Assist Module.................... 8W-56

Park Assist Sensors.................... 8W-56

Park Lamp Relay..................... 8W-10

Park Lamps.......................... 8W-50

Park/Turn Signal Lamps................ 8W-50

Parking Brake Switch.................. 8W-40

Power Folding Mirror Switch............ 8W-62

Power Liftgate Module................. 8W-61

Power Liftgate Motor.................. 8W-61

Power Mirror Switch................... 8W-62

Power Mirrors........................ 8W-62

Power Outlets........................ 8W-41

Power Seat Circuit Breaker.............. 8W-10

Power Seat Motors.................... 8W-63

Power Seat Position Sensors............. 8W-63

Power Seat Switches................... 8W-63

Power Window Circuit Breaker........... 8W-10

Power Window Motors.................. 8W-60

Power Window Switches................ 8W-60

Powertrain Control Module........... 8W-30, 31

PTCs............................... 8W-10

Radiator Fan Relaies................... 8W-42Component Page

Radiator Fans........................ 8W-42

Radio............................... 8W-47

Reading Lamps....................... 8W-44

Rear A/C-Heater Unit.................. 8W-42

Rear Auto Temp Control Switch.......... 8W-42

Rear Blower Control Switches............ 8W-42

Rear Blower Motor Power Module......... 8W-42

Rear Dome Lamp..................... 8W-44

Rear Intrusion Sensor.................. 8W-39

Rear Mode Motor..................... 8W-42

Rear Temperature Motor................ 8W-42

Rear View Mirror................ 8W-49, 55, 62

Rear Window Defogger Grid............. 8W-48

Rear Wiper Motor..................... 8W-53

Recirculation Door Actuator............. 8W-42

Remote Radio Switches................. 8W-47

Repeater Lamps...................... 8W-52

Seat Belt Switches.................... 8W-43

Seat Belt Tensioners................... 8W-43

Seat Weight Sensor.................... 8W-43

Sentry Key Remote Entry Module......... 8W-39

Siren............................... 8W-39

Sliding Door Control Modules............ 8W-61

Sliding Door Latch Sensing Switches...... 8W-61

Sliding Door Lock Motors............... 8W-61

Sliding Door Motors................... 8W-61

Speakers............................ 8W-47

Speed Control Servo................... 8W-33

Speed Control Switches................. 8W-33

Speed Sensors........................ 8W-31

Splices.............................. 8W-70

Starter Motor........................ 8W-21

Starter Motor Relay................... 8W-21

Sunroof Module....................... 8W-64

Sunroof Switch....................... 8W-64

Thatcham Alarm Indicator.............. 8W-39

Thatcham Alarm Module................ 8W-39

Throttle Position Sensor................ 8W-30

Traction Control Switch................. 8W-35

Trailer Tow Connector.................. 8W-54

Transmission Control Module............ 8W-31

Transmission Control Relay............. 8W-31

Transmission Range Sensor.............. 8W-31

Transmission Solenoid/Pressure Switch

Assembly.......................... 8W-31

Turn Signal Lamps.................... 8W-52

Vehicle Speed Sensor................... 8W-30

Vent Motors.......................... 8W-60

Visor/Vanity Lamps.................... 8W-44

Washer Fluid Level Switch.............. 8W-53

Washer Pump Motor................... 8W-53

Water In Fuel Sensor.................. 8W-30

Wheel Speed Sensors................... 8W-35

Wiper Module........................ 8W-53

8W - 02 - 2 8W-02 COMPONENT INDEXRS

Page 698 of 2339

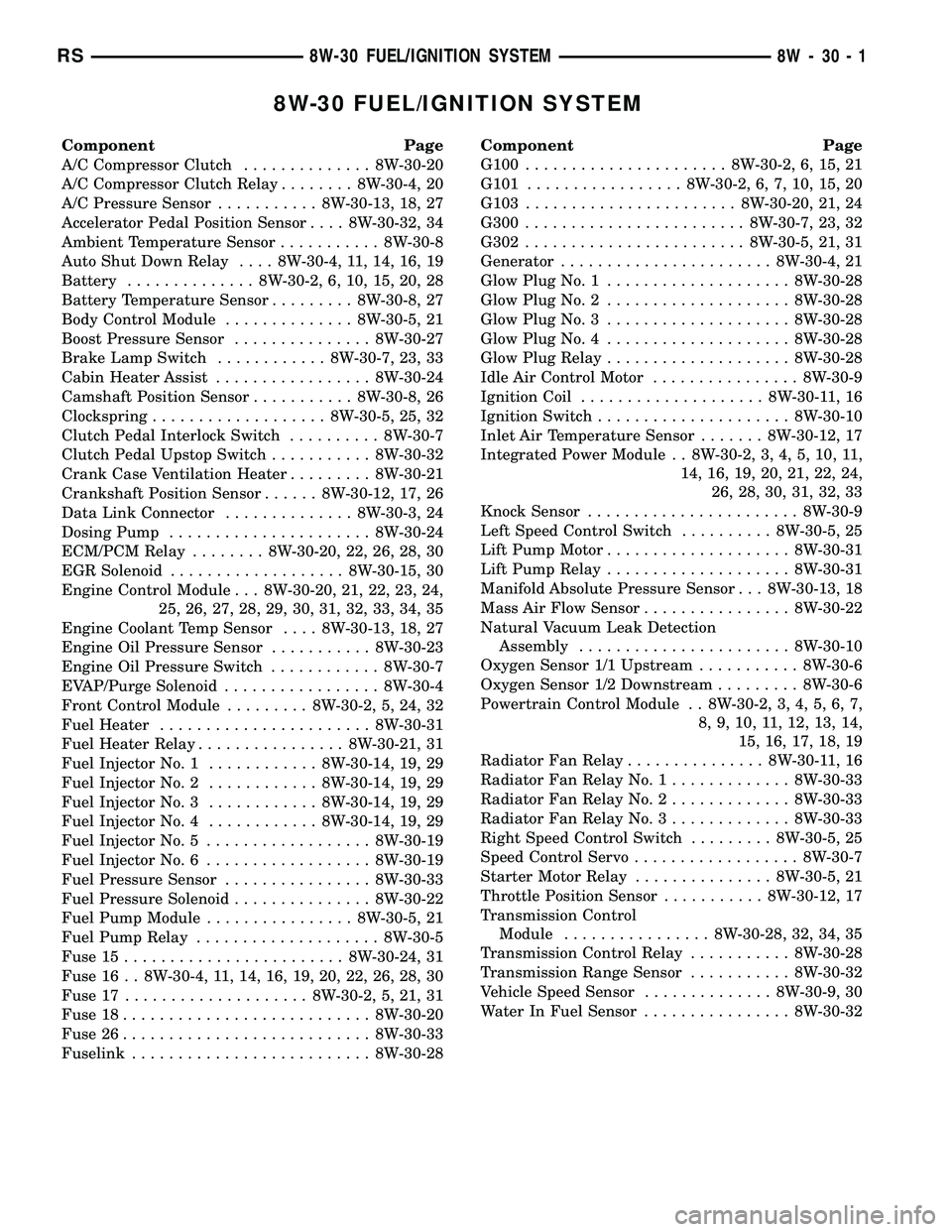

8W-30 FUEL/IGNITION SYSTEM

Component Page

A/C Compressor Clutch.............. 8W-30-20

A/C Compressor Clutch Relay........ 8W-30-4, 20

A/C Pressure Sensor........... 8W-30-13, 18, 27

Accelerator Pedal Position Sensor.... 8W-30-32, 34

Ambient Temperature Sensor........... 8W-30-8

Auto Shut Down Relay.... 8W-30-4, 11, 14, 16, 19

Battery.............. 8W-30-2, 6, 10, 15, 20, 28

Battery Temperature Sensor......... 8W-30-8, 27

Body Control Module.............. 8W-30-5, 21

Boost Pressure Sensor............... 8W-30-27

Brake Lamp Switch............ 8W-30-7, 23, 33

Cabin Heater Assist................. 8W-30-24

Camshaft Position Sensor........... 8W-30-8, 26

Clockspring................... 8W-30-5, 25, 32

Clutch Pedal Interlock Switch.......... 8W-30-7

Clutch Pedal Upstop Switch........... 8W-30-32

Crank Case Ventilation Heater......... 8W-30-21

Crankshaft Position Sensor...... 8W-30-12, 17, 26

Data Link Connector.............. 8W-30-3, 24

Dosing Pump...................... 8W-30-24

ECM/PCM Relay........ 8W-30-20, 22, 26, 28, 30

EGR Solenoid................... 8W-30-15, 30

Engine Control Module . . . 8W-30-20, 21, 22, 23, 24,

25, 26, 27, 28, 29, 30, 31, 32, 33, 34, 35

Engine Coolant Temp Sensor.... 8W-30-13, 18, 27

Engine Oil Pressure Sensor........... 8W-30-23

Engine Oil Pressure Switch............ 8W-30-7

EVAP/Purge Solenoid................. 8W-30-4

Front Control Module......... 8W-30-2, 5, 24, 32

Fuel Heater....................... 8W-30-31

Fuel Heater Relay................ 8W-30-21, 31

Fuel Injector No. 1............ 8W-30-14, 19, 29

Fuel Injector No. 2............ 8W-30-14, 19, 29

Fuel Injector No. 3............ 8W-30-14, 19, 29

Fuel Injector No. 4............ 8W-30-14, 19, 29

Fuel Injector No. 5.................. 8W-30-19

Fuel Injector No. 6.................. 8W-30-19

Fuel Pressure Sensor................ 8W-30-33

Fuel Pressure Solenoid............... 8W-30-22

Fuel Pump Module................ 8W-30-5, 21

Fuel Pump Relay.................... 8W-30-5

Fuse 15........................ 8W-30-24, 31

Fuse 16 . . 8W-30-4, 11, 14, 16, 19, 20, 22, 26, 28, 30

Fuse 17.................... 8W-30-2, 5, 21, 31

Fuse 18........................... 8W-30-20

Fuse 26........................... 8W-30-33

Fuselink.......................... 8W-30-28Component Page

G100...................... 8W-30-2, 6, 15, 21

G101................. 8W-30-2, 6, 7, 10, 15, 20

G103....................... 8W-30-20, 21, 24

G300........................ 8W-30-7, 23, 32

G302........................ 8W-30-5, 21, 31

Generator....................... 8W-30-4, 21

Glow Plug No. 1.................... 8W-30-28

Glow Plug No. 2.................... 8W-30-28

Glow Plug No. 3.................... 8W-30-28

Glow Plug No. 4.................... 8W-30-28

Glow Plug Relay.................... 8W-30-28

Idle Air Control Motor................ 8W-30-9

Ignition Coil.................... 8W-30-11, 16

Ignition Switch..................... 8W-30-10

Inlet Air Temperature Sensor....... 8W-30-12, 17

Integrated Power Module . . 8W-30-2, 3, 4, 5, 10, 11,

14, 16, 19, 20, 21, 22, 24,

26, 28, 30, 31, 32, 33

Knock Sensor....................... 8W-30-9

Left Speed Control Switch.......... 8W-30-5, 25

Lift Pump Motor.................... 8W-30-31

Lift Pump Relay.................... 8W-30-31

Manifold Absolute Pressure Sensor . . . 8W-30-13, 18

Mass Air Flow Sensor................ 8W-30-22

Natural Vacuum Leak Detection

Assembly....................... 8W-30-10

Oxygen Sensor 1/1 Upstream........... 8W-30-6

Oxygen Sensor 1/2 Downstream......... 8W-30-6

Powertrain Control Module . . 8W-30-2, 3, 4, 5, 6, 7,

8, 9, 10, 11, 12, 13, 14,

15, 16, 17, 18, 19

Radiator Fan Relay............... 8W-30-11, 16

Radiator Fan Relay No. 1............. 8W-30-33

Radiator Fan Relay No. 2............. 8W-30-33

Radiator Fan Relay No. 3............. 8W-30-33

Right Speed Control Switch......... 8W-30-5, 25

Speed Control Servo.................. 8W-30-7

Starter Motor Relay............... 8W-30-5, 21

Throttle Position Sensor........... 8W-30-12, 17

Transmission Control

Module................ 8W-30-28, 32, 34, 35

Transmission Control Relay........... 8W-30-28

Transmission Range Sensor........... 8W-30-32

Vehicle Speed Sensor.............. 8W-30-9, 30

Water In Fuel Sensor................ 8W-30-32

RS8W-30 FUEL/IGNITION SYSTEM8W-30-1

Page 974 of 2339

Component Page

Rear Blower Front Control Switch (3 Zone

MTC)......................... 8W-80-124

Rear Blower Motor Power Module C1 (3 Zone

ATC) .......................... 8W-80-125

Rear Blower Motor Power Module C2 (3 Zone

ATC) .......................... 8W-80-125

Rear Blower Rear Control Switch C1 (3 Zone

MTC)......................... 8W-80-125

Rear Blower Rear Control Switch C2 (3 Zone

MTC)......................... 8W-80-125

Rear Dome Lamp (Except Luxury)..... 8W-80-126

Rear Intrusion Sensor (United

Kingdom)...................... 8W-80-126

Rear Mode Motor (3 Zone ATC)....... 8W-80-126

Rear Power Outlet................. 8W-80-126

Rear Temperature Motor (3 Zone ATC) . . 8W-80-127

Rear View Mirror C1 (Luxury)........ 8W-80-127

Rear View Mirror C2 (Hands Free)..... 8W-80-127

Rear Wiper Motor.................. 8W-80-128

Recirculation Door Actuator.......... 8W-80-128

Right B-Pillar Switch (Power Sliding

Door).......................... 8W-80-128

Right Cinch/Release Motor (Power Sliding

Door).......................... 8W-80-128

Right Curtain Airbag Squib.......... 8W-80-129

Right Cylinder Lock Switch (Export) . . . 8W-80-129

Right Door Speaker................ 8W-80-129

Right Fog Lamp................... 8W-80-129

Right Front Door Ajar Switch (Base) . . . 8W-80-130

Right Front Door Lock Motor/Ajar Switch (Except

Base).......................... 8W-80-130

Right Front Impact Sensor........... 8W-80-130

Right Front Park/Turn Signal Lamp.... 8W-80-130

Right Front Wheel Speed Sensor...... 8W-80-131

Right Full Open Switch (Power Sliding

Door).......................... 8W-80-131

Right Headlamp (Caravan/Voyager Except

Export)........................ 8W-80-131

Right Headlamp (Town And Country) . . . 8W-80-131

Right Headlamp Leveling Motor

(Export)....................... 8W-80-132

Right High Beam Lamp (Export)...... 8W-80-132

Right Instrument Panel Speaker...... 8W-80-132

Right Liftgate Flood Lamp........... 8W-80-132

Right Low Beam Lamp (Export)....... 8W-80-133

Right Mid Reading Lamp (Premium/

Luxury)........................ 8W-80-133

Right Park Lamp (Export)........... 8W-80-133

Right Power Mirror................ 8W-80-133

Right Rear Lamp Assembly.......... 8W-80-134

Right Rear Pillar Speaker (Highline

Audio)......................... 8W-80-134Component Page

Right Rear Reading Lamp (Luxury).... 8W-80-134

Right Rear Speaker................ 8W-80-134

Right Rear Vent Motor.............. 8W-80-135

Right Rear Wheel Speed Sensor....... 8W-80-135

Right Remote Radio Switch.......... 8W-80-135

Right Repeater Lamp (Export)........ 8W-80-135

Right Side Impact Sensor 1 (Export) . . . 8W-80-135

Right Side Impact Sensor 1 (Except

Export)........................ 8W-80-136

Right Side Impact Sensor 2.......... 8W-80-136

Right Side Impact Sensor 3.......... 8W-80-136

Right Sliding Door Control Module C1 (Power

Sliding Door)................... 8W-80-136

Right Sliding Door Control Module C2 (Power

Sliding Door)................... 8W-80-137

Right Sliding Door Latch Sensing Switch (Power

Sliding Door)................... 8W-80-137

Right Sliding Door Lock Motor (Power Sliding

Door).......................... 8W-80-137

Right Sliding Door Lock Motor/Ajar Switch (Manual

Sliding Door)................... 8W-80-138

Right Sliding Door Motor (Power Sliding

Door).......................... 8W-80-138

Right Speed Control Switch.......... 8W-80-138

Right Turn Signal Lamp (Export)...... 8W-80-138

Right Visor/Vanity Lamp (Except Base/

Export)........................ 8W-80-139

Sentry Key Remote Entry Module

(SKREEM)..................... 8W-80-139

Siren (United Kingdom)............. 8W-80-139

Speed Control Servo (Gas)........... 8W-80-139

Sunroof Module (Except Export)....... 8W-80-140

Sunroof Switch (Except Export)....... 8W-80-140

Thatcham Alarm Module (United

Kingdom)...................... 8W-80-140

Throttle Position Sensor (Gas)........ 8W-80-141

Traction Control Switch............. 8W-80-141

Trailer Tow Connector (Except Export) . . 8W-80-141

Transmission Control Module (Diesel) . . 8W-80-141

Transmission Control Relay (Diesel).... 8W-80-143

Transmission Range Sensor.......... 8W-80-143

Transmission Solenoid/Pressure Switch

Assembly...................... 8W-80-143

Vehicle Speed Sensor (MTX).......... 8W-80-144

Washer Fluid Level Switch........... 8W-80-144

Washer Pump Motor................ 8W-80-144

Water In Fuel Sensor (Diesel)......... 8W-80-144

Wiper Module..................... 8W-80-144

RS8W-80 CONNECTOR PIN-OUTS8W-80-5

Page 1035 of 2339

EGR SOLENOID (3.3L) - BLACK 6 WAY

CAV CIRCUIT FUNCTION

1 K34 18DB/LG EGR SOLENOID SIGNAL

2 F855 18PK/YL 5 VOLT SUPPLY

3 K900 18DB/DG SENSOR GROUND

4 Z335 18BK/DB GROUND

5- -

6 K35 18DB/VT EGR SOLENOID CONTROL

EGR SOLENOID (DIESEL) - LT. GRAY 2 WAY

CAV CIRCUIT FUNCTION

1 K35 20GY/YL EGR SOLENOID CONTROL

2 K342 16BR/WT ECM/PCM RELAY OUTPUT

ENGINE CONTROL MODULE C1 (DIESEL) - BLACK 81 WAY

CAV CIRCUIT FUNCTION

1 Z130 14BK/BR GROUND

2 Z131 14BK/DG GROUND

3 K20 14BR/GY GENERATOR FIELD CONTROL

4 K342 14BR/WT ECM/PCM RELAY OUTPUT

5 K342 14BR/WT ECM/PCM RELAY OUTPUT

6- -

7 D25 20WT/VT PCI BUS

8 K944 20BK/GY CAMSHAFT POSITION SENSOR SHIELD GROUND

9 K44 20DB/GY CAMSHAFT POSITION SENSOR SIGNAL

10 - -

11 K37 20DB/YL BOOST PRESSURE SENSOR SIGNAL

12 K55 20DB/OR MASS AIR FLOW SENSOR SIGNAL

13 K78 20GY FUEL PRESSURE SENSOR SIGNAL

14 - -

15 K22 20OR/DB ACCELERATOR PEDAL POSITION SENSOR SIGNAL

NO. 1

16 K80 20DB/TN FUEL PRESSURE SENSOR GROUND

17 - -

18 - -

19 K342 20BR/WT ECM/PCM RELAY OUTPUT

20 Z138 20BK/OR GROUND

21 K900 20DB/DG SENSOR GROUND

22 F202 20PK/GY FUSED IGNITION SWITCH OUTPUT (RUN-START)

23 F851 20LB/PK SENSOR REFERENCE VOLTAGE B

24 K3 20BR/OR CRANKSHAFT POSITION SENSOR SIGNAL NO. 1

25 - -

26 - -

27 - -

28 - -

29 - -

30 G6 20VT/GY ENGINE OIL PRESSURE SENSOR SIGNAL

31 F853 20LG/PK WATER IN FUEL SENSOR SIGNAL

32 K25 20BR/TN BATTERY TEMPERATURE SENSOR SIGNAL

8W - 80 - 66 8W-80 CONNECTOR PIN-OUTSRS

Page 1113 of 2339

VEHICLE SPEED SENSOR (MTX) - BLACK 3 WAY

CAV CIRCUIT FUNCTION

1 F855 20PK/YL (2.4L) 5 VOLT SUPPLY

1 F202 18PK/GY (DIESEL) FUSED IGNITION SWITCH OUTPUT (RUN-START)

2 K900 18DB/DG (2.4L) SENSOR GROUND

2 K900 20DB/DG (DIESEL) SENSOR GROUND

3 N7 18DB/OR (2.4L) VEHICLE SPEED SIGNAL

3 N7 20DB/OR (DIESEL) VEHICLE SPEED SENSOR SIGNAL

WASHER FLUID LEVEL SWITCH - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 Z401 18BK/LB (EXCEPT EXPORT) GROUND

1 Z401 20BK/LB (EXPORT) GROUND

2 W1 18BR/TN WASHER FLUID LEVEL SWITCH SENSE

WASHER PUMP MOTOR - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 W20 18BR/YL REAR WASHER PUMP MOTOR CONTROL

2 W10 18BR FRONT WASHER PUMP MOTOR CONTROL

WATER IN FUEL SENSOR (DIESEL) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 F853 20LG/RD WATER IN FUEL SENSOR SIGNAL

2 K900 18RD SENSOR GROUND

WIPER MODULE - DK. GRAY 4 WAY

CAV CIRCUIT FUNCTION

1 W3 14BR/WT FRONT WIPER HIGH/LOW RELAY LOW SPEED OUT-

PUT

2 W7 20BR/GY WIPER PARK SWITCH SENSE

3 W4 14BR/OR FRONT WIPER HIGH/LOW RELAY HIGH SPEED OUT-

PUT

4 Z103 14BK/WT GROUND

8W - 80 - 144 8W-80 CONNECTOR PIN-OUTSRS

Page 1125 of 2339

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Right Sliding Door Motor BK At Sliding Door 45

Right Speed Control Switch WT At Steering Wheel N/S

Right Turn Signal Lamp (Export) OR At Lamp N/S

Right Visor/Vanity Lamp BK At Lamp N/S

Sentry Key Remote Entry Module

(SKREEM)BK At Steering Column 20, 21, 22, 23, 31

Siren (United Kingdom) BK Left Front Body N/S

Speed Control Servo (Gas) BK Near Controller Antilock Brake 11, 17, 18

Sunroof Module (Except Export) BK At Sunroof N/S

Sunroof Switch (Except Export) NAT Near Overhead Console N/S

Thatcham Alarm Module (United

Kingdom)BK Top Right Side of Instrument Panel

Near SpeakerN/S

Throttle Position Sensor (Gas) GY On Throttle Body 10, 11, 17

Traction Control Switch BK Rear of Swtich 21, 22, 31

Trailer Tow Connector (Except

Export)Left Quarter Panel N/S

Transmission Control Relay

(Diesel)Near Transmission 16

Transmission Range Sensor DKGY Top of Transmission 14, 19

Transmission Solenoid/Pressure

Switch AssemblyBK Side of Transmission 14, 19

Vehicle Speed Sensor (MTX) BK Rear of Transmission 16

Washer Fluid Level Switch BK Bottom of Reservoir 3

Washer Pump Motor BK Right Fender Well 3

Water in Fuel Sensor (Diesel) BK Left Rear Engine Compartment N/S

Wiper Module DKGY Left Side Cowl 6

GROUNDS

GROUND NUMBER LOCATION FIG.

G100 Body Ground Near Powertrain Control Module N/S

G101 Above Starter 13, 15, 18

G102 Left Headlamp Area 1

G103 Above Starter 15

G200 Left Side of Instrument Panel 20, 21 29

G201 Right Side of Instrument Panel 20, 24, 29

G202 Near Radio N/S

G300 Left B Pillar 32

G301 Right B Pillar 33, 39

G302 Left Rear Quarter 47

G303 Liftgate Ground 49

8W - 91 - 12 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONRS

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1185 of 2339

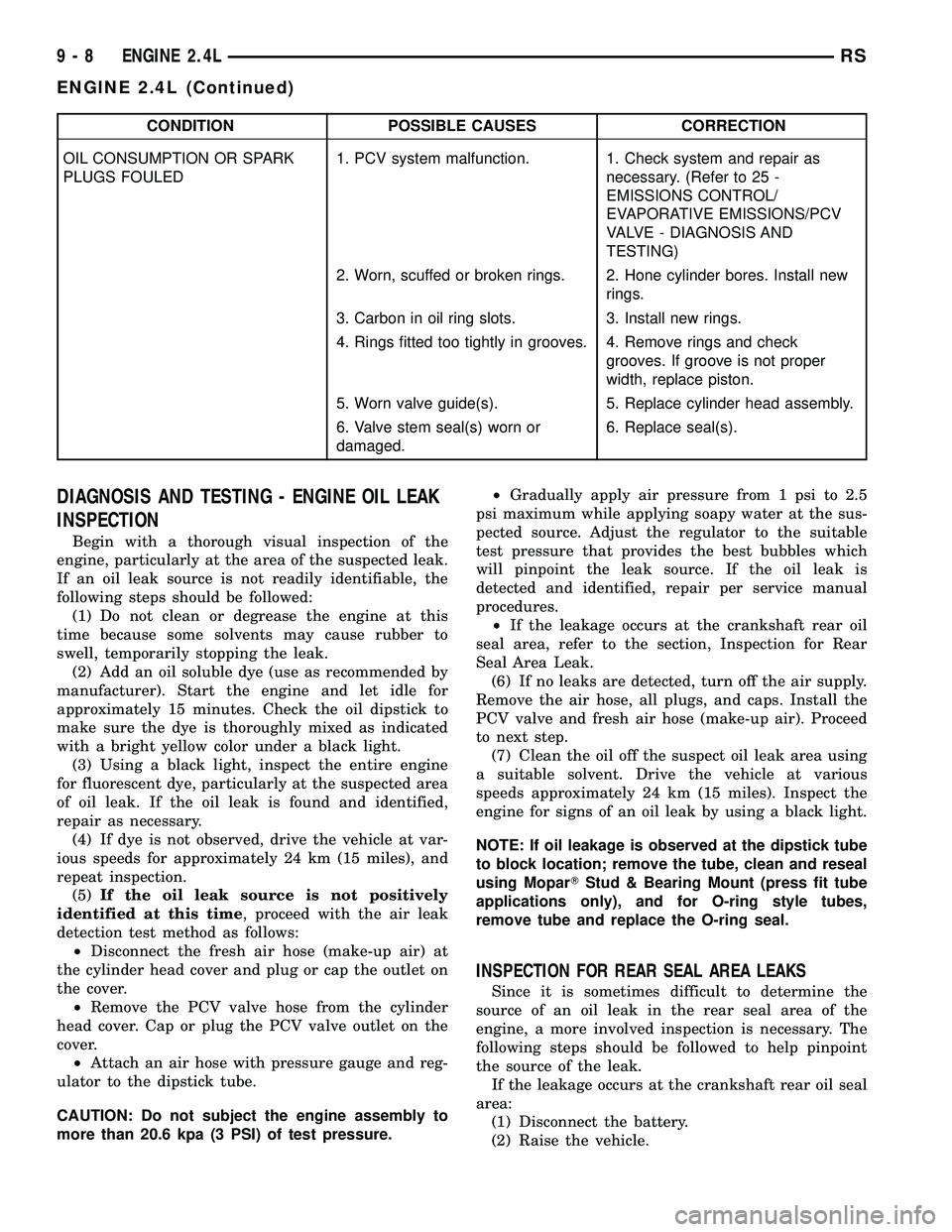

CONDITION POSSIBLE CAUSES CORRECTION

OIL CONSUMPTION OR SPARK

PLUGS FOULED1. PCV system malfunction. 1. Check system and repair as

necessary. (Refer to 25 -

EMISSIONS CONTROL/

EVAPORATIVE EMISSIONS/PCV

VALVE - DIAGNOSIS AND

TESTING)

2. Worn, scuffed or broken rings. 2. Hone cylinder bores. Install new

rings.

3. Carbon in oil ring slots. 3. Install new rings.

4. Rings fitted too tightly in grooves. 4. Remove rings and check

grooves. If groove is not proper

width, replace piston.

5. Worn valve guide(s). 5. Replace cylinder head assembly.

6. Valve stem seal(s) worn or

damaged.6. Replace seal(s).

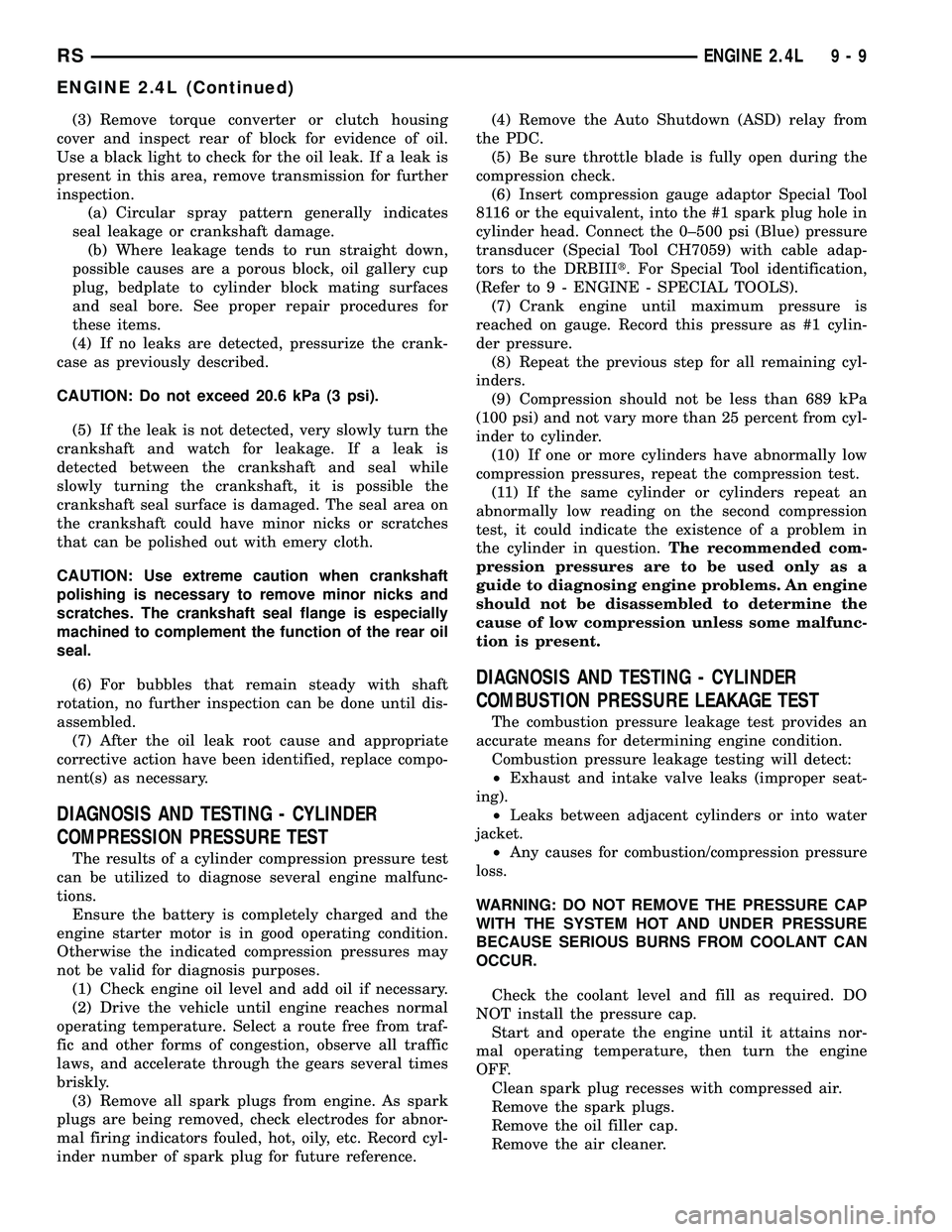

DIAGNOSIS AND TESTING - ENGINE OIL LEAK

INSPECTION

Begin with a thorough visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair as necessary.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24 km (15 miles), and

repeat inspection.

(5)If the oil leak source is not positively

identified at this time, proceed with the air leak

detection test method as follows:

²Disconnect the fresh air hose (make-up air) at

the cylinder head cover and plug or cap the outlet on

the cover.

²Remove the PCV valve hose from the cylinder

head cover. Cap or plug the PCV valve outlet on the

cover.

²Attach an air hose with pressure gauge and reg-

ulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.²Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provides the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

²If the leakage occurs at the crankshaft rear oil

seal area, refer to the section, Inspection for Rear

Seal Area Leak.

(6) If no leaks are detected, turn off the air supply.

Remove the air hose, all plugs, and caps. Install the

PCV valve and fresh air hose (make-up air). Proceed

to next step.

(7) Clean the oil off the suspect oil leak area using

a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

NOTE: If oil leakage is observed at the dipstick tube

to block location; remove the tube, clean and reseal

using MoparTStud & Bearing Mount (press fit tube

applications only), and for O-ring style tubes,

remove tube and replace the O-ring seal.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

9 - 8 ENGINE 2.4LRS

ENGINE 2.4L (Continued)

Page 1186 of 2339

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak. If a leak is

present in this area, remove transmission for further

inspection.

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, oil gallery cup

plug, bedplate to cylinder block mating surfaces

and seal bore. See proper repair procedures for

these items.

(4) If no leaks are detected, pressurize the crank-

case as previously described.

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

(7) After the oil leak root cause and appropriate

corrective action have been identified, replace compo-

nent(s) as necessary.

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Check engine oil level and add oil if necessary.

(2) Drive the vehicle until engine reaches normal

operating temperature. Select a route free from traf-

fic and other forms of congestion, observe all traffic

laws, and accelerate through the gears several times

briskly.

(3) Remove all spark plugs from engine. As spark

plugs are being removed, check electrodes for abnor-

mal firing indicators fouled, hot, oily, etc. Record cyl-

inder number of spark plug for future reference.(4) Remove the Auto Shutdown (ASD) relay from

the PDC.

(5) Be sure throttle blade is fully open during the

compression check.

(6) Insert compression gauge adaptor Special Tool

8116 or the equivalent, into the #1 spark plug hole in

cylinder head. Connect the 0±500 psi (Blue) pressure

transducer (Special Tool CH7059) with cable adap-

tors to the DRBIIIt. For Special Tool identification,

(Refer to 9 - ENGINE - SPECIAL TOOLS).

(7) Crank engine until maximum pressure is

reached on gauge. Record this pressure as #1 cylin-

der pressure.

(8) Repeat the previous step for all remaining cyl-

inders.

(9) Compression should not be less than 689 kPa

(100 psi) and not vary more than 25 percent from cyl-

inder to cylinder.

(10) If one or more cylinders have abnormally low

compression pressures, repeat the compression test.

(11) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.The recommended com-

pression pressures are to be used only as a

guide to diagnosing engine problems. An engine

should not be disassembled to determine the

cause of low compression unless some malfunc-

tion is present.

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

WARNING: DO NOT REMOVE THE PRESSURE CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the pressure cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF.

Clean spark plug recesses with compressed air.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

RSENGINE 2.4L9-9

ENGINE 2.4L (Continued)