battery CHRYSLER VOYAGER 2005 Repair Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 297 of 2339

²SCI Receive

²Speed Control

²Throttle Position Sensor

²Transmission Control Relay (Switched B+)

²Transmission Pressure Switches

²Transmission Temperature Sensor

²Transmission Input Shaft Speed Sensor

²Transmission Output Shaft Speed Sensor

²Transaxle Gear Engagement

²Vehicle Speed

NOTE: PCM Outputs:

²Air Conditioning Clutch Relay

²Automatic Shut Down (ASD) and Fuel Pump

Relays

²Data Link Connector (PCI and SCI Transmit)

²Double Start Override

²EGR Solenoid

²Fuel Injectors

²Generator Field

²High Speed Fan Relay

²Idle Air Control Motor

²Ignition Coils

²Leak Detection Pump

²Low Speed Fan Relay

²MTV Actuator

²Proportional Purge Solenoid

²SRV Valve

²Speed Control Relay

²Speed Control Vent Relay

²Speed Control Vacuum Relay

²8 Volt Output

²5 Volt Output

²Torque Reduction Request

²Transmission Control Relay

²Transmission Solenoids

²Vehicle Speed

Based on inputs it receives, the powertrain control

module (PCM) adjusts fuel injector pulse width, idle

speed, ignition timing, and canister purge operation.

The PCM regulates the cooling fans, air conditioning

and speed control systems. The PCM changes gener-

ator charge rate by adjusting the generator field.

The PCM adjusts injector pulse width (air-fuel

ratio) based on the following inputs.

²Battery Voltage

²Intake Air Temperature Sensor

²Engine Coolant Temperature

²Engine Speed (crankshaft position sensor)

²Exhaust Gas Oxygen Content (heated oxygen

sensors)

²Manifold Absolute Pressure

²Throttle Position

The PCM adjusts engine idle speed through the

idle air control motor based on the following inputs.

²Brake Switch²Engine Coolant Temperature

²Engine Speed (crankshaft position sensor)

²Park/Neutral

²Transaxle Gear Engagement

²Throttle Position

²Vehicle Speed

The PCM adjusts ignition timing based on the fol-

lowing inputs.

²Intake Air Temperature

²Engine Coolant Temperature

²Engine Speed (crankshaft position sensor)

²Knock Sensor

²Manifold Absolute Pressure

²Park/Neutral

²Transaxle Gear Engagement

²Throttle Position

The automatic shut down (ASD) and fuel pump

relays are mounted externally, but turned on and off

by the powertrain control module through the same

circuit.

The camshaft and crankshaft signals are sent to

the powertrain control module. If the PCM does not

receive both signals within approximately one second

of engine cranking, it deactivates the ASD and fuel

pump relays. When these relays are deactivated,

power is shut off to the fuel injectors, ignition coils,

fuel pump and the heating element in each oxygen

sensor.

The PCM contains a voltage converter that

changes battery voltage to a regulated 8.0 volts. The

8.0 volts power the camshaft position sensor, crank-

shaft position sensor and vehicle speed sensor. The

PCM also provides a 5.0 volts supply for the engine

coolant temperature sensor, intake air temperature

sensor, manifold absolute pressure sensor and throt-

tle position sensor.

The PCM engine control strategy prevents reduced

idle speeds until after the engine operates for 320 km

(200 miles). If the PCM is replaced after 320 km (200

miles) of usage, update the mileage in new PCM. Use

the DRBIIItscan tool to change the mileage in the

PCM. Refer to the appropriate Powertrain Diagnostic

Manual and the DRBIIItscan tool.

TRANSMISSION CONTROL

CLUTCH VOLUME INDEX (CVI)

An important function of the PCM is to monitor

Clutch Volume Index (CVI). CVIs represent the vol-

ume of fluid needed to compress a clutch pack.

The PCM monitors gear ratio changes by monitor-

ing the Input and Output Speed Sensors. The Input,

or Turbine Speed Sensor sends an electrical signal to

the PCM that represents input shaft rpm. The Out-

put Speed Sensor provides the PCM with output

shaft speed information.

8E - 12 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

Page 300 of 2339

The power grounds are used to control the ground

side relays, solenoids, ignition coil or injectors. The

signal ground is used for any input that uses sensor

return for ground, and the ground side of any inter-

nal processing component.

The PCM case is shielded to prevent RFI and EMI.

The PCM case is grounded and must be firmly

attached to a good, clean body ground.

Internally all grounds are connected together, how-

ever there is noise suppression on the sensor ground.

For EMI and RFI protection the housing and cover

are also grounded separately from the ground pins.

OPERATION - 5 VOLT SUPPLY - PCM OUTPUT

The PCM supplies 5 volts to the following sensors:

²A/C pressure transducer

²Ambient Temperature sensor

²Battery temperature

²Camshaft Position Sensor (NGC)

²Crankshaft Position Sensor (NGC)

²Engine coolant temperature sensor

²Inlet Air Temperature Sensor

²Knock sensor

²Linear EGR solenoid (if equipped)

²Manifold absolute pressure sensor

²Oil Pressure Switch

²Throttle position sensor

STANDARD PROCEDURE

STANDARD PROCEDURE - OBTAINING

DIAGNOSTIC TROUBLE CODES

BULB CHECK

Key on: Bulb illuminated until vehicle starts, as

long as all once per trip (readiness) monitors com-

pleted. If monitors havenotbeen completed, then:

Key on: bulb check for about 5 to 8 seconds, lamp

then flashes if once per trip (readiness) monitors

havenotbeen completed until vehicle is started,

then MIL is extinguished.

OBTAINING DTC'S USING DRB SCAN TOOL

(1) Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

(2) Turn the ignition switch on and access the

ªRead Faultº screen.

(3) Record all the DTC's and ªfreeze frameº infor-

mation shown on the DRB scan tool.

(4) To erase DTC's, use the ªErase Trouble Codeº

data screen on the DRB scan tool.Do not erase any

DTC's until problems have been investigated

and repairs have been performed.

STANDARD PROCEDURE - PINION FACTOR

SETTING

NOTE: This procedure must be performed if the

PCM has been replaced with a NEW or replacement

unit. Failure to perform this procedure will result in

an inoperative or improperly calibrated speedome-

ter.

The vehicle speed readings for the speedometer are

taken from the output speed sensor. The PCM must

be calibrated to the different combinations of equip-

ment (final drive and tires) available. Pinion Factor

allows the technician to set the Powertrain Control

Module initial setting so that the speedometer read-

ings will be correct. To properly read and/or reset the

Pinion Factor, it is necessary to use a DRBIIItscan

tool.

(1) Plug the DRBIIItscan tool into the diagnostic

connector located under the instrument panel.

(2) Select the Transmission menu.

(3) Select the Miscellaneous menu.

(4) Select Pinion Factor. Then follow the instruc-

tions on the DRBIIItscan tool screen.

STANDARD PROCEDURE - QUICK LEARN

PROCEDURE

The quick learn procedure requires the use of the

DRBIIItscan tool. This program allows the PCM to

recalibrate itself. This will provide the best possible

transaxle operation.

NOTE: The quick learn procedure should be per-

formed if any of the following procedures are per-

formed:

²Transaxle Assembly Replacement

²Powertrain Control Module Replacement

²Solenoid/Pressure Switch Assembly Replacement

²Clutch Plate and/or Seal Replacement

²Valve Body Replacement or Recondition

To perform the Quick Learn Procedure, the follow-

ing conditions must be met:

²The brakes must be applied

²The engine speed must be above 500 rpm

²The throttle angle (TPS) must be less than 3

degrees

²The shift lever position must stay until

prompted to shift to overdrive

²The shift lever position must stay in overdrive

after the Shift to Overdrive prompt until the

DRBIIItindicates the procedure is complete

²The calculated oil temperature must be above

60É and below 200É

RSELECTRONIC CONTROL MODULES8E-15

POWERTRAIN CONTROL MODULE (Continued)

Page 301 of 2339

(1) Plug the DRBIIItscan tool into the diagnostic

connector. The connector is located under the instru-

ment panel.

(2) Go to the Transmission screen.

(3) Go to the Miscellaneous screen.

(4) Select Quick Learn Procedure. Follow the

instructions of the DRBIIItto perform the Quick

Learn Procedure.

REMOVAL

REMOVAL - SBEC CONTROLLER

(1) Disconnect the negative battery cable.

(2) Remove the battery shield, refer to the Battery

section for more information.

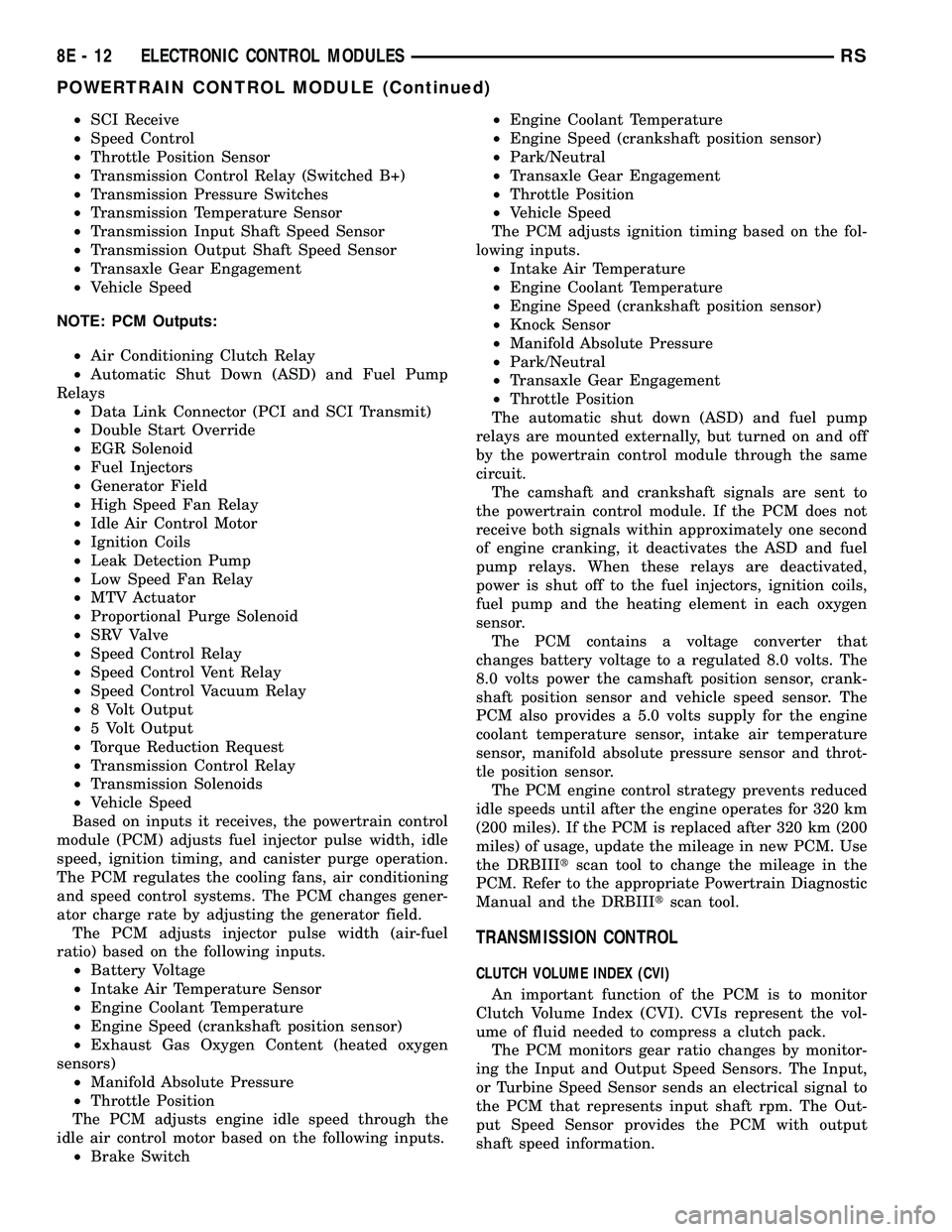

(3) Remove the 2 upper PCM bracket bolts (Fig.

11).

(4) Remove the 2 PCM connectors.

(5) Remove the headlamp, refer to the Lamps sec-

tion for more information.

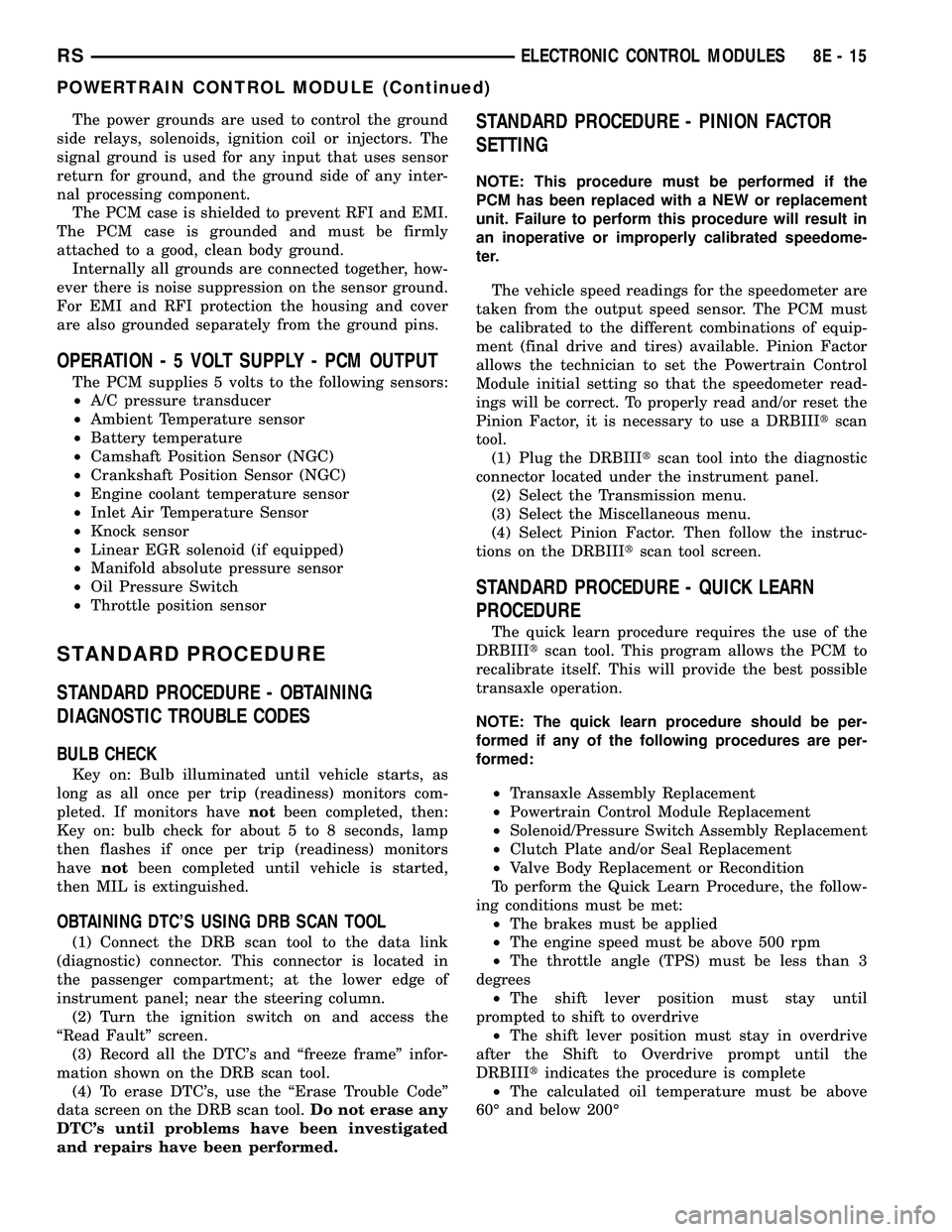

(6) Remove the lower PCM mounting bolt (Fig. 12).

(7) Remove PCM.

REMOVAL - NGC CONTROLLER

The PCM engine control strategy prevents reduced

idle speeds until after the engine operates for 320 km

(200 miles). If the PCM is replaced after 320 km (200

miles) of usage, update the mileage and vehicle iden-

tification number (VIN) in the new PCM. Use the

DRBIIItscan tool to change the millage and VIN in

the PCM. If this step is not done a Diagnostic Trou-

ble Code (DTC) may be set. Refer to the appropriate

Powertrain Diagnostic Manual and the DRBIIItscan

tool.

Fig. 11 PCM

1 - Attaching Bolts

Fig. 12 PCM LOWER BOLT

NGC CONTROLLER LOCATION

8E - 16 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

Page 302 of 2339

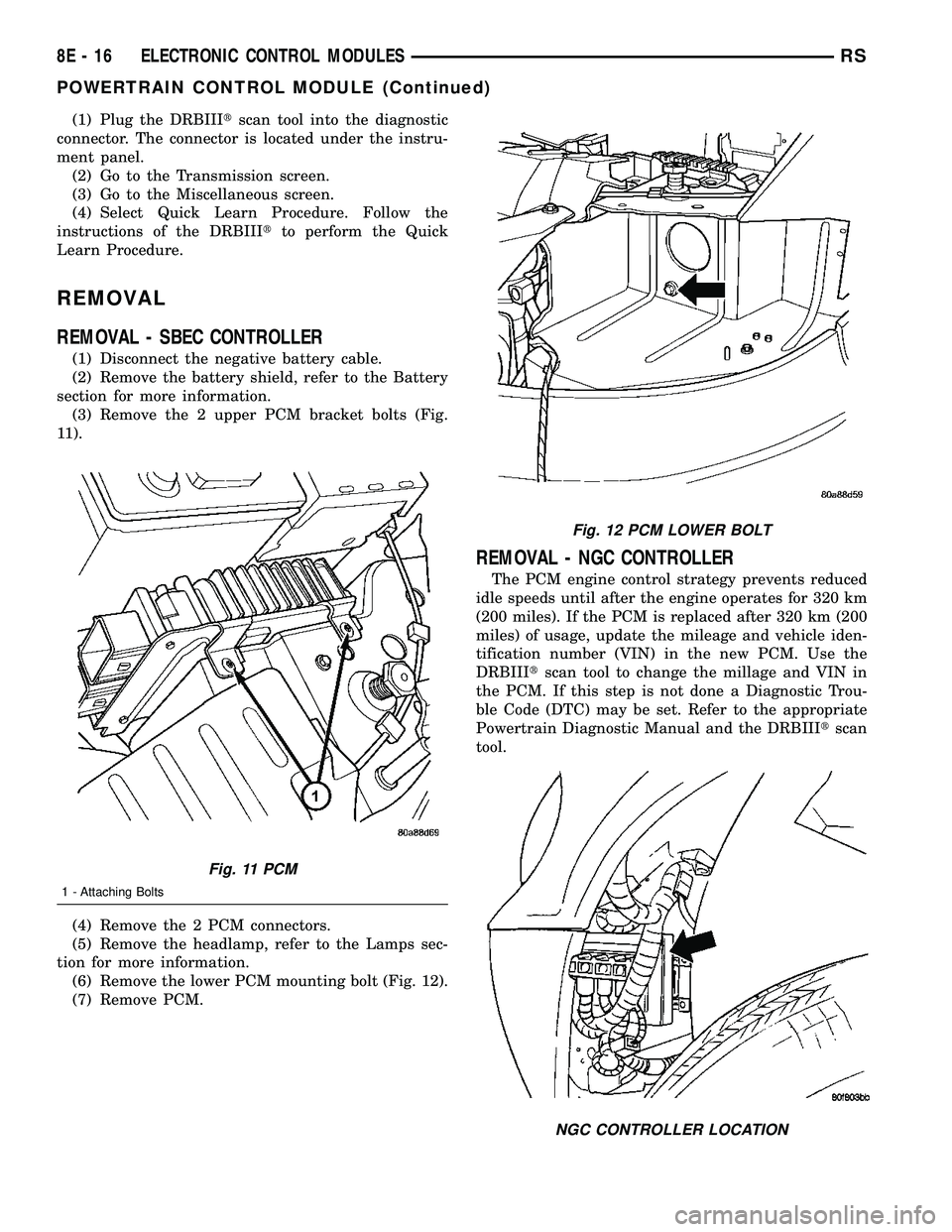

(1) Turn wheels to the left.

(2) Disconnect the negative battery cable.

(3) Raise vehicle and support.

(4) Remove the left front wheel well splash shield

(Fig. 13).

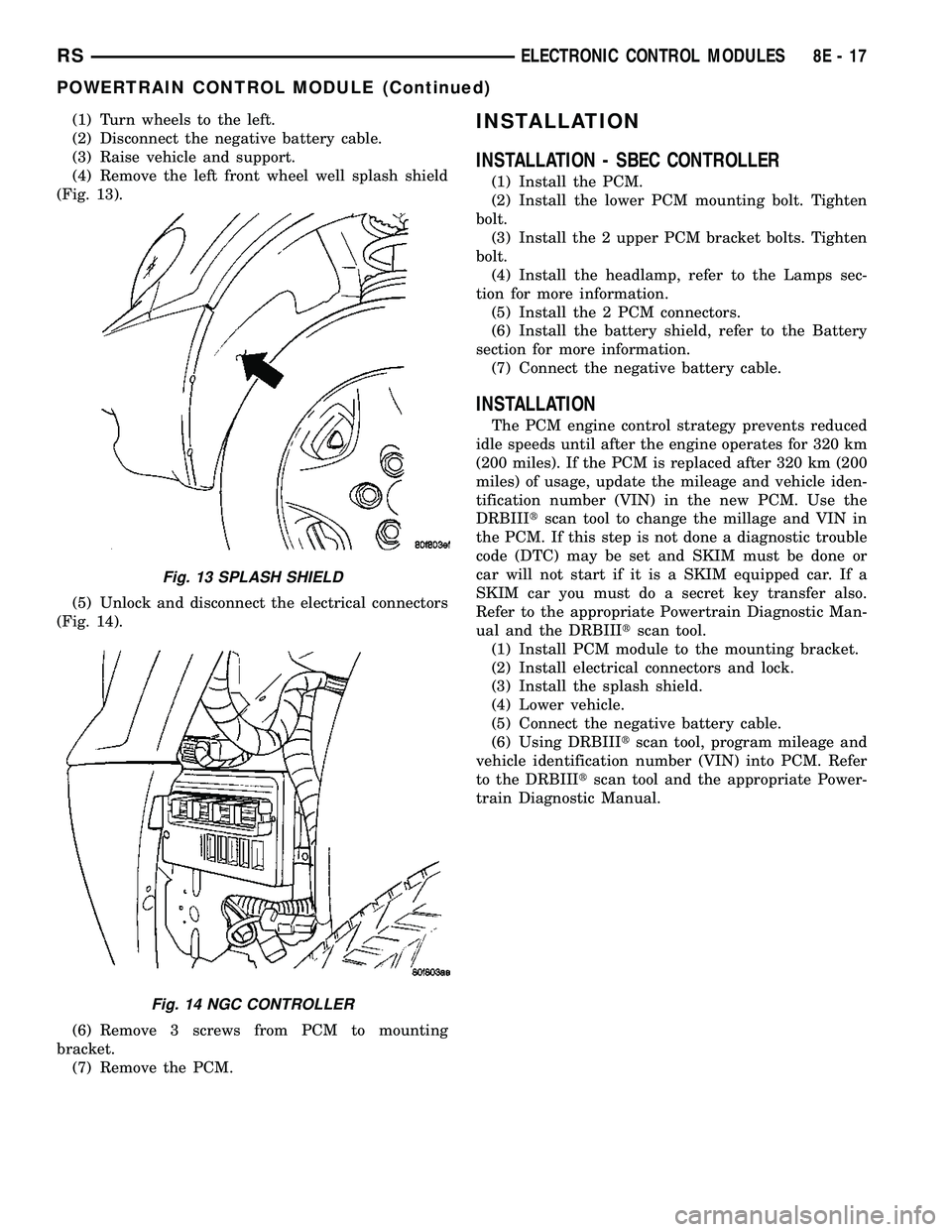

(5) Unlock and disconnect the electrical connectors

(Fig. 14).

(6) Remove 3 screws from PCM to mounting

bracket.

(7) Remove the PCM.INSTALLATION

INSTALLATION - SBEC CONTROLLER

(1) Install the PCM.

(2) Install the lower PCM mounting bolt. Tighten

bolt.

(3) Install the 2 upper PCM bracket bolts. Tighten

bolt.

(4) Install the headlamp, refer to the Lamps sec-

tion for more information.

(5) Install the 2 PCM connectors.

(6) Install the battery shield, refer to the Battery

section for more information.

(7) Connect the negative battery cable.

INSTALLATION

The PCM engine control strategy prevents reduced

idle speeds until after the engine operates for 320 km

(200 miles). If the PCM is replaced after 320 km (200

miles) of usage, update the mileage and vehicle iden-

tification number (VIN) in the new PCM. Use the

DRBIIItscan tool to change the millage and VIN in

the PCM. If this step is not done a diagnostic trouble

code (DTC) may be set and SKIM must be done or

car will not start if it is a SKIM equipped car. If a

SKIM car you must do a secret key transfer also.

Refer to the appropriate Powertrain Diagnostic Man-

ual and the DRBIIItscan tool.

(1) Install PCM module to the mounting bracket.

(2) Install electrical connectors and lock.

(3) Install the splash shield.

(4) Lower vehicle.

(5) Connect the negative battery cable.

(6) Using DRBIIItscan tool, program mileage and

vehicle identification number (VIN) into PCM. Refer

to the DRBIIItscan tool and the appropriate Power-

train Diagnostic Manual.

Fig. 13 SPLASH SHIELD

Fig. 14 NGC CONTROLLER

RSELECTRONIC CONTROL MODULES8E-17

POWERTRAIN CONTROL MODULE (Continued)

Page 303 of 2339

SLIDING DOOR CONTROL

MODULE

DESCRIPTION

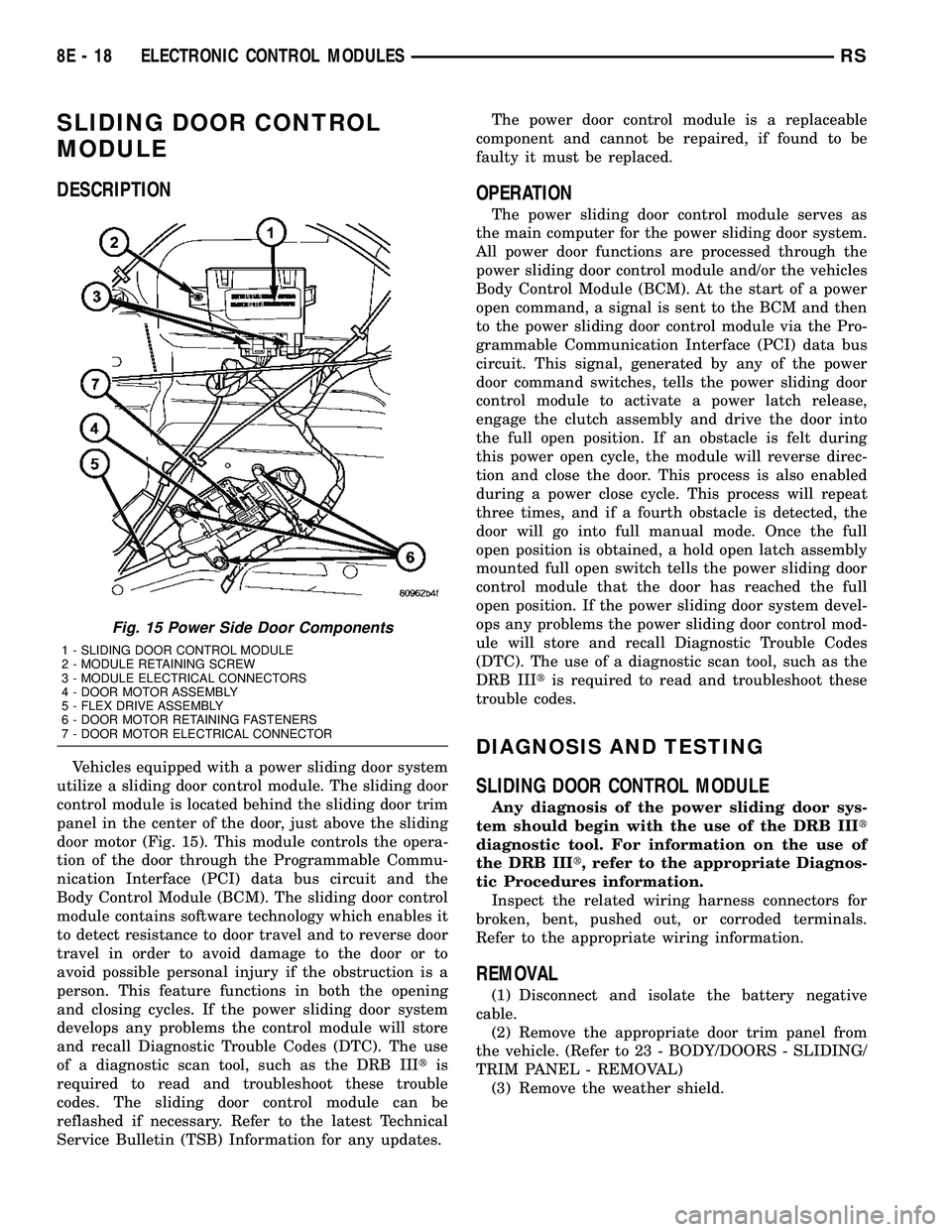

Vehicles equipped with a power sliding door system

utilize a sliding door control module. The sliding door

control module is located behind the sliding door trim

panel in the center of the door, just above the sliding

door motor (Fig. 15). This module controls the opera-

tion of the door through the Programmable Commu-

nication Interface (PCI) data bus circuit and the

Body Control Module (BCM). The sliding door control

module contains software technology which enables it

to detect resistance to door travel and to reverse door

travel in order to avoid damage to the door or to

avoid possible personal injury if the obstruction is a

person. This feature functions in both the opening

and closing cycles. If the power sliding door system

develops any problems the control module will store

and recall Diagnostic Trouble Codes (DTC). The use

of a diagnostic scan tool, such as the DRB IIItis

required to read and troubleshoot these trouble

codes. The sliding door control module can be

reflashed if necessary. Refer to the latest Technical

Service Bulletin (TSB) Information for any updates.The power door control module is a replaceable

component and cannot be repaired, if found to be

faulty it must be replaced.

OPERATION

The power sliding door control module serves as

the main computer for the power sliding door system.

All power door functions are processed through the

power sliding door control module and/or the vehicles

Body Control Module (BCM). At the start of a power

open command, a signal is sent to the BCM and then

to the power sliding door control module via the Pro-

grammable Communication Interface (PCI) data bus

circuit. This signal, generated by any of the power

door command switches, tells the power sliding door

control module to activate a power latch release,

engage the clutch assembly and drive the door into

the full open position. If an obstacle is felt during

this power open cycle, the module will reverse direc-

tion and close the door. This process is also enabled

during a power close cycle. This process will repeat

three times, and if a fourth obstacle is detected, the

door will go into full manual mode. Once the full

open position is obtained, a hold open latch assembly

mounted full open switch tells the power sliding door

control module that the door has reached the full

open position. If the power sliding door system devel-

ops any problems the power sliding door control mod-

ule will store and recall Diagnostic Trouble Codes

(DTC). The use of a diagnostic scan tool, such as the

DRB IIItis required to read and troubleshoot these

trouble codes.

DIAGNOSIS AND TESTING

SLIDING DOOR CONTROL MODULE

Any diagnosis of the power sliding door sys-

tem should begin with the use of the DRB IIIt

diagnostic tool. For information on the use of

the DRB IIIt, refer to the appropriate Diagnos-

tic Procedures information.

Inspect the related wiring harness connectors for

broken, bent, pushed out, or corroded terminals.

Refer to the appropriate wiring information.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the appropriate door trim panel from

the vehicle. (Refer to 23 - BODY/DOORS - SLIDING/

TRIM PANEL - REMOVAL)

(3) Remove the weather shield.

Fig. 15 Power Side Door Components

1 - SLIDING DOOR CONTROL MODULE

2 - MODULE RETAINING SCREW

3 - MODULE ELECTRICAL CONNECTORS

4 - DOOR MOTOR ASSEMBLY

5 - FLEX DRIVE ASSEMBLY

6 - DOOR MOTOR RETAINING FASTENERS

7 - DOOR MOTOR ELECTRICAL CONNECTOR

8E - 18 ELECTRONIC CONTROL MODULESRS

Page 304 of 2339

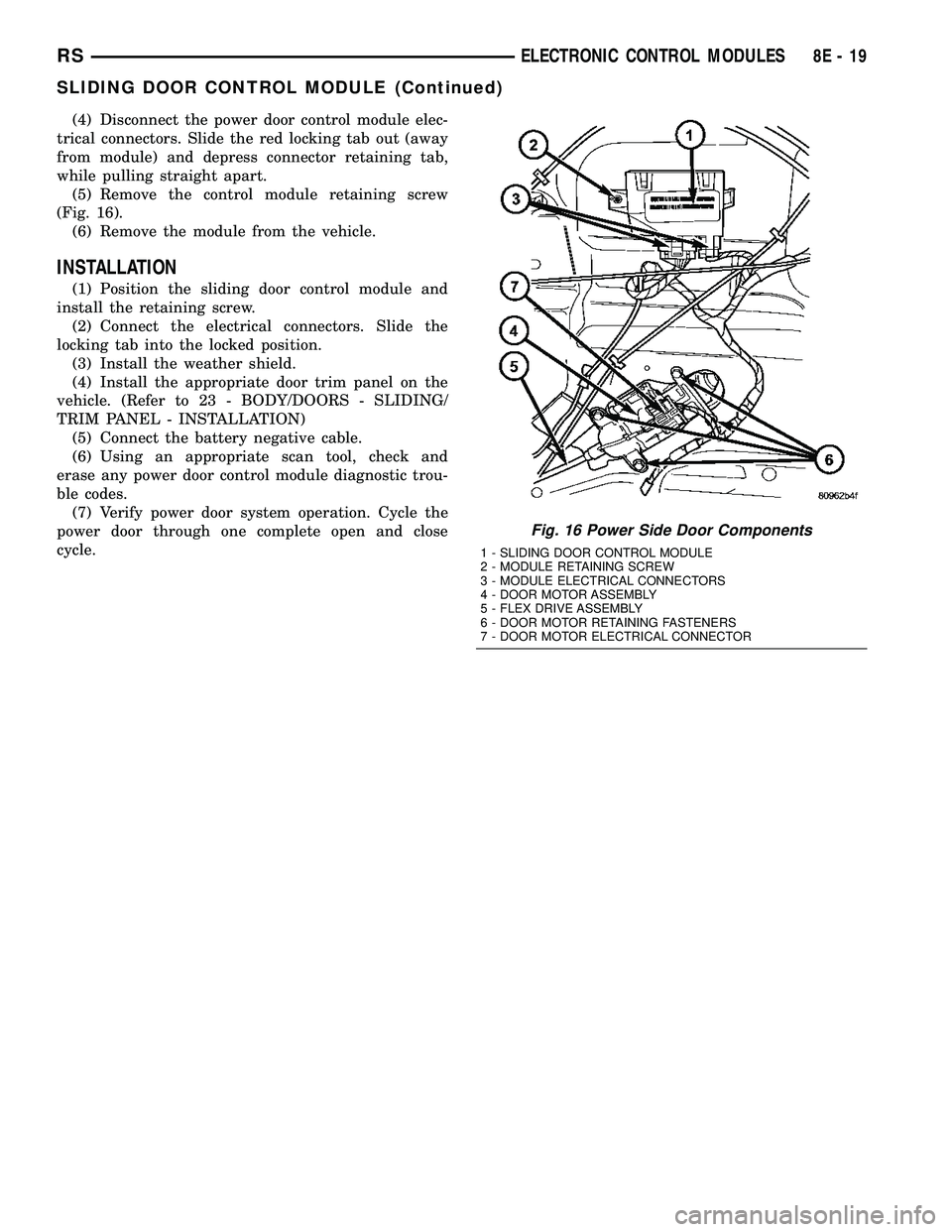

(4) Disconnect the power door control module elec-

trical connectors. Slide the red locking tab out (away

from module) and depress connector retaining tab,

while pulling straight apart.

(5) Remove the control module retaining screw

(Fig. 16).

(6) Remove the module from the vehicle.

INSTALLATION

(1) Position the sliding door control module and

install the retaining screw.

(2) Connect the electrical connectors. Slide the

locking tab into the locked position.

(3) Install the weather shield.

(4) Install the appropriate door trim panel on the

vehicle. (Refer to 23 - BODY/DOORS - SLIDING/

TRIM PANEL - INSTALLATION)

(5) Connect the battery negative cable.

(6) Using an appropriate scan tool, check and

erase any power door control module diagnostic trou-

ble codes.

(7) Verify power door system operation. Cycle the

power door through one complete open and close

cycle.

Fig. 16 Power Side Door Components

1 - SLIDING DOOR CONTROL MODULE

2 - MODULE RETAINING SCREW

3 - MODULE ELECTRICAL CONNECTORS

4 - DOOR MOTOR ASSEMBLY

5 - FLEX DRIVE ASSEMBLY

6 - DOOR MOTOR RETAINING FASTENERS

7 - DOOR MOTOR ELECTRICAL CONNECTOR

RSELECTRONIC CONTROL MODULES8E-19

SLIDING DOOR CONTROL MODULE (Continued)

Page 306 of 2339

ENGINE SYSTEMS

TABLE OF CONTENTS

page page

BATTERY SYSTEM......................... 1

CHARGING.............................. 21STARTING............................... 31

BATTERY SYSTEM

TABLE OF CONTENTS

page page

BATTERY SYSTEM

DESCRIPTION..........................1

OPERATION............................2

DIAGNOSIS AND TESTING

BATTERY SYSTEM.....................2

CLEANING.............................5

INSPECTION...........................5

SPECIFICATIONS

BATTERY............................6

SPECIAL TOOLS

BATTERY SYSTEM SPECIAL TOOLS.......7

BATTERY

DESCRIPTION..........................7

OPERATION............................9

DIAGNOSIS AND TESTING

BATTERY............................9

STANDARD PROCEDURE

SPIRAL PLATE BATTERY CHARGING......10

CONVENTIONAL BATTERY CHARGING....11

OPEN-CIRCUIT VOLTAGE TEST..........13IGNITION-OFF DRAW TEST.............13

CHECKING BATTERY ELECTROLYTE

LEVEL..............................14

MICRO 420 BATTERY TESTER...........15

REMOVAL - BATTERY...................16

INSTALLATION.........................16

BATTERY HOLDDOWN

REMOVAL.............................16

INSTALLATION.........................16

BATTERY CABLES

DESCRIPTION.........................16

OPERATION...........................17

DIAGNOSIS AND TESTING

BATTERY CABLES....................17

REMOVAL.............................19

INSTALLATION.........................19

BATTERY TRAY

DESCRIPTION.........................19

REMOVAL.............................19

INSTALLATION.........................20

BATTERY SYSTEM

DESCRIPTION

This vehicle is equipped with a single 12-volt bat-

tery. All of the components of the battery system are

located within the engine compartment. The battery

system for this vehicle contains the following related

components:

²Battery- The storage battery provides a reli-

able means of storing a renewable source of electrical

energy within the vehicle.

²Battery Cable- The battery cables connect the

battery terminal posts to the vehicle electrical sys-

tem.²Battery Holddown- The battery holddown

hardware secures the battery in the battery tray in

the engine compartment.

²Battery Thermowrap- The battery thermow-

rap insulates the battery to protect it from engine

compartment temperature extremes.

²Battery Tray- The battery tray provides a

secure mounting location in the vehicle for the bat-

tery and an anchor point for the battery holddown

hardware.

RSENGINE SYSTEMS8F-1

Page 307 of 2339

OPERATION

The battery system is designed to provide a safe,

efficient, reliable and mobile means of delivering and

storing electrical energy. This electrical energy is

required to operate the engine starting system, as

well as to operate many of the other vehicle acces-

sory systems for limited durations while the engine

and/or the charging system are not operating. The

battery system is also designed to provide a reserve

of electrical energy to supplement the charging sys-

tem for short durations while the engine is running

and the electrical current demands of the vehicle

exceed the output of the charging system. In addition

to delivering, and storing electrical energy for the

vehicle, the battery system serves as a capacitor and

voltage stabilizer for the vehicle electrical system. It

absorbs most abnormal or transient voltages caused

by the switching of any of the electrical components

or circuits in the vehicle.

DIAGNOSIS AND TESTING

BATTERY SYSTEM

The battery, starting, and charging systems in the

vehicle operate with one another and must be tested

as a complete system. In order for the engine to start

and the battery to maintain its charge properly, all of

the components that are used in these systems must

perform within specifications. It is important that

the battery, starting, and charging systems be thor-

oughly tested and inspected any time a battery needs

to be charged or replaced. The cause of abnormal bat-

tery discharge, overcharging or early battery failuremust be diagnosed and corrected before a battery is

replaced and before a vehicle is returned to service.

The service information for these systems has been

separated within this service manual to make it eas-

ier to locate the specific information you are seeking.

However, when attempting to diagnose any of these

systems, it is important that you keep their interde-

pendency in mind.

The diagnostic procedures used for the battery,

starting, and charging systems include the most

basic conventional diagnostic methods, to the more

sophisticated On-Board Diagnostics (OBD) built into

the Powertrain Control Module (PCM). Use of an

induction-type milliampere ammeter, a volt/ohmme-

ter, a battery charger, a carbon pile rheostat (load

tester) and a 12-volt test lamp may be required. All

OBD-sensed systems are monitored by the PCM.

Each monitored circuit is assigned a Diagnostic Trou-

ble Code (DTC). The PCM will store a DTC in elec-

tronic memory for any failure it detects. (Refer to 8 -

ELECTRICAL/CHARGING - DIAGNOSIS AND

TESTING) for the proper charging system on-board

diagnostic test procedures.MICRO 420 BATTERY TESTER

The Micro 420 automotive battery tester is

designed to help the dealership technicians diagnose

the cause of a defective battery. Follow the instruc-

tion manual supplied with the tester to properly

diagnose a vehicle. If the instruction manual is not

available refer to the standard procedure in this sec-

tion, which includes the directions for using the

Micro 420 battery tester.

8F - 2 BATTERY SYSTEMRS

BATTERY SYSTEM (Continued)

Page 308 of 2339

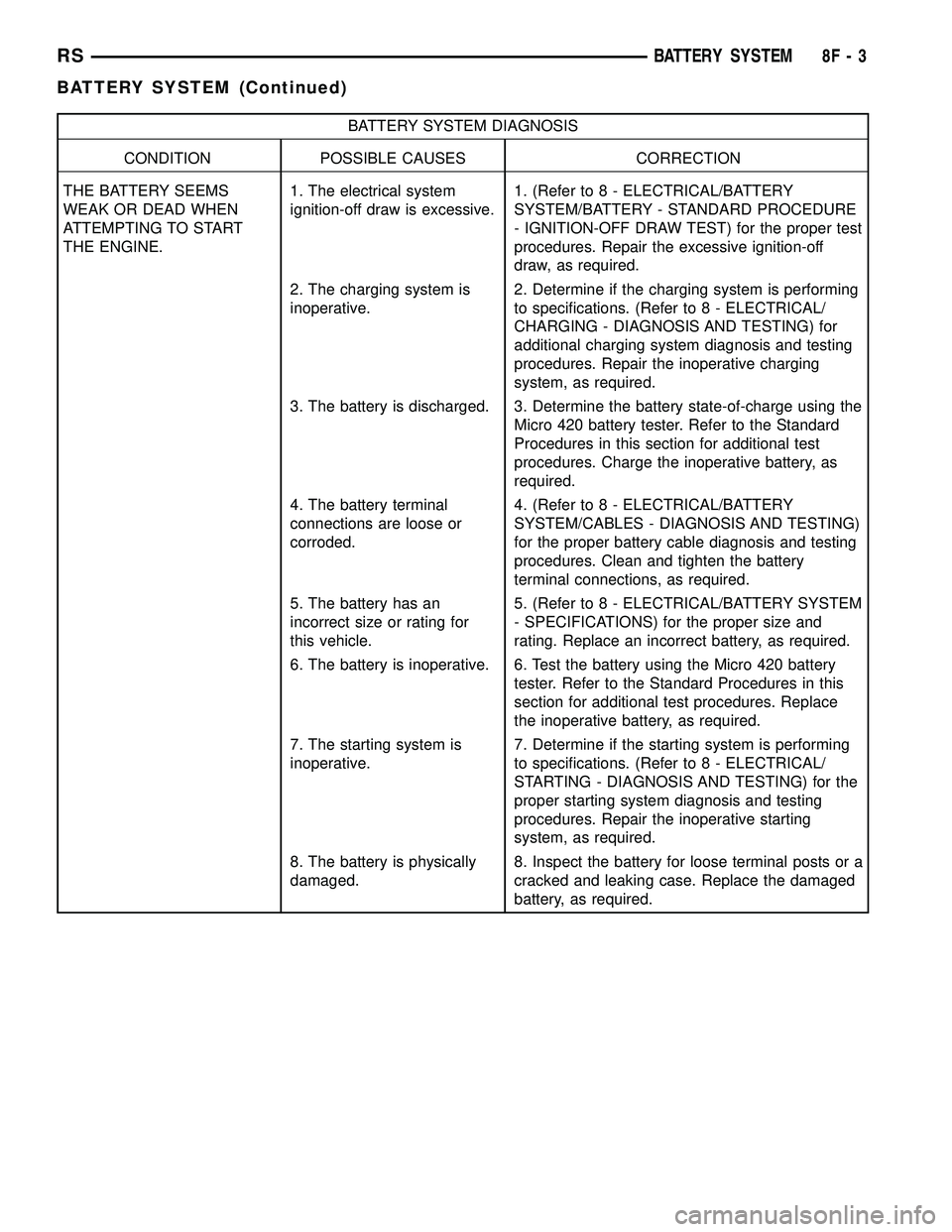

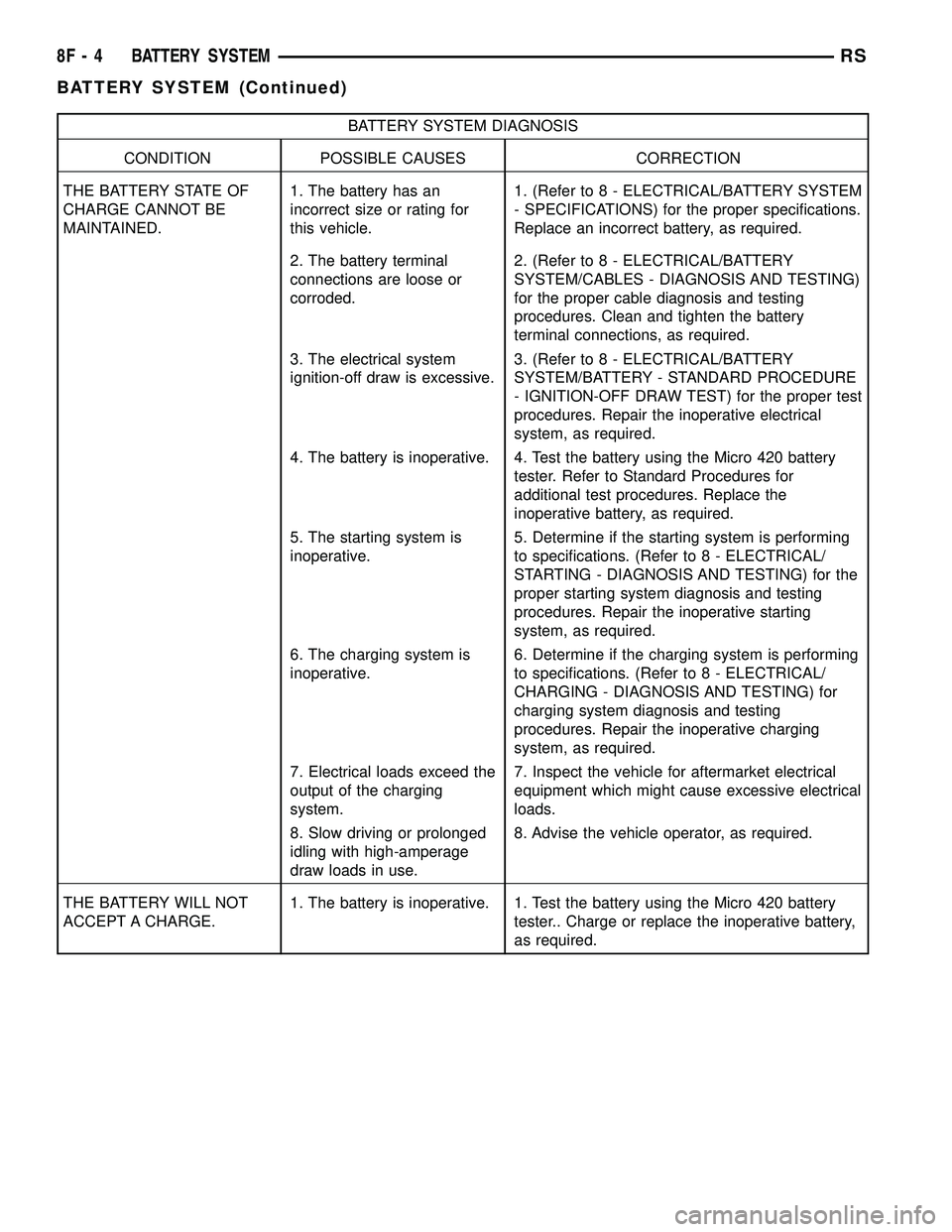

BATTERY SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

THE BATTERY SEEMS

WEAK OR DEAD WHEN

ATTEMPTING TO START

THE ENGINE.1. The electrical system

ignition-off draw is excessive.1. (Refer to 8 - ELECTRICAL/BATTERY

SYSTEM/BATTERY - STANDARD PROCEDURE

- IGNITION-OFF DRAW TEST) for the proper test

procedures. Repair the excessive ignition-off

draw, as required.

2. The charging system is

inoperative.2. Determine if the charging system is performing

to specifications. (Refer to 8 - ELECTRICAL/

CHARGING - DIAGNOSIS AND TESTING) for

additional charging system diagnosis and testing

procedures. Repair the inoperative charging

system, as required.

3. The battery is discharged. 3. Determine the battery state-of-charge using the

Micro 420 battery tester. Refer to the Standard

Procedures in this section for additional test

procedures. Charge the inoperative battery, as

required.

4. The battery terminal

connections are loose or

corroded.4. (Refer to 8 - ELECTRICAL/BATTERY

SYSTEM/CABLES - DIAGNOSIS AND TESTING)

for the proper battery cable diagnosis and testing

procedures. Clean and tighten the battery

terminal connections, as required.

5. The battery has an

incorrect size or rating for

this vehicle.5. (Refer to 8 - ELECTRICAL/BATTERY SYSTEM

- SPECIFICATIONS) for the proper size and

rating. Replace an incorrect battery, as required.

6. The battery is inoperative. 6. Test the battery using the Micro 420 battery

tester. Refer to the Standard Procedures in this

section for additional test procedures. Replace

the inoperative battery, as required.

7. The starting system is

inoperative.7. Determine if the starting system is performing

to specifications. (Refer to 8 - ELECTRICAL/

STARTING - DIAGNOSIS AND TESTING) for the

proper starting system diagnosis and testing

procedures. Repair the inoperative starting

system, as required.

8. The battery is physically

damaged.8. Inspect the battery for loose terminal posts or a

cracked and leaking case. Replace the damaged

battery, as required.

RSBATTERY SYSTEM8F-3

BATTERY SYSTEM (Continued)

Page 309 of 2339

BATTERY SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

THE BATTERY STATE OF

CHARGE CANNOT BE

MAINTAINED.1. The battery has an

incorrect size or rating for

this vehicle.1. (Refer to 8 - ELECTRICAL/BATTERY SYSTEM

- SPECIFICATIONS) for the proper specifications.

Replace an incorrect battery, as required.

2. The battery terminal

connections are loose or

corroded.2. (Refer to 8 - ELECTRICAL/BATTERY

SYSTEM/CABLES - DIAGNOSIS AND TESTING)

for the proper cable diagnosis and testing

procedures. Clean and tighten the battery

terminal connections, as required.

3. The electrical system

ignition-off draw is excessive.3. (Refer to 8 - ELECTRICAL/BATTERY

SYSTEM/BATTERY - STANDARD PROCEDURE

- IGNITION-OFF DRAW TEST) for the proper test

procedures. Repair the inoperative electrical

system, as required.

4. The battery is inoperative. 4. Test the battery using the Micro 420 battery

tester. Refer to Standard Procedures for

additional test procedures. Replace the

inoperative battery, as required.

5. The starting system is

inoperative.5. Determine if the starting system is performing

to specifications. (Refer to 8 - ELECTRICAL/

STARTING - DIAGNOSIS AND TESTING) for the

proper starting system diagnosis and testing

procedures. Repair the inoperative starting

system, as required.

6. The charging system is

inoperative.6. Determine if the charging system is performing

to specifications. (Refer to 8 - ELECTRICAL/

CHARGING - DIAGNOSIS AND TESTING) for

charging system diagnosis and testing

procedures. Repair the inoperative charging

system, as required.

7. Electrical loads exceed the

output of the charging

system.7. Inspect the vehicle for aftermarket electrical

equipment which might cause excessive electrical

loads.

8. Slow driving or prolonged

idling with high-amperage

draw loads in use.8. Advise the vehicle operator, as required.

THE BATTERY WILL NOT

ACCEPT A CHARGE.1. The battery is inoperative. 1. Test the battery using the Micro 420 battery

tester.. Charge or replace the inoperative battery,

as required.

8F - 4 BATTERY SYSTEMRS

BATTERY SYSTEM (Continued)