steering rack CHRYSLER VOYAGER 2005 Repair Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 1412 of 2339

CONDITION POSSIBLE CAUSES CORRECTION

SUCKING AIR SOUND 1. Loose clamp on power steering

fluid return hose.1. Tighten or replace hose clamp.

2. Missing O-Ring on power steering

hose connection.2. Inspect connection and replace

O-Ring as required.

3. Low power steering fluid level. 3. Fill power steering fluid reservoir to

proper level and check for leaks.

4. Loose clamp on fluid supply hose. 4. Tighten or replace hose clamp.

SQUEAK OR RUBBING

SOUND1. Steering column shroud rubbing. 1. Realign shrouds as necessary.

2. Steering column shaft rubbing. 2. Move or realign item rubbing shaft.

3. Clockspring noisy. 3. Remove clockspring. Reinstall wheel.

If noise is gone, replace clockspring.

4. Seal lubrication inadequate. 4. Lube seal (if external).

5. Steering gear internally noisy. 5. Replace steering gear (if no other

cause can be found).

SCRUBBING OR

KNOCKING NOISE.1. Incorrect tire or wheel size. 1. Replace incorrect size tire or wheel

with size used as original equipment.

2. Interference between steering

gear and other vehicle components.2. Check for bent or misaligned

components and correct as necessary.

3. Steering gear internal stops worn

excessively allowing tires to be

steered excessively far.3. Replace steering gear.

* NOTE: There is some noise in all power steering

systems. One of the most common is a hissing

sound evident when turning the steering wheel

when at a standstill or when parking and the steer-

ing wheel is at the end of its travel. Hiss is a very

high frequency noise similar to that experienced

while slowly closing a water tap. The noise is

present in every valve and results when high veloc-

ity fluid passes valve orifice edges. There is no

relationship between this noise and the perfor-

mance of the steering system.** NOTE: A light clunk may be felt or heard during

steering wheel reversal while vehicle is stationary.

This results from internal steering gear rack move-

ment at the bushings and in no way affects the per-

formance of the steering system. This movement

may be felt in the steering components during

steering wheel reversal.

*** NOTE: Power steering pump growl/moan/groan

results from the development of high pressure fluid

flow. Normally this noise level should not be high

enough to be objectionable.

RSSTEERING19-5

STEERING (Continued)

Page 1416 of 2339

CONDITION POSSIBLE CAUSES CORRECTION

AERATED FLUID.* 1. Low fluid level. 1. Fill power steering fluid reservoir to

proper level.

2. Air leak at supply hose, power

steering fluid reservoir or pump.2. Inspect for proper sealing. Repair as

necessary.

3. Cracked power steering pump

housing.3. Replace the power steering pump.

RESERVOIR FLUID

OVERFLOW AND FLUID

THAT IS MILKY IN COLOR1. Water contamination of power

steering fluid.1. Drain the power steering fluid from the

system. Flush the system with fresh clean

power steering fluid, drain, then refill to the

proper level.

* NOTE: Extremely cold temperatures may cause

power steering fluid aeration. Aeration should sub-

side as fluid warms.

SPECIFICATIONS

POWER STEERING FASTENER TORQUE

DESCRIPTION TORQUE

Power Steering Pump:

Flow Control Valve

Pressure Fitting75 N´m (55 ft. lbs.)

Mounting Bolts 54 N´m (40 ft. lbs.)

Rear Bracket To Engine

Mounting Bolts54 N´m (40 ft. lbs.)

Steering Gear:

Mounting Bolt - Size-M14 183 N´m (135 ft. lbs.)

Mounting Bolts -

Size-M1295 N´m (70 ft. lbs.)

Tie Rod Steering Knuckle

Nut75 N´m (55 ft. lbs.)

Tie Rod Jam Nut 75 N´m (55 ft. lbs.)

Coupling Pinch Bolt 28 N´m (250 in. lbs.)

Power Steering Fluid

Hoses:

Hose Tube Nuts 31 N´m (275 in. lbs.)

Routing Bracket Bolts 23 N´m (200 in. lbs.)

SPECIAL TOOLS

POWER STEERING

Power Steering Analyzer 6815

Adapters, Power Steering Analyzer 6893

Hose, Power Steering Analyzer 6959

RSSTEERING19-9

STEERING (Continued)

Page 1422 of 2339

(24) Disconnect the shift cable at the lever pin

(Fig. 15).

(25) Disconnect the shift cable at the bracket, then

feed the cable out through bracket. (Fig. 15).

(26) Remove the hair pin, then the pinch bolt (Fig.

16). Disconnect the column coupling.

(27) Loosen the column lower mounting nuts (Fig.

17).

(28) Remove the column upper mounting nuts

(Fig. 17).(29) Remove the steering column (Fig. 17).

(30) If the steering column is being replaced,

remove the set-screw fastening the multi-function

switch mounting housing to the column (Fig. 18).

Fig. 15 Shift Cable Attachment To Column

1 - LEVER PIN

2 - SHIFT CABLE

3 - BRACKET

Fig. 16 Pinch Bolt

1 - PINCH BOLT

2 - STEERING COLUMN

Fig. 17 Steering Column Mounting

1 - STEERING COLUMN

2 - UPPER MOUNTING NUTS

3 - LOWER MOUNTING NUTS

4 - MOUNTING STUDS

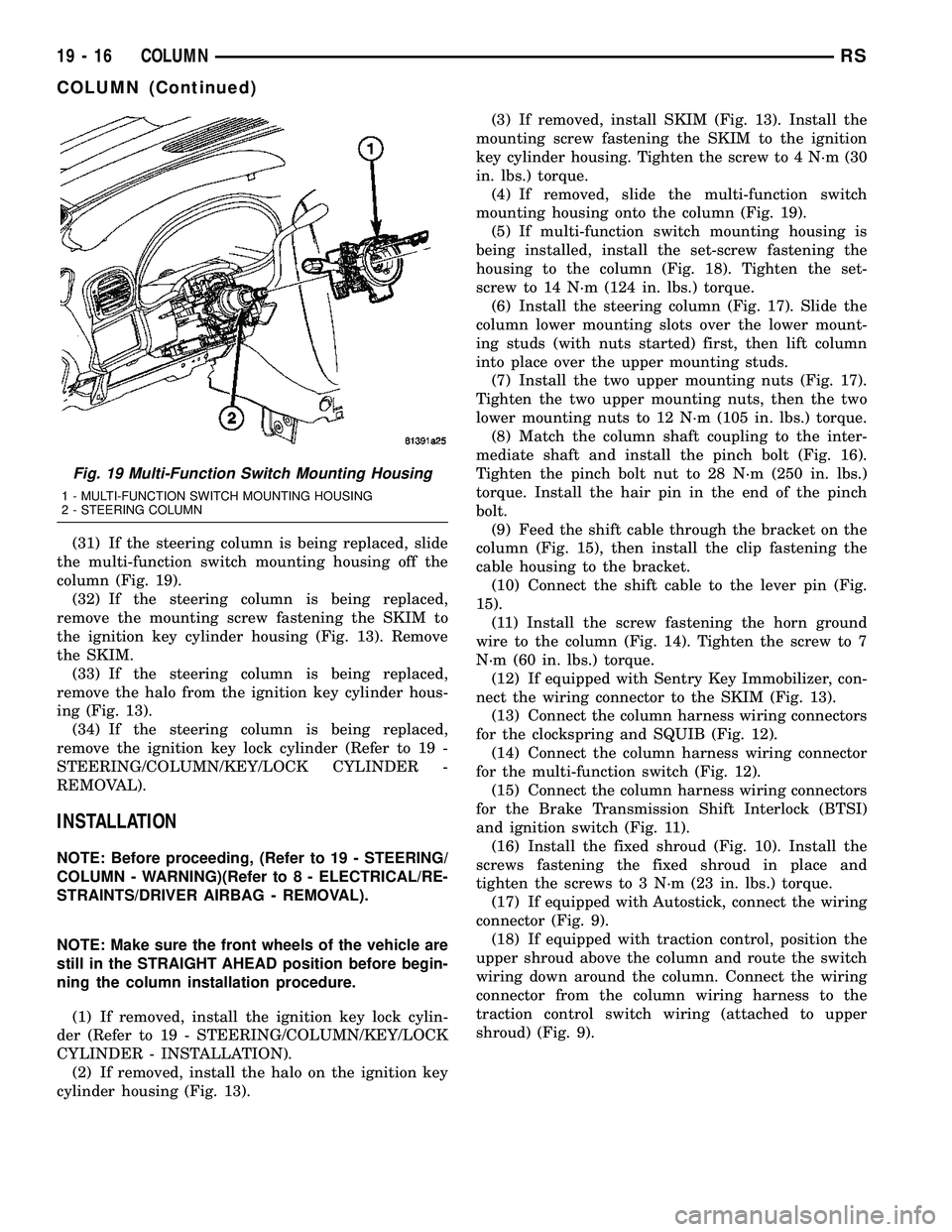

Fig. 18 Multi-Function Switch Mounting Housing

Set-Screw

1 - MULTI-FUNCTION SWITCH MOUNTING HOUSING

2 - STEERING COLUMN

3 - SET-SCREW

RSCOLUMN19-15

COLUMN (Continued)

Page 1423 of 2339

(31) If the steering column is being replaced, slide

the multi-function switch mounting housing off the

column (Fig. 19).

(32) If the steering column is being replaced,

remove the mounting screw fastening the SKIM to

the ignition key cylinder housing (Fig. 13). Remove

the SKIM.

(33) If the steering column is being replaced,

remove the halo from the ignition key cylinder hous-

ing (Fig. 13).

(34) If the steering column is being replaced,

remove the ignition key lock cylinder (Refer to 19 -

STEERING/COLUMN/KEY/LOCK CYLINDER -

REMOVAL).

INSTALLATION

NOTE: Before proceeding, (Refer to 19 - STEERING/

COLUMN - WARNING)(Refer to 8 - ELECTRICAL/RE-

STRAINTS/DRIVER AIRBAG - REMOVAL).

NOTE: Make sure the front wheels of the vehicle are

still in the STRAIGHT AHEAD position before begin-

ning the column installation procedure.

(1) If removed, install the ignition key lock cylin-

der (Refer to 19 - STEERING/COLUMN/KEY/LOCK

CYLINDER - INSTALLATION).

(2) If removed, install the halo on the ignition key

cylinder housing (Fig. 13).(3) If removed, install SKIM (Fig. 13). Install the

mounting screw fastening the SKIM to the ignition

key cylinder housing. Tighten the screw to 4 N´m (30

in. lbs.) torque.

(4) If removed, slide the multi-function switch

mounting housing onto the column (Fig. 19).

(5) If multi-function switch mounting housing is

being installed, install the set-screw fastening the

housing to the column (Fig. 18). Tighten the set-

screw to 14 N´m (124 in. lbs.) torque.

(6) Install the steering column (Fig. 17). Slide the

column lower mounting slots over the lower mount-

ing studs (with nuts started) first, then lift column

into place over the upper mounting studs.

(7) Install the two upper mounting nuts (Fig. 17).

Tighten the two upper mounting nuts, then the two

lower mounting nuts to 12 N´m (105 in. lbs.) torque.

(8) Match the column shaft coupling to the inter-

mediate shaft and install the pinch bolt (Fig. 16).

Tighten the pinch bolt nut to 28 N´m (250 in. lbs.)

torque. Install the hair pin in the end of the pinch

bolt.

(9) Feed the shift cable through the bracket on the

column (Fig. 15), then install the clip fastening the

cable housing to the bracket.

(10) Connect the shift cable to the lever pin (Fig.

15).

(11) Install the screw fastening the horn ground

wire to the column (Fig. 14). Tighten the screw to 7

N´m (60 in. lbs.) torque.

(12) If equipped with Sentry Key Immobilizer, con-

nect the wiring connector to the SKIM (Fig. 13).

(13) Connect the column harness wiring connectors

for the clockspring and SQUIB (Fig. 12).

(14) Connect the column harness wiring connector

for the multi-function switch (Fig. 12).

(15) Connect the column harness wiring connectors

for the Brake Transmission Shift Interlock (BTSI)

and ignition switch (Fig. 11).

(16) Install the fixed shroud (Fig. 10). Install the

screws fastening the fixed shroud in place and

tighten the screws to 3 N´m (23 in. lbs.) torque.

(17) If equipped with Autostick, connect the wiring

connector (Fig. 9).

(18) If equipped with traction control, position the

upper shroud above the column and route the switch

wiring down around the column. Connect the wiring

connector from the column wiring harness to the

traction control switch wiring (attached to upper

shroud) (Fig. 9).

Fig. 19 Multi-Function Switch Mounting Housing

1 - MULTI-FUNCTION SWITCH MOUNTING HOUSING

2 - STEERING COLUMN

19 - 16 COLUMNRS

COLUMN (Continued)

Page 1433 of 2339

GEAR

TABLE OF CONTENTS

page page

GEAR

DESCRIPTION.........................26

OPERATION...........................26

WARNING

WARNINGS AND CAUTIONS.............26

REMOVAL

REMOVAL - LHD GEAR.................26

REMOVAL - RHD GEAR................29INSTALLATION

INSTALLATION - LHD GEAR.............31

INSTALLATION - RHD GEAR.............33

SPECIAL TOOLS

POWER STEERING GEAR..............34

OUTER TIE ROD

REMOVAL.............................34

INSTALLATION.........................35

GEAR

DESCRIPTION

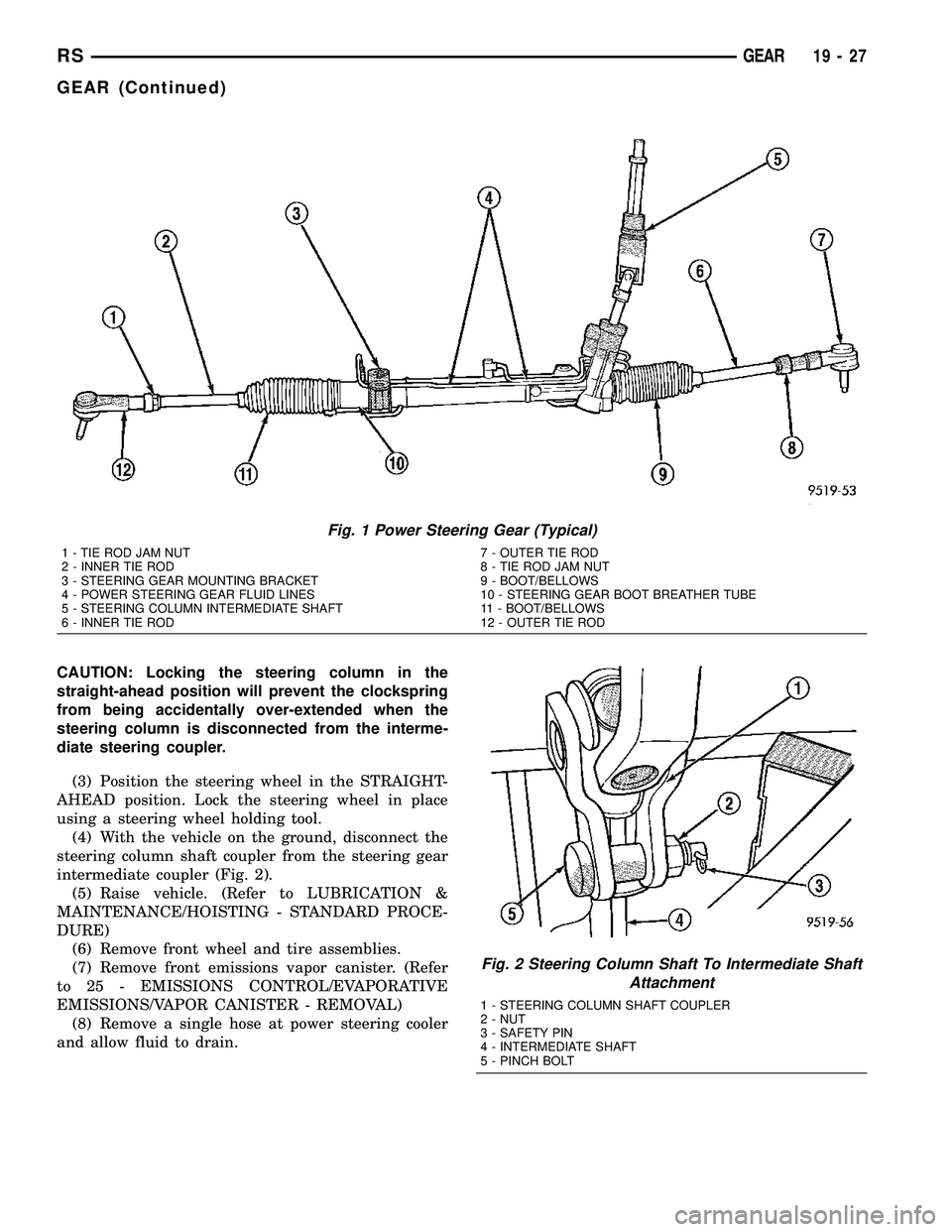

This vehicle is equipped with a rack and pinion

power steering gear (Fig. 1). It is mounted to the

underside of the front suspension cradle/crossmem-

ber.

The steering column is attached to the gear

through the use of an intermediate shaft and cou-

plers. The outer ends of the power steering gear's

outer tie rods connect to the steering knuckles.

NOTE: The power steering gear should NOT be ser-

viced or adjusted unless DaimlerChrysler Corpora-

tion authorizes. If a malfunction or oil leak occurs,

the complete steering gear should be replaced.

Only the outer tie rods may be replaced separately

from the rest of the gear.

OPERATION

Turning of the steering wheel is converted into lin-

ear (side-to-side) travel through the meshing of the

helical pinion teeth with the rack teeth in the steer-

ing gear. This travel pushes and pulls the tie rods to

change the direction of the vehicle's front wheels.

Power assist steering provided by the power steer-

ing pump is controlled by an open center, rotary type

control valve which directs oil from the pump to

either side of the integral rack piston upon demand.

Road feel is controlled by the diameter of a torsion

bar which initially steers the vehicle. As required

steering effort increases, as in a turn, the torsion bar

twists, causing relative rotary motion between the

rotary valve body and the valve spool. This move-

ment directs oil behind the integral rack piston

which, in turn, builds hydraulic pressure and assists

in the turning effort.Manual steering control of the vehicle can be main-

tained if power steering assist is lost. However,

under this condition, steering effort is significantly

increased.

WARNING

WARNINGS AND CAUTIONS

WARNING: POWER STEERING FLUID, ENGINE

PARTS AND EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH THE ENGINE OFF TO PREVENT PERSONAL

INJURY FROM MOVING PARTS.

CAUTION: When the system is open, cap all open

ends of the hoses, power steering pump fittings or

power steering gear ports to prevent entry of for-

eign material into the components.

REMOVAL

REMOVAL - LHD GEAR

(1) Remove cap from power steering fluid reser-

voir.

(2) Using a siphon pump, remove as much fluid as

possible from the power steering fluid reservoir.Use

care not to damage the filter mesh below the

fluid surface.

19 - 26 GEARRS

Page 1434 of 2339

CAUTION: Locking the steering column in the

straight-ahead position will prevent the clockspring

from being accidentally over-extended when the

steering column is disconnected from the interme-

diate steering coupler.

(3) Position the steering wheel in the STRAIGHT-

AHEAD position. Lock the steering wheel in place

using a steering wheel holding tool.

(4) With the vehicle on the ground, disconnect the

steering column shaft coupler from the steering gear

intermediate coupler (Fig. 2).

(5) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(6) Remove front wheel and tire assemblies.

(7) Remove front emissions vapor canister. (Refer

to 25 - EMISSIONS CONTROL/EVAPORATIVE

EMISSIONS/VAPOR CANISTER - REMOVAL)

(8) Remove a single hose at power steering cooler

and allow fluid to drain.

Fig. 1 Power Steering Gear (Typical)

1 - TIE ROD JAM NUT

2 - INNER TIE ROD

3 - STEERING GEAR MOUNTING BRACKET

4 - POWER STEERING GEAR FLUID LINES

5 - STEERING COLUMN INTERMEDIATE SHAFT

6 - INNER TIE ROD7 - OUTER TIE ROD

8 - TIE ROD JAM NUT

9 - BOOT/BELLOWS

10 - STEERING GEAR BOOT BREATHER TUBE

11 - BOOT/BELLOWS

12 - OUTER TIE ROD

Fig. 2 Steering Column Shaft To Intermediate Shaft

Attachment

1 - STEERING COLUMN SHAFT COUPLER

2 - NUT

3 - SAFETY PIN

4 - INTERMEDIATE SHAFT

5 - PINCH BOLT

RSGEAR19-27

GEAR (Continued)

Page 1437 of 2339

(11) Remove both tie rod ends from steering

knuckles using Puller, Special Tool C-3894±A (Fig. 5).

Fig. 7 Hoses To Power Steering Gear - 3.3L/3.8L Engine

1 - RETURN HOSE (TO RESERVOIR)

2 - PRESSURE HOSE (FROM PUMP)

3 - CRADLE CROSSMEMBER

4 - PRESSURE HOSE ROUTING CLAMP

5 - RETURN HOSE ROUTING CLAMP

6 - PRESSURE HOSE TUBE NUT7 - POWER STEERING GEAR

8 - ABS BRACKET

9 - ROUTING CLIP

10 - LEAK DETECTION PUMP FILTER

11 - RETURN HOSE TUBE NUT

12 - ROUTING CLIP

Fig. 8 Steering Gear Mounting To Suspension Cradle

1 - POWER STEERING GEAR

2 - MOUNTING BOLTS (12 MM)

3 - MOUNTING BOLT (14 MM)

4 - FRONT SUSPENSION CRADLE CROSSMEMBER

Fig. 9 Removing Roll Pin From Intermediate Coupler

1 - INTERMEDIATE COUPLER

2 - KNURLED NUT

3 - SUSPENSION CRADLE

4 - REMOVER SPECIAL TOOL 6831A

5 - STEERING GEAR

6 - NUT

7 - ROLL PIN

8 - THREADED ROD

19 - 30 GEARRS

GEAR (Continued)

Page 1444 of 2339

DESCRIPTION - PUMP (DIESEL)

Hydraulic pressure for the operation of the power

steering gear is provided by a belt driven power

steering pump. The power steering pump is mounted

front lower right corner of the engine (Fig. 13).

The pump has a supply fitting for fluid coming

from the reservoir and a pressure port for exiting

fluid that is headed for the steering gear.

OPERATION

The power steering pump is a constant displace-

ment vane type pump. The 2.4L pump has an inte-

gral fluid reservoir and there is a secondary remote

non-flow reservoir which acts only as a fluid fill and

check point. The 3.3L/3.8L pump houses very little

fluid and is therefore supplied by a remote flow

through reservoir.

WARNING

WARNING: POWER STEERING FLUID, ENGINE

PARTS AND EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH THE ENGINE OFF TO PREVENT PERSONAL

INJURY FROM MOVING PARTS.

CAUTION

CAUTION: When the system is open, cap all open

ends of the hoses, power steering pump fittings or

power steering gear ports to prevent entry of for-

eign material into the components.

STANDARD PROCEDURE - POWER STEERING

PUMP INITIAL OPERATION

WARNING: FLUID LEVEL SHOULD BE CHECKED

AND ADJUSTED WITH ENGINE OFF TO PREVENT

INJURY FROM MOVING ENGINE COMPONENTS.

CAUTION: Use only MoparTAutomatic Transmis-

sion Fluid (MS-9602) in power steering system. Use

of other MoparTpower steering fluids (MS5931 and

MS9933) should be avoided to ensure peak perfor-

mance of the power steering system under all oper-

ating conditions. Do not overfill.

Fig. 1 POWER STEERING PUMP (2.4L)

1 - PULLEY

2 - BRACKET

3 - PRESSURE FITTING

4 - RETURN FITTING

5 - SUPPLY FITTING

Fig. 2 POWER STEERING PUMP (3.3L/3.8L)

1 - SUPPLY FITTING

2 - PRESSURE FITTING

3 - PULLEY

RSPUMP19-37

PUMP (Continued)

Page 1445 of 2339

Read the fluid level through the side of the power

steering fluid reservoir. The fluid level should indi-

cateªFILL RANGEºwhen the fluid is at a temper-

ature of approximately 21ÉC to 27ÉC (70ÉF to 80ÉF).

(1) Wipe the filler cap and area clean, then remove

the cap.

(2) Fill the fluid reservoir to the proper level and

let the fluid settle for at least two (2) minutes.

(3) Start the engine and let run for a few seconds,

then turn the engine off.

(4) Add fluid if necessary. Repeat the above steps

until the fluid level remains constant after running

the engine.

(5) Raise the front wheels off the ground.

(6) Start the engine.

(7) Slowly turn the steering wheel right and left,

lightly contacting the wheel stops.

(8) Add fluid if necessary.

(9) Lower the vehicle, then turn the steering wheel

slowly from lock-to-lock.

(10) Stop the engine. Check the fluid level and

refill as required.

(11) If the fluid is extremely foamy, allow the vehi-

cle to stabilize a few minutes, then repeat the above

procedure.

REMOVAL

REMOVAL - PUMP (2.4L ENGINE)

(1) Remove the (-) negative battery cable from the

battery and isolate cable.

(2) Remove the cap from the power steering fluid

reservoir.

(3) Using a siphon pump, remove as much power

steering fluid as possible from the power steering

fluid reservoir.

(4) Raise the vehicle on jack stands or centered on

a frame contact type hoist. See Hoisting in Lubrica-

tion and Maintenance.

(5) Disconnect the oxygen sensor wiring harness

from the vehicle wiring harness at the rear engine

mount bracket.

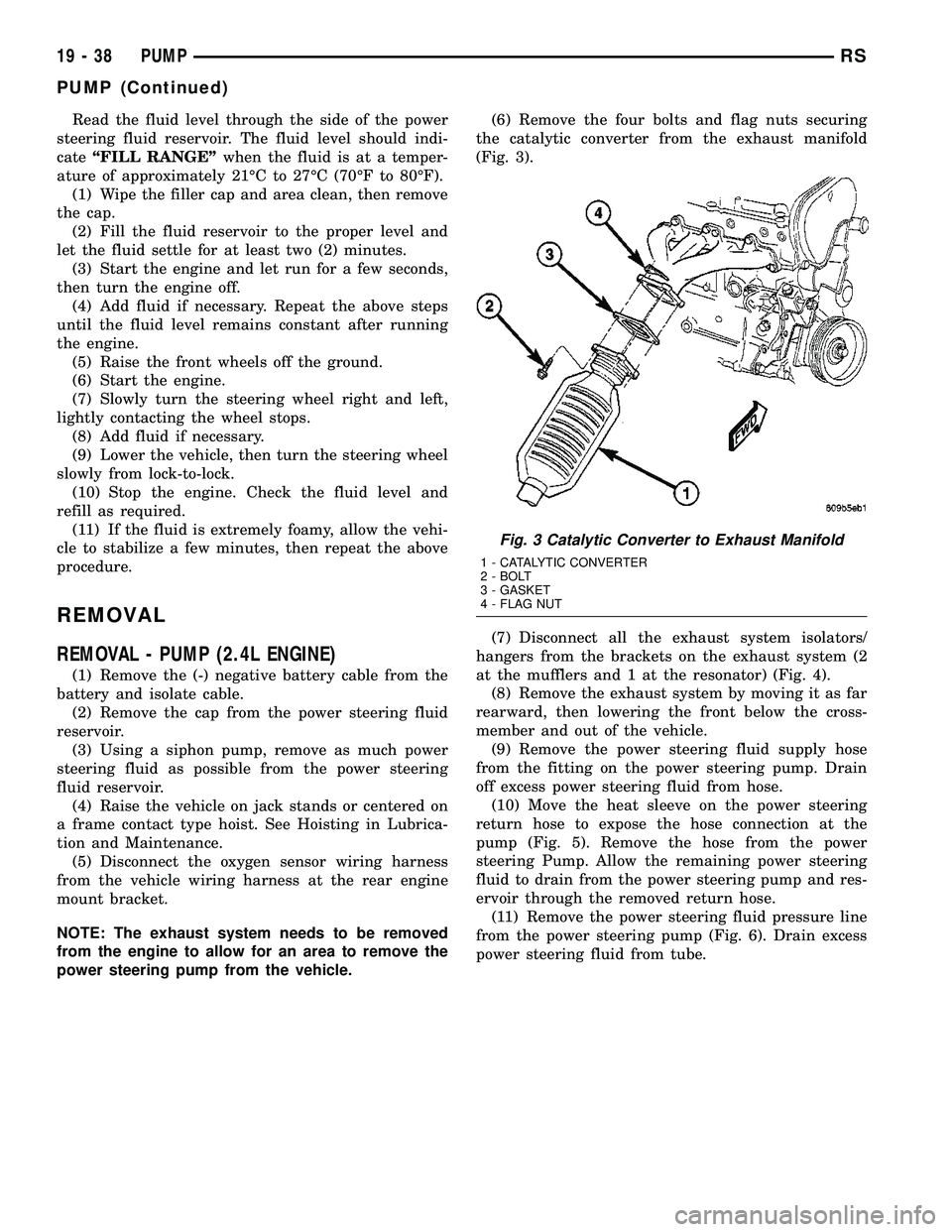

NOTE: The exhaust system needs to be removed

from the engine to allow for an area to remove the

power steering pump from the vehicle.(6) Remove the four bolts and flag nuts securing

the catalytic converter from the exhaust manifold

(Fig. 3).

(7) Disconnect all the exhaust system isolators/

hangers from the brackets on the exhaust system (2

at the mufflers and 1 at the resonator) (Fig. 4).

(8) Remove the exhaust system by moving it as far

rearward, then lowering the front below the cross-

member and out of the vehicle.

(9) Remove the power steering fluid supply hose

from the fitting on the power steering pump. Drain

off excess power steering fluid from hose.

(10) Move the heat sleeve on the power steering

return hose to expose the hose connection at the

pump (Fig. 5). Remove the hose from the power

steering Pump. Allow the remaining power steering

fluid to drain from the power steering pump and res-

ervoir through the removed return hose.

(11) Remove the power steering fluid pressure line

from the power steering pump (Fig. 6). Drain excess

power steering fluid from tube.

Fig. 3 Catalytic Converter to Exhaust Manifold

1 - CATALYTIC CONVERTER

2 - BOLT

3 - GASKET

4 - FLAG NUT

19 - 38 PUMPRS

PUMP (Continued)

Page 1447 of 2339

(12) Remove the fasteners, then the accessory

drive splash shield.

(13) Remove the adjuster nut attaching rear of

power steering pump to the cast mounting bracket.

(Fig. 7)

(14) Remove the front adjuster nut and the lower

pivot bolt (Fig. 8) attaching power steering pump

bracket to cast bracket.

(15) Remove the drive belt from the power steering

pump pulley.

(16) Remove the power steering pump and the

front bracket from the cast bracket on the engine as

an assembly through the exhaust tunnel.(17) Remove the 3 bolts attaching the front

bracket to the power steering pump and separate the

power steering pump from the front bracket.

(18) If the power steering pump pulley needs to be

transferred, (Refer to 19 - STEERING/PUMP - DIS-

ASSEMBLY).

REMOVAL - PUMP (3.3L/3.8L ENGINE)

(1) Remove the (-) negative battery cable from the

battery and isolate cable.

(2) Remove the wiper module (unit)(Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER MOD-

ULE - REMOVAL).

(3) Raise the vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(4) Remove the drive belt splash shield.

(5) Remove the pressure hose routing bracket bolt

(Fig. 9).

(6) lower the vehicle.

(7) Remove cap from power steering fluid reser-

voir.

(8) Using a siphon pump, remove as much power

steering fluid as possible from the power steering

fluid reservoir.

(9) Disconnect the pressure hose from the pump

(Fig. 10).

(10) Disconnect the fluid supply hose from the

pump (Fig. 10).

Fig. 7 Power Steering Pump Attaching Nut

1 - POWER STEERING PUMP MOUNTING BRACKET

2 - FRONT SUSPENSION CRADLE

3 - POWER STEERING PUMP

4 - ADJUSTER NUT

Fig. 8 Pump Front Mounting

1 - ADJUSTER NUT

2 - PIVOT BOLT

3 - PUMP

Fig. 9 Pressure Hose Routing Clamp

1 - PRESSURE HOSE TUBE

2 - STEERING GEAR

3 - CRADLE CROSSMEMBER

4 - DRIVESHAFT

5 - ROUTING CLAMP BRACKET

19 - 40 PUMPRS

PUMP (Continued)