Water CHRYSLER VOYAGER 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 14 of 2339

LUBRICATION & MAINTENANCE

TABLE OF CONTENTS

page page

INTERNATIONAL SYMBOLS

DESCRIPTION..........................1

FLUID TYPES

DESCRIPTION

DESCRIPTION - ENGINE OIL AND

LUBRICANTS.........................1

DESCRIPTION - ENGINE COOLANT........3

DESCRIPTION - FLEXIBLE FUEL ENGINE

OIL .................................3

DESCRIPTION - AUTOMATIC/MANUAL

TRANSAXLE FLUID.....................4

DESCRIPTION - FUEL REQUIREMENTS.....4

DESCRIPTION - FUEL REQUIREMENTS -

DIESEL ENGINE.......................6

DESCRIPTION - ENGINE OIL - DIESEL

ENGINES............................6

DESCRIPTION - AWD REAR DRIVELINE

MODULE FLUIDS......................6

DESCRIPTION - AWD POWER TRANSFER

UNIT FLUID...........................6FLUID CAPACITIES

SPECIFICATIONS - FLUID CAPACITIES.......6

FLUID FILL/CHECK LOCATIONS

DESCRIPTION..........................7

LUBRICATION POINTS

DESCRIPTION..........................7

MAINTENANCE SCHEDULES

DESCRIPTION

DESCRIPTION........................7

DESCRIPTION - EXPORT...............13

DESCRIPTION - DIESEL ENGINES -

EXPORT............................21

HOISTING

STANDARD PROCEDURE - HOISTING.......24

JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING . 25

TOWING

STANDARD PROCEDURE - TOWING........26

INTERNATIONAL SYMBOLS

DESCRIPTION

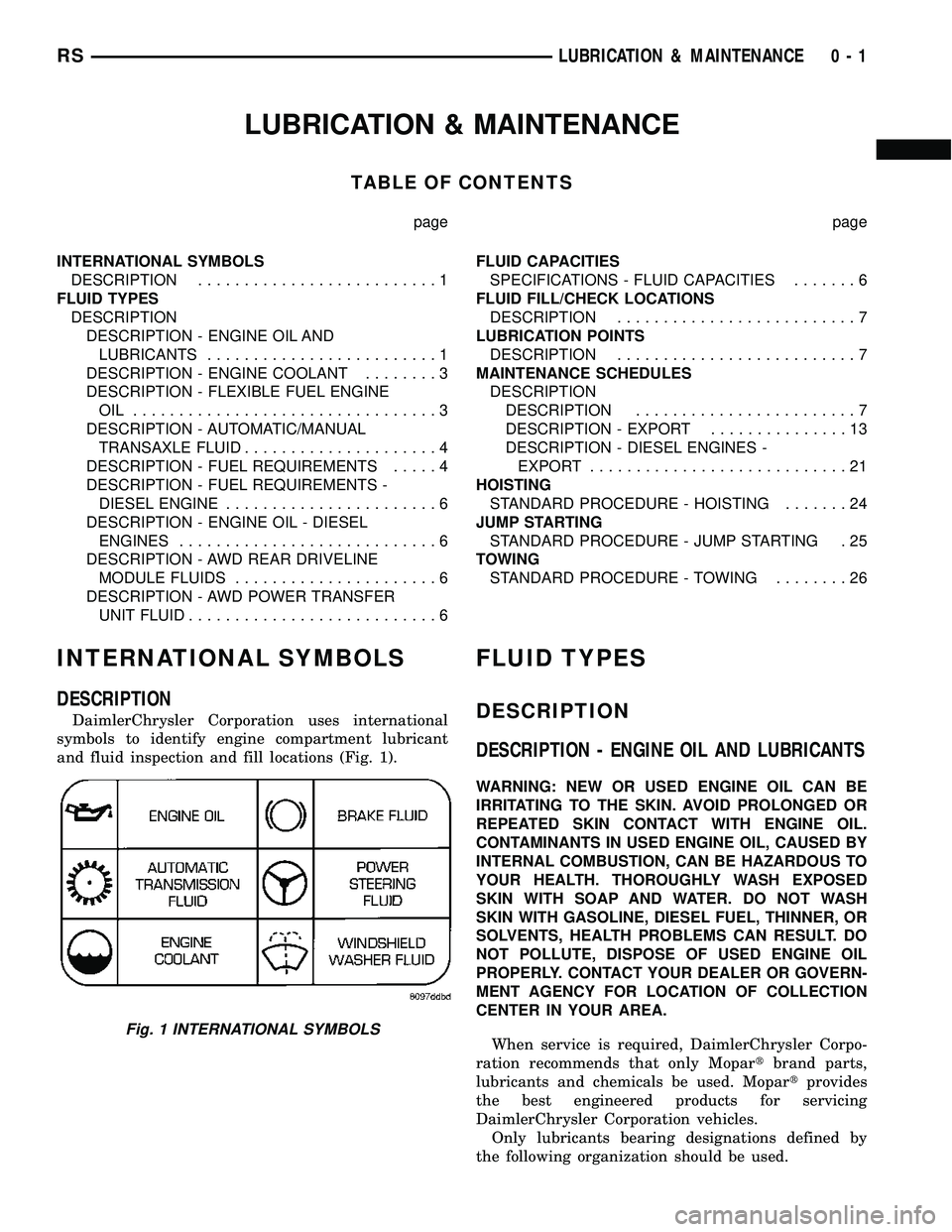

DaimlerChrysler Corporation uses international

symbols to identify engine compartment lubricant

and fluid inspection and fill locations (Fig. 1).

FLUID TYPES

DESCRIPTION

DESCRIPTION - ENGINE OIL AND LUBRICANTS

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY. CONTACT YOUR DEALER OR GOVERN-

MENT AGENCY FOR LOCATION OF COLLECTION

CENTER IN YOUR AREA.

When service is required, DaimlerChrysler Corpo-

ration recommends that only Mopartbrand parts,

lubricants and chemicals be used. Mopartprovides

the best engineered products for servicing

DaimlerChrysler Corporation vehicles.

Only lubricants bearing designations defined by

the following organization should be used.

Fig. 1 INTERNATIONAL SYMBOLS

RSLUBRICATION & MAINTENANCE0-1

Page 16 of 2339

letter ªGº. Chassis lubricant is identified by the letter

ªLº. The letter following the usage letter indicates

the quality of the lubricant. The following symbols

indicate the highest quality.

SPECIALIZED LUBRICANTS AND OILS

Some maintenance or repair procedures may

require the use of specialized lubricants or oils. Con-

sult the appropriate sections in this manual for the

correct application of these lubricants.

DESCRIPTION - ENGINE COOLANT

WARNING: ANTIFREEZE IS AN ETHYLENE GLYCOL

BASE COOLANT AND IS HARMFUL IF SWAL-

LOWED OR INHALED. IF SWALLOWED, DRINK

TWO GLASSES OF WATER AND INDUCE VOMIT-

ING. IF INHALED, MOVE TO FRESH AIR AREA.

SEEK MEDICAL ATTENTION IMMEDIATELY. DO NOT

STORE IN OPEN OR UNMARKED CONTAINERS.

WASH SKIN AND CLOTHING THOROUGHLY AFTER

COMING IN CONTACT WITH ETHYLENE GLYCOL.

KEEP OUT OF REACH OF CHILDREN. DISPOSE OF

GLYCOL BASE COOLANT PROPERLY, CONTACT

YOUR DEALER OR GOVERNMENT AGENCY FOR

LOCATION OF COLLECTION CENTER IN YOUR

AREA. DO NOT OPEN A COOLING SYSTEM WHEN

THE ENGINE IS AT OPERATING TEMPERATURE OR

HOT UNDER PRESSURE, PERSONAL INJURY CAN

RESULT. AVOID RADIATOR COOLING FAN WHEN

ENGINE COMPARTMENT RELATED SERVICE IS

PERFORMED, PERSONAL INJURY CAN RESULT.

CAUTION: Use of Propylene Glycol based coolants

is not recommended, as they provide less freeze

protection and less boiling protection.

The cooling system is designed around the coolant.

The coolant must accept heat from engine metal, in

the cylinder head area near the exhaust valves and

engine block. Then coolant carries the heat to theradiator where the tube/fin radiator can transfer the

heat to the air.

The use of aluminum cylinder blocks, cylinder

heads, and water pumps requires special corrosion

protection. MopartAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769), or the equiva-

lent ethylene glycol base coolant with hybrid organic

corrosion inhibitors (called HOAT, for Hybrid Organic

Additive Technology) is recommended. This coolant

offers the best engine cooling without corrosion when

mixed with 50% Ethylene Glycol and 50% distilled

water to obtain a freeze point of -37ÉC (-35ÉF). If it

loses color or becomes contaminated, drain, flush,

and replace with fresh properly mixed coolant solu-

tion.

The green coolantMUST NOT BE MIXEDwith

the orange or magenta coolants. When replacing cool-

ant the complete system flush must be performed

before using the replacement coolant.

CAUTION: MoparTAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769) may not be

mixed with any other type of antifreeze. Doing so

will reduce the corrosion protection and may result

in premature water pump seal failure. If non-HOAT

coolant is introduced into the cooling system in an

emergency, it should be replaced with the specified

coolant as soon as possible.

DESCRIPTION - FLEXIBLE FUEL ENGINE OIL

The information in this section is for Flexible Fuel

Vehicles (FFV) only. These vehicles can be identified

by the unique Fuel Filler Door Label that states

Ethanol (E-85) or Unleaded Gasoline Only. This sec-

tion only covers those subjects that are unique to

these vehicles. Please refer to the other sections of

this manual for information on features that are

common between Flexible Fuel and gasoline only

powered vehicles.

ETHANOL FUEL (E-85)

E-85 is a mixture of approximately 85% fuel etha-

nol and 15% unleaded gasoline.

WARNING: Ethanol vapors are extremely flammable

and could cause serious personal injury. Never

have any smoking materials lit in or near the vehi-

cle when removing the fuel filler tube cap (gas cap)

or filling the tank. Do not use E-85 as a cleaning

agent and never use it near an open flame.

FUEL REQUIREMENTS

The vehicle will operate on both unleaded gasoline

with an octane rating of 87, or E-85 fuel, or any mix-

ture of these two.

Fig. 4 NLGI SYMBOL

1 - WHEEL BEARINGS

2 - CHASSIS LUBRICATION

3 - CHASSIS AND WHEEL BEARINGS

RSLUBRICATION & MAINTENANCE0-3

FLUID TYPES (Continued)

Page 19 of 2339

DESCRIPTION - FUEL REQUIREMENTS -

DIESEL ENGINE

WARNING: DO NOT USE ALCOHOL OR GASOLINE

AS A FUEL BLENDING AGENT. THEY CAN BE

UNSTABLE UNDER CERTAIN CONDITIONS AND

HAZARDOUS OR EXPLOSIVE WHEN MIXED WITH

DIESEL FUEL.

Use good quality diesel fuel from a reputable sup-

plier. For most year-round service, number 2 diesel

fuel meeting DIN EN 590 (Class0-4)will provide

good performance. If the vehicle is exposed to

extreme cold (below -18ÉC/0ÉF) or is required to oper-

ate at colder than normal conditions for prolonged

periods, use climatize No. 2 diesel fuel or dilute the

No. 2 diesel fuel with 50% No. 1 diesel fuel as long as

it meets ASTM D 975: 1D and 2D and the quality of

lubrication behavior is in accordance with DIN EN

590. This will provide better protection from fuel gel-

ling or wax plugging of the fuel filters.

Diesel fuel is seldom completely free of water. To

prevent fuel system trouble, including fuel line freez-

ing in winter, drain the accumulated water from the

fuel/water separator using the fuel/water separator

drain provided. If you buy good quality fuel and follow

the cold weather advice above, fuel conditioners should

not be required in your vehicle. If available in your

area, a high cetane ªpremiumº diesel fuel may offer

improved cold starting and warm up performance.

DESCRIPTION - ENGINE OIL - DIESEL

ENGINES

Use only Diesel Engine Oil meeting standardMIL-

2104Cor API ClassificationCD or higherorCCML

D4, D5.

SAE VISCOSITY GRADE

CAUTION: Low viscosity oils must have the proper

API quality or the CCMC G5 designation.

To assure of properly formulated engine oils, it is

recommended that SAE Grade 10W-40 engine oils

that meet Chrysler material standard MS-6395, be

used in accordance to ACEA B3, B4 specification.

European Grade 10W-40 oils are also acceptable.

Oils of the SAE 5W-40 grade number are preferred

when minimum temperatures consistently fall below

-15ÉC.

DESCRIPTION - AWD REAR DRIVELINE

MODULE FLUIDS

The AWD Rear Driveline Module Assembly consists

of two subassemblies, the Overrunning Clutch Hous-

ing (front) and the Differential Carrier (rear).The recommended lubricant for the Overrunning

Clutch Housing is MopartATF+4. The recommended

lubricant for the Differential Carrier is Mopart

80W-90 Gear and Axle Lubricant.

DESCRIPTION - AWD POWER TRANSFER UNIT

FLUID

The recommended lubricant for the AWD Power

Transfer Unit is MopartGear and Axle Lubricant

80W-90.

FLUID CAPACITIES

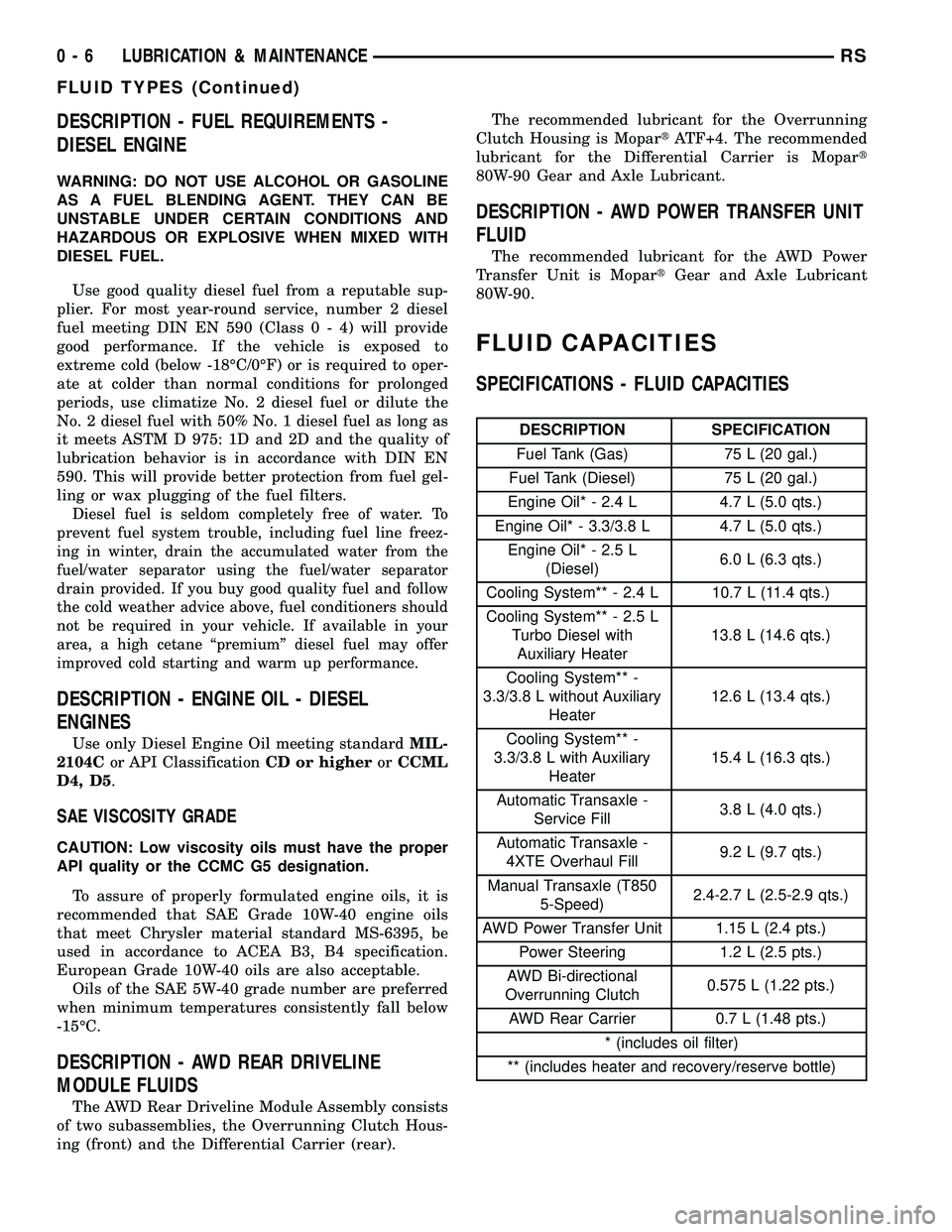

SPECIFICATIONS - FLUID CAPACITIES

DESCRIPTION SPECIFICATION

Fuel Tank (Gas) 75 L (20 gal.)

Fuel Tank (Diesel) 75 L (20 gal.)

Engine Oil* - 2.4 L 4.7 L (5.0 qts.)

Engine Oil* - 3.3/3.8 L 4.7 L (5.0 qts.)

Engine Oil* - 2.5 L

(Diesel)6.0 L (6.3 qts.)

Cooling System** - 2.4 L 10.7 L (11.4 qts.)

Cooling System** - 2.5 L

Turbo Diesel with

Auxiliary Heater13.8 L (14.6 qts.)

Cooling System** -

3.3/3.8 L without Auxiliary

Heater12.6 L (13.4 qts.)

Cooling System** -

3.3/3.8 L with Auxiliary

Heater15.4 L (16.3 qts.)

Automatic Transaxle -

Service Fill3.8 L (4.0 qts.)

Automatic Transaxle -

4XTE Overhaul Fill9.2 L (9.7 qts.)

Manual Transaxle (T850

5-Speed)2.4-2.7 L (2.5-2.9 qts.)

AWD Power Transfer Unit 1.15 L (2.4 pts.)

Power Steering 1.2 L (2.5 pts.)

AWD Bi-directional

Overrunning Clutch0.575 L (1.22 pts.)

AWD Rear Carrier 0.7 L (1.48 pts.)

* (includes oil filter)

** (includes heater and recovery/reserve bottle)

0 - 6 LUBRICATION & MAINTENANCERS

FLUID TYPES (Continued)

Page 35 of 2339

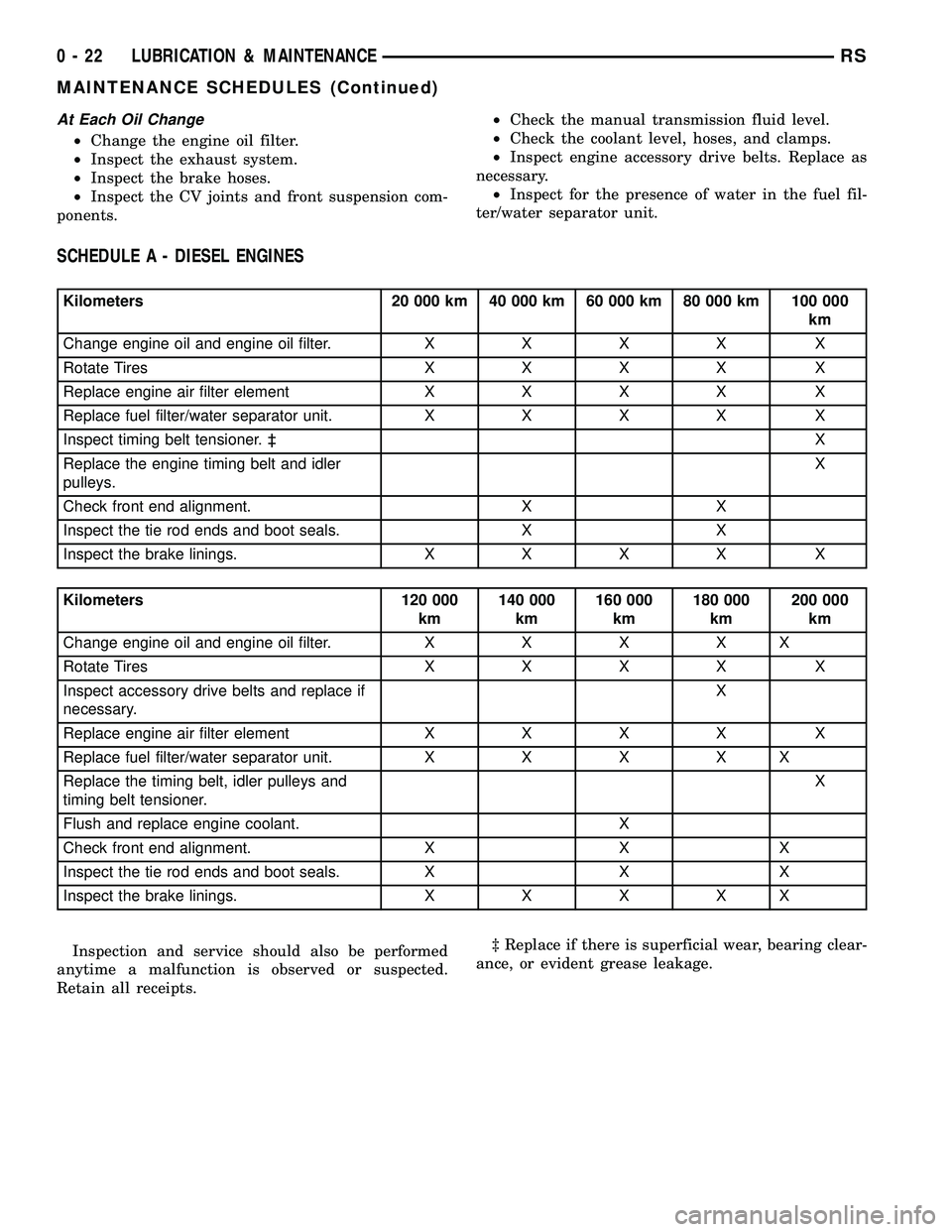

At Each Oil Change

²Change the engine oil filter.

²Inspect the exhaust system.

²Inspect the brake hoses.

²Inspect the CV joints and front suspension com-

ponents.²Check the manual transmission fluid level.

²Check the coolant level, hoses, and clamps.

²Inspect engine accessory drive belts. Replace as

necessary.

²Inspect for the presence of water in the fuel fil-

ter/water separator unit.

SCHEDULE A - DIESEL ENGINES

Kilometers 20 000 km 40 000 km 60 000 km 80 000 km 100 000

km

Change engine oil and engine oil filter.XXXX X

Rotate TiresXXXX X

Replace engine air filter elementXXXX X

Replace fuel filter/water separator unit.XXXX X

Inspect timing belt tensioner. ³X

Replace the engine timing belt and idler

pulleys.X

Check front end alignment. X X

Inspect the tie rod ends and boot seals. X X

Inspect the brake linings.XXXX X

Kilometers 120 000

km140 000

km160 000

km180 000

km200 000

km

Change engine oil and engine oil filter.XXXXX

Rotate TiresXXXX X

Inspect accessory drive belts and replace if

necessary.X

Replace engine air filter elementXXXX X

Replace fuel filter/water separator unit.XXXXX

Replace the timing belt, idler pulleys and

timing belt tensioner.X

Flush and replace engine coolant. X

Check front end alignment. X X X

Inspect the tie rod ends and boot seals. X X X

Inspect the brake linings.XXXXX

Inspection and service should also be performed

anytime a malfunction is observed or suspected.

Retain all receipts.³ Replace if there is superficial wear, bearing clear-

ance, or evident grease leakage.

0 - 22 LUBRICATION & MAINTENANCERS

MAINTENANCE SCHEDULES (Continued)

Page 36 of 2339

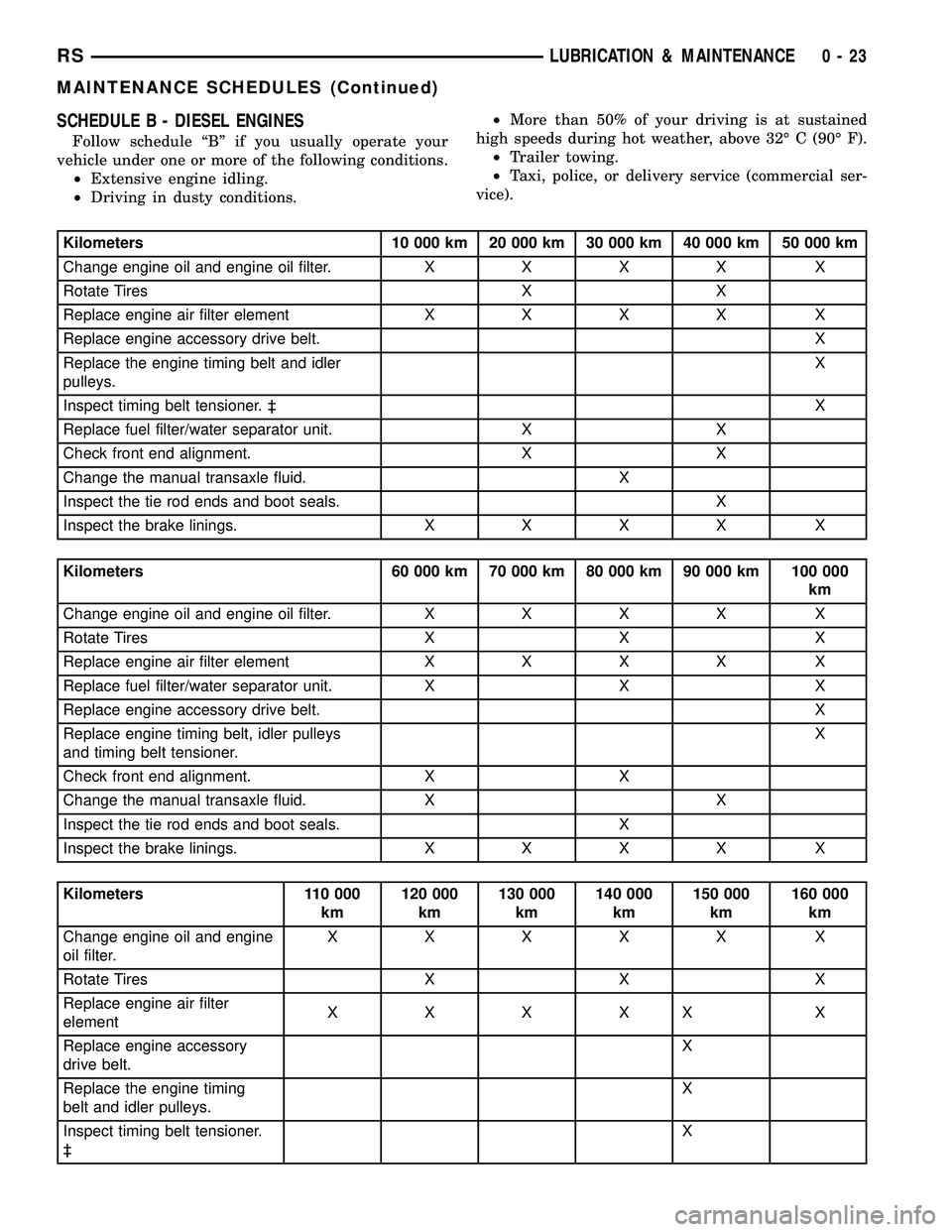

SCHEDULE B - DIESEL ENGINES

Follow schedule ªBº if you usually operate your

vehicle under one or more of the following conditions.

²Extensive engine idling.

²Driving in dusty conditions.²More than 50% of your driving is at sustained

high speeds during hot weather, above 32É C (90É F).

²Trailer towing.

²Taxi, police, or delivery service (commercial ser-

vice).

Kilometers 10 000 km 20 000 km 30 000 km 40 000 km 50 000 km

Change engine oil and engine oil filter.XXXX X

Rotate Tires X X

Replace engine air filter elementXXXX X

Replace engine accessory drive belt. X

Replace the engine timing belt and idler

pulleys.X

Inspect timing belt tensioner. ³X

Replace fuel filter/water separator unit. X X

Check front end alignment. X X

Change the manual transaxle fluid. X

Inspect the tie rod ends and boot seals. X

Inspect the brake linings.XXXX X

Kilometers 60 000 km 70 000 km 80 000 km 90 000 km 100 000

km

Change engine oil and engine oil filter.XXXX X

Rotate Tires X X X

Replace engine air filter elementXXXX X

Replace fuel filter/water separator unit. X X X

Replace engine accessory drive belt. X

Replace engine timing belt, idler pulleys

and timing belt tensioner.X

Check front end alignment. X X

Change the manual transaxle fluid. X X

Inspect the tie rod ends and boot seals. X

Inspect the brake linings.XXXX X

Kilometers 110 000

km120 000

km130 000

km140 000

km150 000

km160 000

km

Change engine oil and engine

oil filter.XXXXX X

Rotate Tires X X X

Replace engine air filter

elementXXXXX X

Replace engine accessory

drive belt.X

Replace the engine timing

belt and idler pulleys.X

Inspect timing belt tensioner.

³X

RSLUBRICATION & MAINTENANCE0-23

MAINTENANCE SCHEDULES (Continued)

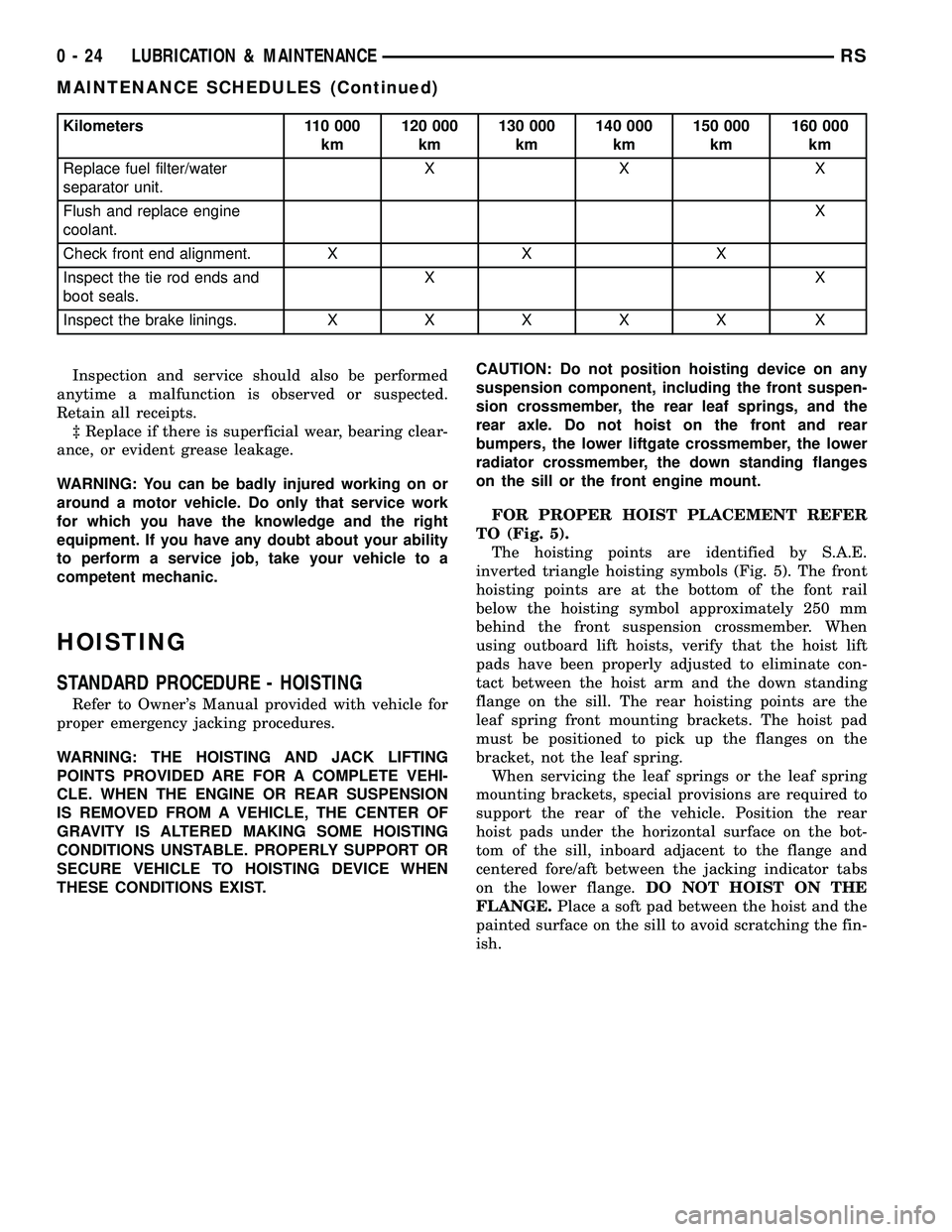

Page 37 of 2339

Kilometers 110 000

km120 000

km130 000

km140 000

km150 000

km160 000

km

Replace fuel filter/water

separator unit.XX X

Flush and replace engine

coolant.X

Check front end alignment. X X X

Inspect the tie rod ends and

boot seals.XX

Inspect the brake linings. XXXXX X

Inspection and service should also be performed

anytime a malfunction is observed or suspected.

Retain all receipts.

³ Replace if there is superficial wear, bearing clear-

ance, or evident grease leakage.

WARNING: You can be badly injured working on or

around a motor vehicle. Do only that service work

for which you have the knowledge and the right

equipment. If you have any doubt about your ability

to perform a service job, take your vehicle to a

competent mechanic.

HOISTING

STANDARD PROCEDURE - HOISTING

Refer to Owner's Manual provided with vehicle for

proper emergency jacking procedures.

WARNING: THE HOISTING AND JACK LIFTING

POINTS PROVIDED ARE FOR A COMPLETE VEHI-

CLE. WHEN THE ENGINE OR REAR SUSPENSION

IS REMOVED FROM A VEHICLE, THE CENTER OF

GRAVITY IS ALTERED MAKING SOME HOISTING

CONDITIONS UNSTABLE. PROPERLY SUPPORT OR

SECURE VEHICLE TO HOISTING DEVICE WHEN

THESE CONDITIONS EXIST.CAUTION: Do not position hoisting device on any

suspension component, including the front suspen-

sion crossmember, the rear leaf springs, and the

rear axle. Do not hoist on the front and rear

bumpers, the lower liftgate crossmember, the lower

radiator crossmember, the down standing flanges

on the sill or the front engine mount.

FOR PROPER HOIST PLACEMENT REFER

TO (Fig. 5).

The hoisting points are identified by S.A.E.

inverted triangle hoisting symbols (Fig. 5). The front

hoisting points are at the bottom of the font rail

below the hoisting symbol approximately 250 mm

behind the front suspension crossmember. When

using outboard lift hoists, verify that the hoist lift

pads have been properly adjusted to eliminate con-

tact between the hoist arm and the down standing

flange on the sill. The rear hoisting points are the

leaf spring front mounting brackets. The hoist pad

must be positioned to pick up the flanges on the

bracket, not the leaf spring.

When servicing the leaf springs or the leaf spring

mounting brackets, special provisions are required to

support the rear of the vehicle. Position the rear

hoist pads under the horizontal surface on the bot-

tom of the sill, inboard adjacent to the flange and

centered fore/aft between the jacking indicator tabs

on the lower flange.DO NOT HOIST ON THE

FLANGE.Place a soft pad between the hoist and the

painted surface on the sill to avoid scratching the fin-

ish.

0 - 24 LUBRICATION & MAINTENANCERS

MAINTENANCE SCHEDULES (Continued)

Page 52 of 2339

REMOVAL

REMOVAL

(1) Remove steering knuckle from vehicle. (Refer

to 2 - SUSPENSION/FRONT/KNUCKLE -

REMOVAL)

(2) Using a screwdriver or other suitable tool, pry

seal boot off of ball joint (Fig. 17).

(3) Inspect ball joint for evidence of dirt or water

intrusion and wipe clean as necessary. If dirt or

water intrusion is extreme and joint cannot be prop-

erly cleaned, lower control arm will need to be

replaced. (Refer to 2 - SUSPENSION/FRONT/

LOWER CONTROL ARM - REMOVAL)

REMOVAL - EXPORT

(1) Remove steering knuckle from vehicle. (Refer

to 2 - SUSPENSION/FRONT/KNUCKLE -

REMOVAL)

(2) Remove shield from seal boot by gently pulling

on it.

(3) Using a screw driver or other suitable tool, pry

seal boot off lower ball joint.

INSTALLATION

INSTALLATION

(1) Place a liberal dab of MopartWheel Bearing

Grease around base of ball joint stud at socket.(2) Install aNEWseal boot by hand as far as pos-

sible on ball joint. Ensure seal boot shield is posi-

tioned outward from control arm as shown (Fig. 18).

CAUTION: Do not use an arbor press to install seal

boot on ball joint. Damage to seal boot will occur if

excessive pressure is applied while it is being

installed.

(3) Place Installer, Special Tool 6758, over top of

seal boot and squarely align it with bottom edge of

seal boot (Fig. 19). Apply hand pressure (or gently

tap with a hammer if necessary) to top of Installer

until seal boot is pressed squarely down against top

surface of lower control arm.

(4) Wipe any grease off ball joint stem using a

clean shop towel with MopartBrake Parts Cleaner

applied to it.

CAUTION: Do not attempt to install a normal grease

zirc in ball joint in an effort to lubricate joint

through zirc fitting.

(5) Install steering knuckle on vehicle. (Refer to 2 -

SUSPENSION/FRONT/KNUCKLE - INSTALLA-

TION)

INSTALLATION - EXPORT

(1) Place a liberal dab of MopartWheel Bearing

Grease around the base of the ball joint stem at the

socket.

(2) Install aNEWseal boot by hand as far as pos-

sible on the ball joint.

Fig. 17 Ball Joint Seal Boot Removal

1 - BALL JOINT STUD

2 - SCREWDRIVER

3 - SEAL BOOT

Fig. 18 Ball Joint Seal Boot Installed Position

1 - BALL JOINT STUD

2 - LOWER CONTROL ARM

3 - SEAL BOOT SHIELD

RSFRONT SUSPENSION2-11

LOWER BALL JOINT SEAL BOOT (Continued)

Page 115 of 2339

WARNING

WARNING: DUST AND DIRT ACCUMULATING ON

BRAKE PARTS DURING NORMAL USE MAY CON-

TAIN ASBESTOS FIBERS FROM PRODUCTION OR

AFTERMARKET BRAKE LININGS. BREATHING

EXCESSIVE CONCENTRATIONS OF ASBESTOS

FIBERS CAN CAUSE SERIOUS BODILY HARM.

EXERCISE CARE WHEN SERVICING BRAKE

PARTS. DO NOT SAND OR GRIND BRAKE LINING

UNLESS EQUIPMENT USED IS DESIGNED TO CON-

TAIN THE DUST RESIDUE. DO NOT CLEAN BRAKE

PARTS WITH COMPRESSED AIR OR BY DRY

BRUSHING. CLEANING SHOULD BE DONE BY

DAMPENING THE BRAKE COMPONENTS WITH A

FINE MIST OF WATER, THEN WIPING THE BRAKE

COMPONENTS CLEAN WITH A DAMPENED CLOTH.

DISPOSE OF CLOTH AND ALL RESIDUE CONTAIN-

ING ASBESTOS FIBERS IN AN IMPERMEABLE

CONTAINER WITH THE APPROPRIATE LABEL. FOL-

LOW PRACTICES PRESCRIBED BY THE OCCUPA-

TIONAL SAFETY AND HEALTH ADMINISTRATION

(OSHA) AND THE ENVIRONMENTAL PROTECTION

AGENCY (EPA) FOR THE HANDLING, PROCESSING,

AND DISPOSING OF DUST OR DEBRIS THAT MAY

CONTAIN ASBESTOS FIBERS.

CAUTION

CAUTION: During service procedures, grease or

any other foreign material must be kept off brake

shoes and braking surfaces of brake rotor or drum,

and external surfaces of hub and bearing assembly.

CAUTION: Brake rotor and caliper handling must be

done in such a way as to avoid damage to the rotor,

especially the machined surfaces, and scratching or

nicking of the brake linings.

CAUTION: Only the recommended jacking or hoist-

ing procedures for this vehicle are to be used

whenever it is necessary to lift a vehicle. Failure to

raise a vehicle utilizing the recommended lift points

can result in damage to the vehicle. (Refer to

LUBRICATION & MAINTENANCE/HOISTING - STAN-

DARD PROCEDURE)

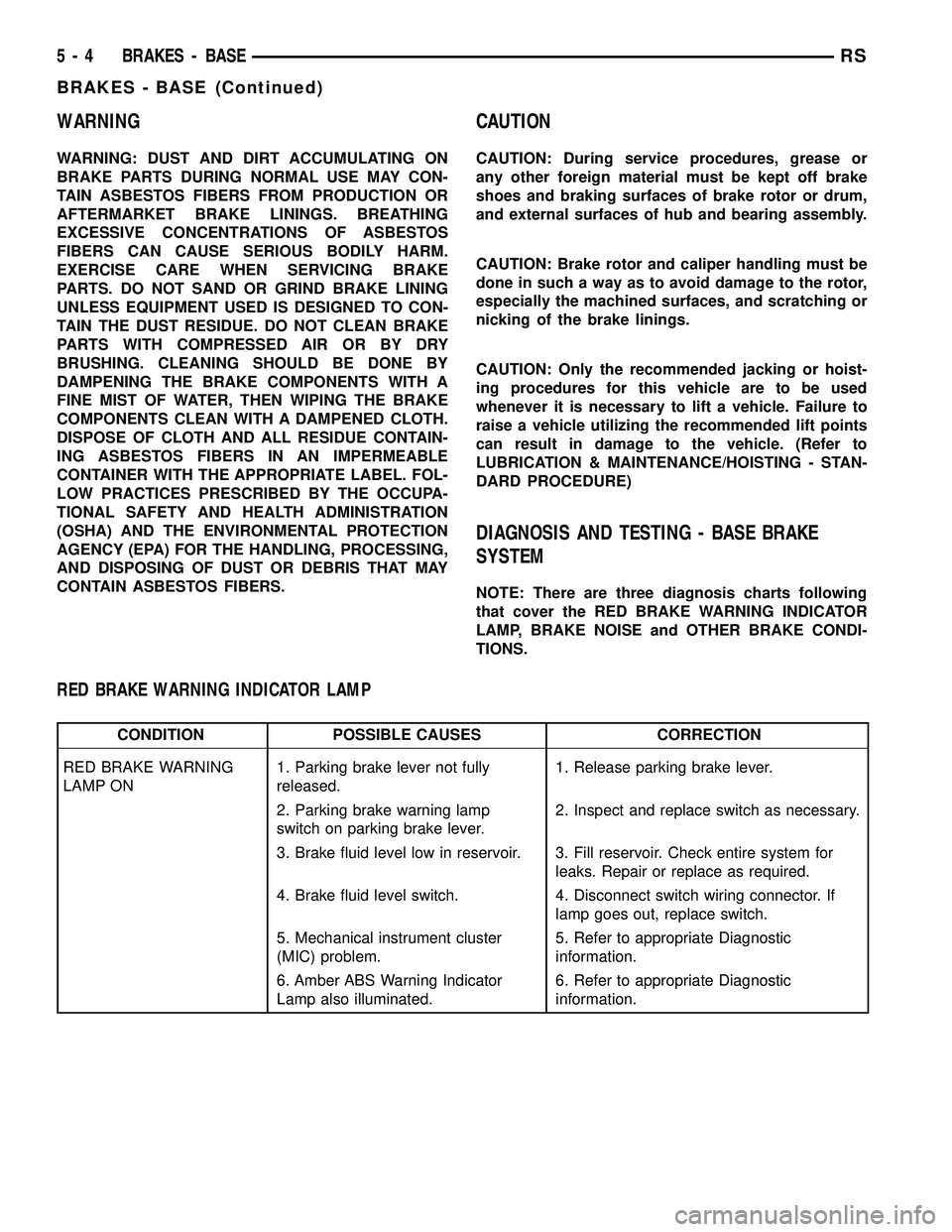

DIAGNOSIS AND TESTING - BASE BRAKE

SYSTEM

NOTE: There are three diagnosis charts following

that cover the RED BRAKE WARNING INDICATOR

LAMP, BRAKE NOISE and OTHER BRAKE CONDI-

TIONS.

RED BRAKE WARNING INDICATOR LAMP

CONDITION POSSIBLE CAUSES CORRECTION

RED BRAKE WARNING

LAMP ON1. Parking brake lever not fully

released.1. Release parking brake lever.

2. Parking brake warning lamp

switch on parking brake lever.2. Inspect and replace switch as necessary.

3. Brake fluid level low in reservoir. 3. Fill reservoir. Check entire system for

leaks. Repair or replace as required.

4. Brake fluid level switch. 4. Disconnect switch wiring connector. If

lamp goes out, replace switch.

5. Mechanical instrument cluster

(MIC) problem.5. Refer to appropriate Diagnostic

information.

6. Amber ABS Warning Indicator

Lamp also illuminated.6. Refer to appropriate Diagnostic

information.

5 - 4 BRAKES - BASERS

BRAKES - BASE (Continued)

Page 127 of 2339

(4) Remove the disc brake caliper from the disc

brake adapter and hang out of the way using wire or

a bungee cord. Use care not to overextend the brake

hose when doing this.

(5) Remove the brake shoes from the disc brake

caliper adapter.

CLEANING - DISC BRAKE SHOES

WARNING: DUST AND DIRT ACCUMULATING ON

BRAKE PARTS DURING NORMAL USE MAY CON-

TAIN ASBESTOS FIBERS FROM PRODUCTION OR

AFTERMARKET BRAKE LININGS. BREATHING

EXCESSIVE CONCENTRATIONS OF ASBESTOS

FIBERS CAN CAUSE SERIOUS BODILY HARM.

EXERCISE CARE WHEN SERVICING BRAKE

PARTS. DO NOT SAND OR GRIND BRAKE LINING

UNLESS EQUIPMENT USED IS DESIGNED TO CON-

TAIN THE DUST RESIDUE. DO NOT CLEAN BRAKE

PARTS WITH COMPRESSED AIR OR BY DRY

BRUSHING. CLEANING SHOULD BE DONE BY

DAMPENING THE BRAKE COMPONENTS WITH A

FINE MIST OF WATER, THEN WIPING THE BRAKE

COMPONENTS CLEAN WITH A DAMPENED CLOTH.

DISPOSE OF CLOTH AND ALL RESIDUE CONTAIN-

ING ASBESTOS FIBERS IN AN IMPERMEABLE

CONTAINER WITH THE APPROPRIATE LABEL. FOL-

LOW PRACTICES PRESCRIBED BY THE OCCUPA-

TIONAL SAFETY AND HEALTH ADMINISTRATION

(OSHA) AND THE ENVIRONMENTAL PROTECTION

AGENCY (EPA) FOR THE HANDLING, PROCESSING,

AND DISPOSING OF DUST OR DEBRIS THAT MAY

CONTAIN ASBESTOS FIBERS.

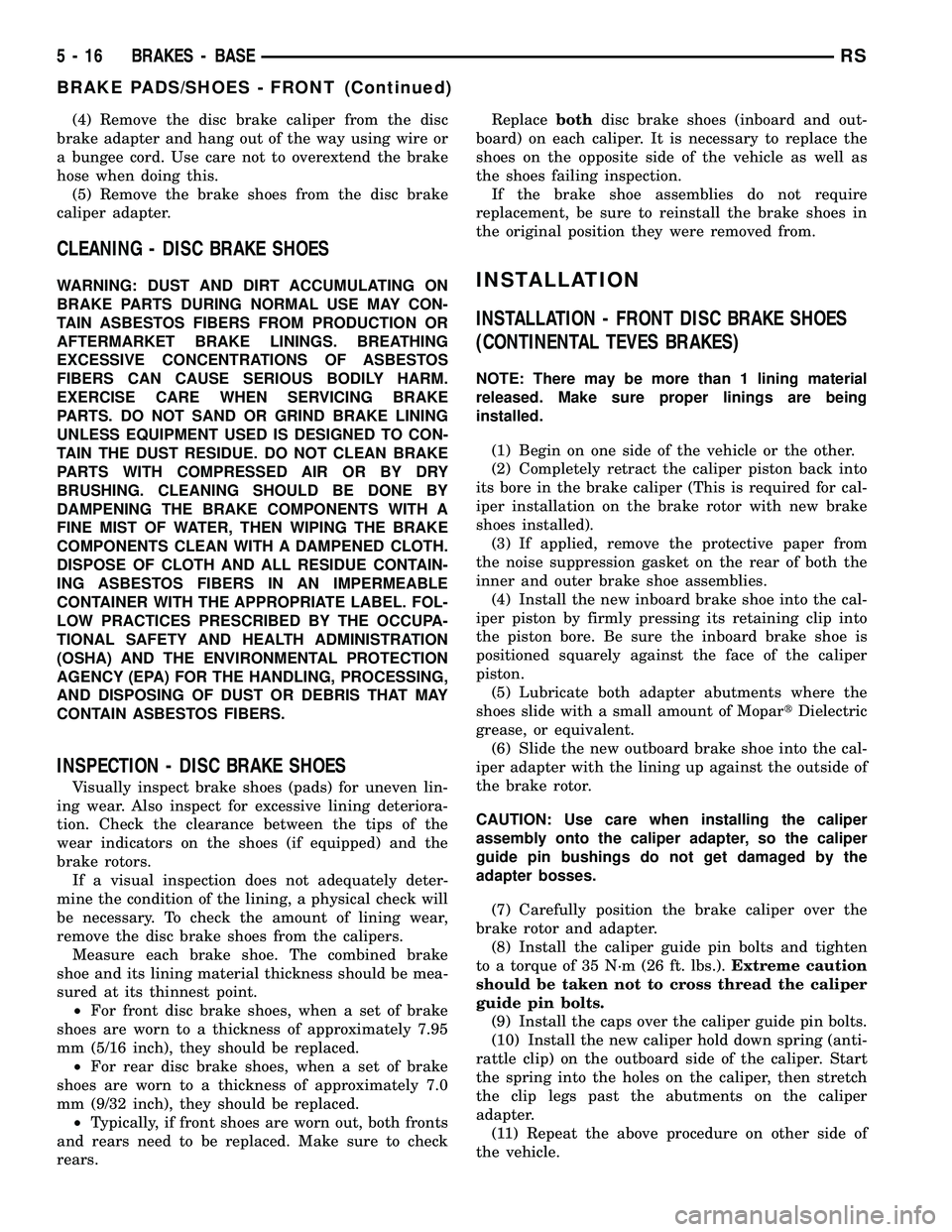

INSPECTION - DISC BRAKE SHOES

Visually inspect brake shoes (pads) for uneven lin-

ing wear. Also inspect for excessive lining deteriora-

tion. Check the clearance between the tips of the

wear indicators on the shoes (if equipped) and the

brake rotors.

If a visual inspection does not adequately deter-

mine the condition of the lining, a physical check will

be necessary. To check the amount of lining wear,

remove the disc brake shoes from the calipers.

Measure each brake shoe. The combined brake

shoe and its lining material thickness should be mea-

sured at its thinnest point.

²For front disc brake shoes, when a set of brake

shoes are worn to a thickness of approximately 7.95

mm (5/16 inch), they should be replaced.

²For rear disc brake shoes, when a set of brake

shoes are worn to a thickness of approximately 7.0

mm (9/32 inch), they should be replaced.

²Typically, if front shoes are worn out, both fronts

and rears need to be replaced. Make sure to check

rears.Replacebothdisc brake shoes (inboard and out-

board) on each caliper. It is necessary to replace the

shoes on the opposite side of the vehicle as well as

the shoes failing inspection.

If the brake shoe assemblies do not require

replacement, be sure to reinstall the brake shoes in

the original position they were removed from.

INSTALLATION

INSTALLATION - FRONT DISC BRAKE SHOES

(CONTINENTAL TEVES BRAKES)

NOTE: There may be more than 1 lining material

released. Make sure proper linings are being

installed.

(1) Begin on one side of the vehicle or the other.

(2) Completely retract the caliper piston back into

its bore in the brake caliper (This is required for cal-

iper installation on the brake rotor with new brake

shoes installed).

(3) If applied, remove the protective paper from

the noise suppression gasket on the rear of both the

inner and outer brake shoe assemblies.

(4) Install the new inboard brake shoe into the cal-

iper piston by firmly pressing its retaining clip into

the piston bore. Be sure the inboard brake shoe is

positioned squarely against the face of the caliper

piston.

(5) Lubricate both adapter abutments where the

shoes slide with a small amount of MopartDielectric

grease, or equivalent.

(6) Slide the new outboard brake shoe into the cal-

iper adapter with the lining up against the outside of

the brake rotor.

CAUTION: Use care when installing the caliper

assembly onto the caliper adapter, so the caliper

guide pin bushings do not get damaged by the

adapter bosses.

(7) Carefully position the brake caliper over the

brake rotor and adapter.

(8) Install the caliper guide pin bolts and tighten

to a torque of 35 N´m (26 ft. lbs.).Extreme caution

should be taken not to cross thread the caliper

guide pin bolts.

(9) Install the caps over the caliper guide pin bolts.

(10) Install the new caliper hold down spring (anti-

rattle clip) on the outboard side of the caliper. Start

the spring into the holes on the caliper, then stretch

the clip legs past the abutments on the caliper

adapter.

(11) Repeat the above procedure on other side of

the vehicle.

5 - 16 BRAKES - BASERS

BRAKE PADS/SHOES - FRONT (Continued)

Page 129 of 2339

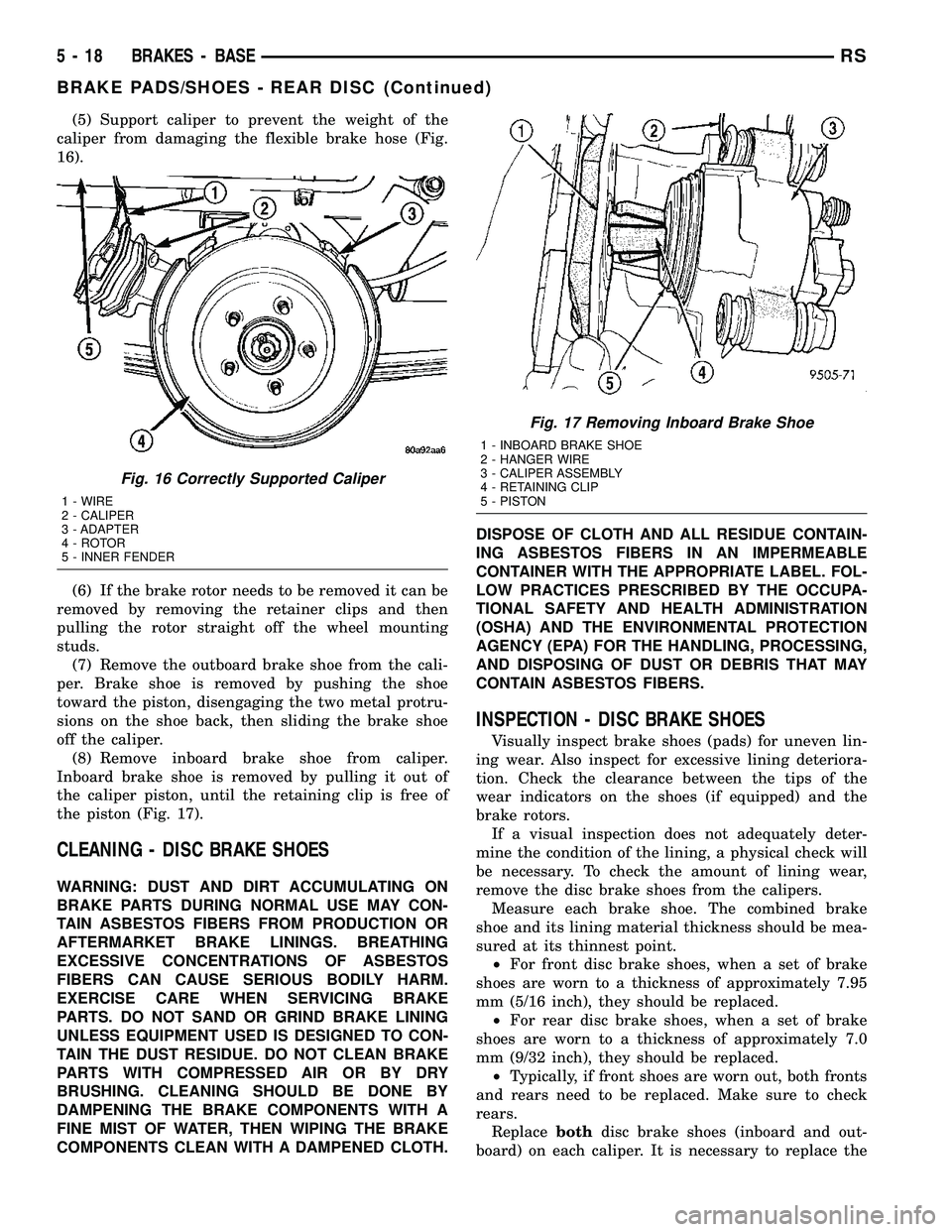

(5) Support caliper to prevent the weight of the

caliper from damaging the flexible brake hose (Fig.

16).

(6) If the brake rotor needs to be removed it can be

removed by removing the retainer clips and then

pulling the rotor straight off the wheel mounting

studs.

(7) Remove the outboard brake shoe from the cali-

per. Brake shoe is removed by pushing the shoe

toward the piston, disengaging the two metal protru-

sions on the shoe back, then sliding the brake shoe

off the caliper.

(8) Remove inboard brake shoe from caliper.

Inboard brake shoe is removed by pulling it out of

the caliper piston, until the retaining clip is free of

the piston (Fig. 17).

CLEANING - DISC BRAKE SHOES

WARNING: DUST AND DIRT ACCUMULATING ON

BRAKE PARTS DURING NORMAL USE MAY CON-

TAIN ASBESTOS FIBERS FROM PRODUCTION OR

AFTERMARKET BRAKE LININGS. BREATHING

EXCESSIVE CONCENTRATIONS OF ASBESTOS

FIBERS CAN CAUSE SERIOUS BODILY HARM.

EXERCISE CARE WHEN SERVICING BRAKE

PARTS. DO NOT SAND OR GRIND BRAKE LINING

UNLESS EQUIPMENT USED IS DESIGNED TO CON-

TAIN THE DUST RESIDUE. DO NOT CLEAN BRAKE

PARTS WITH COMPRESSED AIR OR BY DRY

BRUSHING. CLEANING SHOULD BE DONE BY

DAMPENING THE BRAKE COMPONENTS WITH A

FINE MIST OF WATER, THEN WIPING THE BRAKE

COMPONENTS CLEAN WITH A DAMPENED CLOTH.DISPOSE OF CLOTH AND ALL RESIDUE CONTAIN-

ING ASBESTOS FIBERS IN AN IMPERMEABLE

CONTAINER WITH THE APPROPRIATE LABEL. FOL-

LOW PRACTICES PRESCRIBED BY THE OCCUPA-

TIONAL SAFETY AND HEALTH ADMINISTRATION

(OSHA) AND THE ENVIRONMENTAL PROTECTION

AGENCY (EPA) FOR THE HANDLING, PROCESSING,

AND DISPOSING OF DUST OR DEBRIS THAT MAY

CONTAIN ASBESTOS FIBERS.

INSPECTION - DISC BRAKE SHOES

Visually inspect brake shoes (pads) for uneven lin-

ing wear. Also inspect for excessive lining deteriora-

tion. Check the clearance between the tips of the

wear indicators on the shoes (if equipped) and the

brake rotors.

If a visual inspection does not adequately deter-

mine the condition of the lining, a physical check will

be necessary. To check the amount of lining wear,

remove the disc brake shoes from the calipers.

Measure each brake shoe. The combined brake

shoe and its lining material thickness should be mea-

sured at its thinnest point.

²For front disc brake shoes, when a set of brake

shoes are worn to a thickness of approximately 7.95

mm (5/16 inch), they should be replaced.

²For rear disc brake shoes, when a set of brake

shoes are worn to a thickness of approximately 7.0

mm (9/32 inch), they should be replaced.

²Typically, if front shoes are worn out, both fronts

and rears need to be replaced. Make sure to check

rears.

Replacebothdisc brake shoes (inboard and out-

board) on each caliper. It is necessary to replace the

Fig. 16 Correctly Supported Caliper

1 - WIRE

2 - CALIPER

3 - ADAPTER

4 - ROTOR

5 - INNER FENDER

Fig. 17 Removing Inboard Brake Shoe

1 - INBOARD BRAKE SHOE

2 - HANGER WIRE

3 - CALIPER ASSEMBLY

4 - RETAINING CLIP

5 - PISTON

5 - 18 BRAKES - BASERS

BRAKE PADS/SHOES - REAR DISC (Continued)