accumulator CHRYSLER VOYAGER 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 200 of 2339

START-UP CYCLE

When the ignition is turned on, a popping sound

and a slight brake pedal movement may be noticed.

The ABS warning lamp will also be on for up to 5

seconds after the ignition is turned on. When the

vehicle is first driven off, a humming may be heard

or felt by the driver at approximately 20±40 kph

(12±25 mph). All of these conditions are a normal

function of ABS as the system is performing a diag-

nosis check.

PREMATURE ABS CYCLING

Symptoms of premature ABS cycling include: click-

ing sounds from the solenoid valves; pump/motor

running; and pulsations in the brake pedal. Prema-

ture ABS cycling can occur at any braking rate of the

vehicle and on any type of road surface. Neither the

red BRAKE warning lamp, nor the amber ABS warn-

ing lamp, illuminate and no fault codes are stored in

the CAB.

Premature ABS cycling is a condition that needs to

be correctly assessed when diagnosing problems with

the antilock brake system. It may be necessary to use

a DRB scan tool to detect and verify premature ABS

cycling.

Check the following common causes when diagnos-

ing premature ABS cycling: damaged tone wheels;

incorrect tone wheels; damaged steering knuckle

wheel speed sensor mounting bosses; loose wheel

speed sensor mounting bolts; excessive tone wheel

runout; or an excessively large tone wheel-to-wheel

speed sensor air gap. Give special attention to these

components when diagnosing a vehicle exhibiting

premature ABS cycling.

After diagnosing the defective component, repair or

replace it as required. When the component repair or

replacement is completed, test drive the vehicle to

verify that premature ABS cycling has been cor-

rected.

OPERATION - ELECTRONIC VARIABLE BRAKE

PROPORTIONING

Upon entry into EVBP the inlet valve for the rear

brake circuit is switched on so that the fluid supply

from the master cylinder is shut off. In order to

decrease the rear brake pressure, the outlet valve for

the rear brake circuit is pulsed. This allows fluid to

enter the low pressure accumulator (LPA) in the

hydraulic control unit (HCU) resulting in a drop in

fluid pressure to the rear brakes. In order to increase

the rear brake pressure, the outlet valve is switched

off and the inlet valve is pulsed. This increases the

pressure to the rear brakes. This back-and-forth pro-

cess will continue until the required slip difference is

obtained. At the end of EVBP braking (brakes

released) the fluid in the LPA drains back to themaster cylinder by switching on the outlet valve and

draining through the inlet valve check valve. At the

same time the inlet valve is switched on in case of

another brake application.

The EVBP will remain functional during many

ABS fault modes. If both the red BRAKE and amber

ABS warning indicators are illuminated, the EVBP

may not be functioning.

OPERATION - TRACTION CONTROL SYSTEM

The traction control module monitors wheel speed.

During acceleration, if the module detects front

(drive) wheel slip and the brakes are not applied, the

module enters traction control mode. Traction control

operation proceeds in the following order:

(1) Close the normally open isolation valves.

(2) Start the pump/motor and supply volume and

pressure to the front (drive) hydraulic circuit. (The

pump/motor runs continuously during traction con-

trol operation.)

(3) Open and close the build and decay valves to

maintain minimum wheel slip and maximum trac-

tion.

The cycling of the build and decay valves during

traction control is similar to that during antilock

braking, except the valves work to control wheel spin

by applying the brakes, whereas the ABS function is

to control wheel skid by releasing the brakes.

If the brakes are applied at anytime during a trac-

tion control cycle, the brake lamp switch triggers the

controller to switch off traction control.

HYDRAULIC SHUTTLE VALVES

Two pressure relief hydraulic shuttle valves allow

pressure and volume to return to the master cylinder

reservoir when not consumed by the build and decay

valves. These valves are necessary because the

pump/motor supplies more volume than the system

requires.

TRACTION CONTROL LAMP

The traction control system is enabled at each igni-

tion cycle. It may be turned off by depressing the

Traction Control Off switch button when the ignition

is in the ON position. The traction control function

lamp (TRAC OFF) illuminates immediately upon

depressing the button.

The traction control function lamp illuminates dur-

ing a traction control cycle, displaying TRAC.

If the CAB calculates that the brake temperatures

are high, the traction control system becomes inoper-

ative until a time-out period has elapsed. During this

ªthermo-protection mode,º the traction control func-

tion lamp illuminates TRAC OFF; note that no trou-

ble code is registered.

RSBRAKES - ABS5-89

BRAKES - ABS (Continued)

Page 206 of 2339

(2) Disconnect traction control switch harness from

column harness (Fig. 5).

(3) Using an ohmmeter, check for continuity

between pins 1 and 2. With the switch actuated,

there should be continuity between the two pins.

With the switch off, there should be no continuity.

REMOVAL

The traction control switch is located in the upper

shroud. (Refer to 19 - STEERING/COLUMN/UPPER

SHROUD - REMOVAL)

INSTALLATION

The traction control switch is located in the upper

shroud. (Refer to 19 - STEERING/COLUMN/UPPER

SHROUD - INSTALLATION)

HYDRAULIC/MECHANICAL

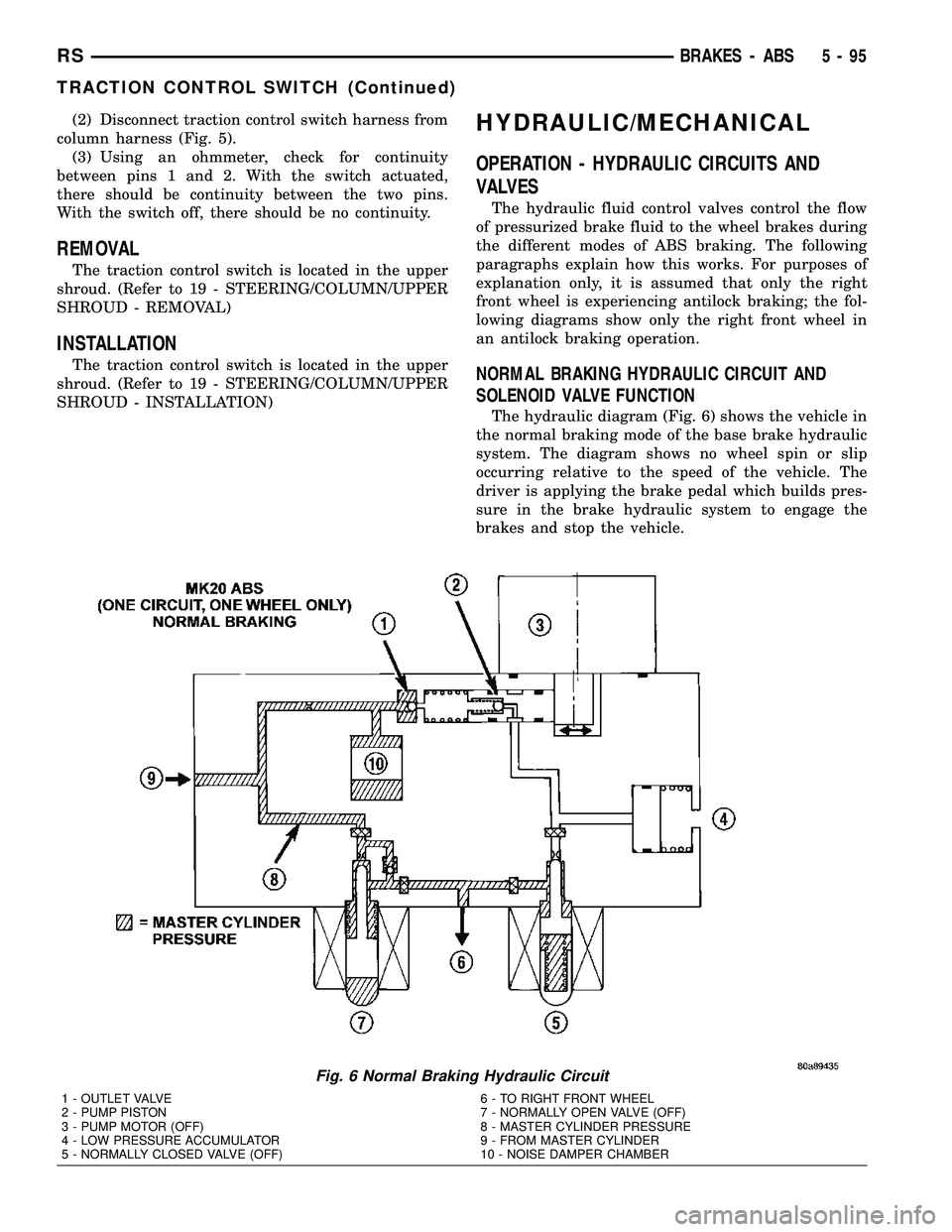

OPERATION - HYDRAULIC CIRCUITS AND

VALVES

The hydraulic fluid control valves control the flow

of pressurized brake fluid to the wheel brakes during

the different modes of ABS braking. The following

paragraphs explain how this works. For purposes of

explanation only, it is assumed that only the right

front wheel is experiencing antilock braking; the fol-

lowing diagrams show only the right front wheel in

an antilock braking operation.

NORMAL BRAKING HYDRAULIC CIRCUIT AND

SOLENOID VALVE FUNCTION

The hydraulic diagram (Fig. 6) shows the vehicle in

the normal braking mode of the base brake hydraulic

system. The diagram shows no wheel spin or slip

occurring relative to the speed of the vehicle. The

driver is applying the brake pedal which builds pres-

sure in the brake hydraulic system to engage the

brakes and stop the vehicle.

Fig. 6 Normal Braking Hydraulic Circuit

1 - OUTLET VALVE

2 - PUMP PISTON

3 - PUMP MOTOR (OFF)

4 - LOW PRESSURE ACCUMULATOR

5 - NORMALLY CLOSED VALVE (OFF)6 - TO RIGHT FRONT WHEEL

7 - NORMALLY OPEN VALVE (OFF)

8 - MASTER CYLINDER PRESSURE

9 - FROM MASTER CYLINDER

10 - NOISE DAMPER CHAMBER

RSBRAKES - ABS5-95

TRACTION CONTROL SWITCH (Continued)

Page 207 of 2339

ABS PRIMARY HYDRAULIC CIRCUIT AND

SOLENOID VALVE FUNCTION (ABS WITHOUT

TRACTION CONTROL)

The hydraulic diagram (Fig. 7) shows the vehicle in

the ABS braking mode. The diagram shows one

wheel is slipping because the driver is attempting to

stop the vehicle at a faster rate than is allowed by

the surface on which the tires are riding.

²The normally open and normally closed valves

modulate (build/decay) the brake hydraulic pressure

as required.

²The pump/motor is switched on so that the

brake fluid from the low pressure accumulators is

returned to the master cylinder circuits.

²The brake fluid is routed to either the master

cylinder or the wheel brake depending on the posi-

tion of the normally open valve.

Fig. 7 ABS Without Traction Control - Primary Hydraulic Circuit

1 - OUTLET VALVE

2 - PUMP PISTON

3 - PUMP MOTOR (ON)

4 - LOW PRESSURE ACCUMULATOR PRESSURE

5 - LOW PRESSURE ACCUMULATOR

6 - NORMALLY CLOSED VALVE (MODULATING)

7 - TO RIGHT FRONT WHEEL8 - NORMALLY OPEN VALVE (MODULATING)

9 - FROM MASTER CYLINDER

10 - MASTER CYLINDER PRESSURE

11 - CONTROLLED WHEEL PRESSURE

12 - PUMP INTERSTAGE PRESSURE

13 - NOISE DAMPER CHAMBER

5 - 96 BRAKES - ABSRS

HYDRAULIC/MECHANICAL (Continued)

Page 208 of 2339

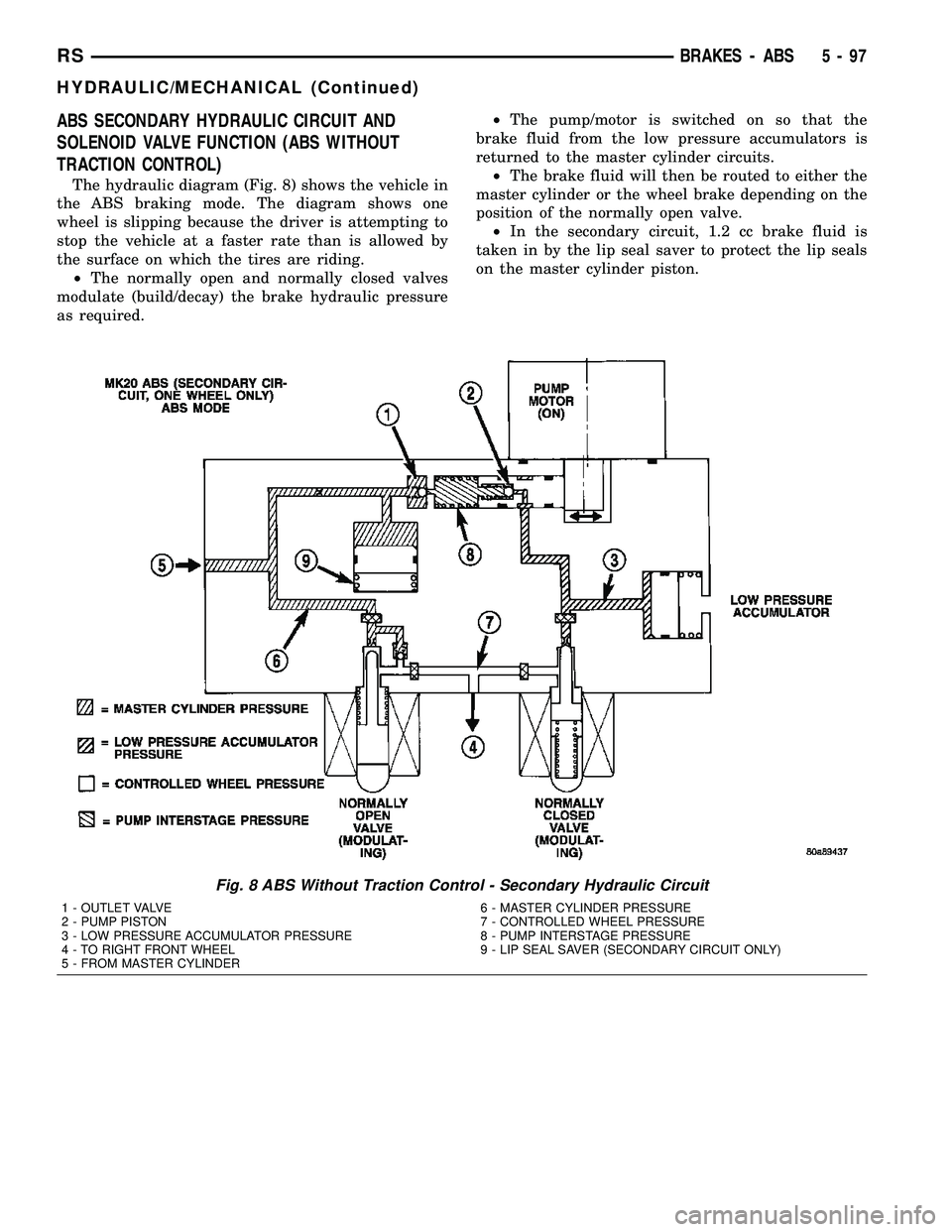

ABS SECONDARY HYDRAULIC CIRCUIT AND

SOLENOID VALVE FUNCTION (ABS WITHOUT

TRACTION CONTROL)

The hydraulic diagram (Fig. 8) shows the vehicle in

the ABS braking mode. The diagram shows one

wheel is slipping because the driver is attempting to

stop the vehicle at a faster rate than is allowed by

the surface on which the tires are riding.

²The normally open and normally closed valves

modulate (build/decay) the brake hydraulic pressure

as required.²The pump/motor is switched on so that the

brake fluid from the low pressure accumulators is

returned to the master cylinder circuits.

²The brake fluid will then be routed to either the

master cylinder or the wheel brake depending on the

position of the normally open valve.

²In the secondary circuit, 1.2 cc brake fluid is

taken in by the lip seal saver to protect the lip seals

on the master cylinder piston.

Fig. 8 ABS Without Traction Control - Secondary Hydraulic Circuit

1 - OUTLET VALVE

2 - PUMP PISTON

3 - LOW PRESSURE ACCUMULATOR PRESSURE

4 - TO RIGHT FRONT WHEEL

5 - FROM MASTER CYLINDER6 - MASTER CYLINDER PRESSURE

7 - CONTROLLED WHEEL PRESSURE

8 - PUMP INTERSTAGE PRESSURE

9 - LIP SEAL SAVER (SECONDARY CIRCUIT ONLY)

RSBRAKES - ABS5-97

HYDRAULIC/MECHANICAL (Continued)

Page 209 of 2339

NORMAL BRAKING HYDRAULIC CIRCUIT,

SOLENOID VALVE, AND SHUTTLE VALVE

FUNCTION (ABS WITH TRACTION CONTROL)

The hydraulic diagram (Fig. 9) shows a vehicle

with traction control in the normal braking mode.

The diagram shows no wheel spin or slip occurring

relative to the speed of the vehicle. The driver is

applying the brake pedal which builds pressure in

the brake hydraulic system to engage the brakes and

stop the vehicle. the hydraulic shuttle valve closes

with every brake pedal application so pressure is not

created at the inlet to the pump/motor.

Fig. 9 ABS With Traction Control - Normal Braking Hydraulic Circuit

1 - OUTLET VALVE

2 - PUMP PISTON

3 - PUMP MOTOR (OFF)

4 - SUCTION VALVE

5 - LOW PRESSURE ACCUMULATOR

6 - NORMALLY CLOSED VALVE (OFF)

7 - TO RIGHT FRONT WHEEL8 - NORMALLY OPEN VALVE (OFF)

9 - NORMALLY OPEN ASR VALVE (OFF)

10 - FROM MASTER CYLINDER

11 - HYDRAULIC SHUTTLE VALVE

12 - MASTER CYLINDER PRESSURE

13 - NOISE DAMPER CHAMBER

5 - 98 BRAKES - ABSRS

HYDRAULIC/MECHANICAL (Continued)

Page 210 of 2339

ABS BRAKING HYDRAULIC CIRCUIT, SOLENOID

VALVE, AND SHUTTLE VALVE FUNCTION (ABS

WITH TRACTION CONTROL)

The hydraulic diagram (Fig. 10) shows the vehicle

in the ABS braking mode. The diagram shows one

wheel is slipping because the driver is attempting to

stop the vehicle at a faster rate than is allowed by

the surface on which the tires are riding.

²The hydraulic shuttle valve closes upon brake

application so that the pump/motor cannot siphon

brake fluid from the master cylinder.²The normally open and normally closed valves

modulate (build/decay) the brake hydraulic pressure

as required.

²The pump/motor is switched on so that the

brake fluid from the low pressure accumulators is

returned to the master cylinder circuits.

²The brake fluid is routed to either the master

cylinder or the wheel brake depending on the posi-

tion of the normally open valve.

Fig. 10 ABS With Traction Control - ABS Braking Hydraulic Circuit

1 - OUTLET VALVE

2 - PUMP PISTON

3 - PUMP MOTOR (ON)

4 - SUCTION VALVE

5 - LOW PRESSURE ACCUMULATOR

6 - NORMALLY CLOSED VALVE (MODULATING)

7 - TO RIGHT FRONT WHEEL

8 - NORMALLY OPEN VALVE (MODULATING)9 - NORMALLY OPEN ASR VALVE (OFF)

10 - FROM MASTER CYLINDER

11 - HYDRAULIC SHUTTLE VALVE

12 - MASTER CYLINDER PRESSURE

13 - CONTROLLED WHEEL PRESSURE

14 - LOW PRESSURE ACCUMULATOR PRESSURE

15 - PUMP INTERSTAGE PRESSURE

16 - NOISE DAMPER CHAMBER

RSBRAKES - ABS5-99

HYDRAULIC/MECHANICAL (Continued)

Page 211 of 2339

ABS TRACTION CONTROL HYDRAULIC CIRCUIT,

SOLENOID VALVE, AND SHUTTLE VALVE

FUNCTION (ABS WITH TRACTION CONTROL)

The hydraulic diagram (Fig. 11) shows the vehicle

in the ABS braking mode. The diagram shows a drive

wheel is spinning and brake pressure is required to

reduce its speed.

²The normally open ASR valve is energized to iso-

late the brake fluid being pumped from the master

cylinder and to isolate the driven wheel.

²The normally open ASR valve bypasses the

pump output back to the master cylinder at a fixed

pressure setting.

²The normally open and normally closed valves

modulate (build/decay) the brake pressure as

required to the spinning wheel.

HCU (HYDRAULIC CONTROL

UNIT)

DESCRIPTION

The hydraulic control unit (HCU) is mounted to

the CAB as part of the ICU (Fig. 22). The HCU con-

trols the flow of brake fluid to the brakes using a

series of valves and accumulators. A pump/motor is

mounted on the HCU to supply build pressure to the

brakes during an ABS stop.

The HCU on a vehicle equipped with ABS and

traction control has a valve block housing that is

approximately 1 inch longer on the low pressure fluid

accumulators side than a HCU on a vehicle that is

equipped with only ABS.

Fig. 11 Traction Control Hydraulic Circuit

1 - OUTLET VALVE

2 - PUMP PISTON

3 - PUMP MOTOR (ON)

4 - LOW PRESSURE ACCUMULATOR PRESSURE

5 - LOW PRESSURE ACCUMULATOR

6 - NORMALLY CLOSED VALVE (MODULATING)

7 - TO RIGHT FRONT WHEEL (SPINNING)

8 - NORMALLY OPEN VALVE (MODULATING)

9 - NORMALLY OPEN ASR VALVE ON (REGULATING)10 - FROM MASTER CYLINDER

11 - HYDRAULIC SHUTTLE VALVE

12 - CONTROLLED WHEEL PRESSURE

13 - SUCTION VALVE

14 - PUMP INTERSTAGE PRESSURE

15 - NOISE DAMPER CHAMBER

16 - MASTER CYLINDER PRESSURE

17 - PUMP PRESSURE

5 - 100 BRAKES - ABSRS

HYDRAULIC/MECHANICAL (Continued)

Page 212 of 2339

For more information, (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ICU (INTEGRATED CON-

TROL UNIT) - DESCRIPTION)

OPERATION

For information on the operation of the HCU as a

whole, refer to Hydraulic Circuits And Valve Opera-

tion which can be found elsewhere in this section.

For information on the operation of the components

within the HCU, refer to the following three topics.

VALVES AND SOLENOIDS

The valve block contains four inlet valves and four

outlet valves. The inlet valves are spring-loaded in

the open position and the outlet valves are spring-

loaded in the closed position during normal braking.

The fluid is allowed to flow from the master cylinder

to the wheel brakes.

During an ABS stop, these valves cycle to maintain

the proper slip ratio for each wheel. The inlet valve

closes preventing further pressure increase and the

outlet valve opens to provide a path from the wheel

brake to the HCU accumulators and pump/motor.

This releases (decays) pressure from the wheel brake,

thus releasing the wheel from excessive slippage.

Once the wheel is no longer slipping, the outlet valve

is closed and the inlet valve is opened to reapply

(build) pressure.

On vehicles with traction control, there is an extra

set of valves and solenoids. The ASR valves, mounted

in the HCU valve block, are normally in the open

position and close only when the traction control is

applied.

These isolator valves are used to isolate the rear

(non-driving) wheels of the vehicle from the hydraulic

pressure that the HCU pump/motor is sending to the

front (driving) wheels when traction control is being

applied. The rear brakes need to be isolated from the

master cylinder when traction control is being

applied so the rear wheels do not drag. For more

information, refer to Traction Control System in this

section.

BRAKE FLUID ACCUMULATORS

There are two fluid accumulators in the HCU±one

for the primary hydraulic circuit and one for the sec-

ondary hydraulic circuit. Each hydraulic circuit uses

a 5 cc accumulator.

The fluid accumulators temporarily store brake

fluid that is removed from the wheel brakes during

an ABS cycle. This stored fluid is used by the pump/

motor to provide build pressure for the brake hydrau-

lic system. When the antilock stop is complete, the

accumulators are drained by the pump/motor.

On ABS-only vehicles, there is a mini-accumulator

on the secondary hydraulic circuit that protects the

master cylinder seals during an ABS stop, and there

is a noise dampening chamber on the primary circuit.

On ABS with traction control vehicles, there are

two noise dampening chambers in the HCU.

PUMP/MOTOR

There are two pump assemblies in the HCUÐone

for the primary hydraulic circuit and one for the sec-

ondary hydraulic circuit. Both pumps are driven by a

common electric motor. This DC-type motor is inte-

gral to the HCU and is controlled by the CAB.

The pump/motor provides the extra amount of

brake fluid needed during antilock braking. Brake

fluid is released to the accumulators when the outlet

valve is opened during an antilock stop. The pump

mechanism consists of two opposing pistons operated

by an eccentric camshaft. In operation, one piston

draws fluid from the accumulators, and the opposing

piston pumps fluid to the master cylinder circuits.

When the antilock stop is complete, the pump/motor

drains the accumulators.

The CAB may turn on the pump/motor when an

antilock stop is detected. The pump/motor continues

to run during the antilock stop and is turned off after

the stop is complete. Under some conditions, the

pump/motor runs to drain the accumulators during

the next drive-off.

The pump/motor is not a serviceable item; if it

requires replacement, the HCU must be replaced.

RSBRAKES - ABS5 - 101

HCU (HYDRAULIC CONTROL UNIT) (Continued)

Page 213 of 2339

ICU (INTEGRATED CONTROL

UNIT)

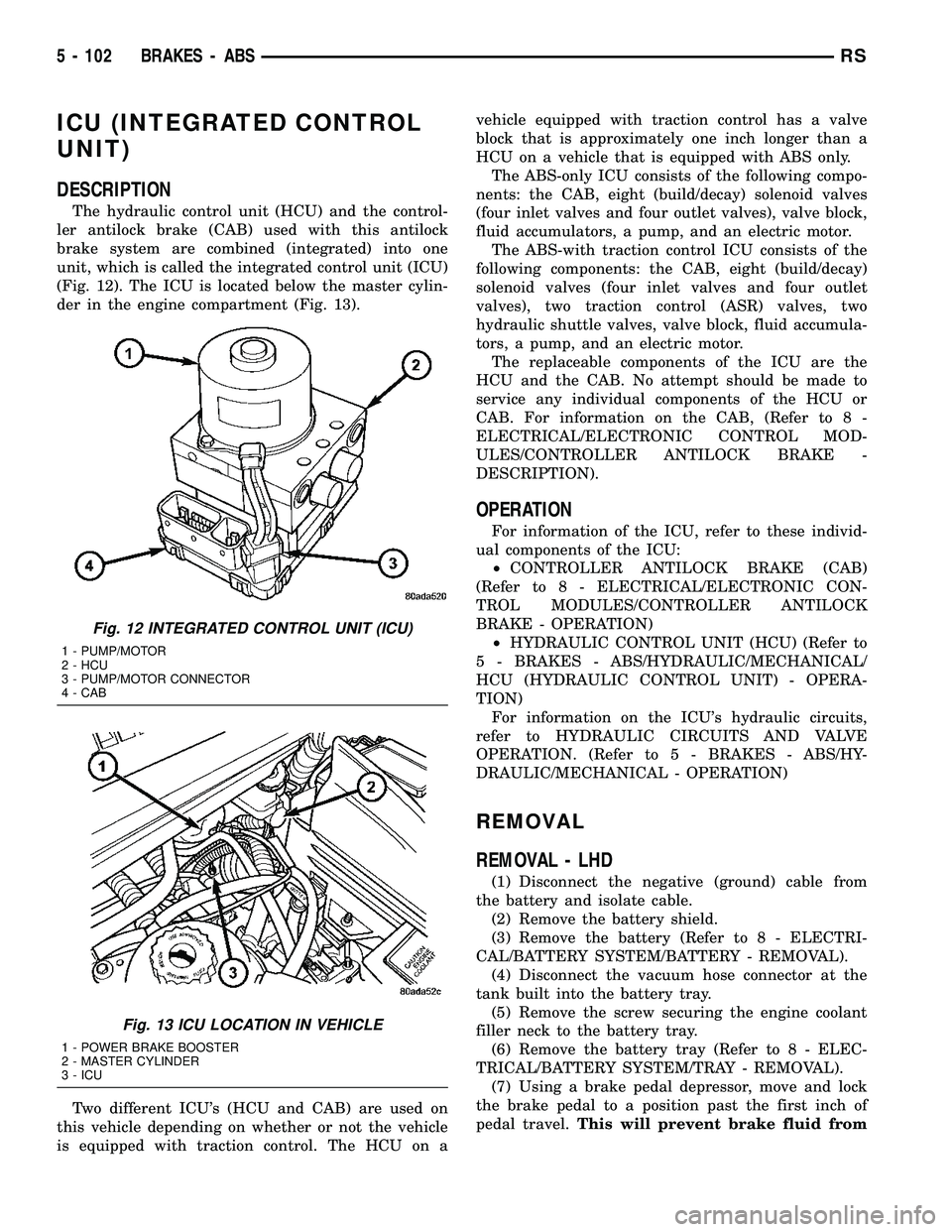

DESCRIPTION

The hydraulic control unit (HCU) and the control-

ler antilock brake (CAB) used with this antilock

brake system are combined (integrated) into one

unit, which is called the integrated control unit (ICU)

(Fig. 12). The ICU is located below the master cylin-

der in the engine compartment (Fig. 13).

Two different ICU's (HCU and CAB) are used on

this vehicle depending on whether or not the vehicle

is equipped with traction control. The HCU on avehicle equipped with traction control has a valve

block that is approximately one inch longer than a

HCU on a vehicle that is equipped with ABS only.

The ABS-only ICU consists of the following compo-

nents: the CAB, eight (build/decay) solenoid valves

(four inlet valves and four outlet valves), valve block,

fluid accumulators, a pump, and an electric motor.

The ABS-with traction control ICU consists of the

following components: the CAB, eight (build/decay)

solenoid valves (four inlet valves and four outlet

valves), two traction control (ASR) valves, two

hydraulic shuttle valves, valve block, fluid accumula-

tors, a pump, and an electric motor.

The replaceable components of the ICU are the

HCU and the CAB. No attempt should be made to

service any individual components of the HCU or

CAB. For information on the CAB, (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/CONTROLLER ANTILOCK BRAKE -

DESCRIPTION).

OPERATION

For information of the ICU, refer to these individ-

ual components of the ICU:

²CONTROLLER ANTILOCK BRAKE (CAB)

(Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/CONTROLLER ANTILOCK

BRAKE - OPERATION)

²HYDRAULIC CONTROL UNIT (HCU) (Refer to

5 - BRAKES - ABS/HYDRAULIC/MECHANICAL/

HCU (HYDRAULIC CONTROL UNIT) - OPERA-

TION)

For information on the ICU's hydraulic circuits,

refer to HYDRAULIC CIRCUITS AND VALVE

OPERATION. (Refer to 5 - BRAKES - ABS/HY-

DRAULIC/MECHANICAL - OPERATION)

REMOVAL

REMOVAL - LHD

(1) Disconnect the negative (ground) cable from

the battery and isolate cable.

(2) Remove the battery shield.

(3) Remove the battery (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - REMOVAL).

(4) Disconnect the vacuum hose connector at the

tank built into the battery tray.

(5) Remove the screw securing the engine coolant

filler neck to the battery tray.

(6) Remove the battery tray (Refer to 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - REMOVAL).

(7) Using a brake pedal depressor, move and lock

the brake pedal to a position past the first inch of

pedal travel.This will prevent brake fluid from

Fig. 12 INTEGRATED CONTROL UNIT (ICU)

1 - PUMP/MOTOR

2 - HCU

3 - PUMP/MOTOR CONNECTOR

4 - CAB

Fig. 13 ICU LOCATION IN VEHICLE

1 - POWER BRAKE BOOSTER

2 - MASTER CYLINDER

3 - ICU

5 - 102 BRAKES - ABSRS

Page 1462 of 2339

TRANSMISSION/TRANSAXLE

TABLE OF CONTENTS

page page

40TE AUTOMATIC TRANSAXLE..............141TE AUTOMATIC TRANSAXLE............146

40TE AUTOMATIC TRANSAXLE

TABLE OF CONTENTS

page page

40TE AUTOMATIC TRANSAXLE

DESCRIPTION..........................2

OPERATION............................4

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - 4XTE

TRANSAXLE GENERAL DIAGNOSIS........5

DIAGNOSIS AND TESTING - ROAD TEST....5

DIAGNOSIS AND TESTING - HYDRAULIC

PRESSURE TESTS.....................6

DIAGNOSIS AND TESTING - CLUTCH AIR

PRESSURE TESTS.....................8

DIAGNOSIS AND TESTING - TORQUE

CONVERTER HOUSING FLUID LEAKAGE....9

REMOVAL.............................9

DISASSEMBLY.........................12

ASSEMBLY............................29

INSTALLATION.........................51

SCHEMATICS AND DIAGRAMS

4XTE TRANSAXLE HYDRAULIC

SCHEMATICS........................54

SPECIFICATIONS - 41TE TRANSAXLE.......66

SPECIAL TOOLS.......................68

ACCUMULATOR

DESCRIPTION.........................73

OPERATION...........................73

DRIVING CLUTCHES

DESCRIPTION.........................74

OPERATION...........................74

FINAL DRIVE

DESCRIPTION.........................74

OPERATION...........................75

DISASSEMBLY.........................75

ASSEMBLY............................78

ADJUSTMENTS

DIFFERENTIAL BEARING PRELOAD

MEASUREMENT AND ADJUSTMENT......79FLUID

STANDARD PROCEDURE

FLUID LEVEL AND CONDITION CHECK....82

STANDARD PROCEDURE - FLUID AND

FILTER SERVICE......................82

GEAR SHIFT CABLE

REMOVAL.............................84

HOLDING CLUTCHES

DESCRIPTION.........................86

OPERATION...........................86

INPUT CLUTCH ASSEMBLY

DISASSEMBLY.........................86

ASSEMBLY............................95

OIL PUMP

DESCRIPTION........................110

OPERATION..........................110

DISASSEMBLY........................110

ASSEMBLY...........................112

PLANETARY GEARTRAIN

DESCRIPTION........................112

OPERATION..........................112

SEAL - OIL PUMP

REMOVAL............................113

INSTALLATION........................113

SHIFT INTERLOCK SOLENOID

DESCRIPTION........................113

OPERATION..........................114

DIAGNOSIS AND TESTING - BRAKE/

TRANSMISSION SHIFT INTERLOCK

SOLENOID..........................115

REMOVAL............................115

INSTALLATION........................116

SOLENOID/PRESSURE SWITCH ASSY

DESCRIPTION........................117

OPERATION..........................118

REMOVAL............................118

INSTALLATION........................119

RSTRANSMISSION/TRANSAXLE21-1