torque CHRYSLER VOYAGER 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 2 of 2339

INTRODUCTION

TABLE OF CONTENTS

page page

BODY CODE PLATE

DESCRIPTION..........................1

FASTENER IDENTIFICATION

DESCRIPTION..........................2

FASTENER USAGE

DESCRIPTION

FASTENER USAGE.....................5

THREADED HOLE REPAIR...............5

INTERNATIONAL SYMBOLS

DESCRIPTION..........................5

METRIC SYSTEM

DESCRIPTION..........................6TORQUE REFERENCES

DESCRIPTION..........................8

VEHICLE IDENTIFICATION NUMBER

DESCRIPTION..........................9

VEHICLE CERTIFICATION LABEL

DESCRIPTION.........................11

E-MARK LABEL

DESCRIPTION.........................11

VECI LABEL

DESCRIPTION.........................11

MANUFACTURER PLATE

DESCRIPTION.........................11

BODY CODE PLATE

DESCRIPTION

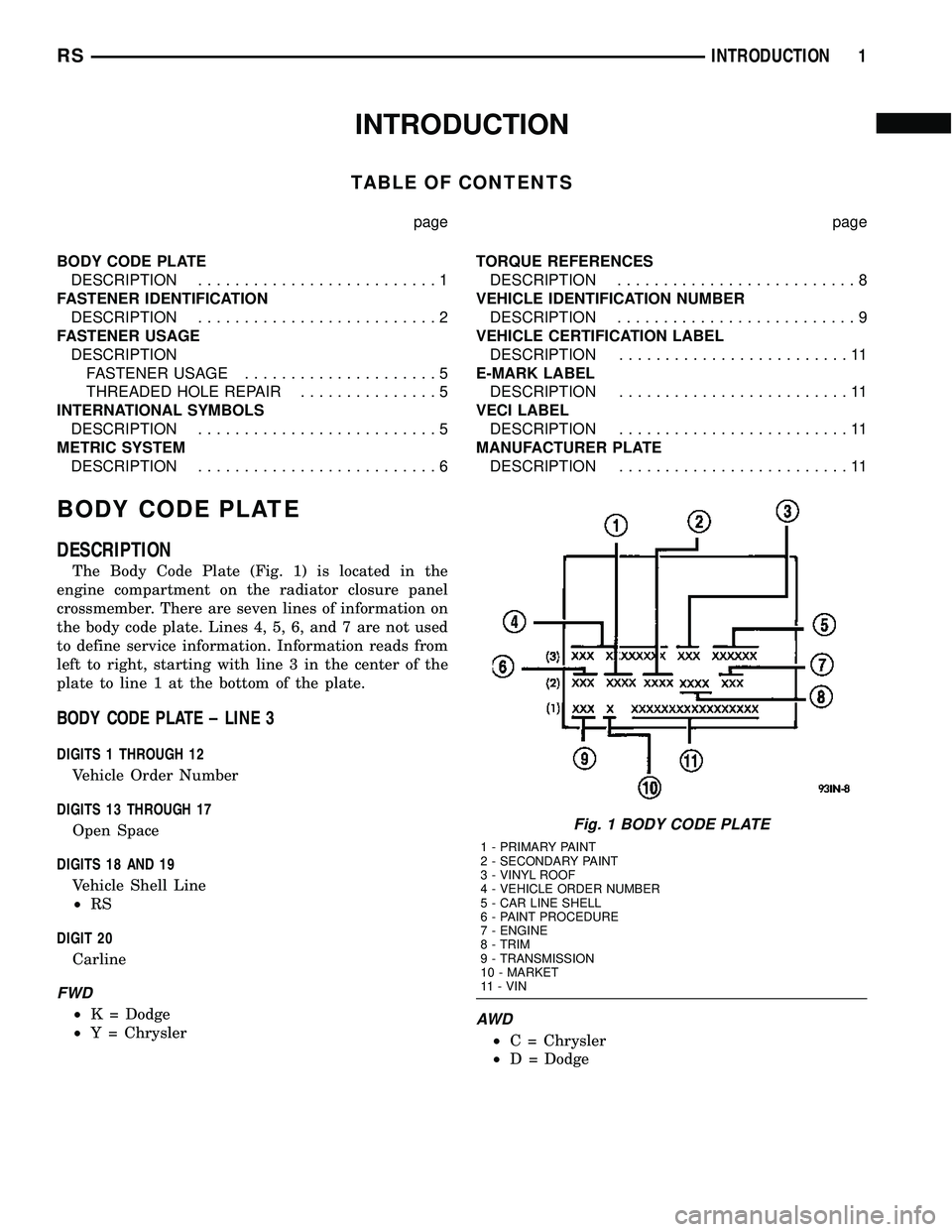

The Body Code Plate (Fig. 1) is located in the

engine compartment on the radiator closure panel

crossmember. There are seven lines of information on

the body code plate. Lines 4, 5, 6, and 7 are not used

to define service information. Information reads from

left to right, starting with line 3 in the center of the

plate to line 1 at the bottom of the plate.

BODY CODE PLATE ± LINE 3

DIGITS 1 THROUGH 12

Vehicle Order Number

DIGITS 13 THROUGH 17

Open Space

DIGITS 18 AND 19

Vehicle Shell Line

²RS

DIGIT 20

Carline

FWD

²K = Dodge

²Y = ChryslerAW D

²C = Chrysler

²D = Dodge

Fig. 1 BODY CODE PLATE

1 - PRIMARY PAINT

2 - SECONDARY PAINT

3 - VINYL ROOF

4 - VEHICLE ORDER NUMBER

5 - CAR LINE SHELL

6 - PAINT PROCEDURE

7 - ENGINE

8 - TRIM

9 - TRANSMISSION

10 - MARKET

11 - VIN

RSINTRODUCTION1

Page 6 of 2339

FASTENER USAGE

DESCRIPTION

FASTENER USAGE

WARNING: USE OF AN INCORRECT FASTENER

MAY RESULT IN COMPONENT DAMAGE OR PER-

SONAL INJURY.

Fasteners and torque specifications references in

this Service Manual are identified in metric and SAE

format.

During any maintenance or repair procedures, it is

important to salvage all fasteners (nuts, bolts, etc.)

for reassembly. If the fastener is not salvageable, a

fastener of equivalent specification must be used.

THREADED HOLE REPAIR

Most stripped threaded holes can be repaired using

a Helicoilt. Follow the vehicle or Helicoiltrecommen-

dations for application and repair procedures.

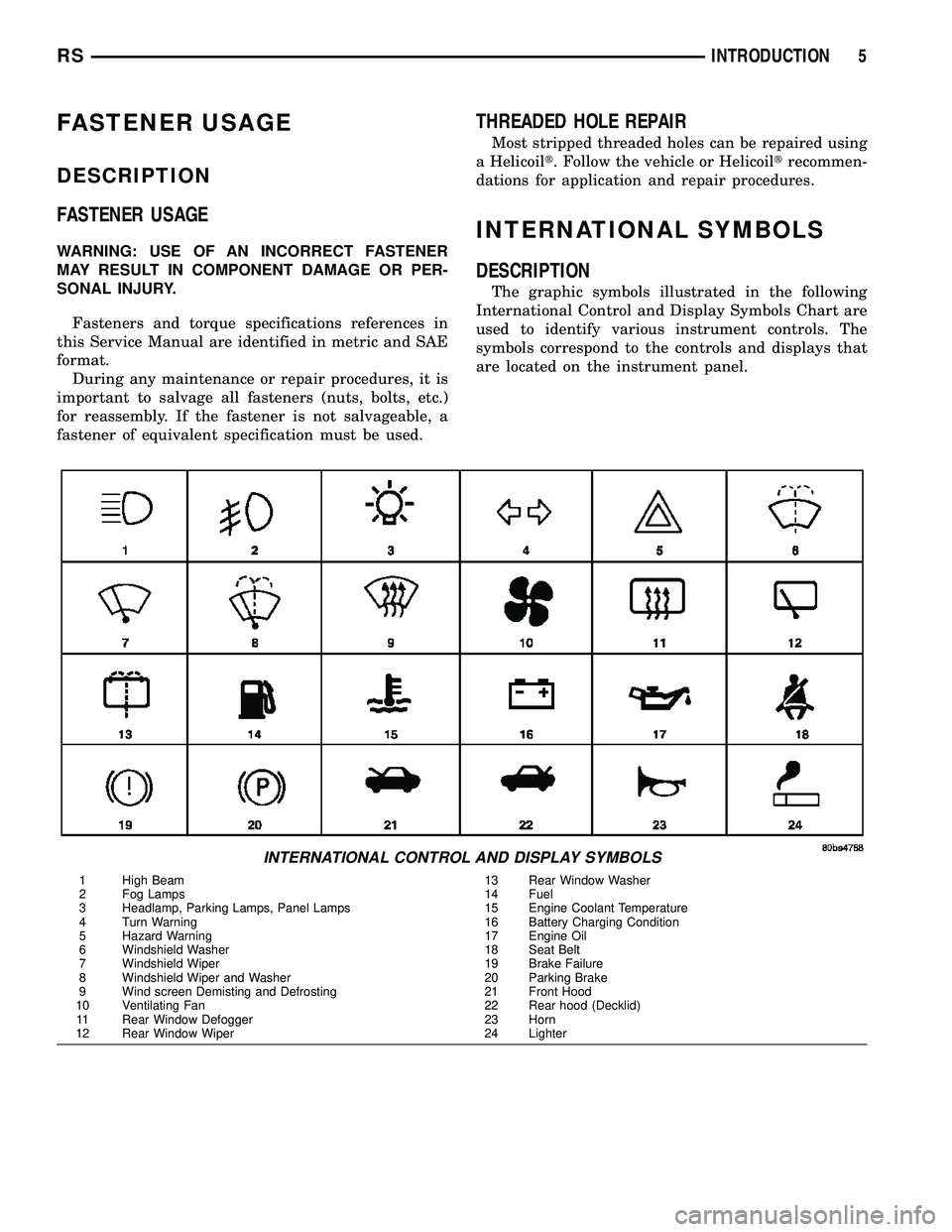

INTERNATIONAL SYMBOLS

DESCRIPTION

The graphic symbols illustrated in the following

International Control and Display Symbols Chart are

used to identify various instrument controls. The

symbols correspond to the controls and displays that

are located on the instrument panel.

INTERNATIONAL CONTROL AND DISPLAY SYMBOLS

1 High Beam 13 Rear Window Washer

2 Fog Lamps 14 Fuel

3 Headlamp, Parking Lamps, Panel Lamps 15 Engine Coolant Temperature

4 Turn Warning 16 Battery Charging Condition

5 Hazard Warning 17 Engine Oil

6 Windshield Washer 18 Seat Belt

7 Windshield Wiper 19 Brake Failure

8 Windshield Wiper and Washer 20 Parking Brake

9 Wind screen Demisting and Defrosting 21 Front Hood

10 Ventilating Fan 22 Rear hood (Decklid)

11 Rear Window Defogger 23 Horn

12 Rear Window Wiper 24 Lighter

RSINTRODUCTION5

Page 7 of 2339

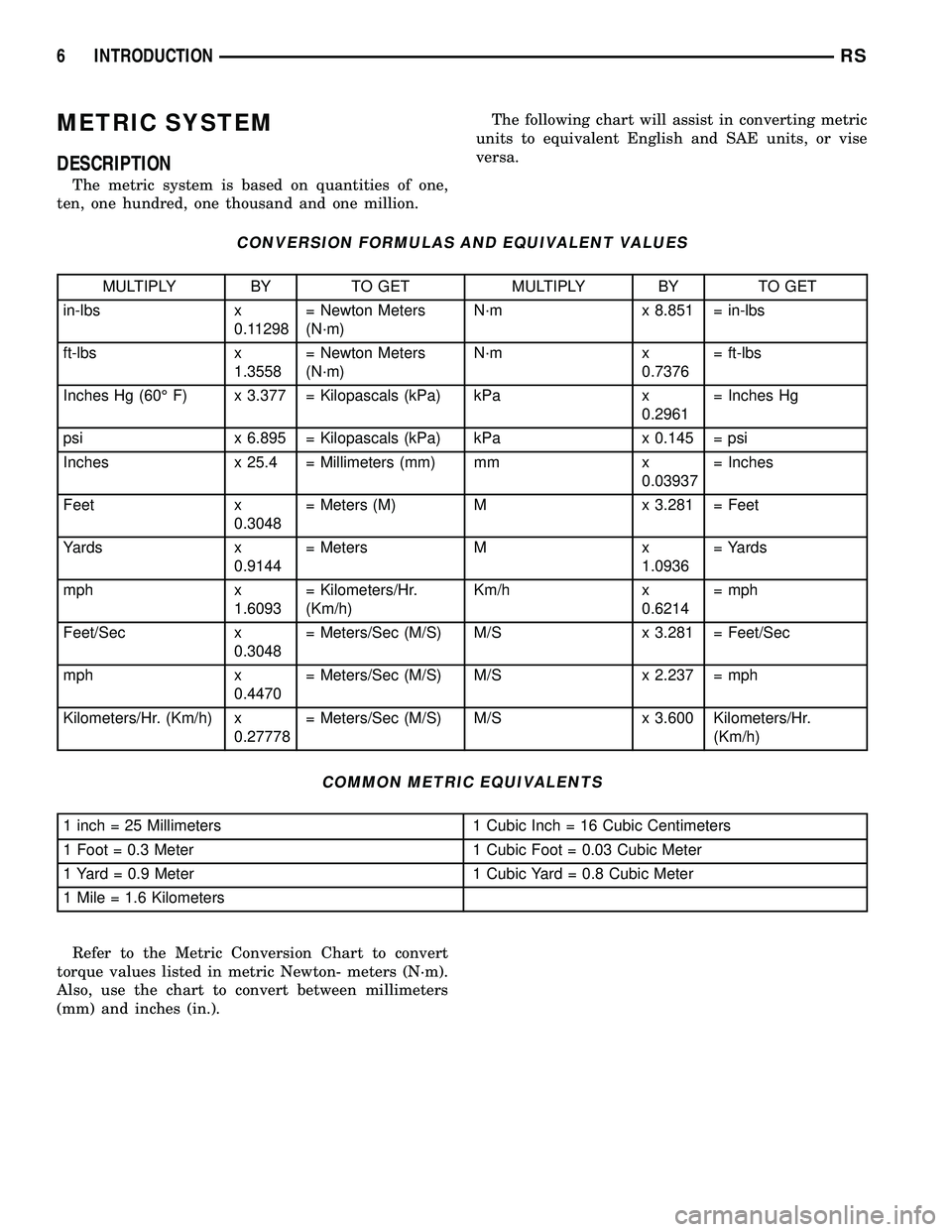

METRIC SYSTEM

DESCRIPTION

The metric system is based on quantities of one,

ten, one hundred, one thousand and one million.The following chart will assist in converting metric

units to equivalent English and SAE units, or vise

versa.

CONVERSION FORMULAS AND EQUIVALENT VALUES

MULTIPLY BY TO GET MULTIPLY BY TO GET

in-lbs x

0.11298= Newton Meters

(N´m)N´m x 8.851 = in-lbs

ft-lbs x

1.3558= Newton Meters

(N´m)N´m x

0.7376= ft-lbs

Inches Hg (60É F) x 3.377 = Kilopascals (kPa) kPa x

0.2961= Inches Hg

psi x 6.895 = Kilopascals (kPa) kPa x 0.145 = psi

Inches x 25.4 = Millimeters (mm) mm x

0.03937= Inches

Feet x

0.3048= Meters (M) M x 3.281 = Feet

Yards x

0.9144= Meters M x

1.0936= Yards

mph x

1.6093= Kilometers/Hr.

(Km/h)Km/h x

0.6214= mph

Feet/Sec x

0.3048= Meters/Sec (M/S) M/S x 3.281 = Feet/Sec

mph x

0.4470= Meters/Sec (M/S) M/S x 2.237 = mph

Kilometers/Hr. (Km/h) x

0.27778= Meters/Sec (M/S) M/S x 3.600 Kilometers/Hr.

(Km/h)

COMMON METRIC EQUIVALENTS

1 inch = 25 Millimeters 1 Cubic Inch = 16 Cubic Centimeters

1 Foot = 0.3 Meter 1 Cubic Foot = 0.03 Cubic Meter

1 Yard = 0.9 Meter 1 Cubic Yard = 0.8 Cubic Meter

1 Mile = 1.6 Kilometers

Refer to the Metric Conversion Chart to convert

torque values listed in metric Newton- meters (N´m).

Also, use the chart to convert between millimeters

(mm) and inches (in.).

6 INTRODUCTIONRS

Page 9 of 2339

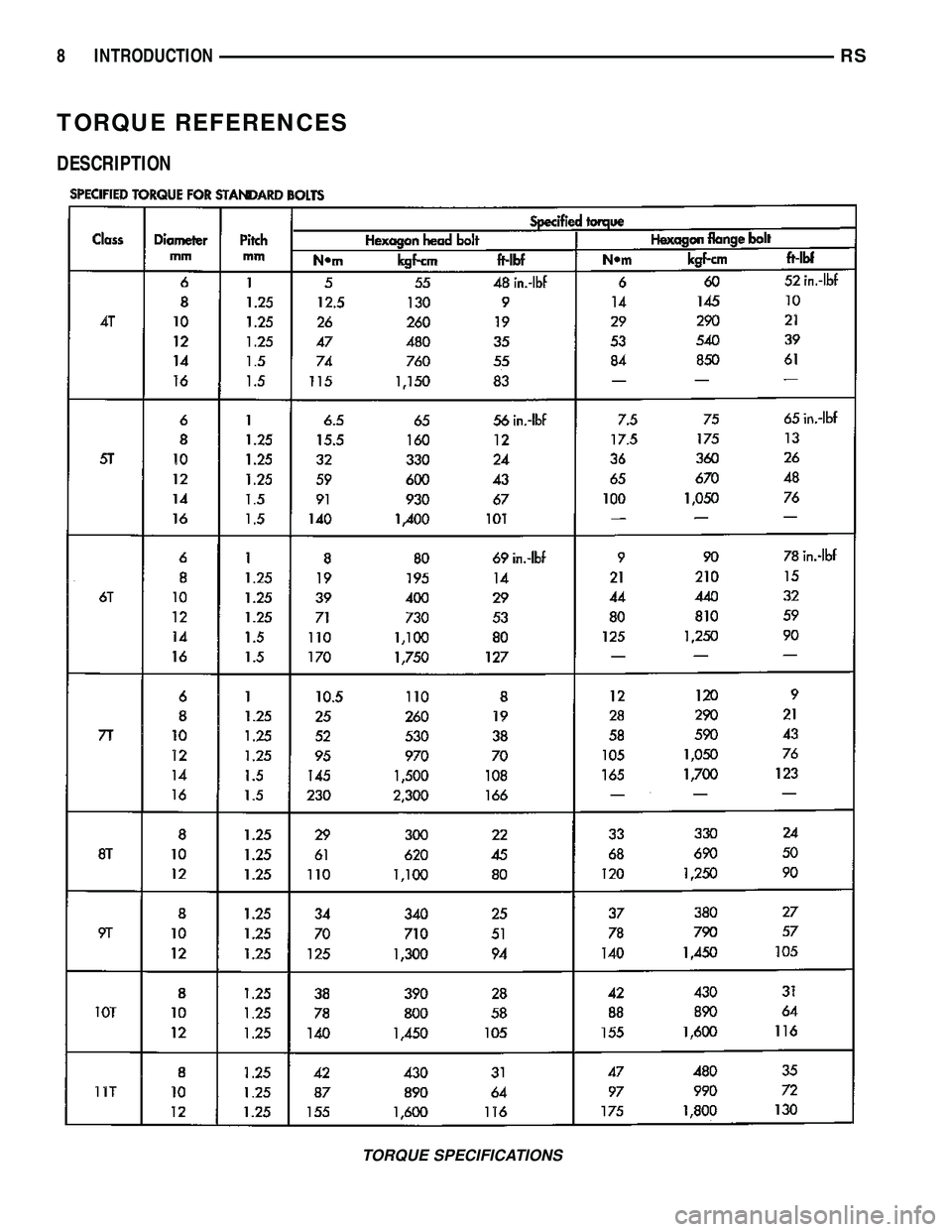

TORQUE REFERENCES

DESCRIPTION

TORQUE SPECIFICATIONS

8 INTRODUCTIONRS

Page 10 of 2339

Individual Torque Charts appear within many or

the Groups. Refer to the Standard Torque Specifica-

tions Chart for torque references not listed in the

individual torque charts.

VEHICLE IDENTIFICATION

NUMBER

DESCRIPTION

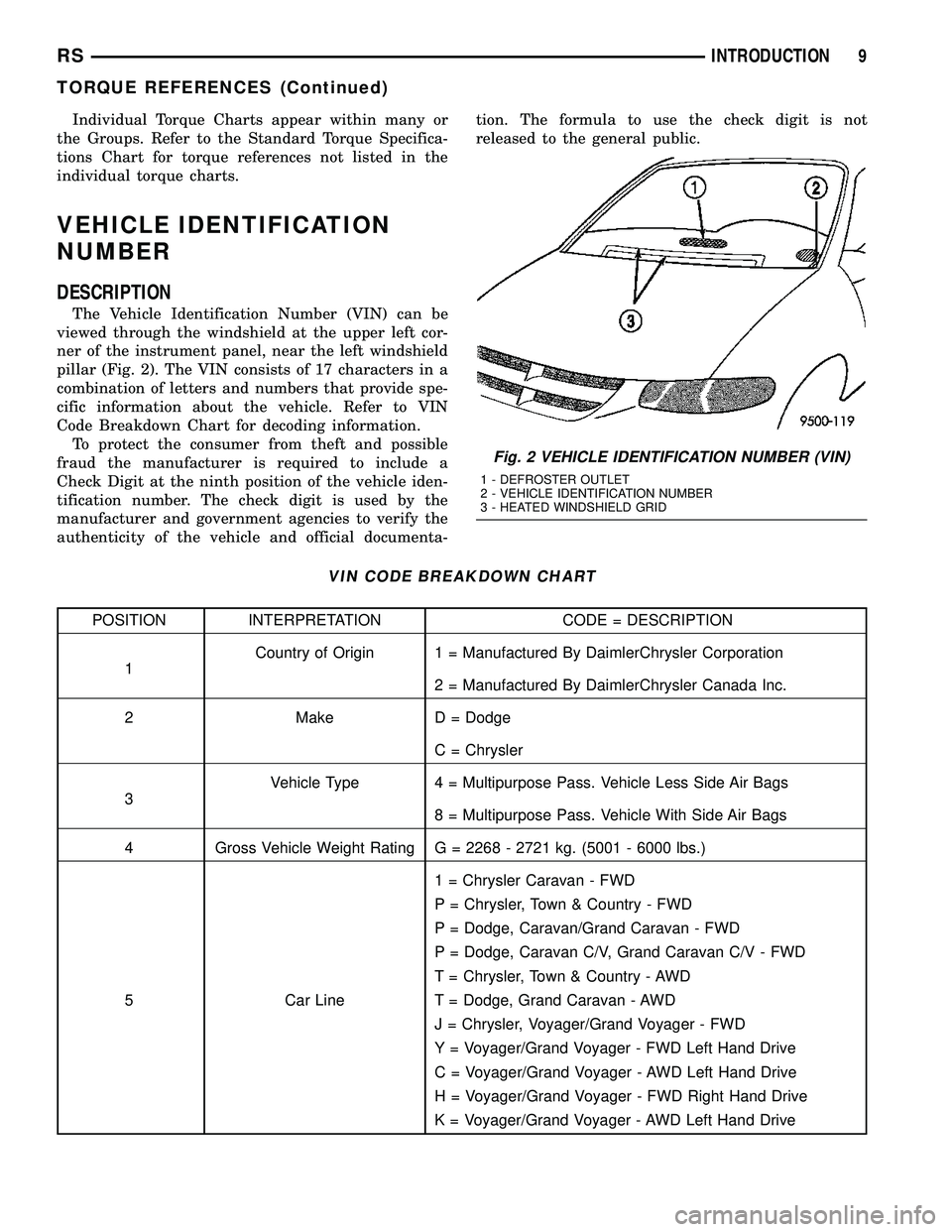

The Vehicle Identification Number (VIN) can be

viewed through the windshield at the upper left cor-

ner of the instrument panel, near the left windshield

pillar (Fig. 2). The VIN consists of 17 characters in a

combination of letters and numbers that provide spe-

cific information about the vehicle. Refer to VIN

Code Breakdown Chart for decoding information.

To protect the consumer from theft and possible

fraud the manufacturer is required to include a

Check Digit at the ninth position of the vehicle iden-

tification number. The check digit is used by the

manufacturer and government agencies to verify the

authenticity of the vehicle and official documenta-tion. The formula to use the check digit is not

released to the general public.

VIN CODE BREAKDOWN CHART

POSITION INTERPRETATION CODE = DESCRIPTION

1Country of Origin 1 = Manufactured By DaimlerChrysler Corporation

2 = Manufactured By DaimlerChrysler Canada Inc.

2 Make D = Dodge

C = Chrysler

3Vehicle Type 4 = Multipurpose Pass. Vehicle Less Side Air Bags

8 = Multipurpose Pass. Vehicle With Side Air Bags

4 Gross Vehicle Weight Rating G = 2268 - 2721 kg. (5001 - 6000 lbs.)

5 Car Line1 = Chrysler Caravan - FWD

P = Chrysler, Town & Country - FWD

P = Dodge, Caravan/Grand Caravan - FWD

P = Dodge, Caravan C/V, Grand Caravan C/V - FWD

T = Chrysler, Town & Country - AWD

T = Dodge, Grand Caravan - AWD

J = Chrysler, Voyager/Grand Voyager - FWD

Y = Voyager/Grand Voyager - FWD Left Hand Drive

C = Voyager/Grand Voyager - AWD Left Hand Drive

H = Voyager/Grand Voyager - FWD Right Hand Drive

K = Voyager/Grand Voyager - AWD Left Hand Drive

Fig. 2 VEHICLE IDENTIFICATION NUMBER (VIN)

1 - DEFROSTER OUTLET

2 - VEHICLE IDENTIFICATION NUMBER

3 - HEATED WINDSHIELD GRID

RSINTRODUCTION9

TORQUE REFERENCES (Continued)

Page 42 of 2339

SUSPENSION

TABLE OF CONTENTS

page page

FRONT SUSPENSION.....................1

REAR SUSPENSION......................26WHEEL ALIGNMENT.....................47

FRONT SUSPENSION

TABLE OF CONTENTS

page page

FRONT SUSPENSION

DESCRIPTION - FRONT SUSPENSION.......2

OPERATION - FRONT SUSPENSION.........2

STANDARD PROCEDURE - LUBRICATION....2

SPECIFICATIONS

FRONT SUSPENSION FASTENER TORQUE . . 3

SPECIAL TOOLS

FRONT SUSPENSION...................3

BUSHINGS

REMOVAL - STABILIZER BAR CUSHION......4

INSTALLATION - STABILIZER BAR CUSHION . . . 4

HUB / BEARING

DESCRIPTION..........................5

OPERATION............................5

DIAGNOSIS AND TESTING - HUB AND

BEARING............................5

REMOVAL.............................5

INSTALLATION..........................5

KNUCKLE

DESCRIPTION..........................6

OPERATION............................7

REMOVAL - STEERING KNUCKLE...........7

INSPECTION - STEERING KNUCKLE.........9

INSTALLATION - STEERING KNUCKLE.......9

LOWER BALL JOINT

DESCRIPTION.........................10

OPERATION...........................10

DIAGNOSIS AND TESTING - LOWER BALL

JOINT..............................10

LOWER BALL JOINT SEAL BOOT

DESCRIPTION - EXPORT.................10

REMOVAL

REMOVAL...........................11

REMOVAL - EXPORT...................11INSTALLATION

INSTALLATION.......................11

INSTALLATION - EXPORT...............11

LOWER CONTROL ARM

DESCRIPTION.........................12

OPERATION...........................12

REMOVAL - LOWER CONTROL ARM........12

DISASSEMBLY

DISASSEMBLY - LOWER CONTROL ARM

(REAR BUSHING - STANDARD)..........13

DISASSEMBLY - LOWER CONTROL ARM

(REAR BUSHING - HYDRO).............13

INSPECTION - LOWER CONTROL ARM......14

ASSEMBLY

ASSEMBLY - LOWER CONTROL ARM

(REAR BUSHING - STANDARD)..........14

ASSEMBLY - LOWER CONTROL ARM

(REAR BUSHING - HYDRO).............15

INSTALLATION - LOWER CONTROL ARM....15

STABILIZER BAR

DESCRIPTION.........................16

OPERATION...........................16

REMOVAL.............................17

INSPECTION..........................17

INSTALLATION.........................17

STRUT

DESCRIPTION - STRUT ASSEMBLY.........19

OPERATION - STRUT ASSEMBLY..........19

DIAGNOSIS AND TESTING - STRUT

ASSEMBLY..........................20

REMOVAL - STRUT ASSEMBLY............20

DISASSEMBLY - STRUT ASSEMBLY........21

ASSEMBLY - STRUT ASSEMBLY...........23

INSTALLATION - STRUT ASSEMBLY........25

RSSUSPENSION2-1

Page 44 of 2339

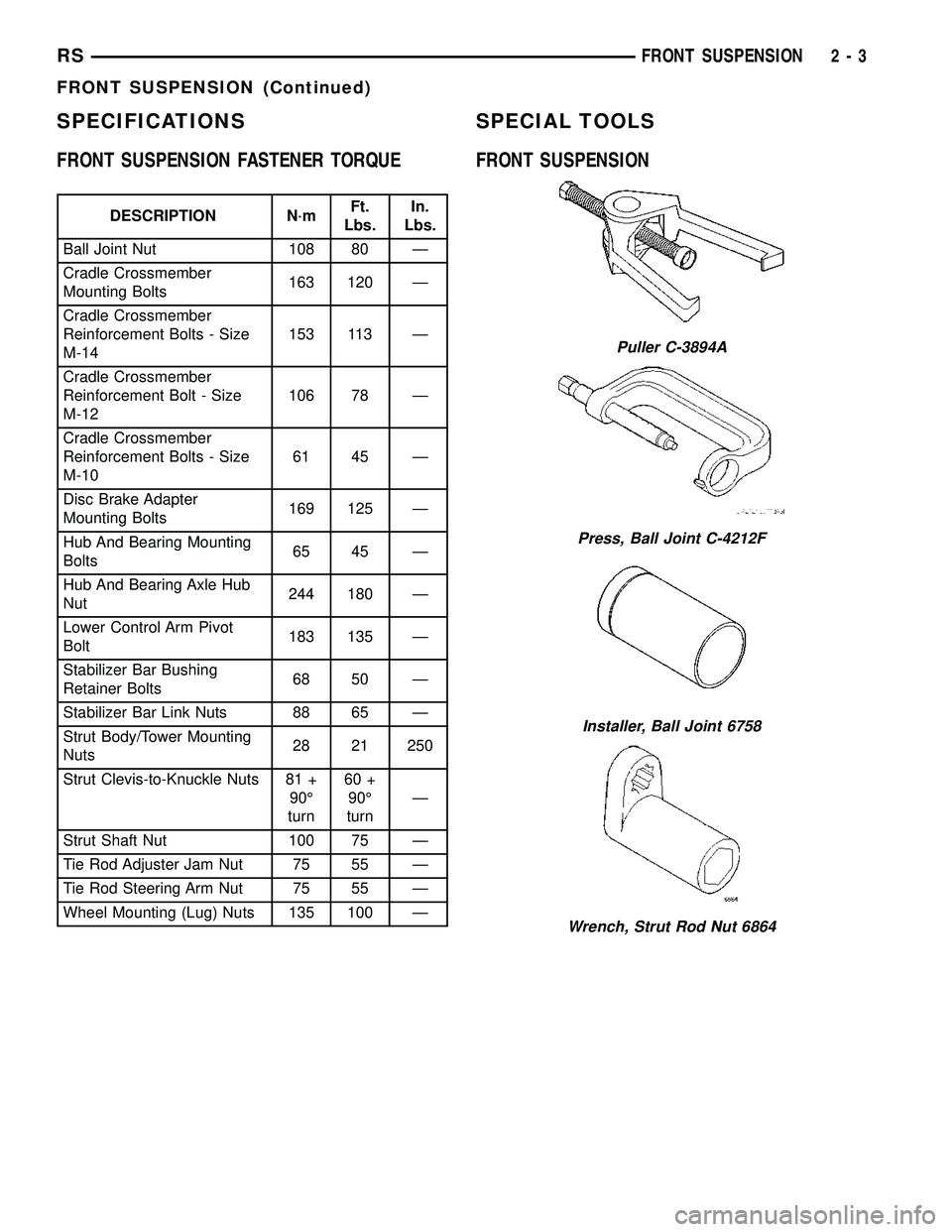

SPECIFICATIONS

FRONT SUSPENSION FASTENER TORQUE

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Ball Joint Nut 108 80 Ð

Cradle Crossmember

Mounting Bolts163 120 Ð

Cradle Crossmember

Reinforcement Bolts - Size

M-14153 113 Ð

Cradle Crossmember

Reinforcement Bolt - Size

M-12106 78 Ð

Cradle Crossmember

Reinforcement Bolts - Size

M-1061 45 Ð

Disc Brake Adapter

Mounting Bolts169 125 Ð

Hub And Bearing Mounting

Bolts65 45 Ð

Hub And Bearing Axle Hub

Nut244 180 Ð

Lower Control Arm Pivot

Bolt183 135 Ð

Stabilizer Bar Bushing

Retainer Bolts68 50 Ð

Stabilizer Bar Link Nuts 88 65 Ð

Strut Body/Tower Mounting

Nuts28 21 250

Strut Clevis-to-Knuckle Nuts 81 +

90É

turn60 +

90É

turnÐ

Strut Shaft Nut 100 75 Ð

Tie Rod Adjuster Jam Nut 75 55 Ð

Tie Rod Steering Arm Nut 75 55 Ð

Wheel Mounting (Lug) Nuts 135 100 Ð

SPECIAL TOOLS

FRONT SUSPENSION

Puller C-3894A

Press, Ball Joint C-4212F

Installer, Ball Joint 6758

Wrench, Strut Rod Nut 6864

RSFRONT SUSPENSION2-3

FRONT SUSPENSION (Continued)

Page 45 of 2339

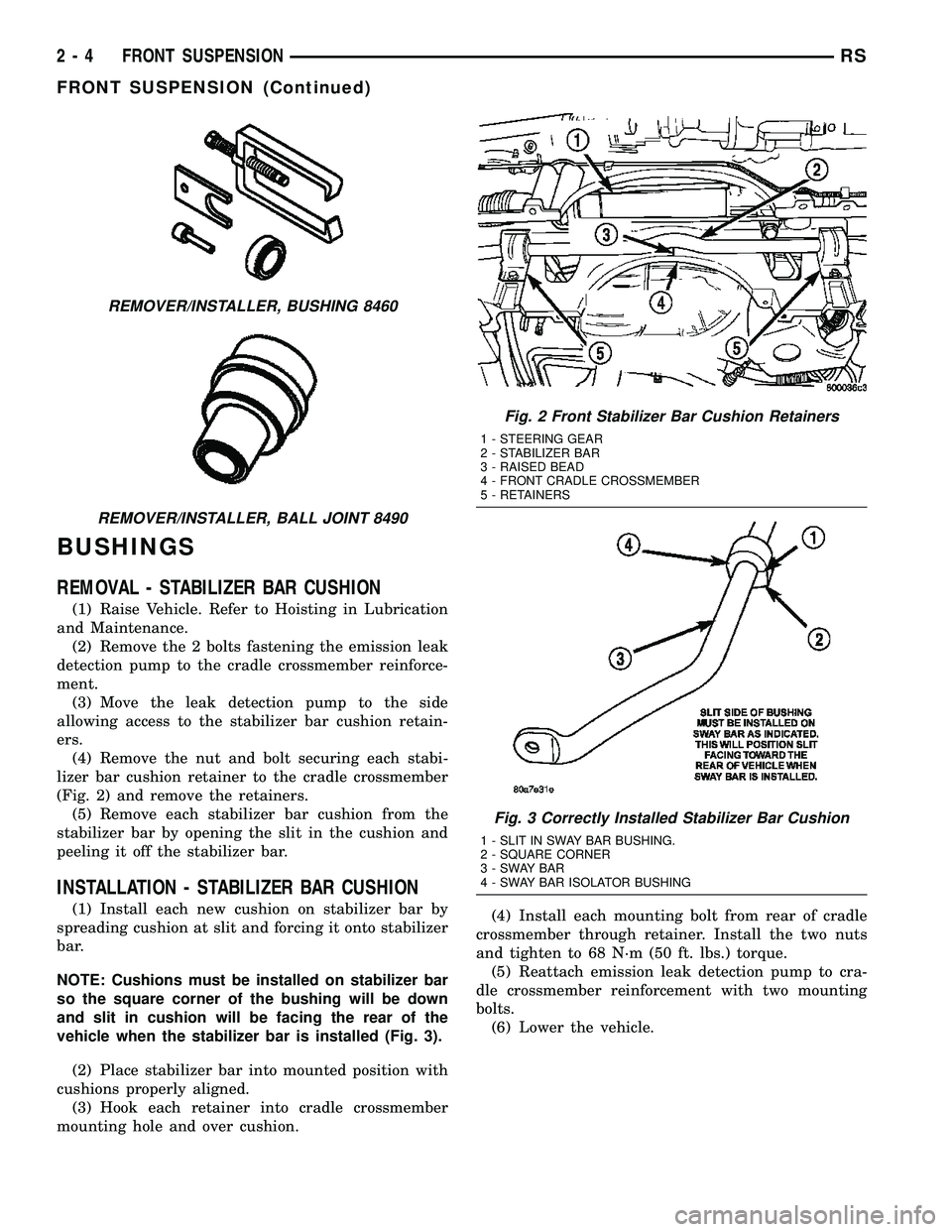

BUSHINGS

REMOVAL - STABILIZER BAR CUSHION

(1) Raise Vehicle. Refer to Hoisting in Lubrication

and Maintenance.

(2) Remove the 2 bolts fastening the emission leak

detection pump to the cradle crossmember reinforce-

ment.

(3) Move the leak detection pump to the side

allowing access to the stabilizer bar cushion retain-

ers.

(4) Remove the nut and bolt securing each stabi-

lizer bar cushion retainer to the cradle crossmember

(Fig. 2) and remove the retainers.

(5) Remove each stabilizer bar cushion from the

stabilizer bar by opening the slit in the cushion and

peeling it off the stabilizer bar.

INSTALLATION - STABILIZER BAR CUSHION

(1) Install each new cushion on stabilizer bar by

spreading cushion at slit and forcing it onto stabilizer

bar.

NOTE: Cushions must be installed on stabilizer bar

so the square corner of the bushing will be down

and slit in cushion will be facing the rear of the

vehicle when the stabilizer bar is installed (Fig. 3).

(2) Place stabilizer bar into mounted position with

cushions properly aligned.

(3) Hook each retainer into cradle crossmember

mounting hole and over cushion.(4) Install each mounting bolt from rear of cradle

crossmember through retainer. Install the two nuts

and tighten to 68 N´m (50 ft. lbs.) torque.

(5) Reattach emission leak detection pump to cra-

dle crossmember reinforcement with two mounting

bolts.

(6) Lower the vehicle.

REMOVER/INSTALLER, BUSHING 8460

REMOVER/INSTALLER, BALL JOINT 8490

Fig. 2 Front Stabilizer Bar Cushion Retainers

1 - STEERING GEAR

2 - STABILIZER BAR

3 - RAISED BEAD

4 - FRONT CRADLE CROSSMEMBER

5 - RETAINERS

Fig. 3 Correctly Installed Stabilizer Bar Cushion

1 - SLIT IN SWAY BAR BUSHING.

2 - SQUARE CORNER

3-SWAYBAR

4 - SWAY BAR ISOLATOR BUSHING

2 - 4 FRONT SUSPENSIONRS

FRONT SUSPENSION (Continued)

Page 47 of 2339

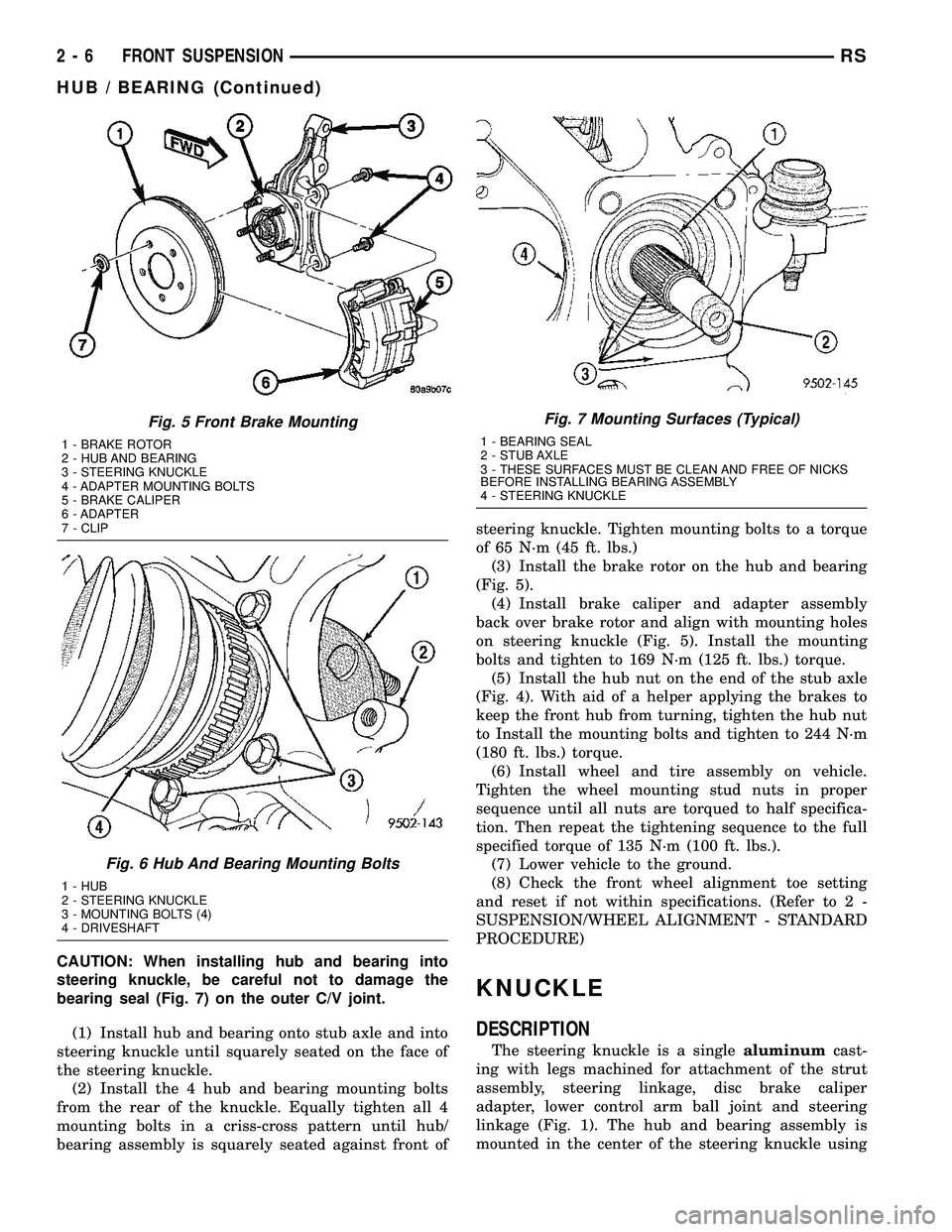

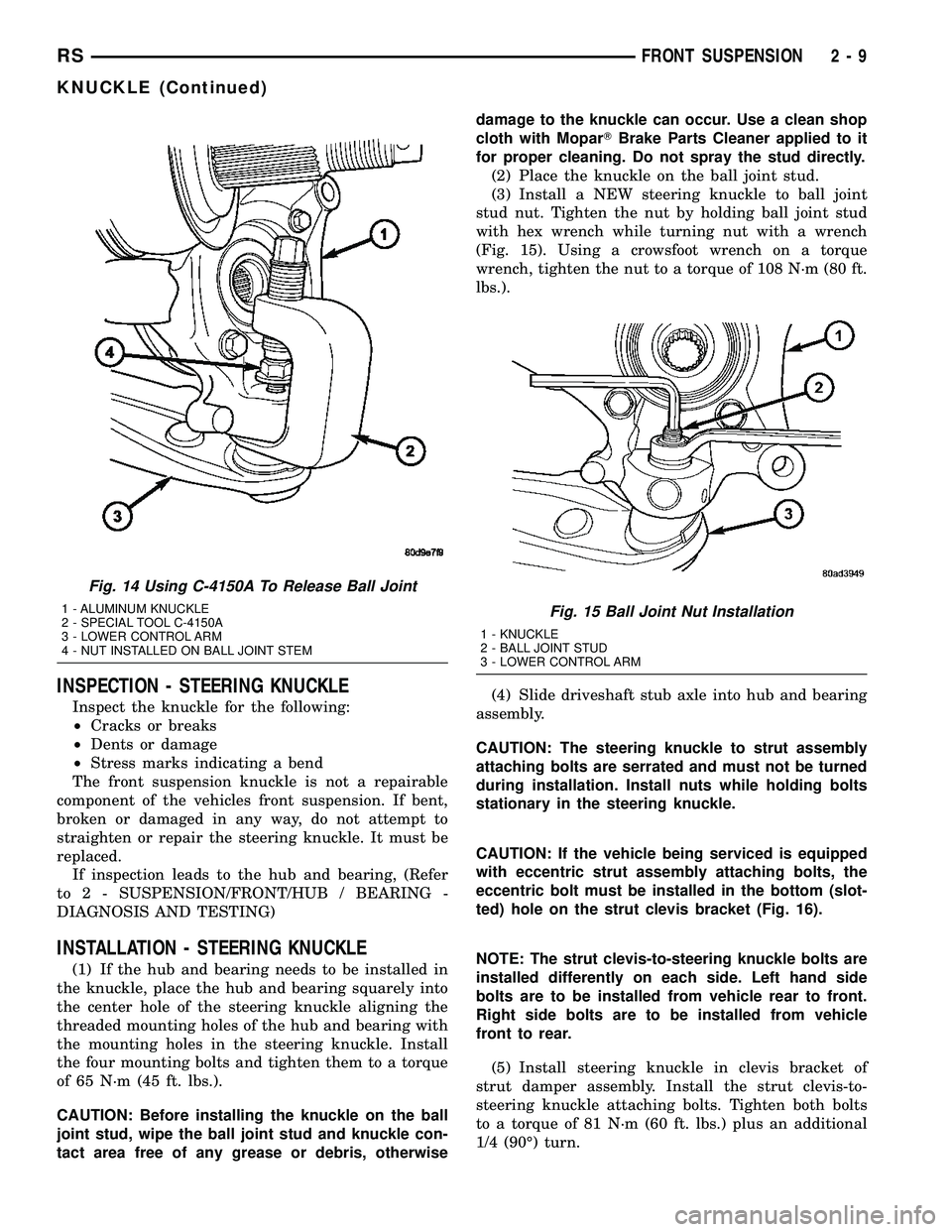

CAUTION: When installing hub and bearing into

steering knuckle, be careful not to damage the

bearing seal (Fig. 7) on the outer C/V joint.

(1) Install hub and bearing onto stub axle and into

steering knuckle until squarely seated on the face of

the steering knuckle.

(2) Install the 4 hub and bearing mounting bolts

from the rear of the knuckle. Equally tighten all 4

mounting bolts in a criss-cross pattern until hub/

bearing assembly is squarely seated against front ofsteering knuckle. Tighten mounting bolts to a torque

of 65 N´m (45 ft. lbs.)

(3) Install the brake rotor on the hub and bearing

(Fig. 5).

(4) Install brake caliper and adapter assembly

back over brake rotor and align with mounting holes

on steering knuckle (Fig. 5). Install the mounting

bolts and tighten to 169 N´m (125 ft. lbs.) torque.

(5) Install the hub nut on the end of the stub axle

(Fig. 4). With aid of a helper applying the brakes to

keep the front hub from turning, tighten the hub nut

to Install the mounting bolts and tighten to 244 N´m

(180 ft. lbs.) torque.

(6) Install wheel and tire assembly on vehicle.

Tighten the wheel mounting stud nuts in proper

sequence until all nuts are torqued to half specifica-

tion. Then repeat the tightening sequence to the full

specified torque of 135 N´m (100 ft. lbs.).

(7) Lower vehicle to the ground.

(8) Check the front wheel alignment toe setting

and reset if not within specifications. (Refer to 2 -

SUSPENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE)

KNUCKLE

DESCRIPTION

The steering knuckle is a singlealuminumcast-

ing with legs machined for attachment of the strut

assembly, steering linkage, disc brake caliper

adapter, lower control arm ball joint and steering

linkage (Fig. 1). The hub and bearing assembly is

mounted in the center of the steering knuckle using

Fig. 5 Front Brake Mounting

1 - BRAKE ROTOR

2 - HUB AND BEARING

3 - STEERING KNUCKLE

4 - ADAPTER MOUNTING BOLTS

5 - BRAKE CALIPER

6 - ADAPTER

7 - CLIP

Fig. 6 Hub And Bearing Mounting Bolts

1 - HUB

2 - STEERING KNUCKLE

3 - MOUNTING BOLTS (4)

4 - DRIVESHAFT

Fig. 7 Mounting Surfaces (Typical)

1 - BEARING SEAL

2 - STUB AXLE

3 - THESE SURFACES MUST BE CLEAN AND FREE OF NICKS

BEFORE INSTALLING BEARING ASSEMBLY

4 - STEERING KNUCKLE

2 - 6 FRONT SUSPENSIONRS

HUB / BEARING (Continued)

Page 50 of 2339

INSPECTION - STEERING KNUCKLE

Inspect the knuckle for the following:

²Cracks or breaks

²Dents or damage

²Stress marks indicating a bend

The front suspension knuckle is not a repairable

component of the vehicles front suspension. If bent,

broken or damaged in any way, do not attempt to

straighten or repair the steering knuckle. It must be

replaced.

If inspection leads to the hub and bearing, (Refer

to 2 - SUSPENSION/FRONT/HUB / BEARING -

DIAGNOSIS AND TESTING)

INSTALLATION - STEERING KNUCKLE

(1) If the hub and bearing needs to be installed in

the knuckle, place the hub and bearing squarely into

the center hole of the steering knuckle aligning the

threaded mounting holes of the hub and bearing with

the mounting holes in the steering knuckle. Install

the four mounting bolts and tighten them to a torque

of 65 N´m (45 ft. lbs.).

CAUTION: Before installing the knuckle on the ball

joint stud, wipe the ball joint stud and knuckle con-

tact area free of any grease or debris, otherwisedamage to the knuckle can occur. Use a clean shop

cloth with MoparTBrake Parts Cleaner applied to it

for proper cleaning. Do not spray the stud directly.

(2) Place the knuckle on the ball joint stud.

(3) Install a NEW steering knuckle to ball joint

stud nut. Tighten the nut by holding ball joint stud

with hex wrench while turning nut with a wrench

(Fig. 15). Using a crowsfoot wrench on a torque

wrench, tighten the nut to a torque of 108 N´m (80 ft.

lbs.).

(4) Slide driveshaft stub axle into hub and bearing

assembly.

CAUTION: The steering knuckle to strut assembly

attaching bolts are serrated and must not be turned

during installation. Install nuts while holding bolts

stationary in the steering knuckle.

CAUTION: If the vehicle being serviced is equipped

with eccentric strut assembly attaching bolts, the

eccentric bolt must be installed in the bottom (slot-

ted) hole on the strut clevis bracket (Fig. 16).

NOTE: The strut clevis-to-steering knuckle bolts are

installed differently on each side. Left hand side

bolts are to be installed from vehicle rear to front.

Right side bolts are to be installed from vehicle

front to rear.

(5) Install steering knuckle in clevis bracket of

strut damper assembly. Install the strut clevis-to-

steering knuckle attaching bolts. Tighten both bolts

to a torque of 81 N´m (60 ft. lbs.) plus an additional

1/4 (90É) turn.

Fig. 14 Using C-4150A To Release Ball Joint

1 - ALUMINUM KNUCKLE

2 - SPECIAL TOOL C-4150A

3 - LOWER CONTROL ARM

4 - NUT INSTALLED ON BALL JOINT STEMFig. 15 Ball Joint Nut Installation

1 - KNUCKLE

2 - BALL JOINT STUD

3 - LOWER CONTROL ARM

RSFRONT SUSPENSION2-9

KNUCKLE (Continued)