clock CHRYSLER VOYAGER 2023 Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2023, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2023Pages: 256, PDF Size: 13.97 MB

Page 42 of 256

40GETTING TO KNOW YOUR VEHICLE

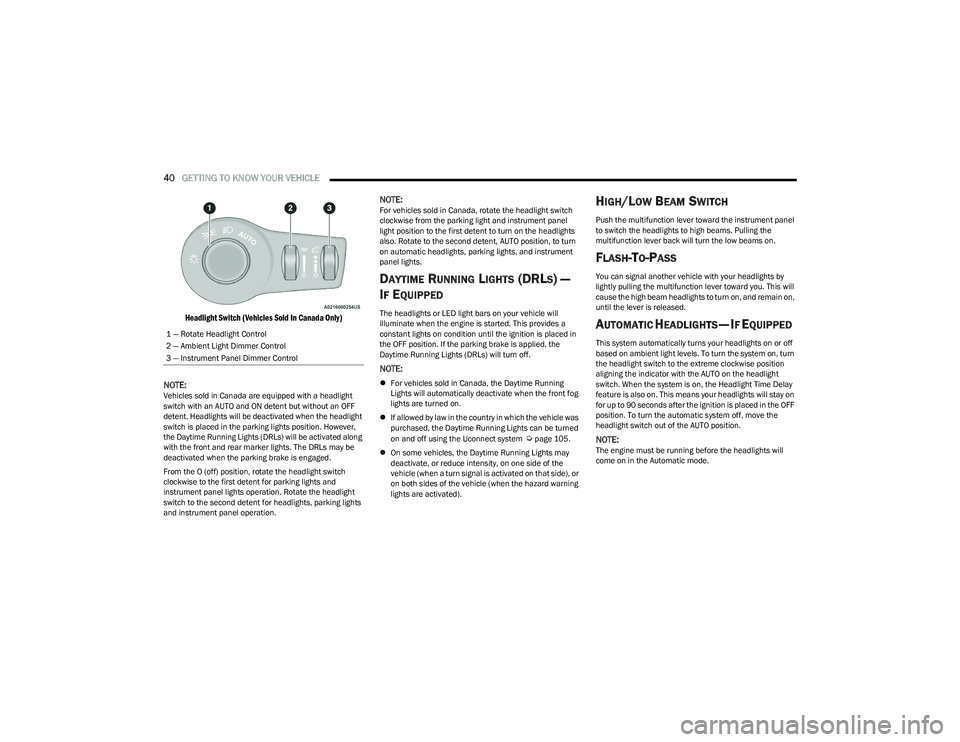

Headlight Switch (Vehicles Sold In Canada Only)

NOTE:

Vehicles sold in Canada are equipped with a headlight

switch with an AUTO and ON detent but without an OFF

detent. Headlights will be deactivated when the headlight

switch is placed in the parking lights position. However,

the Daytime Running Lights (DRLs) will be activated along

with the front and rear marker lights. The DRLs may be

deactivated when the parking brake is engaged.

From the O (off) position, rotate the headlight switch

clockwise to the first detent for parking lights and

instrument panel lights operation. Rotate the headlight

switch to the second detent for headlights, parking lights

and instrument panel operation.

NOTE:For vehicles sold in Canada, rotate the headlight switch

clockwise from the parking light and instrument panel

light position to the first detent to turn on the headlights

also. Rotate to the second detent, AUTO position, to turn

on automatic headlights, parking lights, and instrument

panel lights.

DAYTIME RUNNING LIGHTS (DRLS) —

I

F EQUIPPED

The headlights or LED light bars on your vehicle will

illuminate when the engine is started. This provides a

constant lights on condition until the ignition is placed in

the OFF position. If the parking brake is applied, the

Daytime Running Lights (DRLs) will turn off.

NOTE:

For vehicles sold in Canada, the Daytime Running

Lights will automatically deactivate when the front fog

lights are turned on.

If allowed by law in the country in which the vehicle was

purchased, the Daytime Running Lights can be turned

on and off using the Uconnect system

Úpage 105.

On some vehicles, the Daytime Running Lights may

deactivate, or reduce intensity, on one side of the

vehicle (when a turn signal is activated on that side), or

on both sides of the vehicle (when the hazard warning

lights are activated).

HIGH/LOW BEAM SWITCH

Push the multifunction lever toward the instrument panel

to switch the headlights to high beams. Pulling the

multifunction lever back will turn the low beams on.

FLASH-TO-PASS

You can signal another vehicle with your headlights by

lightly pulling the multifunction lever toward you. This will

cause the high beam headlights to turn on, and remain on,

until the lever is released.

AUTOMATIC HEADLIGHTS — IF EQUIPPED

This system automatically turns your headlights on or off

based on ambient light levels. To turn the system on, turn

the headlight switch to the extreme clockwise position

aligning the indicator with the AUTO on the headlight

switch. When the system is on, the Headlight Time Delay

feature is also on. This means your headlights will stay on

for up to 90 seconds after the ignition is placed in the OFF

position. To turn the automatic system off, move the

headlight switch out of the AUTO position.

NOTE:The engine must be running before the headlights will

come on in the Automatic mode.

1 — Rotate Headlight Control

2 — Ambient Light Dimmer Control

3 — Instrument Panel Dimmer Control

23_RUV_OM_EN_US_t.book Page 40

Page 48 of 256

46GETTING TO KNOW YOUR VEHICLE

Blower Control

Blower Control is used to regulate the amount

of air forced through the Climate Control

system. There are seven blower speeds

available. The speeds can be selected using

either the blower control knob on the faceplate or the

buttons on the touchscreen.

Faceplate: The blower speed increases as you turn the

blower control knob clockwise from the lowest blower

setting. The blower speed decreases as you turn the

blower control knob counterclockwise.

Touchscreen: Use the small blower icon to reduce the

blower setting and the large blower icon to increase the

blower setting. Blower speed can also be selected by

pressing the blower bar area between the icons.

Mode Control

The airflow distribution mode can be adjusted

so air comes from the instrument panel outlets,

floor outlets, defrost outlets and demist

outlets.

Faceplate: Push the button in the center of the knob to

change the airflow distribution mode.

Touchscreen: Select Mode by pressing one of the Mode

Buttons on the touchscreen.

Panel Mode

Air comes from the outlets in the instrument

panel. Each of these outlets can be individually

adjusted to direct the flow of air. The air vanes

of the center outlets and outboard outlets can

be moved up and down or side to side to regulate airflow direction. There is a shut-off wheel located below the air

vanes to shut off or adjust the amount of airflow from

these outlets.

Bi-Level Mode

Air comes from the instrument panel outlets

and floor outlets. A slight amount of air is

directed through the defrost and side window

demister outlets.

NOTE:Bi-Level mode is designed under comfort conditions to

provide cooler air out of the panel outlets and warmer air

from the floor outlets.

Floor Mode

Air comes from the floor outlets. A slight

amount of air is directed through the defrost

and side window demister outlets.

Mix Mode

Air is directed through the floor, defrost, and

side window demister outlets. This setting

works best in cold or snowy conditions that

require extra heat to the windshield. This

setting is good for maintaining comfort while reducing

moisture on the windshield.

Climate Control OFF Button

Press and release this button to turn the

Climate Control ON/OFF.

Controlling The Rear Climate Controls

From The Front MTC Display/Touchscreen

The Three-Zone Manual Temperature Control (MTC)

system allows for adjustment of the rear climate controls

from the front MTC display/touchscreen.

To change the rear system settings:

Press the Rear Climate button on the touchscreen to

display the rear climate controls. The control functions

now operate the rear system.

Press the Front Climate button on the touchscreen to

return to the front climate controls.

REAR CLIMATE CONTROL BUTTON

Press and release this button to access the rear

climate controls. The indicator will illuminate when

the rear climate controls are on.

REAR LOCK BUTTON

Press and release this button to lock out the

rear manual temperature controls from

adjusting the rear temperature and blower

settings.

FRONT CLIMATE BUTTON

Press and release this button to change the

display on the Uconnect system back to the

Front Climate Controls.

23_RUV_OM_EN_US_t.book Page 46

Page 85 of 256

STARTING AND OPERATING83

The following indicators should be used to ensure that you

have properly engaged the transmission into the PARK

position:

Look at the transmission gear position display and

verify that it indicates the PARK position (P), and is not

blinking.

With the brake pedal released, verify that the gear

selector will not move out of PARK.

REVERSE (R)

This range is for moving the vehicle backward. Shift into

REVERSE only after the vehicle has come to a complete stop.

NEUTRAL (N)

Use this range when the vehicle is standing for prolonged

periods with the engine running. The engine may be

started in this range. Apply the parking brake and shift the

transmission into PARK if you must exit the vehicle.

DRIVE (D)

This range should be used for most city and highway driving. It

provides the smoothest upshifts and downshifts, and the best

fuel economy. The transmission automatically upshifts through

all forward gears. The DRIVE position provides optimum driving

characteristics under all normal operating conditions.

If the transmission temperature exceeds normal operating

limits, the transmission controller may modify the transmission

shift schedule, reduce engine torque, and/or expand the range

of torque converter clutch engagement. This is done to prevent

transmission damage due to overheating.

If the transmission becomes extremely hot, the

Transmission Temperature Warning Light will illuminate, a

warning message will appear in the instrument cluster,

and the transmission may operate differently until the

transmission cools down.

During cold temperatures, transmission operation may be

modified depending on engine and transmission temperature

as well as vehicle speed. This feature improves warm-up time

of the engine and transmission to achieve maximum efficiency.

Engagement of the torque converter clutch, and shifts into

EIGHTH or NINTH gear, are inhibited until the transmission fluid

is warm

Ú

page 84. Normal operation will resume once the

transmission temperature has risen to a suitable level.

LOW (L)

Use this range for engine braking when descending

very steep grades. In this range, the transmission will

downshift for increased engine braking. To access the

LOW position, push down on the gear selector and rotate

it fully clockwise.

Transmission Limp Home Mode

Transmission function is monitored electronically for

abnormal conditions. If a condition is detected that could

result in transmission damage, Transmission Limp Home

Mode is activated. In this mode, the transmission may

operate only in a fixed gear, or may remain in NEUTRAL.

The Malfunction Indicator Light (MIL) may be illuminated.

Limp Home Mode may allow the vehicle to be driven to an

authorized dealer for service without damaging the

transmission.

CAUTION!

Before moving the transmission gear selector out of

PARK, you must start the engine, and also press the

brake pedal. Otherwise, damage to the gear selector

could result.

DO NOT race the engine when shifting from PARK

or NEUTRAL into another gear range, as this can

damage the drivetrain.

WARNING!

Do not coast in NEUTRAL and never turn off the ignition to

coast down a hill. These are unsafe practices that limit your

response to changing traffic or road conditions. You might

lose control of the vehicle and have a collision.

CAUTION!

Towing the vehicle, coasting, or driving for any other

reason with the transmission in NEUTRAL can cause

severe transmission damage.

If Recreational Towing

Úpage 101.

If Towing A Disabled Vehicle

Úpage 190.

4

23_RUV_OM_EN_US_t.book Page 83

Page 95 of 256

STARTING AND OPERATING93

REFUELING THE VEHICLE

There is no fuel filler cap. Two flapper doors inside the pipe

seal the system.

1. Put the vehicle in PARK and switch the ignition OFF.

2. Push the center-rear edge of the fuel filler door

(3 o'clock position) and release to open. Rotate to

full open position.

Fuel Filler Door

3. Insert the fuel nozzle fully into the filler pipe; the nozzle opens and holds both flapper doors while

refueling.

4. When the fuel nozzle “clicks” or shuts off, the fuel tank is full.

5. Keep the nozzle in the filler for five seconds after the nozzle clicks to allow fuel to drain from the nozzle. 6. Remove the fuel filler nozzle.

7. To close the fuel filler door, push the center-rear edge

(3 o’clock position) of the fuel filler door and then

release. The fuel filler door will latch closed.

NOTE:In certain cold conditions, ice may prevent the fuel filler

door from opening. If this occurs, lightly push on the fuel

filler door around the perimeter to break the ice buildup.

VEHICLE LOADING

CERTIFICATION LABEL

As required by National Highway Traffic Safety

Administration regulations, your vehicle has a certification

label affixed to the driver's side door or pillar.

This label contains the month and year of manufacture,

Gross Vehicle Weight Rating (GVWR), front and rear Gross

Axle Weight Rating (GAWR), and Vehicle Identification

Number (VIN). A Month-Day-Hour (MDH) number is

included on this label and indicates the Month, Day and

Hour of manufacture. The bar code that appears on the

bottom of the label is your VIN.

Gross Vehicle Weight Rating (GVWR)

The GVWR is the total permissible weight of your vehicle

including driver, passengers, vehicle, options and cargo.

The label also specifies maximum capacities of front and

rear GAWR. Total load must be limited so GVWR and front

and rear GAWR are not exceeded.

CAUTION!

To avoid vehicle damage, ParkView should only be used

as a parking aid. The ParkView camera is unable to view

every obstacle or object in your drive path.

To avoid vehicle damage, the vehicle must be driven

slowly when using ParkView to be able to stop in time

when an obstacle is seen. It is recommended that

the driver look frequently over his/her shoulder when

using ParkView.

WARNING!

Never have any smoking materials lit in or near the

vehicle when the fuel door is open or the tank is

being filled.

Never add fuel when the engine is running. This is in

violation of most state and federal fire regulations

and may cause the Malfunction Indicator Light to

turn on.

A fire may result if fuel is pumped into a portable

container that is inside of a vehicle. You could be

burned. Always place fuel containers on the ground

while filling.

CAUTION!

To avoid fuel spillage and overfilling, do not “top off” the

fuel tank after filling.

4

23_RUV_OM_EN_US_t.book Page 93

Page 113 of 256

MULTIMEDIA111

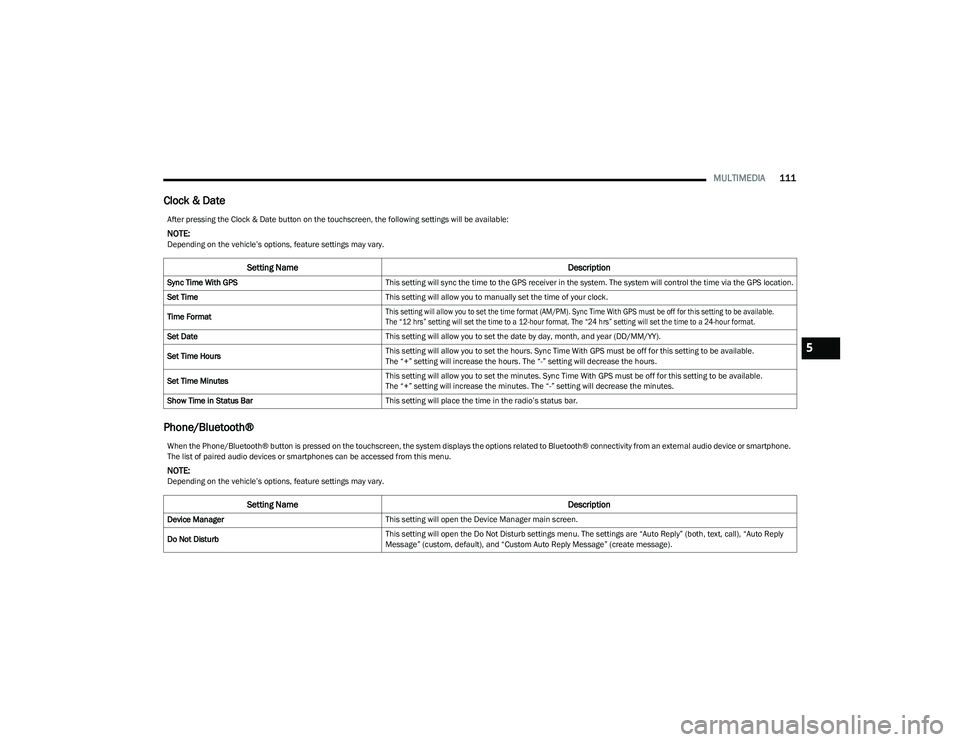

Clock & Date

Phone/Bluetooth®

After pressing the Clock & Date button on the touchscreen, the following settings will be available:

NOTE:Depending on the vehicle’s options, feature settings may vary.

Setting Name Description

Sync Time With GPSThis setting will sync the time to the GPS receiver in the system. The system will control the time via the GPS location.

Set Time This setting will allow you to manually set the time of your clock.

Time Format

This setting will allow you to set the time format (AM/PM). Sync Time With GPS must be off for this setting to be available.

The “12 hrs” setting will set the time to a 12-hour format. The “24 hrs” setting will set the time to a 24-hour format.

Set Date This setting will allow you to set the date by day, month, and year (DD/MM/YY).

Set Time Hours This setting will allow you to set the hours. Sync Time With GPS must be off for this setting to be available.

The “+” setting will increase the hours. The “-” setting will decrease the hours.

Set Time Minutes This setting will allow you to set the minutes. Sync Time With GPS must be off for this setting to be available.

The “+” setting will increase the minutes. The “-” setting will decrease the minutes.

Show Time in Status Bar This setting will place the time in the radio’s status bar.

When the Phone/Bluetooth® button is pressed on the touchscreen, the system displays the options related to Bluetooth® connectivity from an external audio device or smartphone.

The list of paired audio devices or smartphones can be accessed from this menu.

NOTE:Depending on the vehicle’s options, feature settings may vary.

Setting Name Description

Device ManagerThis setting will open the Device Manager main screen.

Do Not Disturb This setting will open the Do Not Disturb settings menu. The settings are “Auto Reply” (both, text, call), “Auto Reply

Message” (custom, default), and “Custom Auto Reply Message” (create message).

5

23_RUV_OM_EN_US_t.book Page 111

Page 177 of 256

IN CASE OF EMERGENCY175

(Continued)

3. Remove Jack by turning the jack screw counter

-

clockwise to collapse from storage area that is

located behind the tire.

Jack Location

JACKING INSTRUCTIONS

Jack Warning Label Extending The Wrench

1. Loosen (but do not remove) the wheel lug nuts by

turning them to the left, one turn while the wheel is

still on the ground.

1 — Jack Screw

2 — Jack

WARNING!

Carefully follow these tire changing warnings to help

prevent personal injury or damage to your vehicle:

Always park on a firm, level surface as far from the

edge of the roadway as possible before raising the

vehicle.

Turn on the Hazard Warning Flashers.

Apply the parking brake firmly and set the transmis -

sion in PARK.

Block the wheel diagonally opposite the wheel to be

raised.

Do not let any passenger sit in the vehicle when it is

on a jack.

Do not get under the vehicle when it is on a jack.

If you need to get under a raised vehicle, take it to a

service center where it can be raised on a lift.

Only use the jack in the positions indicated and for

lifting this vehicle during a tire change.

If working on or near a roadway, be extremely careful

of motor traffic.

WARNING!CAUTION!

Do not attempt to raise the vehicle by jacking on

locations other than those indicated in the Jacking

Instructions for this vehicle.

7

23_RUV_OM_EN_US_t.book Page 175

Page 179 of 256

IN CASE OF EMERGENCY177

3. Place the wrench on the jack screw and turn

clockwise until the jack head is properly engaged in

the described location. Do not raise the vehicle until

you are sure the jack is securely engaged.

4. Raise the vehicle by turning the jack screw clockwise, using the swivel wrench. Raise the vehicle only until

the tire just clears the surface and enough clearance

is obtained to install the compact spare tire.

Minimum tire lift provides maximum stability.

5. Remove the wheel lug nuts, for vehicles with wheel covers, remove the cover from the wheel by hand.

Do not pry the wheel cover off. Then pull the wheel off

the hub.

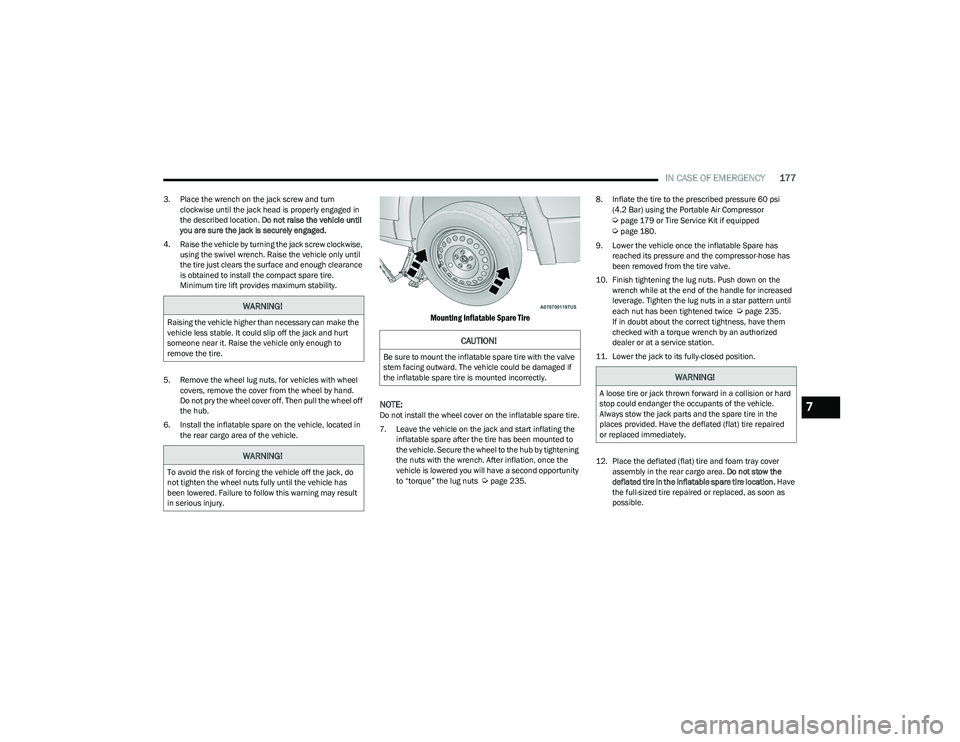

6. Install the inflatable spare on the vehicle, located in the rear cargo area of the vehicle.

Mounting Inflatable Spare Tire

NOTE:

Do not install the wheel cover on the inflatable spare tire.

7. Leave the vehicle on the jack and start inflating the inflatable spare after the tire has been mounted to

the vehicle. Secure the wheel to the hub by tightening

the nuts with the wrench. After inflation, once the

vehicle is lowered you will have a second opportunity

to “torque” the lug nuts

Úpage 235. 8. Inflate the tire to the prescribed pressure 60 psi

(4.2 Bar) using the Portable Air Compressor

Úpage 179 or Tire Service Kit if equipped Úpage 180.

9. Lower the vehicle once the inflatable Spare has reached its pressure and the compressor-hose has

been removed from the tire valve.

10. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until

each nut has been tightened twice

Úpage 235.

If in doubt about the correct tightness, have them

checked with a torque wrench by an authorized

dealer or at a service station.

11. Lower the jack to its fully-closed position.

12. Place the deflated (flat) tire and foam tray cover assembly in the rear cargo area. Do not stow the

deflated tire in the inflatable spare tire location. Have

the full-sized tire repaired or replaced, as soon as

possible.WARNING!

Raising the vehicle higher than necessary can make the

vehicle less stable. It could slip off the jack and hurt

someone near it. Raise the vehicle only enough to

remove the tire.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the wheel nuts fully until the vehicle has

been lowered. Failure to follow this warning may result

in serious injury.

CAUTION!

Be sure to mount the inflatable spare tire with the valve

stem facing outward. The vehicle could be damaged if

the inflatable spare tire is mounted incorrectly.

WARNING!

A loose tire or jack thrown forward in a collision or hard

stop could endanger the occupants of the vehicle.

Always stow the jack parts and the spare tire in the

places provided. Have the deflated (flat) tire repaired

or replaced immediately.

7

23_RUV_OM_EN_US_t.book Page 177

Page 180 of 256

178IN CASE OF EMERGENCY

13. Stow the jack back in the stowage compartment and

place the access panel back. The stud of the storage

area must be threaded through the lower part of the

jack. Then turn the Jack Screw clockwise to secure it

in place.

NOTE:Stow the foam tray and components in the cargo area.

Storing The Jack

ROAD TIRE INSTALLATION

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels with wheel covers, install two lug nuts on the mounting

studs which are on each side of the valve stem. Install

the lug nuts with the cone shaped end of the nut

toward the wheel. Lightly tighten the lug nuts.

Tire And Wheel Cover Or Center Cap

3. Align the valve notch in the wheel cover with the valve stem on the wheel. Install the cover by hand, snapping the

cover over the two lug nuts. Do not use a hammer or

excessive force to install the cover.

4. Install the remaining lug nuts with the cone shaped end of the nut toward the wheel. Lightly tighten all the lug nuts

until the wheel sits flush onto the hub and there is no play.

The nuts will have to be fully tightened once the vehicle is

lowered. Tightening an improperly seated wheel under

vehicle load can damage the threads, cause vibration, and

undermine safety.

5. Lower the vehicle to the ground by turning the jack handle counterclockwise.

6. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased leverage.

Tighten the lug nuts in a star pattern until each nut has

been tightened twice. Details for proper wheel lug nut

torque

Ú

page 235. If in doubt about the correct

tightness, have them checked with a torque wrench

by an authorized dealer or at a service station.

7. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are

properly seated against the wheel.

1 — Jack Screw

2 — Jack

3 — Stud

1 — Valve Stem

2 — Valve Notch

3 — Road Tire

4 — Wheel Cover

5 — Wheel Lug Nut

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the wheel nuts fully until the vehicle has

been lowered. Failure to follow this warning may result

in serious injury.

23_RUV_OM_EN_US_t.book Page 178

Page 218 of 256

216SERVICING AND MAINTENANCE

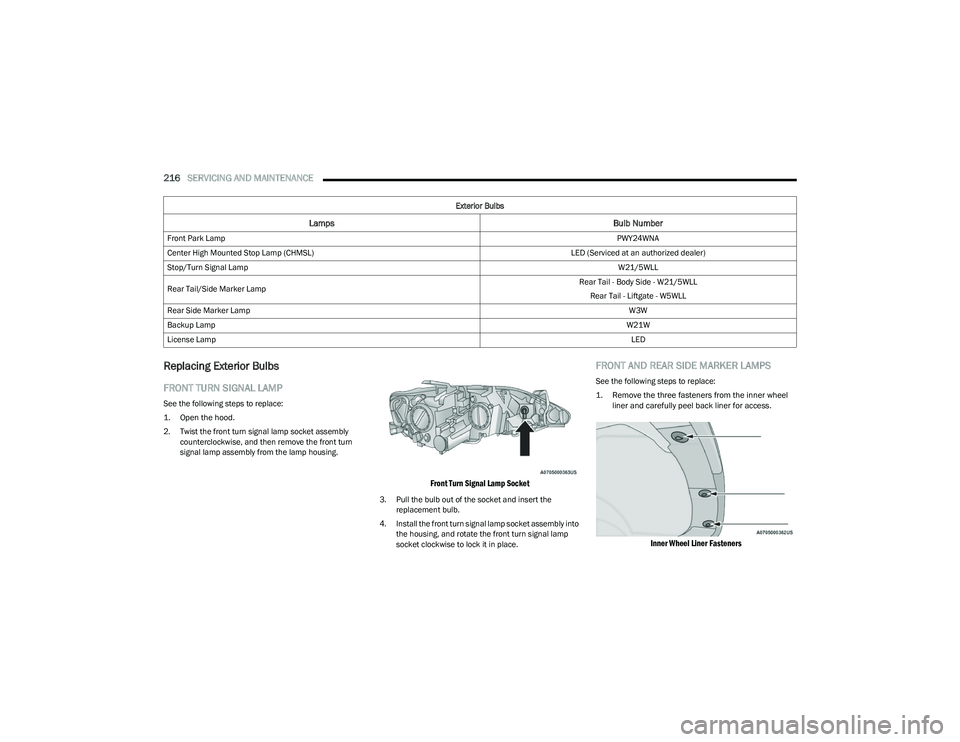

Replacing Exterior Bulbs

FRONT TURN SIGNAL LAMP

See the following steps to replace:

1. Open the hood.

2. Twist the front turn signal lamp socket assembly

counterclockwise, and then remove the front turn

signal lamp assembly from the lamp housing.

Front Turn Signal Lamp Socket

3. Pull the bulb out of the socket and insert the replacement bulb.

4. Install the front turn signal lamp socket assembly into the housing, and rotate the front turn signal lamp

socket clockwise to lock it in place.

FRONT AND REAR SIDE MARKER LAMPS

See the following steps to replace:

1. Remove the three fasteners from the inner wheel liner and carefully peel back liner for access.

Inner Wheel Liner Fasteners

Front Park Lamp PWY24WNA

Center High Mounted Stop Lamp (CHMSL) LED (Serviced at an authorized dealer)

Stop/Turn Signal Lamp W21/5WLL

Rear Tail/Side Marker Lamp Rear Tail - Body Side - W21/5WLL

Rear Tail - Liftgate - W5WLL

Rear Side Marker Lamp W3W

Backup Lamp W21W

License Lamp LED

Exterior Bulbs

Lamps

Bulb Number

23_RUV_OM_EN_US_t.book Page 216

Page 219 of 256

SERVICING AND MAINTENANCE217

2. Firmly grab the front side marker lamp socket and

rotate a quarter turn counterclockwise to remove it

from the lamp assembly.

Front Side Marker Lamp Bulb Removal

3. Remove bulb from the front side marker lamp socket and replace with a new bulb.

4. Install front side marker lamp socket in lamp assembly and rotate a quarter turn clockwise to lock

into place.

5. Position the inner wheel liner in place and install the three fasteners.

TIRES

TIRE SAFETY INFORMATION

Tire safety information will cover aspects of the following

information: Tire Markings, Tire Identification Numbers,

Tire Terminology and Definitions, Tire Pressures, and Tire

Loading.

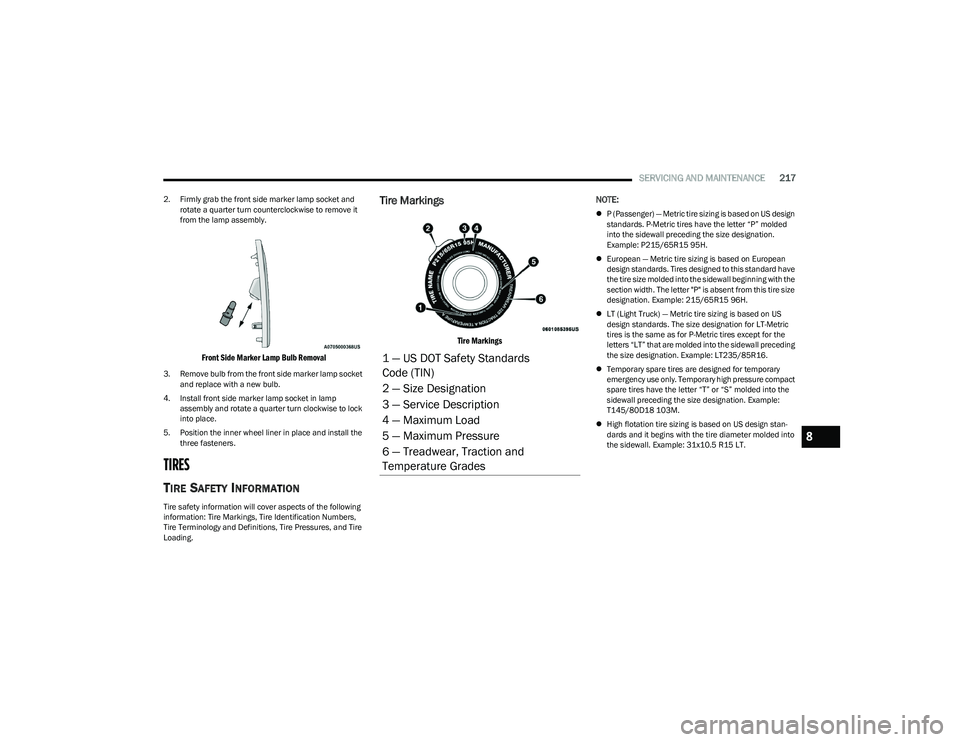

Tire Markings

Tire Markings

NOTE:

P (Passenger) — Metric tire sizing is based on US design

standards. P-Metric tires have the letter “P” molded

into the sidewall preceding the size designation.

Example: P215/65R15 95H.

European — Metric tire sizing is based on European

design standards. Tires designed to this standard have

the tire size molded into the sidewall beginning with the

section width. The letter "P" is absent from this tire size

designation. Example: 215/65R15 96H.

LT (Light Truck) — Metric tire sizing is based on US

design standards. The size designation for LT-Metric

tires is the same as for P-Metric tires except for the

letters “LT” that are molded into the sidewall preceding

the size designation. Example: LT235/85R16.

Temporary spare tires are designed for temporary

emergency use only. Temporary high pressure compact

spare tires have the letter “T” or “S” molded into the

sidewall preceding the size designation. Example:

T145/80D18 103M.

High flotation tire sizing is based on US design stan -

dards and it begins with the tire diameter molded into

the sidewall. Example: 31x10.5 R15 LT.

1 — US DOT Safety Standards

Code (TIN)

2 — Size Designation

3 — Service Description

4 — Maximum Load

5 — Maximum Pressure

6 — Treadwear, Traction and

Temperature Grades

8

23_RUV_OM_EN_US_t.book Page 217