Switch Citroen BERLINGO 2005 1.G User Guide

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: BERLINGO, Model: Citroen BERLINGO 2005 1.GPages: 462, PDF Size: 10.48 MB

Page 291 of 462

![Citroen BERLINGO 2005 1.G User Guide Downloaded from www.Manualslib.com manuals search engine 285

INJECTION

CHECKS: LOW PRESSURE FUEL SUPPLY CIRCUIT

Tools.

[1] Ø 10 mm low pressure connector: 4215-T

[2] Pressure gauge for testing boost Citroen BERLINGO 2005 1.G User Guide Downloaded from www.Manualslib.com manuals search engine 285

INJECTION

CHECKS: LOW PRESSURE FUEL SUPPLY CIRCUIT

Tools.

[1] Ø 10 mm low pressure connector: 4215-T

[2] Pressure gauge for testing boost](/img/9/4138/w960_4138-290.png)

Downloaded from www.Manualslib.com manuals search engine 285

INJECTION

CHECKS: LOW PRESSURE FUEL SUPPLY CIRCUIT

Tools.

[1] Ø 10 mm low pressure connector: 4215-T

[2] Pressure gauge for testing boost pressure: 4073-T.A Toolkit 4073-T

IMPERATIVE: Respect the safety and cleanliness specific to high pressure diesel injection

engines.

Remove the air filter duct.

Link tool [1]in series, downstream of the injectors, between the fuel high pressure pump and the

fuel filter at «a»and «b».

WARNING: Any checking of pressure downstream of the fuel filter is prohibited.

Switch on the ignition.

ESSENTIAL: Check that the tool [2] is clean.

Check the negative pressure according to the table below:

Vacuum Observations

10 ± 05 cmhgEngine driven by the starter motor

20 ± 20 cmhgEngine running under full load

60 ± 05 cmhgSupply circuit obstructed

(full tank strainer, piping, fuel filter

B1BP2PHC

Engines: 9HZ - 9HY

XSARA PICASSO

Angl.-t2-page283-305-2005 9/01/06 10:18 Page 285

Page 294 of 462

![Citroen BERLINGO 2005 1.G User Guide Downloaded from www.Manualslib.com manuals search engine 288

INJECTION

CHECKS: LOW PRESSURE FUEL SUPPLY CIRCUIT

Tools.

[1] Ø 10 mm low pressure connector: 4215-T

[2] Ø 8 mmlow pressure connector: 42 Citroen BERLINGO 2005 1.G User Guide Downloaded from www.Manualslib.com manuals search engine 288

INJECTION

CHECKS: LOW PRESSURE FUEL SUPPLY CIRCUIT

Tools.

[1] Ø 10 mm low pressure connector: 4215-T

[2] Ø 8 mmlow pressure connector: 42](/img/9/4138/w960_4138-293.png)

Downloaded from www.Manualslib.com manuals search engine 288

INJECTION

CHECKS: LOW PRESSURE FUEL SUPPLY CIRCUIT

Tools.

[1] Ø 10 mm low pressure connector: 4215-T

[2] Ø 8 mmlow pressure connector: 4218-T

[3]Pressure gauge for testing boost pressure: 4073-T Kit 4073-T

Connect the tool [1]between the booster pump and the fuel filter

(white mark at "a" on the fuel

supply pipe).

Connect the tool [2]downstream of the diesel injectors, between the high pressure fuel pump and

the fuel filter

(green mark at "b" on the fuel return pipe).

WARNING: Any check of pressure downstream of the fuel filter is PROHIBITED.

Checks on pressure: static.

- Switch on ignition.

For 3 seconds

(normal functioning):

- Fuel supply pressure shown by the pressure gauge [3] = 1.8 ± 0.4 bar.

- Fuel return pressure shown by the pressure gauge [3] = 0.5 ± 0.4 bar.

B1BP1TWD

Engines: RHY - RHZ

XSARA PICASSO

Angl.-t2-page283-305-2005 9/01/06 10:18 Page 288

Page 305 of 462

![Citroen BERLINGO 2005 1.G User Guide Downloaded from www.Manualslib.com manuals search engine 299

INJECTION

CHECKING THE AIR SUPPLY CIRCUIT

B1BP33ZC

B1BP340C

Engine: RHR

B1BP341C

B1BP342C

Tool.

[1]Manual pressure-vacuum pump: FACOM DA 16 Citroen BERLINGO 2005 1.G User Guide Downloaded from www.Manualslib.com manuals search engine 299

INJECTION

CHECKING THE AIR SUPPLY CIRCUIT

B1BP33ZC

B1BP340C

Engine: RHR

B1BP341C

B1BP342C

Tool.

[1]Manual pressure-vacuum pump: FACOM DA 16](/img/9/4138/w960_4138-304.png)

Downloaded from www.Manualslib.com manuals search engine 299

INJECTION

CHECKING THE AIR SUPPLY CIRCUIT

B1BP33ZC

B1BP340C

Engine: RHR

B1BP341C

B1BP342C

Tool.

[1]Manual pressure-vacuum pump: FACOM DA 16

IMPERATIVE: Respect the safety and cleanliness specific to high pressure diesel

injection engines.

WARNING: After switching off the ignition, wait 15 minutes before disconnecting

the battery

(to guarantee memorisation of the initialisations of the different ECUS).

Checking the vacuum source

(vacuum pump).

Connect the tool [1] on the take-off «a».

Start the engine.

The value should be: 1 ± 0,2.

Turbocharging pressure electrovalve.

Connect the tool [1]on the vacuum supply «b»of the electrovalve (1).

Start the engine.

The value should be: 1 ± 0,2.

Cold air circuit electrovalve.

Connect the tool [1]on the vacuum supply «c»of the electrovalve (2).

Start the engine.

The value should be: 1 ± 0,2.

Warm air circuit electrovalve.

Connect the tool [1]on the vacuum supply «d»of the electrovalve (3).

Start the engine.

The value should be: 1 ± 0,2.

C4

Angl.-t2-page283-305-2005 9/01/06 10:18 Page 299

Page 325 of 462

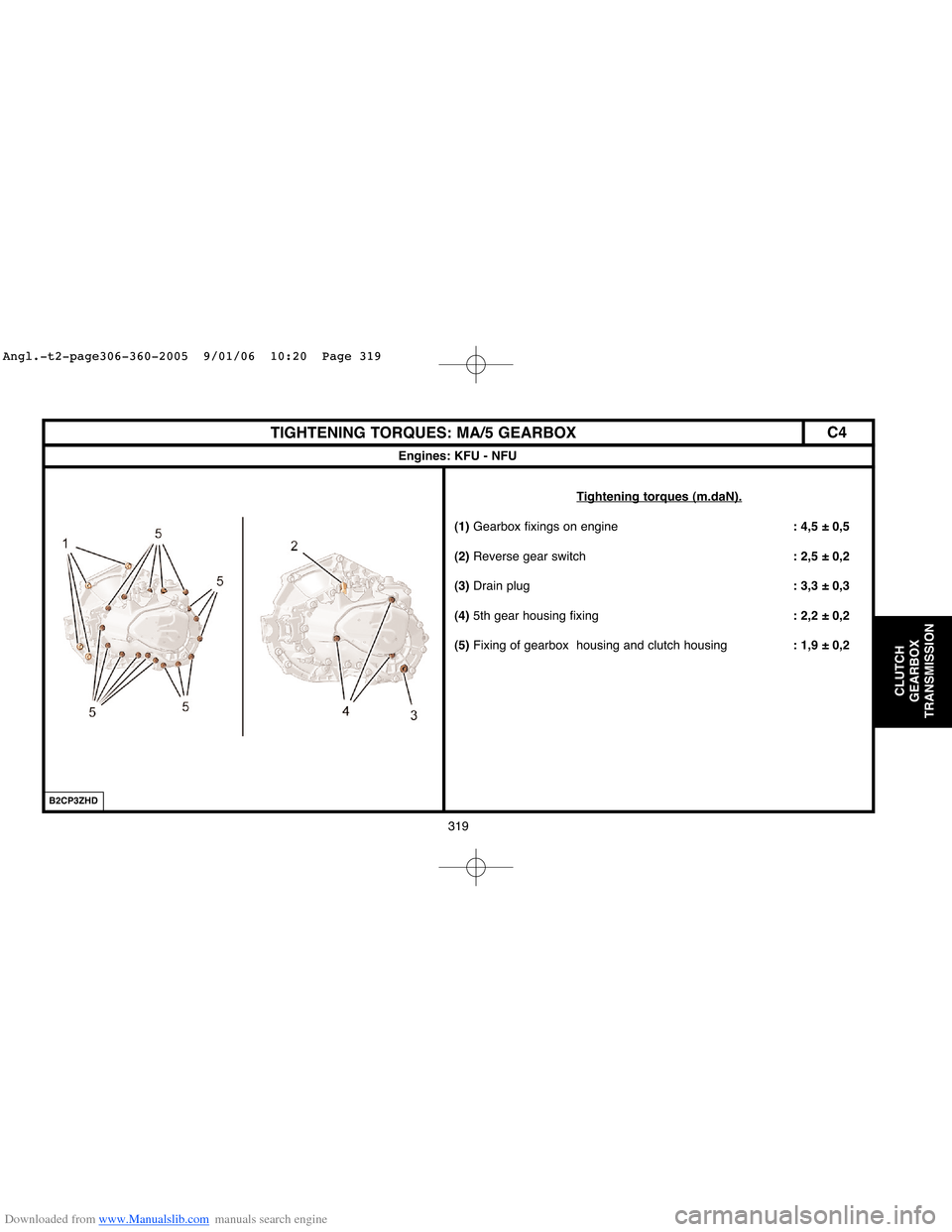

Downloaded from www.Manualslib.com manuals search engine 319

CLUTCH

GEARBOX

TRANSMISSION

TIGHTENING TORQUES: MA/5 GEARBOX

Engines: KFU - NFU

Tightening torques (m.daN).

(1)Gearbox fixings on engine: 4,5 ± 0,5

(2)Reverse gear switch: 2,5 ± 0,2

(3)Drain plug: 3,3 ± 0,3

(4)5th gear housing fixing: 2,2 ± 0,2

(5)Fixing of gearbox housing and clutch housing: 1,9 ± 0,2

B2CP3ZHD

C4

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 319

Page 329 of 462

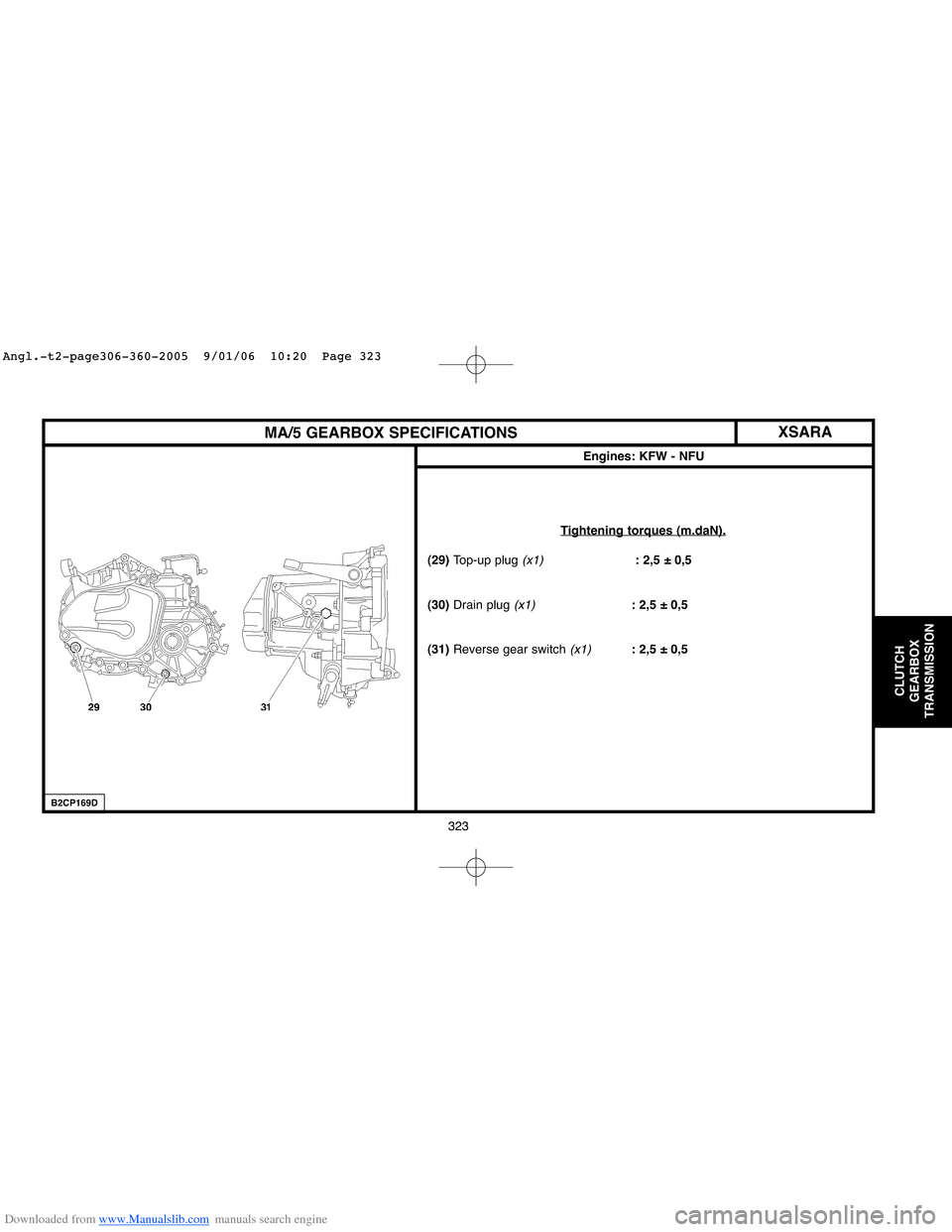

Downloaded from www.Manualslib.com manuals search engine 323

CLUTCH

GEARBOX

TRANSMISSION

MA/5 GEARBOX SPECIFICATIONS

Engines: KFW - NFU

Tightening torques (m.daN).

(29) Top-up plug (x1): 2,5 ± 0,5

(30)Drain plug

(x1): 2,5 ± 0,5

(31)Reverse gear switch

(x1): 2,5 ± 0,5

B2CP169D

XSARA

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 323

Page 330 of 462

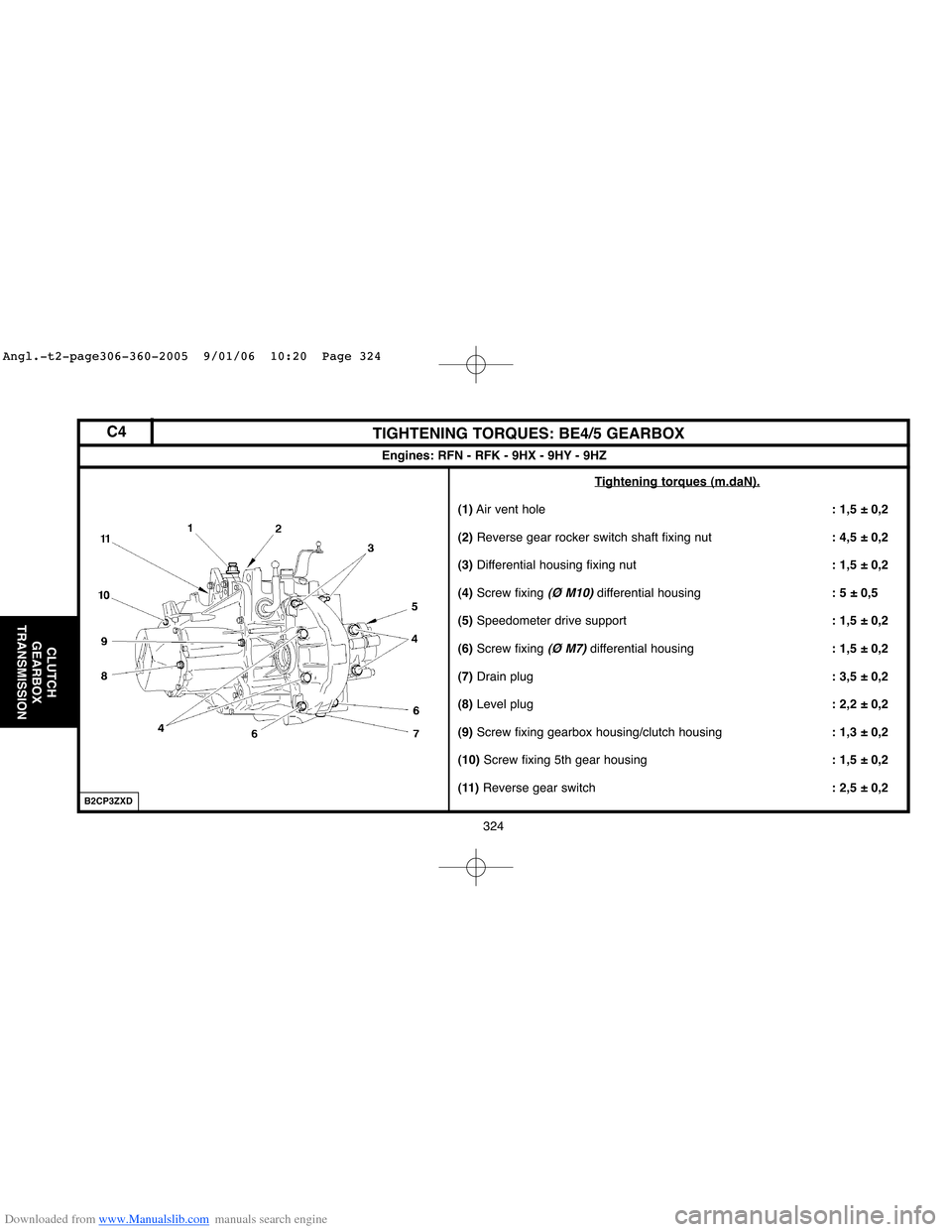

Downloaded from www.Manualslib.com manuals search engine 324

CLUTCH

GEARBOX

TRANSMISSION

TIGHTENING TORQUES: BE4/5 GEARBOX

Engines: RFN - RFK - 9HX - 9HY - 9HZ

Tightening torques (m.daN).

(1)Air vent hole : 1,5 ± 0,2

(2)Reverse gear rocker switch shaft fixing nut: 4,5 ± 0,2

(3) Differential housing fixing nut: 1,5 ± 0,2

(4)Screw fixing

(Ø M10)differential housing: 5 ± 0,5

(5)Speedometer drive support: 1,5 ± 0,2

(6)Screw fixing

(Ø M7)differential housing: 1,5 ± 0,2

(7)Drain plug : 3,5 ± 0,2

(8)Level plug: 2,2 ± 0,2

(9)Screw fixing gearbox housing/clutch housing: 1,3 ± 0,2

(10) Screw fixing 5th gear housing: 1,5 ± 0,2

(11)Reverse gear switch: 2,5 ± 0,2

B2CP3ZXD

C4

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 324

Page 333 of 462

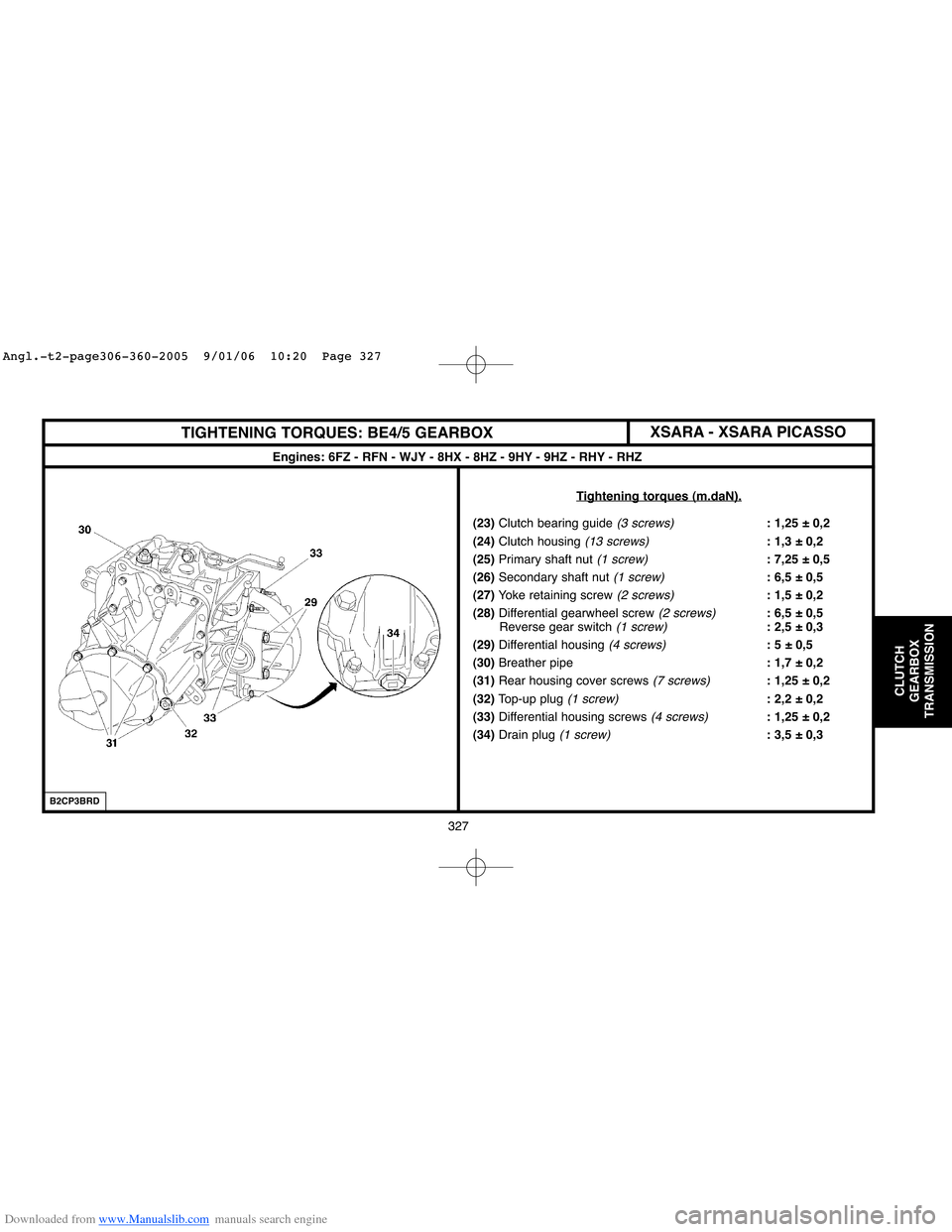

Downloaded from www.Manualslib.com manuals search engine 327

CLUTCH

GEARBOX

TRANSMISSION

TIGHTENING TORQUES: BE4/5 GEARBOX

Engines: 6FZ - RFN - WJY - 8HX - 8HZ - 9HY - 9HZ - RHY - RHZ

T

ightening torques (m.daN).

(23)Clutch bearing guide (3 screws): 1,25 ± 0,2

(24)Clutch housing

(13 screws): 1,3 ± 0,2

(25)Primary shaft nut

(1 screw): 7,25 ± 0,5

(26)Secondary shaft nut

(1 screw): 6,5 ± 0,5

(27)Yoke retaining screw

(2 screws): 1,5 ± 0,2

(28)Differential gearwheel screw

(2 screws): 6,5 ± 0,5

Reverse gear switch (1 screw): 2,5 ± 0,3

(29)Differential housing

(4 screws): 5 ± 0,5

(30)Breather pipe: 1,7 ± 0,2

(31)Rear housing cover screws

(7 screws): 1,25 ± 0,2

(32)Top-up plug

(1 screw): 2,2 ± 0,2

(33) Differential housing screws

(4 screws): 1,25 ± 0,2

(34)Drain plug

(1 screw): 3,5 ± 0,3

B2CP3BRD

XSARA - XSARA PICASSO

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 327

Page 335 of 462

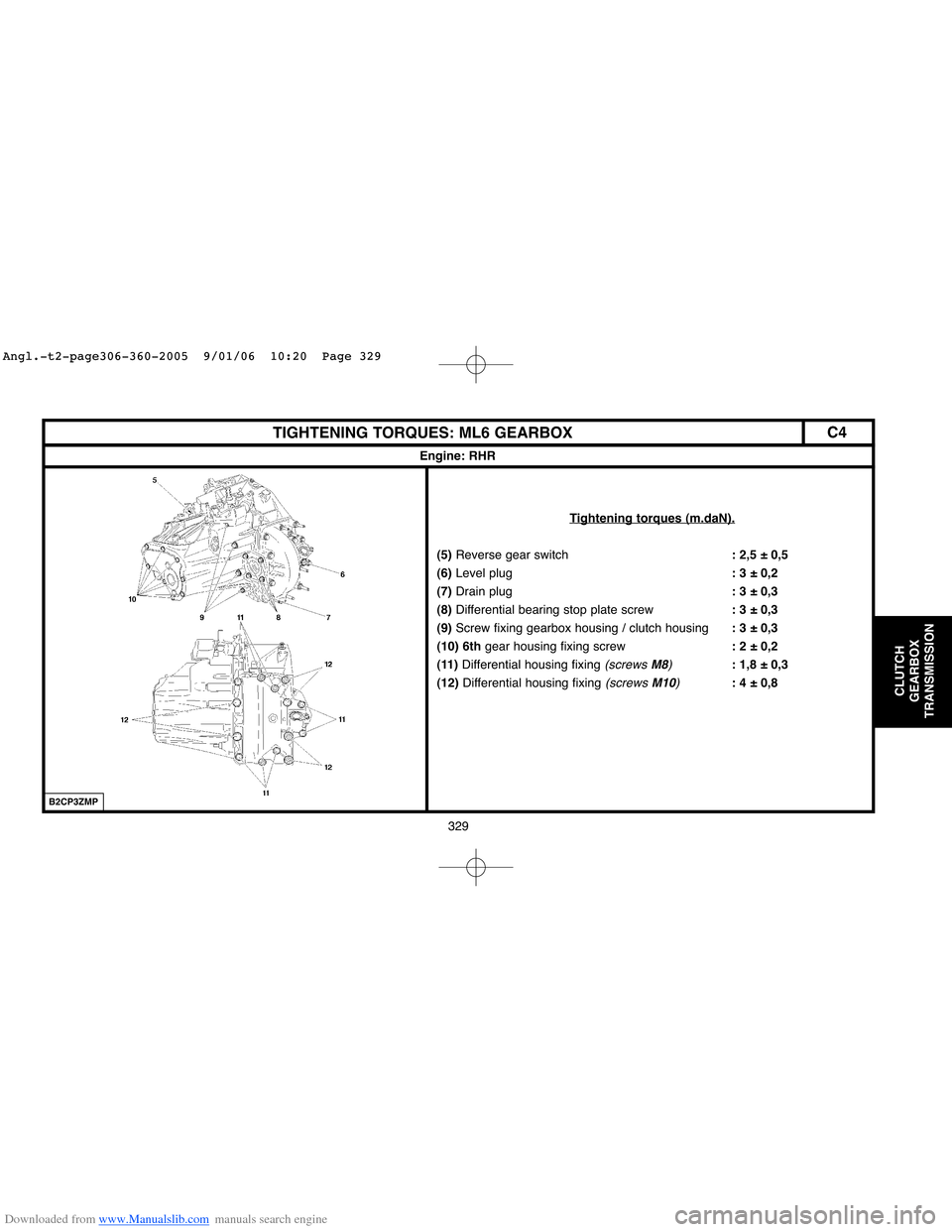

Downloaded from www.Manualslib.com manuals search engine 329

CLUTCH

GEARBOX

TRANSMISSION

TIGHTENING TORQUES: ML6 GEARBOX

Engine: RHR

Tightening torques (m.daN).

(5)Reverse gear switch: 2,5 ± 0,5

(6)Level plug: 3 ± 0,2

(7)Drain plug: 3 ± 0,3

(8)Differential bearing stop plate screw: 3 ± 0,3

(9)Screw fixing gearbox housing / clutch housing: 3 ± 0,3

(10) 6thgear housing fixing screw: 2 ± 0,2

(11)Differential housing fixing

(screws M8): 1,8 ± 0,3

(12)Differential housing fixing

(screws M10): 4 ± 0,8

B2CP3ZMP

C4

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 329

Page 355 of 462

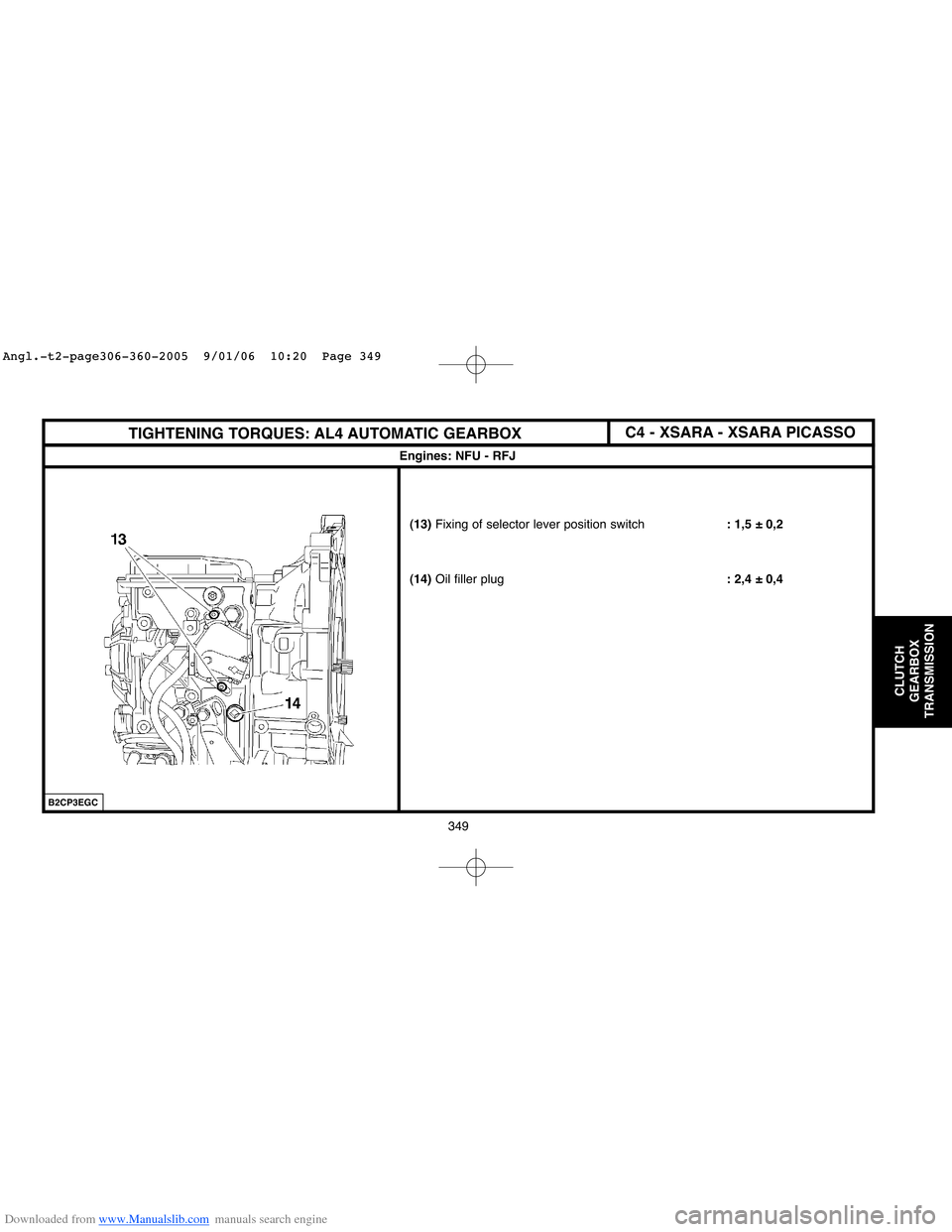

Downloaded from www.Manualslib.com manuals search engine 349

CLUTCH

GEARBOX

TRANSMISSION

Engines: NFU - RFJ

B2CP3EGC

(13)Fixing of selector lever position switch: 1,5 ± 0,2

(14)Oil filler plug: 2,4 ± 0,4

TIGHTENING TORQUES: AL4 AUTOMATIC GEARBOXC4 - XSARA - XSARA PICASSO

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 349

Page 357 of 462

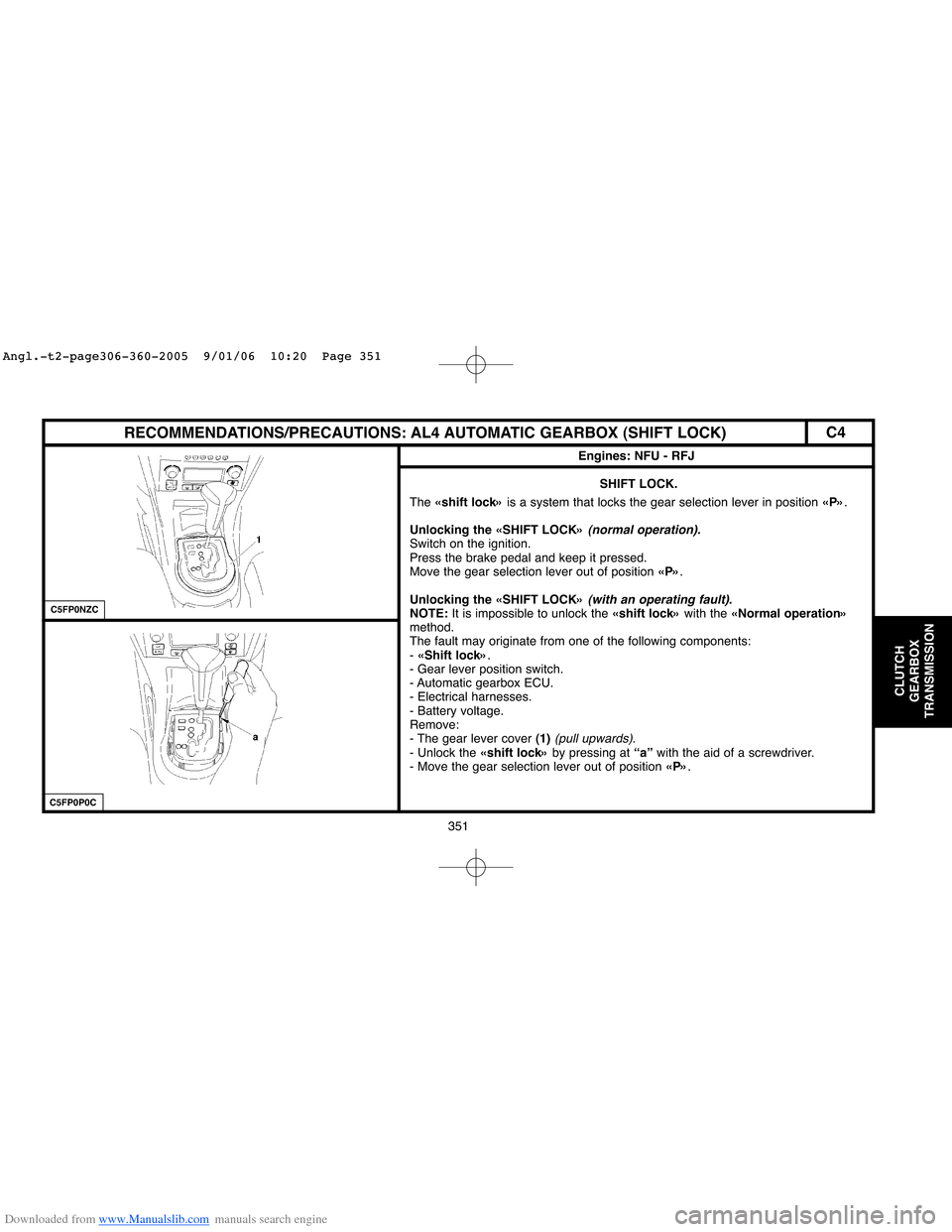

Downloaded from www.Manualslib.com manuals search engine 351

CLUTCH

GEARBOX

TRANSMISSION

RECOMMENDATIONS/PRECAUTIONS: AL4 AUTOMATIC GEARBOX (SHIFT LOCK)

Engines: NFU - RFJ

C5FP0NZC

C5FP0P0C

SHIFT LOCK.

The «shift lock»is a system that locks the gear selection lever in position «P».

Unlocking the «SHIFT LOCK»

(normal operation).Switch on the ignition.

Press the brake pedal and keep it pressed.

Move the gear selection lever out of position «P».

Unlocking the «SHIFT LOCK»

(with an operating fault).

NOTE:It is impossible to unlock the «shift lock»with the «Normal operation»

method.

The fault may originate from one of the following components:

- «Shift lock».

- Gear lever position switch.

- Automatic gearbox ECU.

- Electrical harnesses.

- Battery voltage.

Remove:

- The gear lever cover (1)

(pull upwards).

- Unlock the «shift lock»by pressing at “a”with the aid of a screwdriver.

- Move the gear selection lever out of position «P».

C4

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 351