check engine Citroen BERLINGO 2005 1.G User Guide

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: BERLINGO, Model: Citroen BERLINGO 2005 1.GPages: 462, PDF Size: 10.48 MB

Page 53 of 462

Downloaded from www.Manualslib.com manuals search engine 47

ENGINE

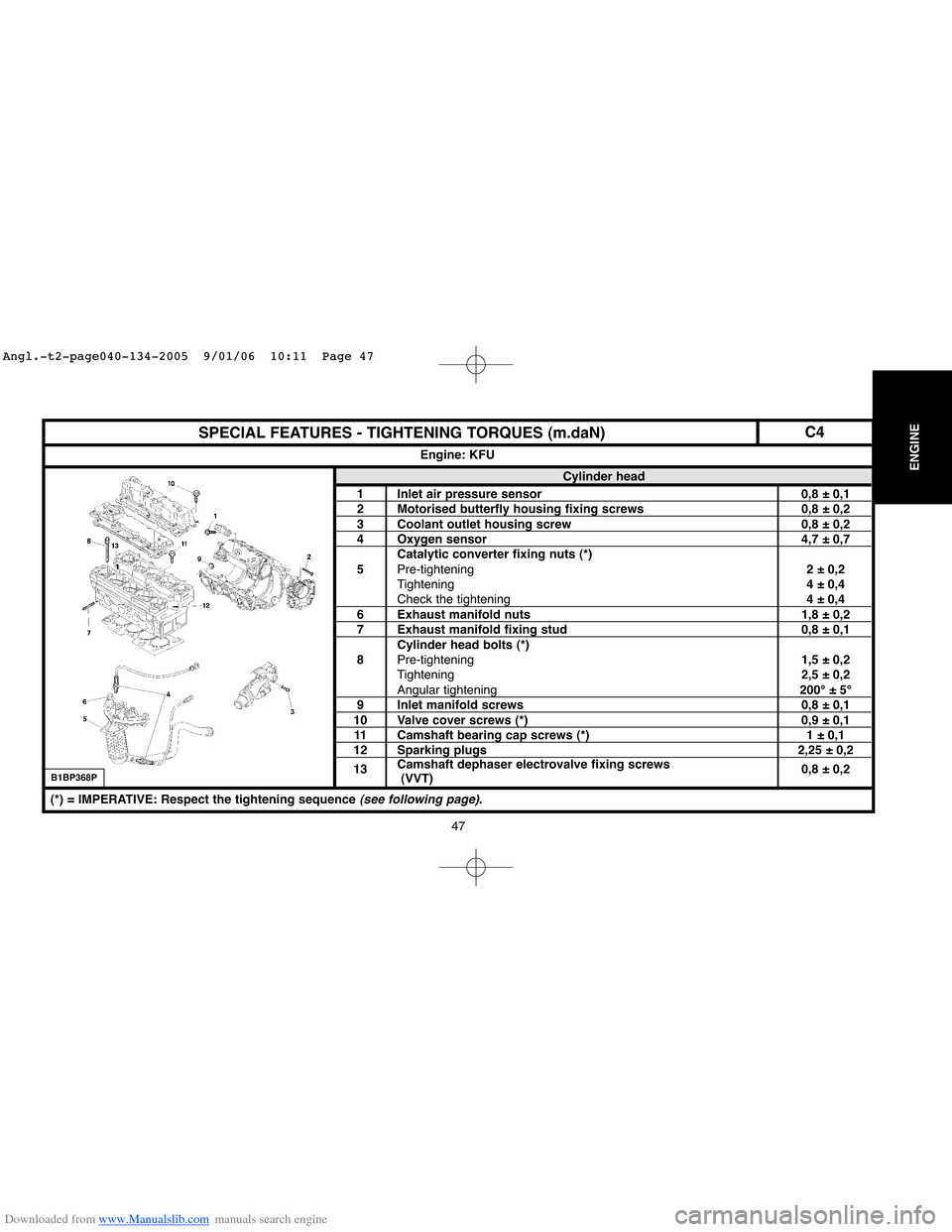

SPECIAL FEATURES - TIGHTENING TORQUES (m.daN)

Cylinder head

1 Inlet air pressure sensor 0,8 ± 0,12 Motorised butterfly housing fixing screws 0,8 ± 0,23 Coolant outlet housing screw 0,8 ± 0,24 Oxygen sensor 4,7 ± 0,7

Catalytic converter fixing nuts (*)

5Pre-tightening2 ± 0,2

Tightening4 ± 0,4

Check the tightening4 ± 0,46 Exhaust manifold nuts 1,8 ± 0,27 Exhaust manifold fixing stud 0,8 ± 0,1

Cylinder head bolts (*)

8Pre-tightening1,5 ± 0,2

Tightening2,5 ± 0,2

Angular tightening200° ± 5°9 Inlet manifold screws 0,8 ± 0,110 Valve cover screws (*) 0,9 ± 0,111 Camshaft bearing cap screws (*) 1 ± 0,112 Sparking plugs 2,25 ± 0,2

13Camshaft dephaser electrovalve fixing screws

0,8 ± 0,2

(VVT)

Engine: KFU

B1BP368P

(*) = IMPERATIVE: Respect the tightening sequence (see following page).

C4

Angl.-t2-page040-134-2005 9/01/06 10:11 Page 47

Page 61 of 462

Downloaded from www.Manualslib.com manuals search engine 55

ENGINE

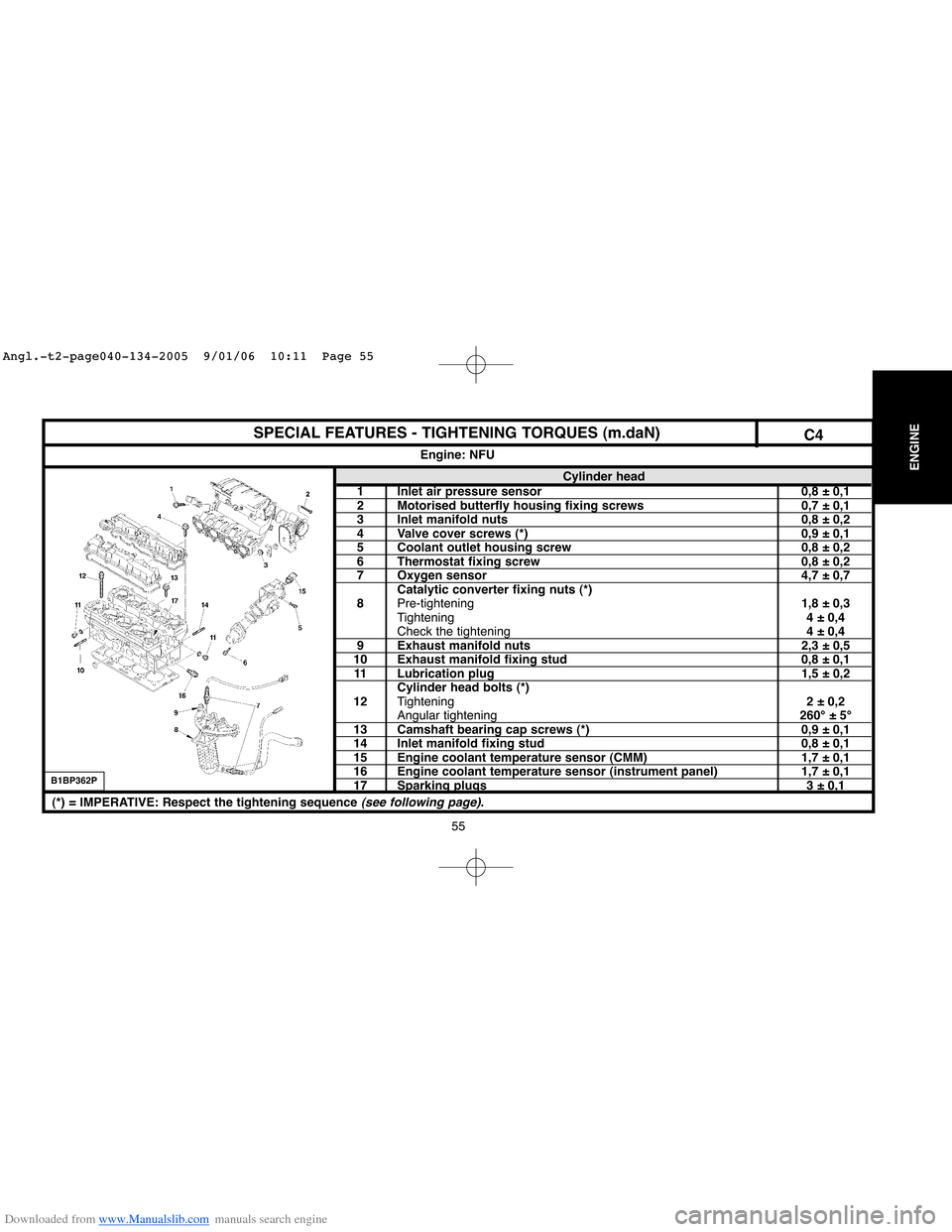

SPECIAL FEATURES - TIGHTENING TORQUES (m.daN)

Cylinder head1 Inlet air pressure sensor 0,8 ± 0,12 Motorised butterfly housing fixing screws 0,7 ± 0,13 Inlet manifold nuts 0,8 ± 0,24 Valve cover screws (*) 0,9 ± 0,15 Coolant outlet housing screw 0,8 ± 0,26 Thermostat fixing screw 0,8 ± 0,27 Oxygen sensor 4,7 ± 0,7

Catalytic converter fixing nuts (*)

8Pre-tightening1,8 ± 0,3

Tightening4 ± 0,4

Check the tightening4 ± 0,49 Exhaust manifold nuts 2,3 ± 0,510 Exhaust manifold fixing stud 0,8 ± 0,111 Lubrication plug 1,5 ± 0,2

Cylinder head bolts (*)

12Tightening2 ± 0,2

Angular tightening260° ± 5°13 Camshaft bearing cap screws (*) 0,9 ± 0,114 Inlet manifold fixing stud 0,8 ± 0,115 Engine coolant temperature sensor (CMM) 1,7 ± 0,116 Engine coolant temperature sensor (instrument panel) 1,7 ± 0,1

17 Sparking plugs 3 ± 0,1

Engine: NFU

B1BP362P

(*) = IMPERATIVE: Respect the tightening sequence (see following page).

C4

Angl.-t2-page040-134-2005 9/01/06 10:11 Page 55

Page 160 of 462

Downloaded from www.Manualslib.com manuals search engine 154

ENGINEAUXILIARY EQUIPMENT DRIVE BELT

Engines: All Types Petrol and Diesel

Tools.

- Belt tension measuring instrument: 4122 - T (C.TRONIC 105.5).

WARNING: If using tool 4099-T (C.TRONIC 105).

Essential.

- Before refitting the auxiliary equipment drive belt, check that:

- 1 / The roller(s) rotate freely (no play or stiffness).

- 2 / The belt is correctly engaged in the grooves of the various pulleys.

Angl.-t2-page135-239-2005 9/01/06 10:13 Page 154

Page 163 of 462

![Citroen BERLINGO 2005 1.G User Guide Downloaded from www.Manualslib.com manuals search engine 157

ENGINE

B1EP1GQD

AUXILIARY EQUIPMENT DRIVE BELT

Engine: KFU

Véhicule with air conditioning.

Removing.

Place tool [4]at «a».

Compress the Citroen BERLINGO 2005 1.G User Guide Downloaded from www.Manualslib.com manuals search engine 157

ENGINE

B1EP1GQD

AUXILIARY EQUIPMENT DRIVE BELT

Engine: KFU

Véhicule with air conditioning.

Removing.

Place tool [4]at «a».

Compress the](/img/9/4138/w960_4138-162.png)

Downloaded from www.Manualslib.com manuals search engine 157

ENGINE

B1EP1GQD

AUXILIARY EQUIPMENT DRIVE BELT

Engine: KFU

Véhicule with air conditioning.

Removing.

Place tool [4]at «a».

Compress the dynamic tensioner roller.

Place tool [3]at «b».

Remove the auxiliary equipment drive belt.

IMPERATIVE: Check that the dynamic tensioner roller turns freely

(without play and without tight

spots).

Refitting.

NOTE: Visually check the condition of the auxiliary equipment drive belt prior to refitting.

Place tool [4]at «a».

Compress the dynamic tensioner roller.

Remove tool [3].

Refit the auxiliary equipment drive belt.

Respect the following sequence:

- Crankshaft pinion, aircon compressor pulley, alternator pulley, dynamic tensioner roller.

Remove the tools.

Complete the refitting.

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 157

Page 164 of 462

![Citroen BERLINGO 2005 1.G User Guide Downloaded from www.Manualslib.com manuals search engine 158

ENGINE

B1BP234C

XSARA PICASSOAUXILIARY EQUIPMENT DRIVE BELT

Engine: NFV

Without air conditioning

Tools.

[1]Pliers for removing plastic pegs Citroen BERLINGO 2005 1.G User Guide Downloaded from www.Manualslib.com manuals search engine 158

ENGINE

B1BP234C

XSARA PICASSOAUXILIARY EQUIPMENT DRIVE BELT

Engine: NFV

Without air conditioning

Tools.

[1]Pliers for removing plastic pegs](/img/9/4138/w960_4138-163.png)

Downloaded from www.Manualslib.com manuals search engine 158

ENGINE

B1BP234C

XSARA PICASSOAUXILIARY EQUIPMENT DRIVE BELT

Engine: NFV

Without air conditioning

Tools.

[1]Pliers for removing plastic pegs: 7504 -T

[2]Belt tension measuring instrument: 4122 -T

[3] TORX spanner

Remove.

Release the central screw (1), tool[3].

Detension the tensioner roller (2)

(flat spanner 27on flat).

Remove the belt.

Refit.

Position the belt.

Hold the belt in position using the tensioner roller (2).

Pre-tension the belt 120 SEEMunits, tool [2].

Lock the central screw (1)tool [3].

Remove the tool [2].

Rotate the crankshaft 2to 4 times.

Check the tension, 120 SEEMunits.

If not, restart the operation.

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 158

Page 167 of 462

![Citroen BERLINGO 2005 1.G User Guide Downloaded from www.Manualslib.com manuals search engine 161

ENGINE

B1EP1FUD

B1EP1FVC

AUXILIARY EQUIPMENT DRIVE BELT

Engine: RFJ

Tool.

[1]«Junior» T extension: (-).1608.E

Removing.

Engage tool [1]in Citroen BERLINGO 2005 1.G User Guide Downloaded from www.Manualslib.com manuals search engine 161

ENGINE

B1EP1FUD

B1EP1FVC

AUXILIARY EQUIPMENT DRIVE BELT

Engine: RFJ

Tool.

[1]«Junior» T extension: (-).1608.E

Removing.

Engage tool [1]in](/img/9/4138/w960_4138-166.png)

Downloaded from www.Manualslib.com manuals search engine 161

ENGINE

B1EP1FUD

B1EP1FVC

AUXILIARY EQUIPMENT DRIVE BELT

Engine: RFJ

Tool.

[1]«Junior» T extension: (-).1608.E

Removing.

Engage tool [1]in the notch «a».

Exert on the roller (1)an effort upwards to hold it at maximum.

Remove the auxiliaries drive belt.

Carefully release the tensioner roller (1)to reach its minimum.

Remove tool[1].

IMPERATIVE: Check that the roller (1) turns freely

(without play and without tight spots).

Refitting.

If removing the auxiliaries drive belt tensioner roller, tighten the screws 2 ± 0,2 m.daN.

Engage tool [1]in the notch at «a».

Exert on the roller (1)an effort upwards to hold it at maximum.

Position the

(new)auxiliaries drive belt, in the following sequence:

- Auxiliaries drive pulley (4), aircon compressor pulley (3), tensioner roller (1)and alternator pulley (2).

IMPERATIVE: Make sure that the auxiliaries drive belt is correctly positioned in the grooves of

the various pulleys.

Release the tensioner roller (1).

Remove tool [1].

Checking the tension of the auxiliaries drive belt.

Check the tension of the auxiliaries drive belt:

- Mark «b»at the level of mark «c», new belt.

- Mark «b»at the level of mark «d», belt to be changed.

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 161

Page 169 of 462

Downloaded from www.Manualslib.com manuals search engine 163

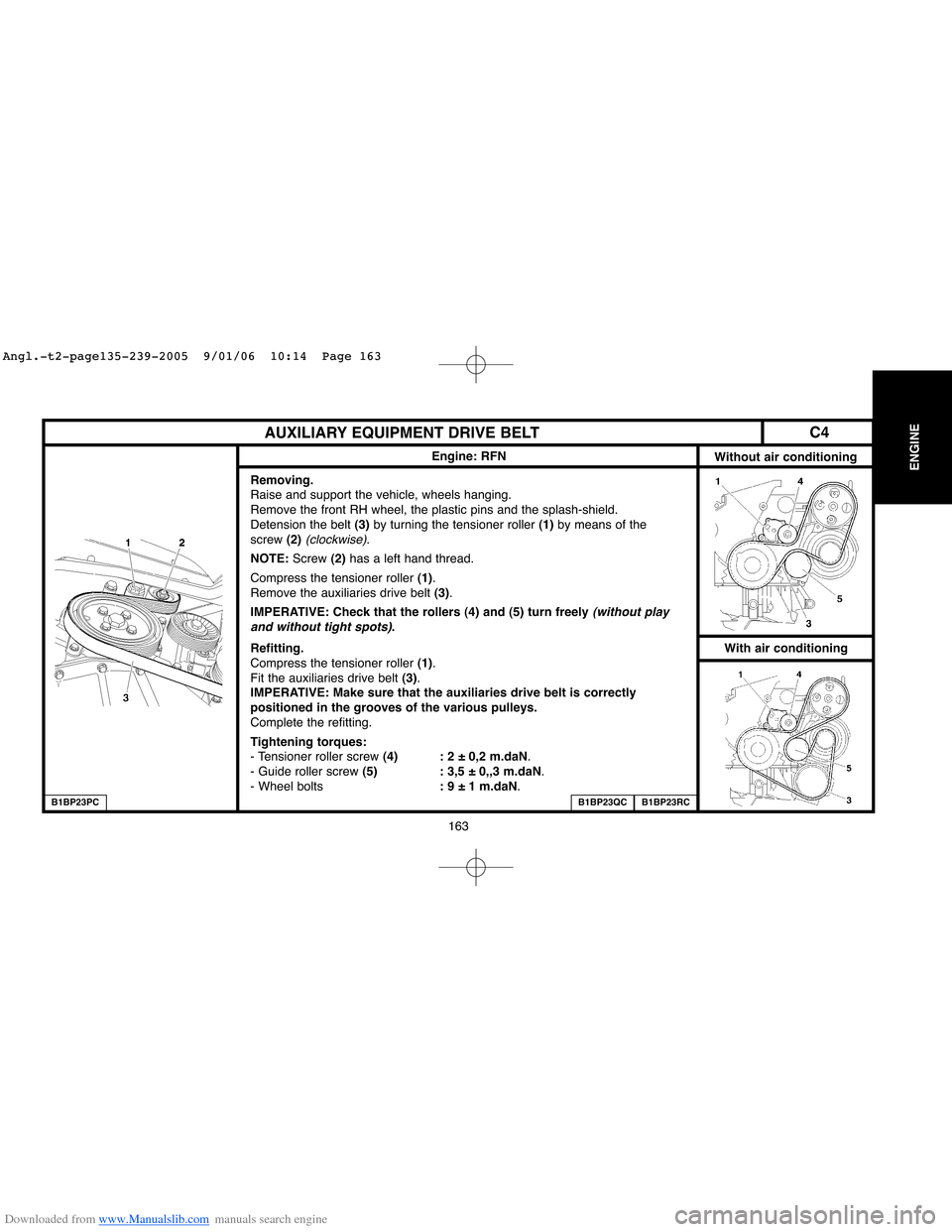

ENGINE

AUXILIARY EQUIPMENT DRIVE BELT

Engine: RFN

Without air conditioning

Removing.

Raise and support the vehicle, wheels hanging.

Remove the front RH wheel, the plastic pins and the splash-shield.

Detension the belt (3)by turning the tensioner roller (1)by means of the

screw (2)

(clockwise).

NOTE:Screw (2)has a left hand thread.

Compress the tensioner roller (1).

Remove the auxiliaries drive belt (3).

IMPERATIVE: Check that the rollers (4) and (5) turn freely

(without play

and without tight spots).

Refitting.

Compress the tensioner roller (1).

Fit the auxiliaries drive belt (3).

IMPERATIVE: Make sure that the auxiliaries drive belt is correctly

positioned in the grooves of the various pulleys.

Complete the refitting.

Tightening torques:

- Tensioner roller screw (4) : 2 ± 0,2 m.daN.

- Guide roller screw (5) : 3,5 ± 0,,3 m.daN.

- Wheel bolts: 9 ± 1 m.daN.

B1BP23PCB1BP23QCB1BP23RC

With air conditioning

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 163

Page 170 of 462

![Citroen BERLINGO 2005 1.G User Guide Downloaded from www.Manualslib.com manuals search engine 164

ENGINE

B1BP39AC

B1BP23RC

AUXILIARY EQUIPMENT DRIVE BELT

Engine: RFK

Tools.

[1]Detensioning lever for auxiliaries drive belt tensioner rolle Citroen BERLINGO 2005 1.G User Guide Downloaded from www.Manualslib.com manuals search engine 164

ENGINE

B1BP39AC

B1BP23RC

AUXILIARY EQUIPMENT DRIVE BELT

Engine: RFK

Tools.

[1]Detensioning lever for auxiliaries drive belt tensioner rolle](/img/9/4138/w960_4138-169.png)

Downloaded from www.Manualslib.com manuals search engine 164

ENGINE

B1BP39AC

B1BP23RC

AUXILIARY EQUIPMENT DRIVE BELT

Engine: RFK

Tools.

[1]Detensioning lever for auxiliaries drive belt tensioner roller:

Dynamic spanner extension: FACOM SJ.214

Adaptor for socket 9x12 : FACOM J.274

Polygon socket 9x12 : 016

Removing.

Raise and support the vehicle, wheels hanging.

Remove the front RH wheel, the plastic pins and the splash-shield.

Turn the tensioner roller(1)by the screw (2)

(anti-clockwise), using tool [1]to detension the belt (3).

NOTE: Screw (2)has a left hand thread.

Remove the auxiliaries drive belt (3).

Refitting.

IMPERATIVE: Check that the rollers (4) and (5) turn freely

(without play and without tight spots).

Refitting.

Compress the tensioner roller (1), using tool [1].

Fit the auxiliaries drive belt (3).

IMPERATIVE: Make sure that the auxiliaries drive belt is correctly positioned in the grooves of

the various pulleys.

Complete the refitting.

Tightening torques:

- Tensioner roller screw (4)tighten to: 2 ± 0,2 m.daN.

- Guide roller screw (5)tighten to: 3,5 ± 0,3 m.daN.

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 164

Page 171 of 462

![Citroen BERLINGO 2005 1.G User Guide Downloaded from www.Manualslib.com manuals search engine 165

ENGINE

XSARA

AUXILIARY EQUIPMENT DRIVE BELT

Tools.

[1] Dynamic tensioner compression lever: (-).0188.Z

[2] Peg for dynamic tensioner roller Citroen BERLINGO 2005 1.G User Guide Downloaded from www.Manualslib.com manuals search engine 165

ENGINE

XSARA

AUXILIARY EQUIPMENT DRIVE BELT

Tools.

[1] Dynamic tensioner compression lever: (-).0188.Z

[2] Peg for dynamic tensioner roller](/img/9/4138/w960_4138-170.png)

Downloaded from www.Manualslib.com manuals search engine 165

ENGINE

XSARA

AUXILIARY EQUIPMENT DRIVE BELT

Tools.

[1] Dynamic tensioner compression lever: (-).0188.Z

[2] Peg for dynamic tensioner roller: (-).0194.F

Removing.

IMPERATIVE: Respect the safety and cleanliness requirements specific to High pressure

Diesel injection (HDi) engine versions.

Remove:

- the front RH wheel.

- the sound insulation under the engine.

- the splash-shield.

WARNING: Mark the direction of fitting of the accessories belt if it is to be re-used.

Compress the dynamic tensioner roller (1)by acting at «a»

(clockwise), using tool [1].

Peg at «b». using tool [2].

Keep the dynamic tensioner roller (1)compressed and remove the auxiliaries drive belt.

IMPERATIVE: Check that the rollers (1) and (2) can turn freely

(without play and without

tight spots).

B1BP2VZD

Engines: 8HX - 8HZ

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 165

Page 172 of 462

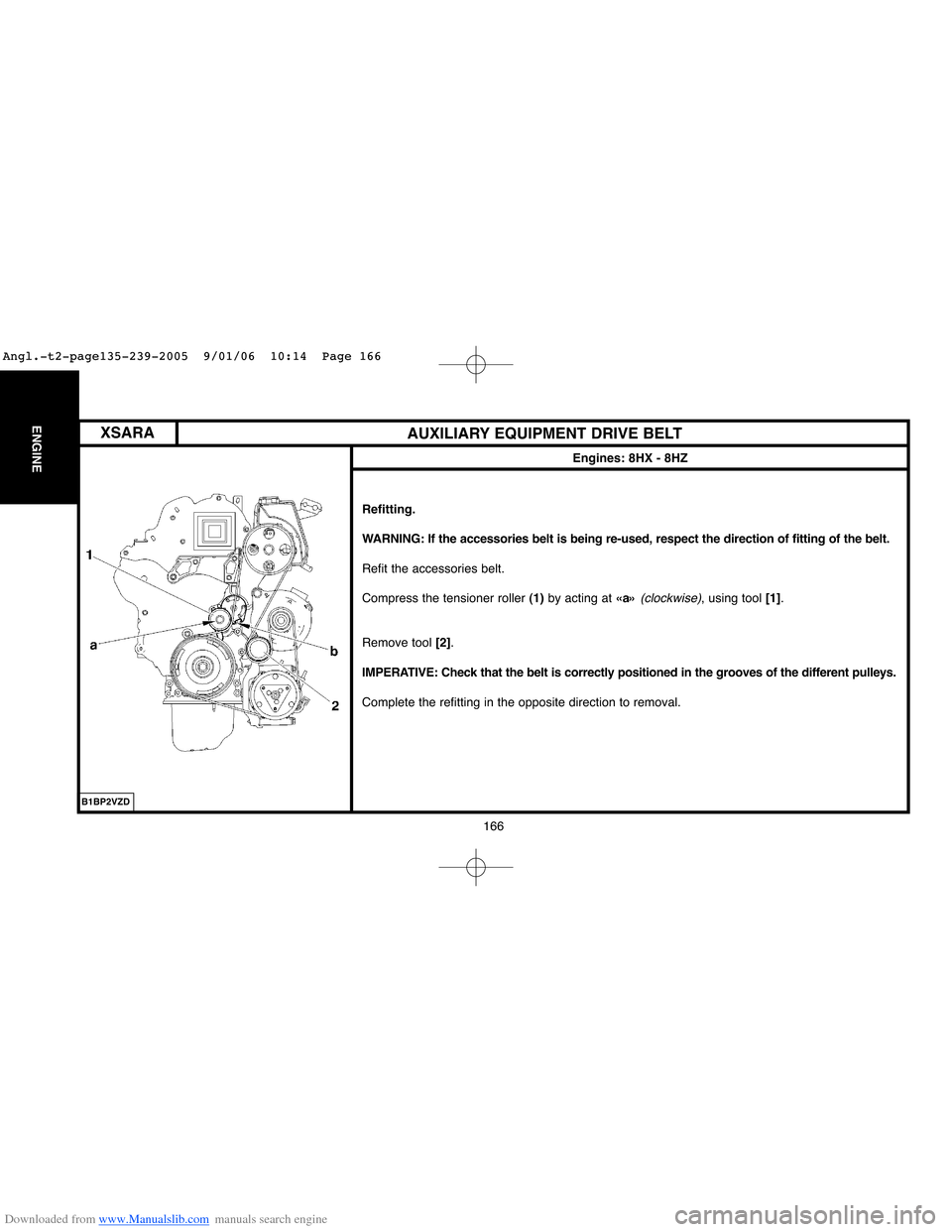

Downloaded from www.Manualslib.com manuals search engine 166

ENGINEXSARA

AUXILIARY EQUIPMENT DRIVE BELT

Refitting.

WARNING: If the accessories belt is being re-used, respect the direction of fitting of the belt.

Refit the accessories belt.

Compress the tensioner roller (1)by acting at «a»

(clockwise), using tool [1].

Remove tool [2].

IMPERATIVE: Check that the belt is correctly positioned in the grooves of the different pulleys.

Complete the refitting in the opposite direction to removal.

Engines: 8HX - 8HZ

B1BP2VZD

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 166