Cooling Citroen C4 2005 2.G User Guide

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: C4, Model: Citroen C4 2005 2.GPages: 462, PDF Size: 10.48 MB

Page 95 of 462

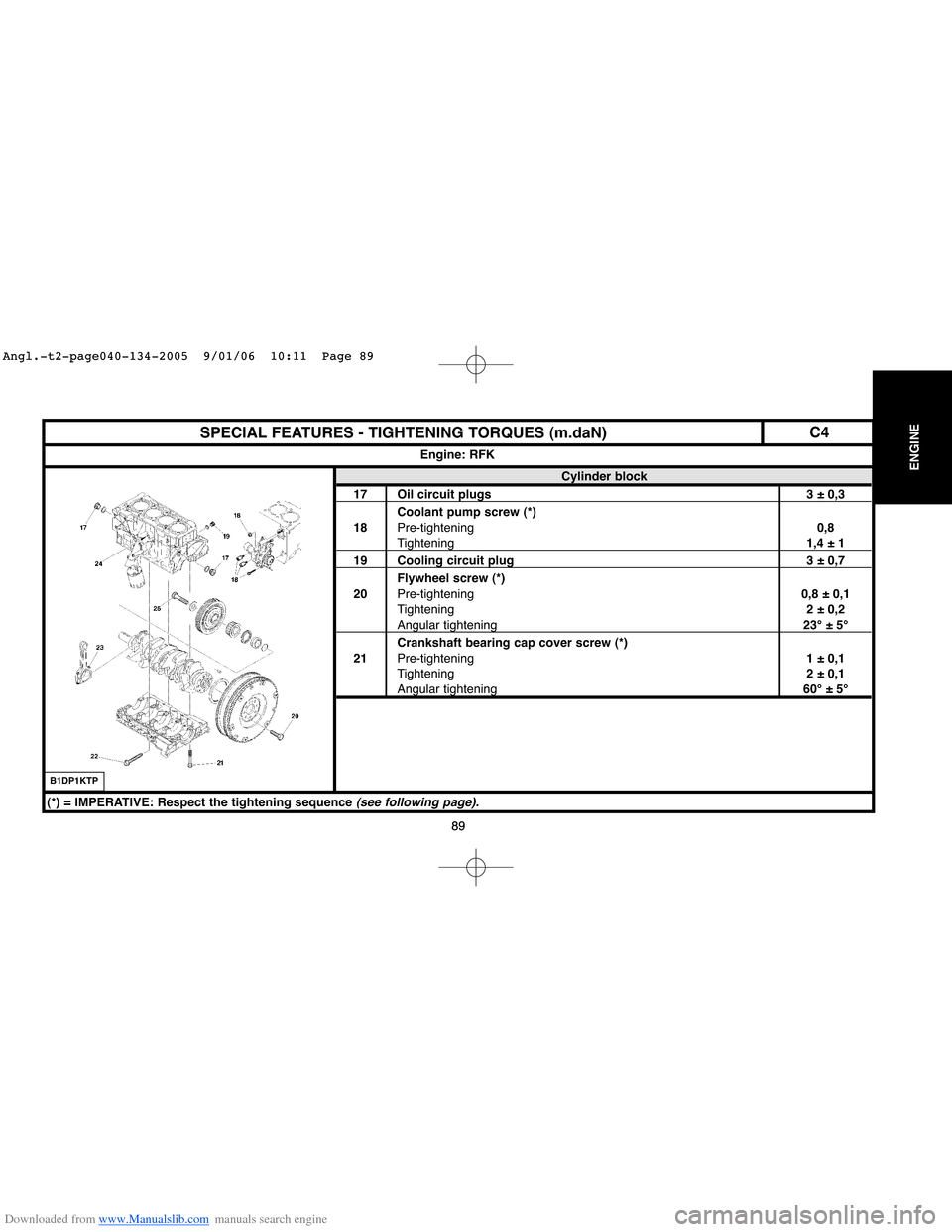

Downloaded from www.Manualslib.com manuals search engine 89

ENGINE

89

SPECIAL FEATURES - TIGHTENING TORQUES (m.daN)

Cylinder block

17 Oil circuit plugs 3 ± 0,3

Coolant pump screw (*)

18Pre-tightening0,8

Tightening1,4 ± 1

19 Cooling circuit plug 3 ± 0,7

Flywheel screw (*)

20Pre-tightening0,8 ± 0,1

Tightening2 ± 0,2

Angular tightening23°±5°

Crankshaft bearing cap cover screw (*)

21Pre-tightening1 ± 0,1

Tightening2 ± 0,1

Angular tightening60°±5°

Engine: RFK

B1DP1KTP

(*) = IMPERATIVE: Respect the tightening sequence (see following page).

C4

Angl.-t2-page040-134-2005 9/01/06 10:11 Page 89

Page 104 of 462

Downloaded from www.Manualslib.com manuals search engine 98

ENGINESPECIAL FEATURES - TIGHTENING TORQUES (m.daN)

Engines8HX - 8HZ

Diesel injection circuit

Spherical-base screws for diesel injection fixing fork 0,3 ± 0,1

Fuel high pressure common injection rail on engine block 2 ± 0,2

Unions on fuel high pressure common injection rail

Pre-tightening1,7± 0,2

Tightening2,25 ± 0,2

Diesel injection pump on support

Union on diesel injection pump2,25 ± 0,2

Diesel injection pump pulley5 ± 0,5

Union on diesel high pressure pump 2,25 ± 0,2

Cooling circuit

Coolant pump

Pre-tightening0,3 ± 0,06

Tightening1 ± 0,1

Coolant outlet housing

Pre-tightening0,3 ± 0,06

Tightening0,7 ± 0,08

XSARA

Angl.-t2-page040-134-2005 9/01/06 10:11 Page 98

Page 135 of 462

Downloaded from www.Manualslib.com manuals search engine 129

ENGINE

XSARA PICASSOSPECIAL FEATURES - TIGHTENING TORQUES (m.daN)

Engines9HZ - 9HY

Diesel injection circuit (continued)

Diesel injection pump pulley5 ± 0,5

Union on fuel high pressure pump

Pre-tightening2 ± 0,5

Tightening2,5 ± 0,3

Cooling circuit

Coolant pump

Pre-tightening0,3 ± 0,1

Tightening0,9 ± 0,1

Coolant outlet housing

Pre-tightening0,3 ± 0,1

Tightening0,7 ± 0,1

Angl.-t2-page040-134-2005 9/01/06 10:11 Page 129

Page 139 of 462

Downloaded from www.Manualslib.com manuals search engine 133

ENGINE

SPECIAL FEATURES - TIGHTENING TORQUES (m.daN)

Flywheel

Flywheel4,8 ± 0,4

Clutch mechanism2 ± 0,2

Lubrication circuit

Oil pump2,3 ± 0,2

Coolant/oil heat exchanger7 ± 0,7

Injection circuit

Injector on cylinder head9 ± 0,9

Diesel fuel heater1,5 ± 0,1

Injection pump2 ± 0,2

Union on injector2,5 ± 0,2

Injection pump pulley2,3 ± 0,2

Cooling circuit

Coolant pump1,5 ± 0,1

Coolant inlet housing1,8 ± 0,1 Engine: WJY

XSARA

Angl.-t2-page040-134-2005 9/01/06 10:11 Page 133

Page 142 of 462

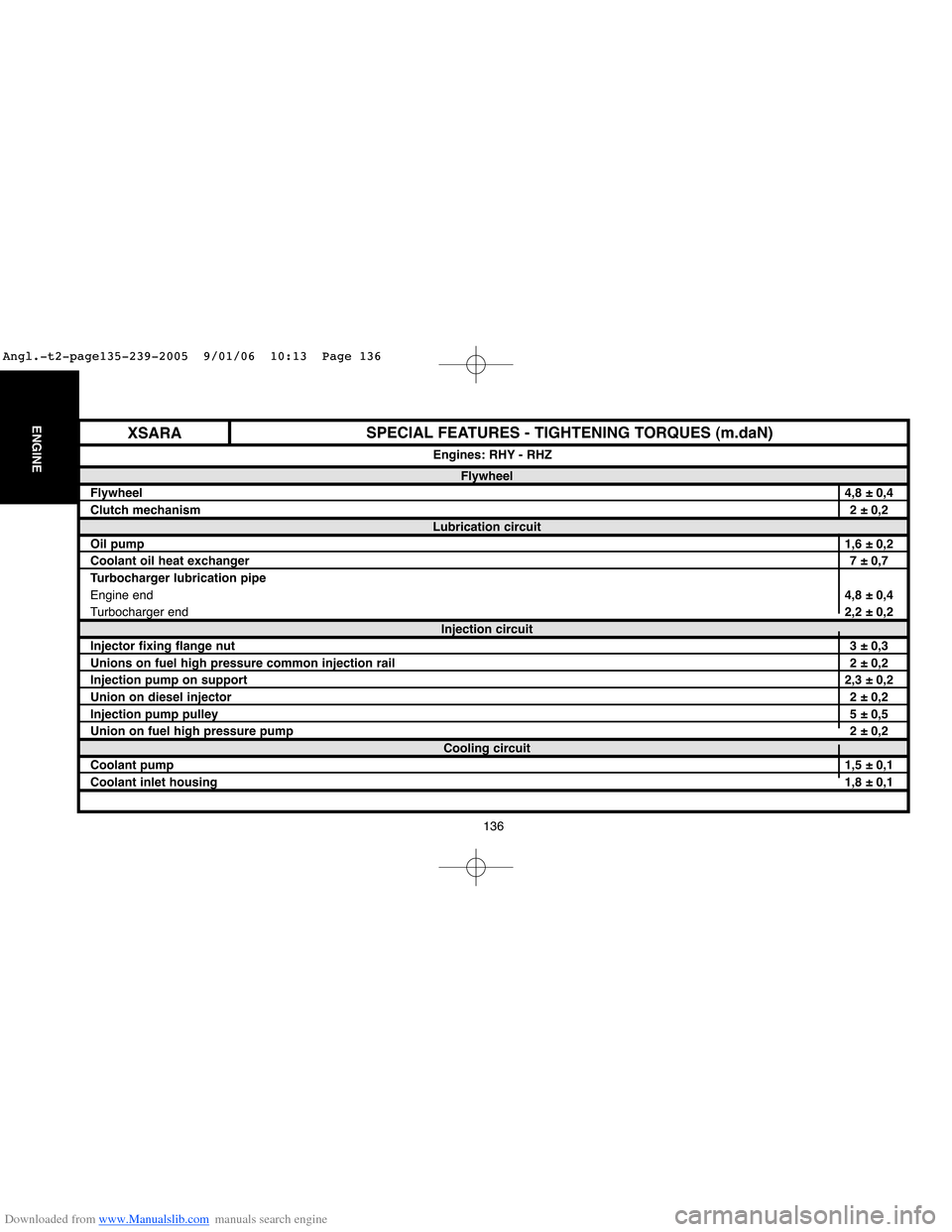

Downloaded from www.Manualslib.com manuals search engine 136

ENGINESPECIAL FEATURES - TIGHTENING TORQUES (m.daN)

Flywheel

Flywheel4,8 ± 0,4

Clutch mechanism2 ± 0,2

Lubrication circuit

Oil pump1,6 ± 0,2

Coolant oil heat exchanger7 ± 0,7

Turbocharger lubrication pipe

Engine end4,8 ± 0,4

Turbocharger end2,2 ± 0,2

Injection circuit

Injector fixing flange nut3 ± 0,3

Unions on fuel high pressure common injection rail2 ± 0,2

Injection pump on support2,3 ± 0,2

Union on diesel injector2 ± 0,2

Injection pump pulley5 ± 0,5

Union on fuel high pressure pump2 ± 0,2

Cooling circuit

Coolant pump1,5 ± 0,1

Coolant inlet housing1,8 ± 0,1 Engines: RHY - RHZ

XSARA

Angl.-t2-page135-239-2005 9/01/06 10:13 Page 136

Page 270 of 462

![Citroen C4 2005 2.G User Guide Downloaded from www.Manualslib.com manuals search engine 264

ENGINECHECKING AND SETTING THE VALVE TIMING

Tools.

[1]Belt tension measuring equipment : 4122-T

[2]Tension lever: (-).0188.J2

[3]Engine fly Citroen C4 2005 2.G User Guide Downloaded from www.Manualslib.com manuals search engine 264

ENGINECHECKING AND SETTING THE VALVE TIMING

Tools.

[1]Belt tension measuring equipment : 4122-T

[2]Tension lever: (-).0188.J2

[3]Engine fly](/img/9/4138/w960_4138-269.png)

Downloaded from www.Manualslib.com manuals search engine 264

ENGINECHECKING AND SETTING THE VALVE TIMING

Tools.

[1]Belt tension measuring equipment : 4122-T

[2]Tension lever: (-).0188.J2

[3]Engine flywheel peg: (-).0188.Y

[4] Belt clamp: (-).0188.AD

[5]Camshaft pulley peg: (-).0188.M

[6] Engine flywheel lock: (-).0188.F

[7] Set of blocking plugs: (-).0188.T

[8] Pulley extractor: (-).0188.P

[9] 2 mm Øpeg: (-).0188.Q2Removing.

IMPERATIVE: Respect the safety and cleanliness requirements

that are specific to high pressure diesel injection (HDi) engines.

Undo the front RH wheel bolts.

Raise and support the vehicle on the front RH side.

Disconnect the battery negative terminal.

Remove:

- The under-engine sound-deadening.

- The front RH wheel.

- The front RH splash-shield.

- The engine cover.

Unclip and move aside the cooling hose.

Remove the accessories drive belt

(see corresponding operation).

XSARA - XSARA PICASSO

Engines: RHY - RHZ

Angl.-t2-page240-282-2005 9/01/06 10:16 Page 264

Page 276 of 462

![Citroen C4 2005 2.G User Guide Downloaded from www.Manualslib.com manuals search engine 270

ENGINECHECKING AND SETTING THE VALVE TIMING

Engines: RHY - RHZ

Remove:

- Tools [3]and [5], Screw (7)and the spacer.

Refit:

- The lower, i Citroen C4 2005 2.G User Guide Downloaded from www.Manualslib.com manuals search engine 270

ENGINECHECKING AND SETTING THE VALVE TIMING

Engines: RHY - RHZ

Remove:

- Tools [3]and [5], Screw (7)and the spacer.

Refit:

- The lower, i](/img/9/4138/w960_4138-275.png)

Downloaded from www.Manualslib.com manuals search engine 270

ENGINECHECKING AND SETTING THE VALVE TIMING

Engines: RHY - RHZ

Remove:

- Tools [3]and [5], Screw (7)and the spacer.

Refit:

- The lower, intermediate and upper covers (5).

- Screw (7), tighten to 1,5 ± 0,1 m.daN.

- Screws (3), (4)and (6).

- The bracket (13).

Screws (11), tighten to 6,1 ± 0,5 m.daN.

The nut (12), tighten to 4,5 ± 0,5 m.daN.

Fit the bearing shell (10).

Take away the workshop hoist.

Clip the fuel delivery and return pipes.

Remove the tool [7].

Couple:

- The fuel delivery pipe (12).

- The fuel return pipe (1).

- Coat the screw (8)with loctite FRENETANCH.

Refit the tool [6]and the screw (8)with the washer (22), tighten to 7 ± 0,2 m.daN

and angular tighten to A= 60°±5°.

Refit the torque reaction rod on the lower engine support.

Remove the tool [6].

Reposition and reclip the cooling hose.

Complete the refitting of components in reverse order to removal.

B1EP1A7CB1BP2R4CB1EP1ADC

XSARA - XSARA PICASSO

Angl.-t2-page240-282-2005 9/01/06 10:16 Page 270

Page 441 of 462

![Citroen C4 2005 2.G User Guide Downloaded from www.Manualslib.com manuals search engine 435

AIR

CONDITIONING

SPECIAL FEATURES: AIR CONDITIONING SYSTEM (R 134.a)

Changing the filtering/drying cartridge

Tools.

[1]Charge station:

( Citroen C4 2005 2.G User Guide Downloaded from www.Manualslib.com manuals search engine 435

AIR

CONDITIONING

SPECIAL FEATURES: AIR CONDITIONING SYSTEM (R 134.a)

Changing the filtering/drying cartridge

Tools.

[1]Charge station:

(](/img/9/4138/w960_4138-440.png)

Downloaded from www.Manualslib.com manuals search engine 435

AIR

CONDITIONING

SPECIAL FEATURES: AIR CONDITIONING SYSTEM (R 134.a)

Changing the filtering/drying cartridge

Tools.

[1]Charge station:

(according to workshop equipment)[2]TORX adaptor: TORX 70 FACOM

Removing.

Depressurise the aircon circuit, using tool [1].

Uncouple the hose (2).

Remove:

- The air filter assembly (3).

- The nuts (1).

Protect the radiator harness with strong cardboard cut to the dimensions of the radiator.

Move aside the cooling fan.

Remove:

- The screws (4).

- The brackets (5).

B1BP23FCB1BP23GC

XSARA PICASSO

Angl.-t2-page428-456-2005 9/01/06 10:25 Page 435

Page 446 of 462

Downloaded from www.Manualslib.com manuals search engine 440

AIR

CONDITIONING

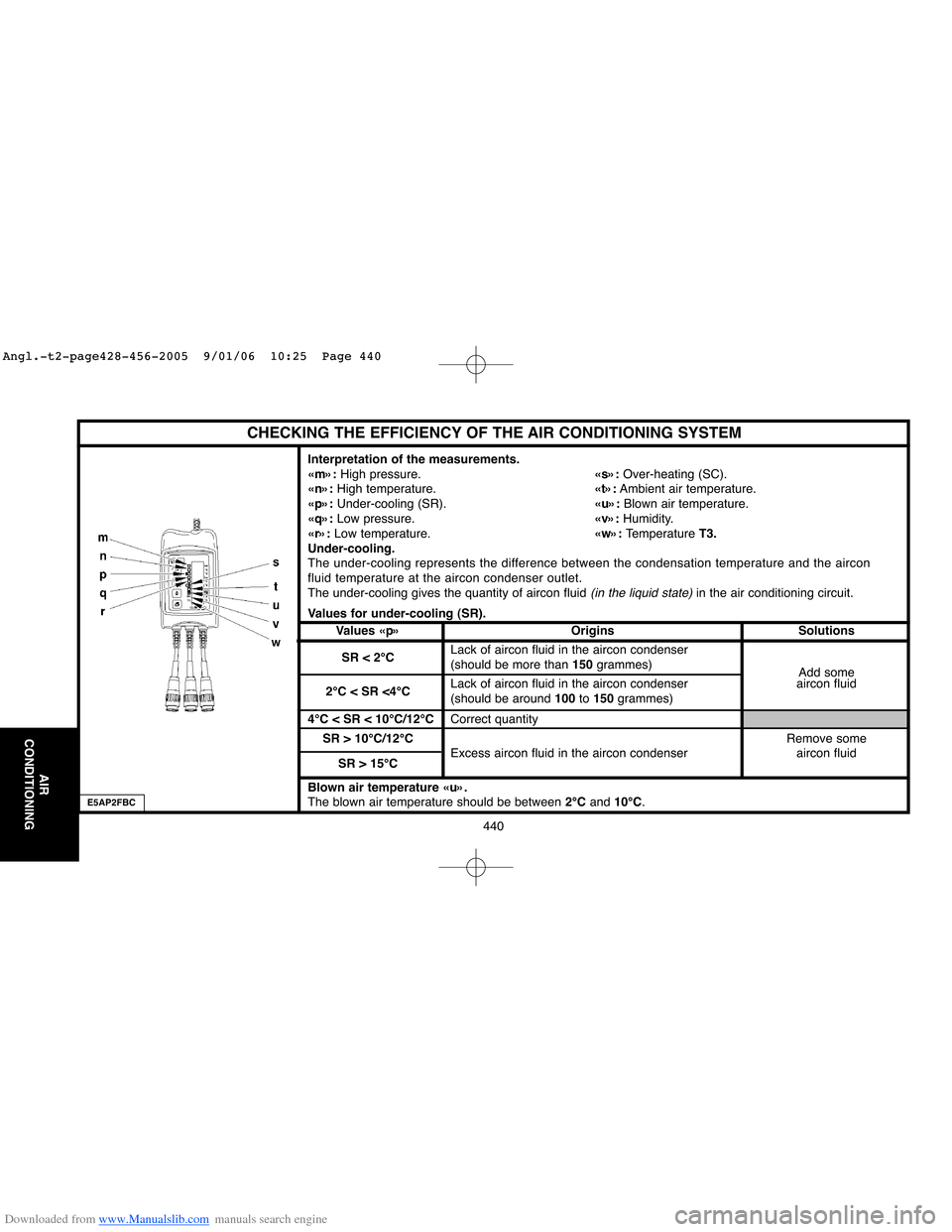

CHECKING THE EFFICIENCY OF THE AIR CONDITIONING SYSTEM

Interpretation of the measurements.

«m»:High pressure.«s»:Over-heating (SC).

«n»:High temperature.«t»:Ambient air temperature.

«p»:Under-cooling (SR).«u»:Blown air temperature.

«q»:Low pressure.«v»: Humidity.

«r»:Low temperature.«w»: Temperature T3.

Under-cooling.

The under-cooling represents the difference between the condensation temperature and the aircon

fluid temperature at the aircon condenser outlet.

The under-cooling gives the quantity of aircon fluid

(in the liquid state)in the air conditioning circuit.

Values for under-cooling (SR).

Values «p» Origins Solutions

SR < 2°CLack of aircon fluid in the aircon condenser

(should be more than 150grammes)

Add some

2°C < SR <4°CLack of aircon fluid in the aircon condenser aircon fluid

(should be around 100to 150grammes)

4°C < SR < 10°C/12°CCorrect quantity

SR > 10°C/12°CRemove some

Excess aircon fluid in the aircon condenser aircon fluid

SR > 15°C

Blown air temperature «u».

The blown air temperature should be between 2°Cand 10°C.

E5AP2FBC

Angl.-t2-page428-456-2005 9/01/06 10:25 Page 440

Page 447 of 462

Downloaded from www.Manualslib.com manuals search engine 441

AIR

CONDITIONING

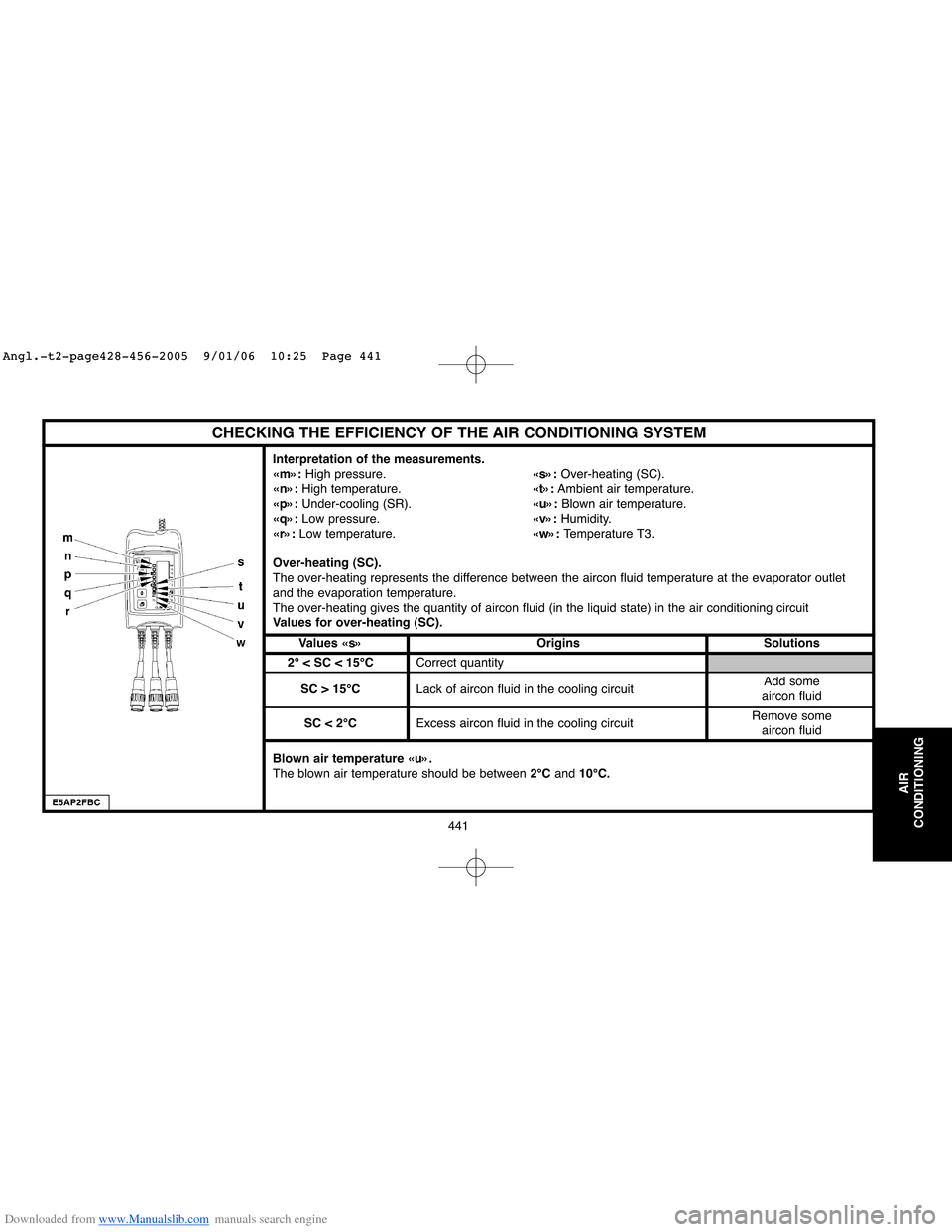

CHECKING THE EFFICIENCY OF THE AIR CONDITIONING SYSTEM

Interpretation of the measurements.

«m»:High pressure.«s»: Over-heating (SC).

«n»:High temperature.«t»:Ambient air temperature.

«p»:Under-cooling (SR).«u»:Blown air temperature.

«q»:Low pressure.«v»:Humidity.

«r»: Low temperature.«w»: Temperature T3.

Over-heating (SC).

The over-heating represents the difference between the aircon fluid temperature at the evaporator outlet

and the evaporation temperature.

The over-heating gives the quantity of aircon fluid (in the liquid state) in the air conditioning circuit

Values for over-heating (SC).

Values «s» Origins Solutions

2° < SC < 15°CCorrect quantity

SC > 15°CLack of aircon fluid in the cooling circuitAdd some

aircon fluid

SC < 2°CExcess aircon fluid in the cooling circuitRemove some

aircon fluid

Blown air temperature «u».

The blown air temperature should be between 2°Cand 10°C.

E5AP2FBC

Angl.-t2-page428-456-2005 9/01/06 10:25 Page 441