check oil Citroen C4 2005 2.G Owner's Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: C4, Model: Citroen C4 2005 2.GPages: 462, PDF Size: 10.48 MB

Page 286 of 462

Downloaded from www.Manualslib.com manuals search engine 280

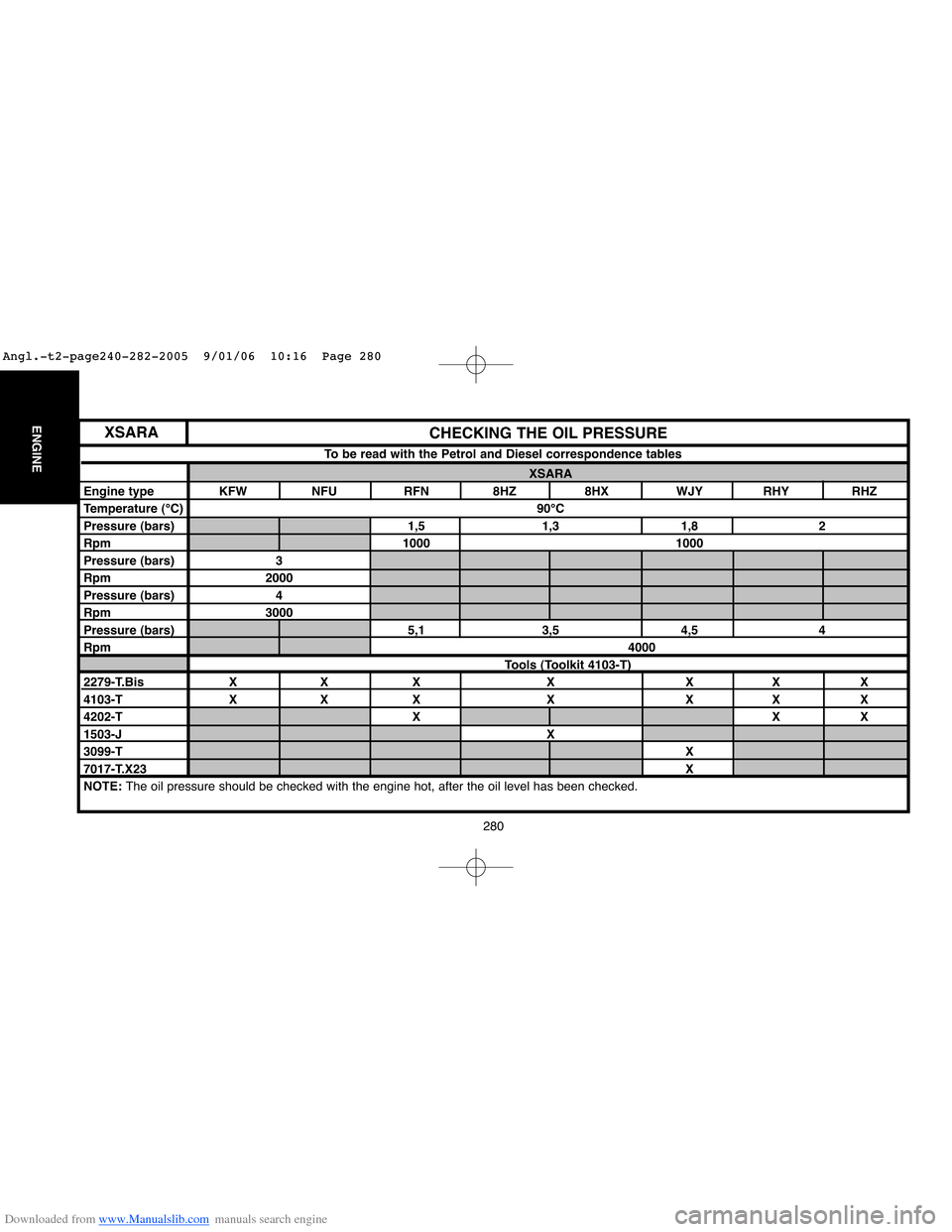

ENGINECHECKING THE OIL PRESSURE

To be read with the Petrol and Diesel correspondence tables

XSARA

Engine type KFW NFU RFN 8HZ 8HX WJY RHY RHZ

Temperature (°C) 90°C

Pressure (bars) 1,5 1,3 1,8 2

Rpm 1000 1000

Pressure (bars) 3

Rpm 2000

Pressure (bars) 4

Rpm 3000

Pressure (bars) 5,1 3,5 4,5 4

Rpm4000

Tools (Toolkit 4103-T)

2279-T.Bis X X X X X X X

4103-T X X X X X X X

4202-T X X X

1503-JX

3099-TX

7017-T.X23X

NOTE: The oil pressure should be checked with the engine hot, after the oil level has been checked.

XSARA

Angl.-t2-page240-282-2005 9/01/06 10:16 Page 280

Page 287 of 462

Downloaded from www.Manualslib.com manuals search engine 281

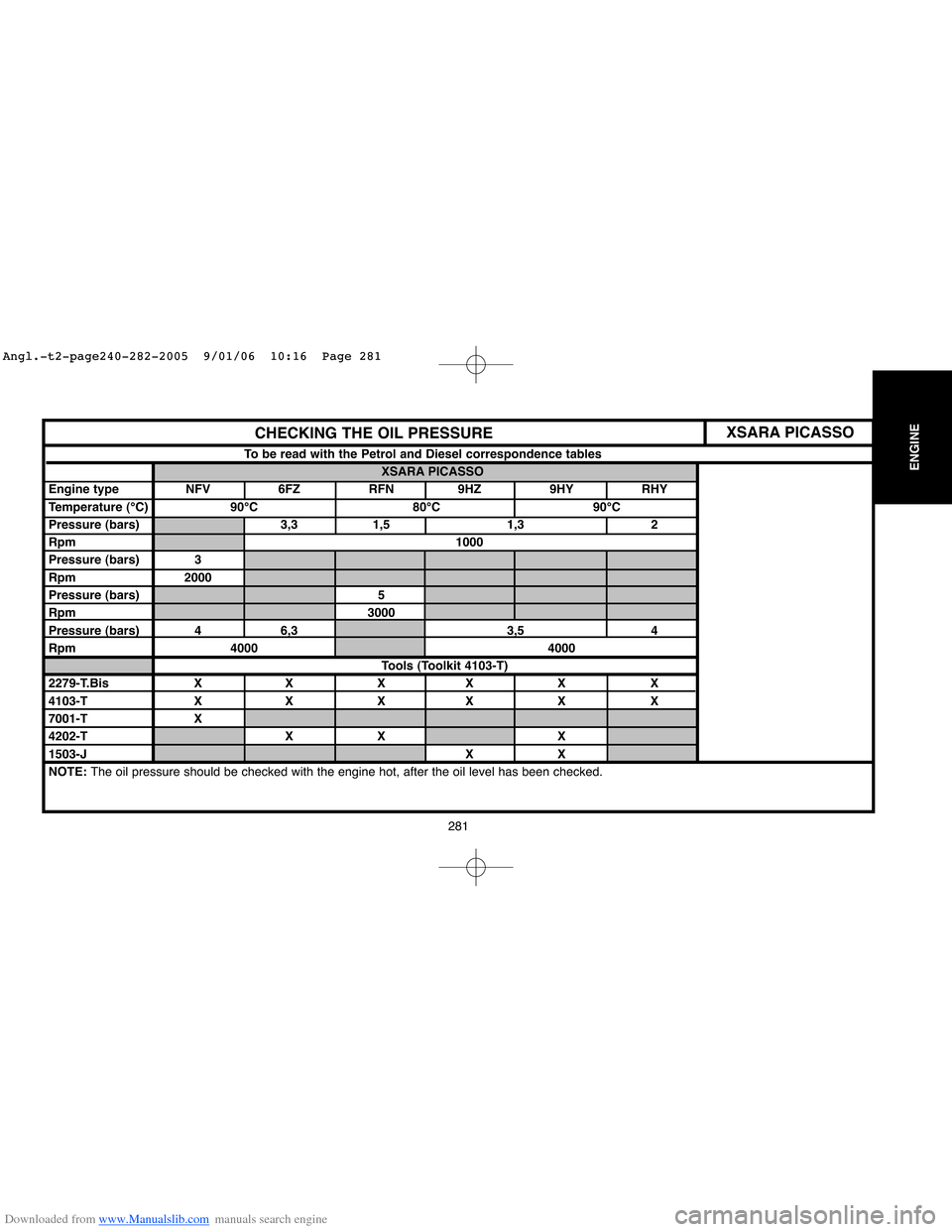

ENGINE

CHECKING THE OIL PRESSURE

To be read with the Petrol and Diesel correspondence tables

XSARA PICASSO

Engine type NFV 6FZ RFN 9HZ 9HY RHY

Temperature (°C) 90°C 80°C 90°C

Pressure (bars) 3,3 1,5 1,3 2

Rpm 1000

Pressure (bars) 3

Rpm 2000

Pressure (bars) 5

Rpm 3000

Pressure (bars) 4 6,3 3,5 4

Rpm 4000 4000

Tools (Toolkit 4103-T)

2279-T.Bis X X X X X X

4103-T X X X X X X

7001-T X

4202-T X X X

1503-J X X

NOTE: The oil pressure should be checked with the engine hot, after the oil level has been checked.

XSARA PICASSO

Angl.-t2-page240-282-2005 9/01/06 10:16 Page 281

Page 351 of 462

Downloaded from www.Manualslib.com manuals search engine 345

CLUTCH

GEARBOX

TRANSMISSION

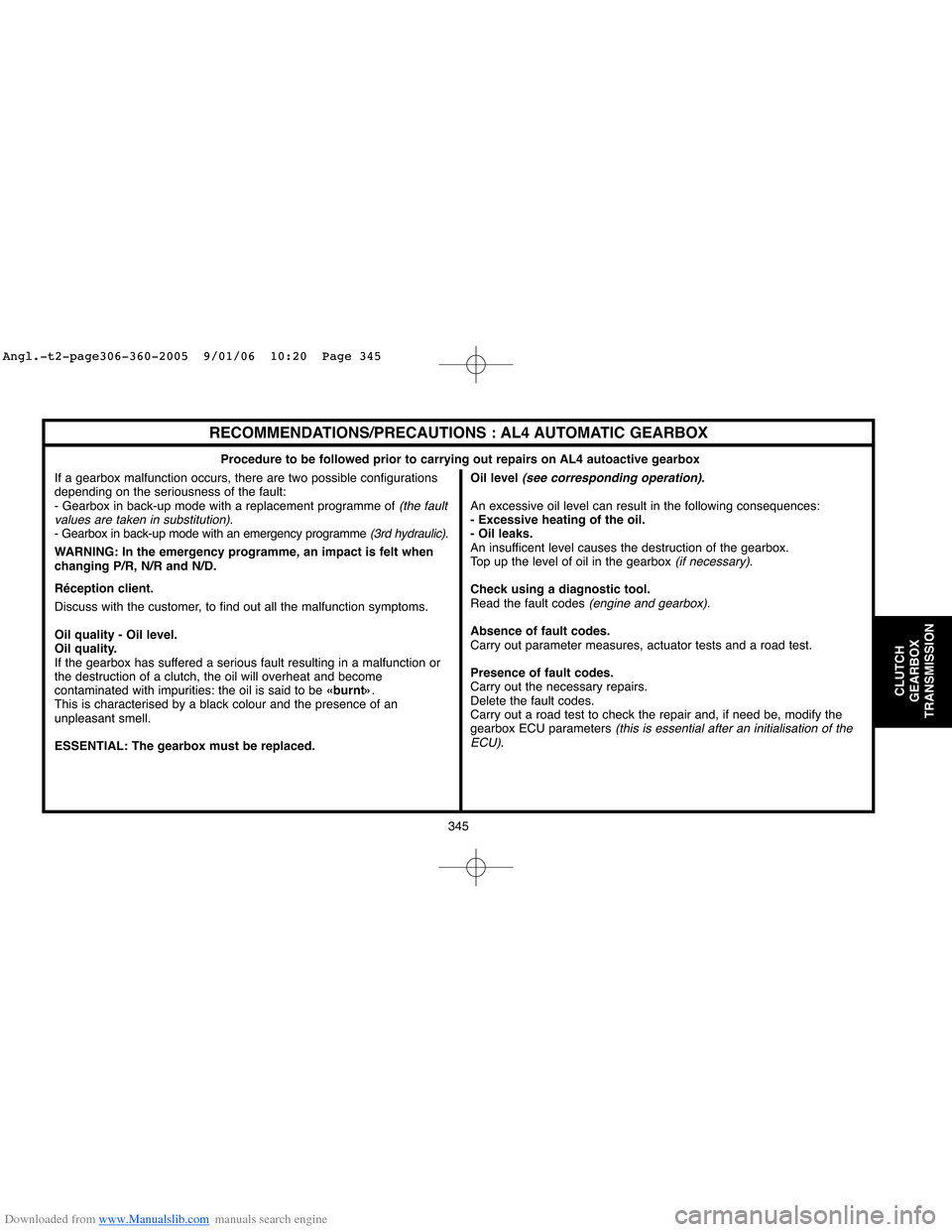

RECOMMENDATIONS/PRECAUTIONS : AL4 AUTOMATIC GEARBOX

Procedure to be followed prior to carrying out repairs on AL4 autoactive gearbox

If a gearbox malfunction occurs, there are two possible configurations

depending on the seriousness of the fault:

- Gearbox in back-up mode with a replacement programme of

(the fault

values are taken in substitution).

- Gearbox in back-up mode with an emergency programme (3rd hydraulic).

WARNING: In the emergency programme, an impact is felt when

changing P/R, N/R and N/D.

Réception client.

Discuss with the customer, to find out all the malfunction symptoms.

Oil quality - Oil level.

Oil quality.

If the gearbox has suffered a serious fault resulting in a malfunction or

the destruction of a clutch, the oil will overheat and become

contaminated with impurities: the oil is said to be «burnt».

This is characterised by a black colour and the presence of an

unpleasant smell.

ESSENTIAL: The gearbox must be replaced.Oil level

(see corresponding operation).

An excessive oil level can result in the following consequences:

- Excessive heating of the oil.

- Oil leaks.

An insufficent level causes the destruction of the gearbox.

Top up the level of oil in the gearbox

(if necessary).

Check using a diagnostic tool.

Read the fault codes

(engine and gearbox).

Absence of fault codes.

Carry out parameter measures, actuator tests and a road test.

Presence of fault codes.

Carry out the necessary repairs.

Delete the fault codes.

Carry out a road test to check the repair and, if need be, modify the

gearbox ECU parameters

(this is essential after an initialisation of the

ECU).

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 345

Page 435 of 462

Downloaded from www.Manualslib.com manuals search engine 429

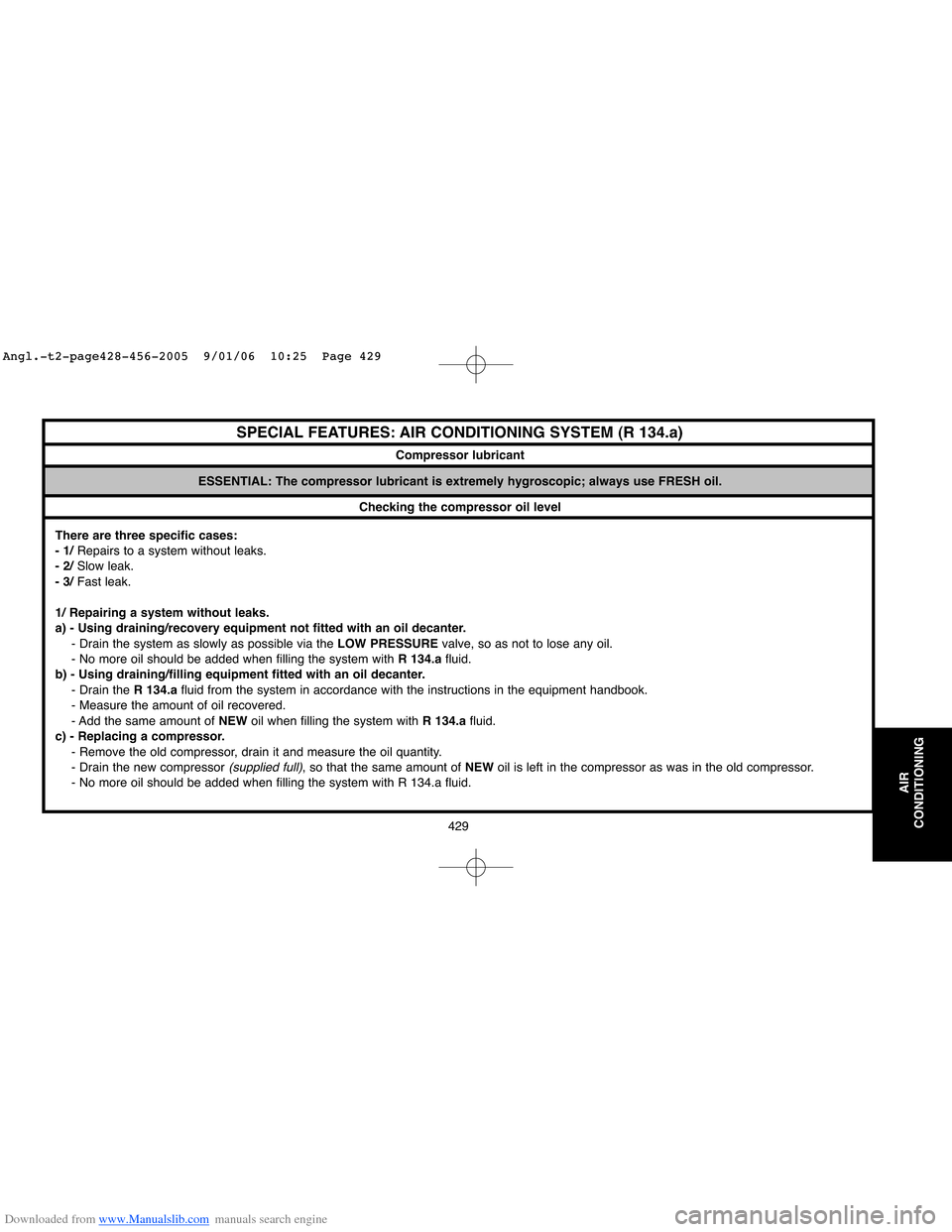

AIR

CONDITIONING

ESSENTIAL: The compressor lubricant is extremely hygroscopic; always use FRESH oil.

Checking the compressor oil level

There are three specific cases:

- 1/Repairs to a system without leaks.

- 2/Slow leak.

- 3/Fast leak.

1/ Repairing a system without leaks.

a) - Using draining/recovery equipment not fitted with an oil decanter.

- Drain the system as slowly as possible via the LOW PRESSUREvalve, so as not to lose any oil.

- No more oil should be added when filling the system with R 134.afluid.

b) - Using draining/filling equipment fitted with an oil decanter.

- Drain the R 134.afluid from the system in accordance with the instructions in the equipment handbook.

- Measure the amount of oil recovered.

- Add the same amount of NEWoil when filling the system with R 134.afluid.

c) - Replacing a compressor.

- Remove the old compressor, drain it and measure the oil quantity.

- Drain the new compressor

(supplied full), so that the same amount of NEWoil is left in the compressor as was in the old compressor.

- No more oil should be added when filling the system with R 134.a fluid.

SPECIAL FEATURES: AIR CONDITIONING SYSTEM (R 134.a)

Compressor lubricant

Angl.-t2-page428-456-2005 9/01/06 10:25 Page 429

Page 436 of 462

Downloaded from www.Manualslib.com manuals search engine 430

AIR

CONDITIONING

Checking the compressor oil level (continued)

2/ Slow leak.

Slow leaks do not lead to oil loss, therefore the same procedure should be followed as if there was no leak at all.

3/ Fast leak.

This type of leak causes both oil loss as well as allowing air to enter the system.

It is therefore necessary to:

- Replace the dehydrator.

- Drain as much oil as possible

(when replacing the faulty component).

Either before or during filling of the system with R 134.afluid, introduce 80 ccof NEWoil into the circuit.

When changing one of the following components, add the quantity stated:

- A drying bottle : 15 ccof compressor oil.

- A condenser or an evaporator : 20 ccof compressor oil.

- High pressure or low pressure pipework : 5 ccof compressor oil.

- A drying cartridge : 15 ccof compressor oil.

SPECIAL FEATURES: AIR CONDITIONING SYSTEM (R 134.a)

Angl.-t2-page428-456-2005 9/01/06 10:25 Page 430

Page 442 of 462

Downloaded from www.Manualslib.com manuals search engine 436

AIR

CONDITIONING

SPECIAL FEATURES: AIR CONDITIONING SYSTEM (R 134.a)

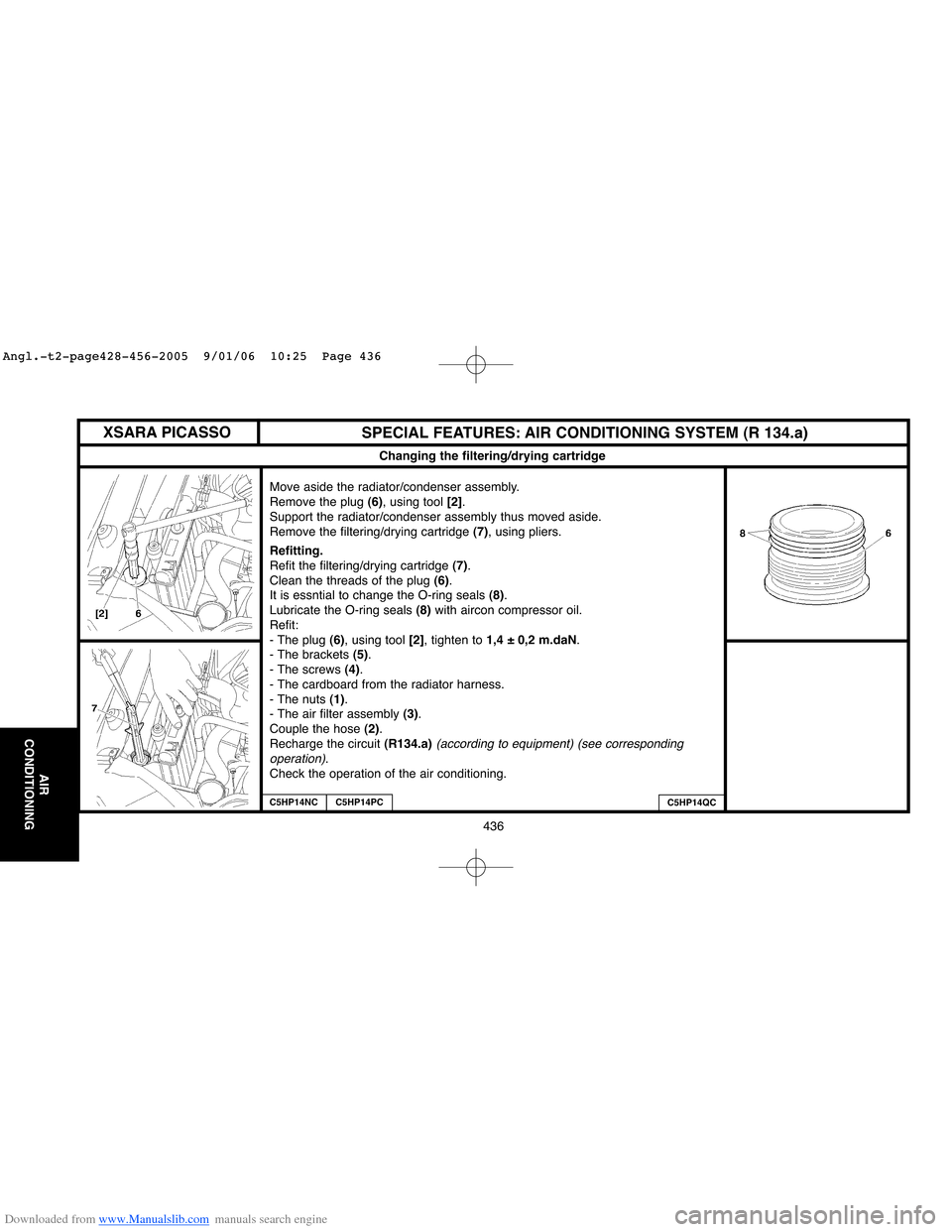

Changing the filtering/drying cartridge

Move aside the radiator/condenser assembly.

Remove the plug (6), using tool [2].

Support the radiator/condenser assembly thus moved aside.

Remove the filtering/drying cartridge (7), using pliers.

Refitting.

Refit the filtering/drying cartridge (7).

Clean the threads of the plug (6).

It is essntial to change the O-ring seals (8).

Lubricate the O-ring seals (8)with aircon compressor oil.

Refit:

- The plug (6), using tool [2], tighten to 1,4 ± 0,2 m.daN.

- The brackets (5).

- The screws (4).

- The cardboard from the radiator harness.

- The nuts (1).

- The air filter assembly (3).

Couple the hose (2).

Recharge the circuit (R134.a)

(according to equipment) (see corresponding

operation).

Check the operation of the air conditioning.

C5HP14NCC5HP14PCC5HP14QC

XSARA PICASSO

Angl.-t2-page428-456-2005 9/01/06 10:25 Page 436