warning Citroen C4 2005 2.G Repair Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: C4, Model: Citroen C4 2005 2.GPages: 462, PDF Size: 10.48 MB

Page 345 of 462

Downloaded from www.Manualslib.com manuals search engine 339

CLUTCH

GEARBOX

TRANSMISSION

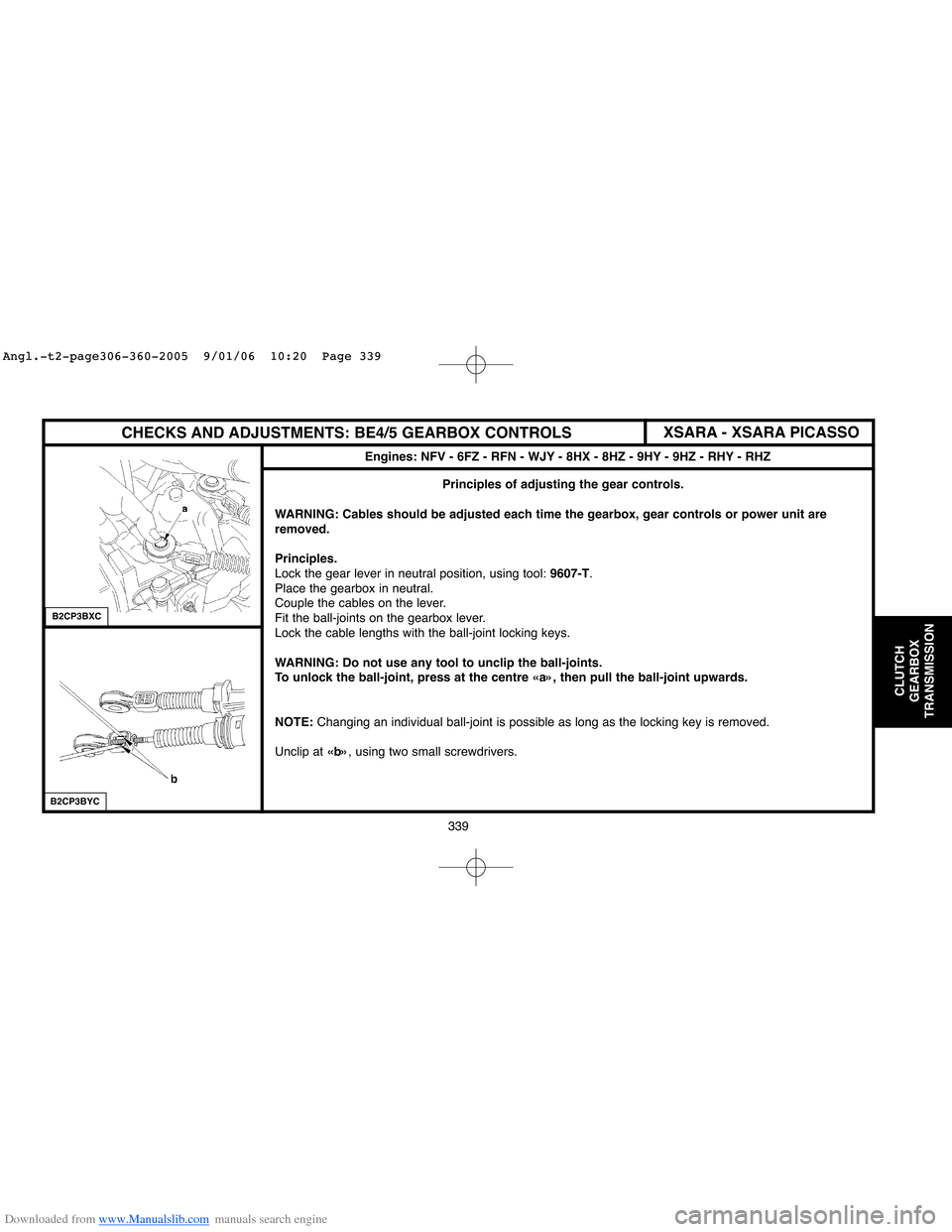

CHECKS AND ADJUSTMENTS: BE4/5 GEARBOX CONTROLS

Principles of adjusting the gear controls.

WARNING: Cables should be adjusted each time the gearbox, gear controls or power unit are

removed.

Principles.

Lock the gear lever in neutral position, using tool: 9607-T.

Place the gearbox in neutral.

Couple the cables on the lever.

Fit the ball-joints on the gearbox lever.

Lock the cable lengths with the ball-joint locking keys.

WARNING: Do not use any tool to unclip the ball-joints.

To unlock the ball-joint, press at the centre «a», then pull the ball-joint upwards.

NOTE:Changing an individual ball-joint is possible as long as the locking key is removed.

Unclip at «b», using two small screwdrivers.

Engines: NFV - 6FZ - RFN - WJY - 8HX - 8HZ - 9HY - 9HZ - RHY - RHZ

XSARA - XSARA PICASSO

B2CP3BXC

B2CP3BYC

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 339

Page 346 of 462

![Citroen C4 2005 2.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 340

CLUTCH

GEARBOX

TRANSMISSION

CHECKS AND ADJUSTMENTS: BE4/5 GEARBOX CONTROLS

Tools.

[1]Tool for positioning the gear lever: 9607-T

Adjustment Citroen C4 2005 2.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 340

CLUTCH

GEARBOX

TRANSMISSION

CHECKS AND ADJUSTMENTS: BE4/5 GEARBOX CONTROLS

Tools.

[1]Tool for positioning the gear lever: 9607-T

Adjustment](/img/9/4138/w960_4138-345.png)

Downloaded from www.Manualslib.com manuals search engine 340

CLUTCH

GEARBOX

TRANSMISSION

CHECKS AND ADJUSTMENTS: BE4/5 GEARBOX CONTROLS

Tools.

[1]Tool for positioning the gear lever: 9607-T

Adjustments.

WARNING: Cables should be adjusted each time

the gearbox, gear controls or power unit are

removed.

Inside the vehicle.

Remove the trim under the gear lever.

Lock the gear lever in neutral position, using tool [1].

Under the bonnet.

Remove the air filter assembly.

Unlock the ball-joint keys at «a».

Place the gear selection and control levers on neutral.

Lock the cable lengths with the ball-joint locking keys.Checks.

Remove the tool [1].

Check that all the gears engage without «tightness».

Check that the gear lever moves identically forwards

and backwards and to right and left.

If it does not, repeat the adjustment.

Refit the trim under the gear lever.

Refit the air filter assembly.

Adjusting the gear controls Engines: NFV - 6FZ - RFN - WJY - 8HX - 8HZ - 9HZ - 9HY - RHY - RHZ

XSARA - XSARA PICASSO

B2CP3C6CB2CP3C0C

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 340

Page 351 of 462

Downloaded from www.Manualslib.com manuals search engine 345

CLUTCH

GEARBOX

TRANSMISSION

RECOMMENDATIONS/PRECAUTIONS : AL4 AUTOMATIC GEARBOX

Procedure to be followed prior to carrying out repairs on AL4 autoactive gearbox

If a gearbox malfunction occurs, there are two possible configurations

depending on the seriousness of the fault:

- Gearbox in back-up mode with a replacement programme of

(the fault

values are taken in substitution).

- Gearbox in back-up mode with an emergency programme (3rd hydraulic).

WARNING: In the emergency programme, an impact is felt when

changing P/R, N/R and N/D.

Réception client.

Discuss with the customer, to find out all the malfunction symptoms.

Oil quality - Oil level.

Oil quality.

If the gearbox has suffered a serious fault resulting in a malfunction or

the destruction of a clutch, the oil will overheat and become

contaminated with impurities: the oil is said to be «burnt».

This is characterised by a black colour and the presence of an

unpleasant smell.

ESSENTIAL: The gearbox must be replaced.Oil level

(see corresponding operation).

An excessive oil level can result in the following consequences:

- Excessive heating of the oil.

- Oil leaks.

An insufficent level causes the destruction of the gearbox.

Top up the level of oil in the gearbox

(if necessary).

Check using a diagnostic tool.

Read the fault codes

(engine and gearbox).

Absence of fault codes.

Carry out parameter measures, actuator tests and a road test.

Presence of fault codes.

Carry out the necessary repairs.

Delete the fault codes.

Carry out a road test to check the repair and, if need be, modify the

gearbox ECU parameters

(this is essential after an initialisation of the

ECU).

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 345

Page 365 of 462

Downloaded from www.Manualslib.com manuals search engine 359

CLUTCH

GEARBOX

TRANSMISSION

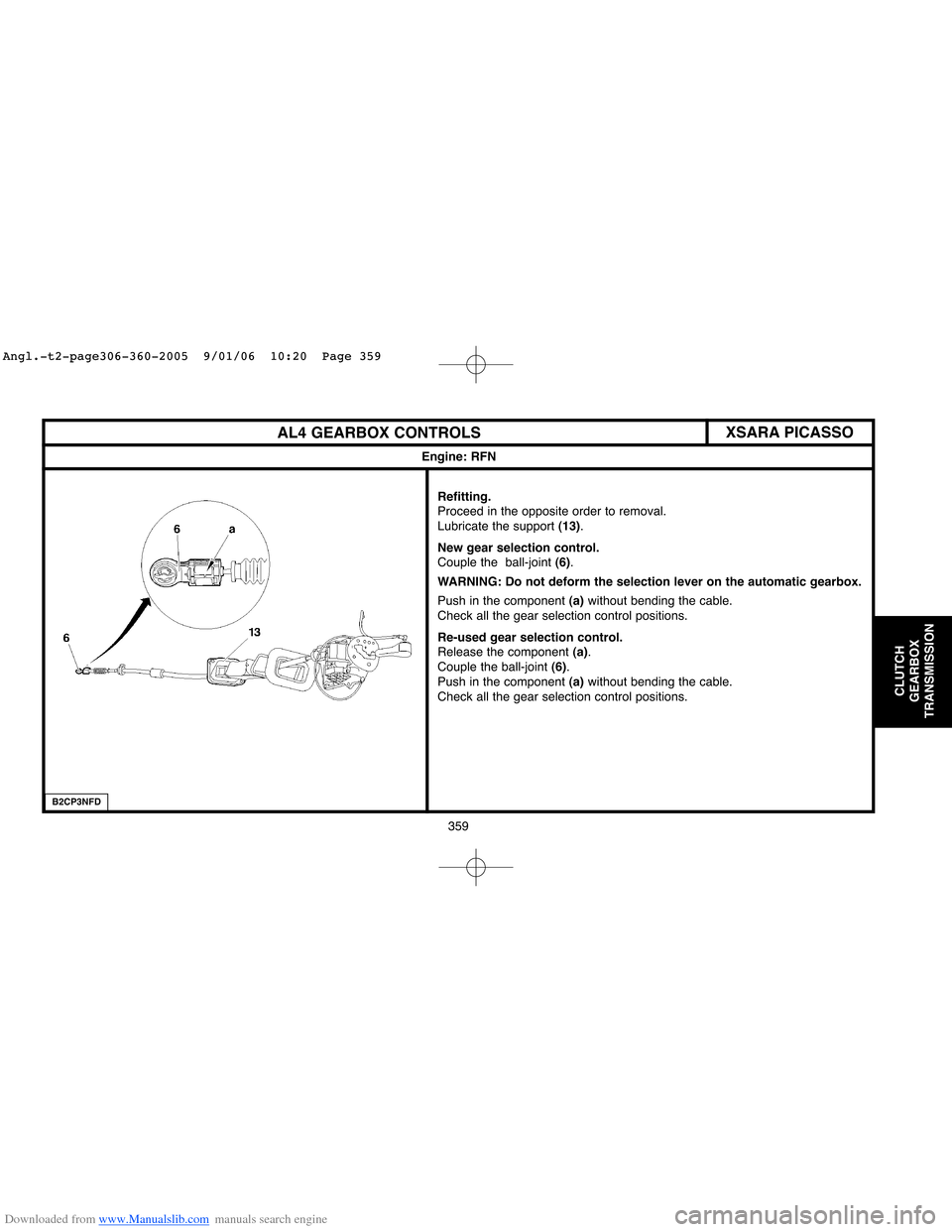

AL4 GEARBOX CONTROLS

Refitting.

Proceed in the opposite order to removal.

Lubricate the support (13).

New gear selection control.

Couple the ball-joint (6).

WARNING: Do not deform the selection lever on the automatic gearbox.

Push in the component (a)without bending the cable.

Check all the gear selection control positions.

Re-used gear selection control.

Release the component (a).

Couple the ball-joint (6).

Push in the component (a)without bending the cable.

Check all the gear selection control positions.

Engine: RFN

XSARA PICASSO

B2CP3NFD

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 359

Page 394 of 462

Downloaded from www.Manualslib.com manuals search engine 388

AXLES

SUSPENSION

STEERING

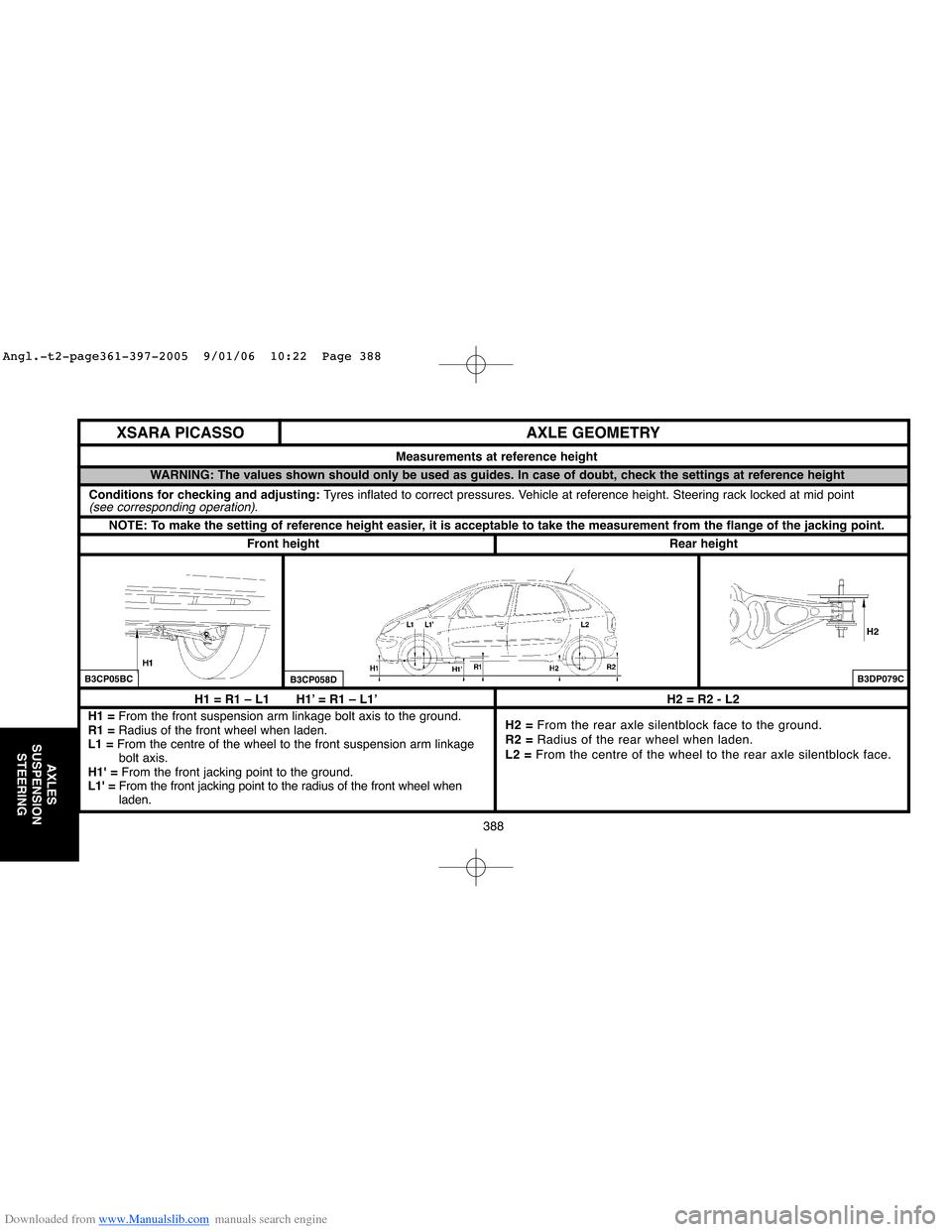

H1 = R1 – L1 H1’ = R1 – L1’

H1 = From the front suspension arm linkage bolt axis to the ground.

R1 =Radius of the front wheel when laden.

L1 =From the centre of the wheel to the front suspension arm linkage

bolt axis.

H1' =From the front jacking point to the ground.

L1' =From the front jacking point to the radius of the front wheel when

laden.H2 = R2 - L2

H2 = From the rear axle silentblock face to the ground.

R2 =Radius of the rear wheel when laden.

L2 =From the centre of the wheel to the rear axle silentblock face.

AXLE GEOMETRY

Measurements at reference height

NOTE: To make the setting of reference height easier, it is acceptable to take the measurement from the flange of the jacking point.

WARNING: The values shown should only be used as guides. In case of doubt, check the settings at reference height

Rear heightFront height

B3CP05BCB3CP058DB3DP079C

XSARA PICASSO

Conditions for checking and adjusting: Tyres inflated to correct pressures. Vehicle at reference height. Steering rack locked at mid point(see corresponding operation).

Angl.-t2-page361-397-2005 9/01/06 10:22 Page 388

Page 404 of 462

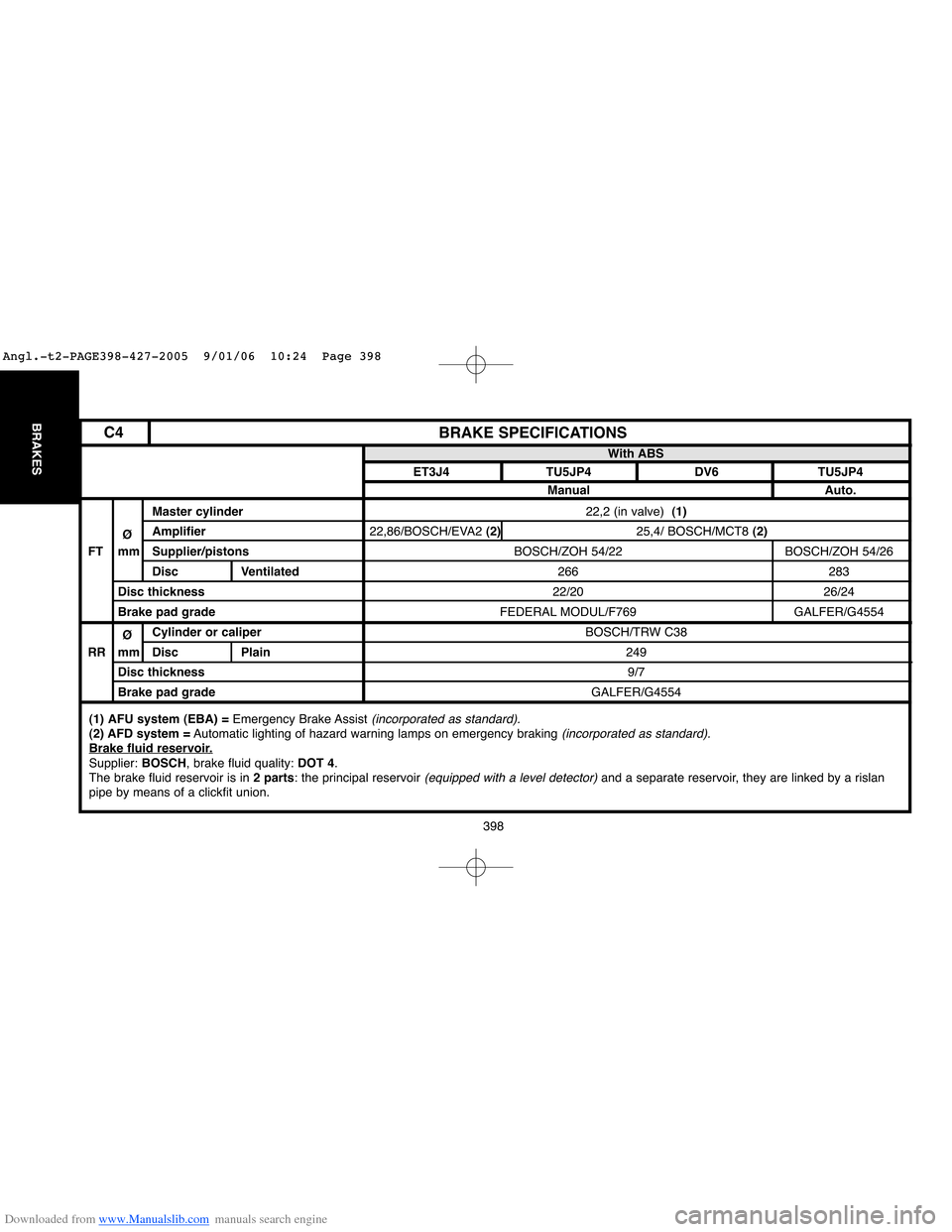

Downloaded from www.Manualslib.com manuals search engine 398

BRAKES

22,2 (in valve) (1)

22,86/BOSCH/EVA2 (2)25,4/ BOSCH/MCT8 (2)

BOSCH/ZOH 54/22 BOSCH/ZOH 54/26

266 283

22/20 26/24

FEDERAL MODUL/F769 GALFER/G4554

BOSCH/TRW C38

249

9/7

GALFER/G4554

BRAKE SPECIFICATIONS

Master cylinder

ØAmplifier

FT mm Supplier/pistons

Disc Ventilated

Disc thickness

Brake pad grade

ØCylinder or caliper

RR mm Disc Plain

Disc thickness

Brake pad gradeWith ABS

ET3J4 TU5JP4 DV6 TU5JP4

Manual Auto.

(1) AFU system (EBA) =Emergency Brake Assist (incorporated as standard).(2) AFD system =Automatic lighting of hazard warning lamps on emergency braking (incorporated as standard).Brake fluid reservoir.Supplier: BOSCH, brake fluid quality: DOT 4.

The brake fluid reservoir is in 2 parts: the principal reservoir (equipped with a level detector)and a separate reservoir, they are linked by a rislan

pipe by means of a clickfit union.

C4

Angl.-t2-PAGE398-427-2005 9/01/06 10:24 Page 398

Page 405 of 462

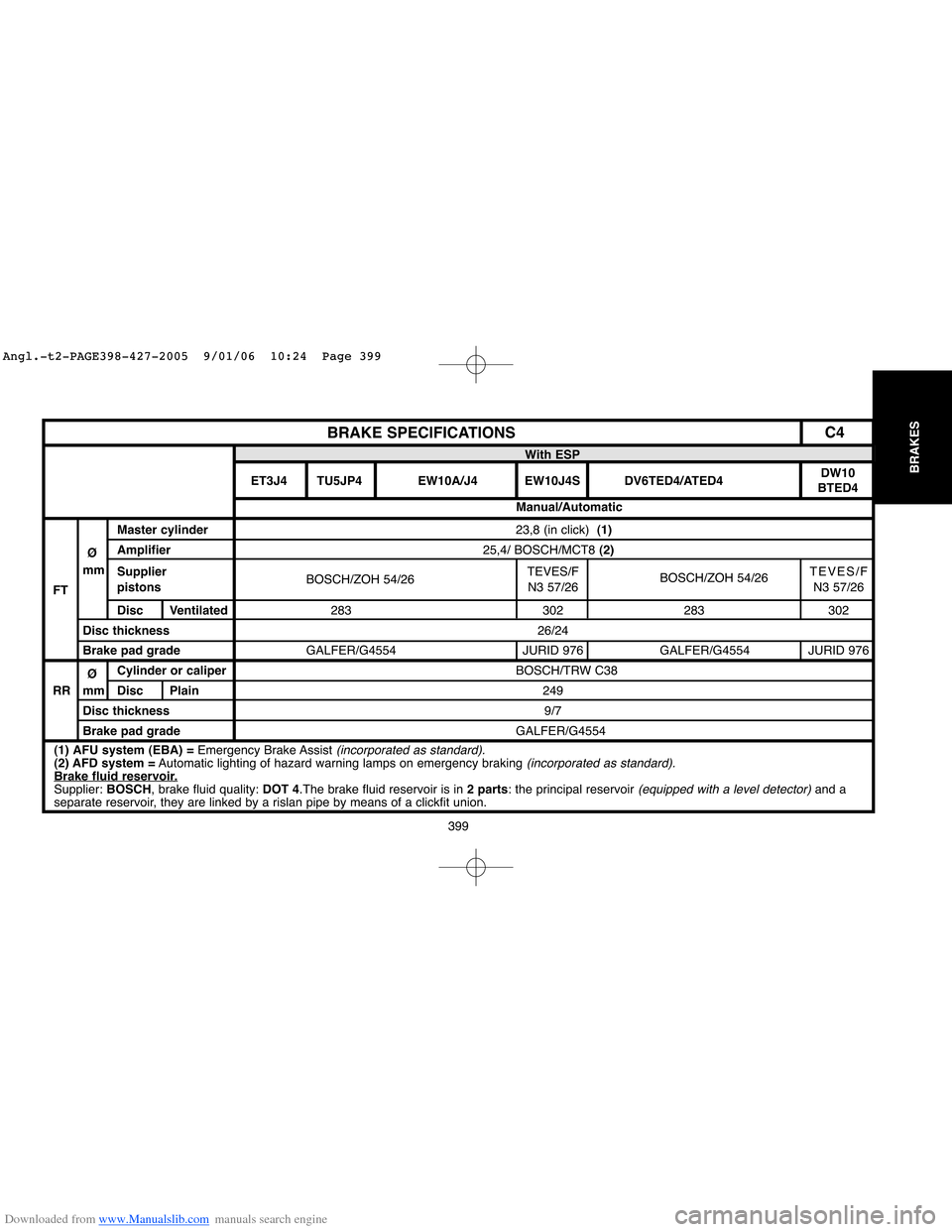

Downloaded from www.Manualslib.com manuals search engine 399

BRAKES

23,8 (in click) (1)

25,4/ BOSCH/MCT8 (2)

BOSCH/ZOH 54/26TEVES/F

BOSCH/ZOH 54/26TEVES/F

N3 57/26 N3 57/26

283 302 283 302

26/24

GALFER/G4554 JURID 976 GALFER/G4554 JURID 976

BOSCH/TRW C38

249

9/7

GALFER/G4554

BRAKE SPECIFICATIONS

Master cylinder

ØAmplifier

mm

Supplier

FTpistons

Disc Ventilated

Disc thickness

Brake pad grade

ØCylinder or caliper

RR mm Disc Plain

Disc thickness

Brake pad gradeWith ESP

ET3J4 TU5JP4 EW10A/J4 EW10J4S DV6TED4/ATED4DW10

BTED4

Manual/Automatic

(1) AFU system (EBA) =Emergency Brake Assist (incorporated as standard).(2) AFD system =Automatic lighting of hazard warning lamps on emergency braking (incorporated as standard).Brake fluid reservoir.Supplier: BOSCH, brake fluid quality: DOT 4.The brake fluid reservoir is in 2 parts: the principal reservoir (equipped with a level detector)and a

separate reservoir, they are linked by a rislan pipe by means of a clickfit union.

C4

Angl.-t2-PAGE398-427-2005 9/01/06 10:24 Page 399

Page 406 of 462

Downloaded from www.Manualslib.com manuals search engine B3FP7E1D

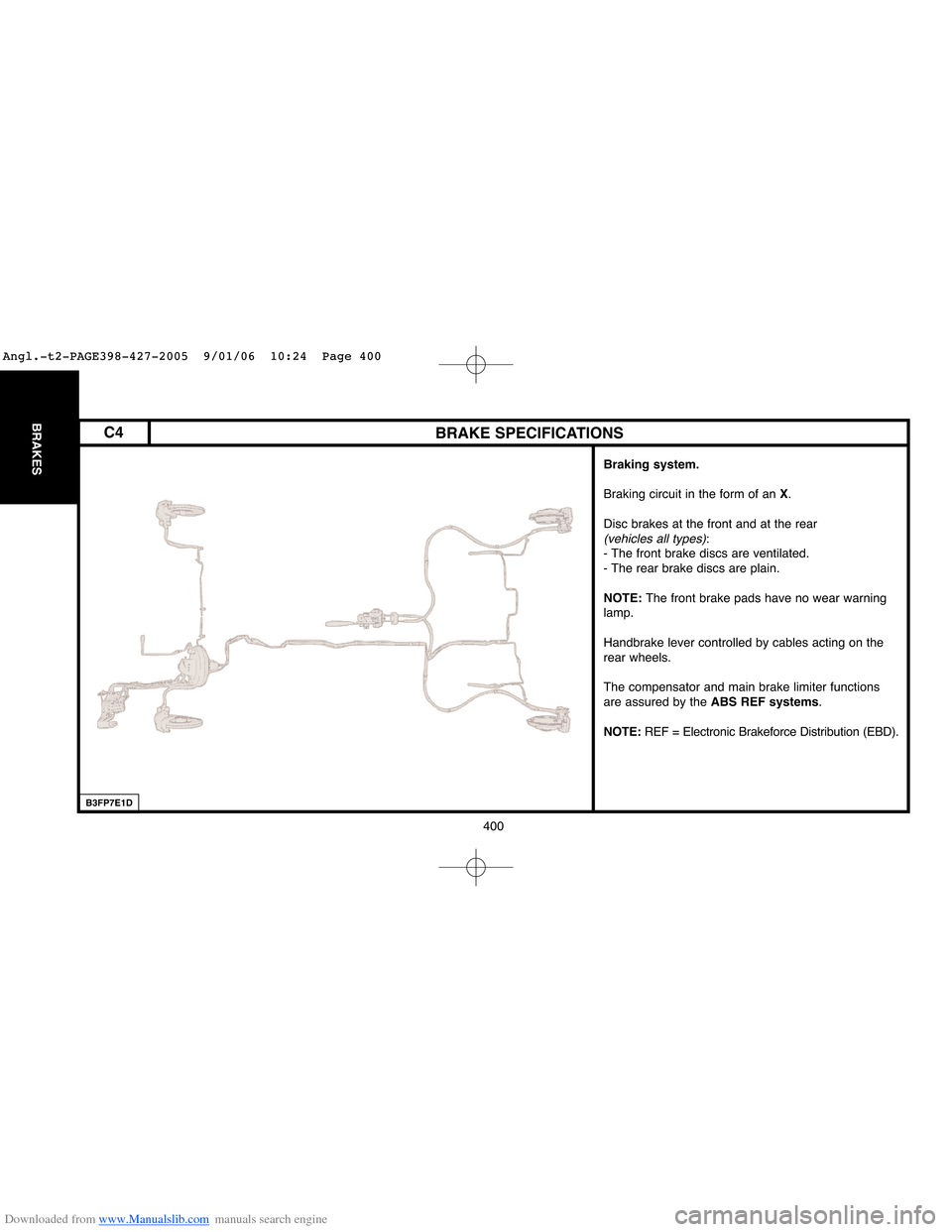

BRAKE SPECIFICATIONS

Braking system.

Braking circuit in the form of an X.

Disc brakes at the front and at the rear

(vehicles all types):

- The front brake discs are ventilated.

- The rear brake discs are plain.

NOTE: The front brake pads have no wear warning

lamp.

Handbrake lever controlled by cables acting on the

rear wheels.

The compensator and main brake limiter functions

are assured by the ABS REF systems.

NOTE:REF = Electronic Brakeforce Distribution (EBD).

400

BRAKESC4

Angl.-t2-PAGE398-427-2005 9/01/06 10:24 Page 400

Page 411 of 462

Downloaded from www.Manualslib.com manuals search engine 405

BRAKES

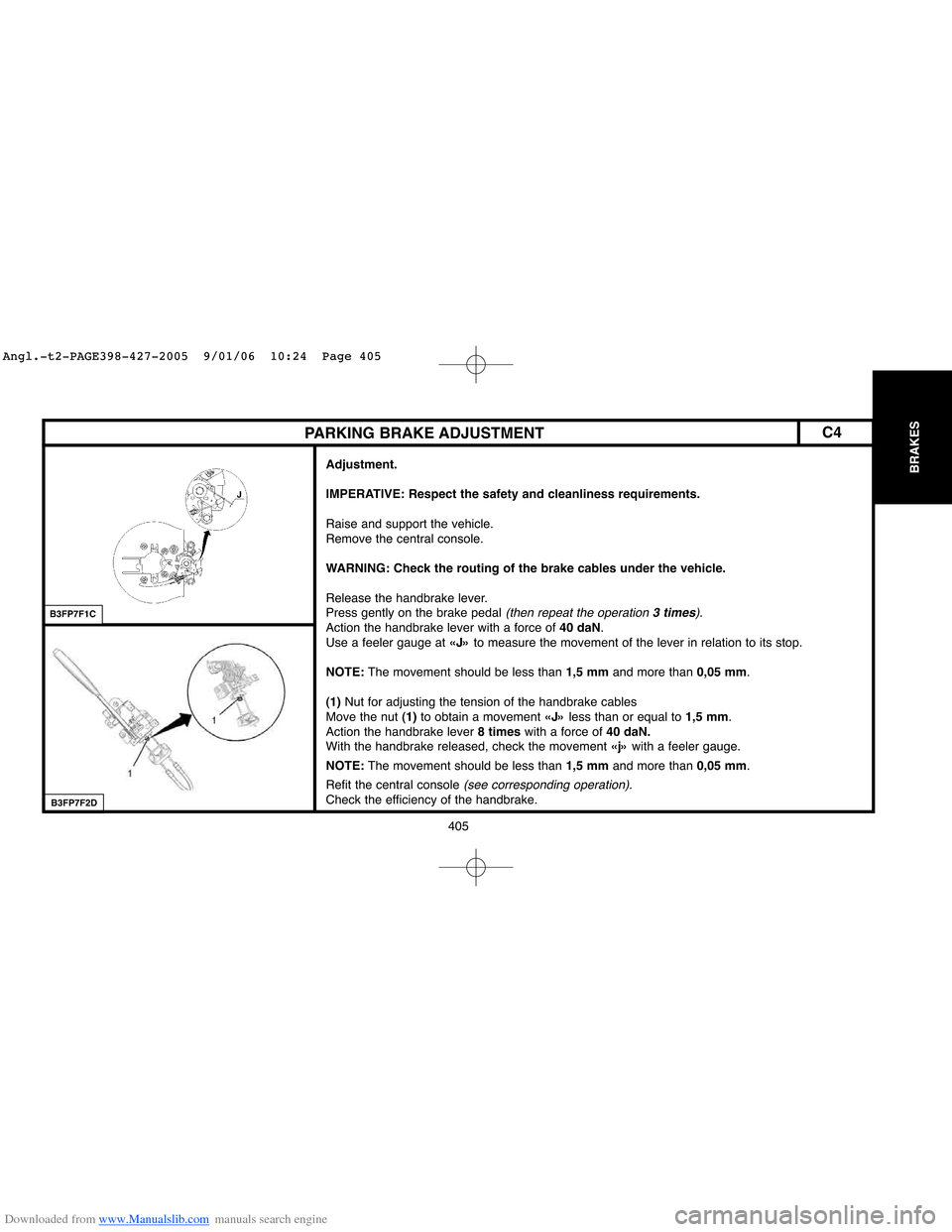

PARKING BRAKE ADJUSTMENT

Adjustment.

IMPERATIVE: Respect the safety and cleanliness requirements.

Raise and support the vehicle.

Remove the central console.

WARNING: Check the routing of the brake cables under the vehicle.

Release the handbrake lever.

Press gently on the brake pedal

(then repeat the operation 3 times).

Action the handbrake lever with a force of 40 daN.

Use a feeler gauge at «J»to measure the movement of the lever in relation to its stop.

NOTE:The movement should be less than 1,5 mmand more than 0,05 mm.

(1)Nut for adjusting the tension of the handbrake cables

Move the nut (1)to obtain a movement «J»less than or equal to 1,5 mm.

Action the handbrake lever 8 timeswith a force of 40 daN.

With the handbrake released, check the movement «j»with a feeler gauge.

NOTE:The movement should be less than 1,5 mmand more than 0,05 mm.

Refit the central console

(see corresponding operation).

Check the efficiency of the handbrake.

B3FP7F1C

B3FP7F2D

C4

Angl.-t2-PAGE398-427-2005 9/01/06 10:24 Page 405

Page 414 of 462

Downloaded from www.Manualslib.com manuals search engine 408

BRAKES

B3FP7EUC

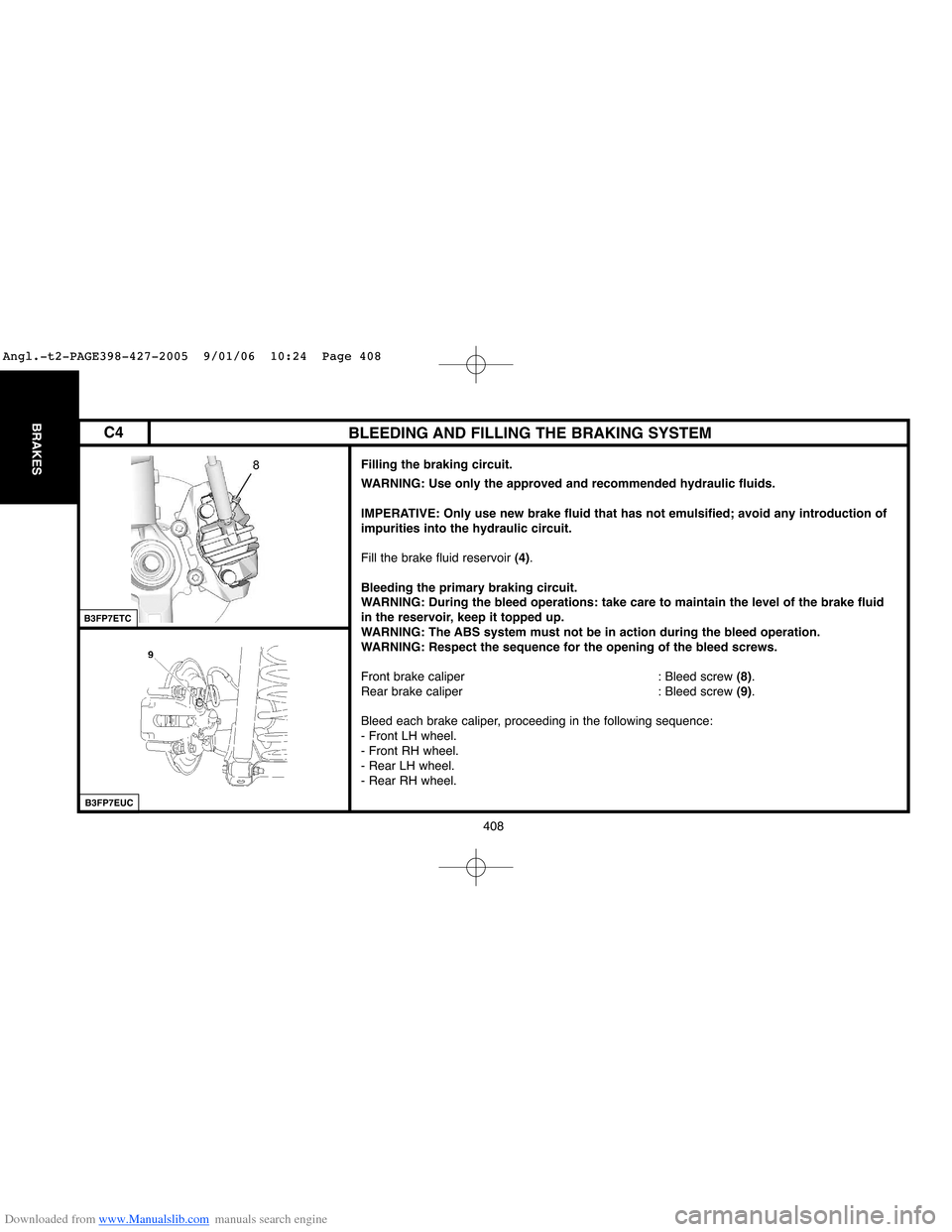

BLEEDING AND FILLING THE BRAKING SYSTEM

Filling the braking circuit.

WARNING: Use only the approved and recommended hydraulic fluids.

IMPERATIVE: Only use new brake fluid that has not emulsified; avoid any introduction of

impurities into the hydraulic circuit.

Fill the brake fluid reservoir (4).

Bleeding the primary braking circuit.

WARNING: During the bleed operations: take care to maintain the level of the brake fluid

in the reservoir, keep it topped up.

WARNING: The ABS system must not be in action during the bleed operation.

WARNING: Respect the sequence for the opening of the bleed screws.

Front brake caliper : Bleed screw (8).

Rear brake caliper : Bleed screw (9).

Bleed each brake caliper, proceeding in the following sequence:

- Front LH wheel.

- Front RH wheel.

- Rear LH wheel.

- Rear RH wheel.

B3FP7ETC

C4

Angl.-t2-PAGE398-427-2005 9/01/06 10:24 Page 408