engine light Citroen C4 2005 2.G Workshop Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: C4, Model: Citroen C4 2005 2.GPages: 462, PDF Size: 10.48 MB

Page 200 of 462

Downloaded from www.Manualslib.com manuals search engine 194

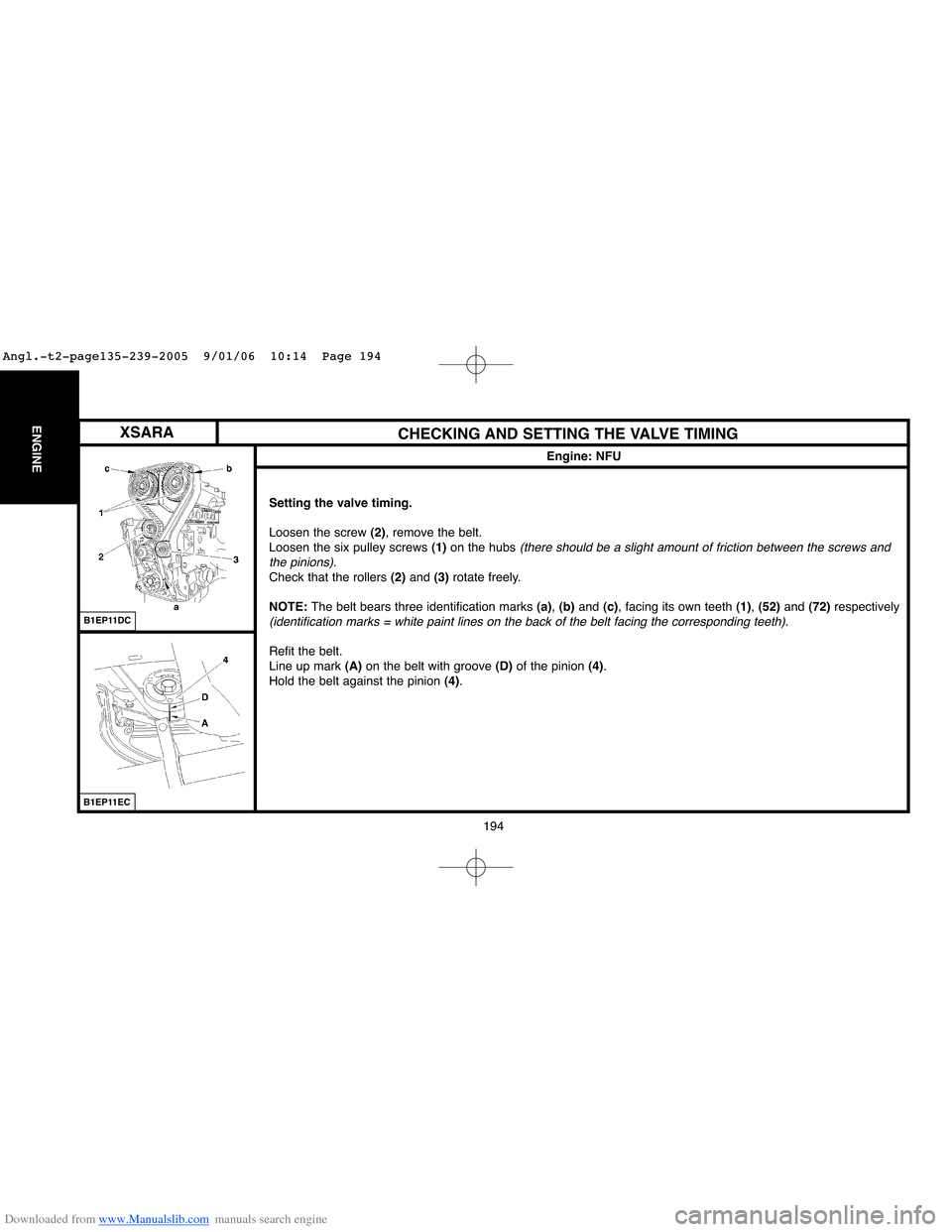

ENGINECHECKING AND SETTING THE VALVE TIMING

Engine: NFU

Setting the valve timing.

Loosen the screw (2), remove the belt.

Loosen the six pulley screws (1)on the hubs

(there should be a slight amount of friction between the screws and

the pinions).

Check that the rollers (2)and (3) rotate freely.

NOTE: The belt bears three identification marks (a), (b)and (c), facing its own teeth (1), (52)and (72)respectively

(identification marks = white paint lines on the back of the belt facing the corresponding teeth).

Refit the belt.

Line up mark (A)on the belt with groove (D)of the pinion (4).

Hold the belt against the pinion (4).

B1EP11EC

B1EP11DC

XSARA

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 194

Page 202 of 462

![Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 196

ENGINECHECKING AND SETTING THE VALVE TIMING

Engine: NFU

Setting the valve timing.

Remove the tools [1], [2], [3]and [4].

Rotate the engine Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 196

ENGINECHECKING AND SETTING THE VALVE TIMING

Engine: NFU

Setting the valve timing.

Remove the tools [1], [2], [3]and [4].

Rotate the engine](/img/9/4138/w960_4138-201.png)

Downloaded from www.Manualslib.com manuals search engine 196

ENGINECHECKING AND SETTING THE VALVE TIMING

Engine: NFU

Setting the valve timing.

Remove the tools [1], [2], [3]and [4].

Rotate the engine by four turnsin the normal direction

(do not turn backwards).

Peg the flywheel [2].

Loosen the six screws (5), while ensuring there is still a slight amount of friction with the pulley.

Peg the camshaft hubs using pegs [3]and [4].

WARNING: In certain cases, it may be necessary to slightly turn the camshaft using the hub fixing screw.

Fit the tool [1].

Loosen the tensioner roller screw (2).

Rotate the roller (2)

(using tool [5])in an anti-clockwise direction to obtain: 37 SEEMunits.

Tighten the tensioner roller screw (2)to 2 m.daN.

Tighten the six pulley screws (1)to 1 m.daN.

Remove the tools.

XSARA

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 196

Page 268 of 462

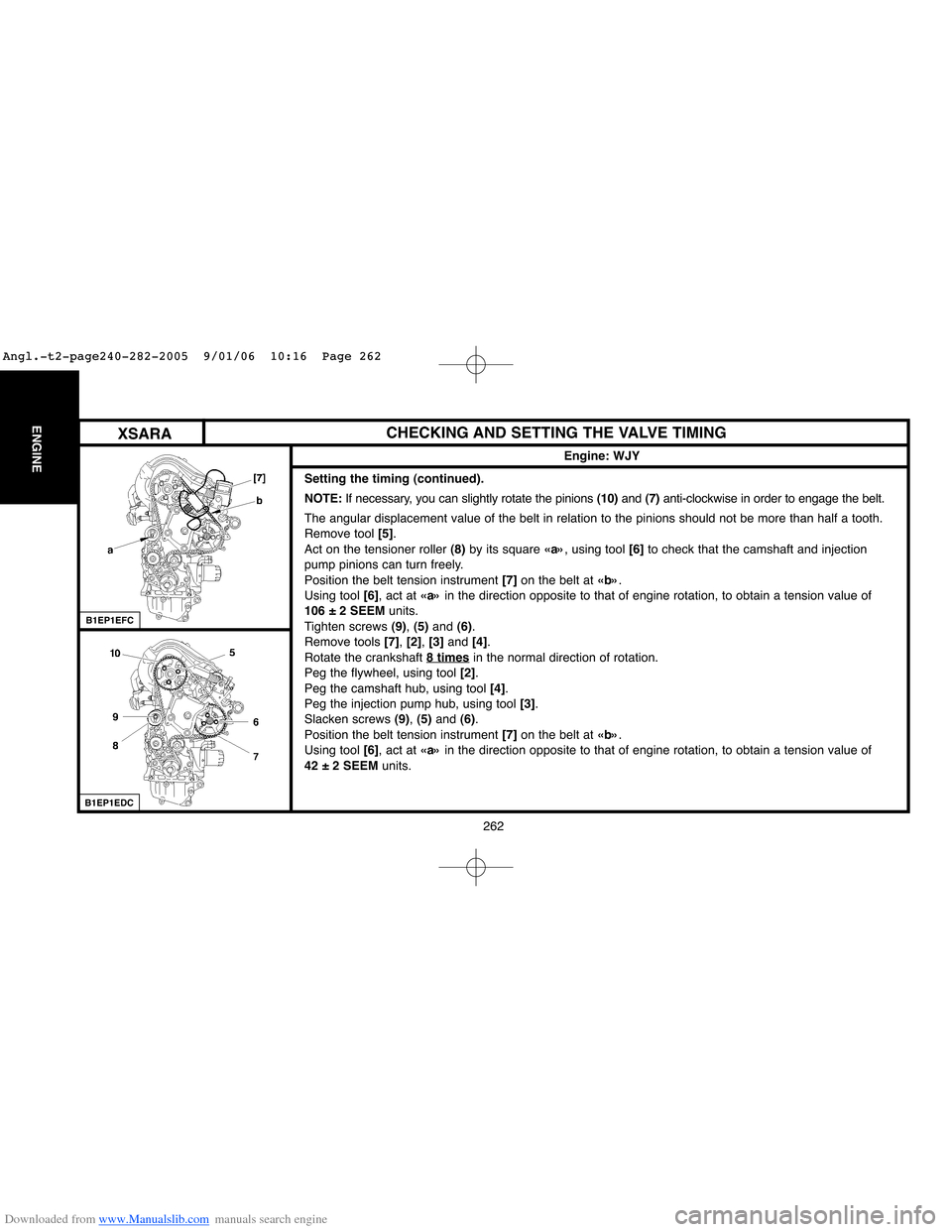

Downloaded from www.Manualslib.com manuals search engine 262

ENGINECHECKING AND SETTING THE VALVE TIMING

Engine: WJY

B1EP1EDC

Setting the timing (continued).

NOTE:If necessary, you can slightly rotate the pinions (10)and (7)anti-clockwise in order to engage the belt.

The angular displacement value of the belt in relation to the pinions should not be more than half a tooth.

Remove tool [5].

Act on the tensioner roller (8)by its square «a», using tool [6]to check that the camshaft and injection

pump pinions can turn freely.

Position the belt tension instrument [7]on the belt at «b».

Using tool [6], act at «a»in the direction opposite to that of engine rotation, to obtain a tension value of

106 ± 2 SEEMunits.

Tighten screws (9), (5) and (6).

Remove tools [7], [2], [3]and [4].

Rotate the crankshaft 8 times

in the normal direction of rotation.

Peg the flywheel, using tool [2].

Peg the camshaft hub, using tool [4].

Peg the injection pump hub, using tool [3].

Slacken screws (9), (5)and (6).

Position the belt tension instrument [7]on the belt at «b».

Using tool [6], act at «a»in the direction opposite to that of engine rotation, to obtain a tension value of

42 ± 2 SEEMunits.

B1EP1EFC

XSARA

Angl.-t2-page240-282-2005 9/01/06 10:16 Page 262

Page 284 of 462

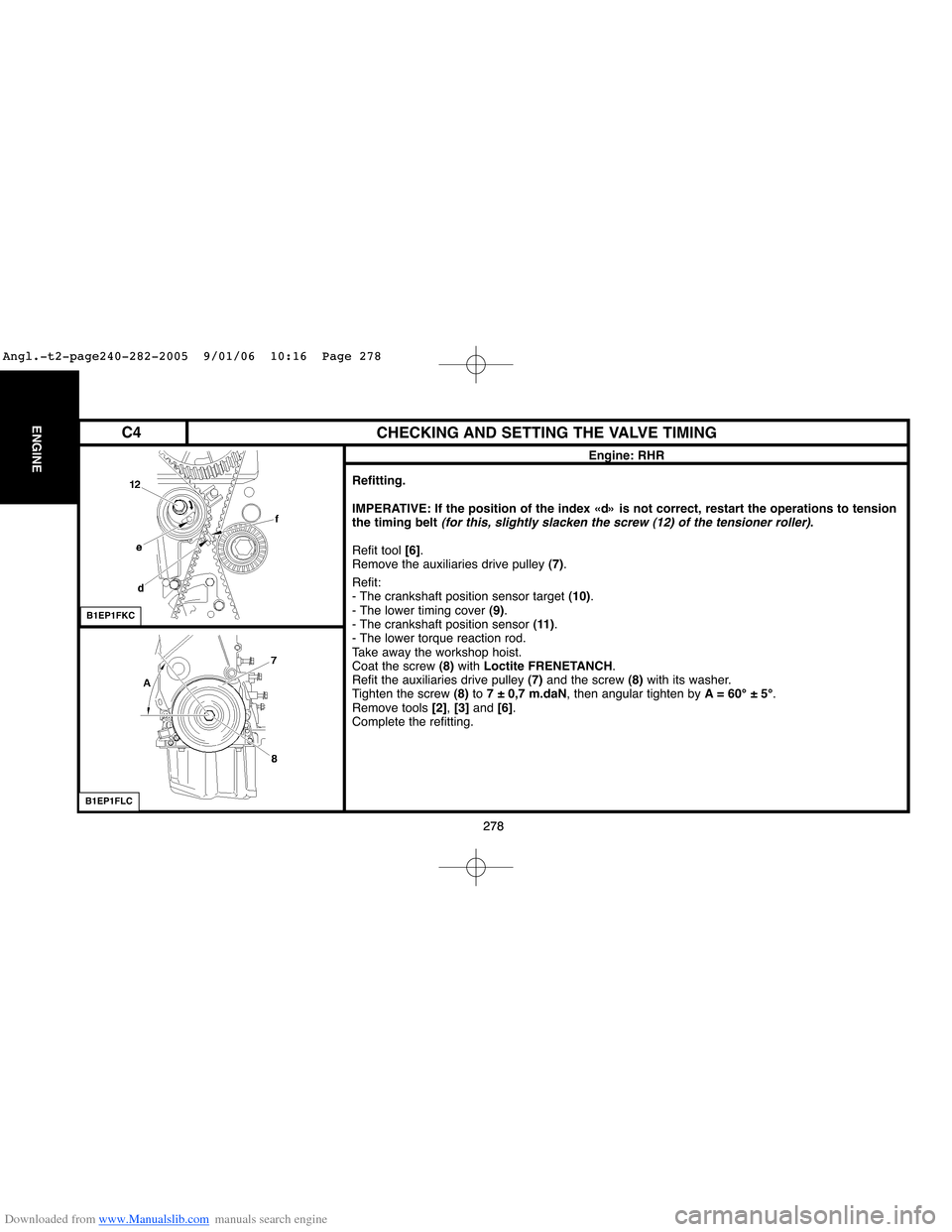

Downloaded from www.Manualslib.com manuals search engine 278 278

ENGINECHECKING AND SETTING THE VALVE TIMING

Engine: RHR

Refitting.

IMPERATIVE: If the position of the index «d» is not correct, restart the operations to tension

the timing belt

(for this, slightly slacken the screw (12) of the tensioner roller).

Refit tool [6].

Remove the auxiliaries drive pulley (7).

Refit:

- The crankshaft position sensor target (10).

- The lower timing cover (9).

- The crankshaft position sensor (11).

- The lower torque reaction rod.

Take away the workshop hoist.

Coat the screw (8)with Loctite FRENETANCH.

Refit the auxiliaries drive pulley (7) and the screw (8)with its washer.

Tighten the screw (8)to 7 ± 0,7 m.daN, then angular tighten by A= 60°±5°.

Remove tools [2], [3] and [6].

Complete the refitting.

B1EP1FKC

B1EP1FLC

C4

Angl.-t2-page240-282-2005 9/01/06 10:16 Page 278

Page 393 of 462

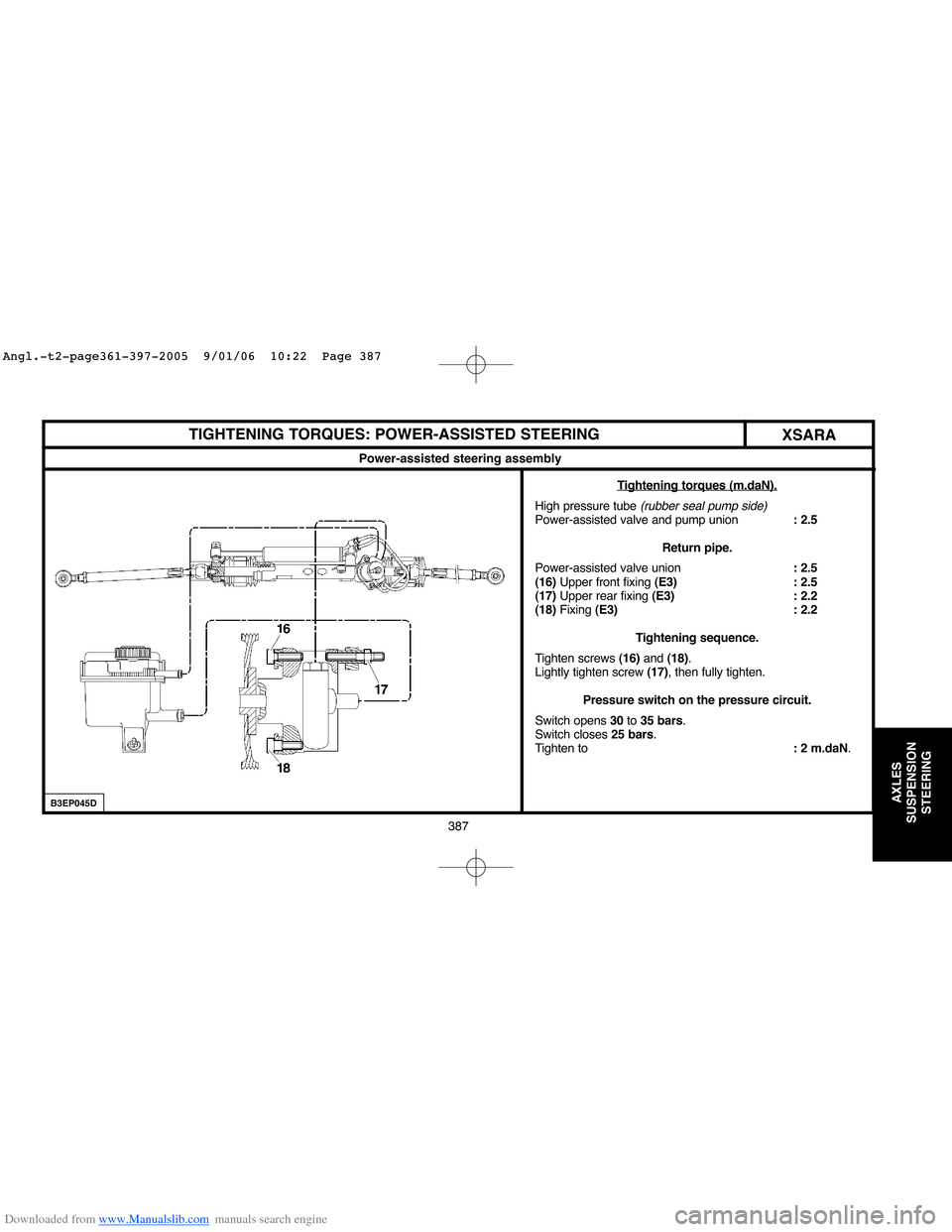

Downloaded from www.Manualslib.com manuals search engine 387

AXLES

SUSPENSION

STEERING

TIGHTENING TORQUES: POWER-ASSISTED STEERING

XSARA

Power-assisted steering assembly

T

ightening torques (m.daN).

High pressure tube (rubber seal pump side)Power-assisted valve and pump union: 2.5

Return pipe.

Power-assisted valve union: 2.5

(16)Upper front fixing (E3) : 2.5

(17)Upper rear fixing (E3) : 2.2

(18)Fixing (E3) : 2.2

Tightening sequence.

Tighten screws (16) and (18).

Lightly tighten screw (17), then fully tighten.

Pressure switch on the pressure circuit.

Switch opens 30to 35 bars.

Switch closes 25 bars.

Tighten to: 2 m.daN.

B3EP045D

Angl.-t2-page361-397-2005 9/01/06 10:22 Page 387

Page 404 of 462

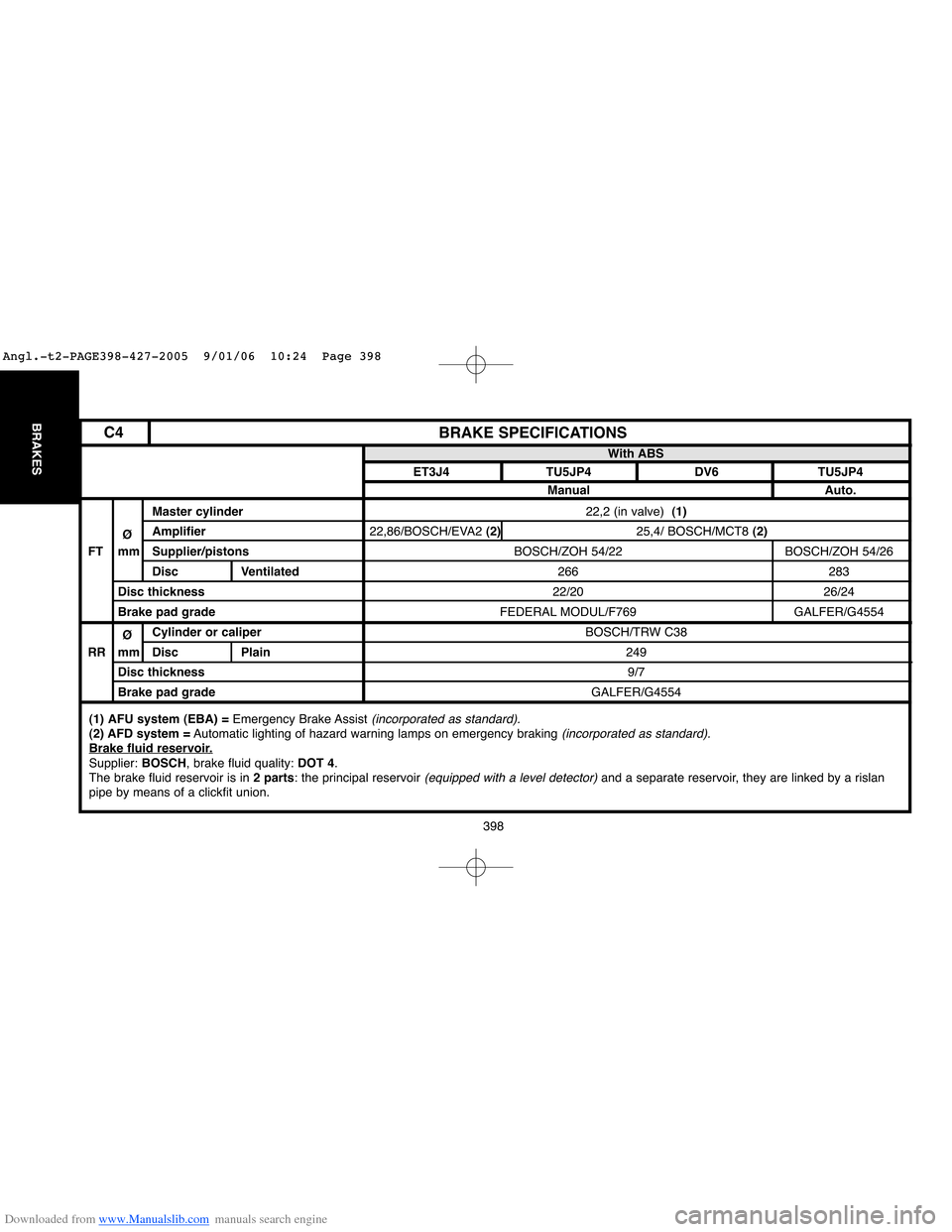

Downloaded from www.Manualslib.com manuals search engine 398

BRAKES

22,2 (in valve) (1)

22,86/BOSCH/EVA2 (2)25,4/ BOSCH/MCT8 (2)

BOSCH/ZOH 54/22 BOSCH/ZOH 54/26

266 283

22/20 26/24

FEDERAL MODUL/F769 GALFER/G4554

BOSCH/TRW C38

249

9/7

GALFER/G4554

BRAKE SPECIFICATIONS

Master cylinder

ØAmplifier

FT mm Supplier/pistons

Disc Ventilated

Disc thickness

Brake pad grade

ØCylinder or caliper

RR mm Disc Plain

Disc thickness

Brake pad gradeWith ABS

ET3J4 TU5JP4 DV6 TU5JP4

Manual Auto.

(1) AFU system (EBA) =Emergency Brake Assist (incorporated as standard).(2) AFD system =Automatic lighting of hazard warning lamps on emergency braking (incorporated as standard).Brake fluid reservoir.Supplier: BOSCH, brake fluid quality: DOT 4.

The brake fluid reservoir is in 2 parts: the principal reservoir (equipped with a level detector)and a separate reservoir, they are linked by a rislan

pipe by means of a clickfit union.

C4

Angl.-t2-PAGE398-427-2005 9/01/06 10:24 Page 398

Page 405 of 462

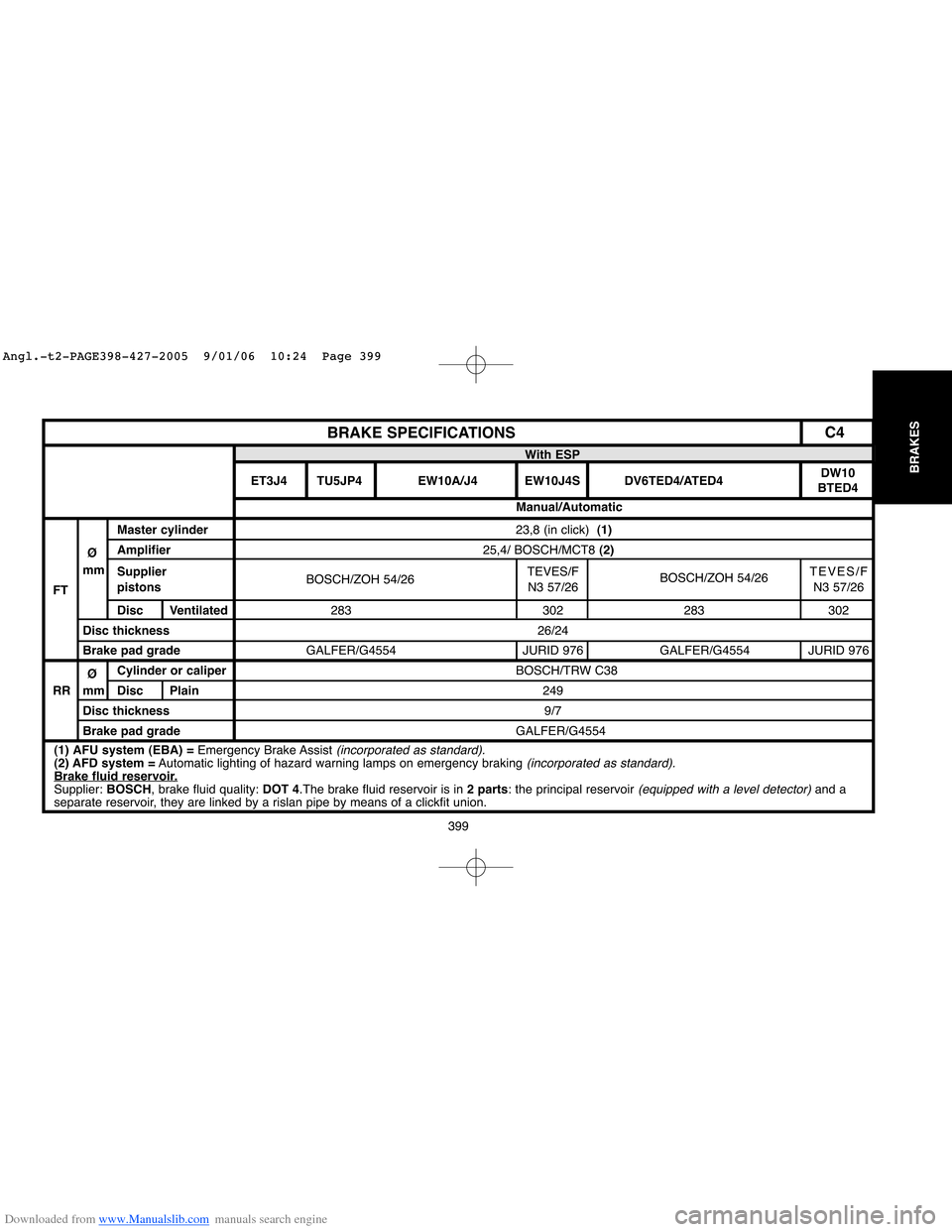

Downloaded from www.Manualslib.com manuals search engine 399

BRAKES

23,8 (in click) (1)

25,4/ BOSCH/MCT8 (2)

BOSCH/ZOH 54/26TEVES/F

BOSCH/ZOH 54/26TEVES/F

N3 57/26 N3 57/26

283 302 283 302

26/24

GALFER/G4554 JURID 976 GALFER/G4554 JURID 976

BOSCH/TRW C38

249

9/7

GALFER/G4554

BRAKE SPECIFICATIONS

Master cylinder

ØAmplifier

mm

Supplier

FTpistons

Disc Ventilated

Disc thickness

Brake pad grade

ØCylinder or caliper

RR mm Disc Plain

Disc thickness

Brake pad gradeWith ESP

ET3J4 TU5JP4 EW10A/J4 EW10J4S DV6TED4/ATED4DW10

BTED4

Manual/Automatic

(1) AFU system (EBA) =Emergency Brake Assist (incorporated as standard).(2) AFD system =Automatic lighting of hazard warning lamps on emergency braking (incorporated as standard).Brake fluid reservoir.Supplier: BOSCH, brake fluid quality: DOT 4.The brake fluid reservoir is in 2 parts: the principal reservoir (equipped with a level detector)and a

separate reservoir, they are linked by a rislan pipe by means of a clickfit union.

C4

Angl.-t2-PAGE398-427-2005 9/01/06 10:24 Page 399