clock Citroen C5 2000 (DC/DE) / 1.G User Guide

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2000, Model line: C5, Model: Citroen C5 2000 (DC/DE) / 1.GPages: 259, PDF Size: 2.29 MB

Page 81 of 259

Downloaded from www.Manualslib.com manuals search engine ENGINE

78

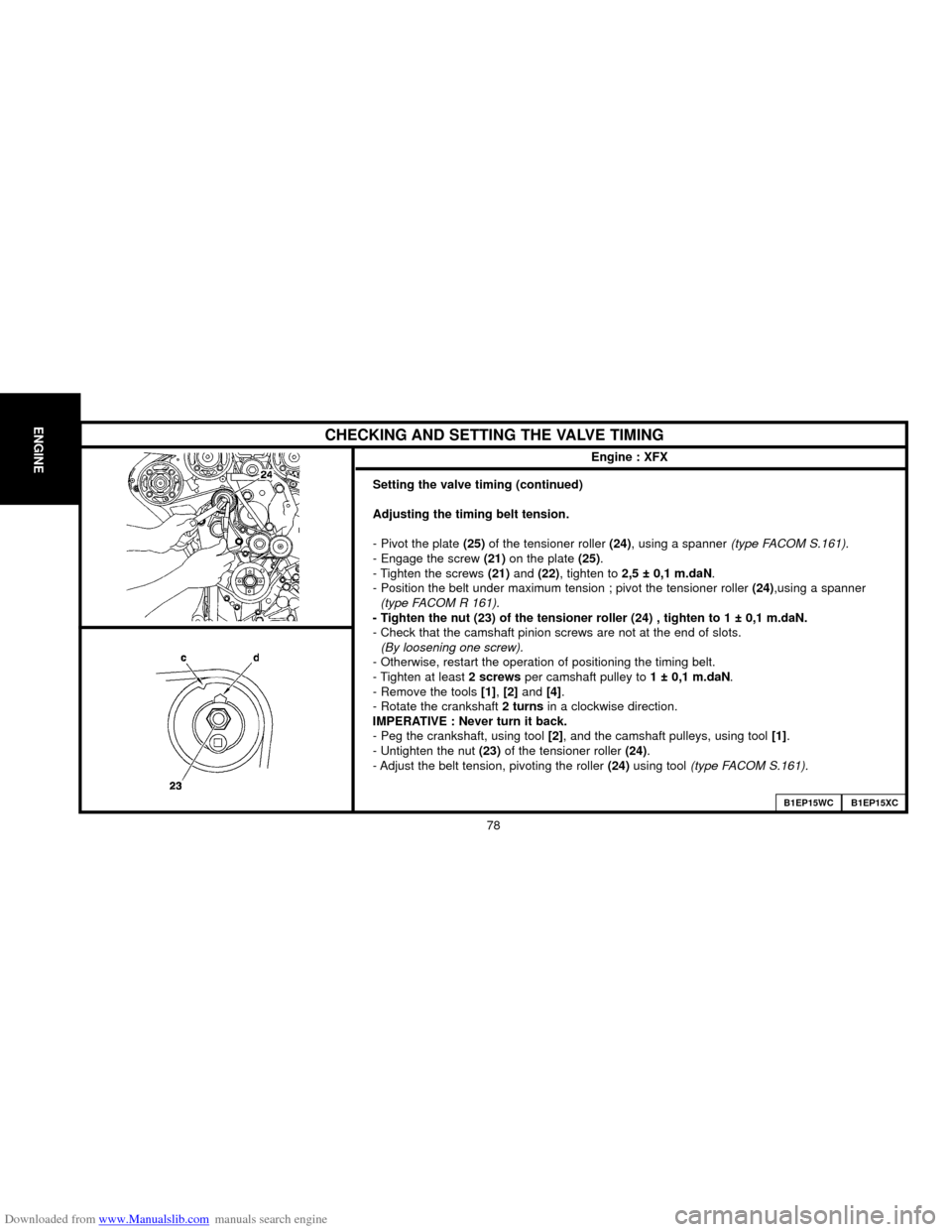

CHECKING AND SETTING THE VALVE TIMING

Engine : XFX

Setting the valve timing (continued)

Adjusting the timing belt tension.

- Pivot the plate (25) of the tensioner roller (24), using a spanner (type FACOM S.161).

- Engage the screw(21)on the plate (25).

- Tighten the screws (21)and (22), tighten to 2,5 ± 0,1 m.daN.

- Position the belt under maximum tension ; pivot the tensioner roller (24),using a spanner

(type FACOM R 161).

- Tighten the nut (23) of the tensioner roller (24) , tighten to 1 ± 0,1 m.daN.

- Check that the camshaft pinion screws are not at the end of slots.

(By loosening one screw).

- Otherwise, restart the operation of positioning the timing belt.

- Tighten at least2 screwsper camshaft pulley to 1 ± 0,1 m.daN.

- Remove the tools [1], [2]and [4].

- Rotate the crankshaft 2 turnsin a clockwise direction.

IMPERATIVE : Never turn it back.

- Peg the crankshaft, using tool[2], and the camshaft pulleys, using tool [1].

- Untighten the nut(23)of the tensioner roller(24).

- Adjust the belt tension, pivoting the roller (24)using tool(type FACOM S.161).

B1EP15WCB1EP15XC

Page 85 of 259

Downloaded from www.Manualslib.com manuals search engine ENGINE

82

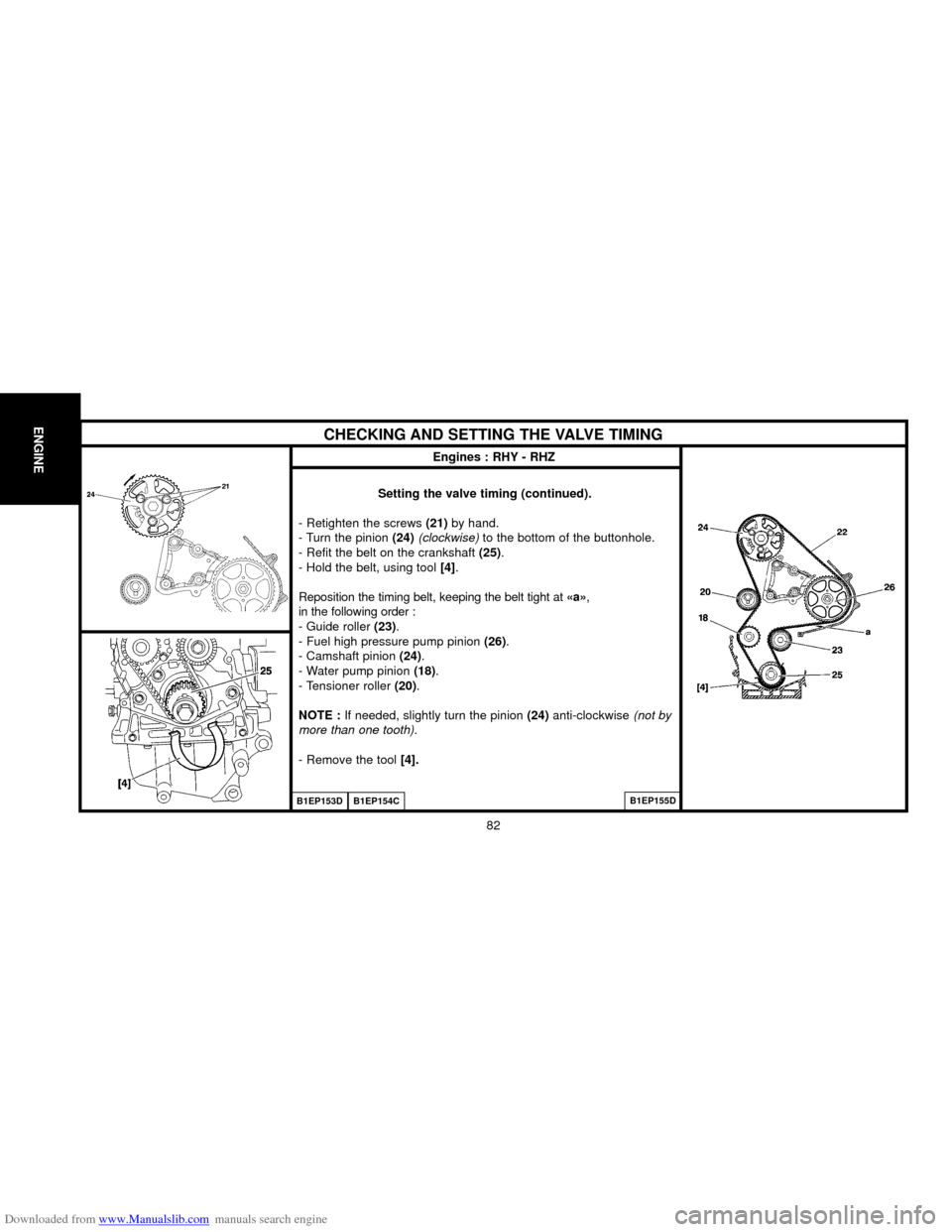

CHECKING AND SETTING THE VALVE TIMING

Engines : RHY - RHZ

Setting the valve timing (continued).

- Retighten the screws (21)by hand.

- Turn the pinion(24)(clockwise) to the bottom of the buttonhole.

- Refit the belt on the crankshaft (25).

- Hold the belt, using tool [4].

Reposition the timing belt, keeping the belt tight at «a»,

in the following order :

- Guide roller (23).

- Fuel high pressure pump pinion (26).

- Camshaft pinion (24).

- Water pump pinion (18).

- Tensioner roller (20).

NOTE :If needed, slightly turn the pinion(24)anti-clockwise (not by

more than one tooth).

- Remove the tool [4].

B1EP154CB1EP155DB1EP153D

Page 86 of 259

![Citroen C5 2000 (DC/DE) / 1.G User Guide Downloaded from www.Manualslib.com manuals search engine ENGINE

83

Setting the valve timing (continued).

- Position tool[1]on the belt at «b».

- Turn the roller (20)(anti-clockwise) using tool[2]to Citroen C5 2000 (DC/DE) / 1.G User Guide Downloaded from www.Manualslib.com manuals search engine ENGINE

83

Setting the valve timing (continued).

- Position tool[1]on the belt at «b».

- Turn the roller (20)(anti-clockwise) using tool[2]to](/img/9/4134/w960_4134-85.png)

Downloaded from www.Manualslib.com manuals search engine ENGINE

83

Setting the valve timing (continued).

- Position tool[1]on the belt at «b».

- Turn the roller (20)(anti-clockwise) using tool[2]to attain a tension of :

98 ± 2 SEEM units.

- Tighten the screw of the roller (19), tighten to 2.5 m.daN.

- Remove one screw (21)from the pinion (24).

(to check that the screws are not against the end of the buttonhole).

- Tighten the screws (21) to 2.m daN.

- Remove tools [1], [2], [3]and [5].

- Rotate the crankshaft 8 times(normal direction of rotation).

- Fit the tool [3].

- Loosen screws (21).

- Fit tool [5].

- Loosen screw (19)(to free the roller).

- Fit tool [1].

- Turn the roller (20)(anti-clockwise),tool [2], to attain a tension of :

54 ± 2 SEEM units.

CHECKING AND SETTING THE VALVE TIMING

Engines : RHY - RHZ

B1EP156D

Page 91 of 259

Downloaded from www.Manualslib.com manuals search engine ENGINE

88

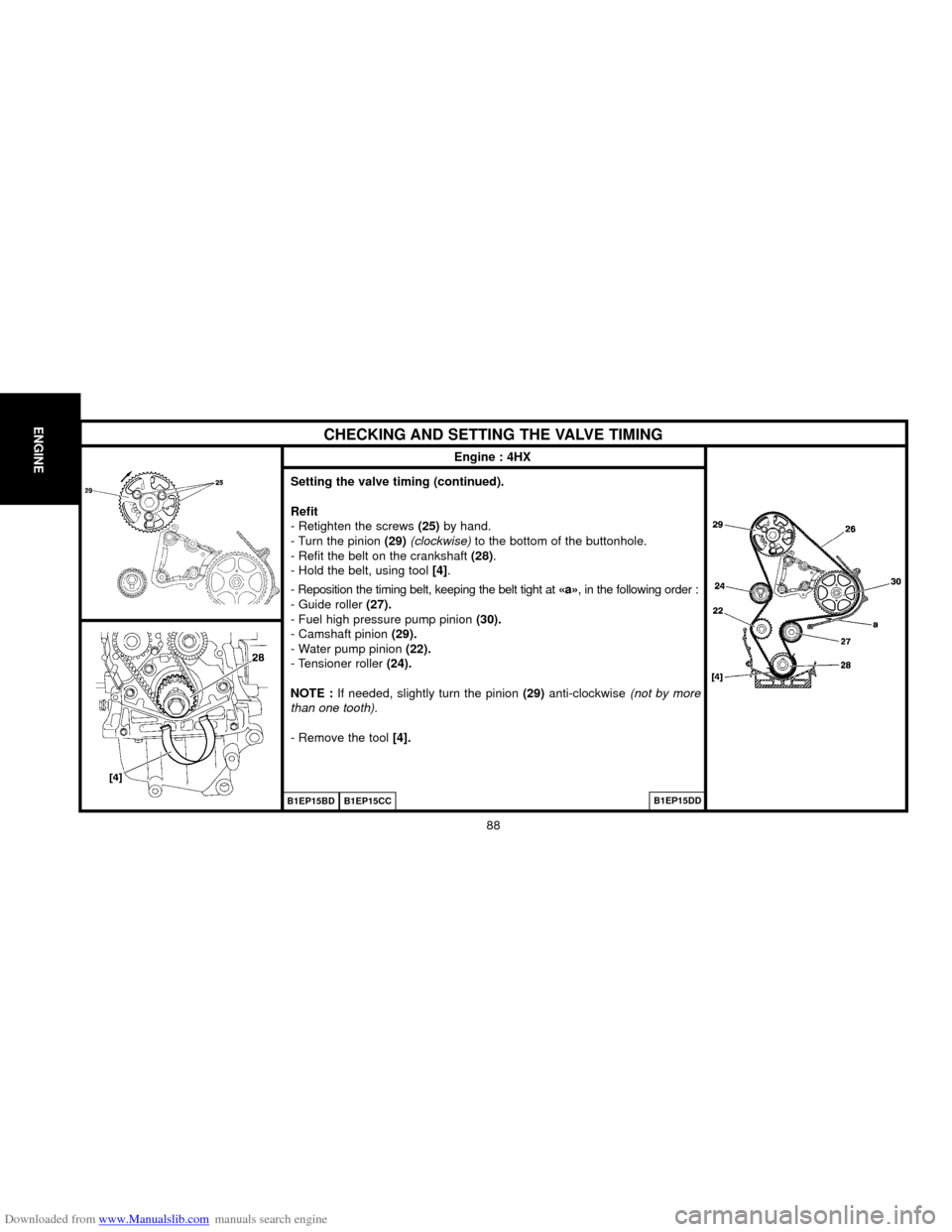

CHECKING AND SETTING THE VALVE TIMING

Engine : 4HX

Setting the valve timing (continued).

Refit

- Retighten the screws (25) by hand.

- Turn the pinion (29)(clockwise)to the bottom of the buttonhole.

- Refit the belt on the crankshaft (28).

- Hold the belt, using tool[4].

- Reposition the timing belt, keeping the belt tight at «a», in the following order :

- Guide roller (27).

- Fuel high pressure pump pinion (30).

- Camshaft pinion (29).

- Water pump pinion (22).

- Tensioner roller (24).

NOTE : If needed, slightly turn the pinion (29)anti-clockwise(not by more

than one tooth).

- Remove the tool [4].

B1EP15CCB1EP15DDB1EP15BD

Page 92 of 259

![Citroen C5 2000 (DC/DE) / 1.G User Guide Downloaded from www.Manualslib.com manuals search engine ENGINE

89

Setting the valve timing (continued)

- Position tool [1]on the belt at«b».

- Turn the tensioner roller (24) (anti-clockwise)using t Citroen C5 2000 (DC/DE) / 1.G User Guide Downloaded from www.Manualslib.com manuals search engine ENGINE

89

Setting the valve timing (continued)

- Position tool [1]on the belt at«b».

- Turn the tensioner roller (24) (anti-clockwise)using t](/img/9/4134/w960_4134-91.png)

Downloaded from www.Manualslib.com manuals search engine ENGINE

89

Setting the valve timing (continued)

- Position tool [1]on the belt at«b».

- Turn the tensioner roller (24) (anti-clockwise)using tool [2]to attain a tension of :

106 SEEM units.

- Tighten screw (23) of the tensioner roller, tighten to 2.5 m.daN.

- Remove one screw (25) from the pinion (29).

(to check that the screws are not against the end of the buttonhole).

- Tighten the screws(25)to 2 m.daN.

- Remove tools [1]. [2]. [3]and [5].

- Rotate the crankshaft 8 times(normal direction of rotation).

- Fit the tool [3].

- Loosen screws (25).

- Fit tool [5].

- Loosen screw (23)(to free the tensioner roller (24).

- Fit tool[1].

- Turn the tensioner roller(24)(anti-clockwise),using tool[2], to attain a tension of :

51 SEEM units.

- Tighten :

- The screw (23) of the tensioner roller(24)to 2.5 ± 0.2 m.daN.

- The screws(25)to 2 ± 0.2 m.daN.

CHECKING AND SETTING THE VALVE TIMING

Engine : 4HX

B1EP15ED

Page 250 of 259

![Citroen C5 2000 (DC/DE) / 1.G User Guide Downloaded from www.Manualslib.com manuals search engine SPECIAL FEATURES : AIR CONDITIONING SYSTEM (R 134.a)

Drying cartridge

Tools

[1] Filling and recycling stationMULLER - ECOTECHNICS

[2]TORX adapt Citroen C5 2000 (DC/DE) / 1.G User Guide Downloaded from www.Manualslib.com manuals search engine SPECIAL FEATURES : AIR CONDITIONING SYSTEM (R 134.a)

Drying cartridge

Tools

[1] Filling and recycling stationMULLER - ECOTECHNICS

[2]TORX adapt](/img/9/4134/w960_4134-249.png)

Downloaded from www.Manualslib.com manuals search engine SPECIAL FEATURES : AIR CONDITIONING SYSTEM (R 134.a)

Drying cartridge

Tools

[1] Filling and recycling stationMULLER - ECOTECHNICS

[2]TORX adaptor70 FACOM

[3] After Sales kit(Bottle /skirt / bottle nozzle /grease / compressor oil)

Reminder : All repairs on an aircon circuit require the aircon circuit to be drained.

After carrying out the dismantling operations necessary to gain access to the condenser, proceed to clean

the area of the skirt (8) of the reservoir(6)using a cloth, then replace the dryer reservoir (6).

Removing the plastic bracket holding the reservoir (6) :

- Remove the screw (3)(Torx 20), from the bracket assembly/plastic counter-bracket (4)and (5).

- Remove the counter-bracket (5). (Rotate it round the hinge in a clockwise direction).

- Disengage the bracket from the harness(1)(Rotate it round the reservoir (6)anti-clockwise).

- Remove the bracket(5) from the reservoir body (6).

Unscrewing the reservoir (6).

- Unscrew the reservoir(6)using the tool[2].

C5HP16ECAIR

CONDITIONING

247