warning Citroen C5 2000 (DC/DE) / 1.G Owner's Guide

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2000, Model line: C5, Model: Citroen C5 2000 (DC/DE) / 1.GPages: 259, PDF Size: 2.29 MB

Page 103 of 259

Downloaded from www.Manualslib.com manuals search engine ENGINE

100

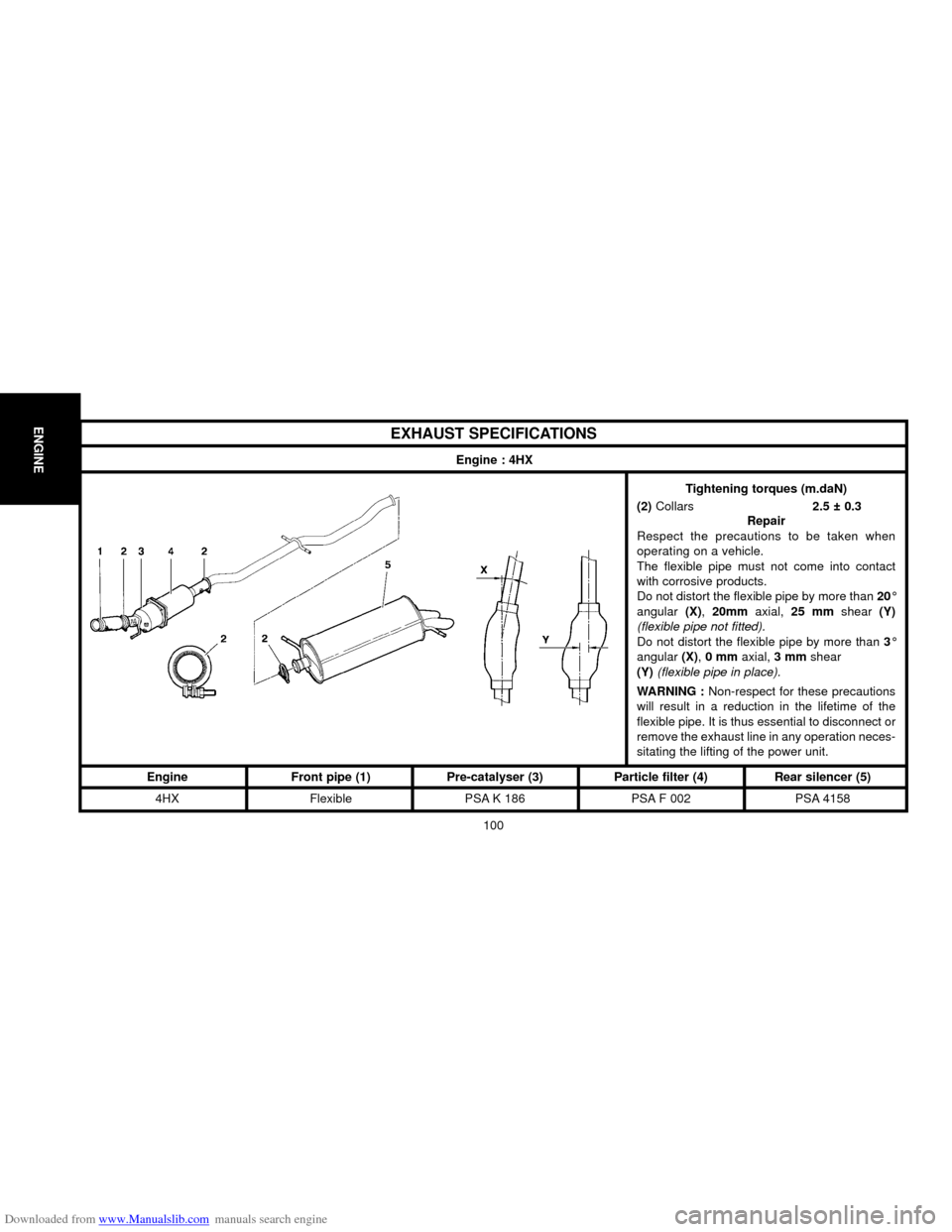

EXHAUST SPECIFICATIONS

Engine : 4HX

Tightening torques (m.daN)

(2) Collars 2.5 ± 0.3

Repair

Respect the precautions to be taken when

operating on a vehicle.

The flexible pipe must not come into contact

with corrosive products.

Do not distort the flexible pipe by more than20°

angular (X), 20mm axial, 25 mmshear (Y)

(flexible pipe not fitted).

Do not distort the flexible pipe by more than 3°

angular (X),0 mmaxial, 3 mmshear

(Y)(flexible pipe in place).

WARNING :Non-respect for these precautions

will result in a reduction in the lifetime of the

flexible pipe. It is thus essential to disconnect or

remove the exhaust line in any operation neces-

sitating the lifting of the power unit.

Engine Front pipe (1) Pre-catalyser (3) Particle filter (4) Rear silencer (5)

4HX Flexible PSA K 186 PSA F 002 PSA 4158

Page 104 of 259

Downloaded from www.Manualslib.com manuals search engine ENGINE

101

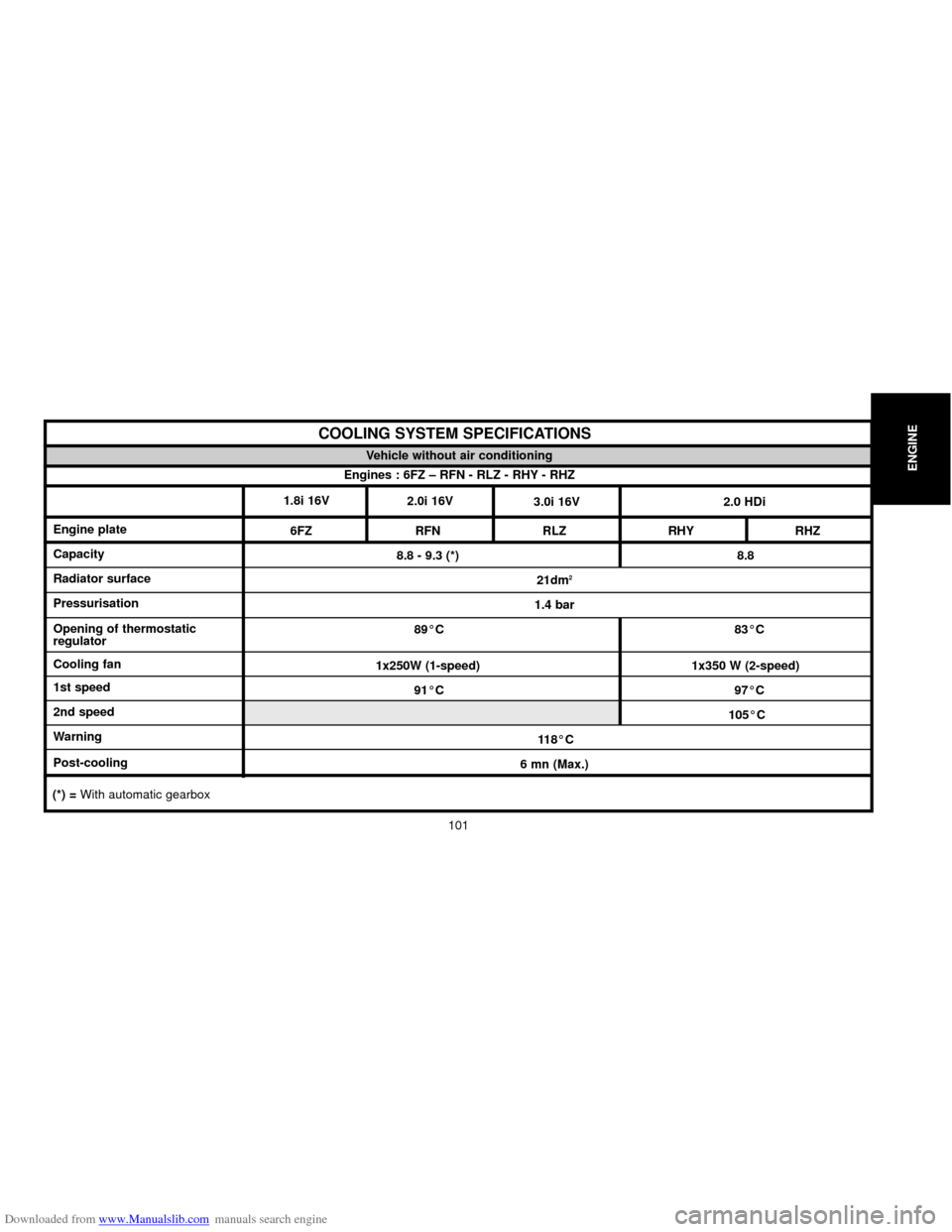

6FZ RFN RLZ RHY RHZ

8.8 - 9.3 (*) 8.8

21dm

2

1.4 bar

89°C 83°C

1x250W (1-speed) 1x350 W (2-speed)

91°C 97°C

105°C

11 8 ° C

6 mn (Max.)

(*) = With automatic gearbox

COOLING SYSTEM SPECIFICATIONS

Engines : 6FZ – RFN - RLZ - RHY - RHZVehicle without air conditioning

Engine plate

Capacity

Radiator surface

Pressurisation

Opening of thermostatic

regulator

Cooling fan

1st speed

2nd speed

Warning

Post-cooling1.8i 16V

2.0i 16V

3.0i 16V 2.0 HDi

Page 105 of 259

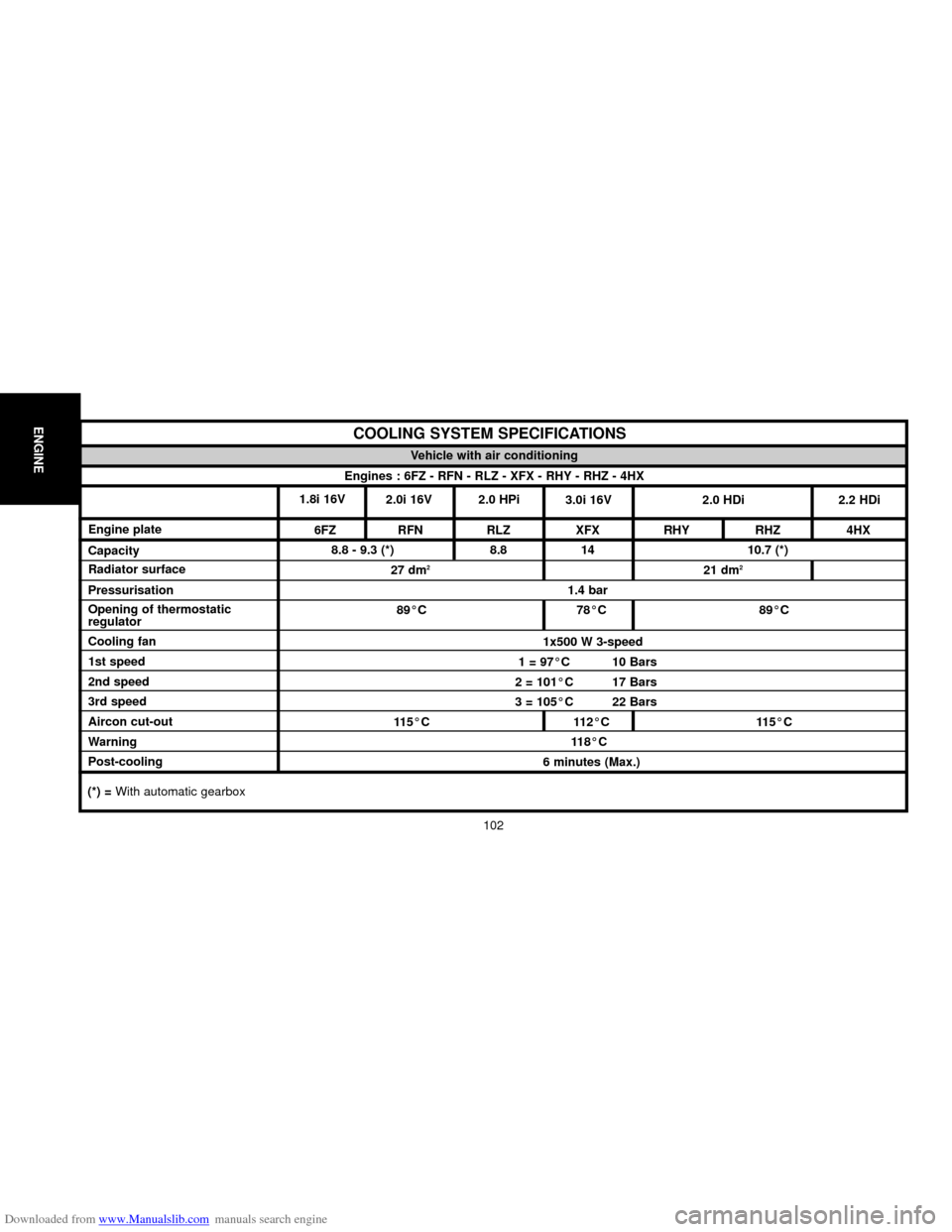

Downloaded from www.Manualslib.com manuals search engine 6FZ RFN RLZ XFX RHY RHZ 4HX

8.8 - 9.3 (*) 8.8 14 10.7 (*)

27 dm

221 dm2

1.4 bar

89°C 78°C 89°C

1x500 W 3-speed

1 = 97°C 10 Bars

2 = 101°C 17 Bars

3 = 105°C 22 Bars

11 5 ° C 11 2 ° C 11 5 ° C

11 8 ° C

6 minutes (Max.)

ENGINE

102

COOLING SYSTEM SPECIFICATIONS

Engines : 6FZ - RFN - RLZ - XFX - RHY - RHZ - 4HXVehicle with air conditioning

Engine plate

Capacity

Radiator surface

Pressurisation

Opening of thermostatic

regulator

Cooling fan

1st speed

2nd speed

3rd speed

Aircon cut-out

Warning

Post-cooling1.8i 16V

2.0i 16V 2.0 HPi

3.0i 16V 2.0 HDi 2.2 HDi

(*) = With automatic gearbox

Page 124 of 259

Downloaded from www.Manualslib.com manuals search engine 121

INJECTION

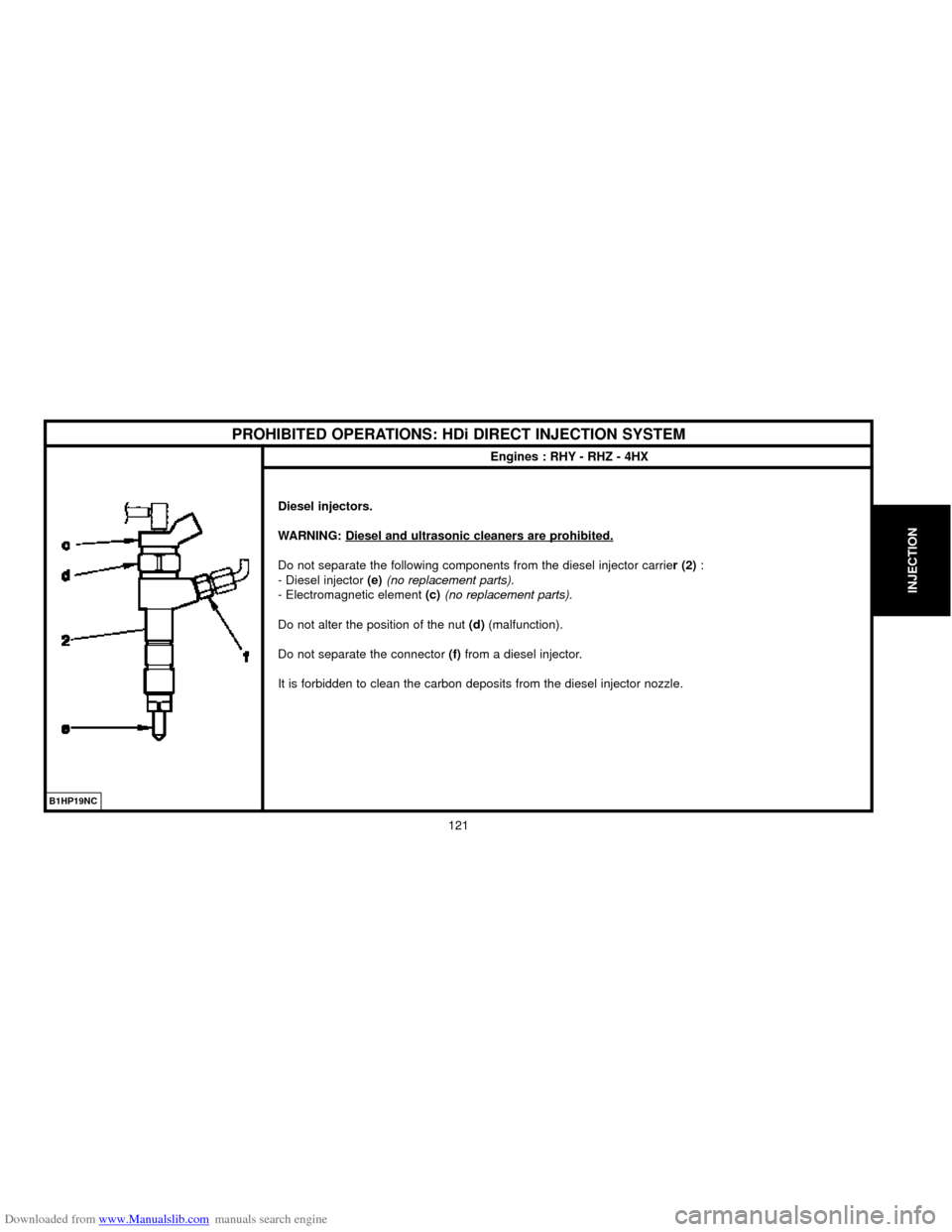

PROHIBITED OPERATIONS: HDi DIRECT INJECTION SYSTEM

Engines : RHY - RHZ - 4HX

Diesel injectors.

WARNING: Diesel and ultrasonic cleaners are prohibited.

Do not separate the following components from the diesel injector carrier (2):

- Diesel injector(e) (no replacement parts).

- Electromagnetic element(c)(no replacement parts).

Do not alter the position of the nut(d)(malfunction).

Do not separate the connector(f)from a diesel injector.

It is forbidden to clean the carbon deposits from the diesel injector nozzle.

B1HP19NC

Page 125 of 259

Downloaded from www.Manualslib.com manuals search engine 122

INJECTION

SAFETY REQUIREMENTS : HDi DIRECT INJECTION SYSTEM

Engines : RHY - RHZ - 4HX

SAFETY REQUIREMENTS

Preamble.

All interventions on the injection system must be carried out to conform with the following requirements and regulations :

- Competent health authorities.

- Accident prevention.

- Environmental protection.

WARNING :Repairs must be carried out by specialised personnel informed of the safety requirements and of the precautions to be taken.

Safety requirements.

IMPERATIVE : Take into account the very high pressures in the high pressure fuel circuit (1350 bars), and respect

the requirements below :

- No smoking in proximity to the high pressure circuit when work is being carried out.

- Avoid working close to flame or sparks.

Engine running :

- Do not work on the high pressure fuel circuit.

- Always stay clear of the trajectory of any possible jet of fuel, which could cause serious injuries.

- Do not place your hand close to any leak in the high pressure fuel circuit.

After the engine has stopped, wait 30 secondsbefore any intervention.

NOTE :This waiting time is necessary in order to allow the high pressure fuel circuit to return to atmospheric pressure.

Page 127 of 259

![Citroen C5 2000 (DC/DE) / 1.G Owners Guide Downloaded from www.Manualslib.com manuals search engine 124

INJECTION

CHECKS : LOW PRESSURE FUEL SUPPLY CIRCUIT

Engines : RHY - RHZ - 4HX

Engines : RHY - RHZ

Engine : 4HX

TOOLS

[1] Ø 10 mmlow pressu Citroen C5 2000 (DC/DE) / 1.G Owners Guide Downloaded from www.Manualslib.com manuals search engine 124

INJECTION

CHECKS : LOW PRESSURE FUEL SUPPLY CIRCUIT

Engines : RHY - RHZ - 4HX

Engines : RHY - RHZ

Engine : 4HX

TOOLS

[1] Ø 10 mmlow pressu](/img/9/4134/w960_4134-126.png)

Downloaded from www.Manualslib.com manuals search engine 124

INJECTION

CHECKS : LOW PRESSURE FUEL SUPPLY CIRCUIT

Engines : RHY - RHZ - 4HX

Engines : RHY - RHZ

Engine : 4HX

TOOLS

[1] Ø 10 mmlow pressure connector: 4215-T.

[2] Ø 8 mmlow pressure connector: 4218 -T.

[3] Pressure gauge for testing boost pressure : 4073-T Tool kit 4073-T

[4] Extension: 4251-T.

Connect the tool[1]Between the booster pump and the fuel filter (white mark at "a" on the

fuel supply pipe).

Connect the tool[2]downstream of the diesel injectors, Between the high pressure fuel

pump and the fuel filter(green mark at "b" on the fuel return pipe).

WARNING : Any check of pressure downstream of the fuel filter is PROHIBITED.

NOTE : To check the pressures while the vehicle is being driven, insert tool[4] Between

tool[3] and tools[1] et[2].

Checks on pressure : static.

- Switch on ignition

- For 3 seconds(normal functioning):

- Fuel supply pressure shown by the pressure gauge [3] = 2.6 ± 0.4 Bar.

- Fuel return pressure shown by the pressure gauge [3] = 0.6 ± 0.4 Bar.

B1BP20JDB1BP27BD

Page 142 of 259

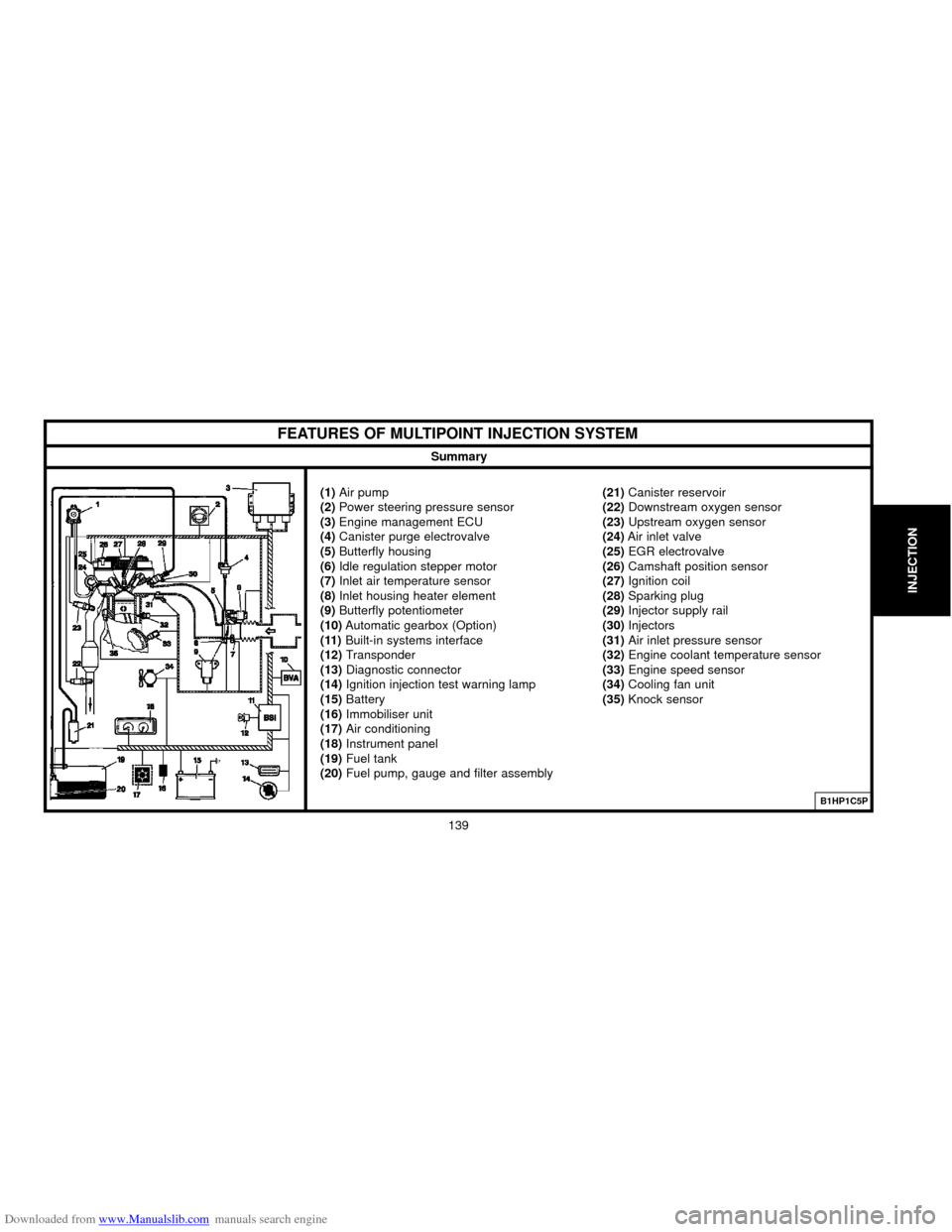

Downloaded from www.Manualslib.com manuals search engine FEATURES OF MULTIPOINT INJECTION SYSTEM

Summary

(1) Air pump

(2) Power steering pressure sensor

(3) Engine management ECU

(4) Canister purge electrovalve

(5)Butterfly housing

(6)Idle regulation stepper motor

(7) Inlet air temperature sensor

(8)Inlet housing heater element

(9)Butterfly potentiometer

(10)Automatic gearbox (Option)

(11)Built-in systems interface

(12) Transponder

(13)Diagnostic connector

(14) Ignition injection test warning lamp

(15)Battery

(16)Immobiliser unit

(17) Air conditioning

(18) Instrument panel

(19)Fuel tank

(20)Fuel pump, gauge and filter assembly(21)Canister reservoir

(22) Downstream oxygen sensor

(23)Upstream oxygen sensor

(24)Air inlet valve

(25)EGR electrovalve

(26)Camshaft position sensor

(27) Ignition coil

(28)Sparking plug

(29) Injector supply rail

(30)Injectors

(31) Air inlet pressure sensor

(32) Engine coolant temperature sensor

(33) Engine speed sensor

(34)Cooling fan unit

(35) Knock sensor

B1HP1C5P

139

INJECTION

Page 150 of 259

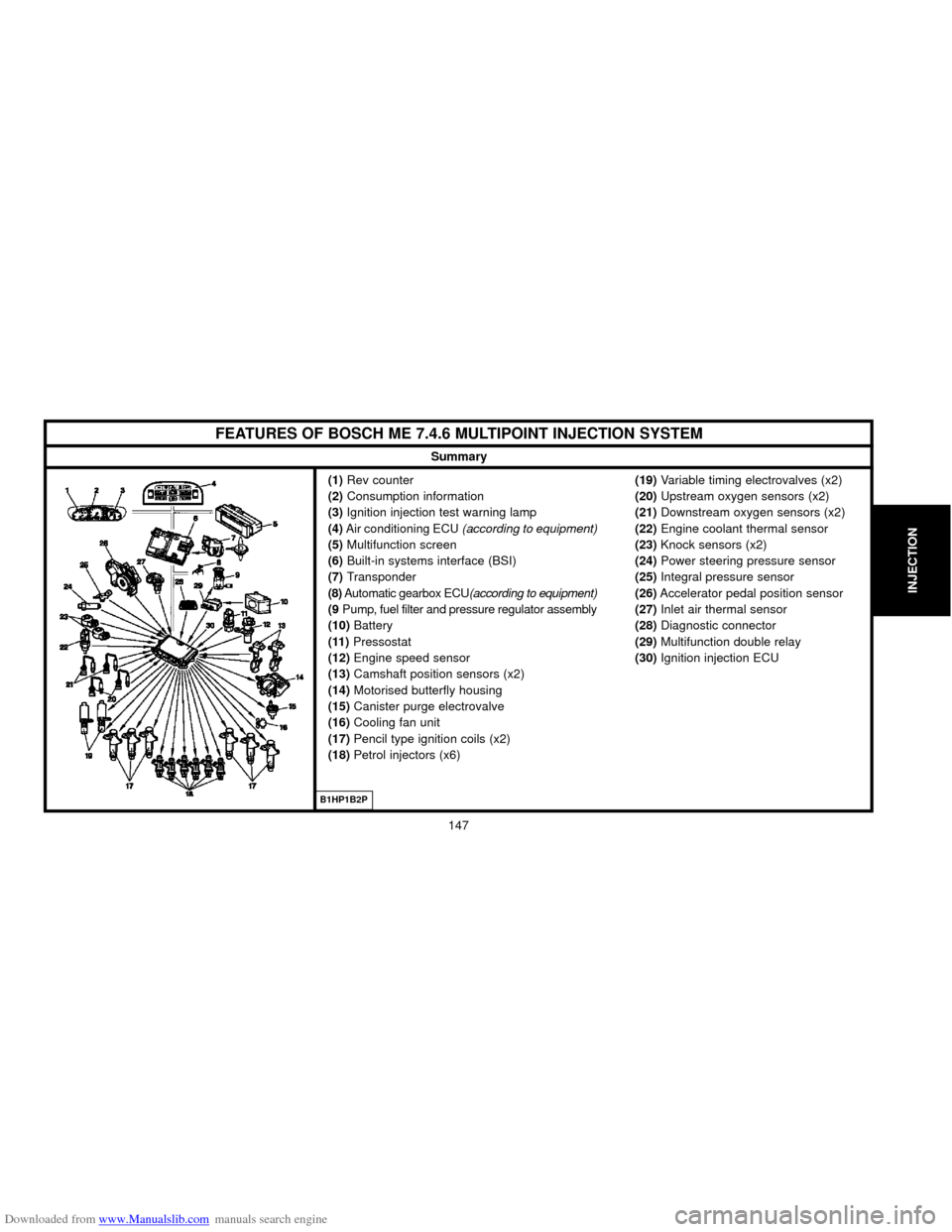

Downloaded from www.Manualslib.com manuals search engine 147

INJECTION

FEATURES OF BOSCH ME 7.4.6 MULTIPOINT INJECTION SYSTEM

Summary

(1) Rev counter

(2)Consumption information

(3)Ignition injection test warning lamp

(4) Air conditioning ECU (according to equipment)

(5)Multifunction screen

(6)Built-in systems interface (BSI)

(7) Transponder

(8)Automatic gearbox ECU(according to equipment)

(9 Pump, fuel filter and pressure regulator assembly

(10)Battery

(11)Pressostat

(12)Engine speed sensor

(13)Camshaft position sensors (x2)

(14)Motorised butterfly housing

(15)Canister purge electrovalve

(16)Cooling fan unit

(17)Pencil type ignition coils (x2)

(18) Petrol injectors (x6)(19) Variable timing electrovalves (x2)

(20)Upstream oxygen sensors (x2)

(21) Downstream oxygen sensors (x2)

(22)Engine coolant thermal sensor

(23) Knock sensors (x2)

(24)Power steering pressure sensor

(25) Integral pressure sensor

(26)Accelerator pedal position sensor

(27)Inlet air thermal sensor

(28) Diagnostic connector

(29) Multifunction double relay

(30) Ignition injection ECU

B1HP1B2P

Page 157 of 259

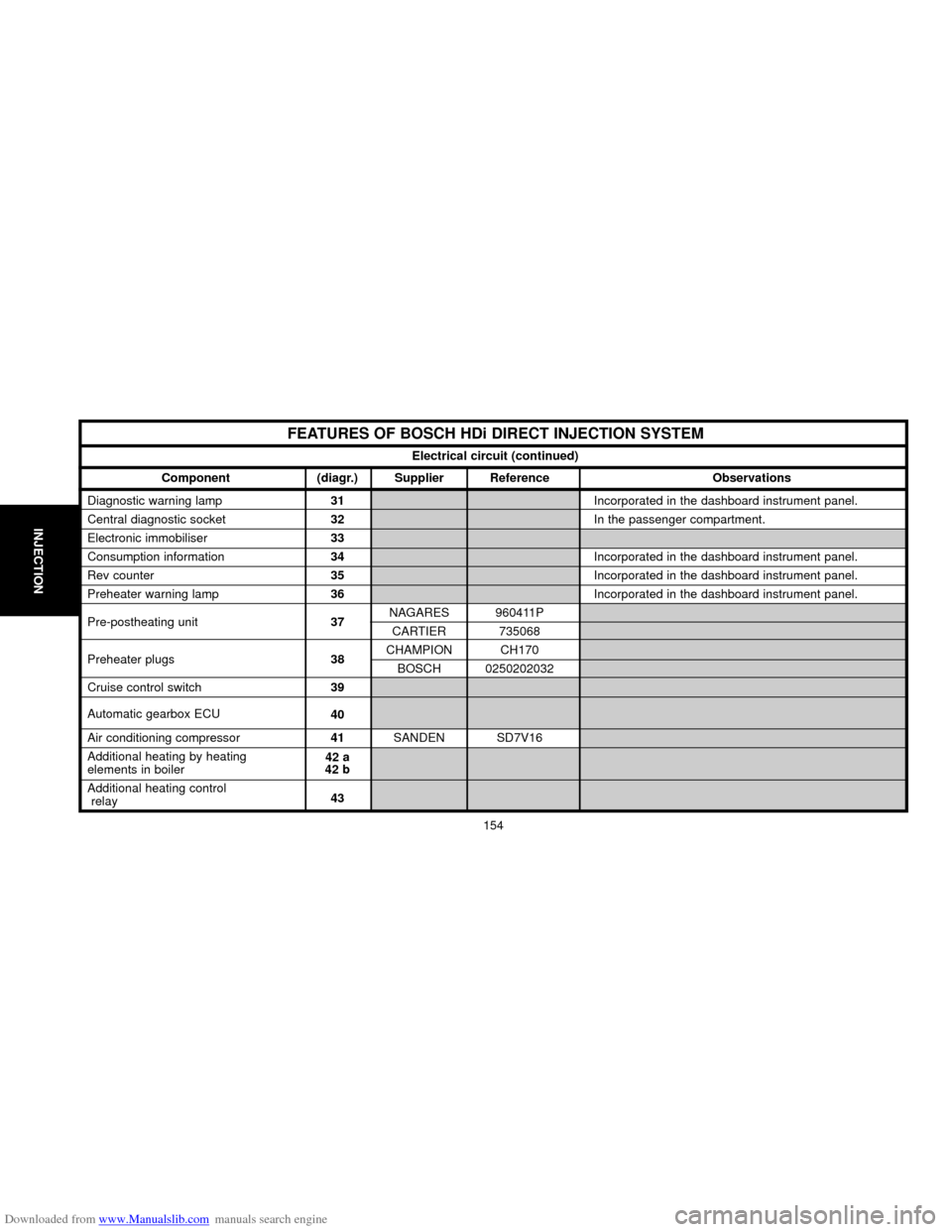

Downloaded from www.Manualslib.com manuals search engine 154

INJECTION

Component (diagr.) Supplier Reference Observations

Diagnostic warning lamp31Incorporated in the dashboard instrument panel.

Central diagnostic socket32In the passenger compartment.

Electronic immobiliser33

Consumption information 34Incorporated in the dashboard instrument panel.

Rev counter35Incorporated in the dashboard instrument panel.

Preheater warning lamp36Incorporated in the dashboard instrument panel.

Pre-postheating unit37NAGARES 960411P

CARTIER 735068

Preheater plugs38CHAMPION CH170

BOSCH0250202032

Cruise control switch39

Automatic gearbox ECU

40

Air conditioning compressor41SANDEN SD7V16

Additional heating by heating

42 a

elements in boiler42 b

Additional heating control

relay43

FEATURES OF BOSCH HDi DIRECT INJECTION SYSTEM

Electrical circuit (continued)

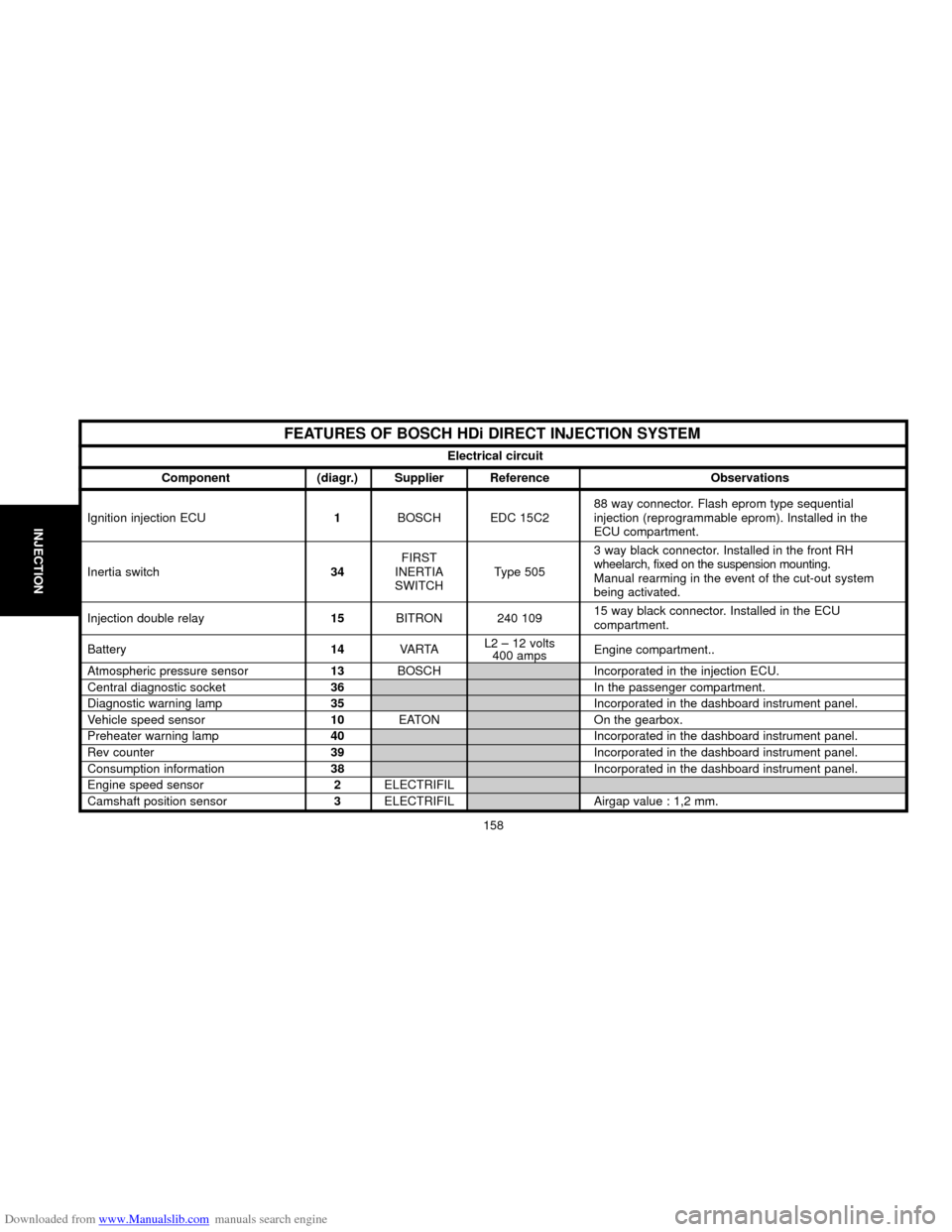

Page 161 of 259

Downloaded from www.Manualslib.com manuals search engine 158

INJECTION

FEATURES OF BOSCH HDi DIRECT INJECTION SYSTEM

Component (diagr.) Supplier Reference Observations

88 way connector. Flash eprom type sequential

Ignition injection ECU1BOSCHEDC 15C2 injection (reprogrammable eprom). Installed in the

ECU compartment.

FIRST3 way black connector. Installed in the front RH

Inertia switch34INERTIA Type 505wheelarch, fixed on the suspension mounting.

SWITCHManual rearming in the event of the cut-out system

being activated.

Injection double relay15BITRON 240 10915 way black connector. Installed in the ECU

compartment.

Battery14VA R TAL2 – 12 volts

400 ampsEngine compartment..

Atmospheric pressure sensor13BOSCHIncorporated in the injection ECU.

Central diagnostic socket36In the passenger compartment.

Diagnostic warning lamp35Incorporated in the dashboard instrument panel.

Vehicle speed sensor10EATON On the gearbox.

Preheater warning lamp40Incorporated in the dashboard instrument panel.

Rev counter39Incorporated in the dashboard instrument panel.

Consumption information 38Incorporated in the dashboard instrument panel.

Engine speed sensor2ELECTRIFIL

Camshaft position sensor3ELECTRIFIL Airgap value : 1,2 mm.

Electrical circuit