Citroen C5 RHD 2015 (RD/TD) / 2.G Owner's Manual

Manufacturer: CITROEN, Model Year: 2015, Model line: C5 RHD, Model: Citroen C5 RHD 2015 (RD/TD) / 2.GPages: 362, PDF Size: 32.4 MB

Page 181 of 362

179

Fuel used for petrol engines

The petrol engines are compatible with

E10 bio-petrol (containing 10 % ethanol),

conforming to European standards EN 228

and EN 15376.

E85 type fuels (containing up to 85 % ethanol)

are reserved exclusively for vehicles marketed

for the use of this type of fuel (BioFlex

vehicles). The quality of the ethanol must

comply with European standard EN 15293.

Fuel used for Diesel

engines

The Diesel engines are compatible with

biofuels which conform to current and future

European standards (Diesel fuel which

complies with standard EN 590 mixed with

a biofuel which complies with standard

EN 14214) available at the pumps (containing

up to 7 % Fatty Acid Methyl Ester).

B30 biofuel can be used in certain Diesel

engines. However, this use, even occasional,

requires strict application of the special

servicing conditions. Contact a CITROËN

dealer or a qualified workshop.

The use of any other type of (bio)fuel

(vegetable or animal oils, pure or diluted,

domestic fuel...) is strictly prohibited (risk of

damage to the engine and fuel system).

Travelling abroad

As Diesel fuel pump nozzles may

be different in other countries, the

presence of the misfuel prevention

device may make refuelling impossible.

Not all Diesel vehicles are fitted with

misfuel protection, so before travelling

abroad, we recommend that you check

with the CITROËN dealer network,

whether your vehicle is suitable for the

fuel pumps in the country in which you

want to travel.

8

Practical information

Page 182 of 362

180

HDi engines make use of advanced

technology.

For any work on your vehicle, contact

a qualified workshop that has the

skills and equipment required, which a

CITROËN dealer is able to provide.

BlueHDi engines

Running out of fuel (Diesel)

Priming the fuel system

HDi 160 engine

If you run out of fuel:

F after filling (minimum 5 litres) and removing

the protective cover to gain access to the

priming pump,

F operate the manual priming pump, until

some resistance is felt,

F operate the starter motor while depressing

the accelerator pedal slightly until the

engine starts. If the engine fails to start at the first attempt,

wait fifteen seconds before trying again.

If the engine fails to start after a few attempts,

operate the priming pump again and then try to

start the engine.

When the engine is idling, accelerate slightly to

complete the bleeding of the circuit.

F

Fill the fuel tank with at least five litres of

Diesel.

F Switch on the ignition (without starting the

engine).

F Wait around 6 seconds and switch off the

ignition.

F Repeat the operation 10 times.

F Operate the starter to run the engine.

Practical information

Page 183 of 362

181

Temporary puncture repair kit

The kit is located in the boot under the floor.

Complete system consisting of a compressor

and a sealant cartridge which permits the

temporary repair of the tyre so that you can

drive to the nearest garage. This repair kit is available from

CITROËN dealers or a qualified

workshop.

It is designed to repair holes of a

maximum diameter of 6 mm, located

exclusively on the tyre tread or

shoulder. Avoid removing any foreign

bodies which have penetrated the tyre.

The vehicle's electric system allows the

connection of a compressor for long

enough to inflate a tyre after a puncture

repair or for inflating a small inflatable

accessory.

All versions*, except BlueHDi

Diesel

BlueHDi Diesel versions

* Depending on the country of sale.

8

Practical information

Page 184 of 362

182

Using the kit

F Switch off the ignition.

F Affix the speed limitation sticker to the

vehicle's steering wheel to remind you that

a wheel is in temporary use. F

Check that the switch A is in position "0" .

F Connect the pipe of the cartridge 1 to the

valve of the tyre to be repaired. F

Connect the compressor's electric plug to

the vehicle's 12 V socket.

F Start the vehicle and leave the engine

running.

Practical information

Page 185 of 362

183

F Remove the compressor and unclip and

store the cartridge in a sealed bag to avoid

staining your vehicle with traces of fluid.

F Drive immediately for approximately

two miles (three kilometres), at reduced

speed (between 15 and 35 mph [20 and

60 km/h]), to plug the puncture.

F Stop to check the repair and the pressure. F

Connect the compressor pipe directly to

the valve of the repaired wheel.

F

Switch on the compressor by moving

the switch A to position "1" until the tyre

pressure reaches 2.0 bars.

If this pressure has not been reached

after approximately five to ten minutes,

the tyre cannot be repaired; contact a

CITROËN dealer to have your vehicle

repaired.

8

Practical information

Page 186 of 362

184

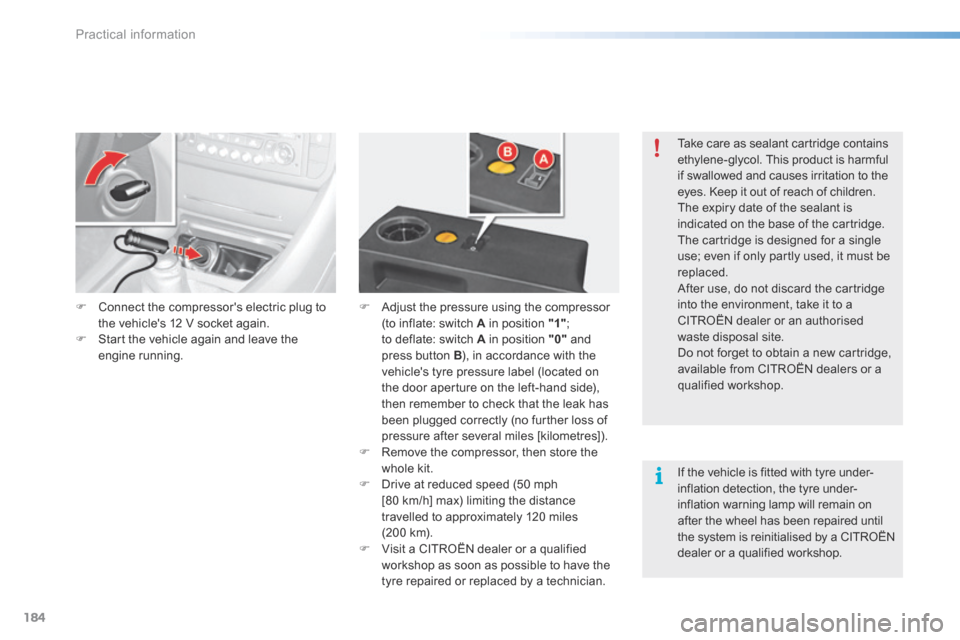

F Connect the compressor's electric plug to

the vehicle's 12 V socket again.

F Start the vehicle again and leave the

engine running. F

Adjust the pressure using the compressor

(to inflate: switch A in position "1" ;

to deflate: switch A in position "0" and

press button B ), in accordance with the

vehicle's tyre pressure label (located on

the door aperture on the left-hand side),

then remember to check that the leak has

been plugged correctly (no further loss of

pressure after several miles [kilometres]).

F Remove the compressor, then store the

whole kit.

F Drive at reduced speed (50 mph

[80 km/h] max) limiting the distance

travelled to approximately 120 miles

(200 km).

F Visit a CITROËN dealer or a qualified

workshop as soon as possible to have the

tyre repaired or replaced by a technician. Take care as sealant cartridge contains

ethylene-glycol. This product is harmful

if swallowed and causes irritation to the

eyes. Keep it out of reach of children.

The expiry date of the sealant is

indicated on the base of the cartridge.

The cartridge is designed for a single

use; even if only partly used, it must be

replaced.

After use, do not discard the cartridge

into the environment, take it to a

CITROËN dealer or an authorised

waste disposal site.

Do not forget to obtain a new cartridge,

available from CITROËN dealers or a

qualified workshop.

If the vehicle is fitted with tyre under-

inflation detection, the tyre under-

inflation warning lamp will remain on

after the wheel has been repaired until

the system is reinitialised by a CITROËN

dealer or a qualified workshop.

Practical information

Page 187 of 362

185

Changing a wheel

Access to the tools

For vehicles supplied with a standard spare

wheel (same size as the four wheels), the tools

are stowed in a carrier, located in the spare

wheel.

F Release the retaining strap for access to it.

List of tools

all of these tools are specific to your vehicle

and may vary according to equipment. Do not

use them for any other purpose. 1.

Wheelbrace.

Used for removing the wheel trim and the

wheel fixing bolts.

2. Jack with integral handle.

Used to raise the vehicle.

3. Bolt head finisher tool.

Used to remove the wheel bolt protectors

(finishers) on wheel bolts with alloy wheels.

4. Wheel chock*.

5. Towing eye.

Do not use:

-

the jack for any purpose other than

lifting the vehicle,

- a different jack from the one

supplied with the vehicle.

If the vehicle does not have its original

jack, contact a CITROËN dealer or a

qualified workshop to obtain the one

listed by the manufacturer. For more information, refer to the

"Towing the vehicle" section.

* Depending on country of sale.

For vehicles supplied with a "space-saver"

type spare wheel

, the tools are stowed in a

storage well, located below the spare wheel.

F Unscrew the central yellow screw and

remove the wheel for access to it.

8

Practical information

Page 188 of 362

186

Access to the spare wheel

Removing the boot floor

F Saloon: raise the boot floor and fold in two.

F Tourer : raise the boot floor and hook it

using the retractable handle. Secure the

hook to the top part of the boot.

Removing the standard spare

wheel

F d etach the strap then push the wheel

for wards so as to be able to lift it.

Repositioning the standard spare

wheel

F Position the spare wheel flat in the boot,

then pull it towards you.

F Next place the toolbox inside the wheel,

then secure the assembly using the strap.

Removing the "space-saver"

spare wheel

F Unscrew the central yellow screw.

F Take the spare wheel from the rear and lift

it towards you.

F Remove the wheel from the boot.

Practical information

Page 189 of 362

187

The tyre pressures are indicated on the

label located on the left hand centre

door pillar.

Tyre pressures are given on this label

for different vehicle loading conditions.Repositioning the "space-saver"

spare wheel

F Return the spare wheel to its housing

above the toolbox.

F Unscrew the central yellow screw by a few

turns, then put it in place in the middle of

the wheel.

F Tighten the central yellow screw until it

clicks so that it is secured in its housing.

Repositioning the boot floor

F Release the boot floor to return it to its

initial position.

8

Practical information

Page 190 of 362

188

Removing a wheel

F Park the vehicle on stable, firm ground that

is not slippery. apply the parking brake.

F If your vehicle is equipped with

"Hydractive III+" suspension, with the

engine running at idle, adjust the ground

clearance to its maximum height.

F Switch off the ignition and engage first gear

(position P for an automatic gearbox).

F If your vehicle is fitted with "Hydractive III+"

suspension, position the chock, whichever

direction the gradient may be in, in front of

the front wheel diametrically opposite to

the one to be replaced.

List of operations

F Remove the protector from each bolt using

tool 3 .

F Fit the security bolt socket to the

wheelbrace to slacken the security bolt

(depending on equipment).

F Slacken the other bolts using just the

wheelbrace 1 .

Before positioning the jack:

F

Always adjust the vehicle’s ground

clearance to the "maximum height"

position and retain this adjustment

for as long as the jack is under the

vehicle (do not use the hydraulic

adjustments),

F Ensure that any passengers have

left the vehicle and are in a safe

place.

Never go underneath the vehicle if it is

supported only by the jack.

The jack and all of the tools are specific

to your vehicle. Do not use them for any

other purposes.

Have the original wheel repaired and

refitted as soon as possible.

Practical information