air filter CITROEN C6 2005 Owners Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: C6, Model: CITROEN C6 2005Pages: 223, PDF Size: 4.26 MB

Page 6 of 223

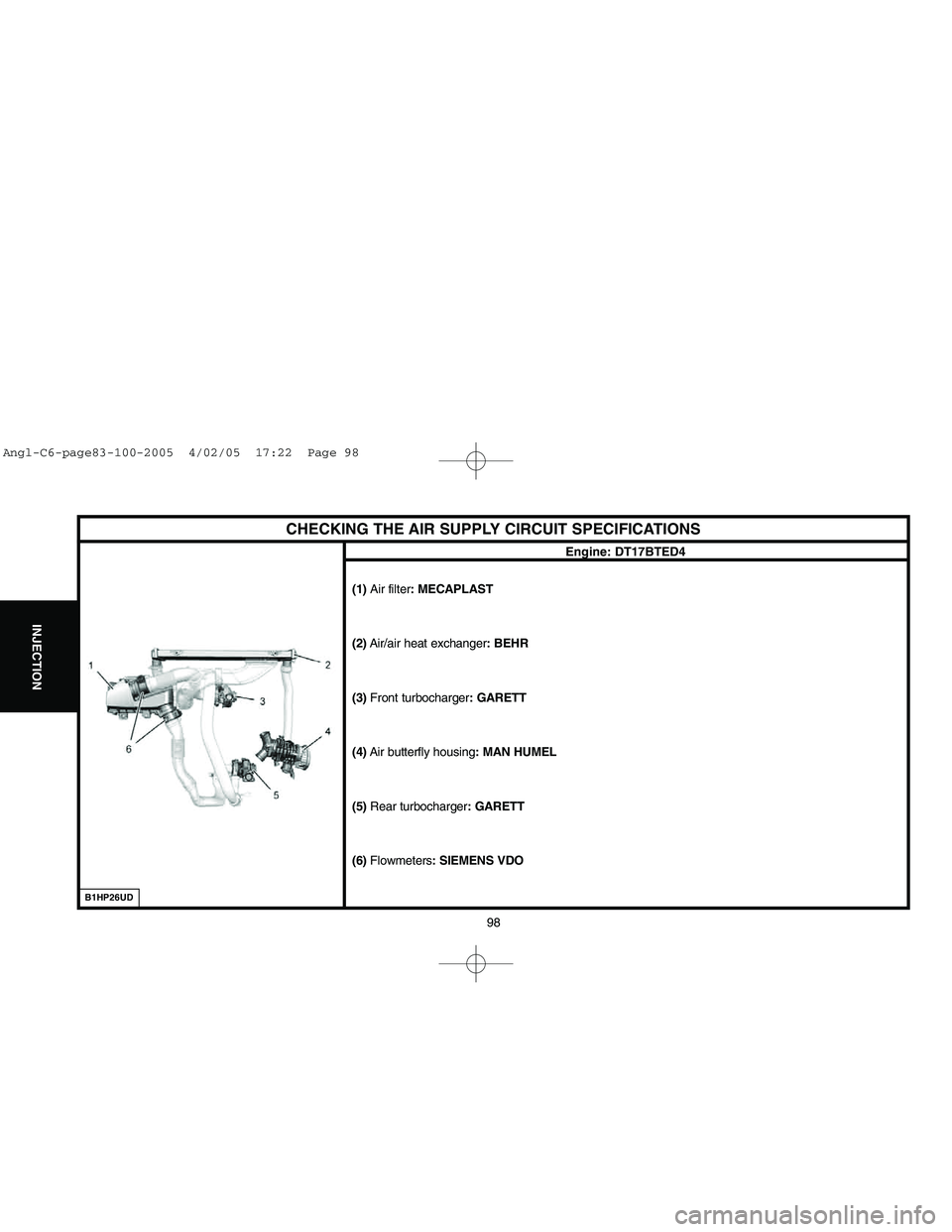

Downloaded from www.Manualslib.com manuals search engine AXLES - SUSPENSION - STEERING

Wheels and tyres121 - 124

Checking and adjusting the vehicle height125 - 128

Values for checking and adjusting

the axle geometries129 - 133

Front axle134 - 135

Front axle tightening torques136 - 139

Rear axle140 - 141

Rear axle tightening torques142 - 143

Active suspension with variable damping144 - 149

Suspension tightening torques150 - 154

Draining-filling-bleeding

the hydraulic steering/suspension circuit155 - 158

Power steering specifications159 - 162

Power steering tightening torques163 - 164

Checking the steering assistance

pressure (ES9A engine)165 - 168

Bleeding the hydraulic steering

assistance circuit169AIR CONDITIONING

Quantities: aircon system R134.a 203

Special features: air conditioning circuit 204 - 205

Pollen filter206

Checking the compressor oil level207 - 208

Checking the efficiency of

the air conditioning circuit209 - 215

Air conditioning circuit: ES9A216

Air conditioning circuit: DT17217

CONTENTS

BRAKES

Brake specifications170

Braking system: general specifications171 - 173

Braking system: tightening torques174 - 177

Values for checking and adjusting

the braking system178

General feataures of

the electric parking brake179 - 189

Brake fluid checks190

Drain-fill-bleed the braking system191 - 194

HYDRAULICS

Safety requirements:

active suspension with variable damping195 - 197

Suspension spheres: general specifications 198

Suspension spheres:

specification - identification199 - 200

Depressurising the hydraulic

suspension circuit201 - 202

Angl-C6-Index-2005 4/02/05 17:10 Page IV

Page 89 of 223

Downloaded from www.Manualslib.com manuals search engine 83

INJECTION

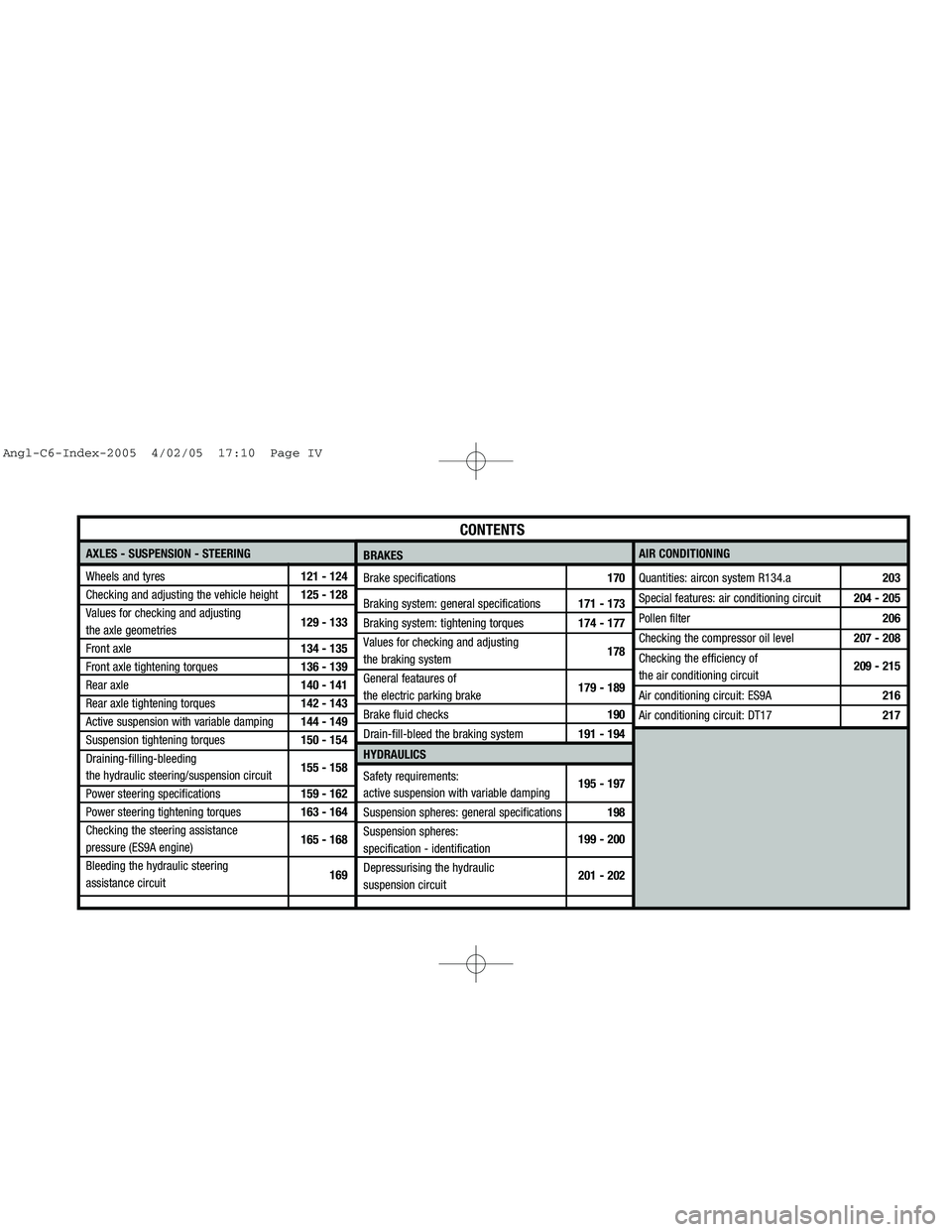

BOSCH ME 7.4.7 INJECTION SYSTEM

Engine: ES9A

Synopsis.

(1) Fuel consumption information

(2)Ignition injection test warning lamp

(3)Rev counter

(4)Air conditioning ECU

(5)Multifunction screen

(6)Built-in systems interface

(7)Transponder

(8)Automatic gearbox ECU

(9)Fuel pump, filter and pressure regulator (except grande exportation)

(10)Battery

(11)Pressostat

(12)Engine speed sensor

(13)Camshaft position sensor (x2)

(14)Motorised butterfly housing

B1HP1Z9P

Angl-C6-page83-100-2005 4/02/05 17:22 Page 83

Page 94 of 223

Downloaded from www.Manualslib.com manuals search engine 88

INJECTION

BOSCH ME 7.4.7 INJECTION SYSTEM

Engine: ES9AElectrical circuit

Component Location Supplier Reference Observations

Inlet air temperature sensor 27 JAEGER 402 084 012-way greyconnector

Fixing: on the air filter inlet duct

Camshaft position

13 ELECTRICFIL14 43 2514 43 3-way grey connector

sensor25

Fixing: on the inlet camshaft bearing cap cover

3-way green connector

Knock sensor 23 BOSCH 0 261 231 10 Fixing: on the central part of the «V»of the engine block

Essential to respect tightening torque: 2 ± 0,5 m.daN

DAV 402 243 032-way greenconnector

Engine coolant temperature 22Fixing: on the coolant outlet housing

sensor

14 43 32Tightening torque:

ELECTRICFILTighten to: 2 ± 0,2 m.daN

Engine speed sensor 12 14 43 282-way blackconnector

Fixing: on the gearbox clutch housing

Angl-C6-page83-100-2005 4/02/05 17:22 Page 88

Page 98 of 223

Downloaded from www.Manualslib.com manuals search engine 92

INJECTION

SAFETY REQUIREMENTS: HDi DIRECT INJECTION SYSTEM

Safety requirements.

Preamble.

All interventions on the injection system must be carried out to conform

with the following requirements and regulations:

- Competent health authorities.

- Accident prevention.

- Environmental protection.

WARNING: Repairs must be carried out by specialised personnel

informed of the safety requirements and of the precautions to be

taken.

Safety requirements.

IMPERATIVE: Take into account the very high pressures in the high

pressure fuel circuit (1600 bars), and respect the requirements

below:

- No smoking in proximity to the high pressure circuit when work is being

carried out.

- Avoid working close to flame or sparks.

Engine running:

- Do not work on the high pressure fuel circuit.

- Always stay clear of the trajectory of any possible jet of fuel, which could

cause serious injuries.

- Do not place your hand close to any leak in the high pressure fuel circuit.After the engine has stopped, wait 30 secondsbefore any intervention.

NOTE:This waiting time is necessary in order to allow the high pressure

fuel circuit to return to atmospheric pressure.

Cleanliness requirements.

Preliminary operations.

IMPERATIVE: The technician should wear clean overall.

Before working on the injection system, it may be necessary to

clean the apertures of the following sensitive componen (refer to

corresponding procedures):

- Fuel filter.

- Fuel high pressure pump.

- Fuel high pressure common injection rail.

- Fuel high pressure pipes

- Diesel injector carriers.

IMPERATIVE: After dismantling, immediately block the apertures of

sensitive components with plugs, to avoid the entry of impurities.

Work area:

- The work area must be clean and free of clutter.

- Components being worked on must be protected from dust.

Angl-C6-page83-100-2005 4/02/05 17:22 Page 92

Page 103 of 223

Downloaded from www.Manualslib.com manuals search engine 97

INJECTION

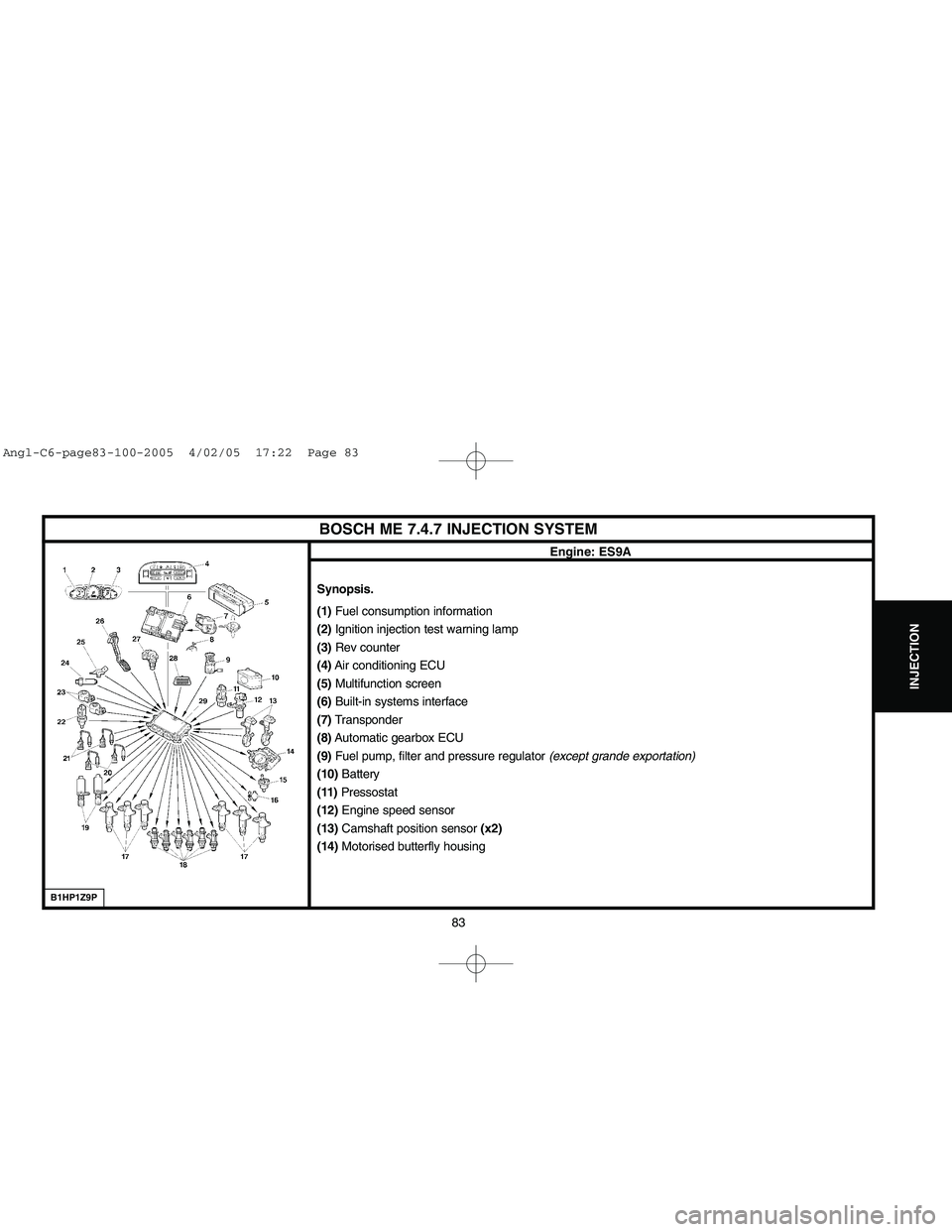

CHECKS: TURBO PRESSURE

Engine: DT17BTED4

Significant difference in pressure between the two turbochargers:

- Stop the engine.

- Remove the air filter with the two flowmeters.

- Mark the flowmeters "d"and "c".

- Remove both flowmeters.

Refit:

- Flowmeter "d"in place of flowmeter "c".

- Flowmeter "c"in place of flowmeter "d".

Start the engine.

Accelerate to 2500 rpm.

Compare the air flows (mg/stroke)from the two turbochargers:

- If the difference in air flow has changed turbochargers, replace the flowmeter that is faulty.

- If the difference in air flow is coming from the same turbocharger, check the condition of the air inlet

and outlet pipes of this turbocharger: replace or repair the parts that are faulty.

- If no anomaly is detected on the air inlet and outlet pipes of the turbocharger: replace the turbocharger.

B1HP24TC

Angl-C6-page83-100-2005 4/02/05 17:22 Page 97

Page 104 of 223

Downloaded from www.Manualslib.com manuals search engine 98

INJECTION

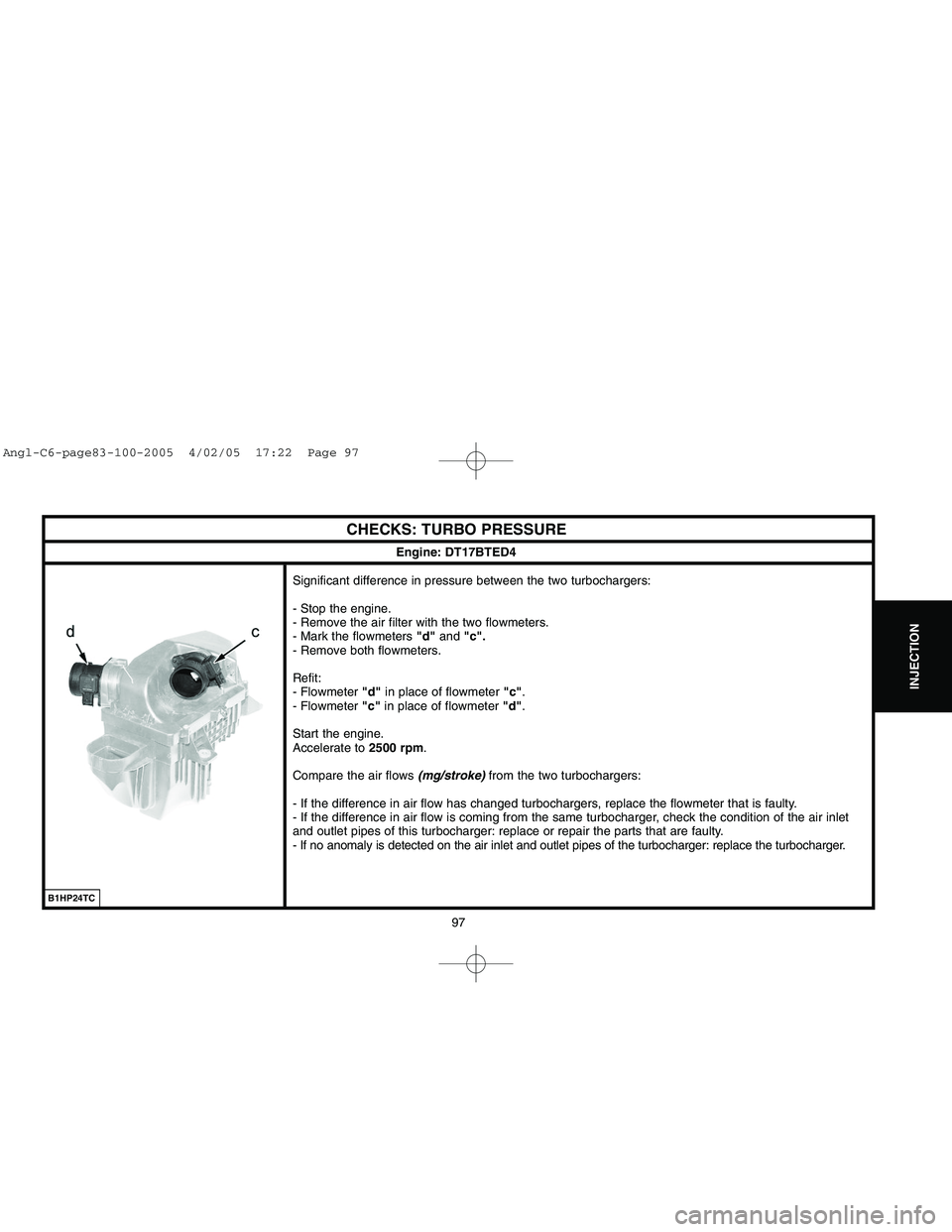

CHECKING THE AIR SUPPLY CIRCUIT SPECIFICATIONS

Engine: DT17BTED4

(1) Air filter: MECAPLAST

(2)Air/air heat exchanger: BEHR

(3) Front turbocharger: GARETT

(4)Air butterfly housing: MAN HUMEL

(5)Rear turbocharger: GARETT

(6)Flowmeters: SIEMENS VDO

B1HP26UD

Angl-C6-page83-100-2005 4/02/05 17:22 Page 98

Page 120 of 223

![CITROEN C6 2005 Owners Manual Downloaded from www.Manualslib.com manuals search engine 114

CLUTCH

GEARBOX

TRANSMISSION

DRAINING, FILLING AND TOPPING UP THE AM6 AUTOMATIC GEARBOX

Tool.

[1] Filling cylinder: (-).0340

Respect the sa CITROEN C6 2005 Owners Manual Downloaded from www.Manualslib.com manuals search engine 114

CLUTCH

GEARBOX

TRANSMISSION

DRAINING, FILLING AND TOPPING UP THE AM6 AUTOMATIC GEARBOX

Tool.

[1] Filling cylinder: (-).0340

Respect the sa](/img/9/57744/w960_57744-119.png)

Downloaded from www.Manualslib.com manuals search engine 114

CLUTCH

GEARBOX

TRANSMISSION

DRAINING, FILLING AND TOPPING UP THE AM6 AUTOMATIC GEARBOX

Tool.

[1] Filling cylinder: (-).0340

Respect the safety and cleanliness requirements.

Draining.

IMPERATIVE: Draining of the gearbox must be done with the oil hot (60°C minimum), in order to

ensure that the impurities in suspension in the oil are eliminated.

NOTE:Drainage is only partial, as the torque converter cannot be drained totally.

Raise the vehicle.

Remove:

- The oil level plug (2)by means of the Torx spanner.

- The drain plug (1)using a hexagonalspanner.

NOTE :Around 3 litresof oil should flow out.

Filling.

Fit the drain plug (1)(with a new seal).

Tighten the plug (1)to: 5 ± 1 mdaN.

Remove:

- The air filter housing.

- The oil filler plug (3).

Use tool [1].

B2CP3WZCB1BP317C

Angl-C6-page101-120-2005 4/02/05 17:25 Page 114

Page 123 of 223

![CITROEN C6 2005 Owners Manual Downloaded from www.Manualslib.com manuals search engine 117

CLUTCH

GEARBOX

TRANSMISSION

CHECKING THE OIL PRESSURE IN THE AM6 AUTOMATIC GEARBOX

Tools.

[1]Flexible pipe and pressure gauge: 4601- TF1 T CITROEN C6 2005 Owners Manual Downloaded from www.Manualslib.com manuals search engine 117

CLUTCH

GEARBOX

TRANSMISSION

CHECKING THE OIL PRESSURE IN THE AM6 AUTOMATIC GEARBOX

Tools.

[1]Flexible pipe and pressure gauge: 4601- TF1 T](/img/9/57744/w960_57744-122.png)

Downloaded from www.Manualslib.com manuals search engine 117

CLUTCH

GEARBOX

TRANSMISSION

CHECKING THE OIL PRESSURE IN THE AM6 AUTOMATIC GEARBOX

Tools.

[1]Flexible pipe and pressure gauge: 4601- TF1 Toolkit 4601-T

[2]Flexible union: (-).0336.X Toolkit 8010-T

IMPERATIVE: Respect the safety and cleanliness requirements.

Preliminary operations.

Remove the air filter housing.

Move aside the pipe (1).

Remove the screw (2).

Screw in the tool [2]in place of the screw (2).

B2CP45GCB2CP45FC

Angl-C6-page101-120-2005 4/02/05 17:25 Page 117

Page 125 of 223

Downloaded from www.Manualslib.com manuals search engine 119

CLUTCH

GEARBOX

TRANSMISSION

CHECKING THE OIL PRESSURE IN THE AM6 AUTOMATIC GEARBOX

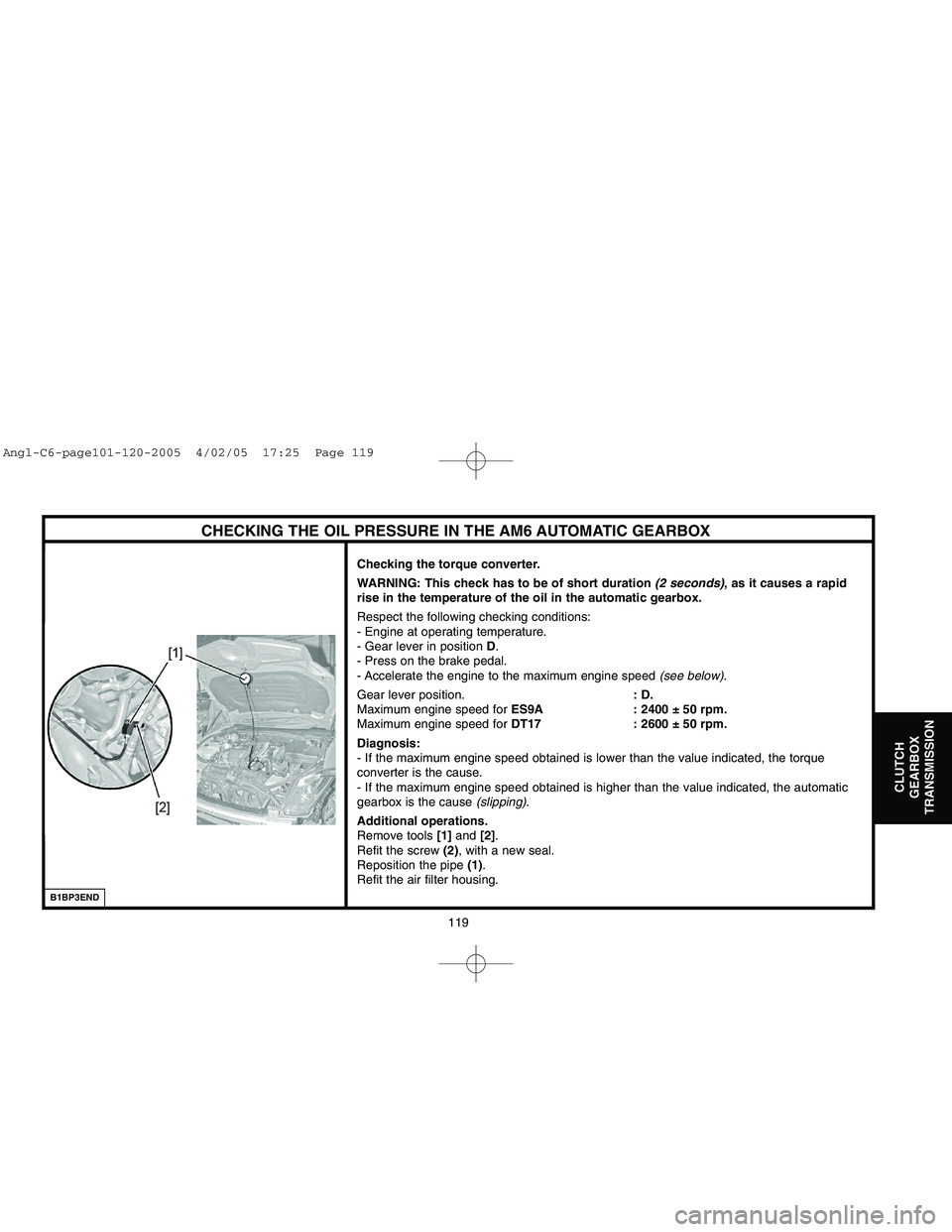

Checking the torque converter.

WARNING: This check has to be of short duration (2 seconds), as it causes a rapid

rise in the temperature of the oil in the automatic gearbox.

Respect the following checking conditions:

- Engine at operating temperature.

- Gear lever in position D.

- Press on the brake pedal.

- Accelerate the engine to the maximum engine speed (see below).

Gear lever position.: D.

Maximum engine speed for ES9A : 2400 ± 50 rpm.

Maximum engine speed for DT17 : 2600 ± 50 rpm.

Diagnosis:

- If the maximum engine speed obtained is lower than the value indicated, the torque

converter is the cause.

- If the maximum engine speed obtained is higher than the value indicated, the automatic

gearbox is the cause (slipping).

Additional operations.

Remove tools [1]and [2].

Refit the screw (2), with a new seal.

Reposition the pipe (1).

Refit the air filter housing.

B1BP3END

Angl-C6-page101-120-2005 4/02/05 17:25 Page 119

Page 210 of 223

Downloaded from www.Manualslib.com manuals search engine Compressor

The variable capacity air conditioning compressor has external control.

The internal pneumatic valve is replaced by an external electrovalve.Condenser

The condenser has a cylinder incorporating the function of aircon fluid

reservoir and with integral filtering cartridge.

NOTE: The filtering cartridge is not interchangeable.

SPECIAL FEATURES: AIR CONDITIONING SYSTEM

204

AIR

CONDITIONING

Angl-C6-page203-217-2005 4/02/05 17:40 Page 204