suspension CITROEN C6 2005 Owners Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: C6, Model: CITROEN C6 2005Pages: 223, PDF Size: 4.26 MB

Page 3 of 223

Downloaded from www.Manualslib.com manuals search engine PRESENTATION

THIS HANDBOOK summarises the specifications, adjustments, checks and special features of CITROËNprivate vehicles, not including UTILITY vehicles for which there exists a

separate handbook.

The handbook is divided into groups representing the main functions:

GENERAL - ENGINE - INJECTION - IGNITION - CLUTCH, GEARBOX, DRIVESHAFTS - AXLES, SUSPENSION, STEERING - BRAKES - HYDRAULICS - AIR CONDITIONING.

Angl-C6-Index-2005 4/02/05 17:10 Page I

Page 5 of 223

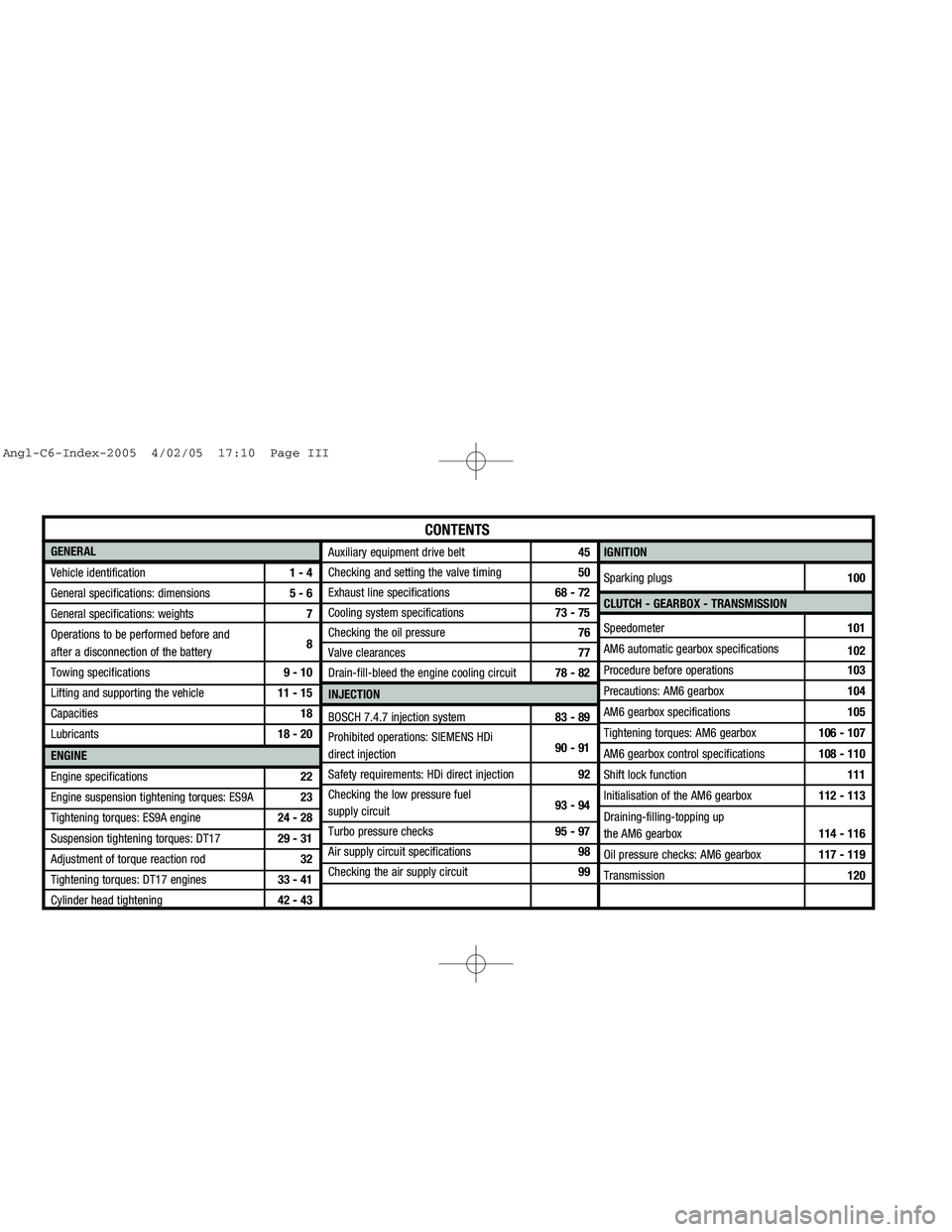

Downloaded from www.Manualslib.com manuals search engine GENERAL

Vehicle identification1 - 4

General specifications: dimensions 5 - 6

General specifications: weights7

Operations to be performed before and

after a disconnection of the battery8

Towing specifications9 - 10

Lifting and supporting the vehicle11 - 15

Capacities18

Lubricants18 - 20

ENGINE

Engine specifications22

Engine suspension tightening torques: ES9A23

Tightening torques: ES9A engine24 - 28

Suspension tightening torques: DT1729 - 31

Adjustment of torque reaction rod32

Tightening torques: DT17 engines33 - 41

Cylinder head tightening42 - 43IGNITION

Sparking plugs100

CLUTCH - GEARBOX - TRANSMISSION

Speedometer101

AM6 automatic gearbox specifications

102

Procedure before operations103

Precautions: AM6 gearbox104

AM6 gearbox specifications105

Tightening torques: AM6 gearbox106 - 107

AM6 gearbox control specifications 108 - 110

Shift lock function111

Initialisation of the AM6 gearbox112 - 113

Draining-filling-topping up

the AM6 gearbox114 - 116

Oil pressure checks: AM6 gearbox117 - 119

Transmission120

CONTENTS

Auxiliary equipment drive belt45

Checking and setting the valve timing50

Exhaust line specifications68 - 72

Cooling system specifications73 - 75

Checking the oil pressure76

Valve clearances77

Drain-fill-bleed the engine cooling circuit78 - 82

INJECTION

BOSCH 7.4.7 injection system83 - 89

Prohibited operations: SIEMENS HDi

direct injection90 - 91

Safety requirements: HDi direct injection92

Checking the low pressure fuel

supply circuit 93 - 94

Turbo pressure checks95 - 97

Air supply circuit specifications98

Checking the air supply circuit99

Angl-C6-Index-2005 4/02/05 17:10 Page III

Page 6 of 223

Downloaded from www.Manualslib.com manuals search engine AXLES - SUSPENSION - STEERING

Wheels and tyres121 - 124

Checking and adjusting the vehicle height125 - 128

Values for checking and adjusting

the axle geometries129 - 133

Front axle134 - 135

Front axle tightening torques136 - 139

Rear axle140 - 141

Rear axle tightening torques142 - 143

Active suspension with variable damping144 - 149

Suspension tightening torques150 - 154

Draining-filling-bleeding

the hydraulic steering/suspension circuit155 - 158

Power steering specifications159 - 162

Power steering tightening torques163 - 164

Checking the steering assistance

pressure (ES9A engine)165 - 168

Bleeding the hydraulic steering

assistance circuit169AIR CONDITIONING

Quantities: aircon system R134.a 203

Special features: air conditioning circuit 204 - 205

Pollen filter206

Checking the compressor oil level207 - 208

Checking the efficiency of

the air conditioning circuit209 - 215

Air conditioning circuit: ES9A216

Air conditioning circuit: DT17217

CONTENTS

BRAKES

Brake specifications170

Braking system: general specifications171 - 173

Braking system: tightening torques174 - 177

Values for checking and adjusting

the braking system178

General feataures of

the electric parking brake179 - 189

Brake fluid checks190

Drain-fill-bleed the braking system191 - 194

HYDRAULICS

Safety requirements:

active suspension with variable damping195 - 197

Suspension spheres: general specifications 198

Suspension spheres:

specification - identification199 - 200

Depressurising the hydraulic

suspension circuit201 - 202

Angl-C6-Index-2005 4/02/05 17:10 Page IV

Page 7 of 223

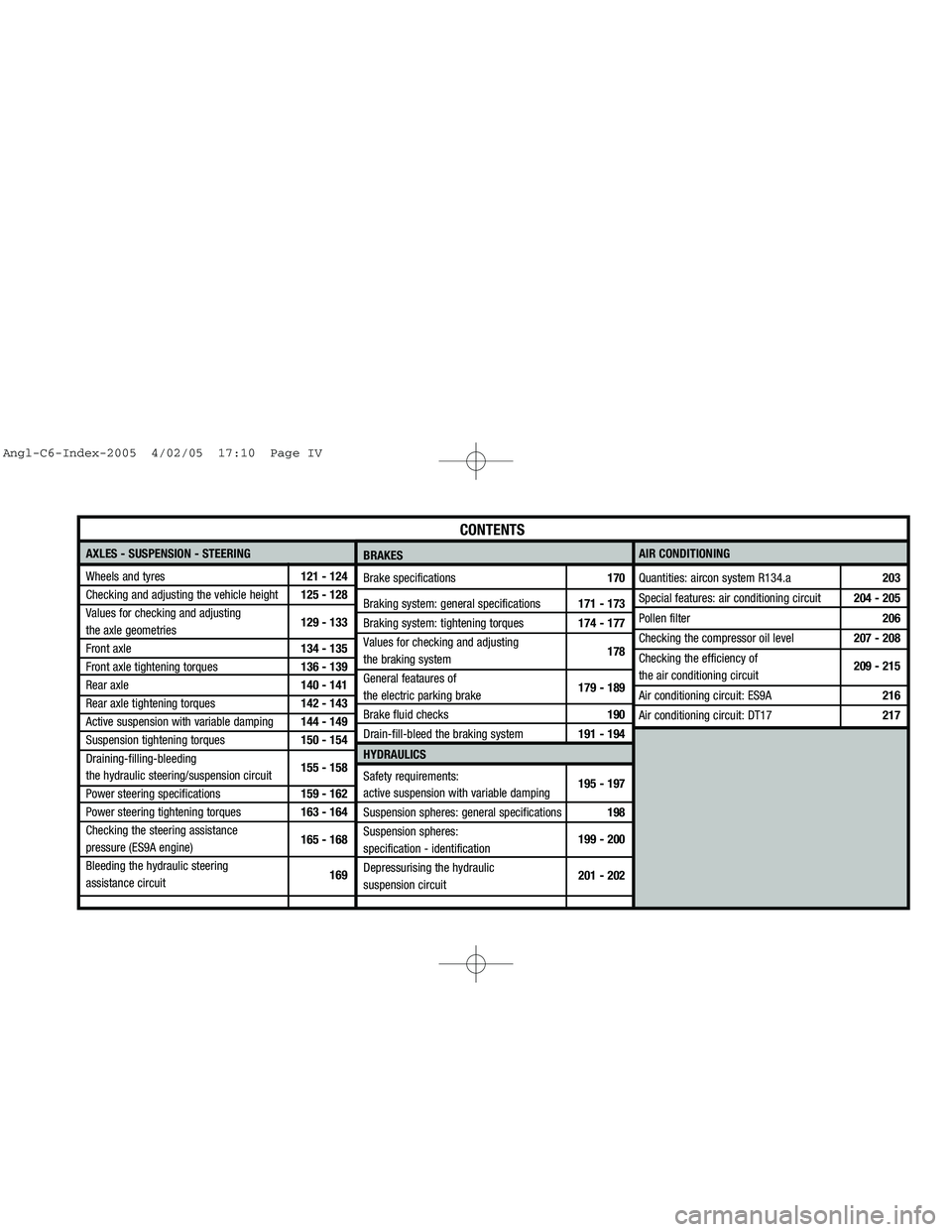

Downloaded from www.Manualslib.com manuals search engine IDENTIFICATION OF VEHICLES

E1AP13LD

A- Chassis stamp

(cold stamp on suspension leg).

B - Chassis stamp

(cold stamp on bodywork below rear screen).

C - Manufacturer's data plate

(on the LH centre pillar).

D - AS/RP No. and RP paint code

(label on front pillar close to driver's door).

E - Inflation pressures and tyre references

(label on front pillar close to driver's door).

F - Serial no. on bodywork.

G - Gearbox reference - Factory serial no.

H - Engine legislation type - Factory serial no.

GENERAL

Angl-C6-page001-21-2005 4/02/05 17:12 Page 1

Page 22 of 223

Downloaded from www.Manualslib.com manuals search engine Draining methods

Oil capacities are defined according to the following methods

16

GENERAL

CAPACITIES (in litres)

Draining of the engine lubrication system by GRAVITY

Place the vehicle on horizontal ground (in the high position if

hydropneumatic suspension).

The engine should be hot (oil temperature 80°C).

Drain the sump by gravity.

Remove the oil filter cartridge (time for draining and drip-drip = 15

minutesapprox.).

Refit the cap with a new seal.

Refit a new oil filter cartridge.

Refill the engine with oil (see table for oil capacity).

Start the engine to fill the oil filter cartridge.

Stop the engine (allow to stabilise for 5 minutes).Draining of the engine lubrication system by SUCTION

Place the vehicle on horizontal ground (in the high position if

hydropneumatic suspension).

The engine should be hot (oil temperature 80°C).

Remove the oil by suction through the dipstick tube.

Remove the oil filter cartridge.

Maintain the suction of oil in the sump (15 minutesapprox.).

Refit a new oil filter cartridge.

Refill the engine with oil (see table for oil capacity).

Start the engine to fill the oil filter cartridge.

Stop the engine (allow to stabilise for 5 minutes).

WARNING: Remove the suction container before starting the engine.

ESSENTIAL: Systematically check the oil level using the oil dipstick.

Angl-C6-page001-21-2005 4/02/05 17:12 Page 16

Page 29 of 223

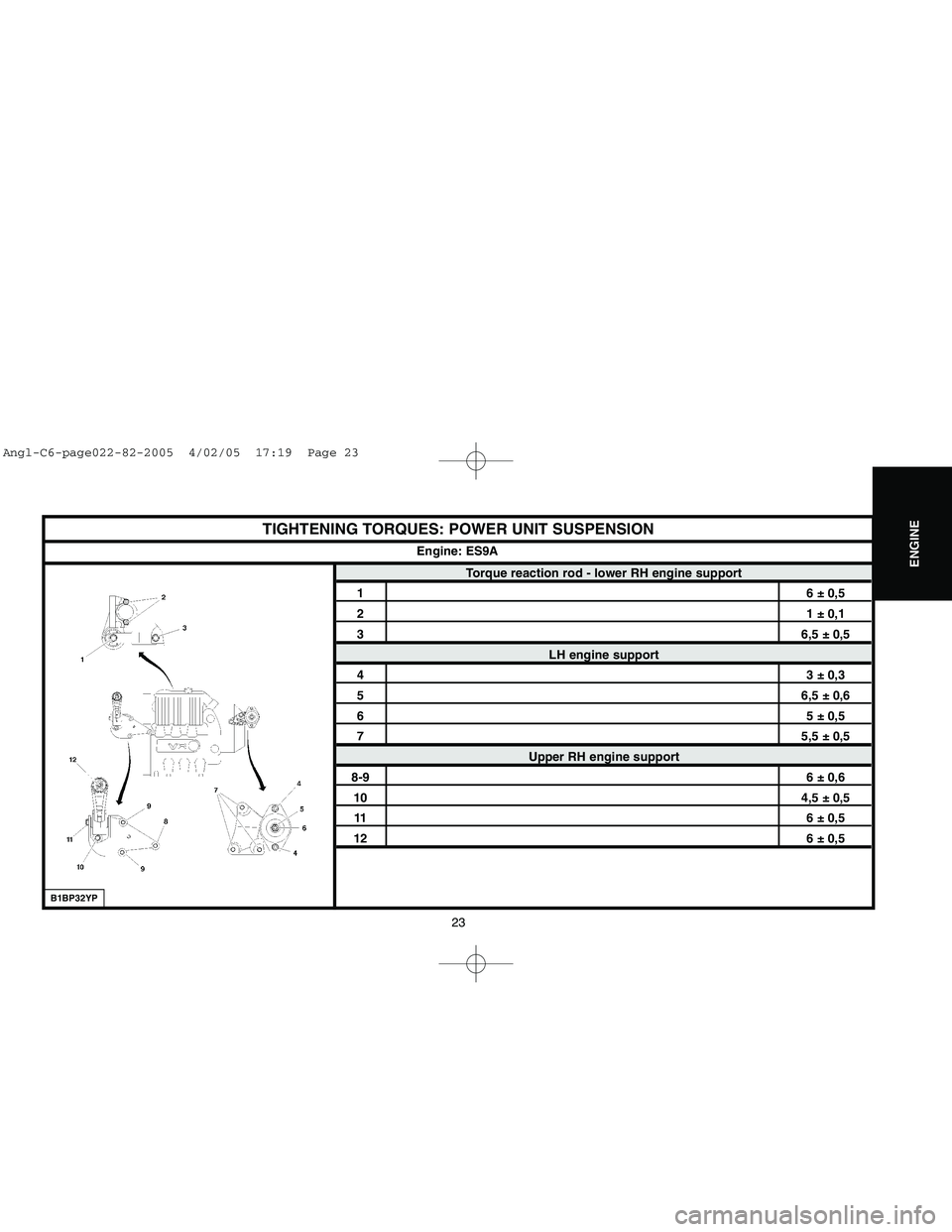

Downloaded from www.Manualslib.com manuals search engine 23

ENGINE

TIGHTENING TORQUES: POWER UNIT SUSPENSION

Torque reaction rod - lower RH engine support

16 ± 0,521 ± 0,136,5 ± 0,5

LH engine support

43 ± 0,356,5 ± 0,665 ± 0,575,5 ± 0,5

Upper RH engine support

8-96 ± 0,6104,5 ± 0,5116 ± 0,5126 ± 0,5

Engine: ES9A

B1BP32YP

Angl-C6-page022-82-2005 4/02/05 17:19 Page 23

Page 35 of 223

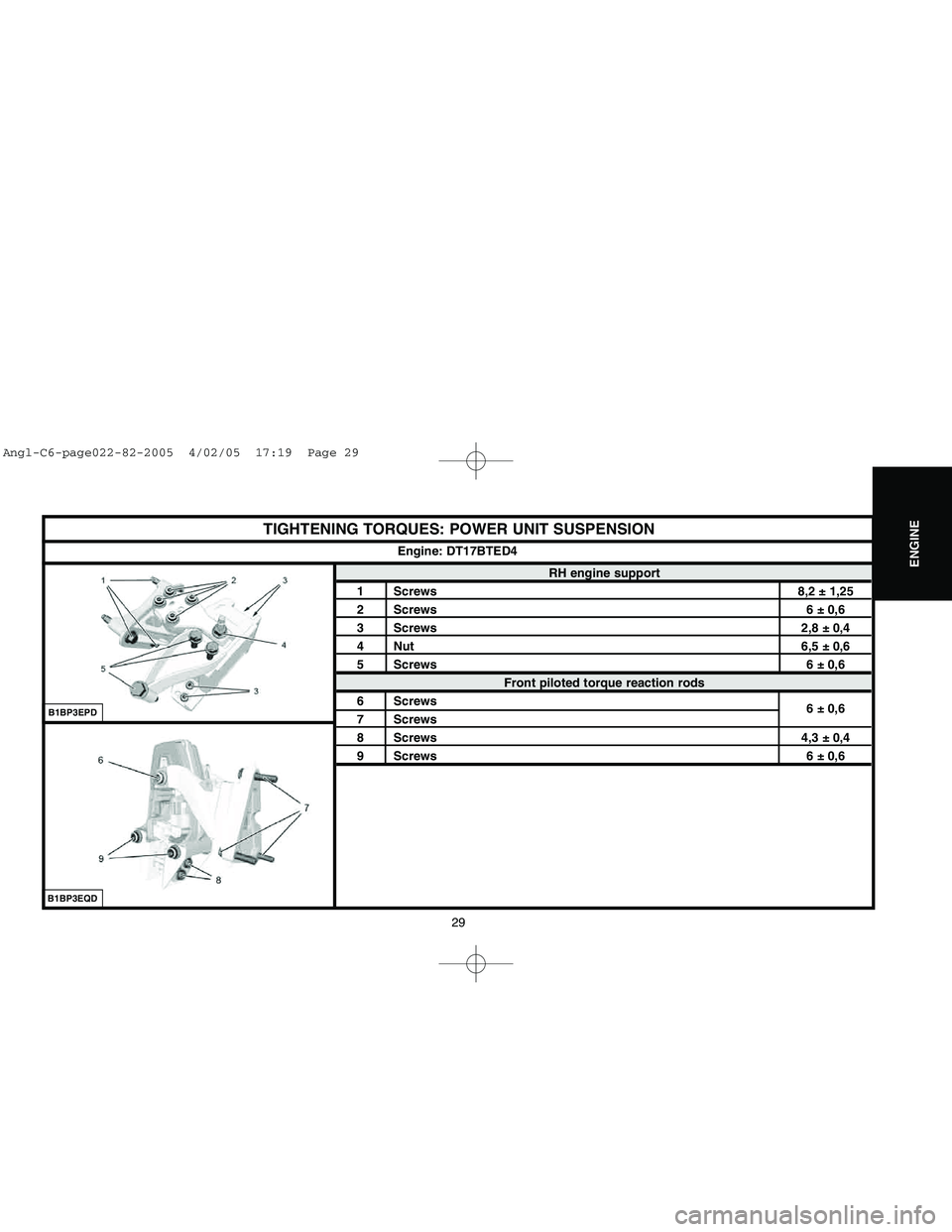

Downloaded from www.Manualslib.com manuals search engine 29

ENGINE

TIGHTENING TORQUES: POWER UNIT SUSPENSION

RH engine support

1 Screws 8,2 ± 1,252 Screws 6 ± 0,63 Screws 2,8 ± 0,44 Nut 6,5 ± 0,65 Screws 6 ± 0,6

Front piloted torque reaction rods

6 Screws

6 ± 0,6

7 Screws8 Screws 4,3 ± 0,49 Screws 6 ± 0,6Engine: DT17BTED4

B1BP3EPDB1BP3EQD

Angl-C6-page022-82-2005 4/02/05 17:19 Page 29

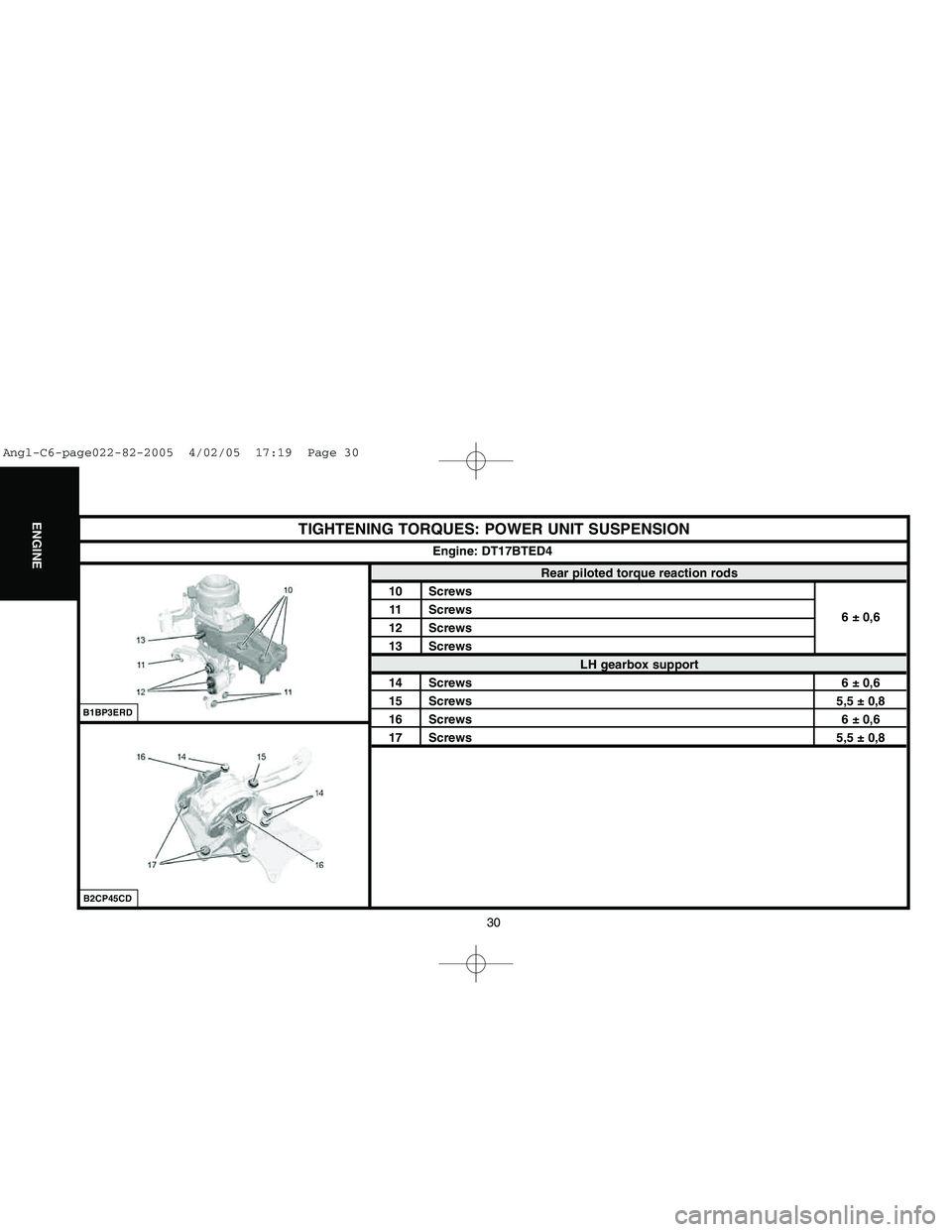

Page 36 of 223

Downloaded from www.Manualslib.com manuals search engine 30

ENGINE

TIGHTENING TORQUES: POWER UNIT SUSPENSION

Rear piloted torque reaction rods

10 Screws

11 Screws

6 ± 0,6

12 Screws

13 Screws

LH gearbox support

14 Screws 6 ± 0,615 Screws 5,5 ± 0,816 Screws 6 ± 0,617 Screws 5,5 ± 0,8Engine: DT17BTED4

B2CP45CDB1BP3ERD

Angl-C6-page022-82-2005 4/02/05 17:19 Page 30

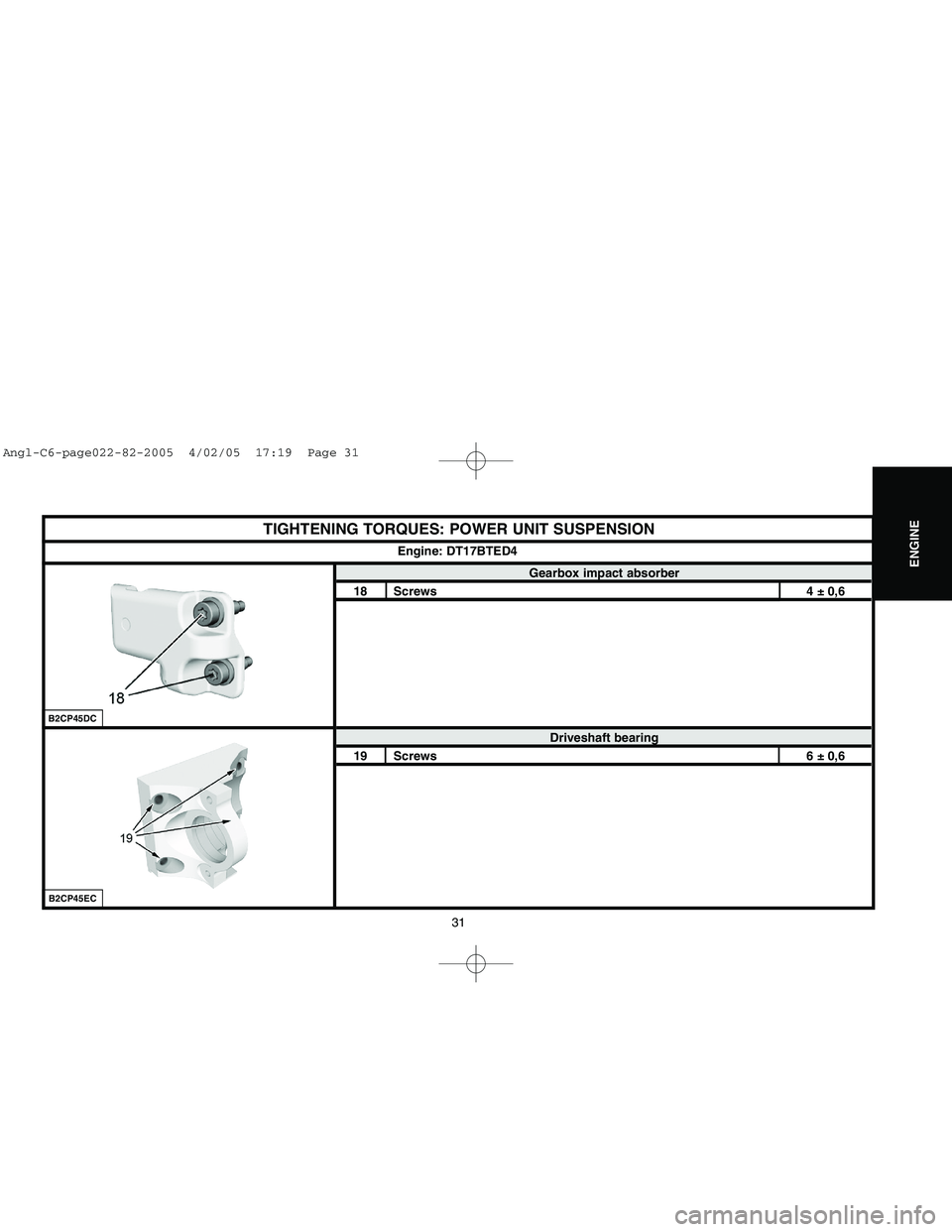

Page 37 of 223

Downloaded from www.Manualslib.com manuals search engine 31

ENGINE

TIGHTENING TORQUES: POWER UNIT SUSPENSION

Gearbox impact absorber

18 Screws 4 ± 0,6

Driveshaft bearing

19 Screws 6 ± 0,6Engine: DT17BTED4

B2CP45ECB2CP45DC

Angl-C6-page022-82-2005 4/02/05 17:19 Page 31

Page 120 of 223

![CITROEN C6 2005 Owners Manual Downloaded from www.Manualslib.com manuals search engine 114

CLUTCH

GEARBOX

TRANSMISSION

DRAINING, FILLING AND TOPPING UP THE AM6 AUTOMATIC GEARBOX

Tool.

[1] Filling cylinder: (-).0340

Respect the sa CITROEN C6 2005 Owners Manual Downloaded from www.Manualslib.com manuals search engine 114

CLUTCH

GEARBOX

TRANSMISSION

DRAINING, FILLING AND TOPPING UP THE AM6 AUTOMATIC GEARBOX

Tool.

[1] Filling cylinder: (-).0340

Respect the sa](/img/9/57744/w960_57744-119.png)

Downloaded from www.Manualslib.com manuals search engine 114

CLUTCH

GEARBOX

TRANSMISSION

DRAINING, FILLING AND TOPPING UP THE AM6 AUTOMATIC GEARBOX

Tool.

[1] Filling cylinder: (-).0340

Respect the safety and cleanliness requirements.

Draining.

IMPERATIVE: Draining of the gearbox must be done with the oil hot (60°C minimum), in order to

ensure that the impurities in suspension in the oil are eliminated.

NOTE:Drainage is only partial, as the torque converter cannot be drained totally.

Raise the vehicle.

Remove:

- The oil level plug (2)by means of the Torx spanner.

- The drain plug (1)using a hexagonalspanner.

NOTE :Around 3 litresof oil should flow out.

Filling.

Fit the drain plug (1)(with a new seal).

Tighten the plug (1)to: 5 ± 1 mdaN.

Remove:

- The air filter housing.

- The oil filler plug (3).

Use tool [1].

B2CP3WZCB1BP317C

Angl-C6-page101-120-2005 4/02/05 17:25 Page 114