fuel Citroen CX 1974 1.G User Guide

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1974, Model line: CX, Model: Citroen CX 1974 1.GPages: 394

Page 52 of 394

Downloaded from www.Manualslib.com manuals search engine I. CHARACTERISTICS

:

0

u

5 Cooling system : Water cooled.

z

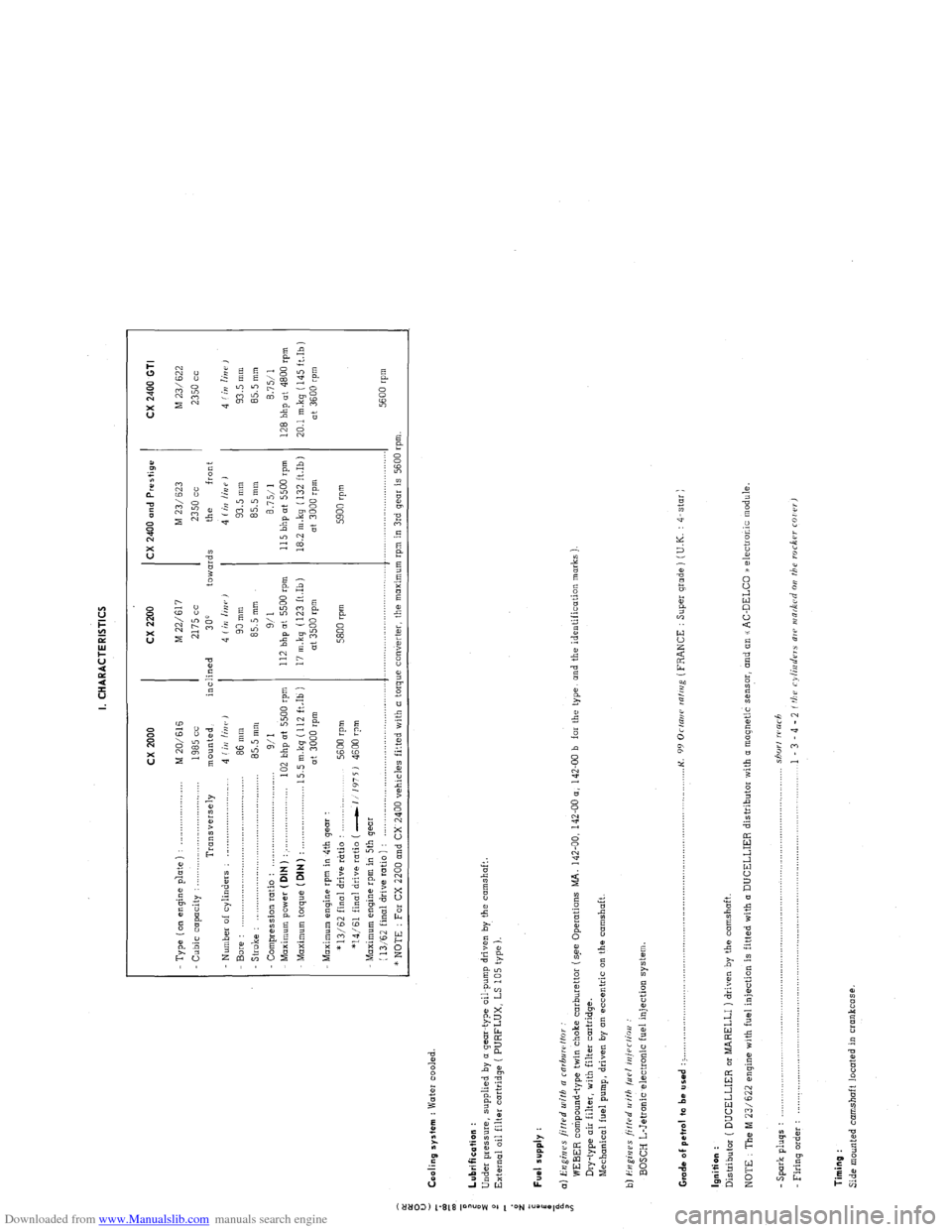

T cx 2000 cx 2200 CX 2400 and Prestige

CX 2400 GTI

- Type ( on engine p’late ) : _..._................... M 20/616 M 22/617 M 23/ 623

M 23/622

Cubic capacity : . . .._......_...............

1985 cc 2175 cc 2350 cc 2350 cc

Transversely mounted, inclined

300 towards the front

Number of cylinders : _........................... 4 (iI/ linr, J 4 Iin linr,)

4 (irr /iUP J 4 f in lin i’ ,

Bore : 86 mm 90 mm 93.5 mm 93.5 mm

- Stroke : .,.,,_,.,.,....____.,.. .._._.....................

85.5 mm 85.5 mm 85.5 mm

85.5 mm

Compression ratio :

9/I 9/l 8.7511 8.7511

Maximum power ( DIN ) : . . . .._................... 102 bhp at 5500 rpm 112 bhp at 5500 rpm 115 bhp ot 5500 rpm

128 bhp at 4800 rpm

Maximum torque (DIN)

: . . 15.5 m.kg (112 ft.Ib ) 17 m.kq (123 ft.Ib) 18.2 m.kg ( 132 ft.Ib)

20.1 mkq (145 ft.Ib)

at 3000 rpm at 3500 rpm at 3000 rpm

at 3600 rpm

Maximum engine rpm in 4th gear :

* 13/62 final drive rtrtio :

5600 rpm 5800 rpm 5900 rpm

*14/61 final drive ratio ( -1 1’175 J 4600 rpm

Maximum engine rpm in 5th gear

(

13,‘62 final drive ratio ) : ,._............,..,........,....,.,........,..,.,..... .._.........,................ .._..._...................

5600 rpm

* NOTE : For CX 2200 and CX 2400 vehicles fitted with a torque converter, the maximum rpm in 3rd gear is 5600 rpm.

: Lubrification :

i

Under pressure, supplied by o gear-type oil-pump driven by the camshaft.

2

External oil filter cartridge ( PURFLUX, LS 105 type ).

d

z

;

i Fuel supply :

a

i a) Engines fitted u~ifh a rnrbuwffor

WEBER compound-type twin choke carburettor (s.ee Operations MA. 142-00, 142-00 a, 142-00 b far the type, and the identification marks )

Dry-type air filter, with filter cartridge.

Mechanical fuel pump, driven by on eccentric on the camshaft.

b) i?ugi,jes ji/f.rd II ith /LIP/ iniPr/ioo :

BOSCH L-Jetronic electronic fuel injection system

Grade of pet,ol to be used : > ._,,,,.,_.._,,,,,.,......... . .._...o....._............................................. K.

99 Orrani ralrrig (FRANCE : Super grade ) (U.K. : 4-star )

Ignition :

Distributor ( DUCELLIER or MARELLI ) driven by the camshaft.

NOTE : The M 23/622 engine with fuel injection is fitted with (I DUCELLIER distributor with a magnetic sensor, and an u AC-DELCO /a electronic module.

- Spark pluqs : .................................................................................................................................... shorf warh

Firing o&r : .................................................................................................................................... 1 - 3 - 4 - 2 f tbu cylinders ale INR&Cd 011 the roc6w COI rr,

Timing :

Side mounted camshaft located in crankcase.

Page 71 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 120.0 : Chrrki,,~ the /iminp. Op. MA. 120-O 1

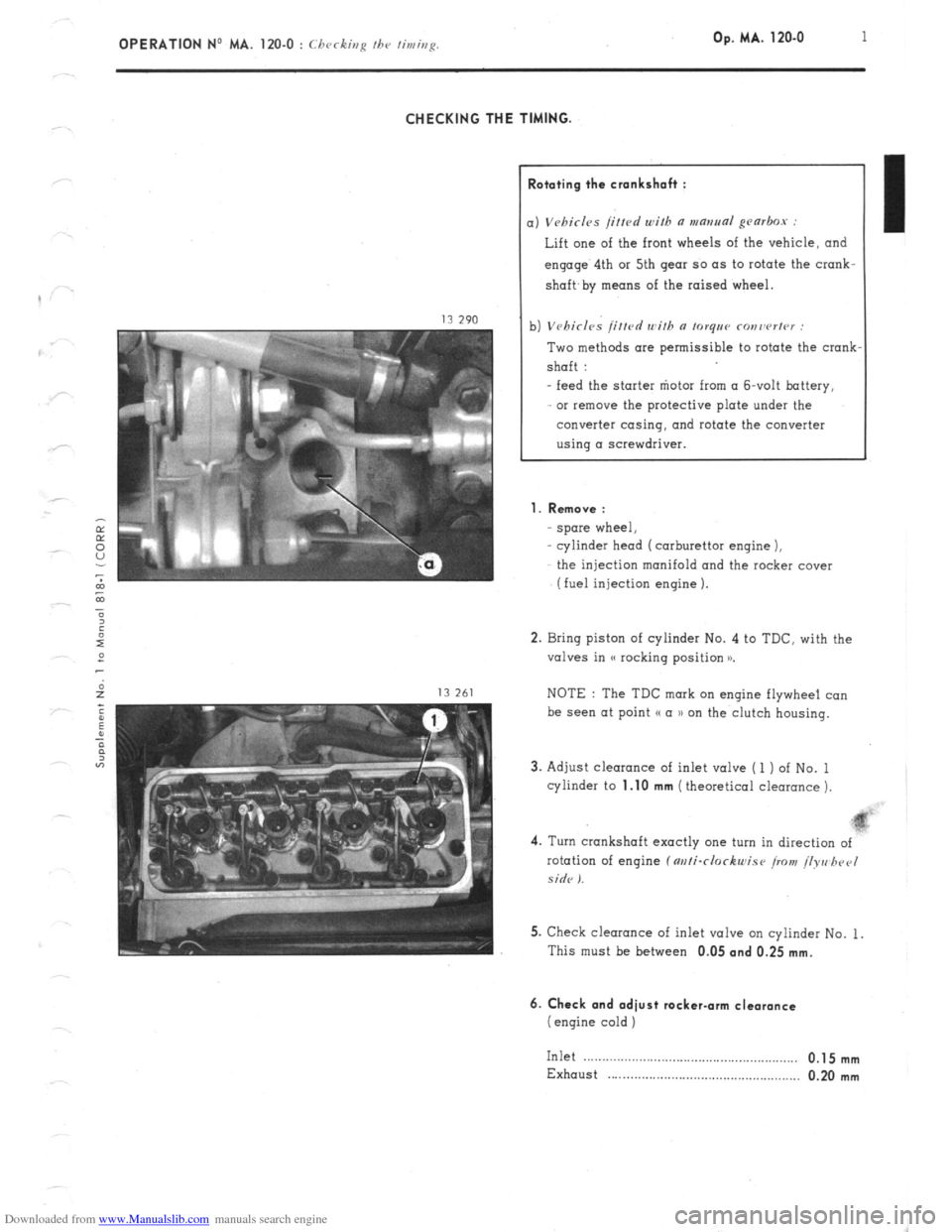

CHECKING THE TIMING.

lototing the crankshah :

) Vebirl~s /i/fed with a mantra~ gearbox :

Lift one of the front wheels of the vehicle, and

engage’ 4th or 5th gear so as to rotate the crank-

shaft,

by means of the raised wheel.

1) Vehicles /itted with n torqee ronrwrter :

Two methods are permissible to rotate the crank

shaft :

- feed the starter “iota from (I &volt battery,

or remove the protective plate under the

converter casing, and rotate the converter

using a screwdriver.

1. Remove :

spore wheel,

cylinder head (carburettor engine 1,

the injection manifold and the rocker cover

(fuel injection engine 1.

2. Bring piston of cylinder No. 4 to TDC. with the

valves in (( rocking position x

NOTE : The TDC mark on engine flywheel co”

be see” at point (( a )) on the clutch housing.

3. Adjust clearance of inlet valve ( 1 ) of No. 1

cylinder to

1.10 mm (theoretical clearance 1.

4. Turn crankshaft exactly one turn in direction of

rotation of engine f m/i-clockwise iro>t! /lyre hpel

side I.

5. Check clearance of inlet valve on cylinder No. 1.

This must be between 0.05

and 0.25 mm.

6. Check and adiust rocker-arm clearance

(engine cold )

Inlet .__....__.............................................,.,, 0.1 5 mm

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.20 mm

Page 84 of 394

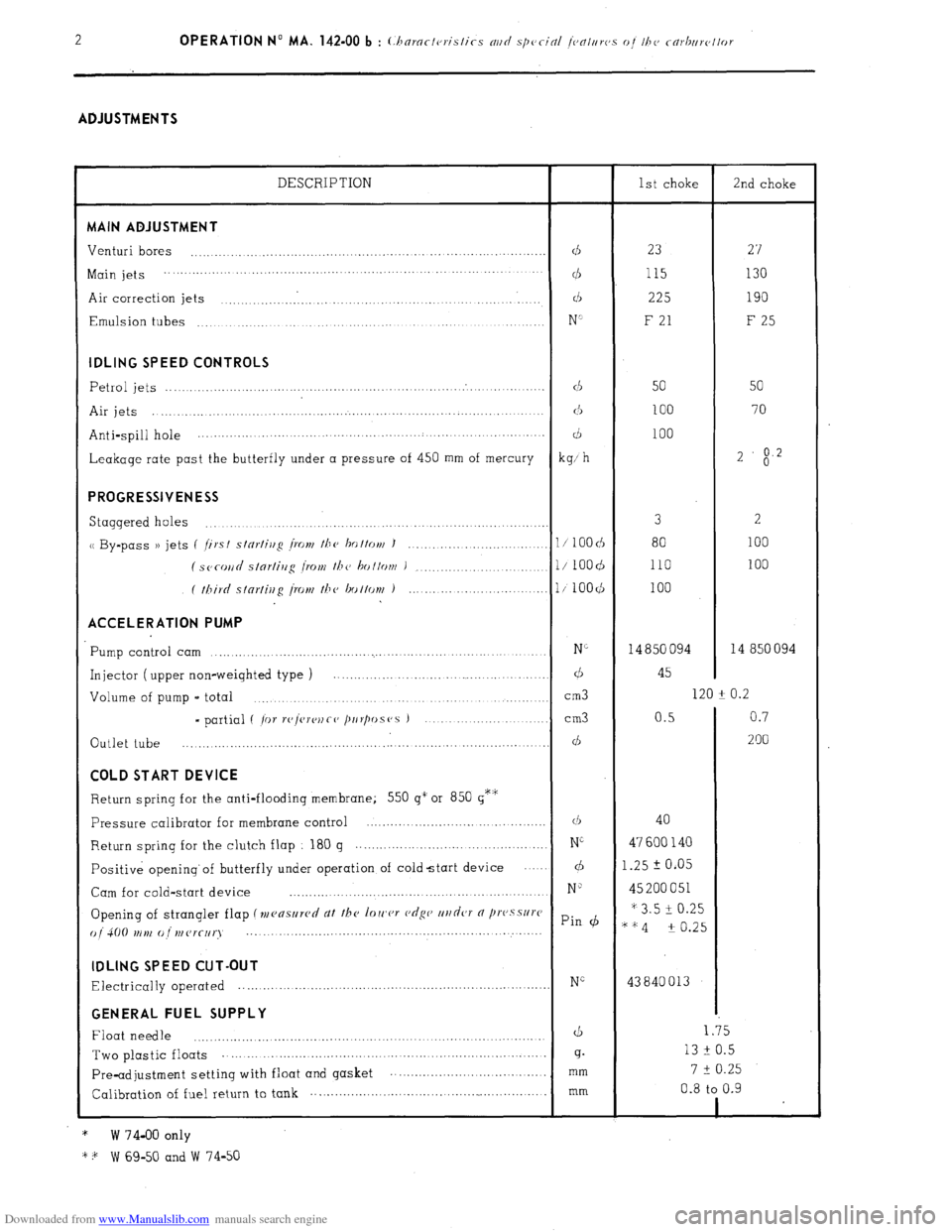

Downloaded from www.Manualslib.com manuals search engine ADJUSTMENTS

DESCRIPTION

1st choke

2nd choke MAIN ADJUSTMENT

Venturi bores

...................................................................................

d 23

27

Main jets ................. ...........................

... ................. ... ....... ...............

cl5 115 130

Air correction jets ..............................................................

d 225 190

Emulsion tubes

...............................................................

......

N’ F 21

F 25 IDLING SPEED CONTROLS

Petrol jets

.......................................................................................

d

50 50

Air jets .....................................................................................

(3

100 70

Anti-spill hole ............... ..............................................

....... ........

d 100

Leakage rate past the butterfly under a pressure of 450 mm of mercury

kg; h 2

$2 PROGRESSIVENESS

Staggered holes 3

2 ...............................................................................

u By-pass )) jets (

/irst stnrtiug /row the ho ttott/ J

100 ............................ 1 / 100 cb 80

( SC~COII~ slnrlirrg I.0Nf the bottom )

...................... l/ 1OOd 110 100

( third stnrfiug [row the bottov~ )

........................... l/100($

100 ACCELERATION PUMP

Pump control cam N”

14 850 094 14 850 094 ...............................................................................

Injector ( upper non-weighted type ) ............................................

d 45

Volume of pump - total

cm3 120 -t 0.2

.......................................................................

- partial ( /or r(‘/vre)~Co /~IIr/wS(‘S ) ................... ...........

cm3 0.5 0.7

Outlet tube

200 ................................................. ....... ...........

............... ... d COLD START DEVICE

Return spring for the anti-flooding membrane; 550 g” or 850 g*‘i;

Pressure calibrator for membrane control ...........................................

(1, 40

Return

spring for the clutch flap

180 g ...............................................

Ni 47 600 140

Positive opening’of butterfly under operation of coldstart device

.... d 1.25 2 0.05

Cam for cold-start device

N” 45 200 051

..............................................................

Opening of strangler flap (mensllrcd dt the loIc,cr c,dgc’ ur/dcJT 0 /lI’(‘.sSlI)‘C * 3.5 i 0.25

() j 4(j(J tr ,),, (J ,,, (Jr(-[,q Pin (b

““4 -t 0.25

..... ... .....................................................

... ...... IDLING SPEED CUT-OUT

Electrically operated NG 43840013 ............................................................................. GENERAL FUEL SUPPLY

Float needle

d 1.35

..................................................................................

Two plastic floats 13 F 0.5 ...................................

............... .............................

g.

7 t 0.25

Pre-adjustment setting with float and gasket ...............................

....... mm

Calibration of fuel return to tank .................................

......................... mm 0.8 to 0.9

1

*

W 74-00 only

* + W 69-50 and W 74-50 .

Page 97 of 394

![Citroen CX 1974 1.G User Guide Downloaded from www.Manualslib.com manuals search engine ELECTRONIC FUEL INJECTION

OPERATION No MA. IE. 144-00 : <:hnrcrctwistics o/ the H I,-]c~trouic’a clcctrovic Op. MA. IE. 144-00 1

fuel iujrc Citroen CX 1974 1.G User Guide Downloaded from www.Manualslib.com manuals search engine ELECTRONIC FUEL INJECTION

OPERATION No MA. IE. 144-00 : <:hnrcrctwistics o/ the H I,-]c~trouic’a clcctrovic Op. MA. IE. 144-00 1

fuel iujrc](/img/9/4131/w960_4131-96.png)

Downloaded from www.Manualslib.com manuals search engine ELECTRONIC FUEL INJECTION

OPERATION No MA. IE. 144-00 : <:hnrcrctwistics o/ the H I,-]c~trouic’a clcctrovic Op. MA. IE. 144-00 1

fuel iujrctian swtem.

I

a L- JETRONIC H

System

Page 98 of 394

Downloaded from www.Manualslib.com manuals search engine 2

OPERATION No MA.IE. 144-00 : Chtiractcristics o/ the e 1,-Jc,tror,ic H clcctroltic

fire1 injc ctiwt systettt.

((L-JETRONIC,,

The H L-Jetronic 1) system is’an intermittent low-pressure injection system which injects petrol into the inlet

manifold.

The system measures the quantity of air drawn in by the engine. which is the main parameter for calculating

the amount of fuel. to be injected. The metering of the fuel is carried out by electro-magnetically triggered

injectors. These are under constant fuel pressure. The quantity of fuel injected is proportional to the duration

of injection. which in turn is optimally determined for any given engin& operating condition by an electronic

control unit ( E.C.U. ) from information supplied by several electric sensors.

One of the principal contributions of the H L-Jetronic H system is the reduction in the level of pollution of the

exhaust emissions.

The (( L-Jetronic v system is made up of the following components :

1

: Electric fuel pump

2 : Fuel filter

3 : Thermal switch

4 :, Double relay

5 : Electronic control unit ( E.C.U. )

6 : Supplementary air control

7 : Pressure regulator

8 : Injectors

9 : Cold-start injector

10. Idling speed adjustment screw

11 : Air-flow sensor ( with incorporated air temperature sensor )

12 : Switch on throttle butterfly spindle

13 : Additional resistors for the injectors (8)

Page 100 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA.IE. 144-00 : Chu~acte~istics of the (( L-Jetronic n electronic

fuel injectiari system Op. MA.IE. 144-00 5

-AIR INLET SYSTEM’

Air drawn in via air filter ( 1 ) passes through the air-flow sensor (2’), via butterfly ( 3) and arrives in the inlet

distribution chamber, each pipe of which (4) leads to a cylinder.

-

‘I

Each cylinder has an electro-magnetic injector which is located very close to the inlet valve in order to improve

engine performance.

The supplementary air control (6) is located in parallel with the butterfly, and supplies the supplementary air

required by the engine to run smoothly when cold.

_ Once the engine has reached its normal running temperature, the idling speed air-flow is provided by a by-pass

valve

$ ( 5) which by-passes the butterfly as well.

.

2

co

T

$ It is important that the system be air-tight downstream from the air-flow sensor, so that no (( secondary )) air can

I

2 be drawn in, which would falsify the air-volume reading.

Page 101 of 394

Downloaded from www.Manualslib.com manuals search engine 6

OPERATION No MA.IE. 144 - 00 : Churacteristics o/ the H L-Jetronic )) electronic

/uel injectian .system. FUEL CIRCUIT

A multiple roller-valve pump ( 2 ) draws the fuel from tank ( 1) and provides the injection pressure,

A filter (4) is fitted to the system.

In the fuel return pipe, the pressure regulator ( 3) maintains, under fuel load! a relative constant fuel pressure of

2 bars ( 29 ‘psi ).

The pressure regulator is connected to the intake manifold by a flexible pipe0 This allows the difference of

pressure betw.een the fuel and the inlet manifold to remain constant.Thus the necessary quantity of fuel delivered

by the injectors ( 5) depends exclusively on its duration of opening.

Page 102 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA.IE. 144-00 : ch arartcristics of the K L-Jetrouic )) elcctrcwic

juel ir2jcctirm system. / Op. MAalE. 144-00 7

FUEL CIRCUIT

I-

Page 103 of 394

Downloaded from www.Manualslib.com manuals search engine 8 OPERATION No MA.IE. 144-00 : Characteristics of the (( L-Jetrovzic n electronic

fuel ivzjectian system. t

E;C.U.

( ELECTRONIC CONTROL UNIT )

I

I’

I

I

I

Page 104 of 394

Downloaded from www.Manualslib.com manuals search engine OPEdATlON N- MA.IE. 144-00 : C1 3aractcJristics o/ the e L-Jetro~ic n elcctrorlir Op. MA.IE. 144-00 9

fuel injectian systwn. E.C.U; ( ELECTRONIC CONTROL UNIT )

Apart from three integrated circuits ( I.C. ) forming the main part of the E.C.U., there are in addition only a few

semi-conducting components condensers, calibrating resistors and filters so as to avoid.any interference.

I

The function of the E.C.U. is ,to supply an impulse to the injectors, and to control their opening for a precisely

defined amount of time. The E.C.U. to this effect uses the information provided by all the engine sensors which

translate the operating conditions of the engine into electric impulses.

All the injectors are connected in parallel, and inject fuel simultaneously twice for each rotation of the camshaft

( therefore,twice for each engine cycle ), injecting half the quantity of fuel required each time With this system

it is not necessary for the camshaft angle to coincide with the beginning of injection point, which eliminates the

need for a generating switch incorporated in the distributor.

The injection impulse control is ensured by the distributor impulses. The distributor produces four impulses for

every operational cycle. Since injection only occurs twice in every cycle, the E.C.U. must divide the frequency

by 2.

The impulses coming from the distriLti, are transformated into square waves by the waveform shaper. Since

injection only occurs twice for each camshaft rotation, whereas the distributor provides 4 impulses in the same

amount of time, the frequency of the impulses must be divided by 2 in the frequency divider.

These signals are used to charge a condenser. The condenser discharge determines the beginning of injection

point; the position of the air-flow sensor flap ( which determines the quantity of air drawn in ) being the main

parameter for calculating the duration of injection.

At the multiplying stage of the E.C.U., various correction values ( full load and idling speed via throttle butterfly

spindle switch, engine temperature via the water temperature sensor, air temperature via the air-temperature sensor

located in the air-flow sensor ) are combined with the signals from the air-flow sensor and the injt,ztion frequency

in order to determine the injection duration which is transmitted to the injectors by way of impulses.

The time it takes for the injector needle to open and close depends on the battery voltage.

As the supply voltage increases, the injection duration increases.

The fact that the quantity of fuel injected depends

on the voltage is cancelled out by the fact that the injection duration is inversely proportional to the voltaqq,in the

E.C.U.

The final impulse determines the time during which the injectors are connected to earth ( injection duration ‘supplied

by the output stage ).