height Citroen CX 1974 1.G Owner's Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1974, Model line: CX, Model: Citroen CX 1974 1.GPages: 394

Page 254 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 430-00 : (lsnmr/eris/irs nvrl .s/jrrinl /c,n/uws 0, /he susfiv,,sias Op. MA. 430-00 3

MANUAL HEIGHT CONTROL

‘hi anual height control quadrant :

I. High position

II. Intermediate high position

III. Normal driving position

IV Low position

G Assembly diagram for manual height control

:

L.43.2

Seen along Fl

Page 255 of 394

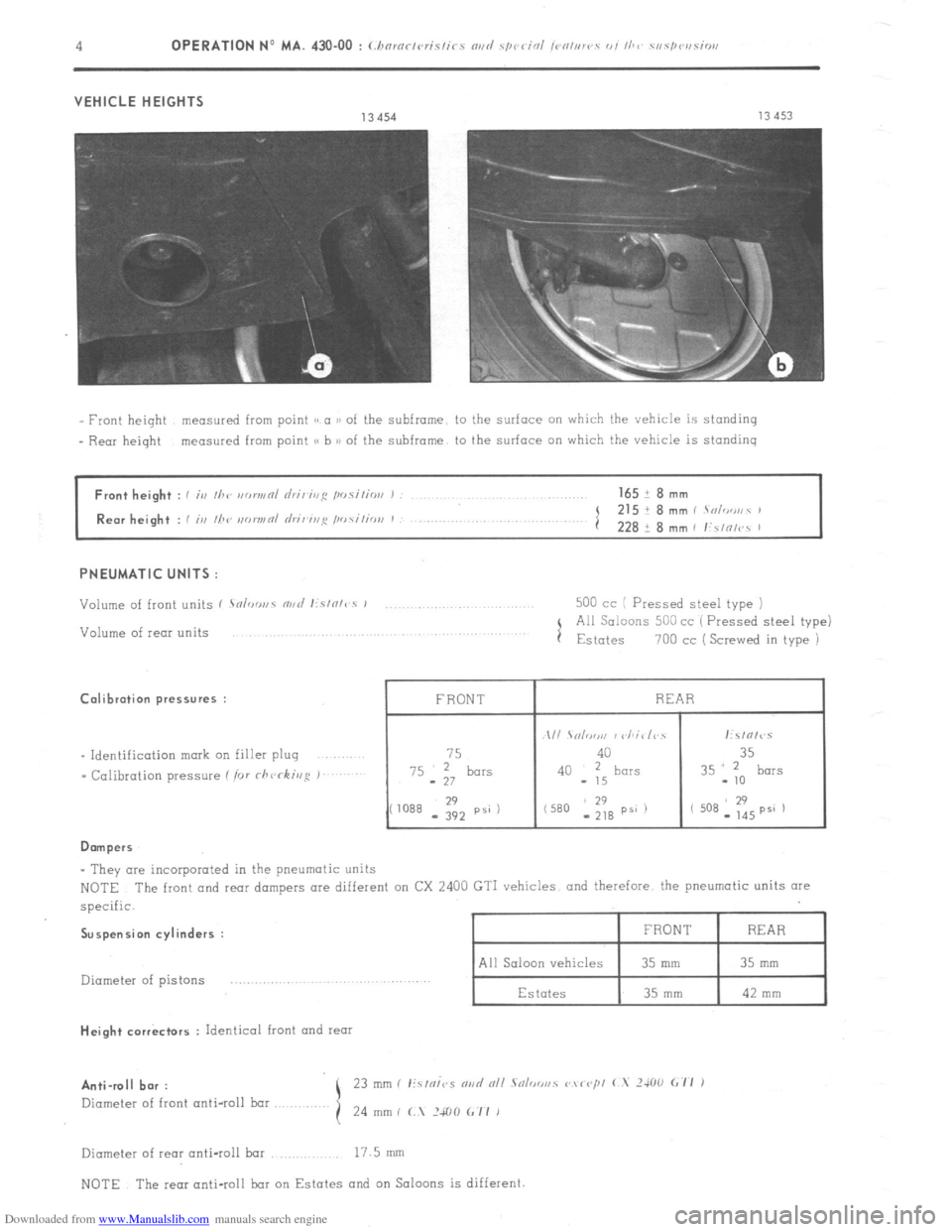

Downloaded from www.Manualslib.com manuals search engine VEHICLE HEIGHTS 13454

- Front height measured from point SG a 8) of the subfrome. to the surface on which the vehicle is stondinq

_ Rear height measured from point (, b )B of the subfrome to the surface on which the vehicle is standinq Calibration pressures :

FRONT REAR

\// \~~lr~r,,i J v/xii

/c,.5 I:\lol,‘s

_ Identification mark on filler plug 75 40 35

- Calibration pressure ( /or rhc’rkiqg 1. 75 2 bars 40 2 bars

- 27 - 15 35 1 ;, bars

(1088 _ ;;, P51 1

(580 : ;;, P51 i ( 508; :',, PSP 1 Dampers

- They are incorporated in the pneumatic units

NOTE The front and rear dampers ore different on CX 2400 GTI vehicles and therefore the pneumatic units are PNEUMATIC UNITS :

Volume of front units i Soloor, mid I:s/fll<,s 1

500 cc f Pressed steel type )

Volume of rear units

i All Saloons 500 cc ‘j Pressed steel type)

Estates 700 cc (Screwed in type i

I

specific. Suspension cylinders :

Diameter of pistons ,,,, Height

corr&tors : Identical front and rear Anti-roll bar :

23 mm i lisfoir~s mid o/l Salormc <~,c,,,,, ( Y ‘Xl(i VII I

Diameter of front anti-roll bar.

i 24 mm , (. 2400 (.‘/I J

Diameter of rear anti-roll bar 17.5 mm

NOTE The rear anti-roll bar on Estates and on Saloons is different.

Page 256 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 430.00 : c ,,<,,a< ,<,r;s,;rs mi/ .s/wrin/ ,vn/srrs oi /he srmf~rw.~ion Op. MA. 430-00 5

II. SPECIAL FEATURES

Adjusting the anti-roll bars :

A, t/xv ,ms,

- Lateral positioning equal protrusion on either side to within 2 mm

- Anti-roll bar bearing preload 300 N ( 30kg) ( 66 lb )

- Lateral clearance of anti-roll bar. under pressure of 500 N i 50kq I( 110 fb i 0.2 to 1 mm

,I, l/X“ rcnr :

- Lateral positioning same thickness of shim on both sides. within 1 mm

- Shimming, if necessary. level with the split collars to within 0.6 mm

Greasing of the suspension piston con-rod ioint :

( Carried out with LHM liquid contained in the dust cover )

- Front suspension cylinder

- Rear suspension cylinder

Upper front wheelarm stops :

WARNING ‘,hc ,,,;,,,i<~, ~,op ,,,I (i, he ii,,, r/ 01 //I< ,,I?<,<‘/ wd. 7cm3

25 cm3

Tightening torques :

- Anti-roll bar link-rod on upper wheelarm. i Bush nut 3 doNm ( 21 11 2 ft.lb )

NYLSTOP nut 4.5 to 5daNd32 1/‘2to 36ft.lb)

- Link-rod on anti-roll bar 4.5 to SdaNm(32 1/2to36ft.lb)

. Screw securing front anti-roll bar bearing 2.7 daNm ( 19 l/2 ft.lb )

^ - Clamps for adjusting pie-load on front anti-roll bar 13 doNm ( 9 l/2 ft.lb)

b2 - 1.5 daNm [ 11 ft.lb i

0 Clomp for height corrector control

rod ( front and rem )

”

6 daNm ( 43 l/ 2 ft.lb ) - . An+iwroff bar 0” rear &&arm ( rear fixing

points ) I /nc<’ nvrl /hrcn,l~r

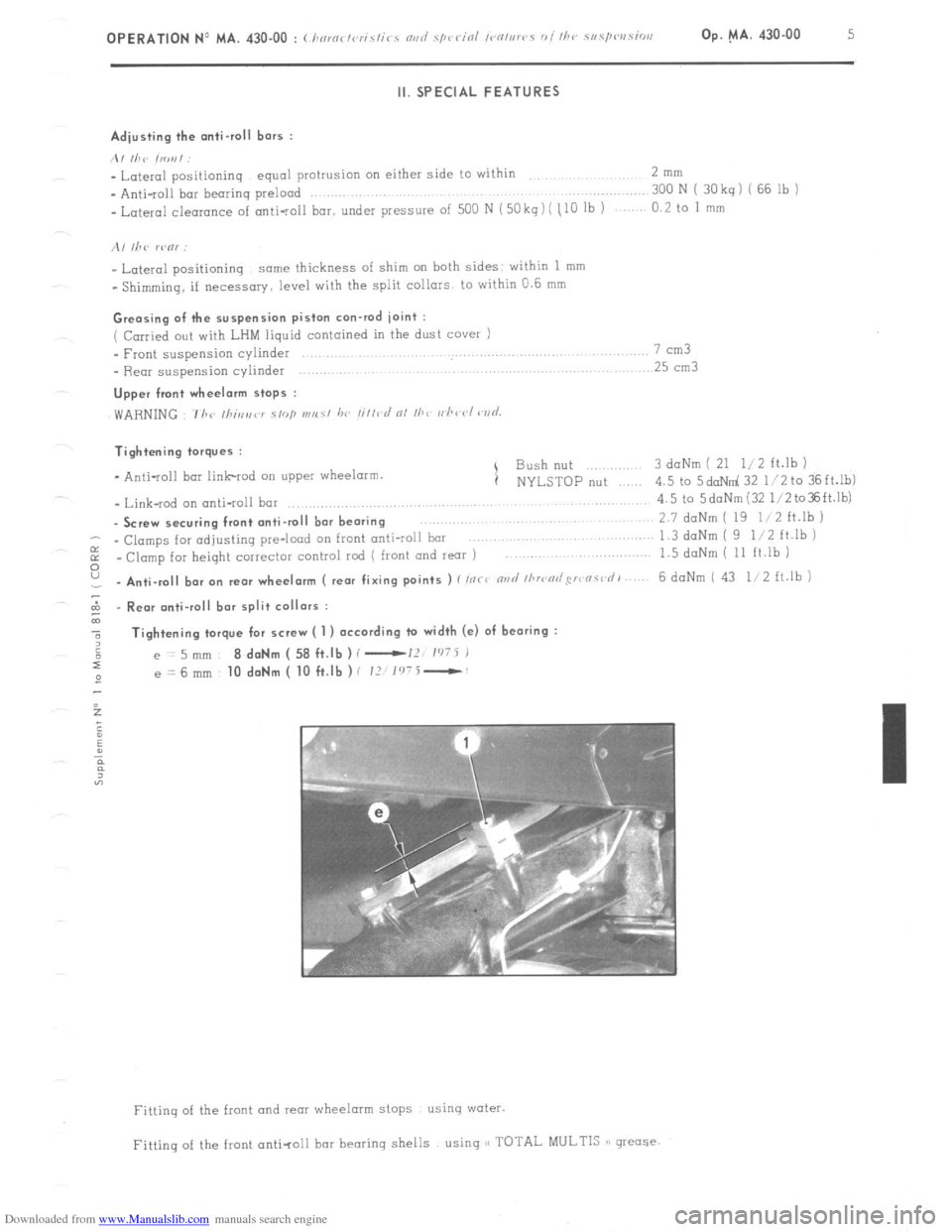

- Rear anti-roll bar split collars :

cc

-5 Tightening torque for screw ( 1 )

according to width (e) of bearing :

:

2

e = 5 mm 8 d.aNm ( 58 ft.lb ) f -I’, I’JiS,

P

e-6mm lOdoNm( lOft.lb)i 121Vi-’

Fitting of the front and rear wheelarm stops using water

Fitting of the front anti-011 bar bearing shells using ,< TOTAL MULTIS I) grease.

Page 257 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 430-O : Checking md ndjusting the suspcusion and its control. 06. MA. 430-O i

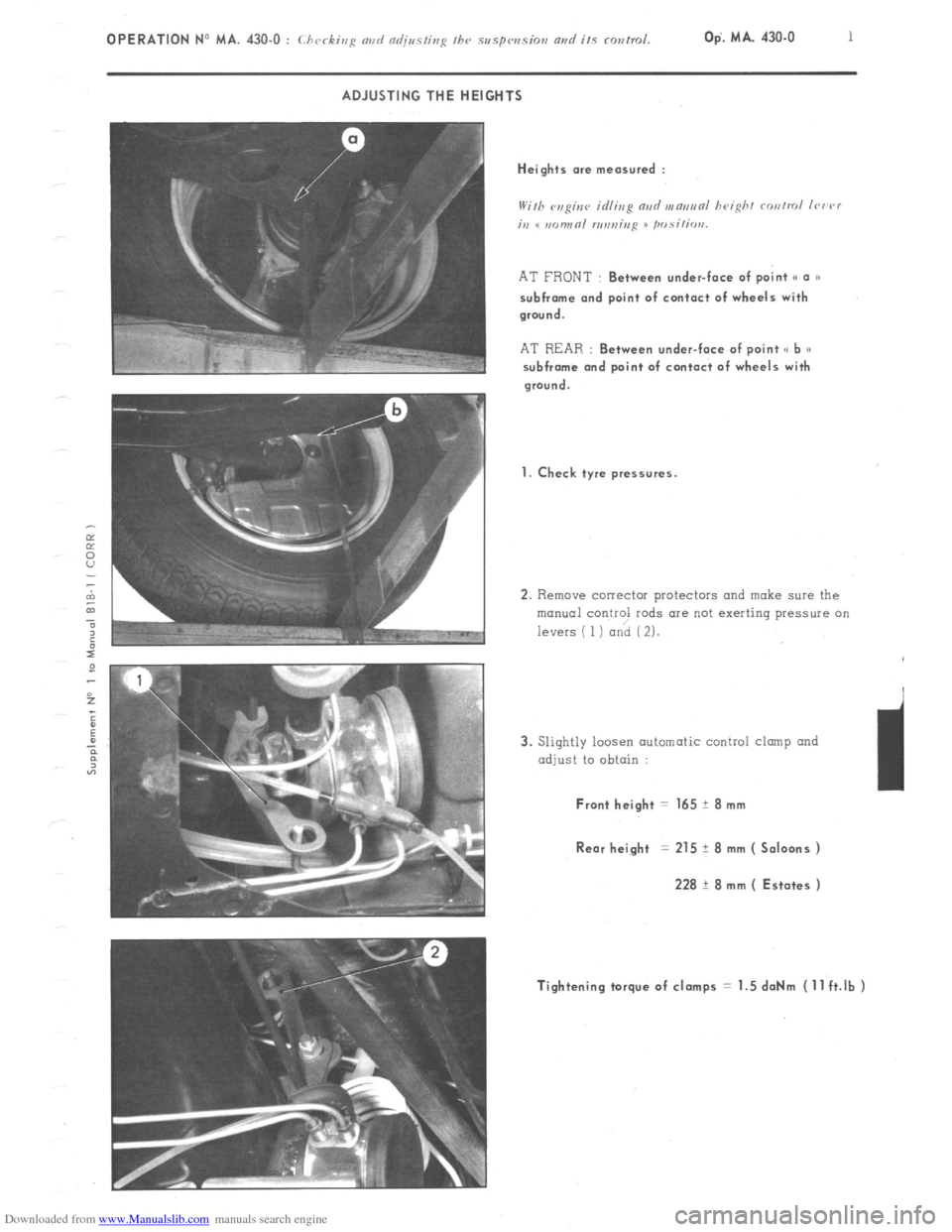

ADJUSTING THE HEIGHTS

AT FRONT : Between under-face of point (c o ))

subfrome ond point of contoct of wheels with

ground.

AT REAR : Between under-face of point <( b a)

subfrome ond point of contact of wheels with

ground.

1. Check tyre pressures.

2. Remove corrector protectors and make sure the

manual control rods are not exerting pressure on

levers ( 1) and ( 2).

3. Slightly loosen automatic control clump and

adjust to obtain :

3

Front height = 165 ? 8 mm

Rear height = 215 ? 8 mm ( Saloons )

228 t 8 mm ( Estates )

Tightening torque of clomps = 1.5 doNm (11 ft.lb )

Page 258 of 394

Downloaded from www.Manualslib.com manuals search engine 2 OPERATION No MA. 430-O : ~hwki~zg nrtd nrijustittg the suspwrsiott ntd its cotttrol

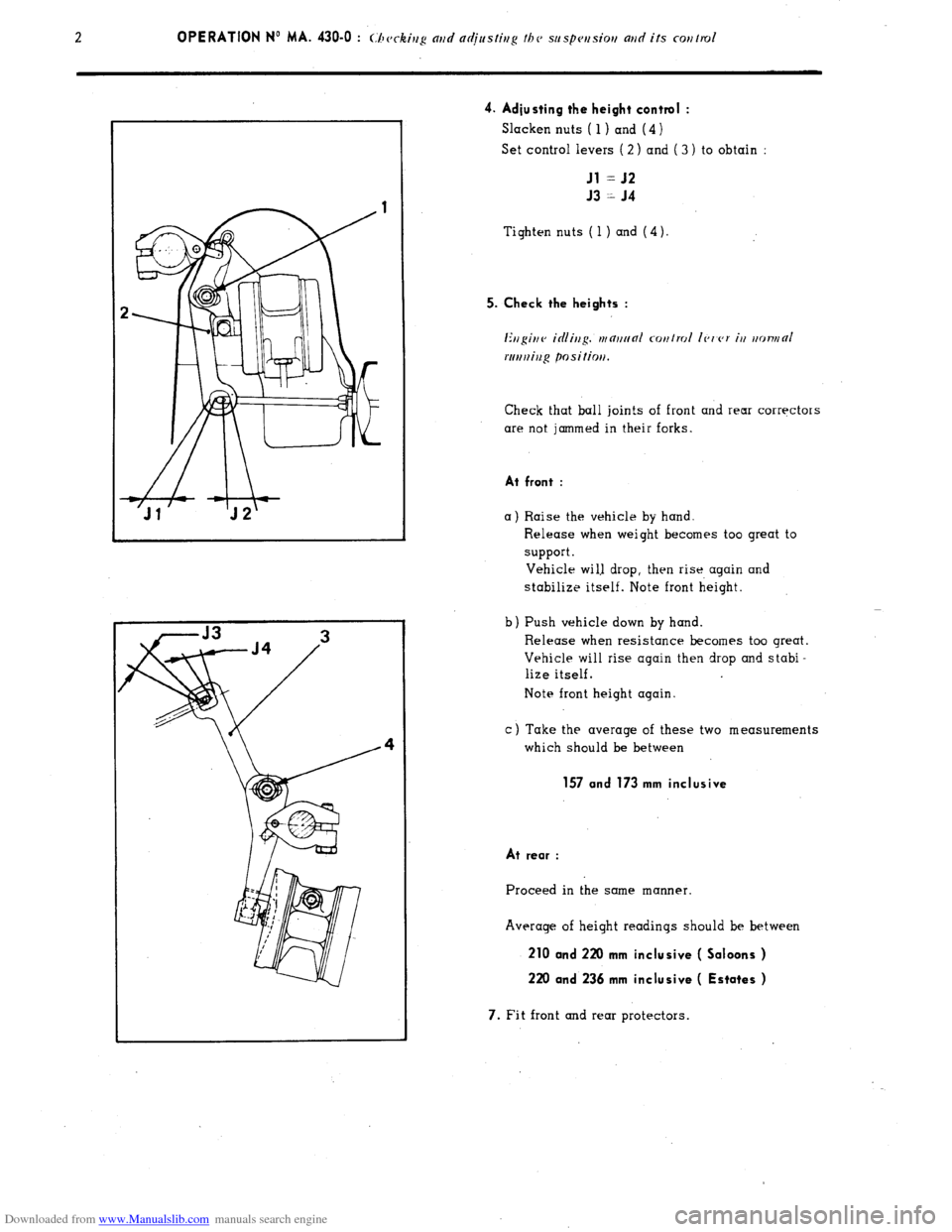

4. Adjusting the height control :

Slacken nuts ( 1) and (4 )

Set control levers ( 2 ) and ( 3 ) to obtain :

Jl = J2

J3 = J4

Tighten nuts ( 1 ) and (4).

5. Check the heights :

Ertgittv icilittg. tttnttt~nl cotttrol Ic,t’c,r itt ttotvttO/

rtrrtttiug positiott.

Check that ball join!s of front and rear corrqctors

are not jammed in their forks.

At front :

a) Raise the vehicle by hand.

b Release when weight becomes too great to

support.

Vehicle wi1.l drop, then rise again and

stabilize itself. Note front height.

Push vehicle down by hand

Release when resistance becomes too great.

Vehicle will rise again then drop and stabi-

lize itself.

Note front height again.

c) Take the average of these two measurements

which should be between

157 and 173 mm inclusive

At rear :

Proceed in the same manner.

Average of height readings should be between

210 and 220 mm inclusive ( Saloons )

220 and 236 mm inclusive ( Estates )

7. Fit front and rear protectors.

Page 283 of 394

Downloaded from www.Manualslib.com manuals search engine Op. MA. 453-O 1

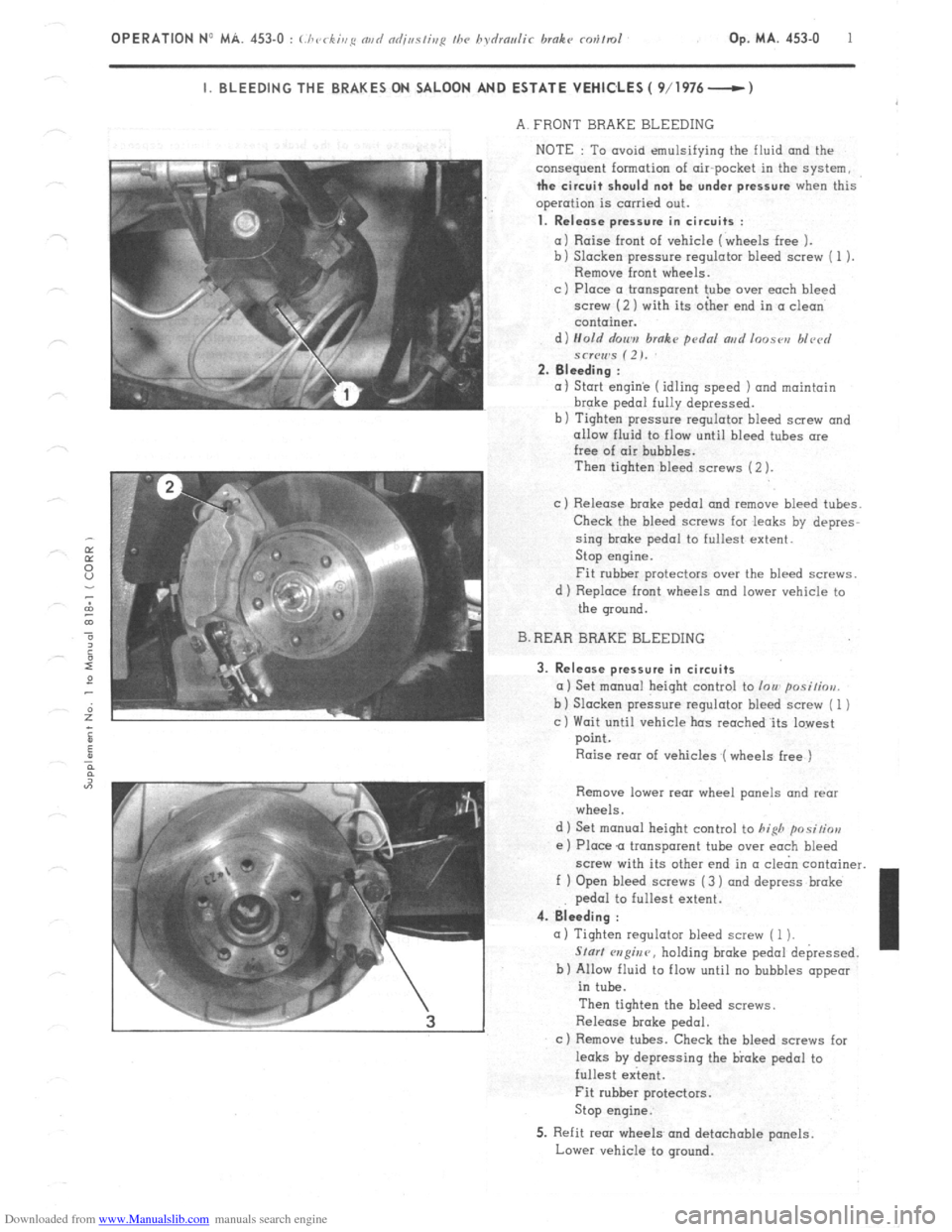

I. BLEEDING THE BRAKES ON SALOON AND ESTATE VEHICLES ( 9/1976- )

A. FRONT BRAKE BLEEDING

NOTE : To avoid emulsifying the fluid

and the

consequent formation of air-pocket in the system,

the circuit should not be under pressure when this

operation is carried out.

1. Release pressure in circuits :

a) Raise front of vehicle (wheels free 1.

b) Slacken pressure regulator bleed screw ( 1 ).

Remove front wheels.

c ) Place CI transparent tube over each bleed

screw (2 ) with its oiher end in CI clean

container.

d) Hold r/on,,,

brake pdnl ar,d loose,, blvcrl

*cr(Iws (2). 2. Bleeding :

(I 1 Start engin’e (idling speed 1 and maintain brake

pedal fully depressed.

b) Tighten pressure regulator bleed screw and

allow fluid to flow until bleed tubes ore

free of air bubbles.

Then tighten bleed screws (2 ).

c) Release broke pedal and remove bleed tubes.

Check the bleed screws for .leaks by depres-

sing brake pedal to fullest extent.

Stop engine.

Fit rubber protectors over the bleed screws.

d 1 Replace front wheels and lower vehicle to

the ground.

B. REAR BRAKE BLEEDING

3. Release pressure in circuits

a) Set monuol height control to lou posi/iou.

b 1 Slacken pressure regulator bleed screw ( 1 )

c) Wait until vehicle has reoched.its lowest

point.

Raise rear of vehicles (wheels free )

Remove lower rear wheel panels and rear

wheels.

d 1 Set manual height control to

hifih positior,

e ) Place Q transparent tube over each bleed

screw with its other end in (I cl&n container.

f ) Open bleed screws (3 ) and depress broke

pedal to fullest extent. 4. Bleeding :

(I) Tighten regulator bleed screw ( 1 1.

Slur/ w?@nr, holding broke pedal depressed.

b) Allow fluid to flow until no bubbles appear

in tube.

Then tighten the bleed screws.

Release brake pedal.

c ) Remove tubes. Check the bleed screws for

leaks by depressing the bloke pedal to

fullest extent. I

Fit rubber protectors.

Stop engine.

5. Refit rear wheels and detachable panels.

Lower vehicle to ground.

Page 284 of 394

Downloaded from www.Manualslib.com manuals search engine 2 OPERATION N” MA. 453-O : (./ ‘cc ,,,g md ndjaslisg I/w hsdrmlir hrnkr rev/m/

k.

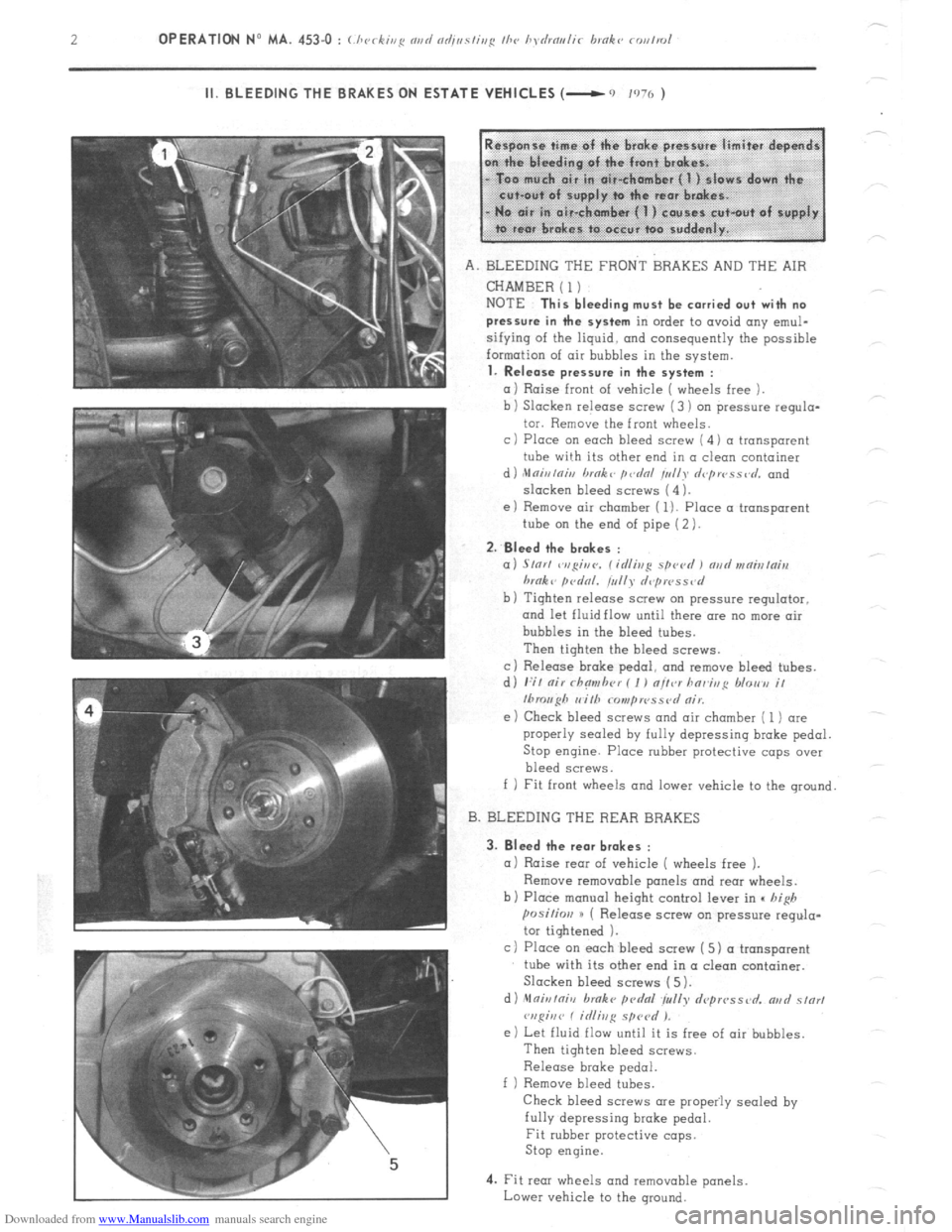

II. BLEEDING THE BRAKES ON ESTA ,TE VEHICLES (- 0 ,970 )

A. BLEEDING THE FRONT BRAKES AND THE AIR

CHAMBER ( 1)

NOTE

This bleeding must be carried out with no

pressure in the system

in order to avoid any emul-

sifying of the liquid. and consequently the possible

formation of air bubbles in the system.

1. Release pressure in the system :

a 1 Raise front of vehicle ( wheels free ).

b ) Slacken release screw (3 ) on $ressure requlo-

tor. Remove the front wheels.

c 1 Place on each bleed screw ( 4 1 a transparent

tube wi!h its other end in a clean container

d ) ,Mnir,lnh, brnk L p&d /u//y d<~pwss,~d. and

slacken bleed screws (4 ).

e) Remove air chamber ( 1). Place a transparent

tube on the end of pipe (2 ).

2.

Bleed the br.kes :

a) S/or/ ~v,gir,c,. C id/ivg spevd I md vrnialni,r

hrnk L firdnl. tullr d,~pwss<~d

b) Tighten release screw on pressure regulator.

and let fluid flow until there are no more air

bubbles in the bleed tubes.

Then tighten the bleed screws.

c) Release broke pedo1, and remove bleed tubes.

d) I:;/ nir rhnmhrr ( I ) nltcr hnr~htg /dorm i/

Ibrouph I, i/h Nmp IPSS ?,I nir.

e ) Check bleed screws and air chamber ( 1) are

properly sealed

by fully depressing brake pedal.

Stop engine. Place rubber protective caps over

bleed screws.

f 1 Fit front wheels and lower vehicle to the ground

B. BLEEDING THE REAR BRAKES

3.

Bleed the rear brakes :

a 1 Raise rear of vehicle ( wheels free ).

Remove removable panels and rear wheels.

b) Place manual height control lever in c high

posi~im H ( Release screw on pressure regula-

tor tightened 1.

c) Place on each bleed screw ( 5) a transparent

tube with its other end in a clean container.

Slacken bleed screws (5).

d) nlfliuiniv broke pcdfll ~yrrlly depwssvd. ar,d s/or,

vspiuv C idiivg sprcd ).

e) Let fluid flow until it is free of air bubbles.

Then tighten bleed screws.

Release brake pedal.

f ) Remove bleed tubes.

Check bleed screws are propeily sealed by

fully depressing broke pedal.

Fit rubber protective cops.

Stop engine.

4. Fit rear wheels and removable panels

Lower vehicle to the ground.

Page 285 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 453=0 : Ch J k’ ( c zng and adjjusfing thr hydraulk brake rontrol Op. MA. 453-O 3

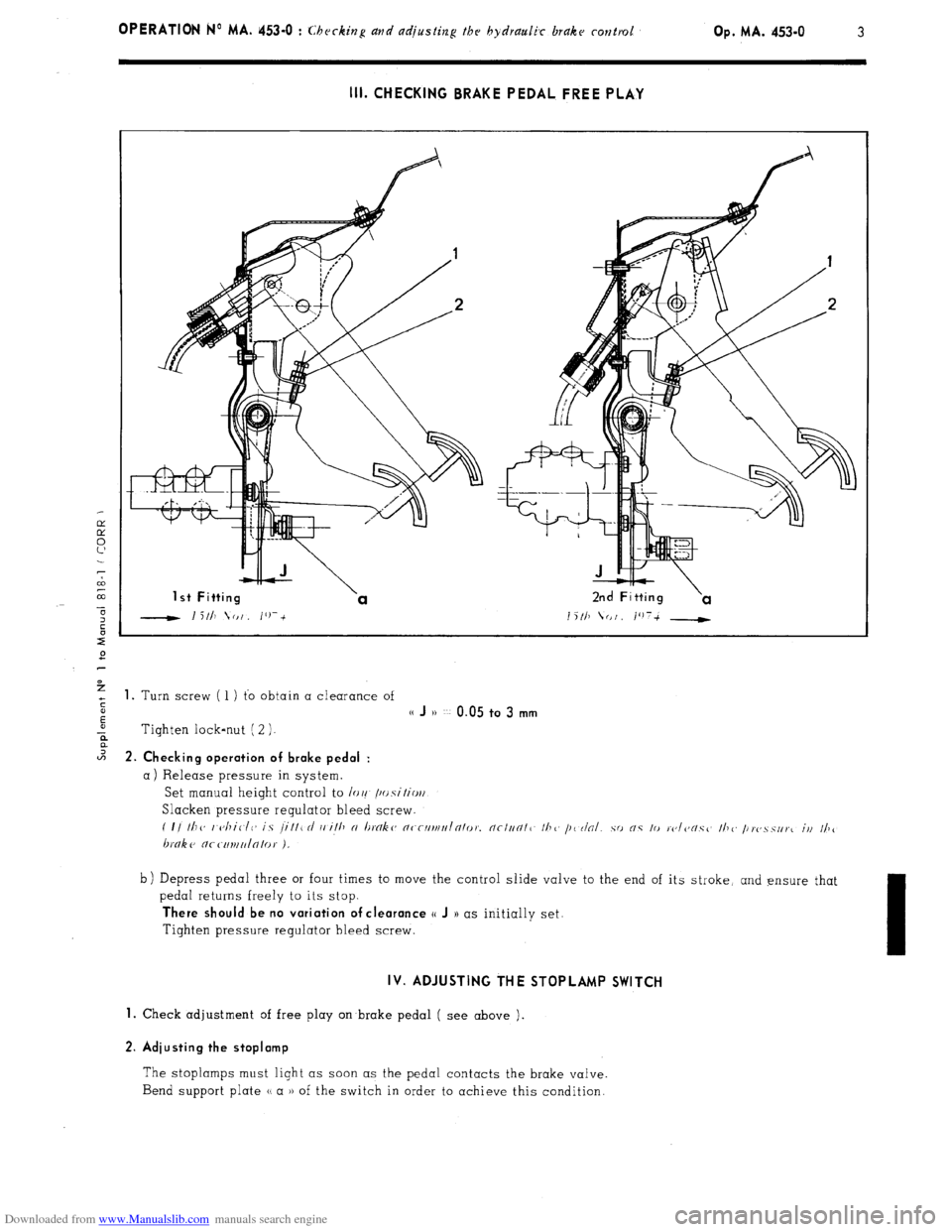

III. CHECKING BRAKE PEDAL FREE PLAY

1 st Fitting 2nd Fitting

1 5 111 (I I /‘)7-t __t i%

+ 1. Turn screw ( 1 ) to obtain a clearance of

s

E

(( J )) ~~ 0.05 to 3 mm

-ii Tighten lock-nut ( 2 ).

2 2. Ch k’ ec Ing operation of brake pedal :

a) Release pressure in system.

Set manual height control to /or! /~~.s\‘itio~/

Slacken pressure regulator bleed screw.

( I/ Ill<, I <~/liClC~ is /ill1 rl i, ill, N I~tYlk~~ n~-rllrlll,Inlo,~. nc/un/1 II?<, /I< r/al.

hnke nr c111uu/n/0,. ).

b) Depress pedal three or four times to move the control slide valve to the end of its stroke, and ensure that

pedal returns freely to its stop.

There should be no variation of clearance o J )) as initially set.

Tighten pressure regulator bleed screw.

IV. ADJUSTING THE STOPLAMP SWITCH

1.

Check adjustment of free play on brake pedal ( see above ).

2. Adiusting the stoplamp

The stoplamps must light as soon as the pedal contacts the brake valve.

Bend support plate u a )) of the switch in order to achieve this condition.

Page 358 of 394

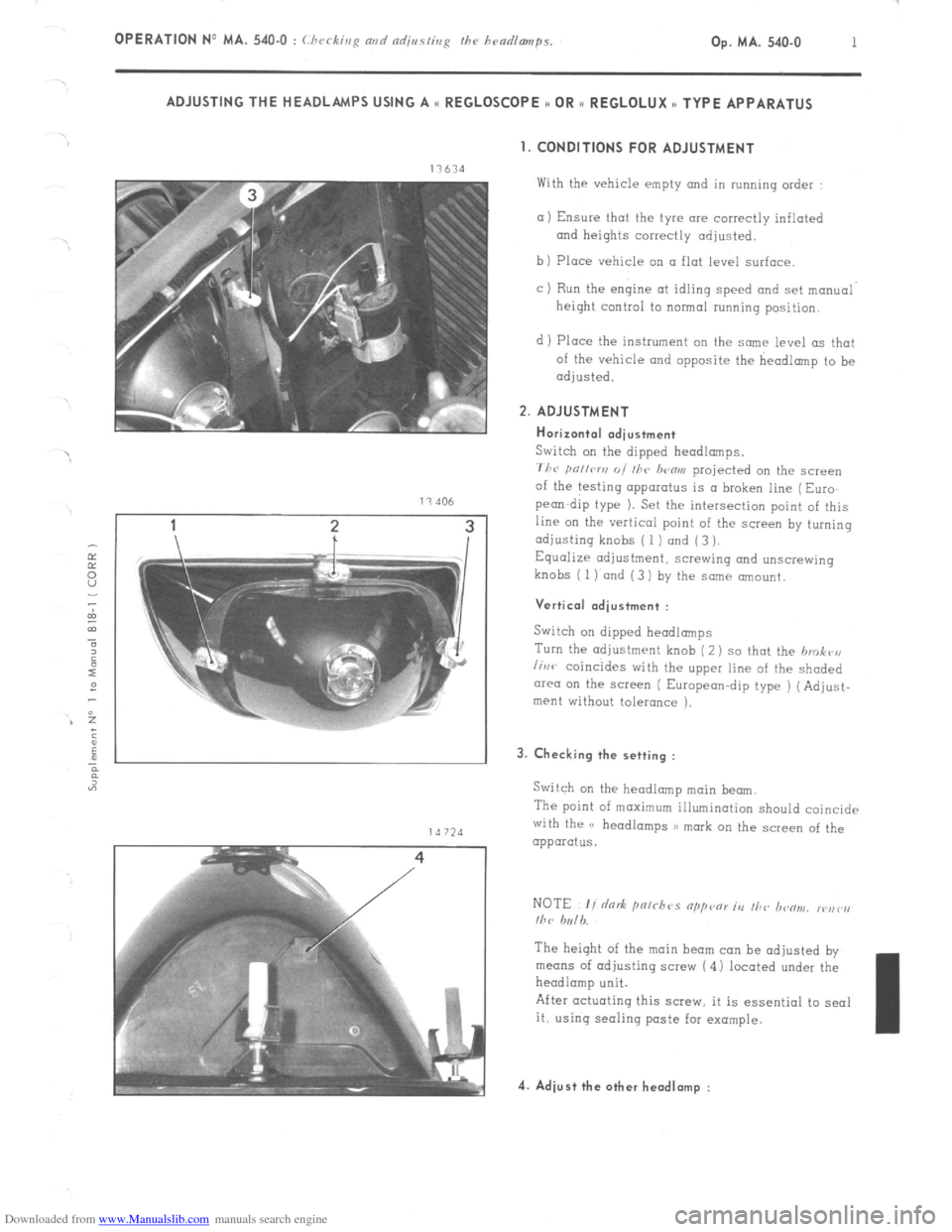

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 540-O : (hcrking and diusfing the hradlmnps. Op. MA. 540.0 1 ADJUSTING THE HEADLAMPS USING A << REGLOSCOPE >> OR I< REGLOLUX n TYPE APPARATUS

I. CONDITIONS FOR ADJUSTMENT

With the vehicle empty and in running order :

a) Ensure that the tyre ore correctly inflated

and heights correctly adjusted.

Place vehicle on CI flat level surface.

Run the engine at idling speed and set manual.

height control to normal running position.

1 Place the instrument on the same level as that

of the vehicle and opposite the headlamp to be

adjusted. 2. ADJUSTMENT

Horizontal adiustment

Switch on the dipped headlamps.

711~ pn,lcrv 01 111~ lwflrn projected on the screen

of the testing apparatus is a broken line (Euro

pea-dip type 1. Set the intersection point of this

line on the vertical point of the screen by turning

adjusting knobs ( 1 ) and (3 ).

Equalize adjustment, screwing and unscrewing

knobs (

1) and (3 1 by the same amount.

Vertical .dius+ment :

Switch on dipped headlamps

Turn the adjustment knob (2) so that the hrokr’n

lirw coincides with the upper line of the shaded

cwea on the screen ( European-dip type ) (Adjust-

ment without tolerance ). 3. Checking the setting :

Switch on the headlamp main beam.

The point of maximum illumination should coincide

with the (’ headlamps 3) mark on the screen of the

apparatus.

The height of the main beam can be adjusted by

means of adjusting screw (4 1 located under the

headlamp unit.

After actuating this screw, it is essential to seal

it, using seoling paste far example. 4. Adiust the other headlamp :

Page 361 of 394

Downloaded from www.Manualslib.com manuals search engine AIR-CONDITIONING

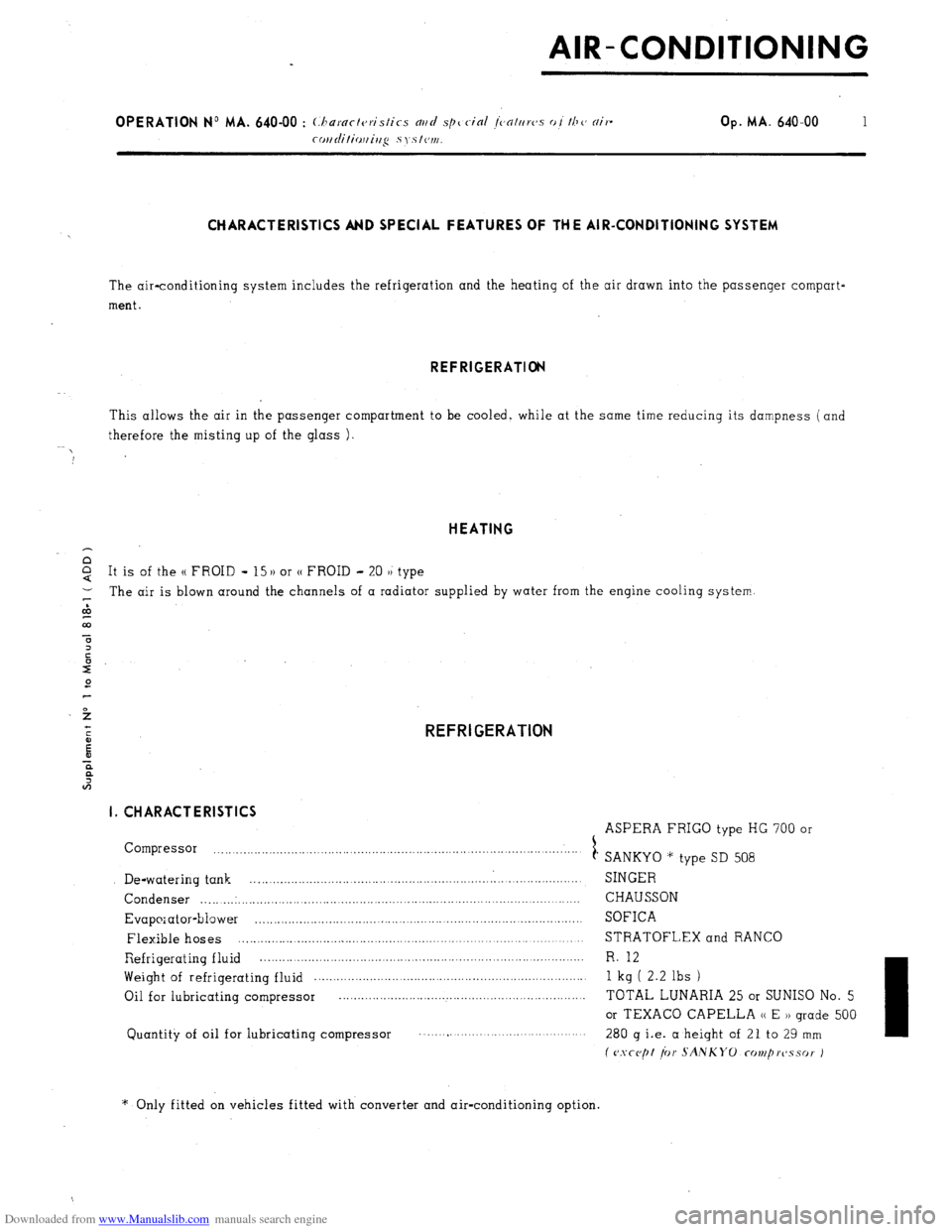

CHARACTERISTICS AND SPECIAL FEATURES OF THE AIR-CONDITIONING SYSTEM

The air-conditioning system includes the refrigeration and the heating of the air drawn into the passenger compart-

ment. REFRIGERATION

This allows the air in the passenger compartment to be cooled, while at the same time reducing its dampness (and

therefore the misting up of the glass ) HEATING

It is of the (( FROID - 15)) or (( FROID - 20 )) type

1 The air is blown around the channels of a radiator supplied by water from the engine cooling system.

&

co

5

3

t

E REFRIGERATION

E I. CHARACTERISTICS

ASPERA FRIGO type HG 700 or

Compressor

1 .

SANKYO * type SD 508

De-watering tank . SINGER

Condenser _.. ._..: _._...... . . . . . . . . . . . CHAUSSON

Evaporator-blower , SOFICA

Flexible hoses ..,_.,....,............................................................................... STRATOFLEX and RANCO

Refrigerating fluid . R. 12 Weight

of refrigerating fluid _..._.._._._..,_..__.................................................... 1 kg ( 2.2 lbs )

Oil for lubricating compressor TOTAL LUNARIA 25 or SUNISO No. 5

or TEXACO CAPELLA (( E )) grade 500

Quantity of oil for lubricating compressor ,

280 g i.e. a height of 21 to 29 mm

f

CJSCC,~~ ior SANKYO UIVI~WSSO~ J

* Only fitted on vehicles fitted with converter and air-conditioning option.