wheel Citroen CX 1981 1.G User Guide

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1981, Model line: CX, Model: Citroen CX 1981 1.GPages: 394

Page 60 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION N” MA. 100-00 : (:hnractc,ri.stics arid specinl j(,atrlres o,/ the> cl,gi?lcJ. Op. MA. 100-00 1

9

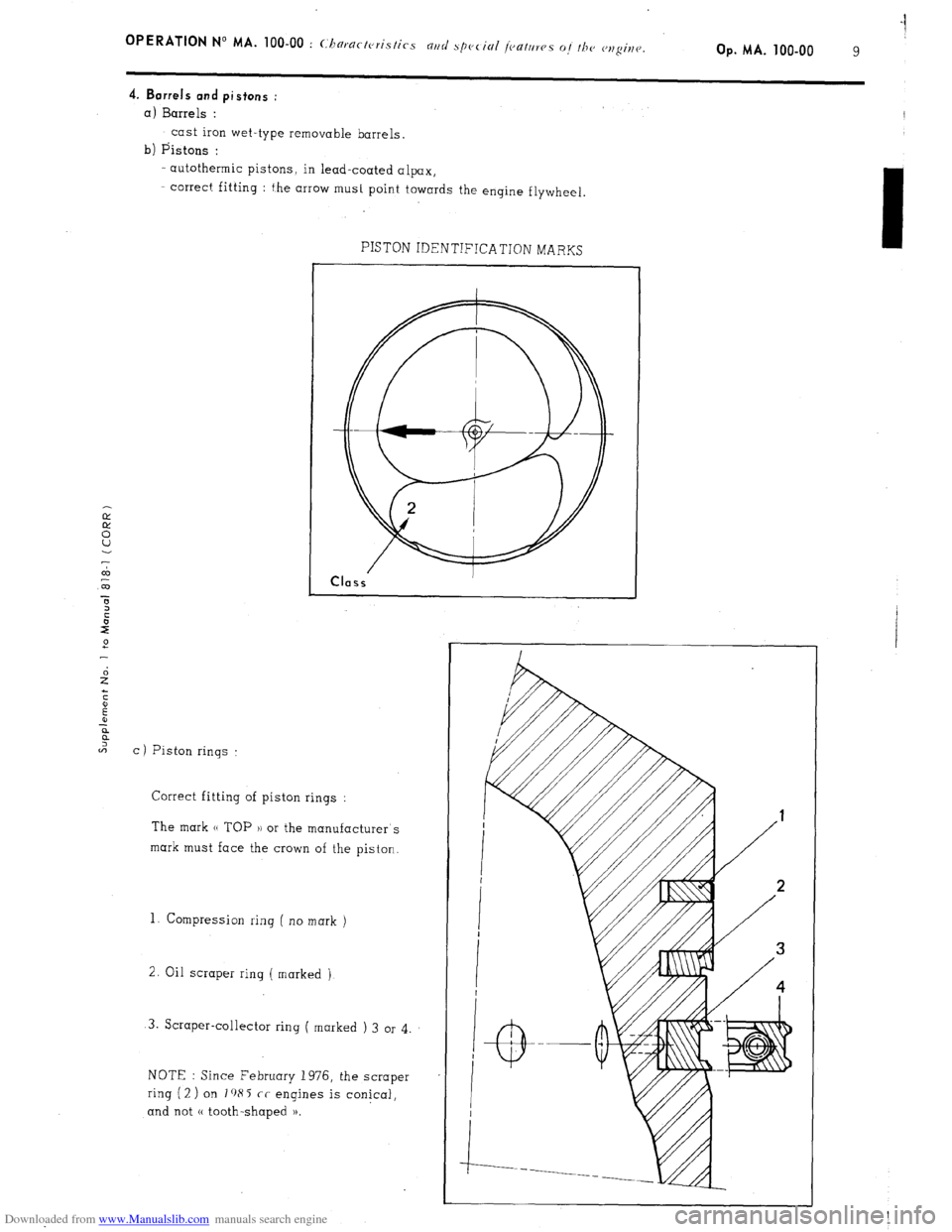

4. Barrels and pistons :

a)

Barrels :

cast iron wet-type removable barrels.

b) Pistons :

-- autothermic pistons, in lead-coated alpax,

- correct fitting : the arrow must point towards the engine flywheel

7

co

m

C ) Piston rings : PISTON IDENTIFICATION MARKS

Correct fitting of piston rings :

The mark (( TOP 1) or the manufacturer’s

mark must face the crown of the piston.

1. Compression ring ( no mark )

2. Oil scraper ring ( marked )

3. Scraper-collector ring ( marked ) 3 or 4

NOTE : Since February 1976, the scraper

ring (2 ) on I a85 cc engines is conical,

and not (( tooth-shaped )).

Page 66 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 100-00 : Characteristics and special features of the engine. Op. MA. 100.00 15

b) Timing chain :

- Clearance between the chain and the chain guide : . . . . . . . . . . . . . . . . . . . . . . . . . . 0.10 to 0.50 mm

c) Rockers :

- Length of push rods :

- Inlet : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189.10 ‘, Og’Q5 mm

- Exhaust : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213.35 + 0.3

- 0.75 mm

- Maximum out of true of pushrods : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 mm

- Rocker clearance (engine cold) :

-Inlet : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.15mm

- Exhaust : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.20 mm

7. Flywheel :

2 - Distance between the clutch mechanism thrust face, and the 0 u clutch disc thrust face : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.5 -is mm

7

co

G NOTE : It is essential to fit the diaphragm or flywheel mounting screws with LOCTITE FRENETANCH.

x

z - Correct fitting of starter ring : non machined face of the ring facing the flywheel shouldering.

s

2

E 8. Lubrication system :

5

z

6%

- Grade of oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TOTAL ALTIGRADE GTS 20/W 50

2

- Capacity of sump :

- after dismantling : . . . . . . . .._................................................................. 5.800 litres ( IO.2 pts )

- after draining and changing the filter : : . . . . . . . . . . . . . . . l......................... 5.306 litres ( 9.3 pts )

- after draining : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.650 litres ( 8.2 pts )

- Oil pressure :

(At a temperature of 100 +‘S’ C)

- at 2000 rpm : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 .bar min. ( 43.5 psi )

- at 4000 rpm : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 to 5 bar ( 58 to 72 l/2 psi )

- Calibration of pressure switch : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 475 to 675 mbar ( 7 to 9.8 psi )

(warning lamp goes oat)

- Calibration of temperature switch (CX 2000 e Jan. 1975) : . . . . 1... 147’ to 150’ C

(warning lamp goes comes on)

(All CX vehicles Jan. 1975 -) : 135” to 138’ C

(warning lamp comes on )

- Calibration of relief valve spring :

- length of spring fully compressed : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 mm

- length of spring under load of 10.9 kg : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 mm

- Filter cartridge :

- calibration of (( by-pass )) valve : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 550 mbar ( 8 psi )

NOTE : When changing the filter cartridge, check the cleanliness of the seal and’the contact area on the filter

housing.

- For removing and fitting the cartridge : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Use Tool 6002-T

Page 69 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 112-O : ChcJcking and adjusting the valrv mechanism. Op. MA. 112-O

1

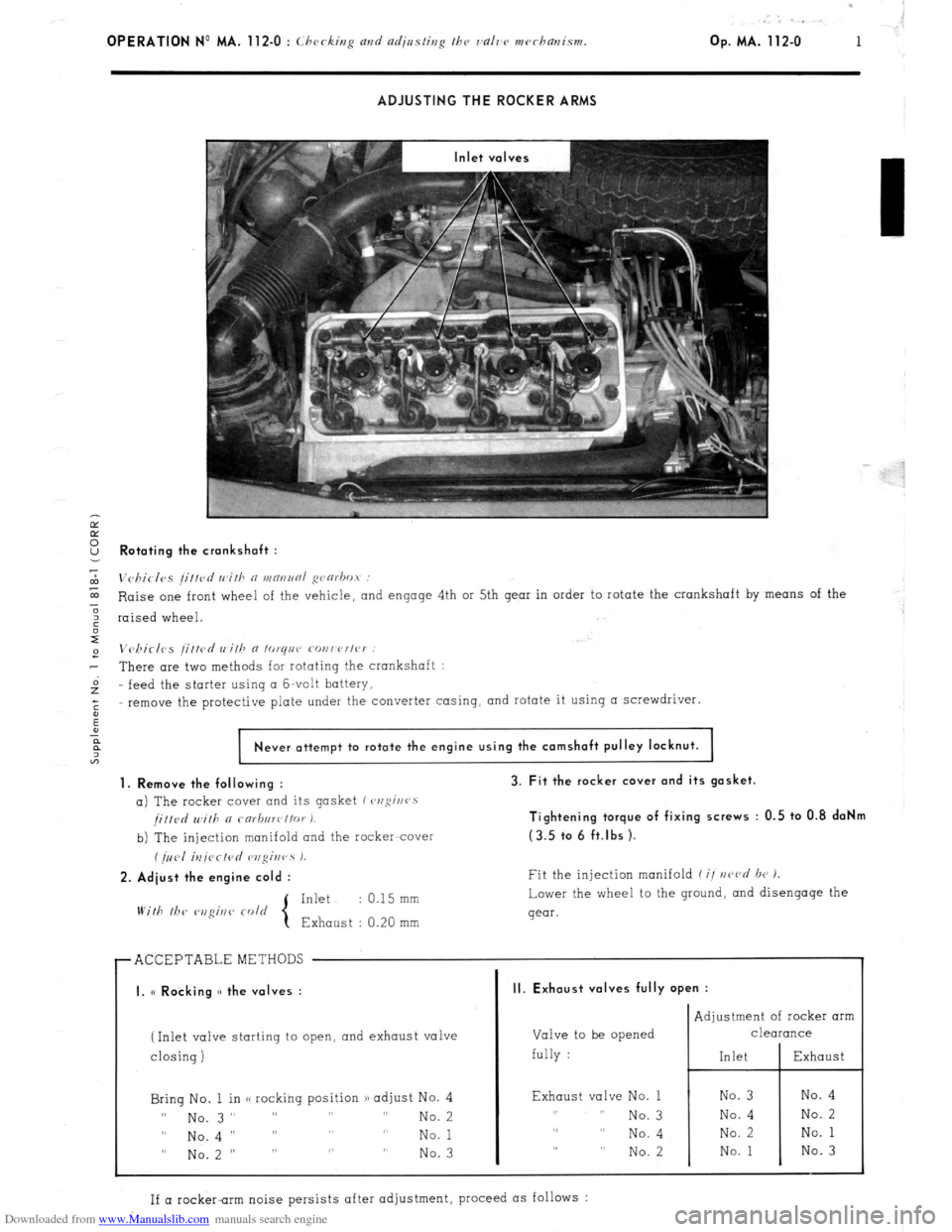

ADJUSTING THE ROCKER ARMS

Ir

E

2 Rotating the crankshaft :

7

m

Vc,birlvs /i//cd wifh n WRIINRI ~varbot :

E Raise one front wheel of the vehicle,

and engage 4th or 5th gear in order to rotate the crankshaft by means of the

3

6 raised wheel.

I

e Vchirlcs /ittcd wilh a lo~qnr covwrlc~ :

- There are two methods for rotating the crankshaft :

Gz feed the

starter using CI G-volt battery,

;

remove the protective plate under the converter casing, and rotate it using a screwdriver.

:

Never attempt to rotate the engine using the camshaft pulley locknut.

1. Remove the following :

a) The rocker cover and its gasket (~,ofii~rr~s

/i//d Will, a rarb,,wt/or I.

b) The injection manifold and the racker-cover

(/,,<,I iU/<~CfPd r,zgir,rs 1.

2. Adiust the engine cold :

Inkt : 0.15 mm

With lb<‘

3. Fit the rocker cover and its gasket.

Tightening torque of fixing screws : 0.5 to 0.8 daNm

(3.5 tc. 6 ft.lbs ).

Fit the injection manifold f i/ nczvd br 1.

Lower the wheel to the ground,

and disengage the

gear.

r ACCEPTABLEMETHODS

I I

I. (< Rocking )> the valves :

(Inlet valve starting to open, and exhaust valve

I

closing) closing)

Bring No. 1 in <, rocking position /) adjust No. 4 Bring No. 1 in <, rocking position /) adjust No. 4

II II

No. 3” ” ” ” No. 3” ” ” ” No. 2 No. 2

0 0

No.4 I’ ” ” ” No.4 I’ ” ” ” No. 1 No. 1

” No.2 ” ” ” ” ” No.2 ” ” ” ” No. 3 No. 3

II. Exhaust valves fully open :

Valve to be opened

fully : Adjustment of rocker arm

CleUKUlCe

Exhaust valve No. 1

,, I, No. 3

,, ,, No. 4

,, ,, No. 2

If a rocker-rim noise persists after adjustment, proceed as follows :

Page 71 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 120.0 : Chrrki,,~ the /iminp. Op. MA. 120-O 1

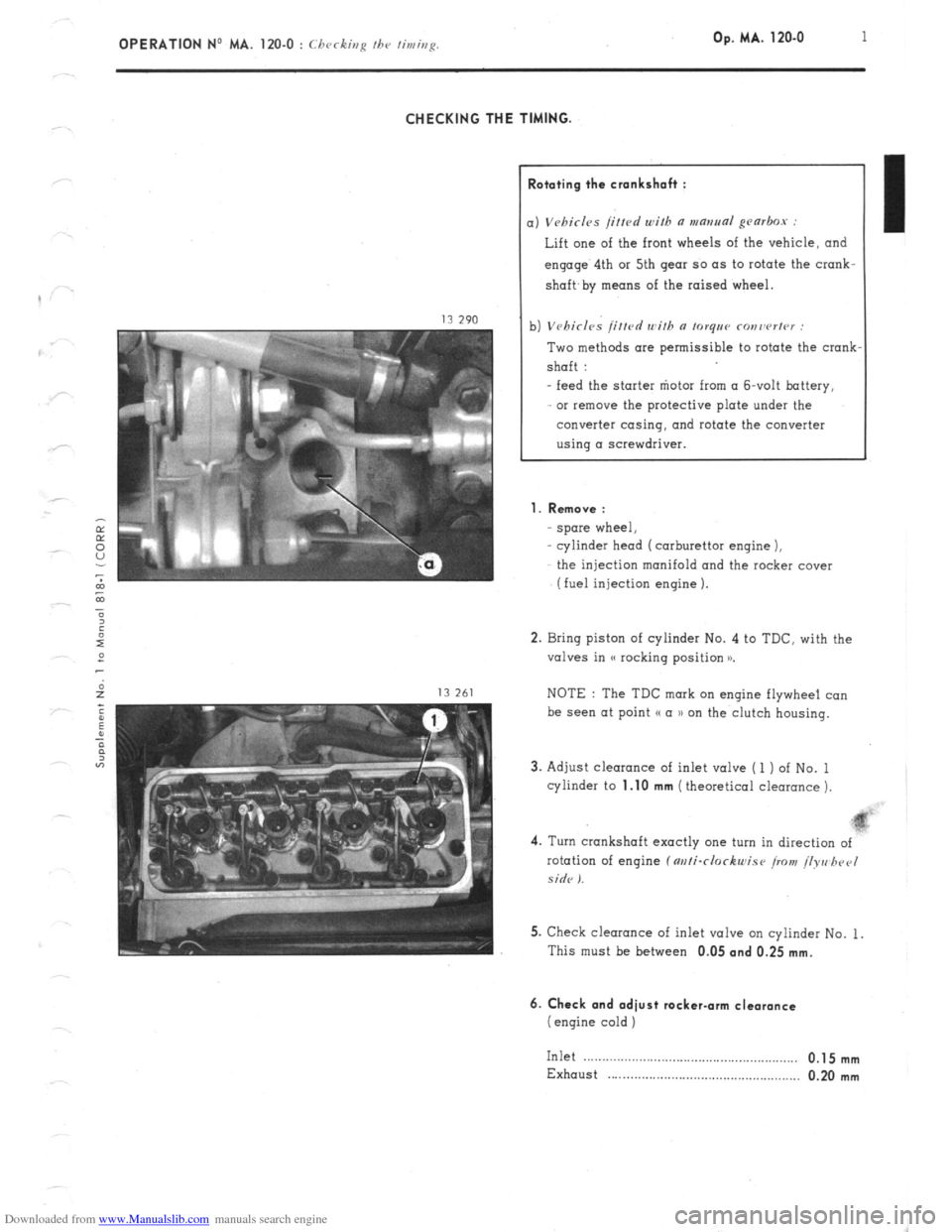

CHECKING THE TIMING.

lototing the crankshah :

) Vebirl~s /i/fed with a mantra~ gearbox :

Lift one of the front wheels of the vehicle, and

engage’ 4th or 5th gear so as to rotate the crank-

shaft,

by means of the raised wheel.

1) Vehicles /itted with n torqee ronrwrter :

Two methods are permissible to rotate the crank

shaft :

- feed the starter “iota from (I &volt battery,

or remove the protective plate under the

converter casing, and rotate the converter

using a screwdriver.

1. Remove :

spore wheel,

cylinder head (carburettor engine 1,

the injection manifold and the rocker cover

(fuel injection engine 1.

2. Bring piston of cylinder No. 4 to TDC. with the

valves in (( rocking position x

NOTE : The TDC mark on engine flywheel co”

be see” at point (( a )) on the clutch housing.

3. Adjust clearance of inlet valve ( 1 ) of No. 1

cylinder to

1.10 mm (theoretical clearance 1.

4. Turn crankshaft exactly one turn in direction of

rotation of engine f m/i-clockwise iro>t! /lyre hpel

side I.

5. Check clearance of inlet valve on cylinder No. 1.

This must be between 0.05

and 0.25 mm.

6. Check and adiust rocker-arm clearance

(engine cold )

Inlet .__....__.............................................,.,, 0.1 5 mm

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.20 mm

Page 152 of 394

Downloaded from www.Manualslib.com manuals search engine IGNITION

OPERATION N’ MA. 210-00 : (:horr/r/c,ri.s/ics nrtrl spccinl /C,O/UTCJS of /he igtti/ioe Op. MA. 210-00 1 M 20/616

M 22/617 M 23/623 ENGINES

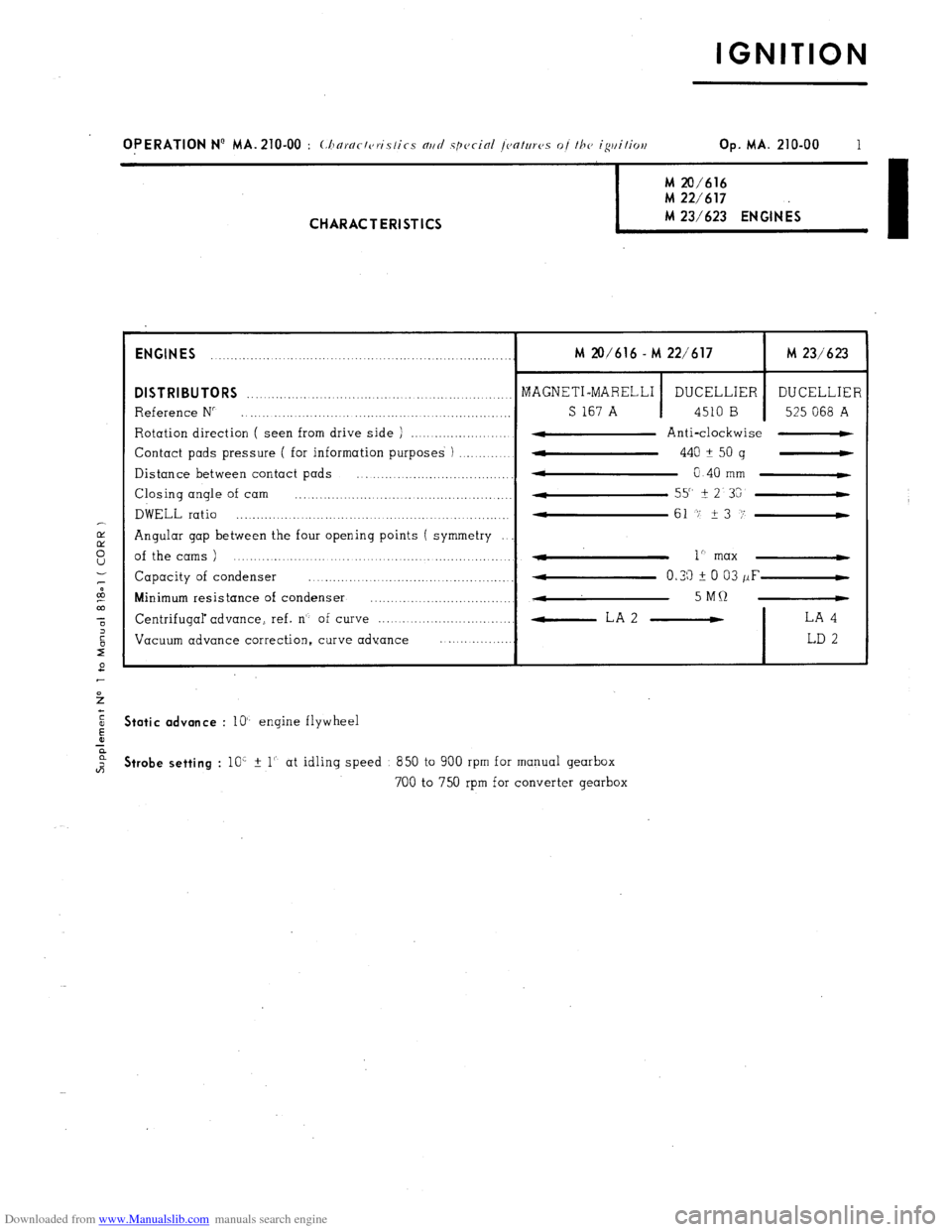

I CHARACTERISTICS

ENGINES

........ ........... ................................................. M 20/616 - M 22/617 M 23/623

DISTRIBUTORS ........................................... MAGNETI-MARELLI _._ ..............

DUCELLIER DUCELLIER

Reference N” ........................... .., ............................. _._ S 167 A 4510 B 525 068 A

Rotation direction ( seen from drive side ) ....................... 4 Anti-clockwise -

Contact pads pressure ( for information purposes ) ..............

w 440 A

50 g -

Distance between contact pads

* ................................... 0 40 mm C

Closing angle of cam ................... .................................. 55" It

2 3G

DWELL ratio ............................................... 4

....... .......... 61 -7 23 i’-

Angular gap between the four opening points ( symmetry

of the cams ) ....................................................... - 1” max 4

Capacity of condenser ......... ... ............... ...... ........ 4 0.33 i 0 03 /IF-

Minimum resistance of condenser ...............................

., ...

4 5MQ -

Centrifugal advance, ref. n’- of curve ................................. -LA2 - LA 4

Vacuum advance correction, curve advance ..................

LD 2 Static advance

: lo’- engine flywheel Strobe setting

: 10’ % 1’. at idling speed 850 to 900 rpm for manual gearbox

700 to 750 rpm for converter gearbox

Page 155 of 394

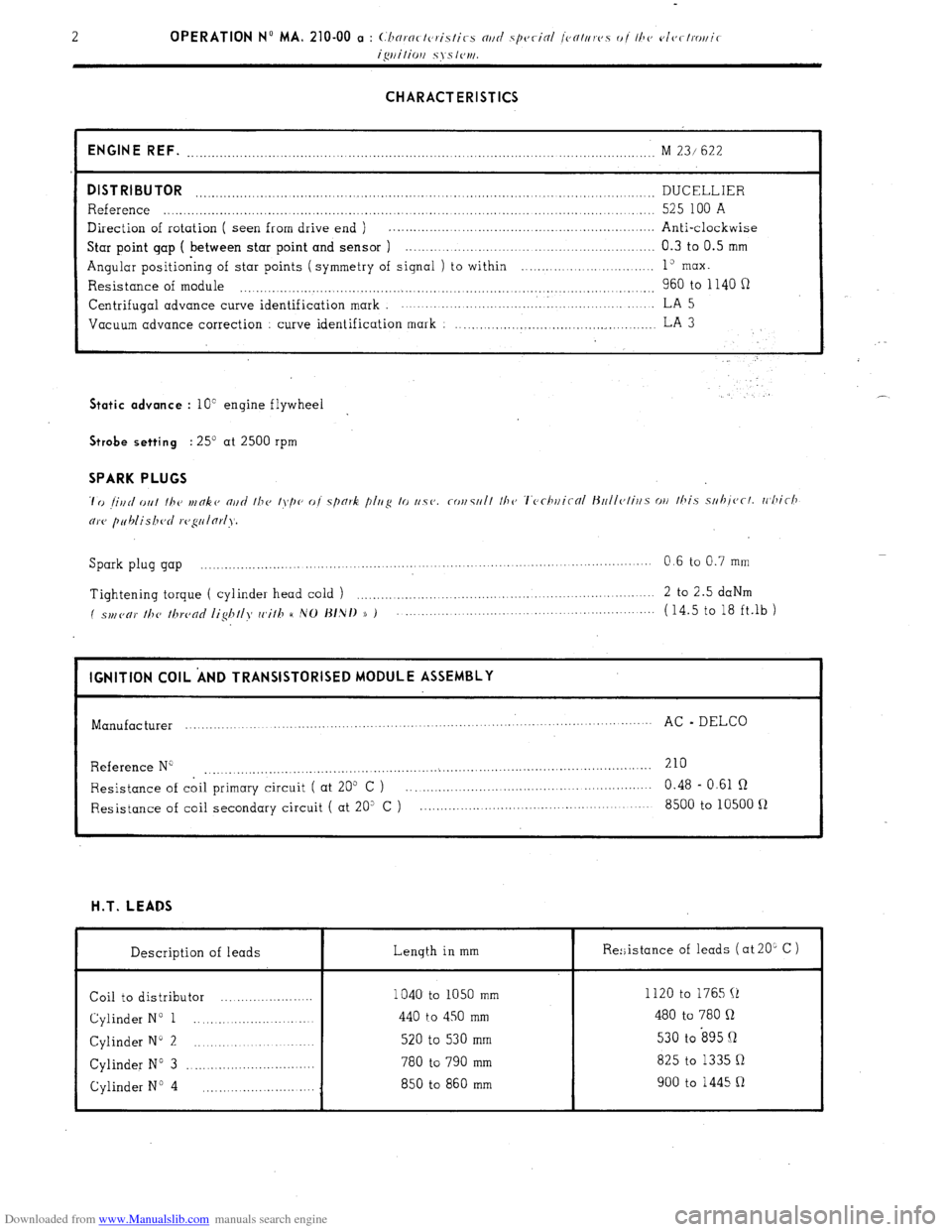

Downloaded from www.Manualslib.com manuals search engine CHARACTERISTICS

ENGINE REF.

........................................................................................... ........................ M 23/ 622

DISTRIBUTOR DUCELLIER ..................................................................................................................

Reference ..................................................................................................................... 525 100 A

Direction of rotation ( seen from drive end ) . .................................................................

Anti-clockwise

Star point gap ( between star point and sensor ) .............................................................. 0.3 to 0.5 mm

Angular positioning of star points ( symmetry of signal ) to within ........... ... ... ....... ..... 1” max.

Resistance of module 960 to 1140 fi .................................................................................................. Centrifugal

advance curve identification mark ................................. . ..................... LA 5

Vacuum advance correction

curve identification mark : ..................................................

LA 3 Static advance

: 10” engine flywheel . .’ Strobe setting

: 25’ at 2500 rpm SPARK PLUGS

Spark plug gap ................. ....

.................... ................... ....... 0.6 to 0.7 mm

......................... .........

Tightening torque ( cylinder head cold ) ....................................................................

2 to 2.5 daNm

( spl,(,c,)’ //T(, /hrc,nc/ /ig/T//>f cc,i//T H ,VO J~/,N/) )) ) ...................................................... (14.5 to 18 ft.lb )

I IGNITION COIL ‘AND TRANSISTORISED MODULE ASSEMBLY

I

Manufacturer ...............

................... ........ .............. .............. .......

AC - DELCO

...........................

Reference N” 210

....................................................... ...

....................................................

Resistance of coil primary circuit ( at 205 C ) ............................................................ 0.48 - 0.61 R

Resistance of coil secondary circuit ( at 20” C ) ......................................................... 8500 to 10500 fl H.T. LEADS

Description of leads Length in mm

Coil to distributor ....................... 1040 to 1050 mm

Cylinder N” 1 ............................ 440 to 450 mm

Cylinder N” 2 ............................. 520 to 530 mm

Cylinder N” 3 ................................ 780 to 790 mm

Cylinder No 4 850 to 860 mm

............................ Re:;istance of leads ( at 20L C )

I

1120 to 1765 (1

480 to 780 Q

530 to s95 Q

825 to 1335 Q

900 to 1445 R

Page 156 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION NO MA. 210-o : chcJckir,R fl,,d fld;linshp the, iRrlihil Op. MA. 210-O 1

M 20/616 M 22/617

M 23/623

ENGINES

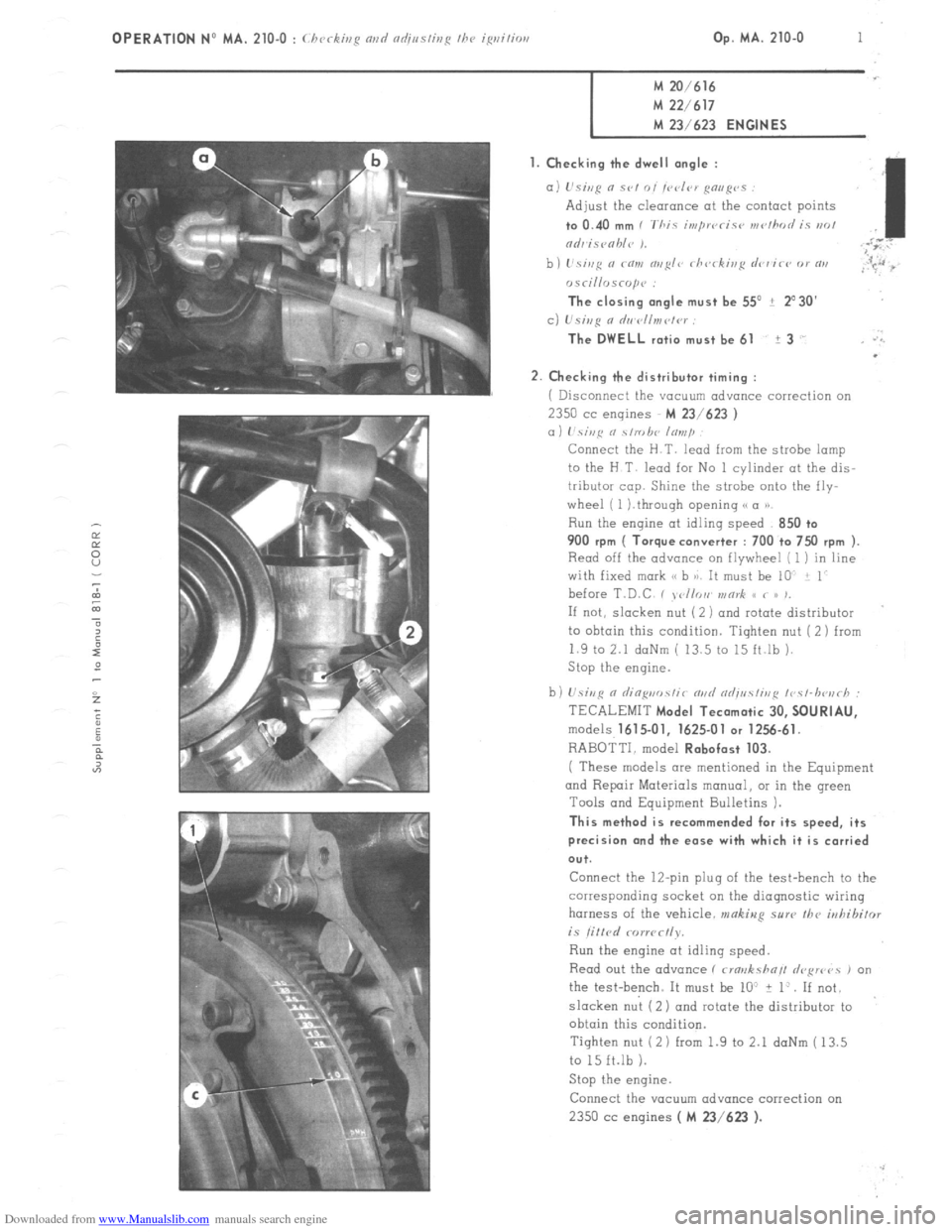

1. Checking the dwell angle :

a) L’siep n SC,, 0, /C‘d‘,V gmg’s

Adjust the clearonce at the contact points to 0.40

mm I ‘Thic in,pwcic~~ wc,/hod iy PK,!

,I

ndr isvohle 1. ;i”

b) I’si,,fi a co,,, o,,~I<~ rh<,rkis~ drr’ir<, or RI,

,r 5.~~ :s

osri//risrop<~ :

The closing angle must be 55’ ? 2’30’

c) L’si,,g 0 d,,~r~ll,,,ct<~r :

The DWELL

ratio must be 61 i 3 .’ .‘.

.

2.

Checking the distributor timing :

i Disconnect the vacuum advance correction on 2350

cc engines M 23/623 )

a) hi,,c o \/robe lo,,,/~

Connect the H.T. lead from the strobe lamp

to the H T lead for No 1 cylinder at the dis-

tributor cop. Shine the strobe onto the fly-

wheel ( 1 ).through opening (( a P)

Run the engine at idling speed 850 +o 900

rpm ( Torque converter : 700 to 7x) rpm ).

Read off the advance on flywheel [ 1 ) in line

with fixed mark (< b 8). It must be 10 i 1

before T.D.C , , <,//or, v,or& S< < /> ,,

If not, slacken nut ( 2 ) and rotate distributor

to ohtoin this condition. Tighten nut (2) from

1.9 to 2.1 daNm ( 13.5 to 15 ft.lb ).

Stop the engine.

b) U.sivR n riin~uo.~~ir m,d od;uc!ir,,~ ~r~c~-lwu~h :

TECALEMIT

Model Tecamatic 30, SOURIAU,

models 1615.01, 1625-01 or 1256.61.

RABOTTI. model Robofast 103.

( These models are mentioned in the Equipment

and Repair Materials manual, OI in the green

Tools and Equipment Bulletins 1.

This method is recommended for its speed, its

precision and the ease with which it is carried

ou+.

Connect the 12-pin plug of the test-bench to the

corresponding socket on the diagnostic wiring

harness of the vehicle. makiug sure the

irrhibifor is litlrd rorwc~ly.

Run the engine at idling speed.

Read out the advance ( rma>rksha// drFwvs , on

the test-bench. It must be lo” + 1:. If not.

slacken nut (2) ond rotate the distributor to

obtain this condition.

Tighten nut (2 1 from 1.9 to 2.1 daNm ( 13.5

to 15 ft.lb 1.

Stop the engine.

Connect the YOCUU~ advance correction on 2350 cc

engines ( M 23/623 ).

Page 159 of 394

Downloaded from www.Manualslib.com manuals search engine 4 OPERATION No MA. 210-O : (hcrkir,p or,

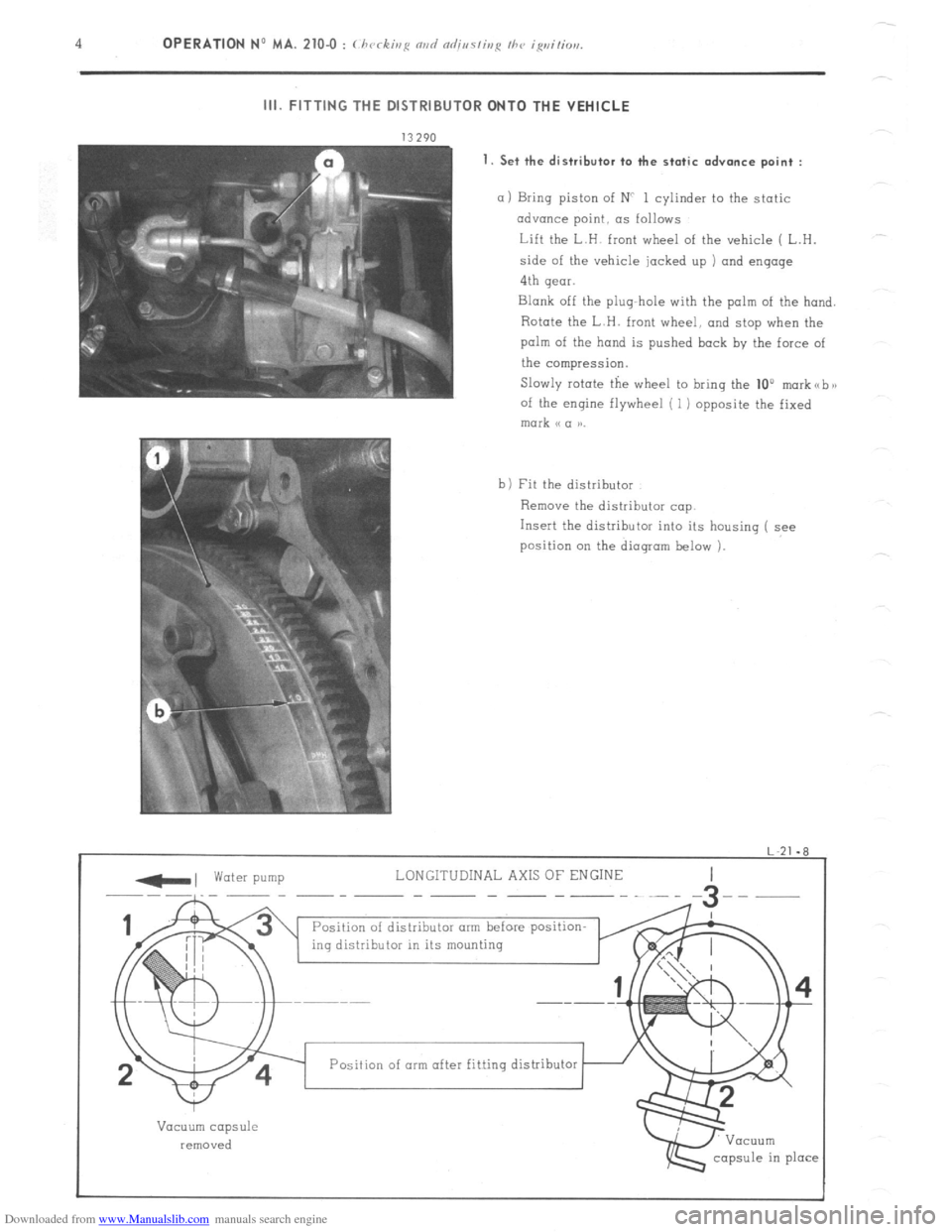

III. FITTING THE DISTRIBUTOR ONTO THE VEHICLE

1. Set the distributor to the static

advance point :

a 1 Bring piston of NC 1 cylinder to the static

advance point, as follows

Lift the L.H. front wheel of the vehicle ( L.H.

side of the vehicle jacked up ) and engage

4th gear.

Blank off the plug-hole with the palm of the hand.

Rotate the L.H. front wheel, and stop when the

palm of the hand is pushed back by the force of

the compression.

Slowly rotate the wheel to bring the 10”

morkabx

of the engine flywheel ( 1) opposite the fixed mark (c a aa.

b) Fit the distributor

Remove the distributor cap.

Insert the distributor into its housing ( see

position on the dioqram below 1.

-, water pump LONGITUDINAL AXIS OF ENGINE

--~-__ -- -- ----~--

Position of distributor arm before position-

ing distributor in its mounting

I

w

Vacuum capsule

removed

capsule in place Position of arm after fitting distributor

Page 161 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 210-O a : C/ ‘CC ,r,,q rind ndj,,s/isp I/W ~~/<~c-/mr,ir ip,itior, 5?‘.5/‘.,11 k’ Op. MA. 210-O a 1

M 23/622 ENGINE

I. CHECKING THE IGNITION OM THE VEHICLE

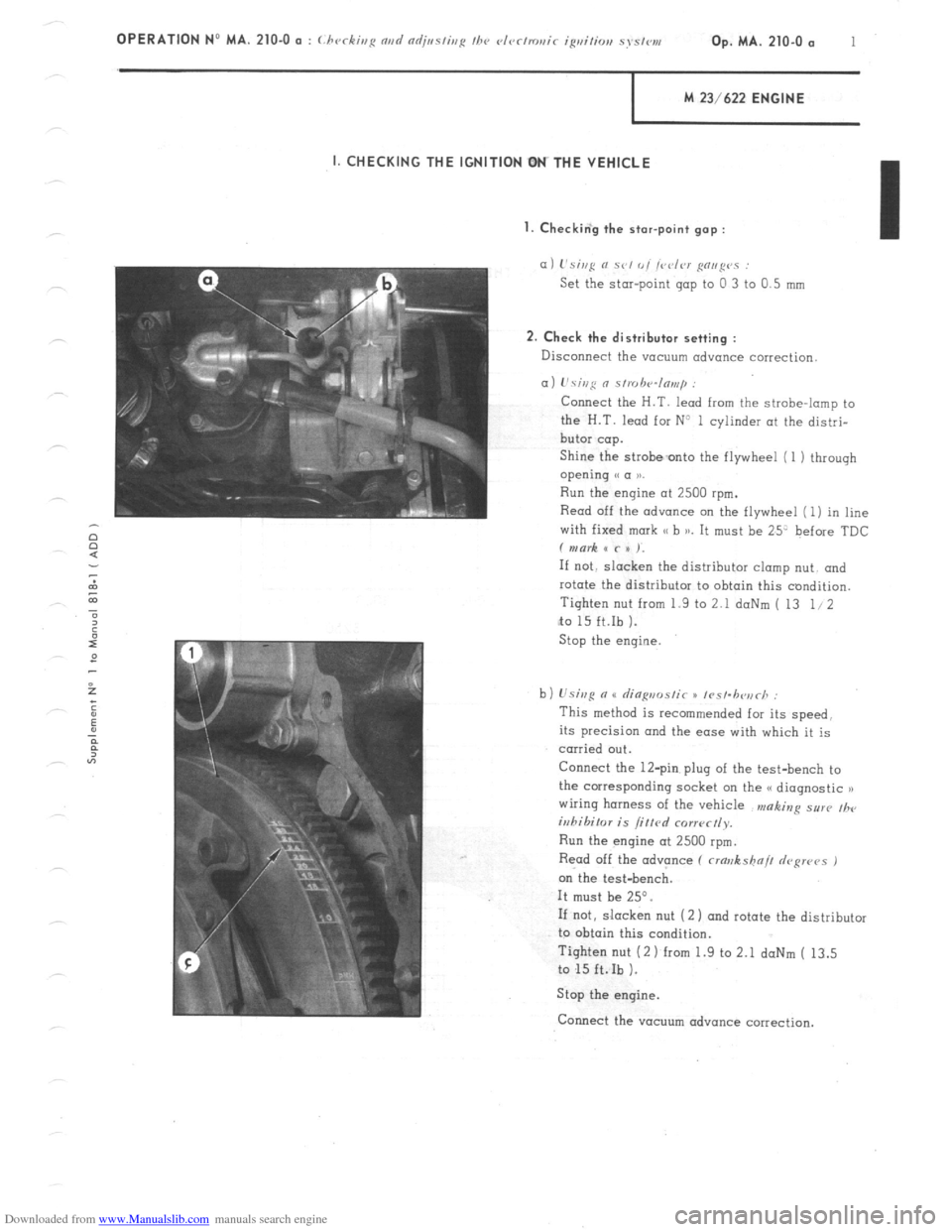

I. Checkin‘g the star-point gap :

a) L’si,,g N se, 0, /vdrr g”,,g”” :

Set the star-point gap to 0 3 to 0.5 mm

2. Check the distributor setting :

Disconnect the vacuum advance correction

a) L’sing 0 s/,uh‘4n,,,,p :

Connect the H.T. lead from the strobe-lamp to

the H.T. lead for N3 1 cylinder at the distri-

butor cap.

Shine the strobeonto the flywheel (1 1 through

opening e a 1).

Run the engine at 2500 rpm.

Read off the advance on the flywheel (1) in line

with fixed mark SC b )a. It must be 25’ before TDC

f mark x c x ).

If not. slacken the distributor clomp nut. and

rotate the distributor to obtain this condition.

Tighten nut from 1.9 to 2.1 doNm ( 13 1.12

to 15 ft.Ib ).

Stop the engine

b) Usisg n u rlia~,,ms/ir x /rs/.h<~,irh :

This method is recommended for its speed.

its precision and the ease with which it is

carried out.

Connect the 12-pin plug of the test-bench to

the corresponding socket on the G< diagnostic n

wiring harness of the vehicle n,aking sur(, ,h,

iuhihilor is /if/cd corr~~ctly.

Run the engine at 2500 rpm.

Read off the advance (

crawkshn// depws 1

on the test-bench.

It must be 25”.

If not, slacken nut (2 1 and rotate the distributor

to obtain this condition.

Tighten nut (2 1 from 1.9 to 2.1 daNm ( 13.5

to 15 ft.Ib ).

Stop the engine.

Connect the vacuum advance correction.

Page 164 of 394

Downloaded from www.Manualslib.com manuals search engine 4 OPERATION No MA. 210-O o : (./wrkh,i: rind nrlj,,s/inp /hc rlvr/,riai< igvi,io,, ~YS/C,,,,.

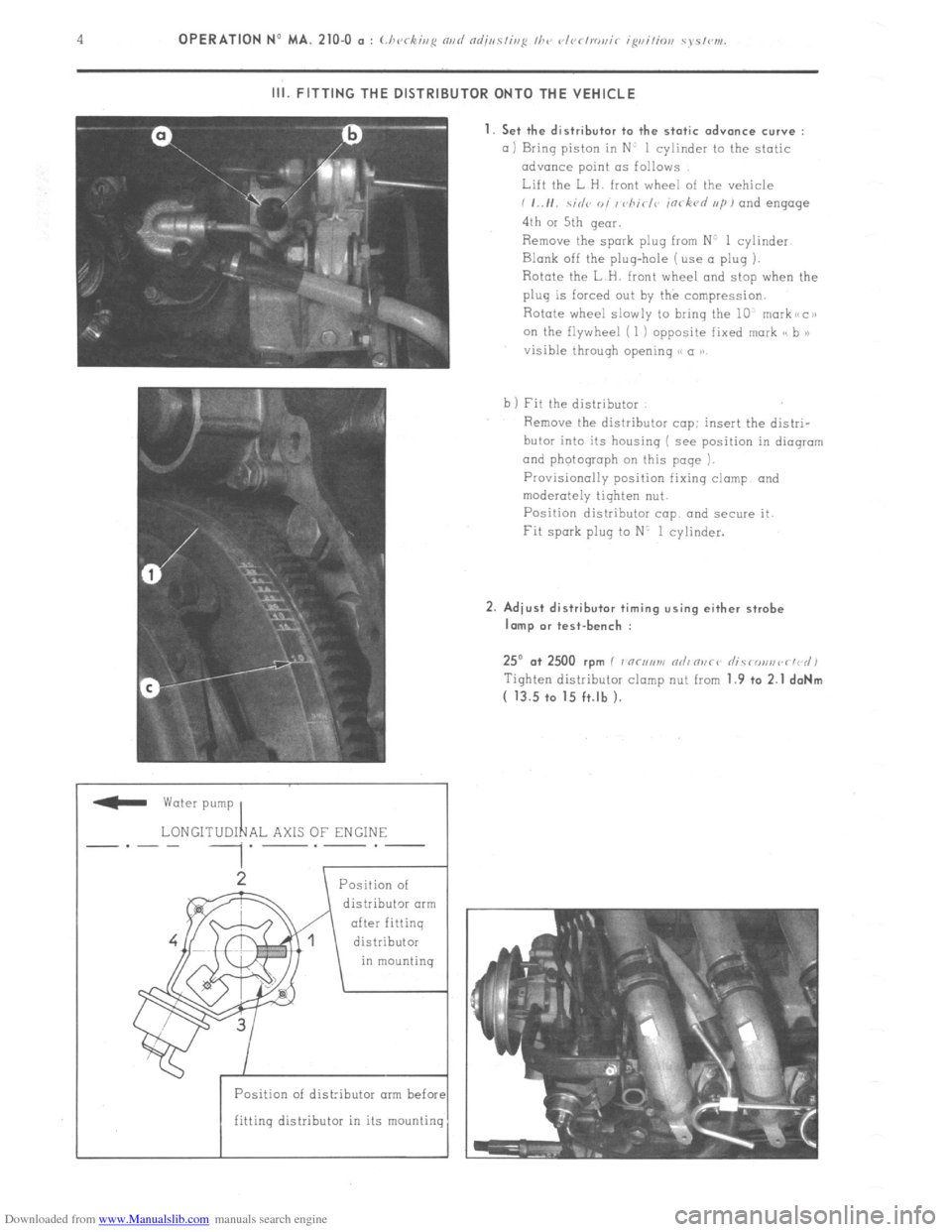

II;. FITTING THE DISTRIBUTOR ONTO THE VEHICLE

_ water pump

LONGITUDI 1 AL AXlS OF ENGINE

.-.-.-

distributor arm

Position of dist:ibutor arm befol

fitting distributor in its mountin 1. Set the distributor to the static advance curve :

a) Bring piston in N’ 1 cylinder to the static

advance point LTS follows

Lift the L H. front wheel of the vehicle

i ,..I,. .\;,I<~ o, / vhirl<~ in< kvd ,,/I, and engage

4th or 5th qeor.

Remove the spark plug from N’ 1 cylinder

Blank off the plug-hole (use a plug ).

Rotate the L H. front wheel and stop when the

plug is forced out by the compression.

Rotate wheel slowly to bring the 10, markiicai

on the flywheel ( 1 ) opposite fixed mark cs b >)

visible throuqh opening S< a ))

b 1 Fit the distributor

Remove the distributor cop: insert the distri-

butor into its housing ( see position in dioqrom

and photograph on this page ).

Provisionally position fixing clamp and

moderately tighten nut.

Position distributor cap and secure it.

Fit spark plug to N’ 1 cylinder. 2. Adiust distributor timing using either strobe

lamp or test-bench :

25” .a+ 2500 rpm I 7 “c,,,m nrli n,,ci’ rlicronsvr~d)

Tiqhten distributor clomp nut from 1.9 +o 2.1 daNm

( 13.5 to 15 ft.lb ).