brake Citroen CX 1981 1.G Owner's Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1981, Model line: CX, Model: Citroen CX 1981 1.GPages: 394

Page 278 of 394

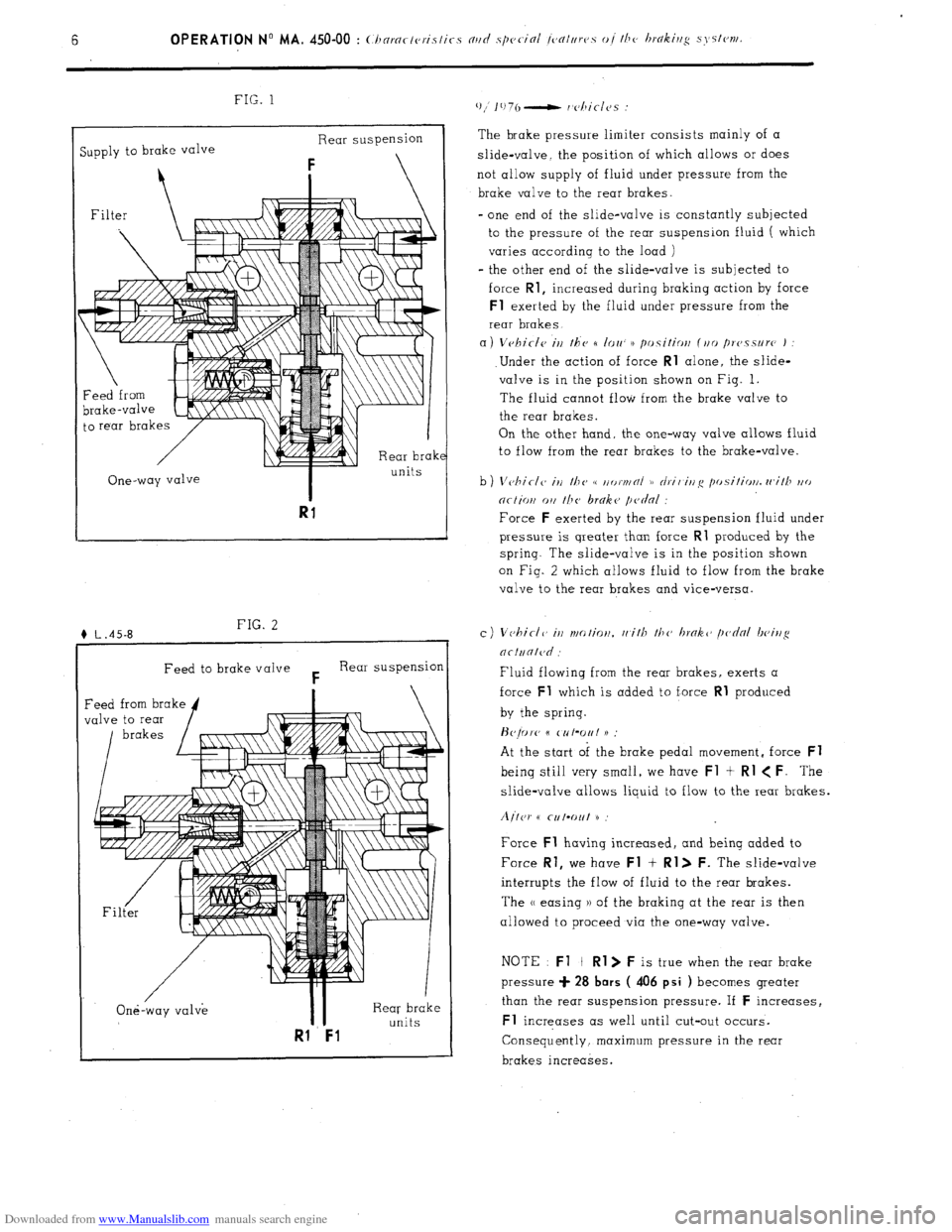

Downloaded from www.Manualslib.com manuals search engine FIG. 1

Supply to brake valve Rear suspension

i

Filter

\--Iii

I

Rear brak

. .

One-way valve

I units

Rl

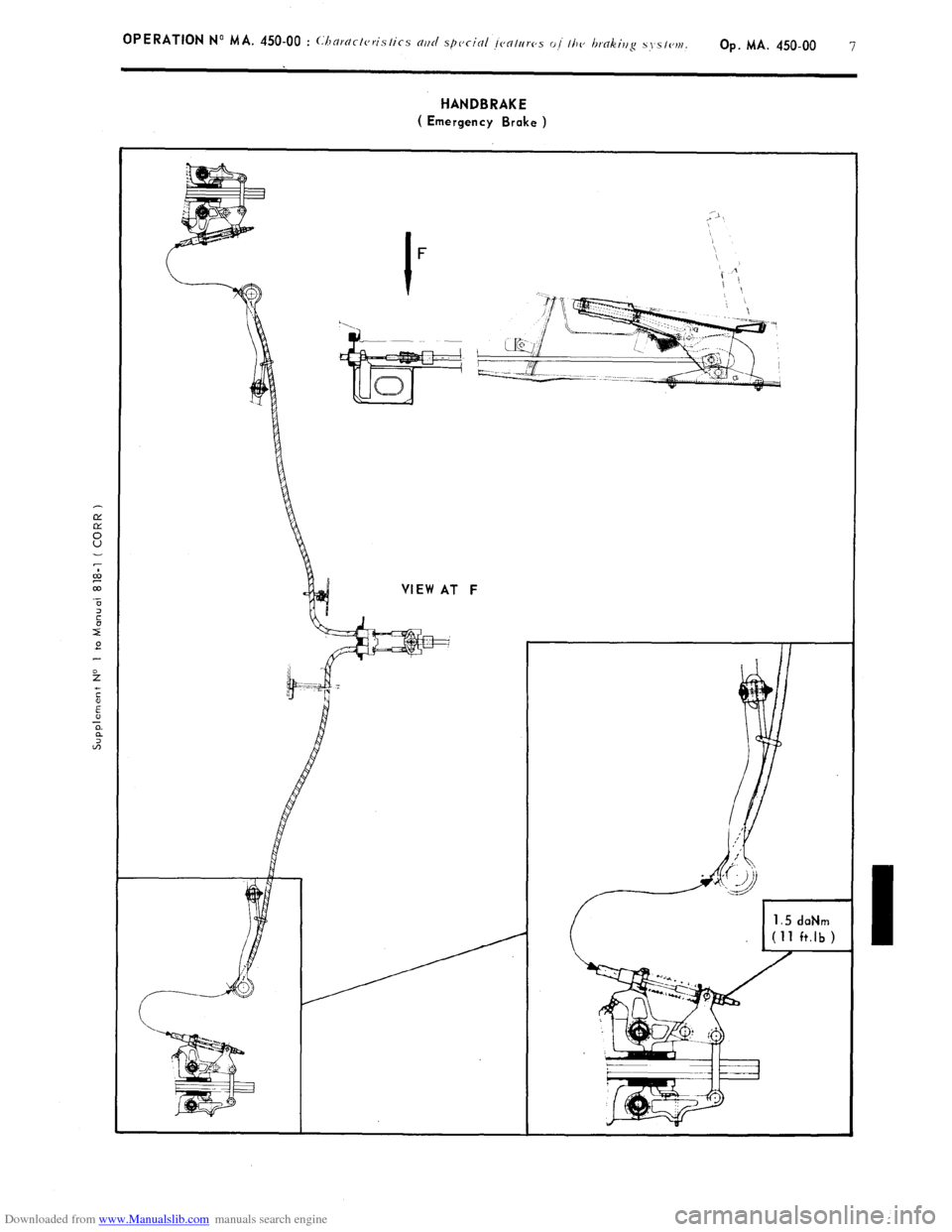

Feed to brake valve F Rear suspension /

One-way valve II Rear brake

Rl Fl

units The brake pressure limiter consists mainly of a

slide-valve, the position of which allows or does

not allow supply of fluid under pressure from the

brake valve to the rear brakes.

-

one end of the slide-valve is constantly subjected

to the pressure of the rear suspension fluid ( which

varies according to the load )

- the other end of the slide-valve is subjected to

force Rl,

increased during braking action by force Fl

exerted by the fluid under pressure from the

rear brakes

a)

Vvhirlc, irl the n IOU N positiolt (,,o /)rc,.ssurc, )

.Under the action of force Rl alone, the slide-

valve is in the position shown on Fig. 1.

The fluid cannot flow from the brake valve to

the rear brakes.

On the other hand, the one-way valve allows fluid

to flow from the rear brakes to the brake-valve.

Force F

exerted by the rear suspension fluid under

pressure is qreater than force Rl

produced by the

spring. The slide-valve is in the position shown

on Fig. 2 which allows fluid to flow from the brake

valve to the rear brakes and vice-versa.

Fluid flowing from the rear brakes, exerts a

force Fl

which is added to force Rl produced

by the spring.

H~prc 6

CNt’Out 11

At the start of the brake pedal movement, force Fl

being still very small, we have Fl t Rl < F. The

slide-valve allows liquid to flow to the rear brakes.

Aitcr t( CIIIW~~ H

Force Fl

having increased, and being added to

Force Rl,

we have Fl + Rl> F. The slide-valve

interrupts the flow of fluid to the rear brakes.

The (( easing )) of the braking at the rear is then

allowed to proceed via the one-way valve.

NOTE : Fl

+ Rl> F is true when the rear brake

pressure + 28 bars

( 406 psi ) becomes greater

than the rear suspension pressure. If F

increases, Fl

Increases as well until cut-out occurs.

Consequently, maximum pressure in the rear

brakes increases.

Page 279 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION N” MA. 450-00

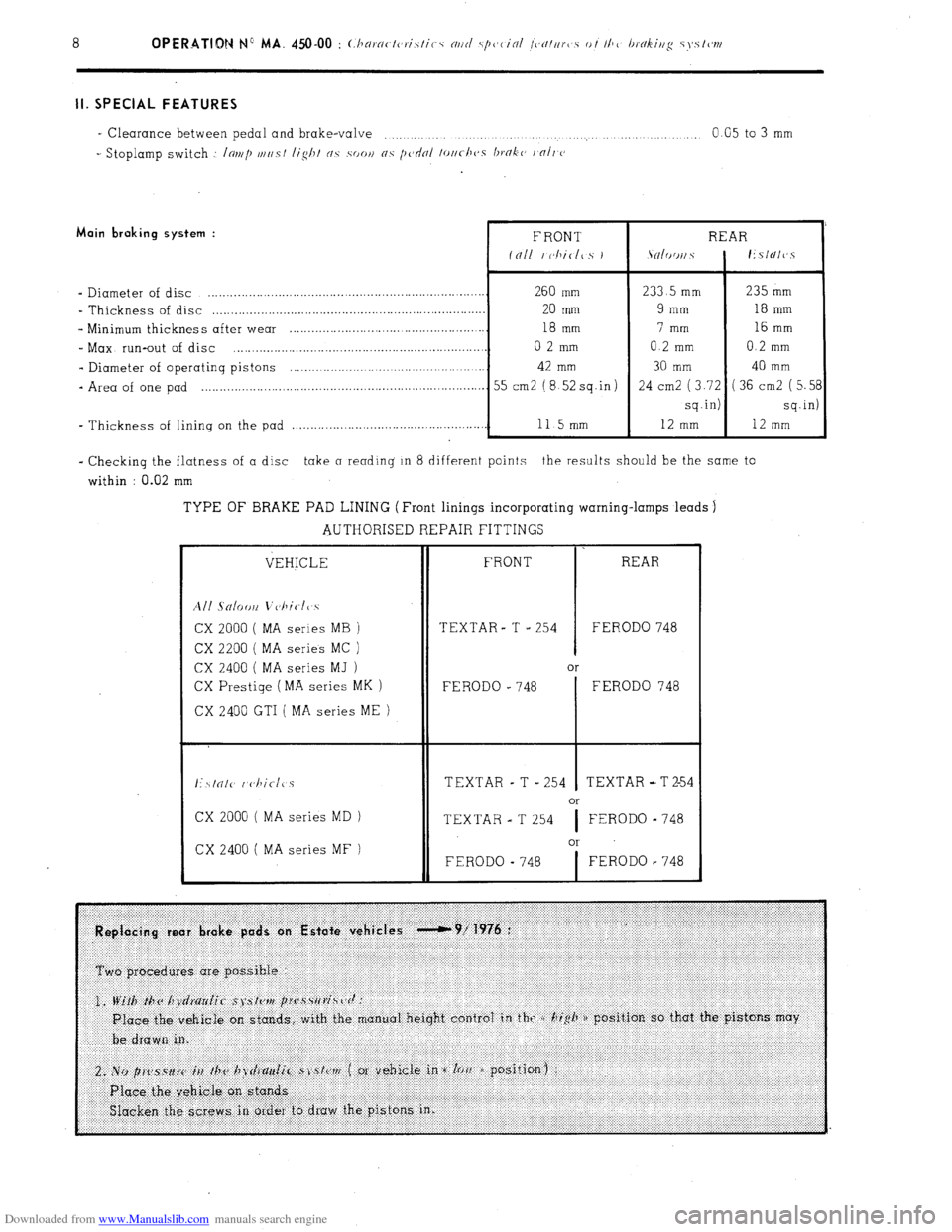

HANDBRAKE

( Emergency Brake )

Page 280 of 394

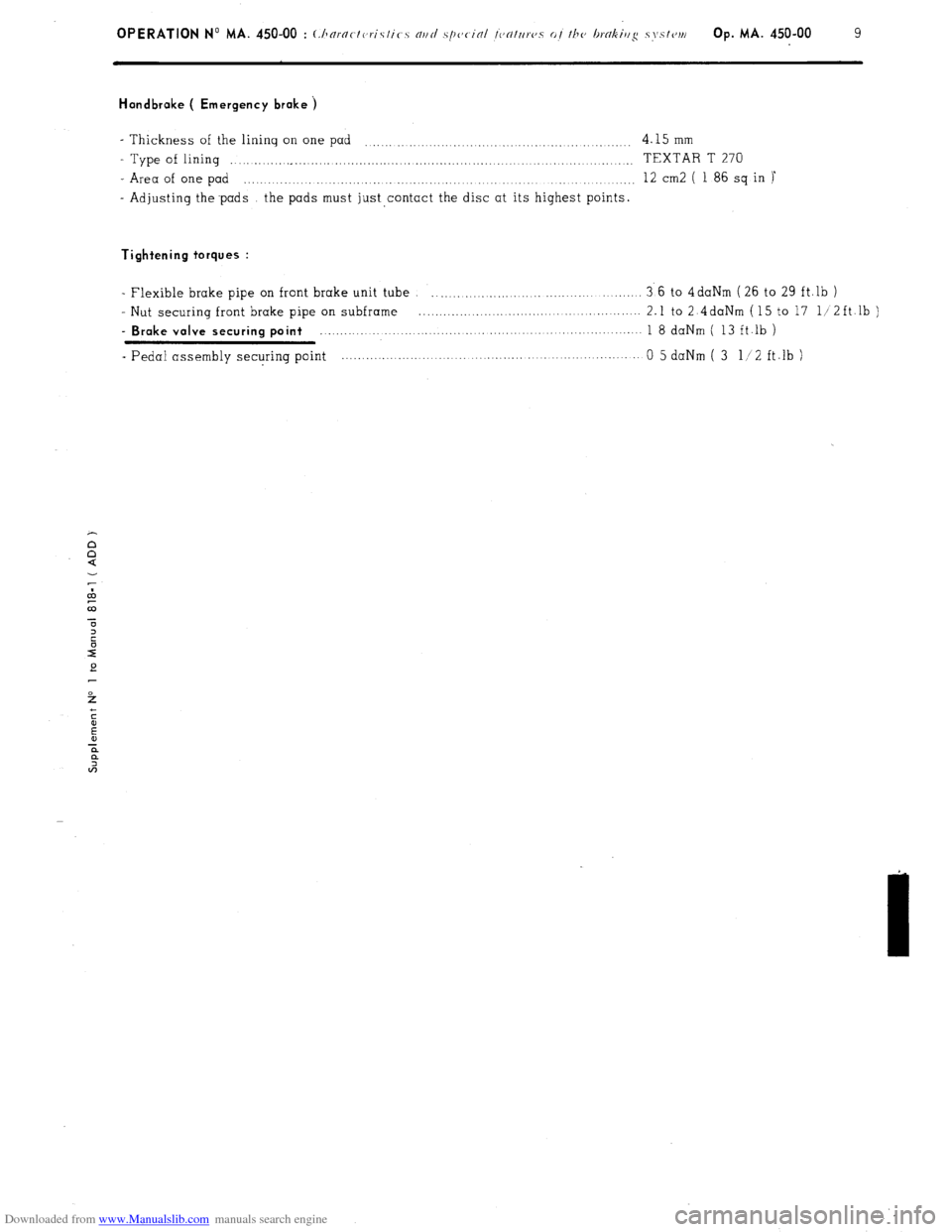

Downloaded from www.Manualslib.com manuals search engine II. SPECIAL FEATURES

- Clearance between pedal and brake-valve

” ..: 0.05 to 3 mm

_ Stoplamp switch ,: Inal/) VII/S/ lislli c/c .soo,~ 05 [I(‘~~II /~//c-/~c,s IJTO~(~ /,fl// (J Main braking system :

- Diameter of disc .......................................................................... 260 mm

- Thickness of disc .........................................................................

20 mm

s Minimum thickness after wear .................................................... 18 mm

_ Max run-out of disc ...................................................................

0 2 mm

- Diameter of operatinq pistons ....................................................

42 mm

- Area of one pad ............................................................................

55 cm2 (8 52sq.in)

- Thickness of lining on the pad .,,_.,..,_.__.._.._,....,.......................... 115mm

233 5 mm 235 mm

9 mm 18 mm

7 mm 16 mm

0.2 mm 0 2 mm

30 mm 40 mm

24 cm2 (3.72 (36cm2 (5.5

sq.in) sq.in

12 mm

12 mm

- Checking the flatness of a disc take a reading in 8 different points the results should be the same to

within : 0.02 mm

TYPE OF BRAKE PAD LINING (Front linings incorporating warning-lamps leads

j

AUTHORISED REPAIR FITTINGS

VEHICLE

All Snlow L’c~l,ir-ll 5

CX 2000

( MA series MB )

CX 2200 ( MA series MC )

CX 2400 ( MA series MJ )

CX Prestiqe (MA series MK )

CX 2400 GTI ( MA series ME )

CX 2000 ( MA series MD )

CX 2400 ( MA series MF )

8

1

FRONT REAR

TEXTAR- T .= 254 FERODO 748

or

FERODO e 748

I FERODO 748

TEXTAR - T - 254 1 TEXTAR -T2-54

or

TEXTAR - T 254

I FERODO - 748

or

FERODO - 748

I FERODO r 748

Page 281 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 450-00 : (:/~ornc.t(,ris/i(- c/r/d ,S/ICJC inl /c,c//r~rc,s ot the brcrkillg s~‘.stc~rt~ Op. MA. 450-00 9

Handbroke ( Emergency broke )

- Thickness of the lininq on one pad

4.15 mm _...... .._.......... _.. .,..........

- Type of lining .__............................._....._._..... .._.... .._.. .._.

TEXTAR T 270

- Area of one pad

._..

12 cm2 ( 1 86 sq in )’

- Adjusting the -pads the pads must just contact the disc at its highest points.

Tightening torques :

- Flexible brake pipe on front brake unit tube .............. ..... ....... ........... ........ 3 6 to 4daNm (26 to 29 ft.lb )

- Nut securing front brake pipe on subframe .................................................

2.1 to 2 4daNm (15 to 17 1/2ft.lb )

- Brake valve securing point .................. .............................. ........... ........ 1 8 daNm ( 13 ft.lb )

. Pedal assembly securing point .....................

...... ..................................

0 5 daNm ( 3 l/2 ft.lb )

Page 282 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 451-O : Uwckirrg the hrflkv rov,~o,rrnts Op. MA. 451.0 1

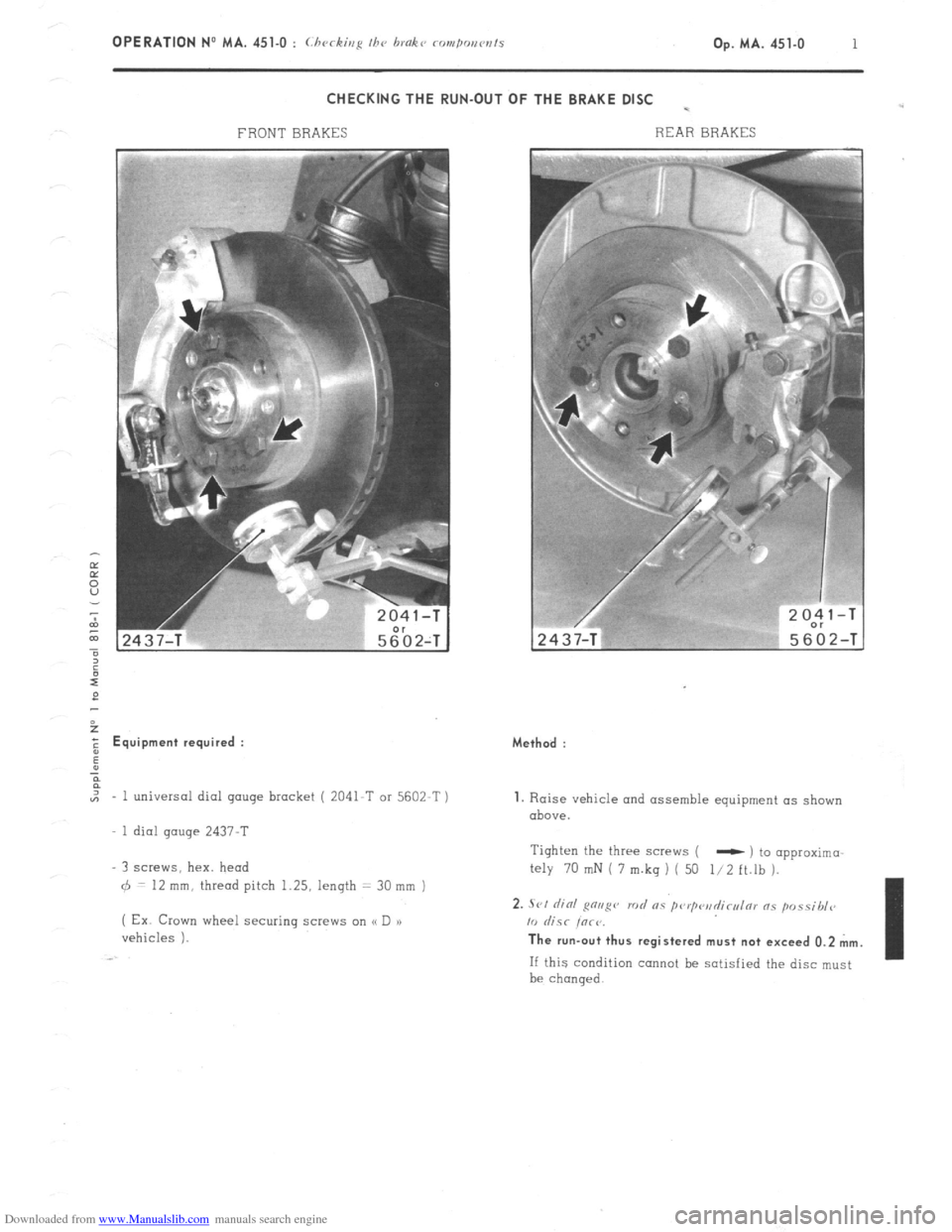

CHECKING THE RUN-OUT OF THE BRAKE DISC -

FRONT BRAKES REAR BRAKES 2

E Equipment required :

,,, - 1 universal dial gauge bracket ( 2041-T or 5602-T )

1 dial gauge 2437-T

3 screws, hex. head

6 = 12 mm, thread pitch 1.25, length = 30 mm )

( Ex Crown wheel securing screw on (< D a)

vehicles ). Method :

1. Raise vehicle and assemble equipment as shown

above.

Tighten the three screws (

- ) to opproximo

My 70 mN i 7 m.kq ) ( 50 l/2 ft.lh ).

2. .Sl,l did g”“g” rod RS pwp<‘il~cl,l171 ns p”ssibl<~

10 &SC iorr. The run-out thus registered must not exceed 0.2 mm.

If this condition cannot be satisfied the disc must

be chanqed.

Page 283 of 394

Downloaded from www.Manualslib.com manuals search engine Op. MA. 453-O 1

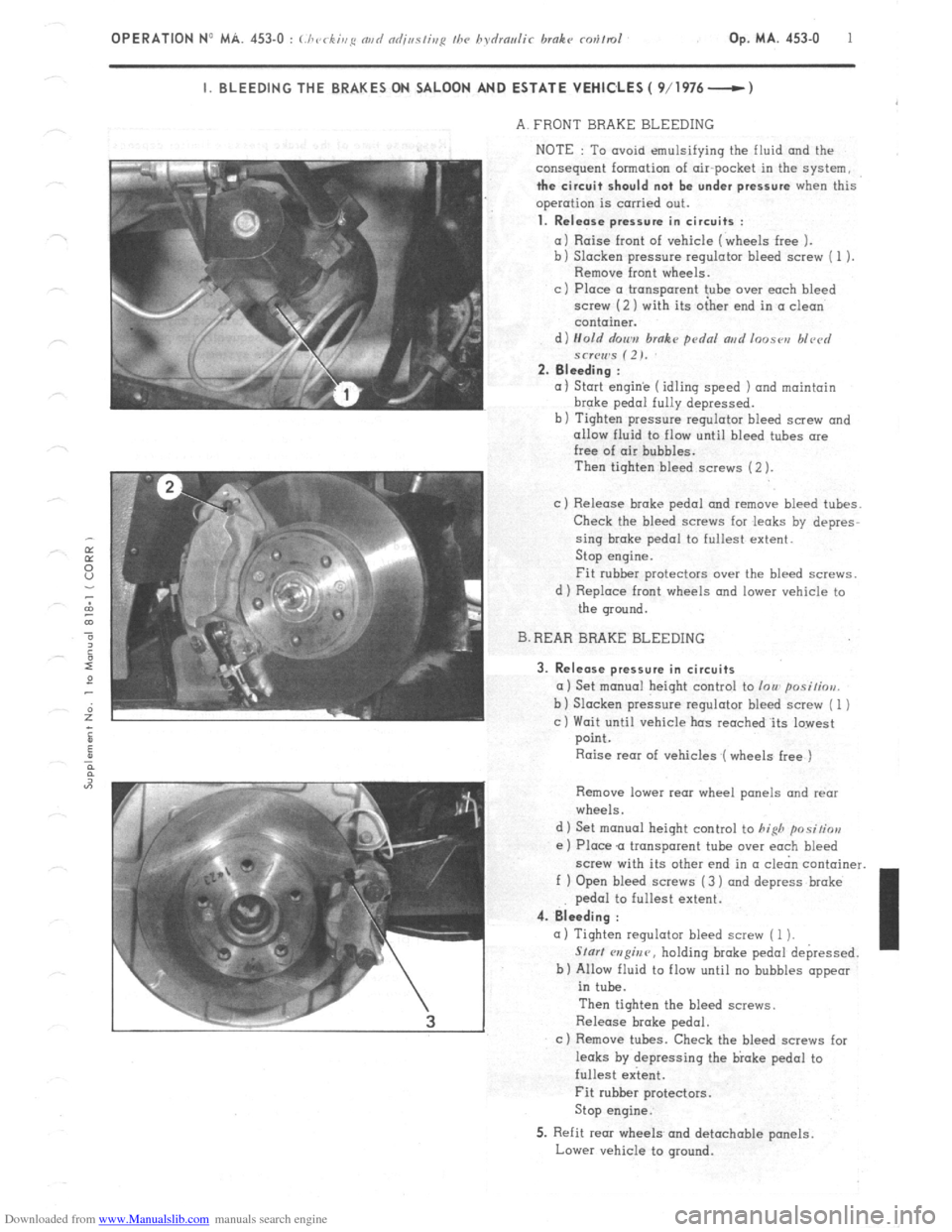

I. BLEEDING THE BRAKES ON SALOON AND ESTATE VEHICLES ( 9/1976- )

A. FRONT BRAKE BLEEDING

NOTE : To avoid emulsifying the fluid

and the

consequent formation of air-pocket in the system,

the circuit should not be under pressure when this

operation is carried out.

1. Release pressure in circuits :

a) Raise front of vehicle (wheels free 1.

b) Slacken pressure regulator bleed screw ( 1 ).

Remove front wheels.

c ) Place CI transparent tube over each bleed

screw (2 ) with its oiher end in CI clean

container.

d) Hold r/on,,,

brake pdnl ar,d loose,, blvcrl

*cr(Iws (2). 2. Bleeding :

(I 1 Start engin’e (idling speed 1 and maintain brake

pedal fully depressed.

b) Tighten pressure regulator bleed screw and

allow fluid to flow until bleed tubes ore

free of air bubbles.

Then tighten bleed screws (2 ).

c) Release broke pedal and remove bleed tubes.

Check the bleed screws for .leaks by depres-

sing brake pedal to fullest extent.

Stop engine.

Fit rubber protectors over the bleed screws.

d 1 Replace front wheels and lower vehicle to

the ground.

B. REAR BRAKE BLEEDING

3. Release pressure in circuits

a) Set monuol height control to lou posi/iou.

b 1 Slacken pressure regulator bleed screw ( 1 )

c) Wait until vehicle has reoched.its lowest

point.

Raise rear of vehicles (wheels free )

Remove lower rear wheel panels and rear

wheels.

d 1 Set manual height control to

hifih positior,

e ) Place Q transparent tube over each bleed

screw with its other end in (I cl&n container.

f ) Open bleed screws (3 ) and depress broke

pedal to fullest extent. 4. Bleeding :

(I) Tighten regulator bleed screw ( 1 1.

Slur/ w?@nr, holding broke pedal depressed.

b) Allow fluid to flow until no bubbles appear

in tube.

Then tighten the bleed screws.

Release brake pedal.

c ) Remove tubes. Check the bleed screws for

leaks by depressing the bloke pedal to

fullest extent. I

Fit rubber protectors.

Stop engine.

5. Refit rear wheels and detachable panels.

Lower vehicle to ground.

Page 284 of 394

Downloaded from www.Manualslib.com manuals search engine 2 OPERATION N” MA. 453-O : (./ ‘cc ,,,g md ndjaslisg I/w hsdrmlir hrnkr rev/m/

k.

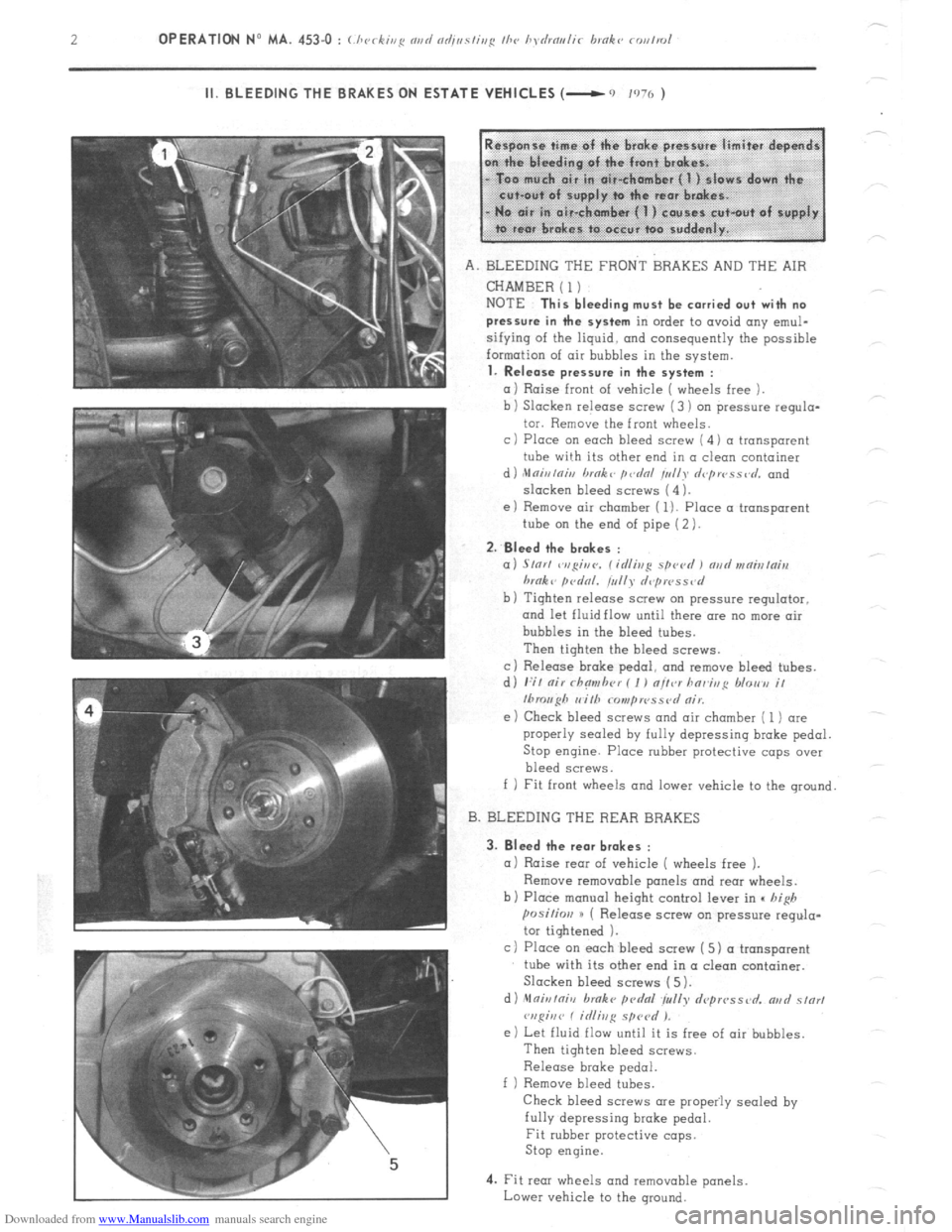

II. BLEEDING THE BRAKES ON ESTA ,TE VEHICLES (- 0 ,970 )

A. BLEEDING THE FRONT BRAKES AND THE AIR

CHAMBER ( 1)

NOTE

This bleeding must be carried out with no

pressure in the system

in order to avoid any emul-

sifying of the liquid. and consequently the possible

formation of air bubbles in the system.

1. Release pressure in the system :

a 1 Raise front of vehicle ( wheels free ).

b ) Slacken release screw (3 ) on $ressure requlo-

tor. Remove the front wheels.

c 1 Place on each bleed screw ( 4 1 a transparent

tube wi!h its other end in a clean container

d ) ,Mnir,lnh, brnk L p&d /u//y d<~pwss,~d. and

slacken bleed screws (4 ).

e) Remove air chamber ( 1). Place a transparent

tube on the end of pipe (2 ).

2.

Bleed the br.kes :

a) S/or/ ~v,gir,c,. C id/ivg spevd I md vrnialni,r

hrnk L firdnl. tullr d,~pwss<~d

b) Tighten release screw on pressure regulator.

and let fluid flow until there are no more air

bubbles in the bleed tubes.

Then tighten the bleed screws.

c) Release broke pedo1, and remove bleed tubes.

d) I:;/ nir rhnmhrr ( I ) nltcr hnr~htg /dorm i/

Ibrouph I, i/h Nmp IPSS ?,I nir.

e ) Check bleed screws and air chamber ( 1) are

properly sealed

by fully depressing brake pedal.

Stop engine. Place rubber protective caps over

bleed screws.

f 1 Fit front wheels and lower vehicle to the ground

B. BLEEDING THE REAR BRAKES

3.

Bleed the rear brakes :

a 1 Raise rear of vehicle ( wheels free ).

Remove removable panels and rear wheels.

b) Place manual height control lever in c high

posi~im H ( Release screw on pressure regula-

tor tightened 1.

c) Place on each bleed screw ( 5) a transparent

tube with its other end in a clean container.

Slacken bleed screws (5).

d) nlfliuiniv broke pcdfll ~yrrlly depwssvd. ar,d s/or,

vspiuv C idiivg sprcd ).

e) Let fluid flow until it is free of air bubbles.

Then tighten bleed screws.

Release brake pedal.

f ) Remove bleed tubes.

Check bleed screws are propeily sealed by

fully depressing broke pedal.

Fit rubber protective cops.

Stop engine.

4. Fit rear wheels and removable panels

Lower vehicle to the ground.

Page 285 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 453=0 : Ch J k’ ( c zng and adjjusfing thr hydraulk brake rontrol Op. MA. 453-O 3

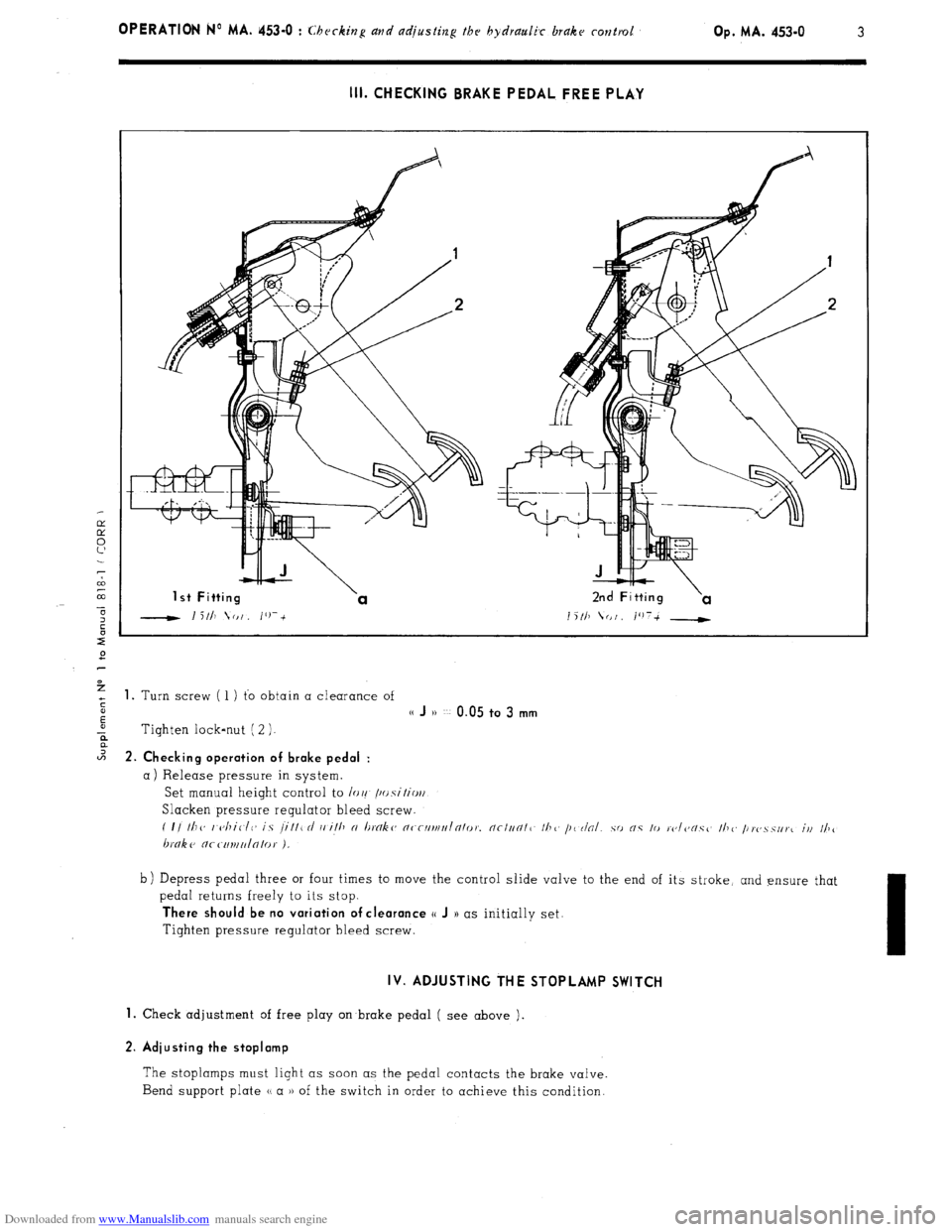

III. CHECKING BRAKE PEDAL FREE PLAY

1 st Fitting 2nd Fitting

1 5 111 (I I /‘)7-t __t i%

+ 1. Turn screw ( 1 ) to obtain a clearance of

s

E

(( J )) ~~ 0.05 to 3 mm

-ii Tighten lock-nut ( 2 ).

2 2. Ch k’ ec Ing operation of brake pedal :

a) Release pressure in system.

Set manual height control to /or! /~~.s\‘itio~/

Slacken pressure regulator bleed screw.

( I/ Ill<, I <~/liClC~ is /ill1 rl i, ill, N I~tYlk~~ n~-rllrlll,Inlo,~. nc/un/1 II?<, /I< r/al.

hnke nr c111uu/n/0,. ).

b) Depress pedal three or four times to move the control slide valve to the end of its stroke, and ensure that

pedal returns freely to its stop.

There should be no variation of clearance o J )) as initially set.

Tighten pressure regulator bleed screw.

IV. ADJUSTING THE STOPLAMP SWITCH

1.

Check adjustment of free play on brake pedal ( see above ).

2. Adiusting the stoplamp

The stoplamps must light as soon as the pedal contacts the brake valve.

Bend support plate u a )) of the switch in order to achieve this condition.

Page 286 of 394

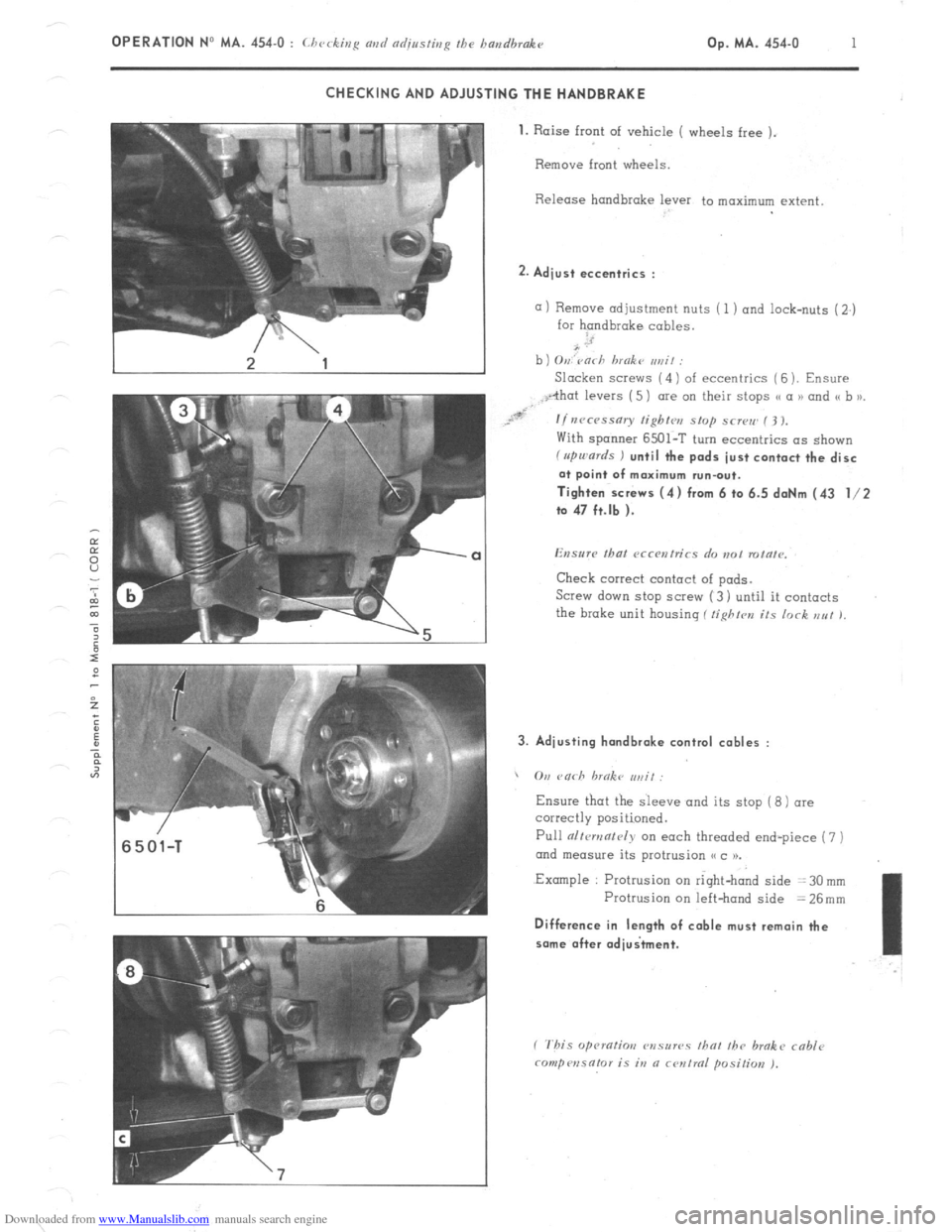

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 454-O : Lhcckiu~ avd adjnsfbrR fhe bandbrake op. MA. 454-u I CHECKING AND ADJUSTING THE HANDBRAKE

1.

Raise front of vehicle ( wheels free ).

Remove front wheels.

Release handbrake lever to maximum extent 2. Adjust eccentrics :

a) Remove adjustment nuts ( 1 ) and lock-nuts (2.)

for handbrake cables.

b ) O,,,‘varh hmokt~ ,,rzit :

Slacken SCI~WS (4) of eccentrics ( 6 ). Ensure

With spanner 6501-T turn eccentrics as shown f rrpu,ards ) until the pads just contact the disc

at point of maximum run-out.

Tighten screws (4) from 6 to 6.5 daNm (43 l/2

to 47 ft.lb ).

Check correct contact of pads.

Screw down stop SCI~W (3) until it contacts

the brake unit housing ( tighfrn its lock EN! 1, 3. Adjusting hondbrake control cables :

, On rnrh hrnkc ,,,, if:

Ensure

Pull alfcmnf~~iy on each threaded end-piece (7 )

ond measure its protrusion (< c 1).

.Example : Protrusion on right-hand side = 30 mm

Protrusion on left-hand side = 26mm Difference in length of cable must remain the

some after adiuitment.

Page 287 of 394

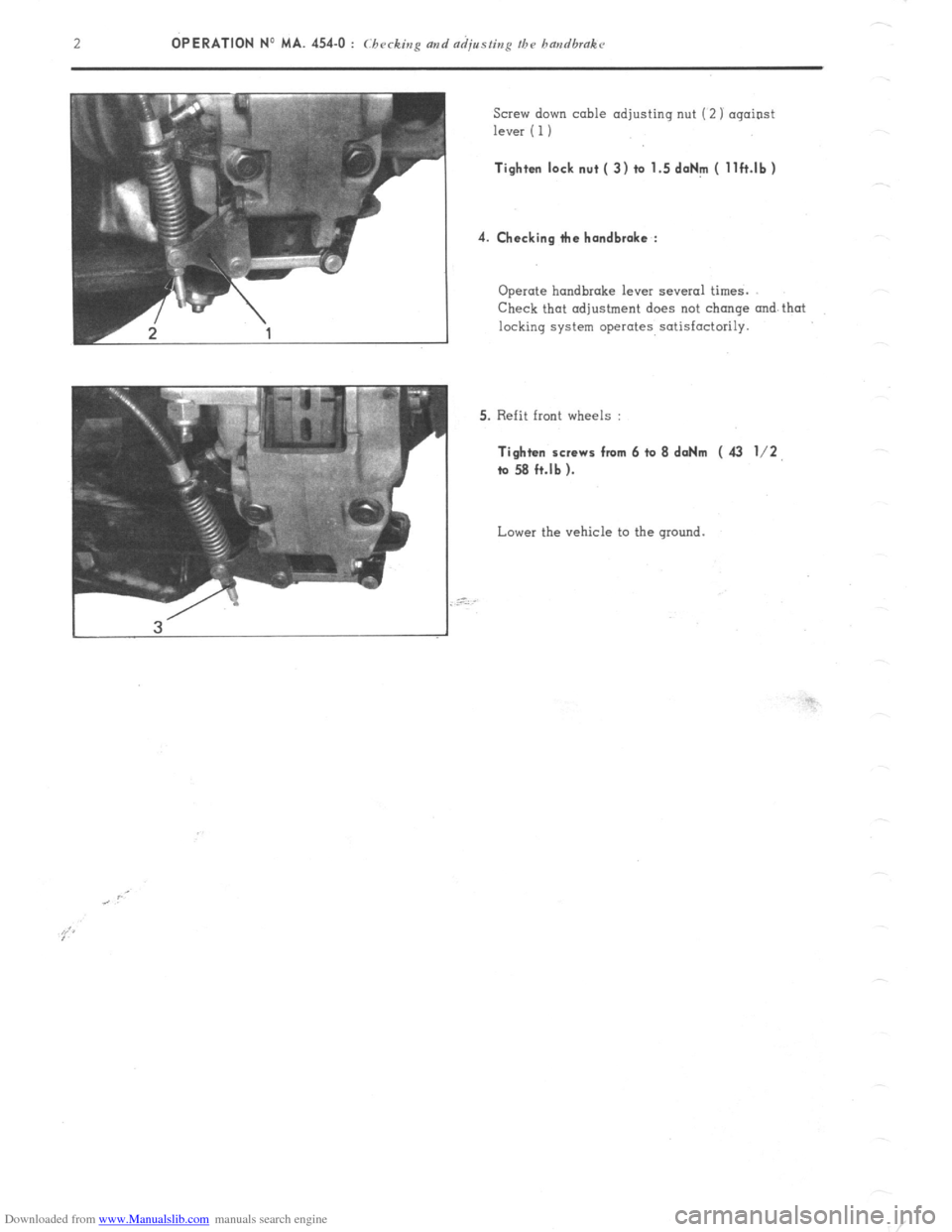

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 454-O : Ch ec tzg and a&sting the handbrakc k’

Screw down cable adjusting nut (2) against

lever ( 1) Tighten lock nut ( 3) to 1.5 doNm ( llft.lb)

4. Checking tie handbrake :

Operate handbrake lever several times.

Check that adjustment does not change and that

locking system operates satisfactorily.

5. Refit front wheels : Tighten screws from 6 to 8 daNm ( 43 l/2,

ta 58 ft.lb ).

Lower the vehicle to the ground.